Patents

Literature

458results about "Cooling beds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

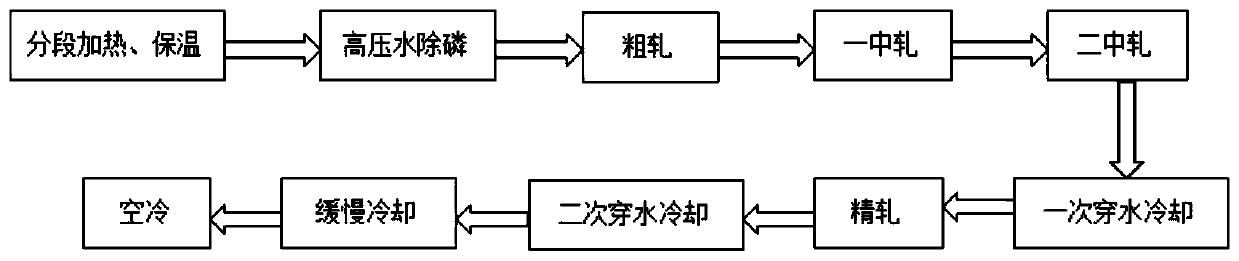

Rolling production method capable of reducing hardness of 42CrMo

ActiveCN106216391AMeet the national standardMeet user needsTemperature control deviceWork treatment devicesAutomatic controlContinuous rolling

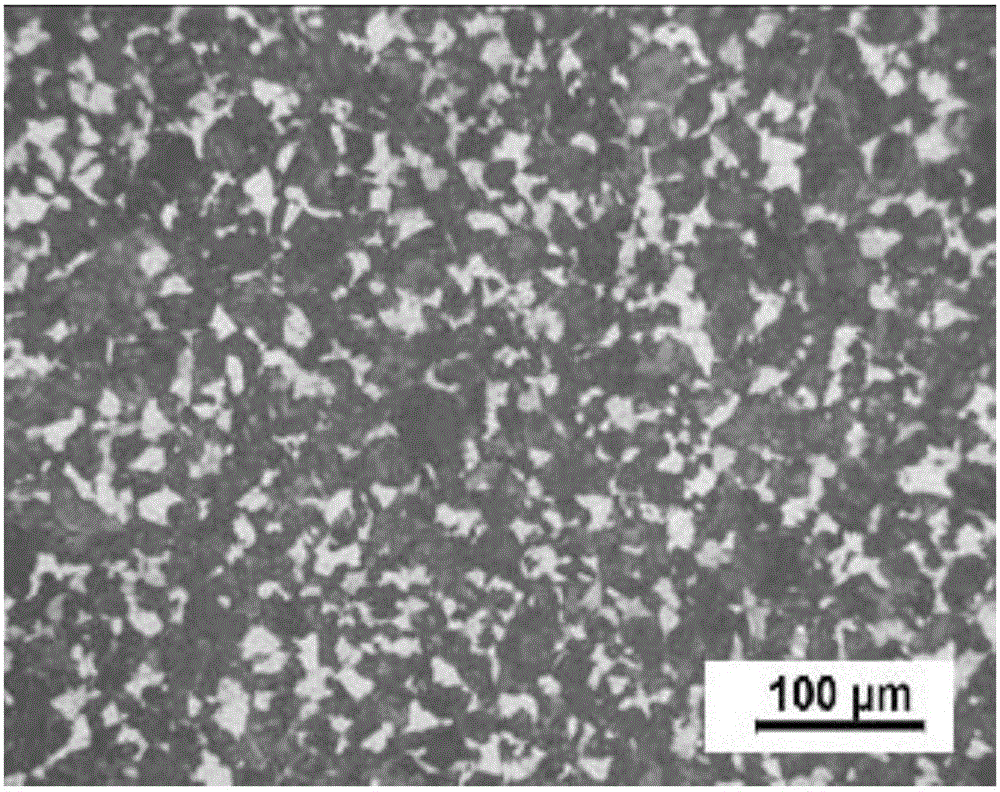

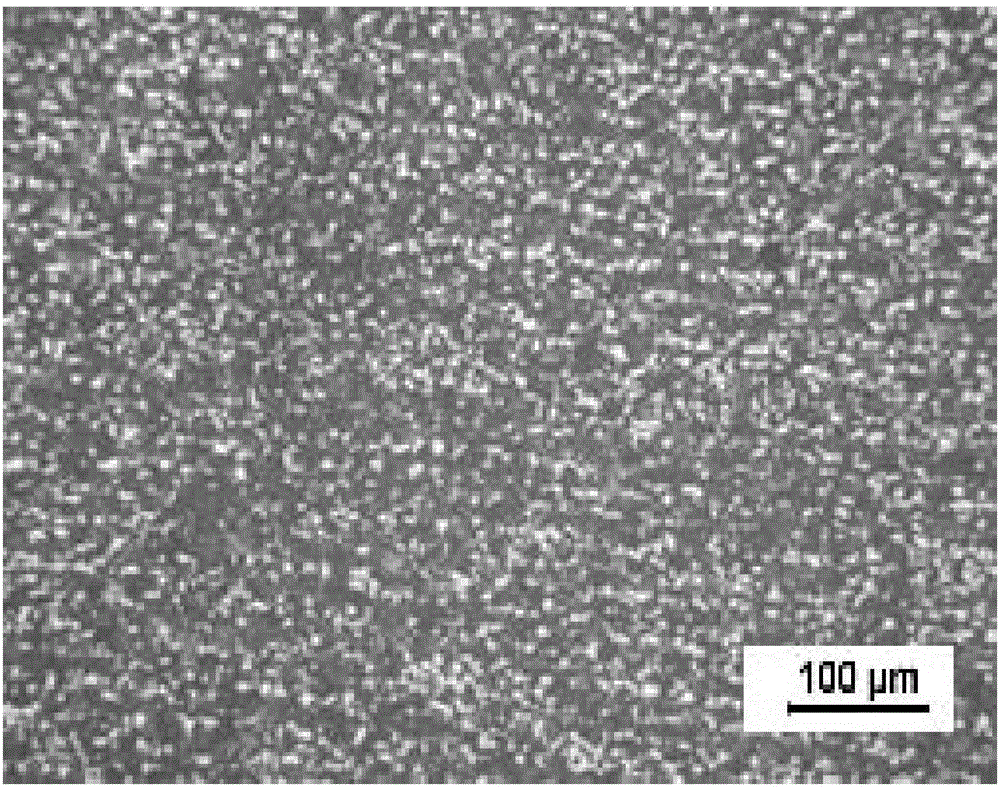

The invention belongs to the field of production machining of special steel of the metallurgical industry, and relates to a rolling production method capable of reducing hardness of 42CrMo. A 42CrMo casting blank serves as a raw material, and the method sequentially comprises following working procedures of heating, descaling, a rough rolling, cooling after rough rolling, continuous rolling, through water cooling, bar reducing sizing mill finish rolling, cooling bed cooling and finally obtaining a finished product bar; by the adoption of the technology, the site operation is simple, online automatic control is easily achieved, and operation labor intensity of a worker is reduced; through the online controlled rolling controlled cold technology, straightness of the 42CrMo steel grade is greatly improved; the subsequent heat treatment technology (annealing technology) is reduced, production cost is saved, the production period is shortened, and the steel market competitiveness is improved; the hardness value range of the obtained 42CrMo steel ranges from 220 HBW to 260 HBW; a metallographic structure comprises ferrite and pearlite; the banded structure is smaller than or equal to 2 levels; the grain size is larger than or equal to 8 levels; and the mechanical property can meet the national standard and user needs.

Owner:DAYE SPECIAL STEEL CO LTD

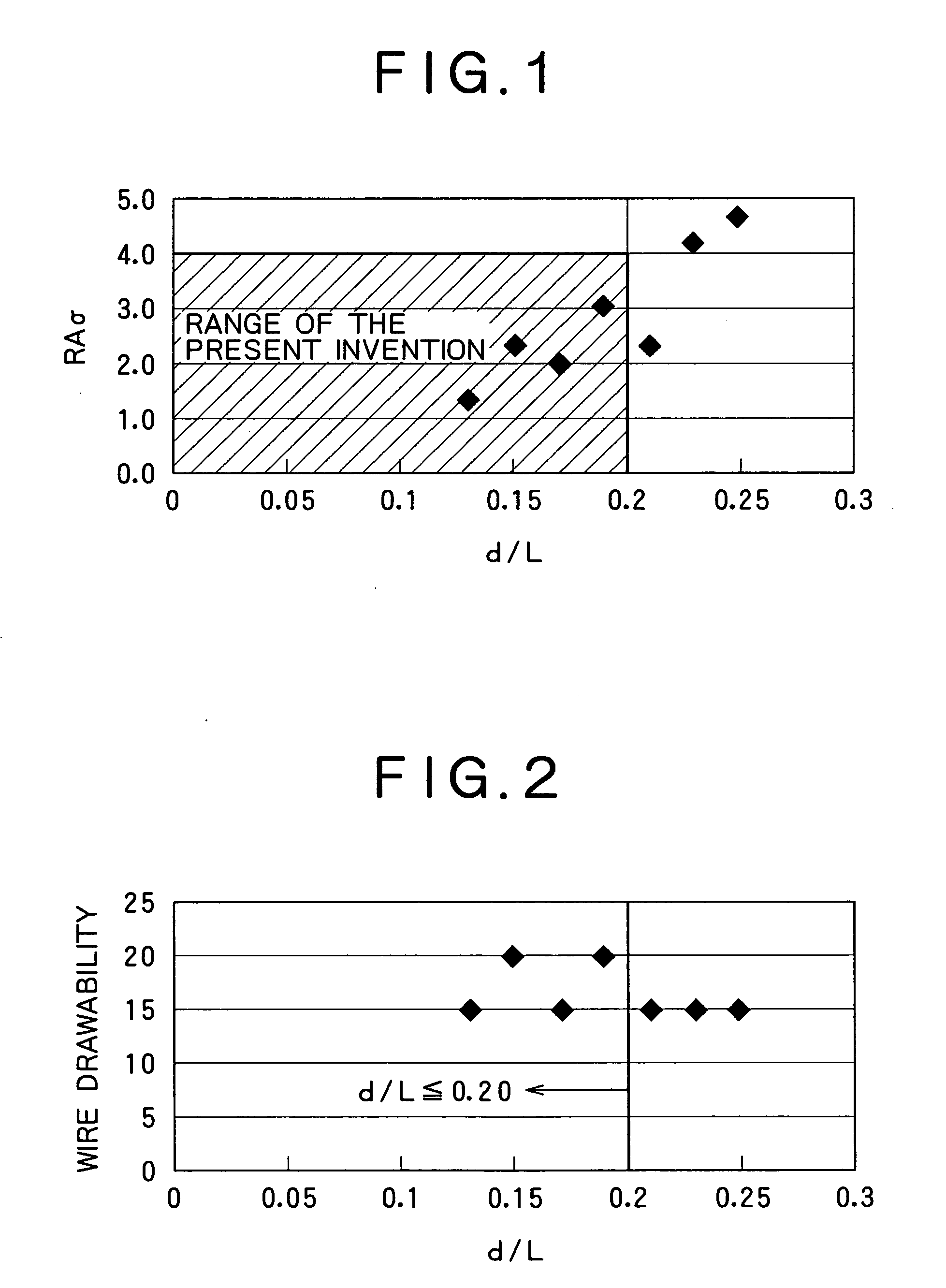

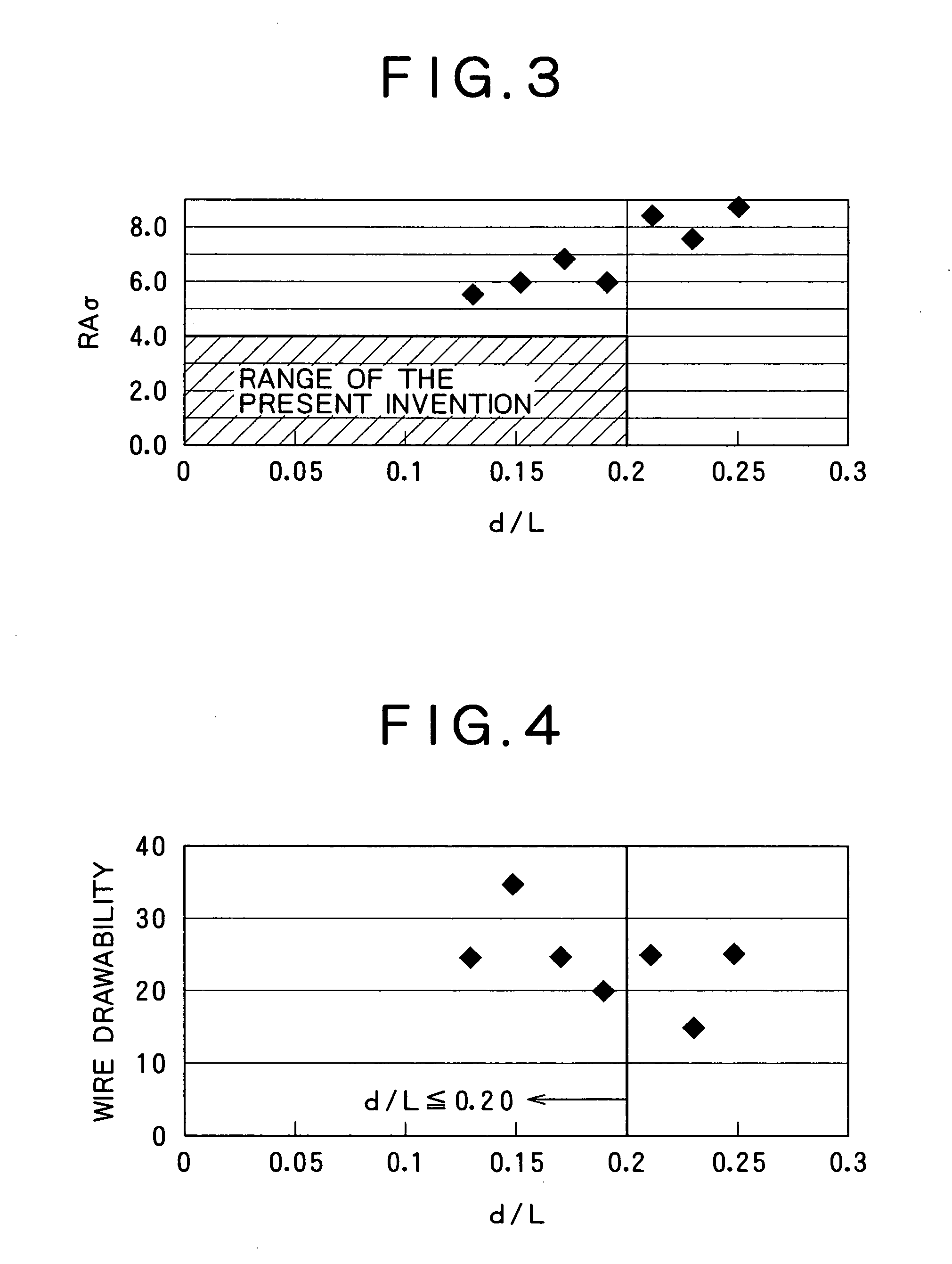

Hot milled wire rod excelling in wire drawability and enabling avoiding heat treatment before wire drawing

InactiveUS20060048864A1Good drawing effectSlow changeFurnace typesCooling bedsWire rodUltimate tensile strength

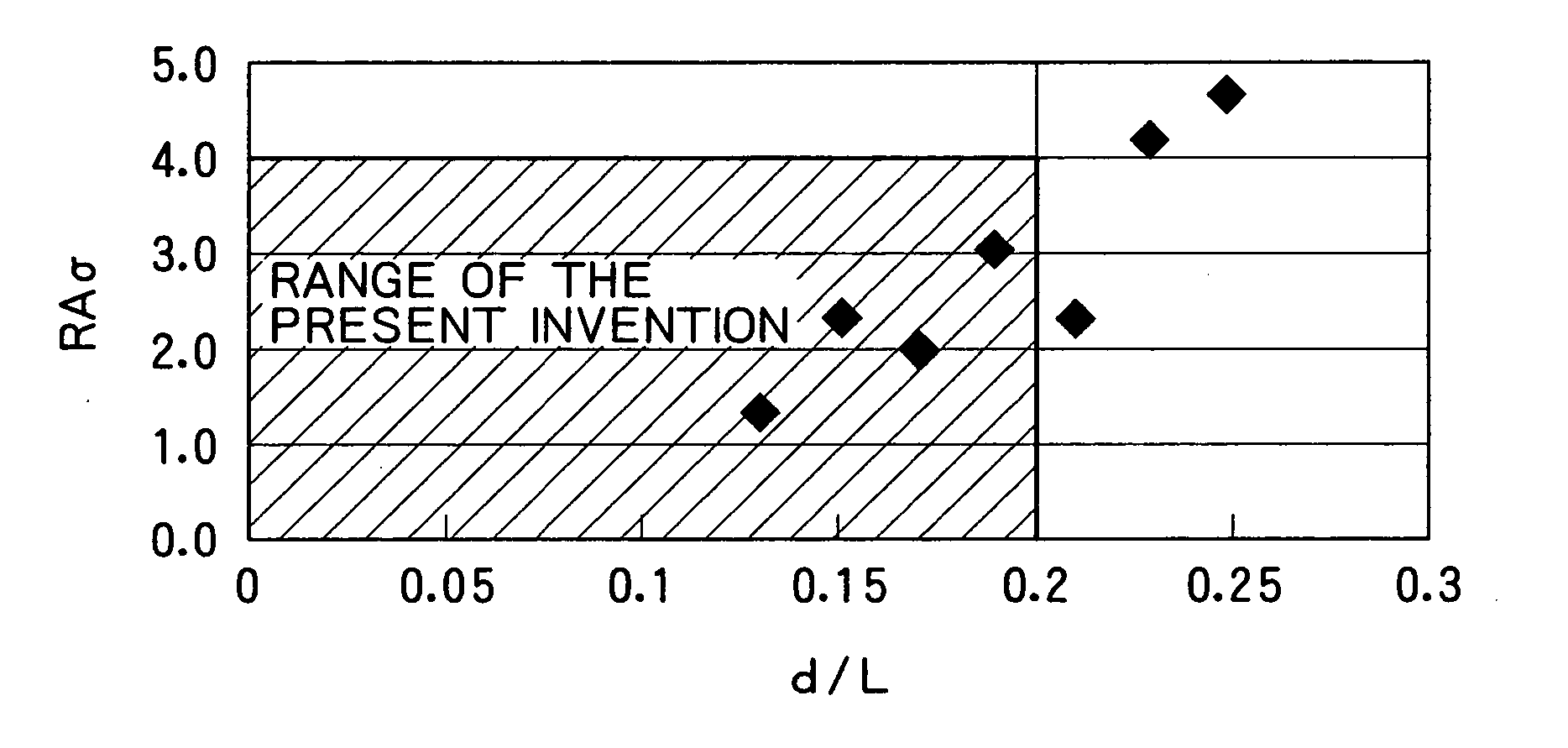

A hot-rolled wire rod: the wire rod being a hot-rolled wire rod 5.0 mm or more in diameter, containing in mass C: 0.6 to 1.0%, Si: 0.1 to 1.5%, Mn: 0.3 to 1.0%, P: 0.02% or less, and S: 0.02% or less; not less than 90% of the wire rod in area percentage being composed of a pearlite structure; and the mechanical properties of the wire rod 4 m in length satisfying the following expressions (1) to (4), (1) TS*−30≦Average value of tensile strength (TSAV in MPa)≦TS*+30, where, TS*=400×{[C]+([Mn]+[Si]) / 5}+670 and the elements in square brackets [ ] in the equality mean the contents of relevant elements in percentage, (2) Standard deviation of tensile strength (TSσ)≦30 MPa, (3) Average value of reduction of area (RAAV)>35%, (4) Standard deviation of reduction of area (RAσ) ≦4%. A hot-rolled wire rod according to the present invention is incomparably excellent in wire drawability and brakes less frequently than a conventional wire rod even when it is processed as hot-rolled with heat treatment such as patenting treatment omitted.

