Paper based frictional material and friction plate producing method

A technology of paper-based friction materials and friction plates, which is applied in the field of paper-based friction materials and friction plates, and can solve the difficult braking conditions of sintered metal friction materials, a large amount of non-ferrous metals and high-temperature sintering, and a large difference between dynamic and static friction coefficients and other issues, to achieve the effect of low manufacturing cost, low noise and strong torque transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

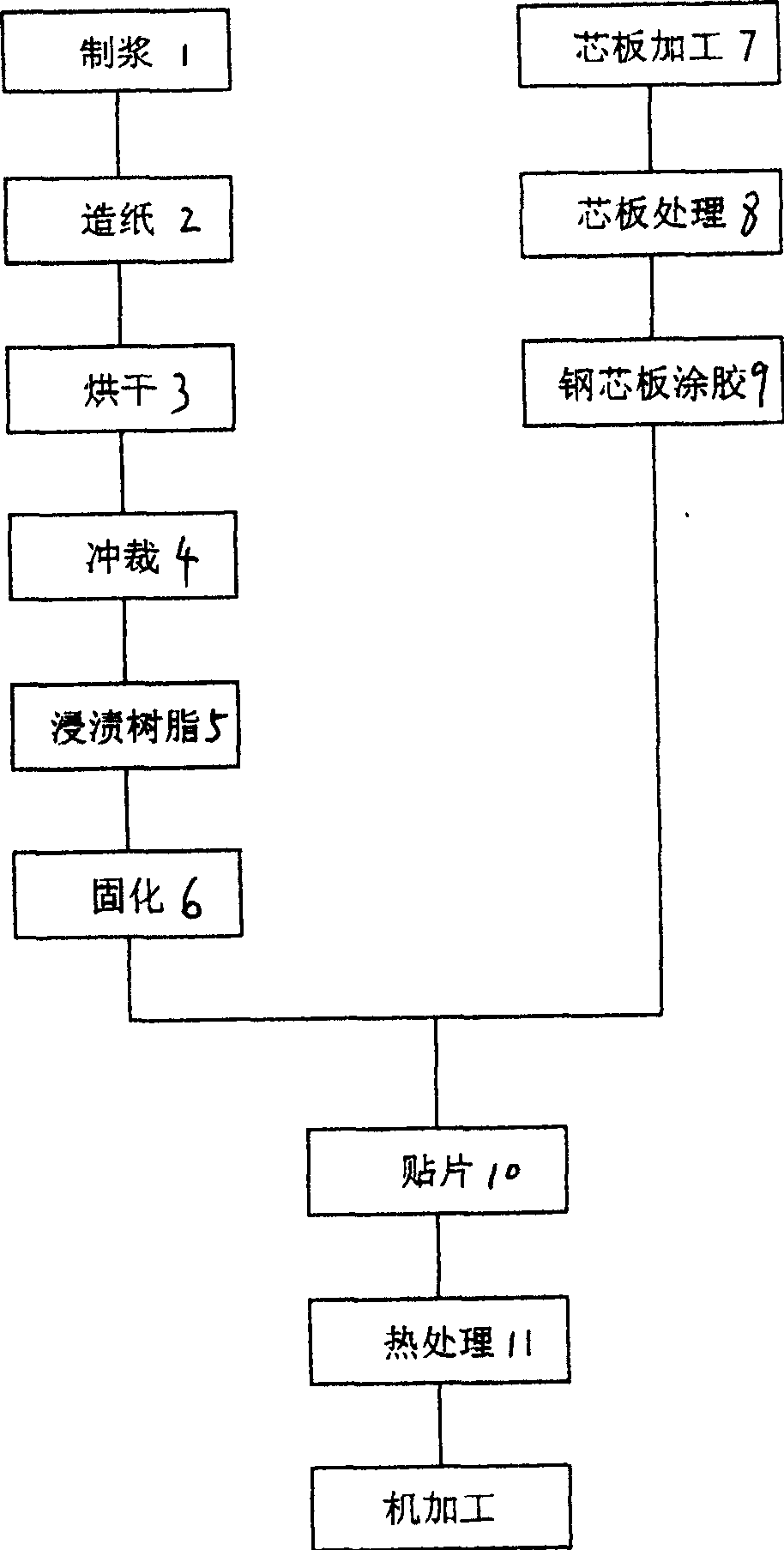

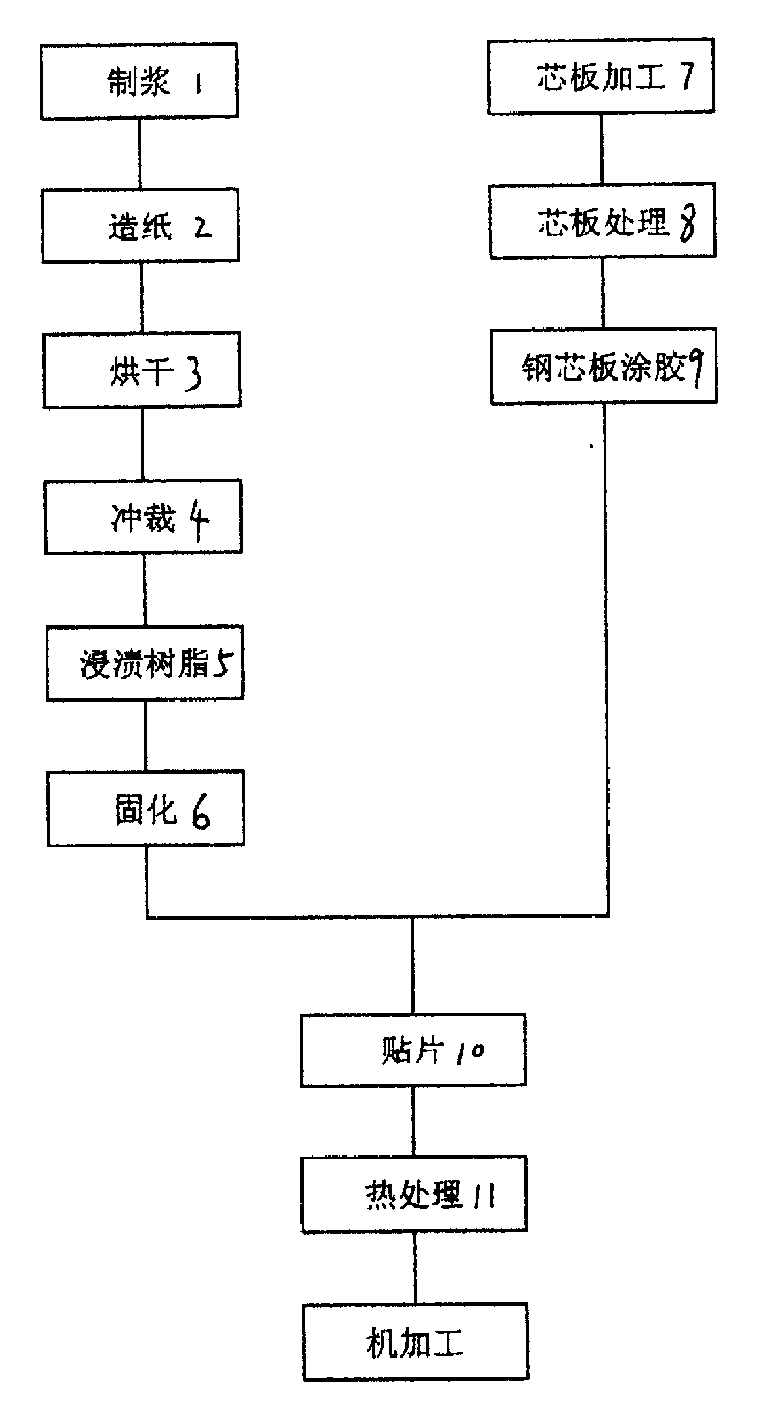

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, select the component ratio (percentage by weight) in the following paper-based friction material composition: cellulose fiber: 27-31%, carbon fiber: 3-5%, resin: 30-35%, graphite: 15- 17%, diatomite 5-8%, feldspar powder 5-8%, friction powder 5-7%, rubber: 3-5%.

[0017] First pulping 1, get 27% cotton, wood fiber (cellulose fiber) and make slurry in the beater, the beating concentration is 3-6%, adopts free beating mode, beating degree is 25-30 ° SR, then in In the refiner, send the beaten cotton and wood pulp back to the beater, add 4% carbon fiber and beat again, and beat to a beating degree of 23-28°SR; put the beaten pulp in the pulp tank, and use the pulp Pump for mixing, and then add various fillers in sequence, including 16% graphite, 6% diatomaceous earth, 5% feldspar powder and circulate for 20 minutes, then add 6% friction powder and 4% rubber regulator, after thorough mixing, add flocculation After the slurry is fully mixed, papermaking is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com