Production process of regenerated anti-static polyester staple fibers

A polyester staple fiber and production process technology, applied in the fiber field, can solve problems such as easy generation and accumulation of charges, poor quality of polyester staple fiber, and easy generation of static electricity in polyester, so as to achieve strong solubility, improve utilization rate, and improve antistatic effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

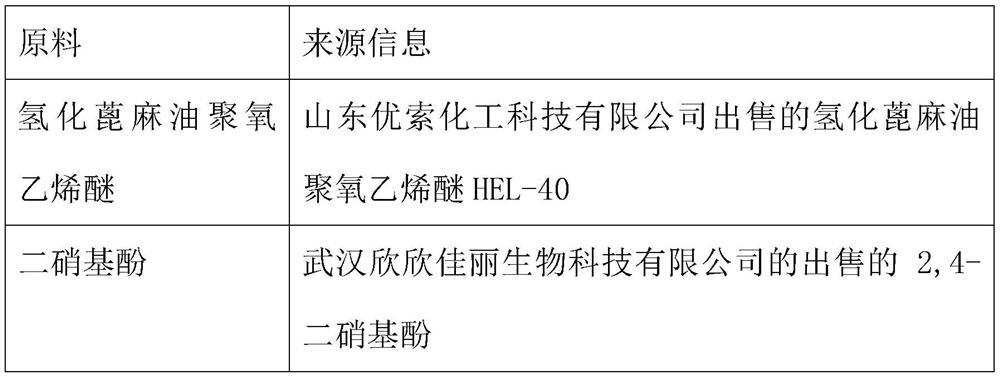

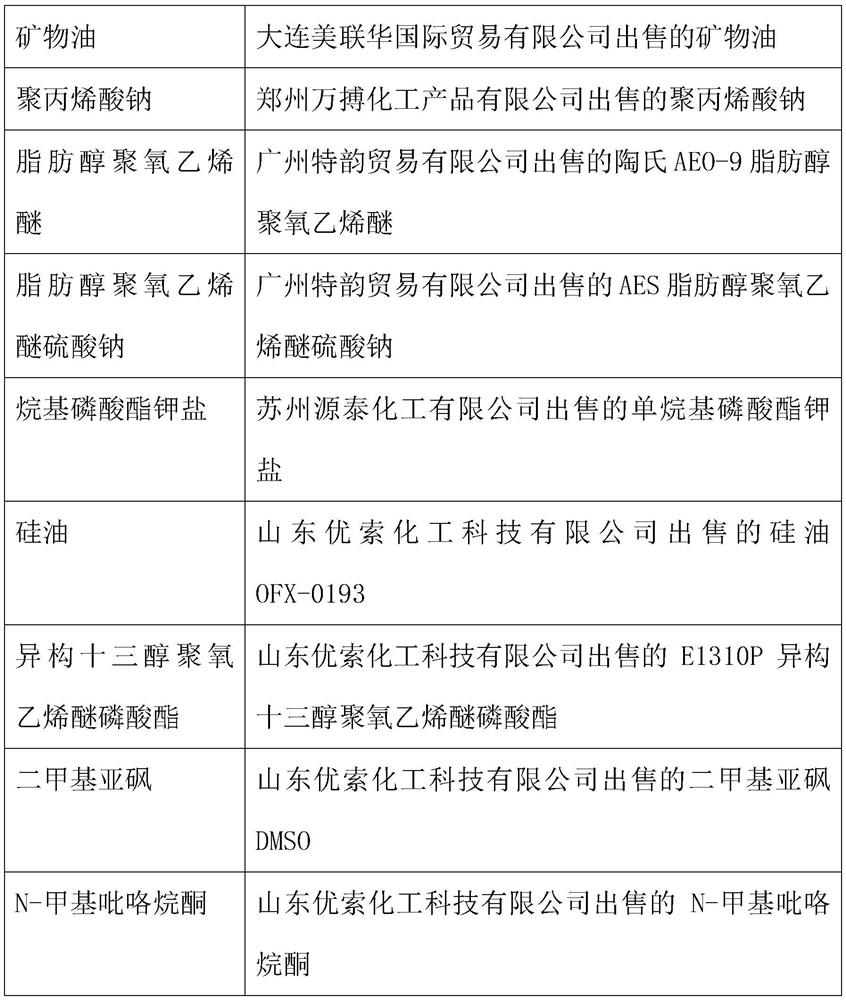

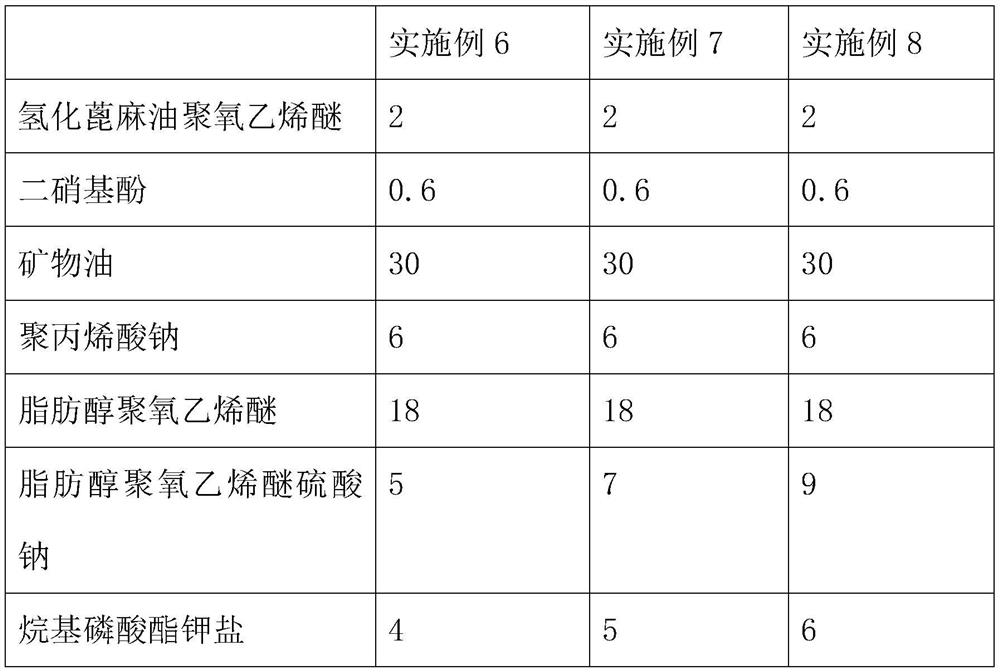

[0065] A kind of polyester oil preparation, comprises following component:

[0066] Hydrogenated castor oil ethoxylates, dinitrophenol, mineral oil, thickener, fatty alcohol ethoxylates.

[0067] The thickener is sodium polyacrylate.

[0068] In embodiment 1-3, the input amount (unit Kg) of each component sees table 2 for details

[0069] Table 2

[0070] Example 1 Example 2 Example 3 Hydrogenated castor oil polyoxyethylene ether 1 2 3 Dinitrophenol 0.4 0.6 0.8 mineral oil 25 30 35 Sodium polyacrylate 5 6 7 Fatty alcohol polyoxyethylene ether 16 18 20

[0071] The preparation method of polyester oil agent in embodiment 1-3 comprises the following steps:

[0072] Step 01), adding hydrogenated castor oil polyoxyethylene ether, dinitrophenol, mineral oil, and fatty alcohol polyoxyethylene ether into the stirring tank in sequence, heating to 50°C while stirring, stirring evenly, and stirring into an oily state to obtain...

Embodiment 4

[0075] A kind of polyester oil agent, compared with embodiment 2, difference only lies in:

[0076] In the preparation method of polyester oil agent:

[0077] In step 01), heating to 40°C;

[0078] In step 02), stir for 30 minutes, and the stirring speed is 600r / min.

Embodiment 5

[0080] A kind of polyester oil agent, compared with embodiment 2, difference only lies in:

[0081] In the preparation method of polyester oil agent:

[0082] In step 01), heating to 60°C;

[0083] In step 02), stir for 40 minutes, and the stirring speed is 800r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com