Owner:KOBE STEEL LTD

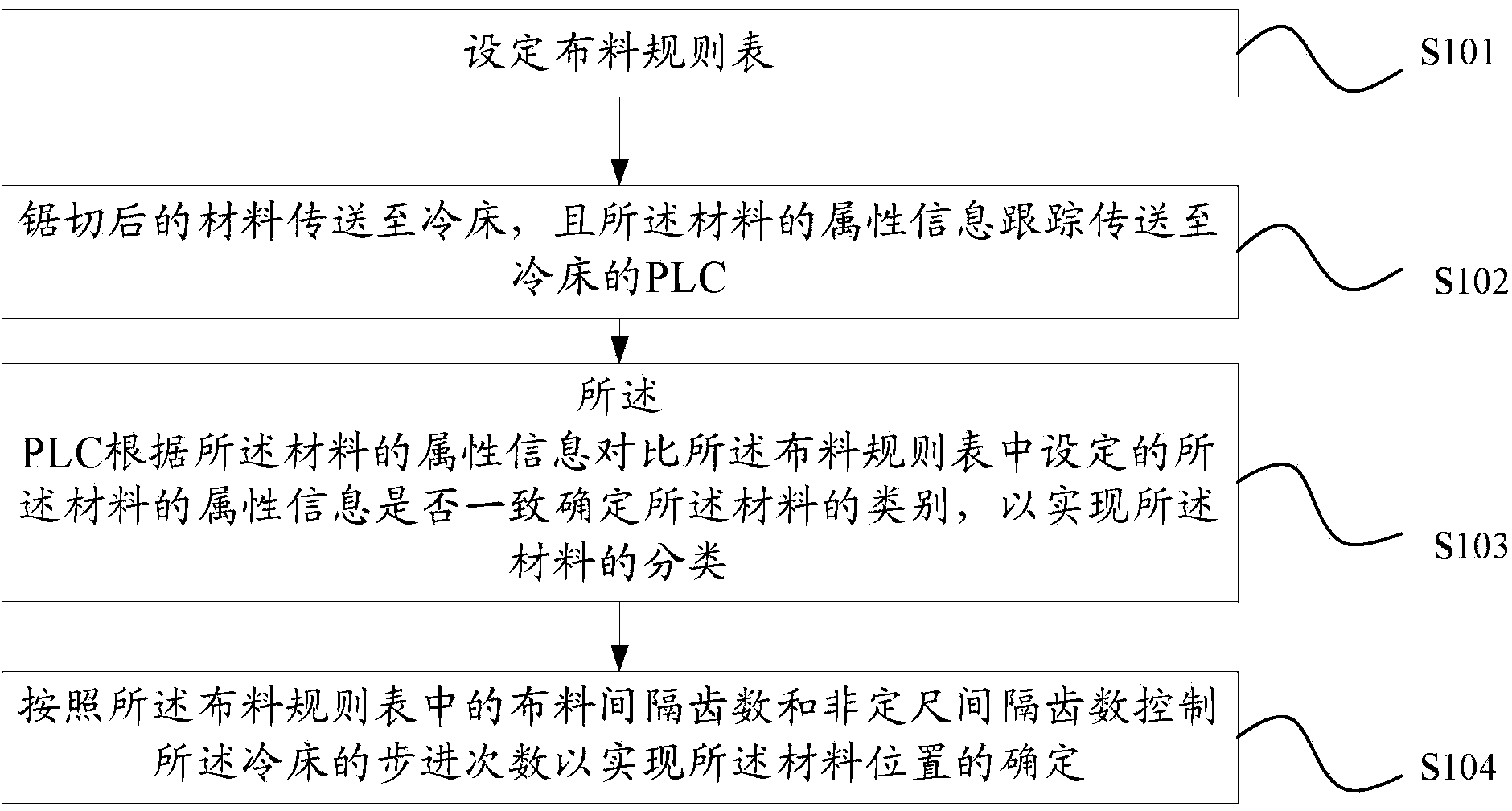

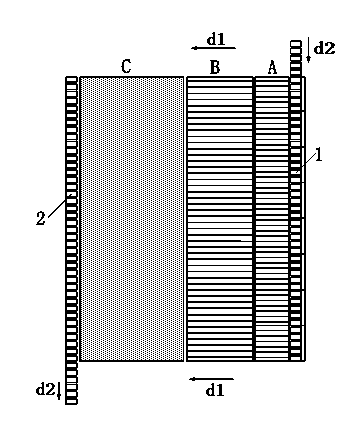

Material distribution method for cold bed

ActiveCN103978050AImplement collection by classRealize fully automatic controlCooling bedsMetal rolling arrangementsAutomatic controlData management

The invention discloses a material distribution method for a cold bed, and belongs to the field of automatic control. The material distribution method for the cold bed comprises the following steps: (1) setting a material distribution rule table; (2) conveying a sawn material to the cold bed, and tracking and transmitting the property information of the material to a PLC (Programmable Logical Controller) in a cold bed area; (3) determining the type of the material by comparing whether the property information of the material is consistent with set property information in the material distribution rule table or not by using the PLC to realize classification of the material; (4) controlling the stepping times of the cold bed according to the number of material distribution interval teeth and the number of non-fixed-length interval teeth in the material distribution rule table to realize the determination of the position of the material. According to the material distribution method for the cold bed, by tracking the property information of the material, the property information of a finished product material can be comprehended in real time, and full-automatic control of the material distribution of the cold bed is well realized. By using the method, data management can be performed conveniently, the manual workload is lowered greatly, the production efficiency is increased, and the stability of a system is ensured.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

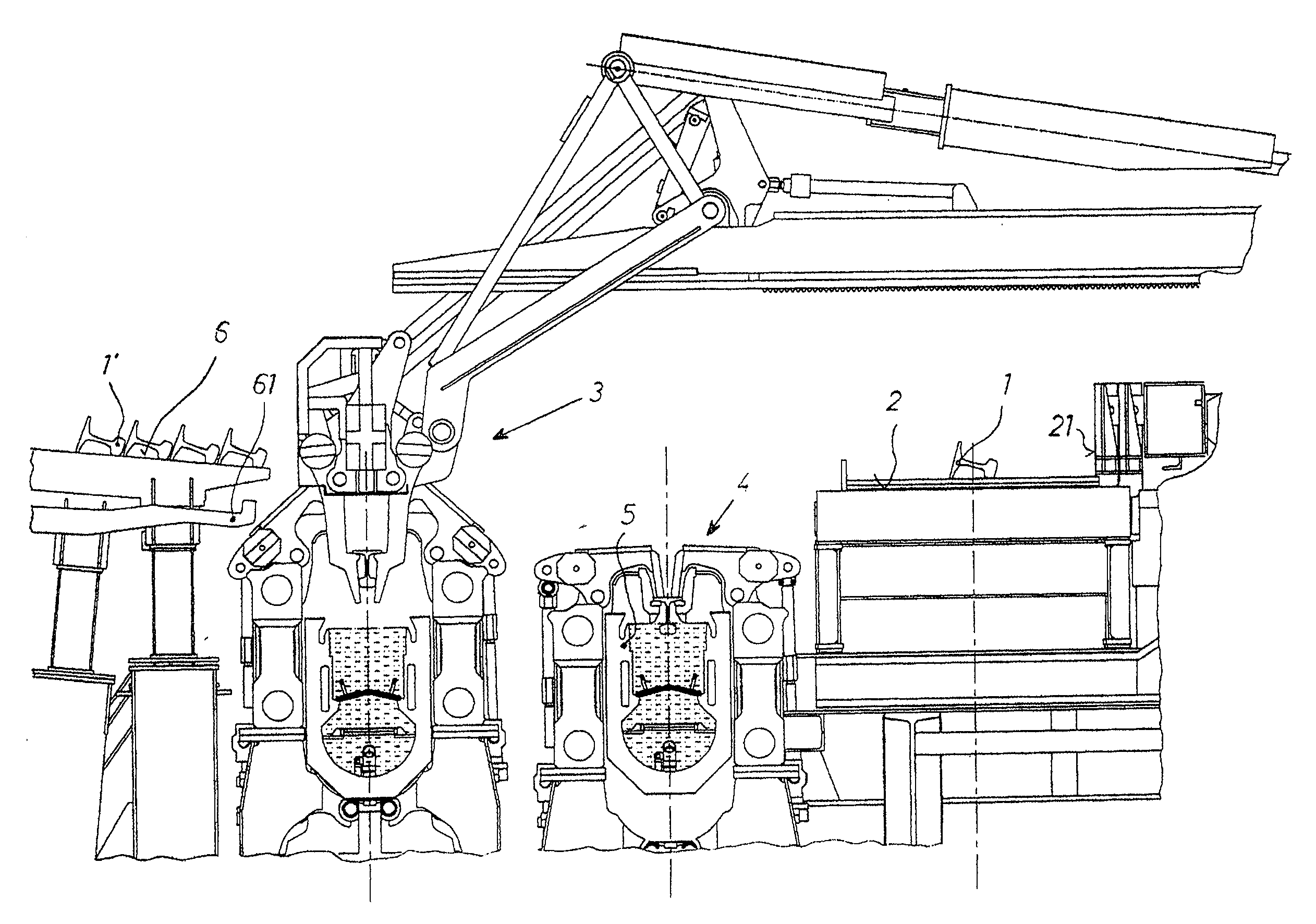

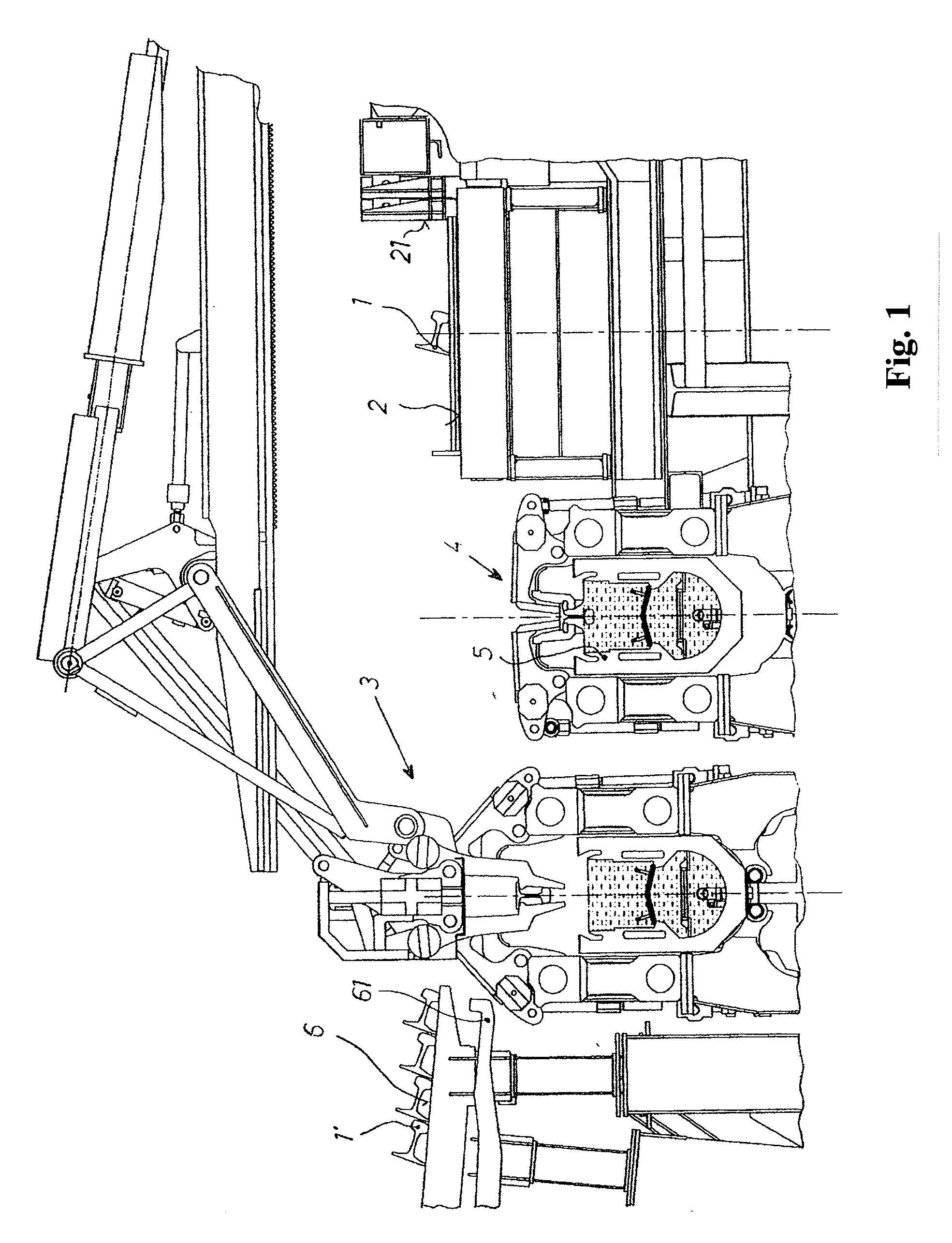

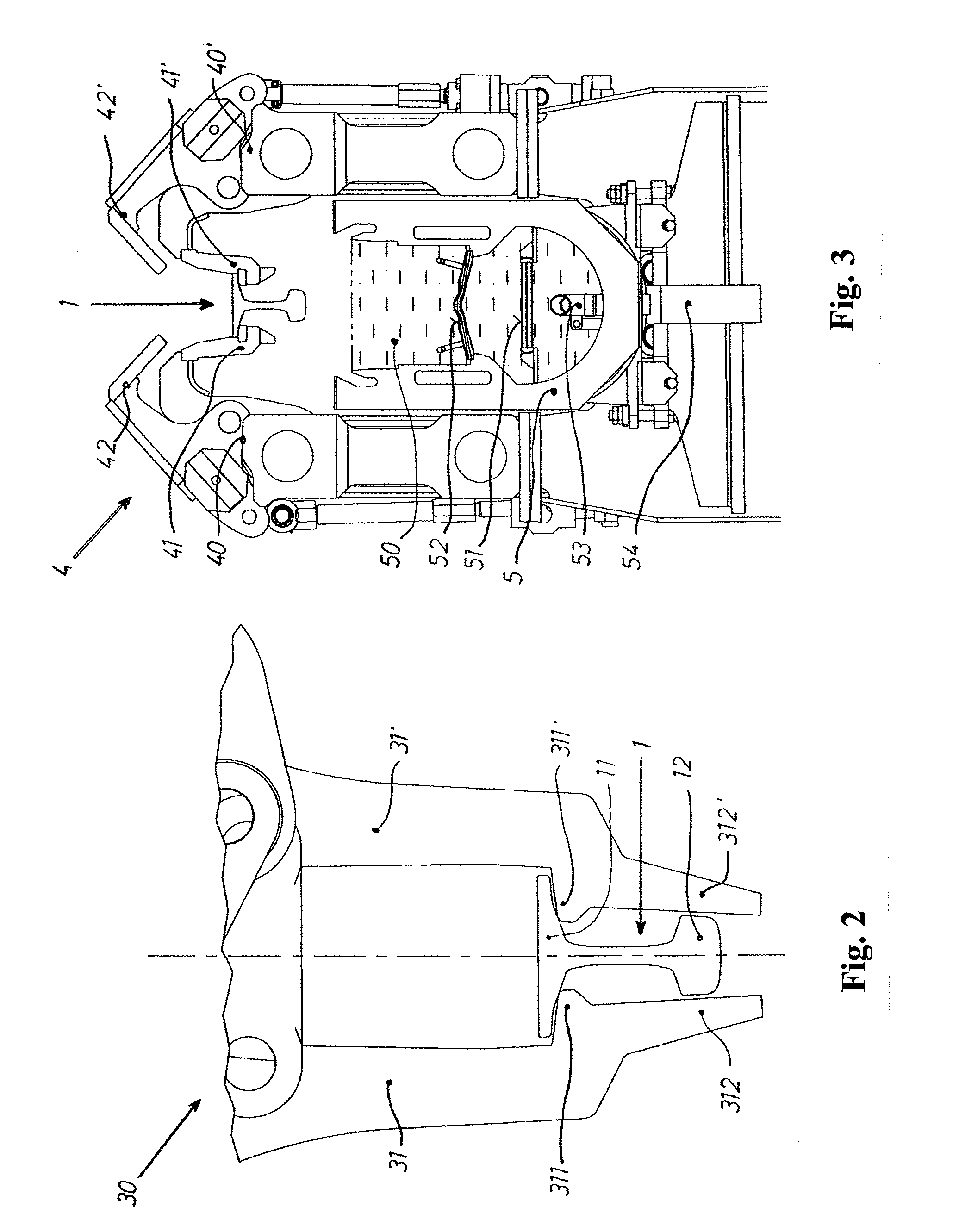

System and method for hardening rails

ActiveUS20090200713A1High-quality railProduced very safely and economicallyFurnace typesWork cooling devicesEngineeringLateral displacement

System and method for hardening rails by cooling, in a cooling medium, at least one part of a respective rail cross-section of a rail over an entire length of the rail. The system includes a cross displacement device arranged in an area of a roller table, at least one positioning device, at least one coolant container containing the cooling medium, a manipulation gripper comprising a plurality of pincers and being structured and arranged to move the rail. The method includes at least one of moving the rail from the roller table to the at least one coolant container positioning the rail into the at least one positioning device via the manipulation gripper, as well as moving the rail into the coolant medium with the at least one positioning device.

Owner:VOEST ALPINE SCHIENEN GMBH

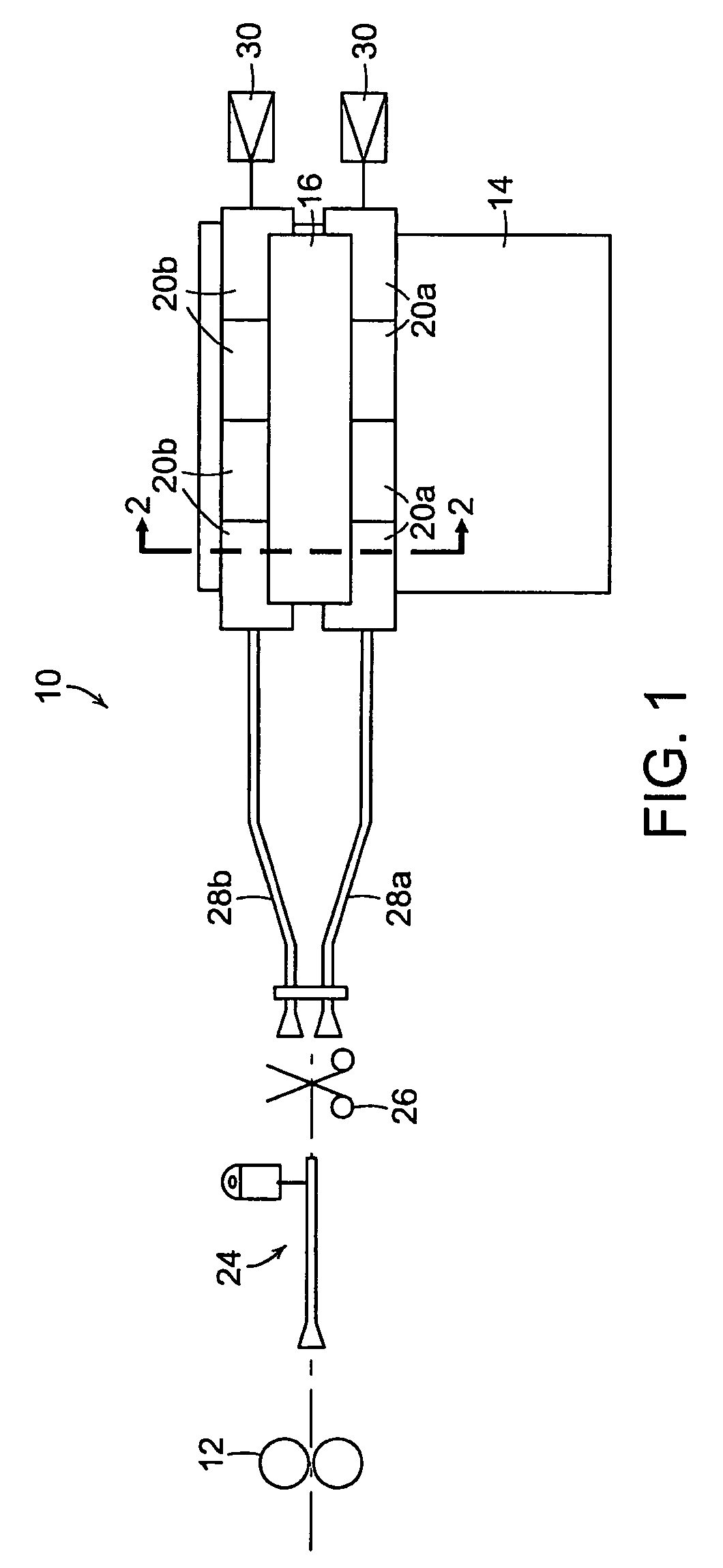

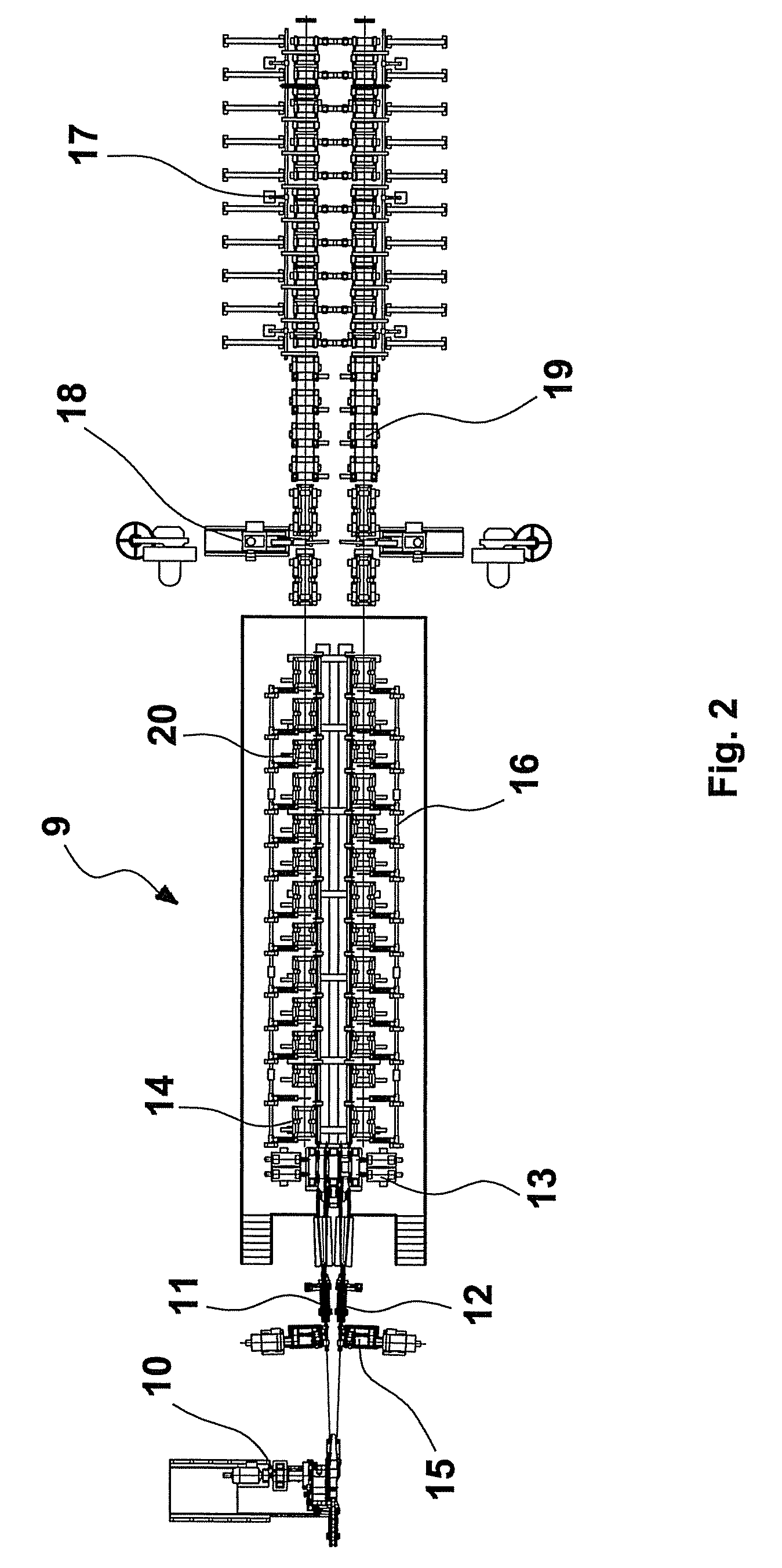

Rolling mill product handling system

ActiveUS7219521B1Guiding/positioning/aligning arrangementsWork manipulationHandling systemRotating drum

A product handling system comprises a support structure defining a pair of stationary inverted first channels with downwardly facing open sides. At least one cylindrical drum is interposed between each of the first channels and an underlying receiver. The drums are rotatable about their axes, with their surfaces arranged to close the open sides of the respective first channels. The drum surfaces are interrupted by second channels, with the first and second channels and the drum axes being arranged in a parallel relationship. Successive product lengths are alternately delivered longitudinally into one and then the other of the first channels. The drums are rotated about their axes resulting in the thus delivered product lengths being sequentially: (i) temporarily retained in the first channels by the rotating drum surfaces; (ii) deposited from the first channels into the second channels when the second channels rotate into radial alignment and communication with the first channels and (iii) downwardly deposited from the second channels to the receiver when the second channels rotate to discharge positions over the underlying receiver.

Owner:PRIMETALS TECH USA

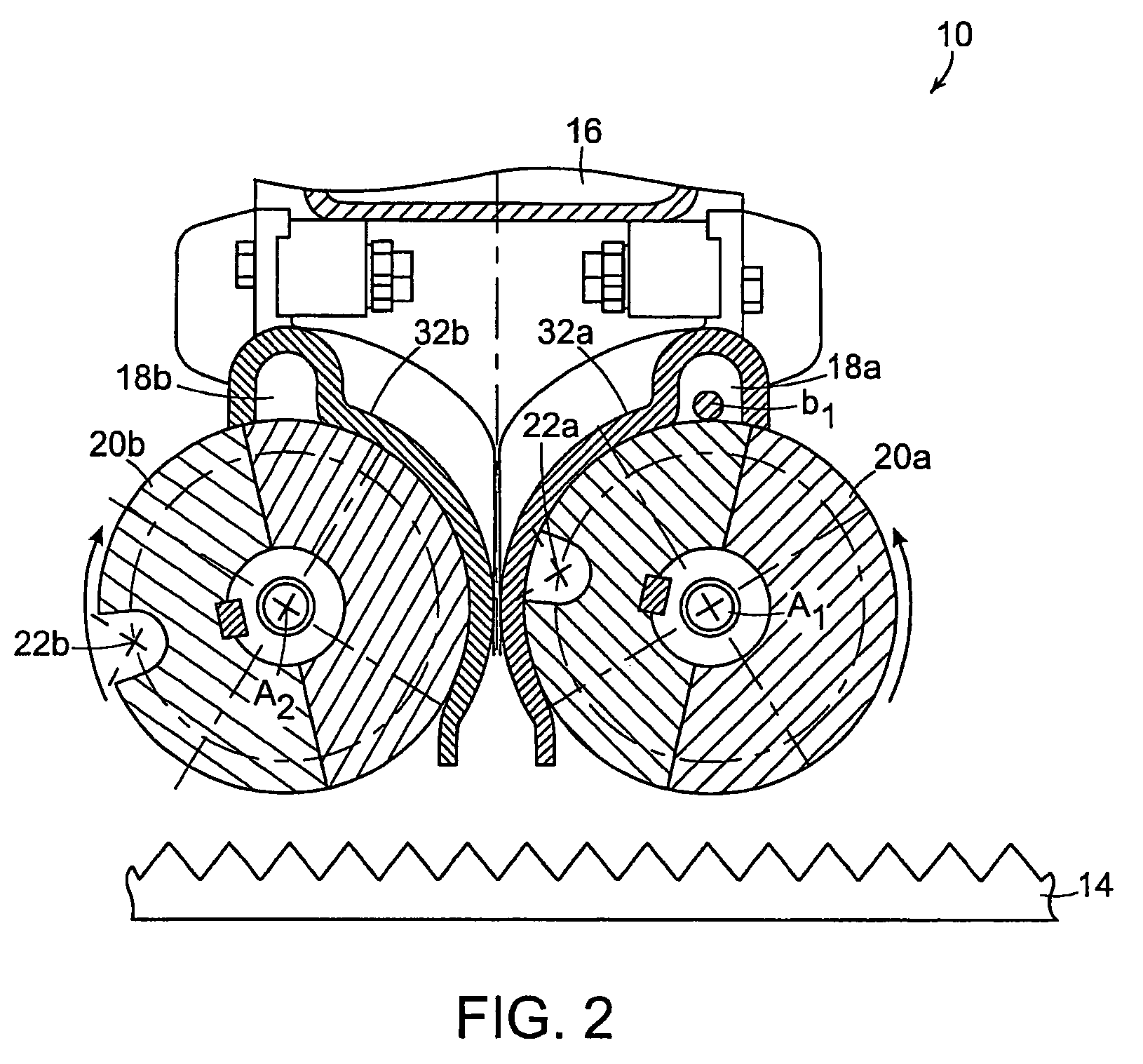

Laminated flowing cooling water side-jetting sweeping system after high-strength low-alloy steel being rolled

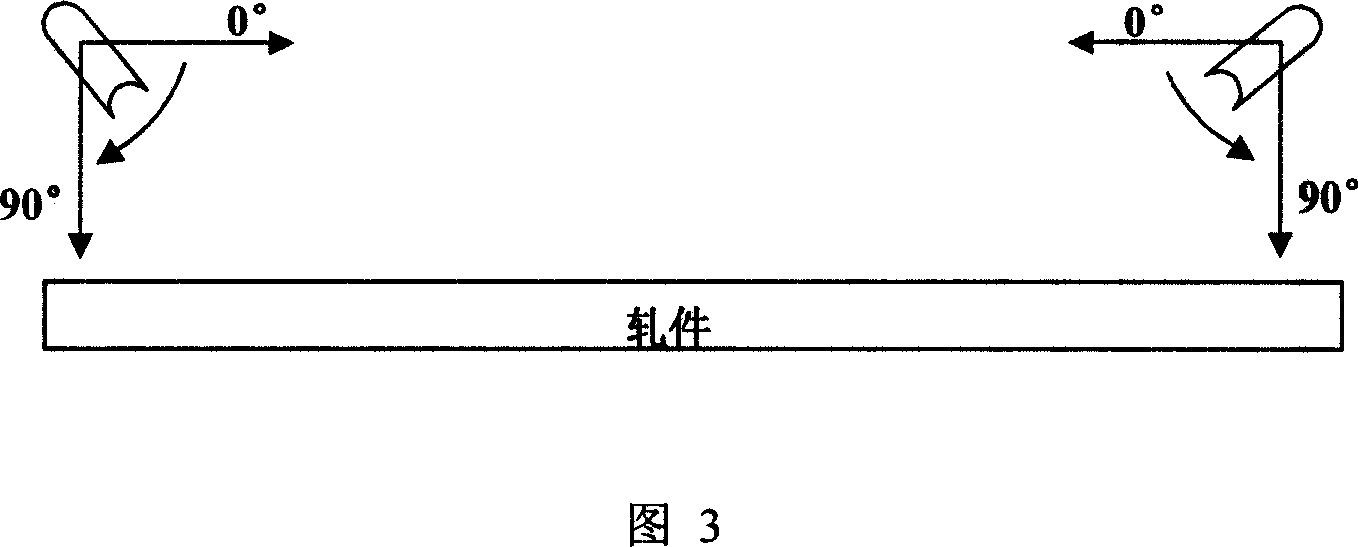

InactiveCN1947876AAvoid defects such as bucklingImprove mechanical propertiesWork treatment devicesCooling bedsSheet steelSprayer

A side-spray scavenge system for the laminar-flow cooling water on the rolled high-strength low-alloy steel is composed of a conveying roller way for conveying the rolled steel on it, and a laminar-flow cooling unit with at least a group of side sprayers arranged at both sides of said roller way, connected to water inlet tube, and with at least one nozzle.

Owner:NANJING IRON & STEEL CO LTD +1

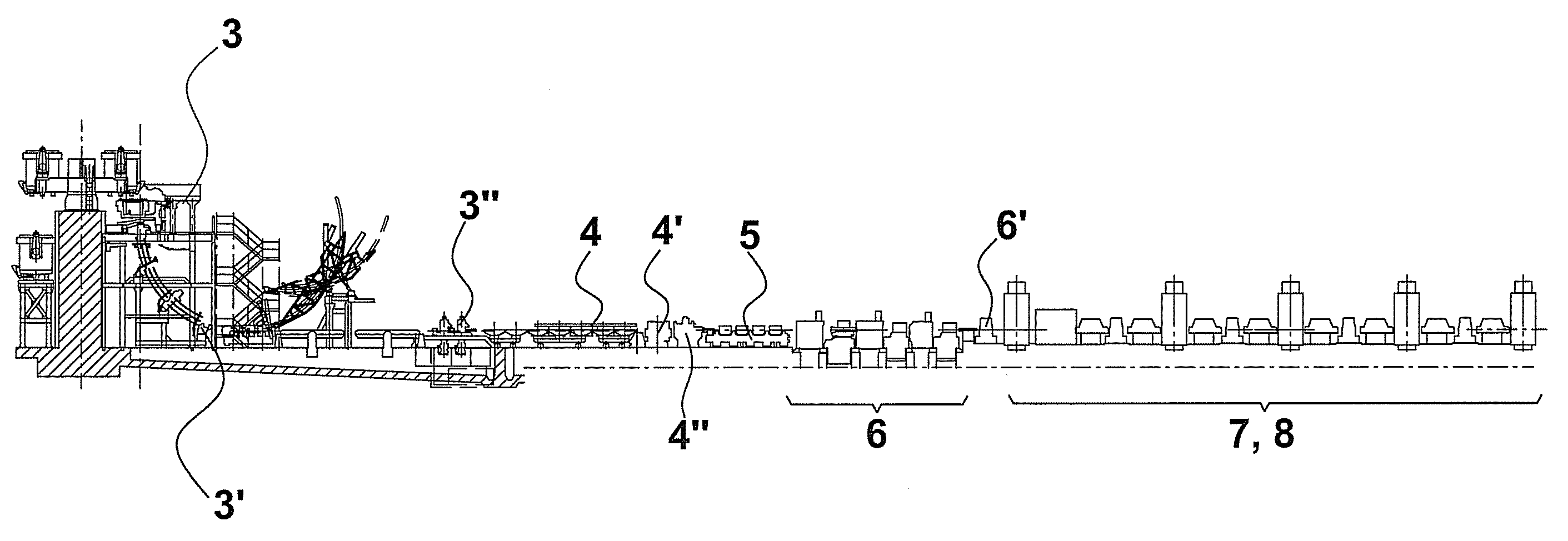

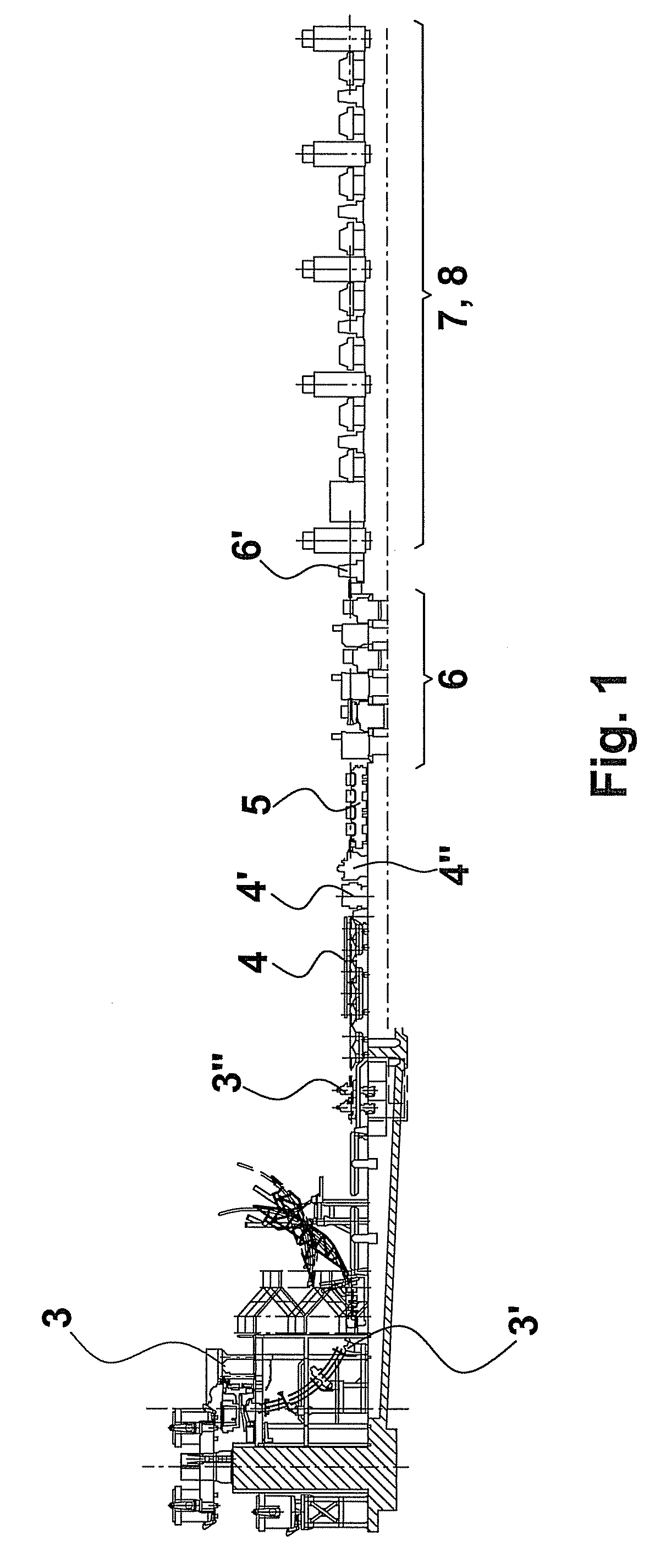

Compact Plant for Continuous Production of Bars and/or Profiles

ActiveUS20080196236A1Low investment costShorten production timeMetal rolling stand detailsGuiding/positioning/aligning arrangementsTO-18Rebar

Compact plant for making steel bars and profiles with which, starting from the scrap, it is possible to obtain the finished product, for example bars with commercial length from 6 to 18 meters, pre-packed, packaged and ready for sale, with all the stations placed in line and operating continuously. All the stations are arranged in reduced spaces, thereby reducing both investment costs and plant management costs, and decreasing production times. Advantageously, the plant of the invention incorporates an extremely compact bar packaging apparatus which, through an innovative arrangement and innovative operating method of the components thereof, allows a further reduction in length.

Owner:DANIELI & C OFF MEC SPA

Technique of hot rolled plate and linear cooling bed for manufacturing trolley track girder

InactiveCN101224538AMeet the requirements of mass productionReduce time spentCooling bedsMetal rolling arrangementsEngineeringExpansion joint

The invention relates to a manufacturing process of a track beam of a cooling bed dolly in a hot rolled plate line, which is characterized in that the invention comprises a welding process and a machining process; the welding process is that the welding is achieved according to the structures of parts; separate shaping and correcting are carried out after the welding is achieved, and the assembly welding and forming are carried out; the machining process is the processing of the track plate by sections before the welding; an expansion seam is preserved at butted position and is aligned and levelled by grinding; after the assembly welding and forming of the track beam, the shaping and correcting are carried out, and a bottom surface and a keyway, etc. are integrally processed through an aging disposal. The invention ensures the qualified rate of the products, saves the occupied time of the large machine tool equipment, reduces the manufacturing cost, and shortens the manufacturing period.

Owner:TIANJIN SERI MACHINERY EQUIP

H-type shape steel vertical rolling method and apparatus

ActiveCN1935402AReduce temperature dropReduce energy consumptionWork manipulationRolling mill drivesMetalFlange

The present invention relates to a vertical rolling method of wide flange steel and its equipment, belonging to the field of metal rolling technology. Said method includes the following steps: billet heating, des caling, blooming, cropping and rolling so as to obtain the rolled material with web plate and flange. Said invention also provides the concrete operation steps of said rolling process.

Owner:MAANSHAN IRON & STEEL CO LTD

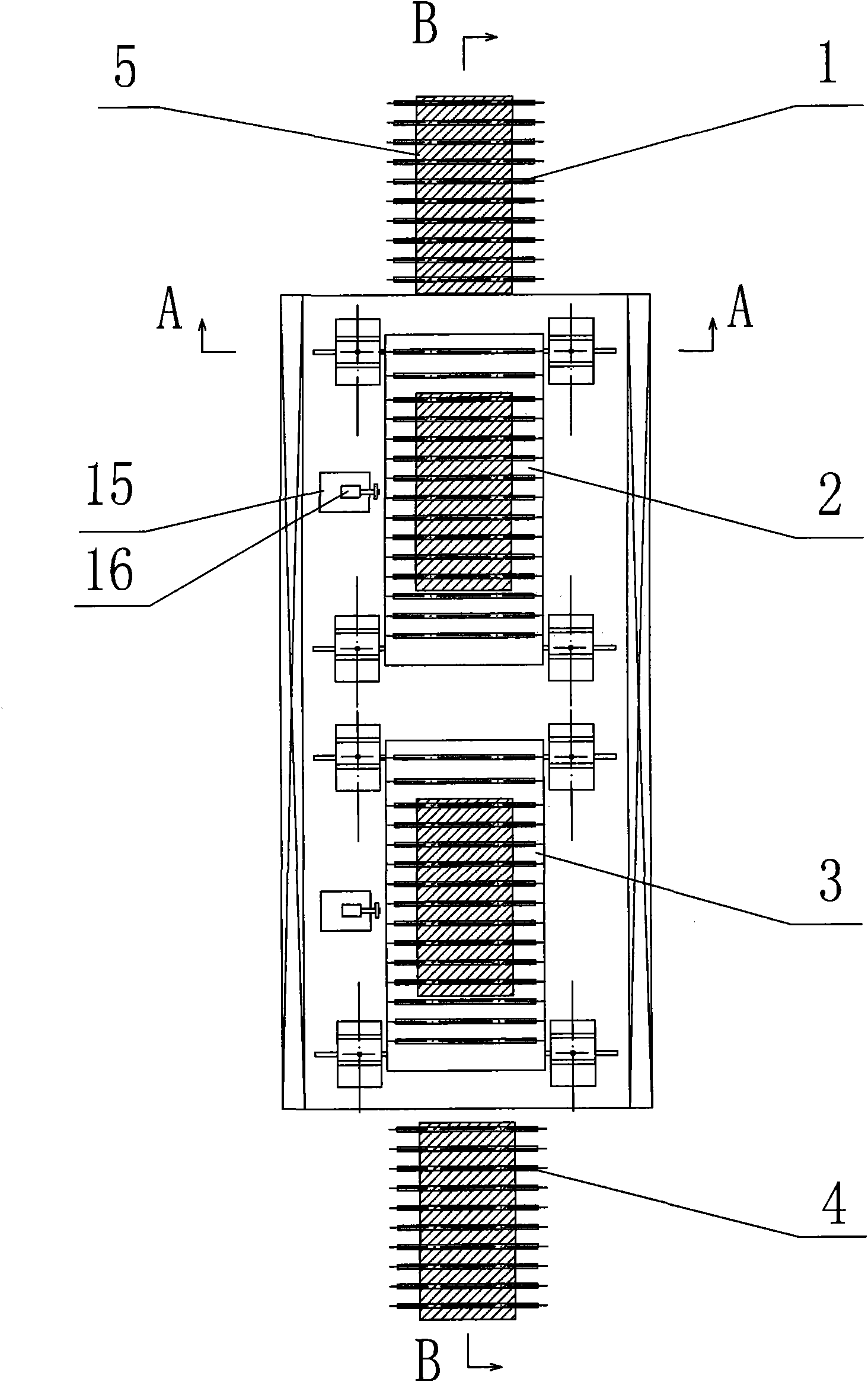

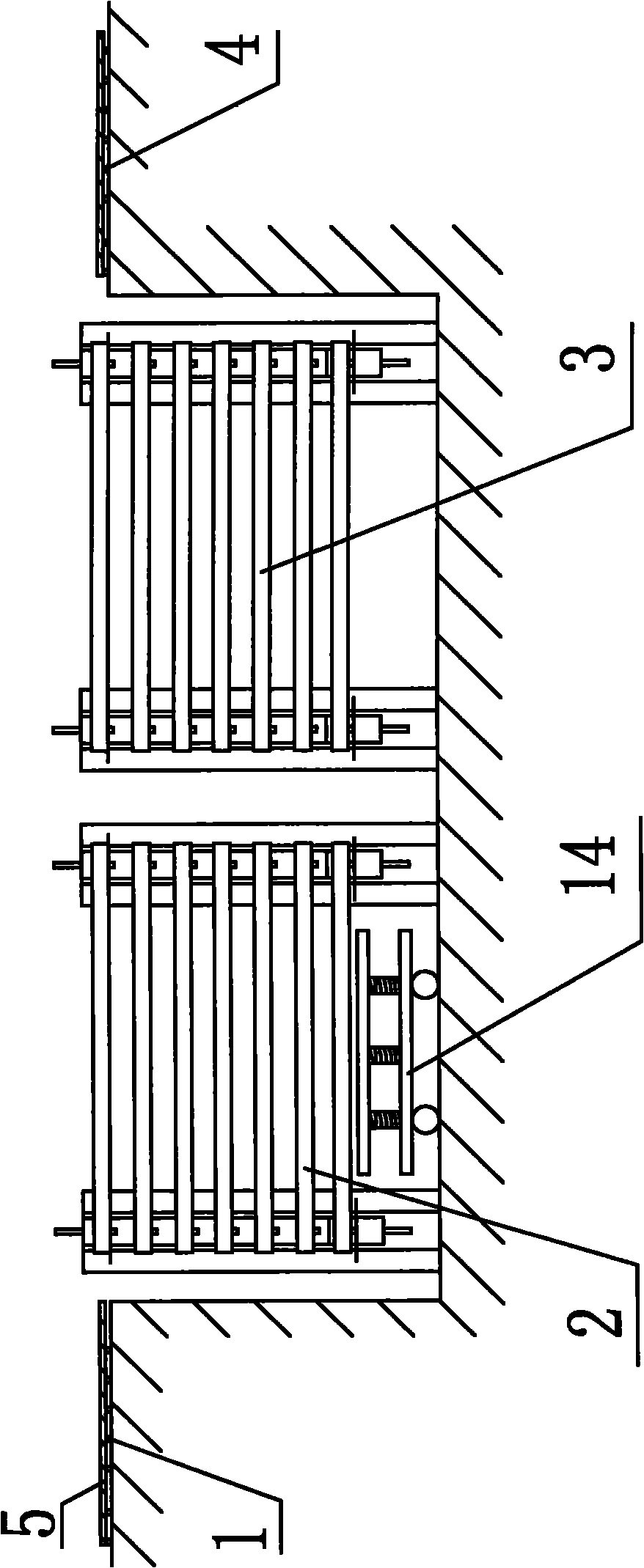

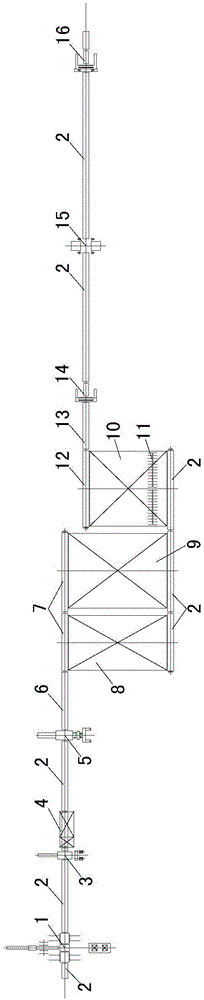

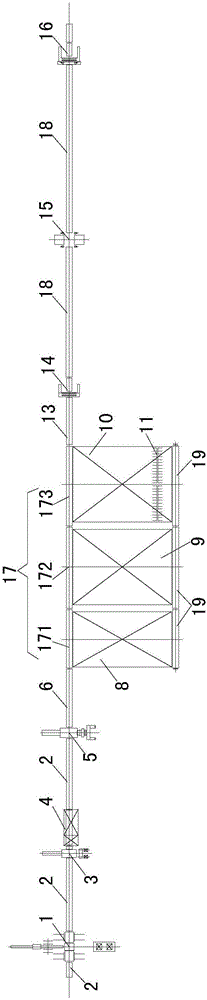

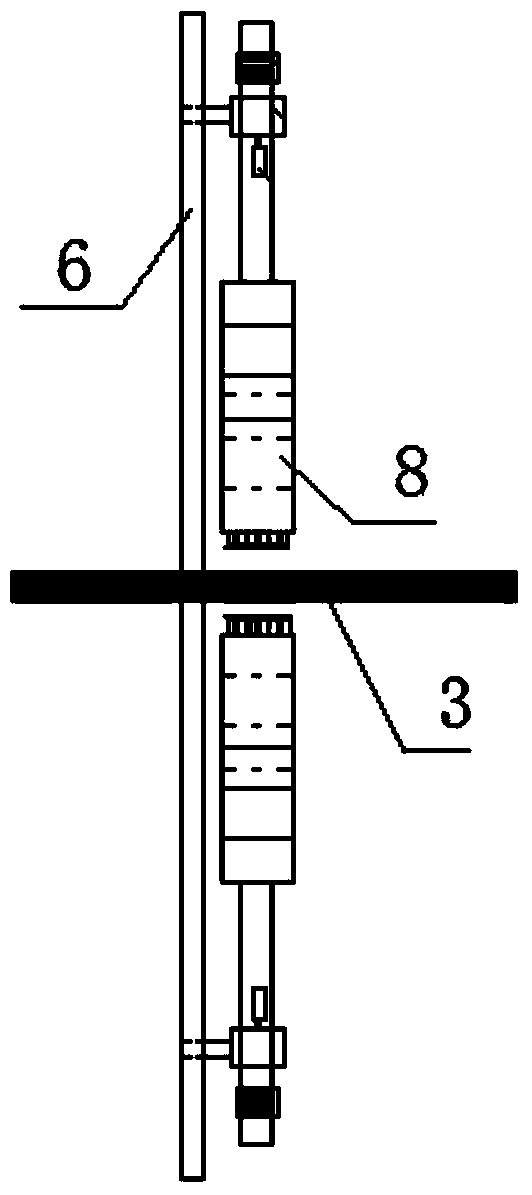

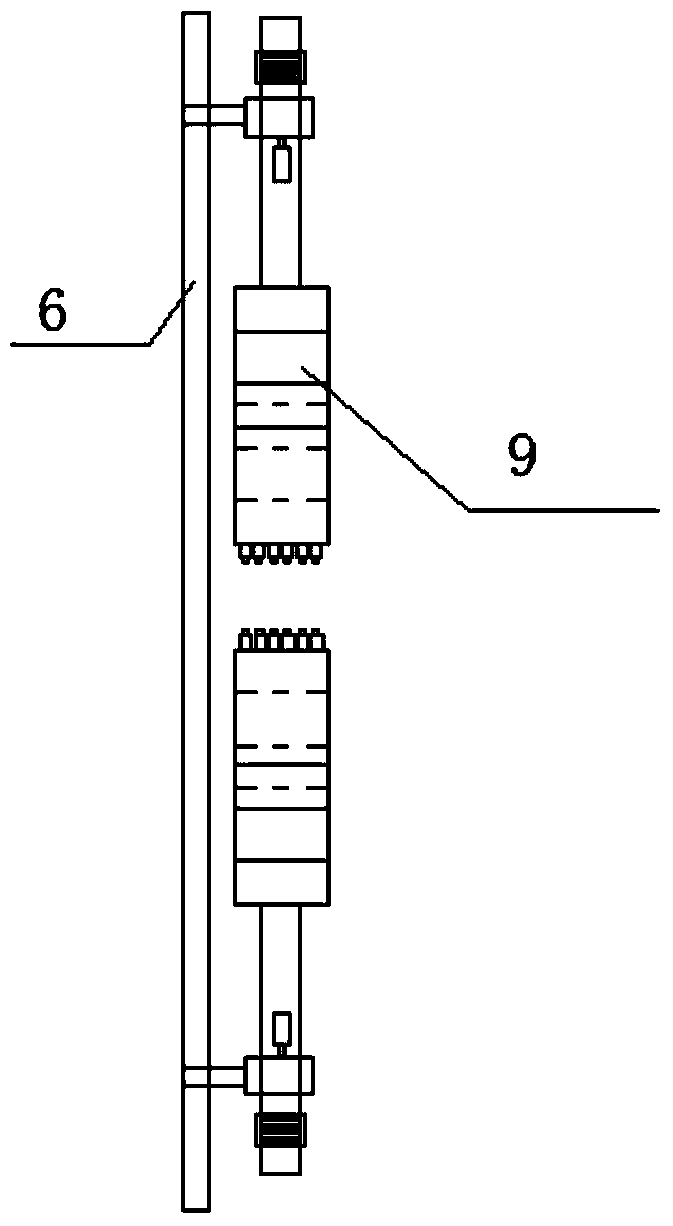

On-line control method of banded structure and hardness of gear steel and post-rolling on-line controlled cooling bed device

InactiveCN103589843AInhibition formationReduce manufacturing costHeat treatment process controlCooling bedsGear wheelEngineering

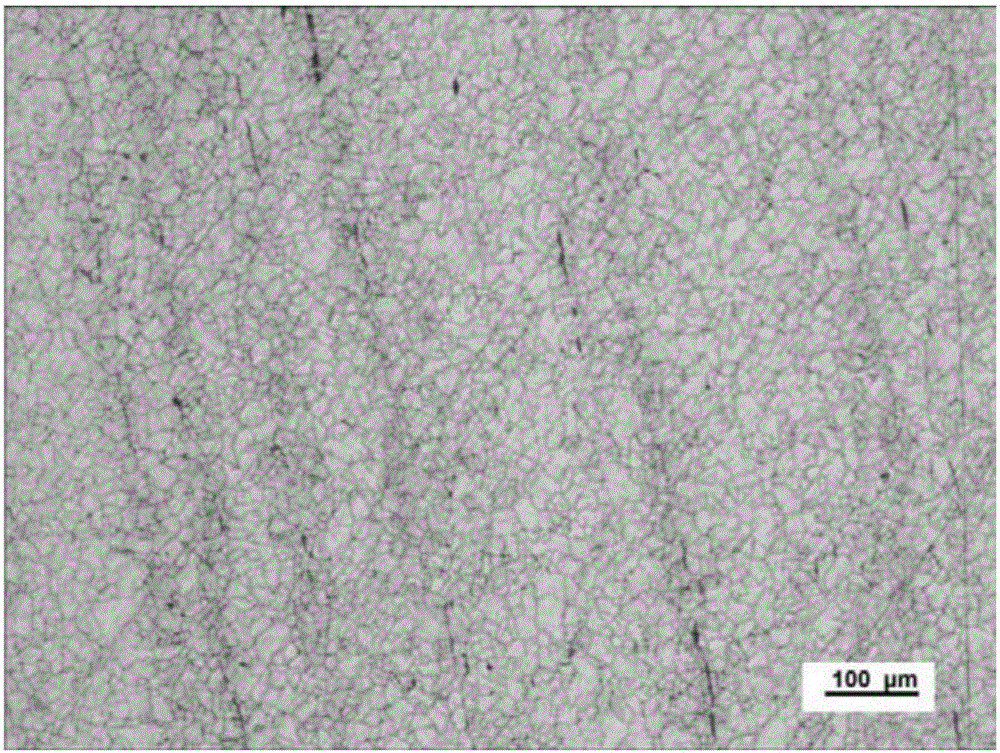

The invention discloses an on-line control method of a banded structure and hardness of gear steel. The method comprises the steps: controlling the finishing temperature of a gear steel rod at 900-980 DEG C, controlling the cooling speed of the gear steel rod in a three-stage cooling manner after rolling: air-cooling the high temperature gear steel rod after the rolling, reducing the surface temperature of the rod to 800-830 DEG C, and controlling the difference between the core temperature and the surface temperature of the rod to be within 150 DEG C, performing forced air cooling on the precooled rod, controlling the surface temperature of the rod, air-cooling to 620-680 DEG C, keeping the rod after the forced cooling warm, slowly cooling, and stopping cooling for 15-50min. The invention further discloses a post-rolling on-line controlled cooling bed device. A cooling bed system of the device is formed by combining three stepped cooling beds, namely a precooling bed, an air cooling bed and a slow cooling bed. The method can control the banded structure within a second stage, the structural homogeneity of the gear steel rod is improved, and the hardness requirements during blanking of the gear steel rod are met.

Owner:SHANGHAI UNIV

Method for fast cooling low-carbon hot-rolling small H-shaped steel

ActiveCN102029296ANo interferenceImprove mechanical propertiesTemperature control deviceCooling bedsComputer moduleHigh pressure

The invention provides a method for fast cooling low-carbon hot-rolling small H-shaped steel, belonging to the technical field of metal pressure processing. The method for fast cooling low-carbon hot-rolling small H-shaped steel is mainly based on the improvement of a cooling-after-rolling device and cooling is carried out by six stages in a high-pressure aerial fog cooling way, wherein each stage comprises four cooling control modules which are respectively arranged at the upper part, the lower part and two sides and are independently controlled and regulated by electromagnetic valves; controlled cooling is performed by regions, and different cooling methods are performed for cooled parts so that a flange part and an R part have larger temperature drop extent so as to fast and uniformly cool the positions of the H-shaped steel. By applying the fast cooling method to Q235 and Q345, the invention enables an H-shaped steel product to have tiny texture grains and larger mechanical property enhancement up to 50 MPa; in addition, the fast cooling method enables the properties of the positions of the H-shaped steel to be more uniform, reduces the cooling wave bending of the H-shaped steel product and enhances the finished product ratio of the H-shaped steel product.

Owner:南京先河工程技术有限公司

Manufacturing method of increasing high strength flat-bulb steel low temperature impact properties percent of pass

InactiveCN101229564ALow temperature impact performance pass rate increasedReduce manufacturing costTemperature control deviceWork treatment devicesHigh intensityMicrostructure

The invention discloses a production method for improving low temperature impact property qualified rate of high strength ball flat steel, which consist of steps of rough rolling, finish rolling, final rolling and cooling after rolling. The web temperature of the final rolling is ranging from 870 DEG C to 930 DEG C and the ball-end temperature is ranging from 910 DEG C to 990 DEG C. For cooling after rolling, air cooling is adopted. By controlling the final rolling temperature and speed of the cooling after rolling, the invention eliminates or reduces granular bainite and widmanstatten in the microstructure of the ball flat steel, thereby greatly improving the low temperature impact property qualified rate of the high strength ball flat steel.

Owner:CHONGQING IRON & STEEL CO LTD

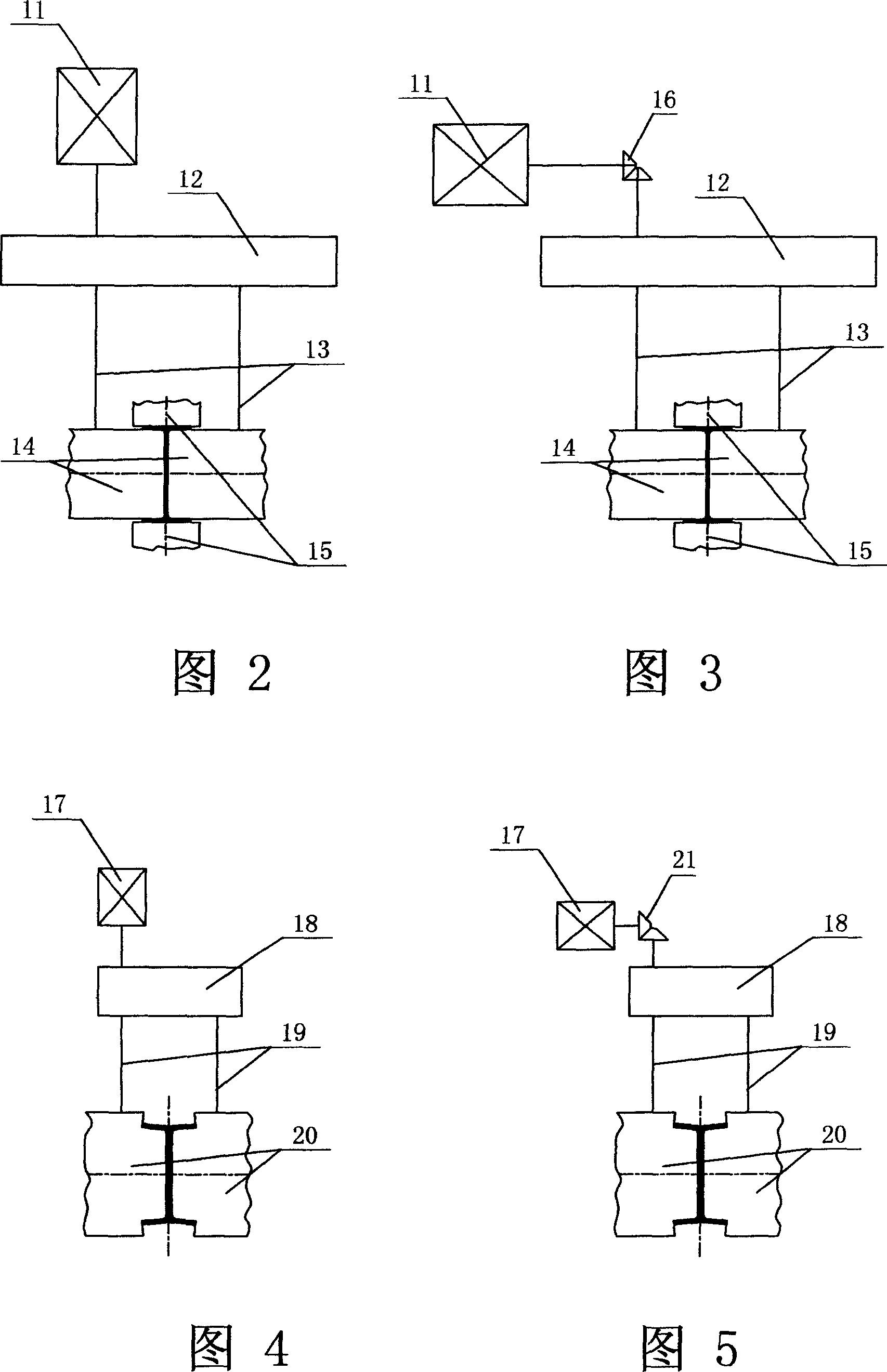

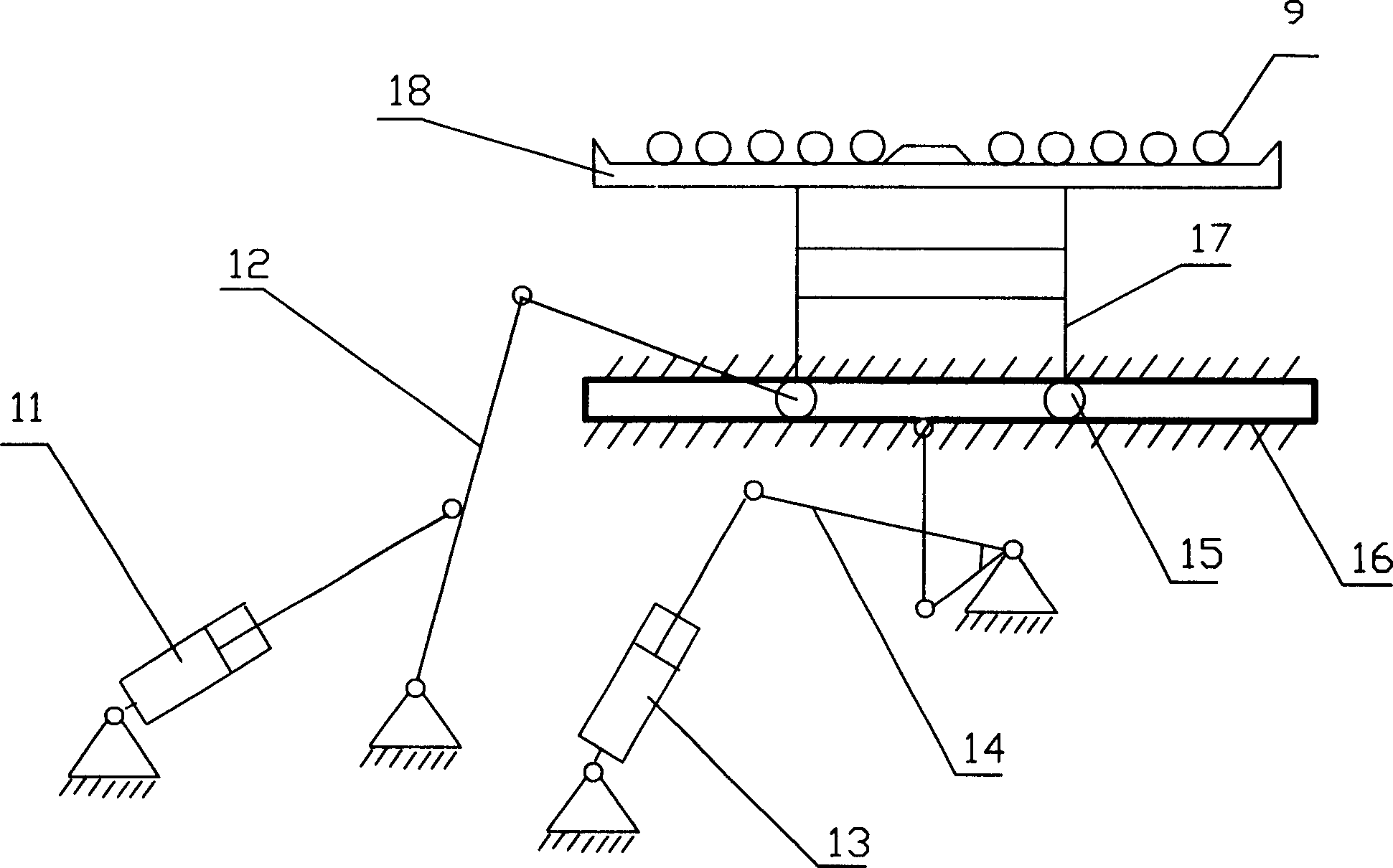

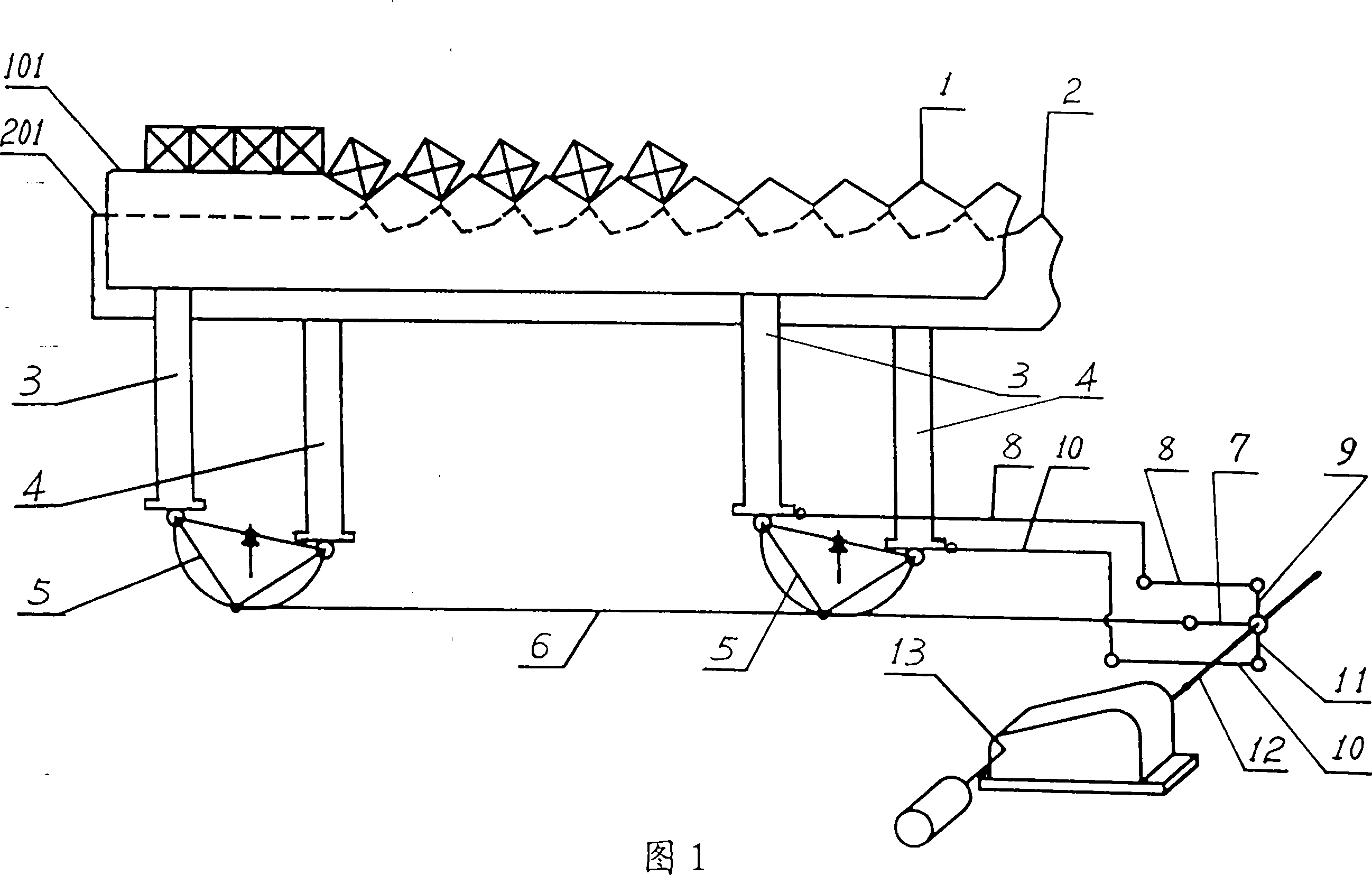

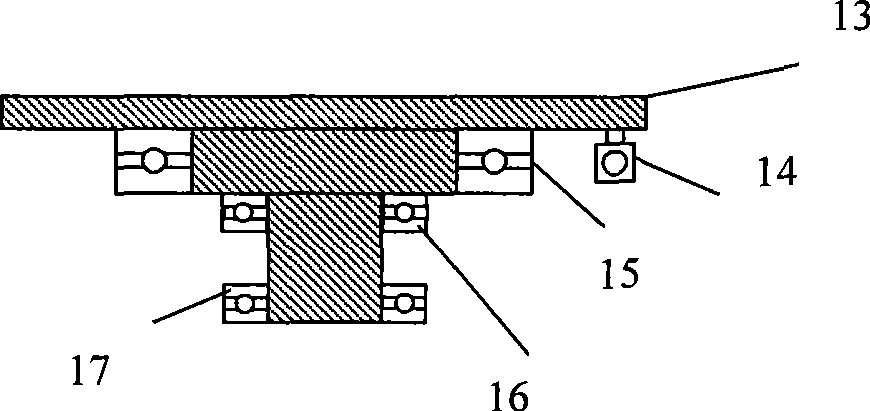

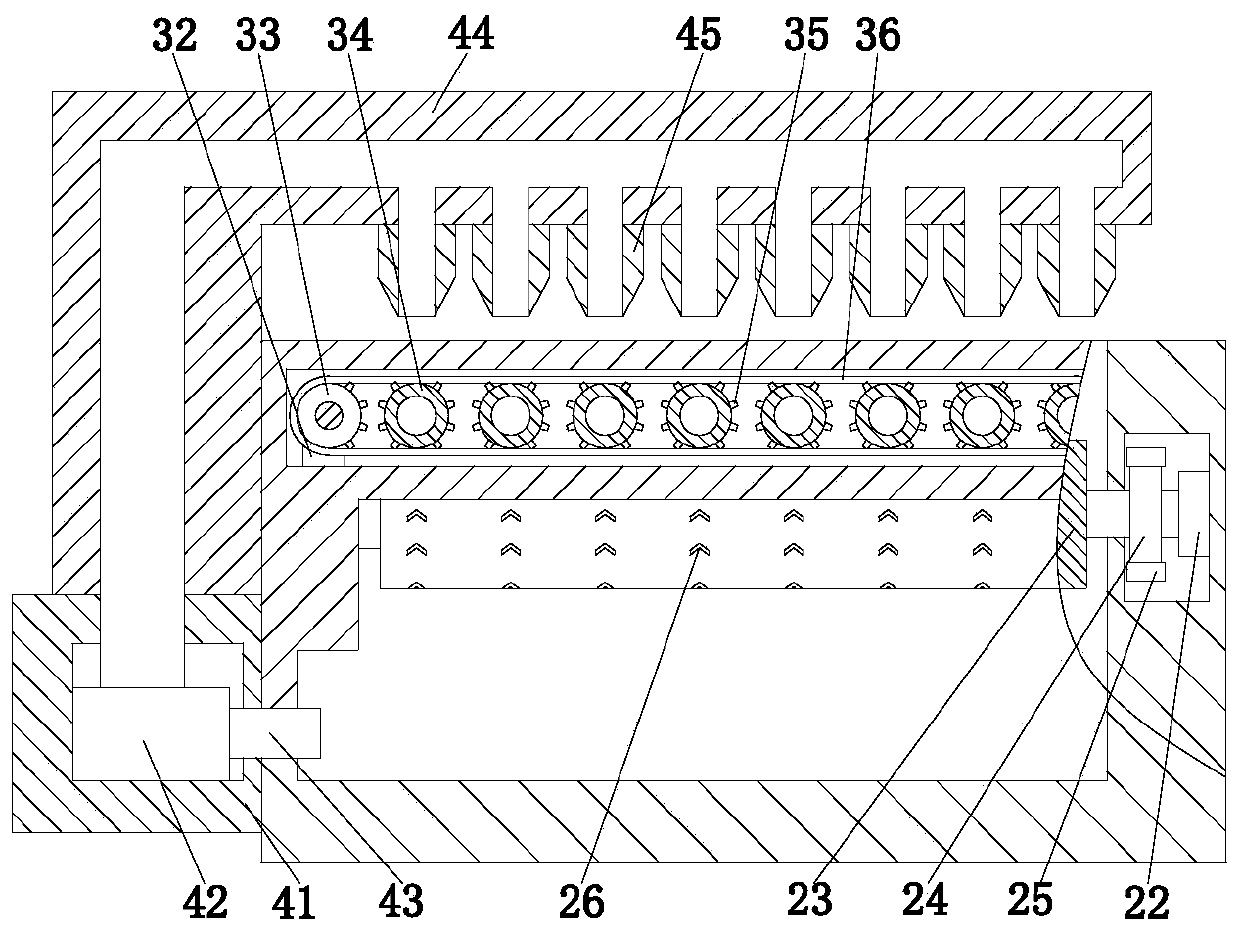

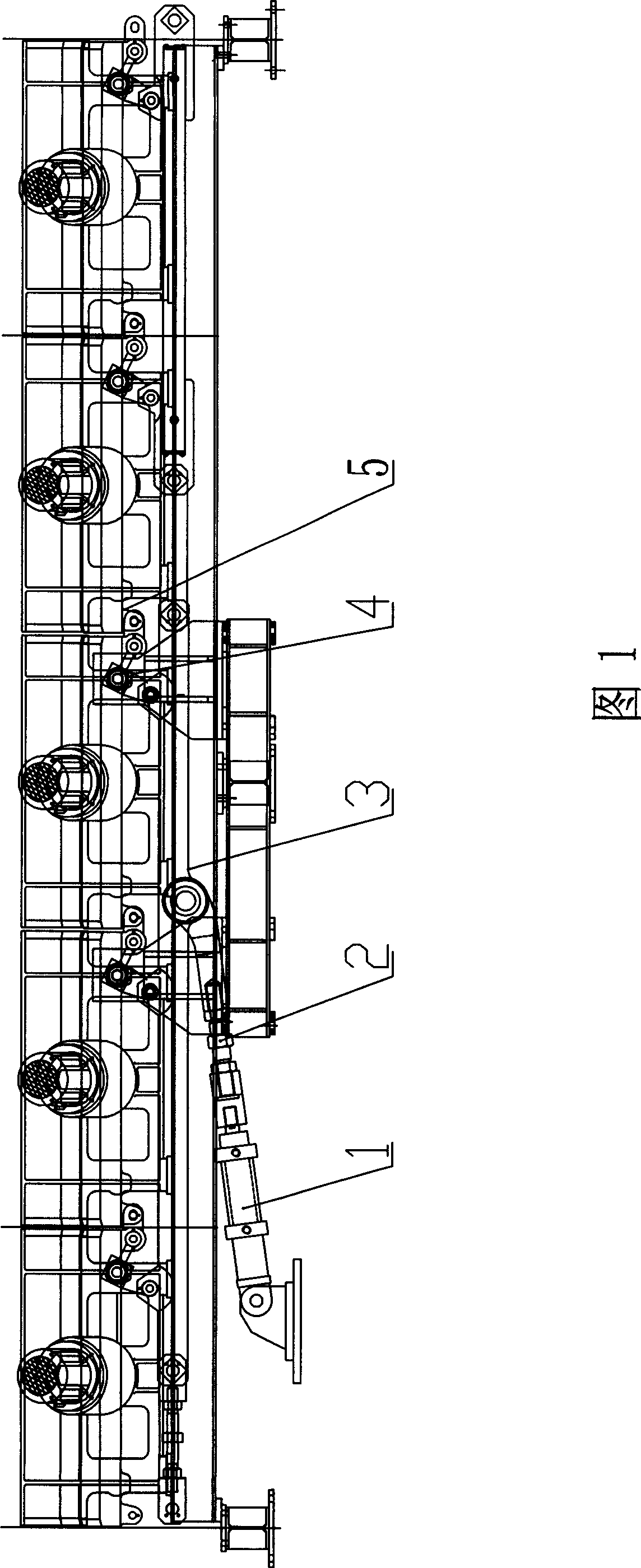

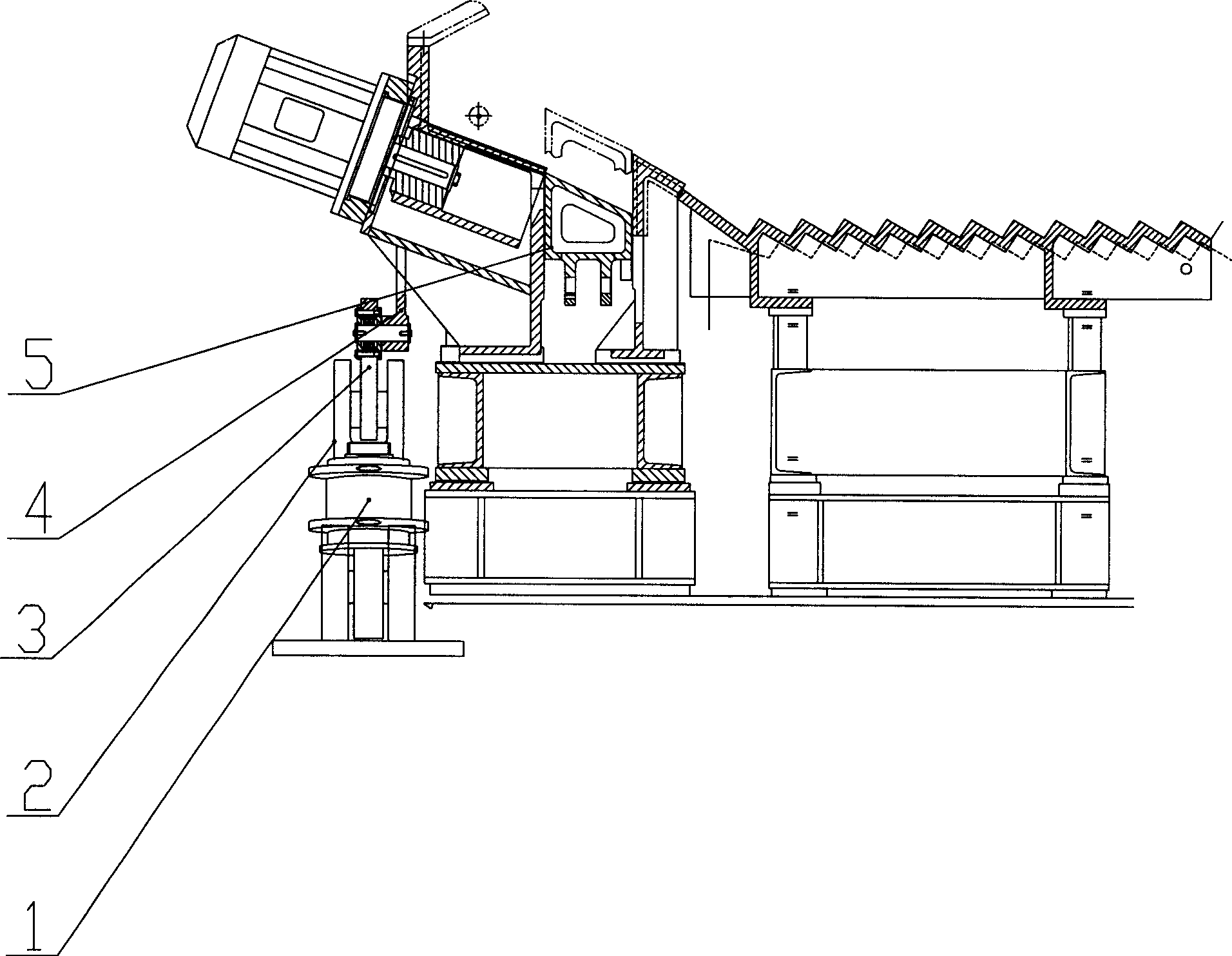

Cooling-bed hydraulic stepping and tread control device and control method thereof

ActiveCN101758088ASimple structureLow costServomotor componentsServomotorsHydraulic cylinderEngineering

The invention relates to a cooling-bed hydraulic stepping and tread control device which at least comprises a hydraulic cylinder block for driving a cooling-bed movable rack beam to move back and forth, wherein the hydraulic cylinder block is composed of a stepping cylinder and a tread cylinder which are connected in series; the two cavities of the stepping cylinder and the two cavities of the tread cylinder are respectively communicated with the corresponding outlets of a cartridge valve bank; the inlet of the cartridge valve is communicated with an electrohydraulic proportion direction valve; and the electrohydraulic proportion direction valve is used for controlling the stepping cylinder and the tread cylinder of the hydraulic cylinder block. The invention adopts the structure of the proportion direction valve and the cartridge valve, and satisfies the requirements for quick speed control and stability. The speed is adjustable, and the invention realizes the control on the stepping cylinder and the tread cylinder by using only one proportion direction valve, thereby integrating the hydraulic stepping control and the hydraulic tread control into a whole. The cooling-bed hydraulic stepping and tread control device of the invention has the advantages of few elements, simple system structure, low cost, convenient electric control and maintenance, safety and reliability.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

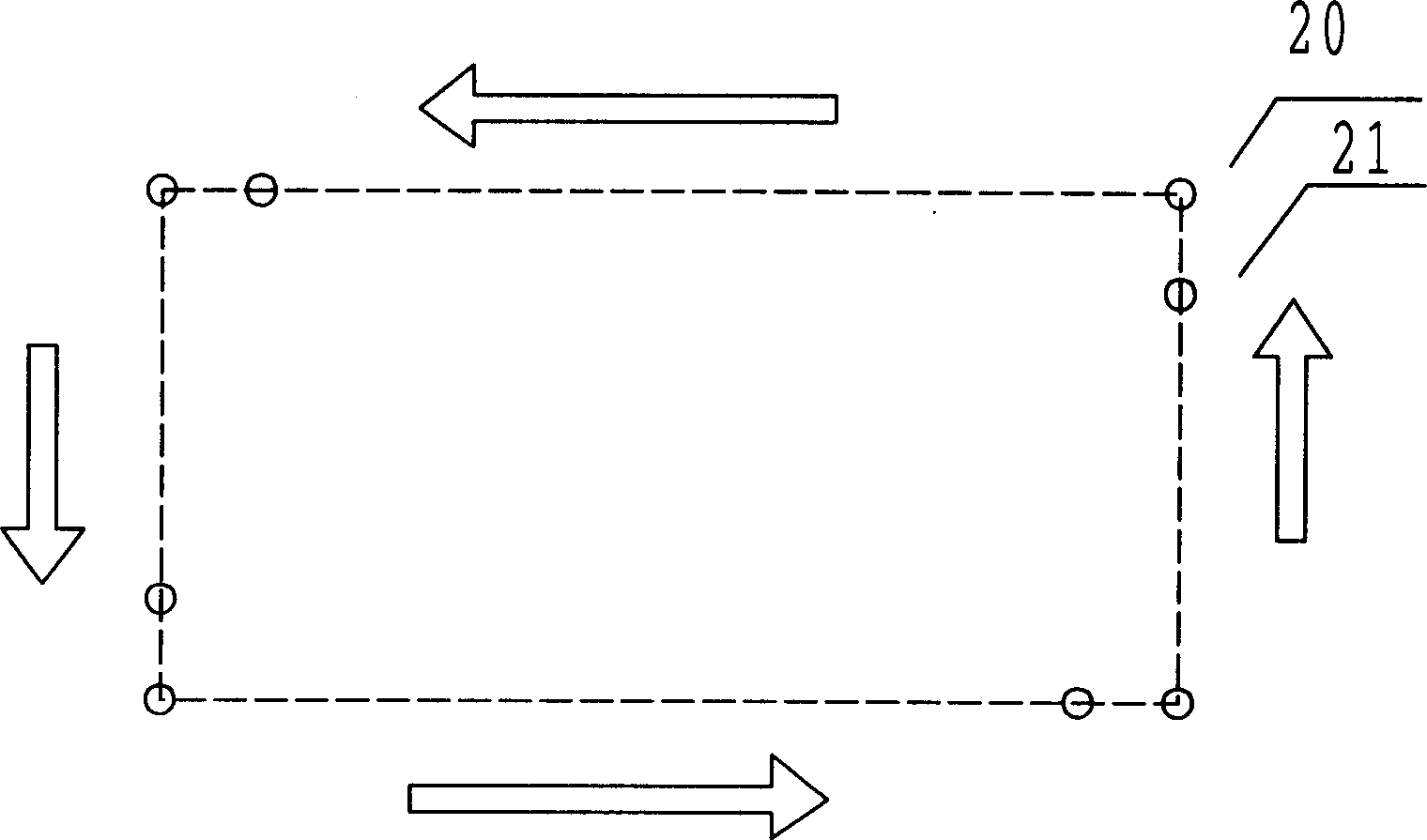

Longitudinal double-row automatic transfer method for fixed length steel in bar production

InactiveCN1876264AIncrease daily productionIncrease productivityCooling bedsMetal rolling arrangementsProduction lineProduction rate

Owner:HEBEI IRON AND STEEL

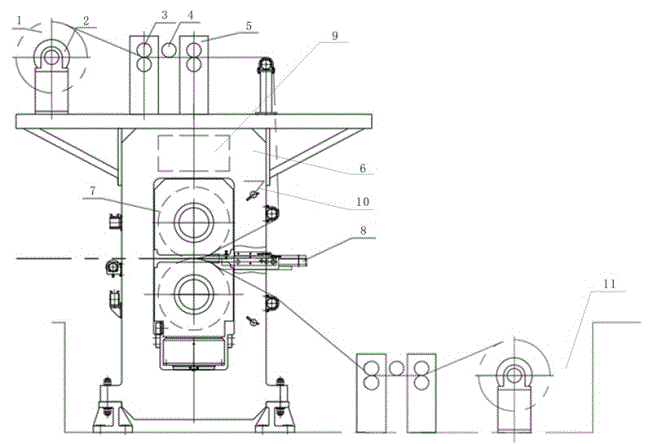

Straight tooth blank-feeding mechanism for square blank overturn cooling bed

ActiveCN101209463ACoordinated driveSimplify organic fitCooling bedsMetal rolling arrangementsPhase differenceDrive shaft

The invention relates to a straight teeth billet feeding mechanism of a square billet turn over cooling bed, pertaining to the technical field of machine. Eccentric drive and straight teeth are the keys of the technology; A V teeth and a straight teeth A are integrated as a whole; the lower end face of the V teeth and the upper end of the a V teeth beam are tightly fastened; A U teeth and a straight teeth B are integrated as a whole and the U teeth and a U teeth beam are tightly fastened; the V teeth beam and the U teeth beam are adjustably connected with two rolling wheels which are adjustably connected with two upper angles of a cradle; a cradle base angle and a cradle pull rod, the cradle pull rod and a cradle eccentric bushing, the lower end of the V teeth beam and a V teeth pull rod, the V teeth pull rod and a V teeth eccentric bushing, the lower end of the U teeth beam and a U teeth pull rod and the U teeth pull rod and a U teeth eccentric bushing are all adjustably connected respectively. The cradle eccentric bushing, the V teeth eccentric bushing and the U teeth eccentric bushing are all connected with a driving shaft by a key and the driving shaft is tightly fastened with an axle of a driving device. The straight teeth billet feeding mechanism has more than two sets and the eccentric phase difference of the V teeth eccentric bushing and the U teeth eccentric bushing is 180 degrees while the eccentric phase difference of V / U teeth eccentric bushing and the cradle eccentric bushing is 90 degrees. The straight teeth billet feeding mechanism of the invention is used for billet supplying of the turn over cooling bed and has the advantages of simple structure, energy saving, manpower saving and good effect.

Owner:中国冶金科工股份有限公司

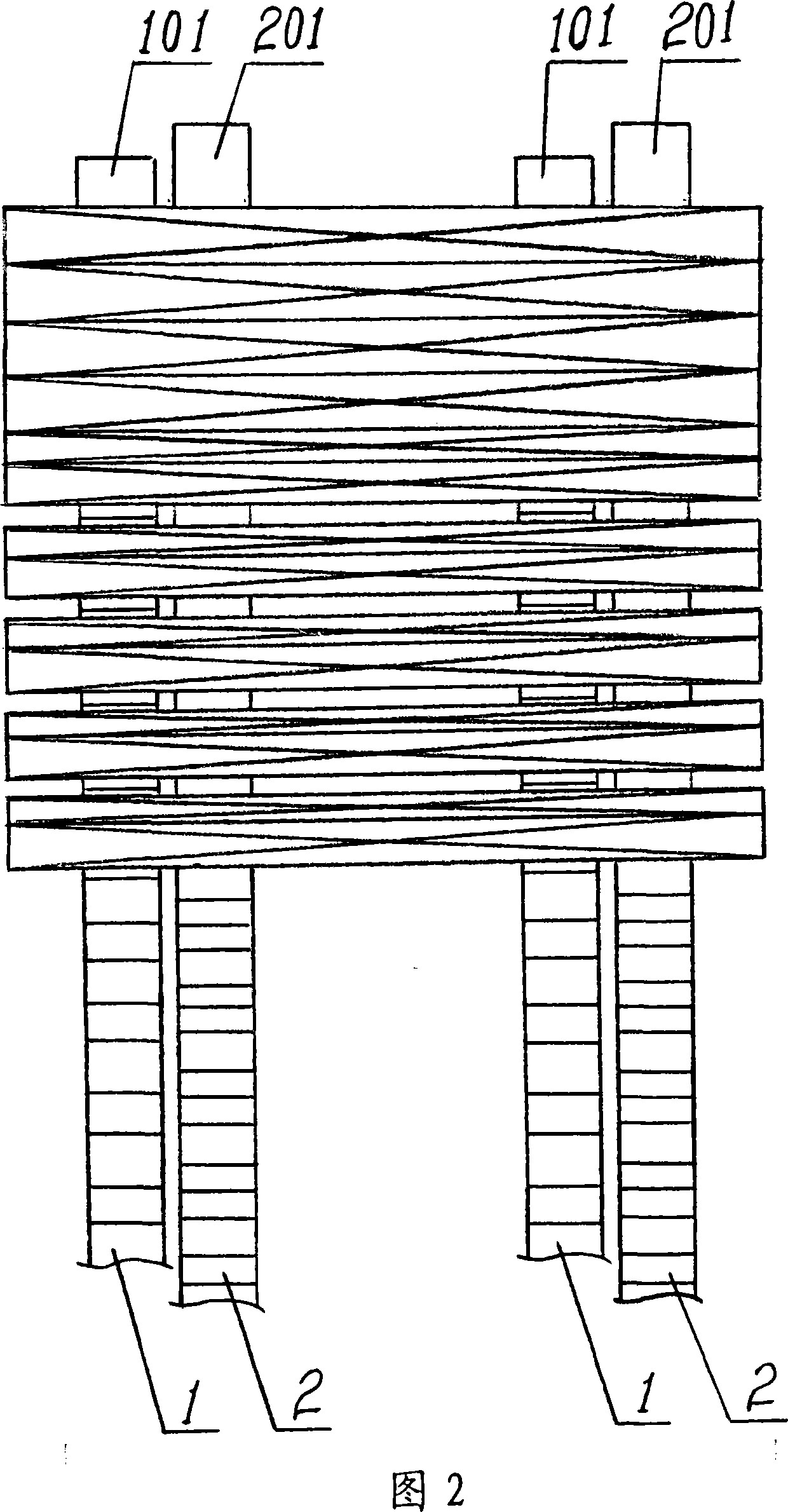

Movable tray stack type material cold bed

InactiveCN101797592ASmall footprintImprove space utilizationCooling bedsMetal rolling arrangementsThick plateSheet steel

The invention relates to a cold bed which is suitable for the cooling of coils, medium and heavy plates, bars and the like after being heated. The movable tray stack type material cold bed is characterized by comprising steel plate downgoing stacks, steel upgoing stacks and conveying dollies, wherein the steel plate downgoing stacks and the steel plate upgoing stacks are sequentially arranged from a feed end to a discharge end; the left sides and the right sides of the steel plate downgoing stacks and the steel plate upgoing stacks are respectively provided with a heat exchanger; the steel plate upgoing stacks have the same structure as that of the steel plate downgoing stacks; the lower end parts of the steel plate downgoing stacks and the steel plate upgoing stacks are provided with conveying dolly passages, and the conveying dollies are positioned in the conveying dolly passages; and the steel plate downgoing stack comprises a fixed frame, an annular moving mechanism, a mobile tray, a roller group and a steel plate conveying motor. The cold bed has the characteristics of high space utilization ratio and sensible heat recovery.

Owner:WISDRI WUHAN WIS IND FURNACE

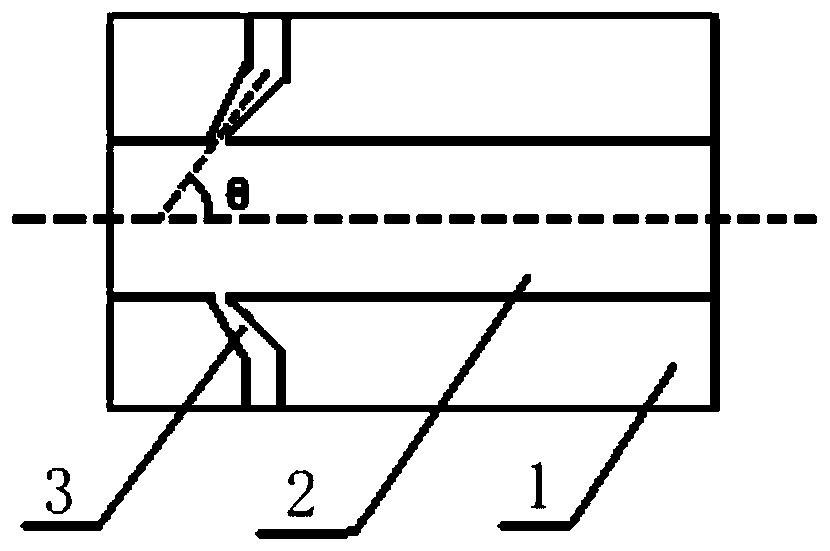

Hot-rolled seamless tube on-line accelerated cooling device and method

InactiveCN101396695AChange forward speedAdjust the timeTemperature control deviceWork treatment devicesEngineeringSteel tube

A hot-rolled seamless steel pipe on-line cooling accelerator and a method thereof are characterized in that an opposite tapered roller way set is divided into two roller sets and each set is provided with a set of horizontal revolving gear and a set of electric element control device below the opposite tapered roller way; therefore, each roller way set can form the set with changeable angle and the length of each roller way set with changeable angle is at least equal to the length of the manufactured steel pipe. The usage method is that by changing the angle of the roller way with changeable angle, the motion type of the hot-rolled seamless steel pipe is changed from horizontal advance to spiral advance after the hot-rolled seamless steel pipe thoroughly pass through a sizing mill. By improving the conventional roller way, the hot-rolled seamless steel pipe on-line cooling accelerator can be manufactured and by changing the advance type of the hot-rolled seamless steel pipe, even heating of the hot-rolled seamless steel pipe along lengthwise direction and circumferential direction can be ensured; therefore, the pipe can be prevented from being bent.

Owner:刘彦春

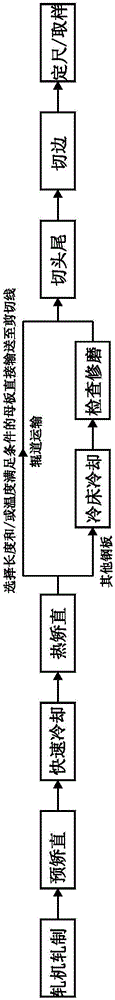

Middle thick plate production line and production method

InactiveCN106345807AThe overall thickness is thinReduce the temperatureMeasuring devicesCooling bedsShear lineManufacturing engineering

Owner:CERI TECH +1

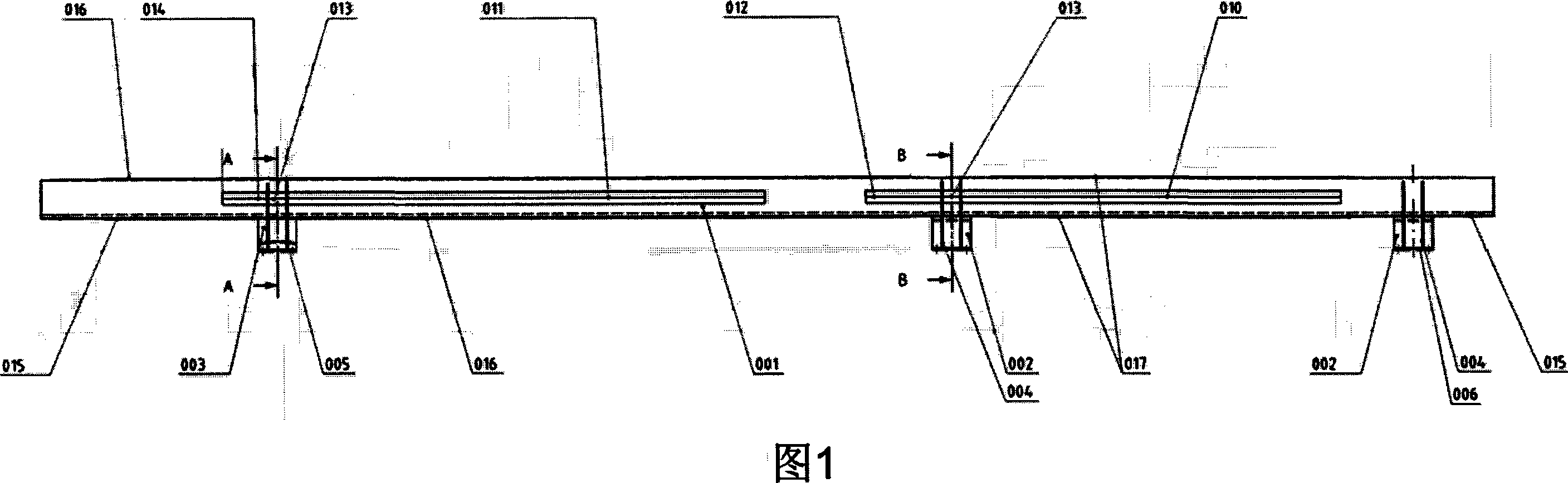

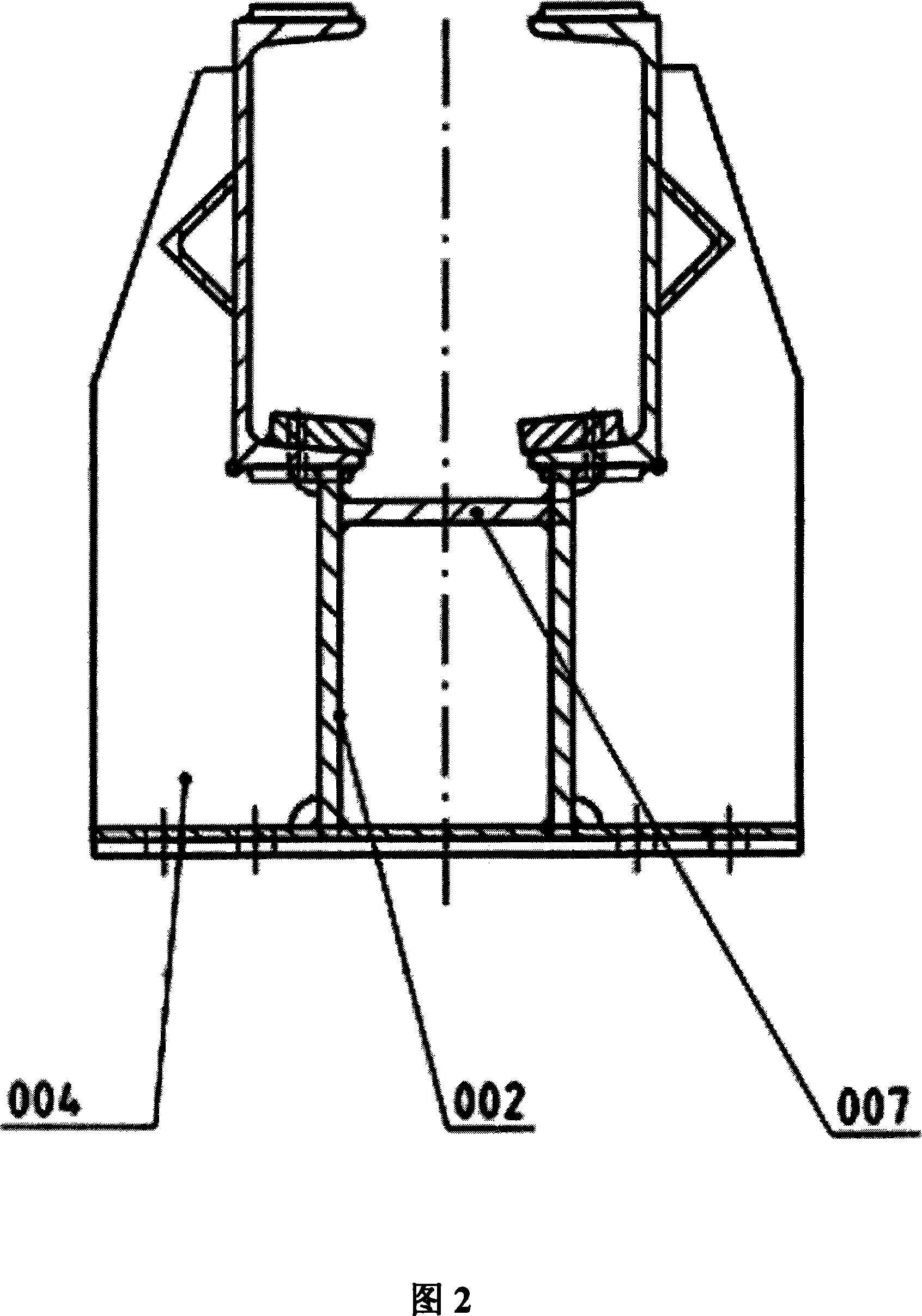

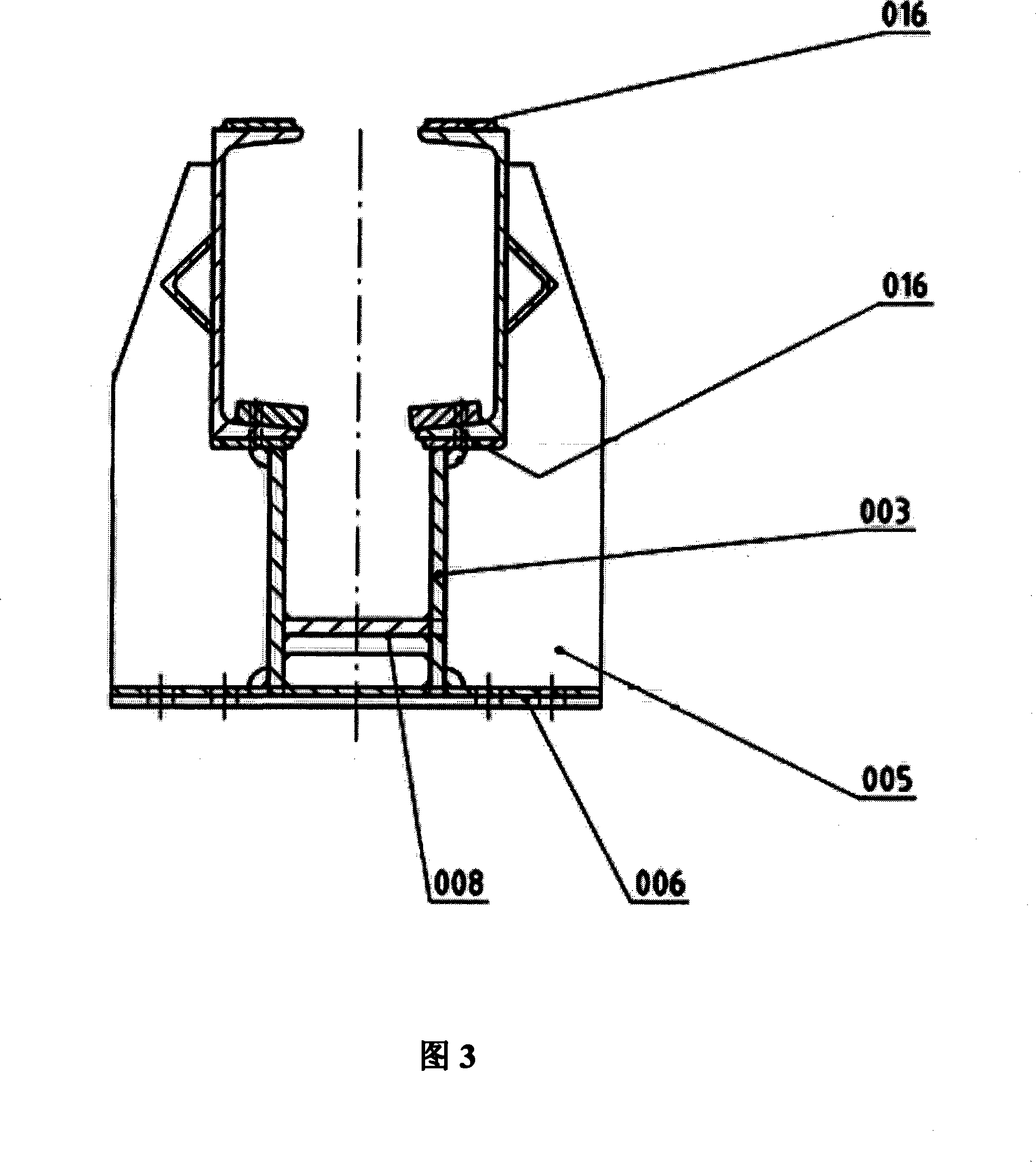

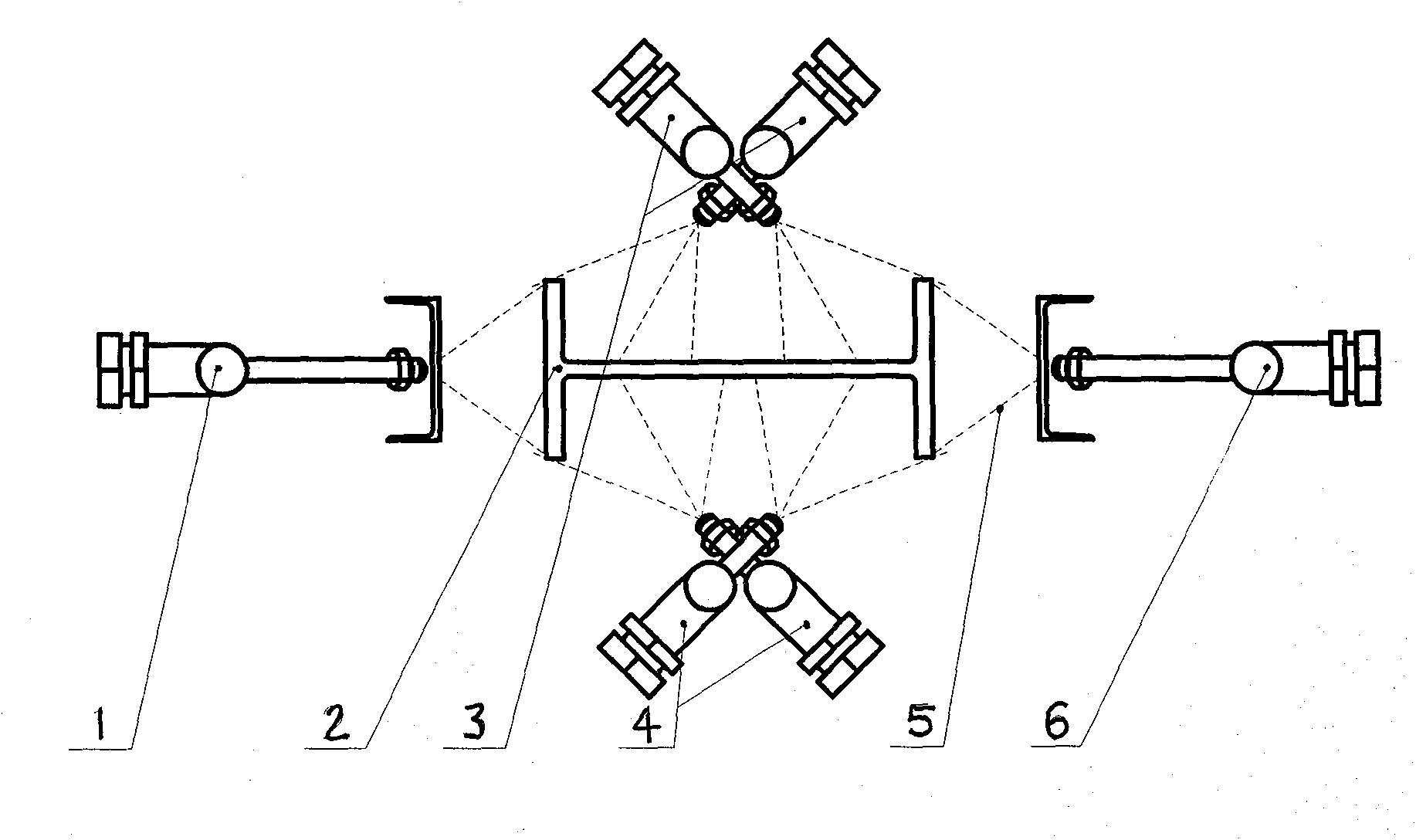

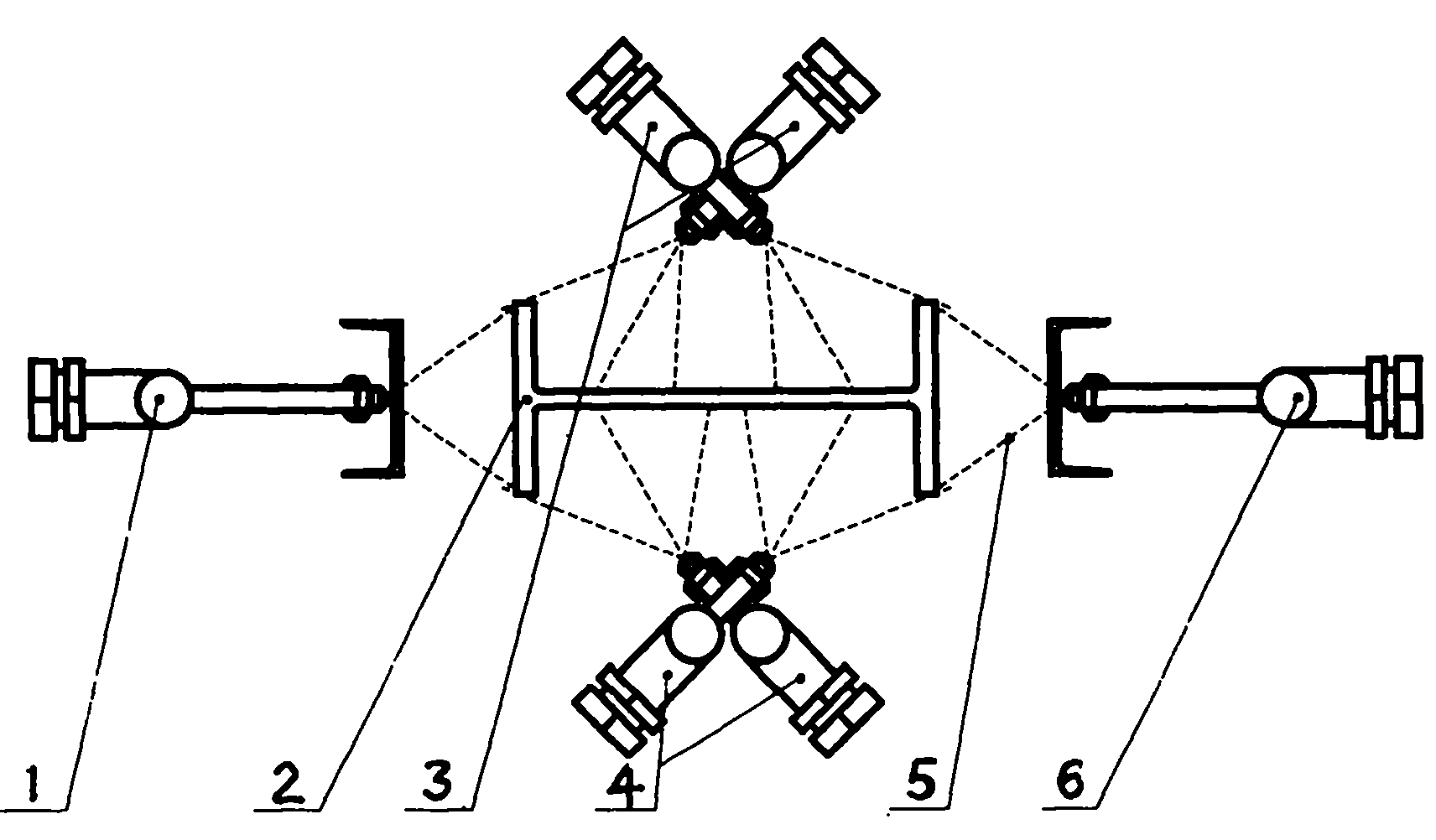

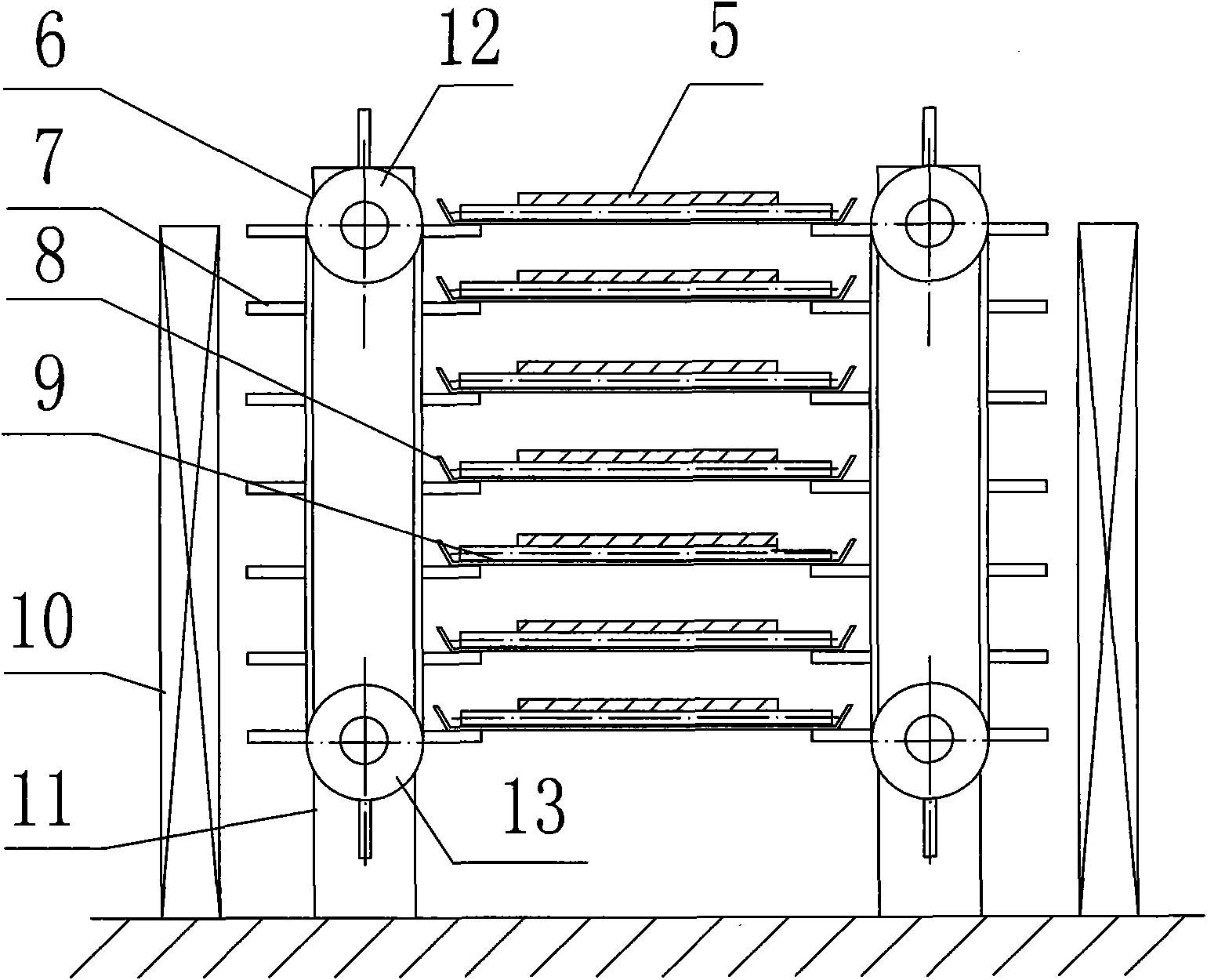

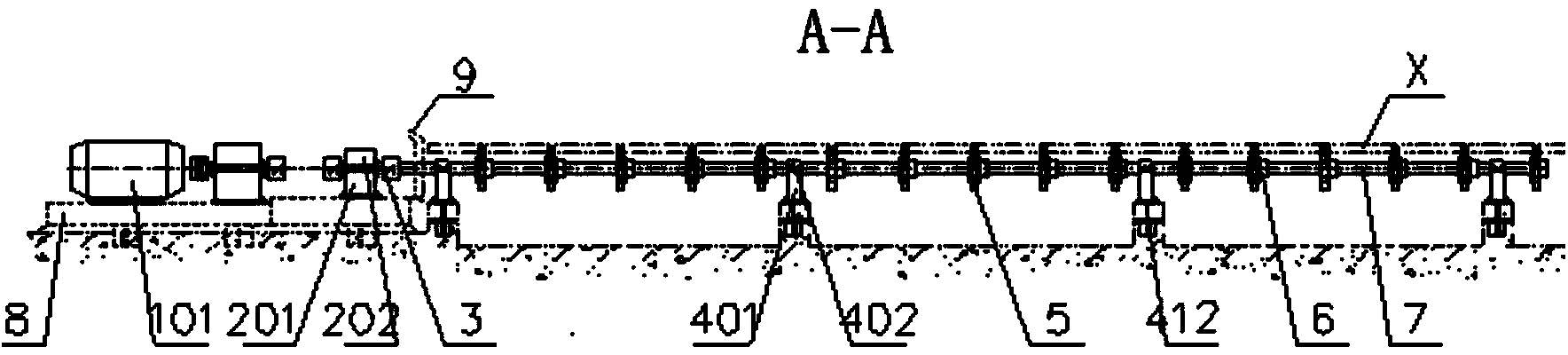

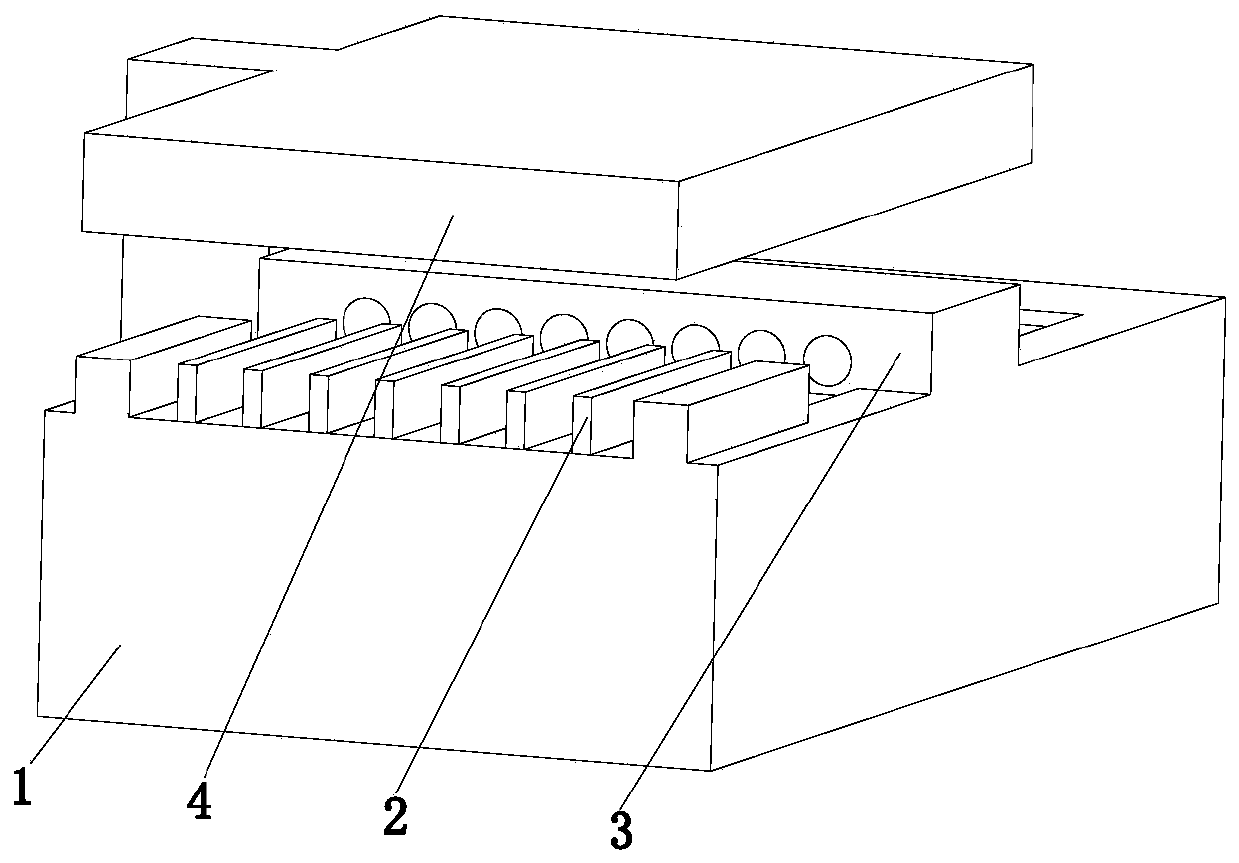

Billet turn-over cooling bed device

ActiveCN103920724AImprove turnover efficiencyConstant speed transmission is easy to realizeWork manipulationCooling bedsCouplingDrive shaft

The invention discloses a billet turn-over cooling bed device and belongs to the field of metallurgical equipment. The billet turn-over cooling bed device comprises a transmission device and a turn-over mechanism, wherein the transmission device drives the turn-over mechanism to turn over billets, the transmission device comprises a main transmission device and a constant-speed transmission set device, the main transmission device transmits torque to the constant-speed transmission set device, the constant-speed transmission set device is connected with the turn-over mechanism through a coupler, the turn-over mechanism comprises a plurality of transmission shafts distributed in parallel, the ends of the transmission shafts are connected to the coupler, tooth-shaped gears are evenly distributed on each transmission shaft, the tooth-shaped gears on every two adjacent transmission shafts are distributed in the same way, and the tooth-shaped gears on every two adjacent transmission shafts are staggered in position. With the device, hot square billets can be turned over, evenly cooled and automatically straightened efficiently, evenly and stably, and therefore the billets can be cooled sufficiently, the quality of the billets and smooth conveying of the billets can be guaranteed, and it is guaranteed that the tooth-shaped gears can support the tooth faces of the billets to normally turn over the billets.

Owner:ANHUI MASTEEL ENG & TECH GRP

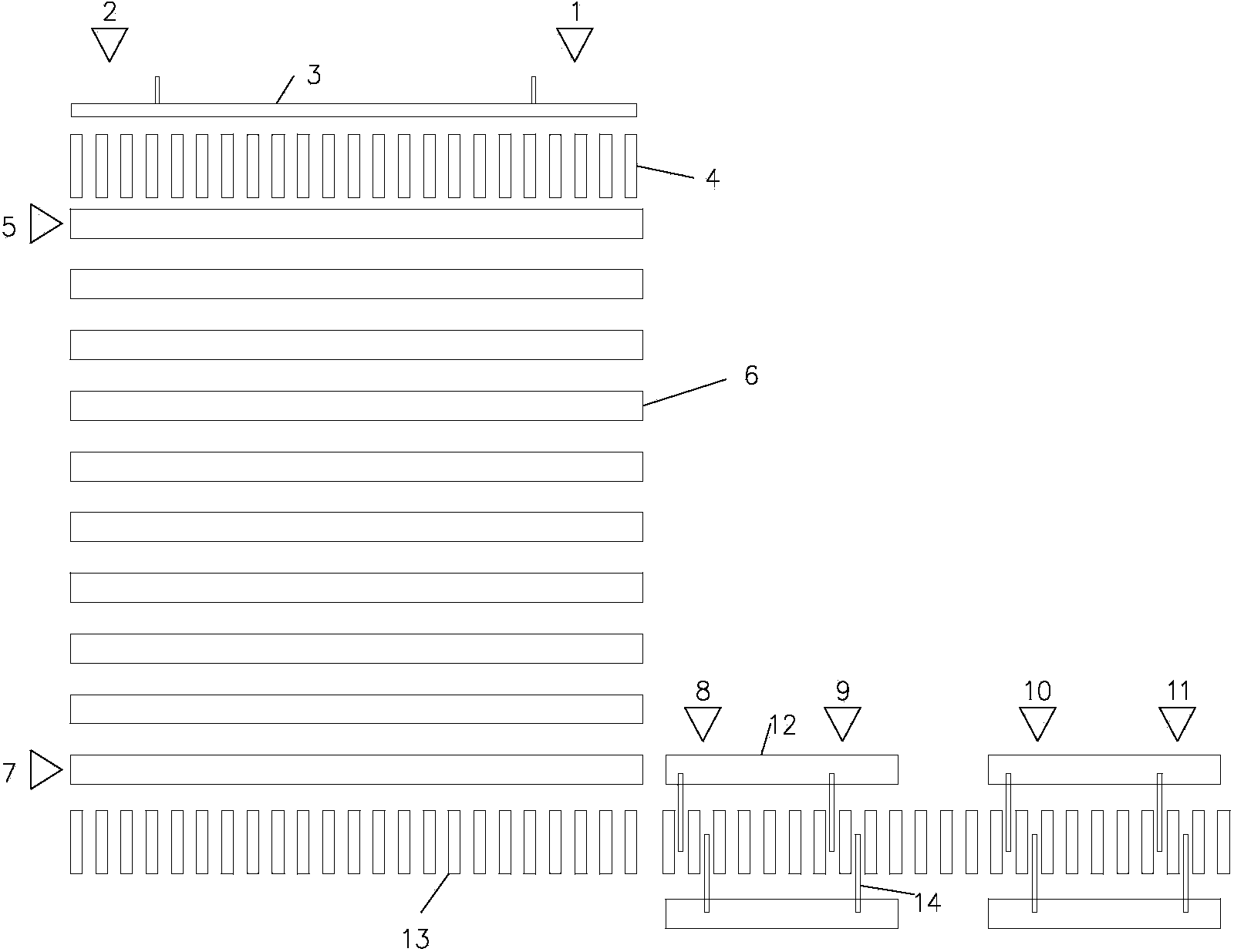

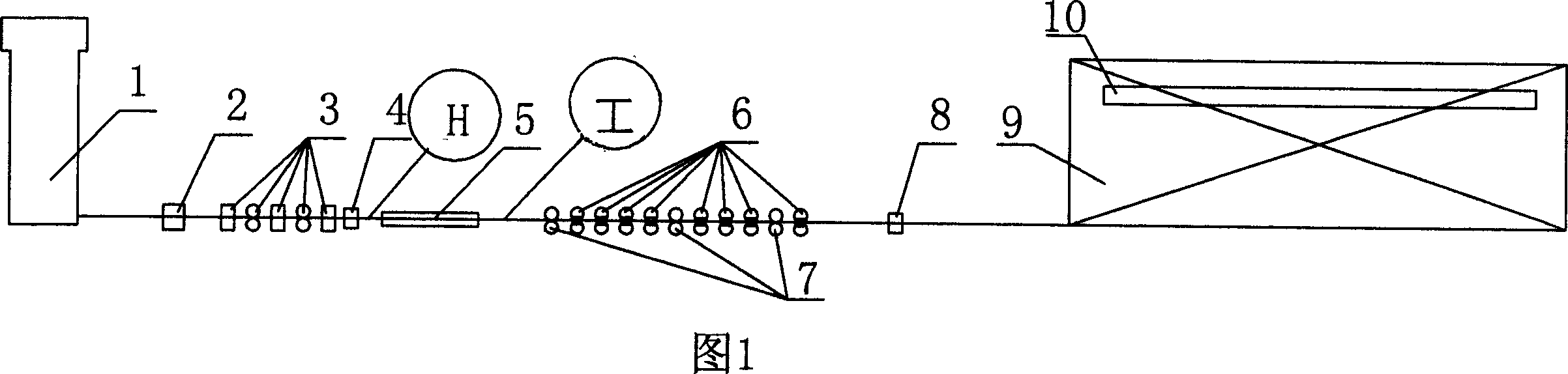

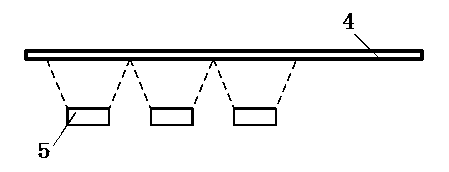

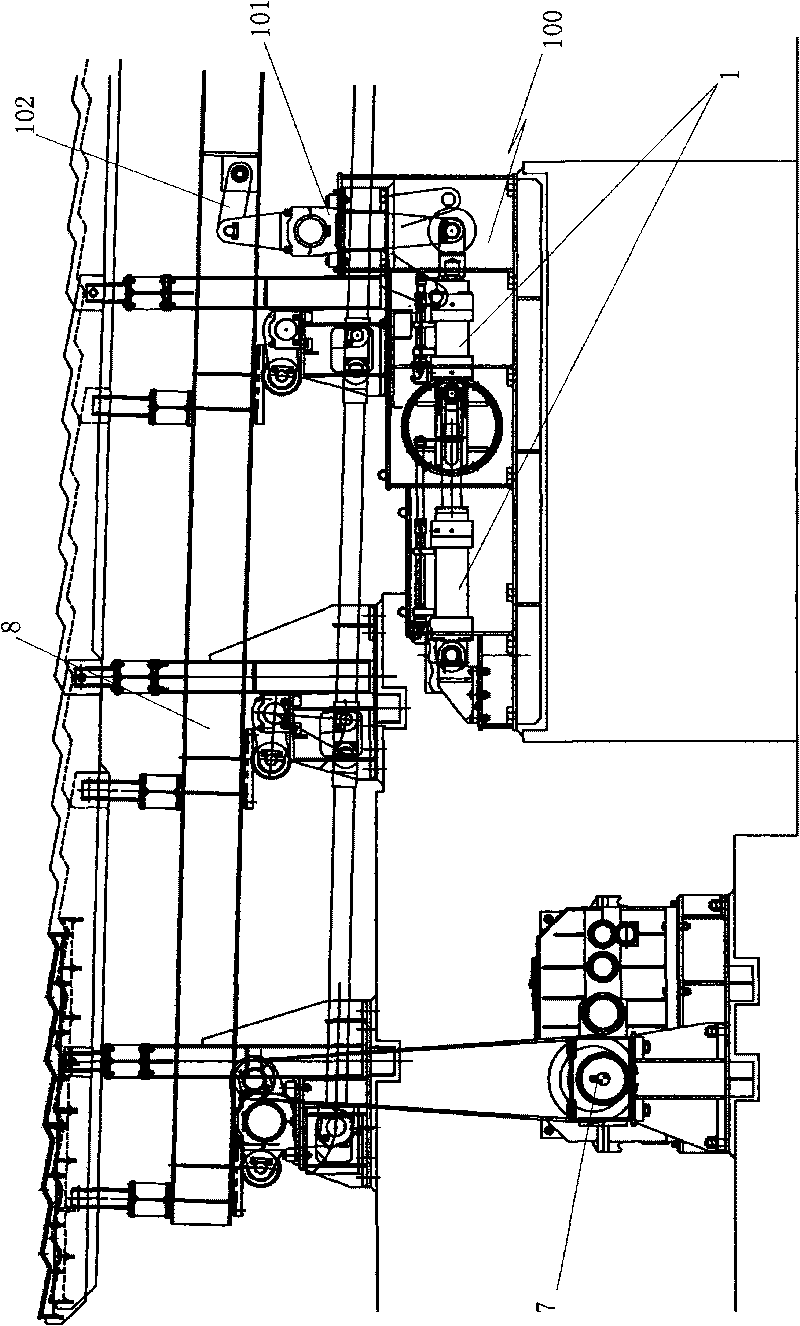

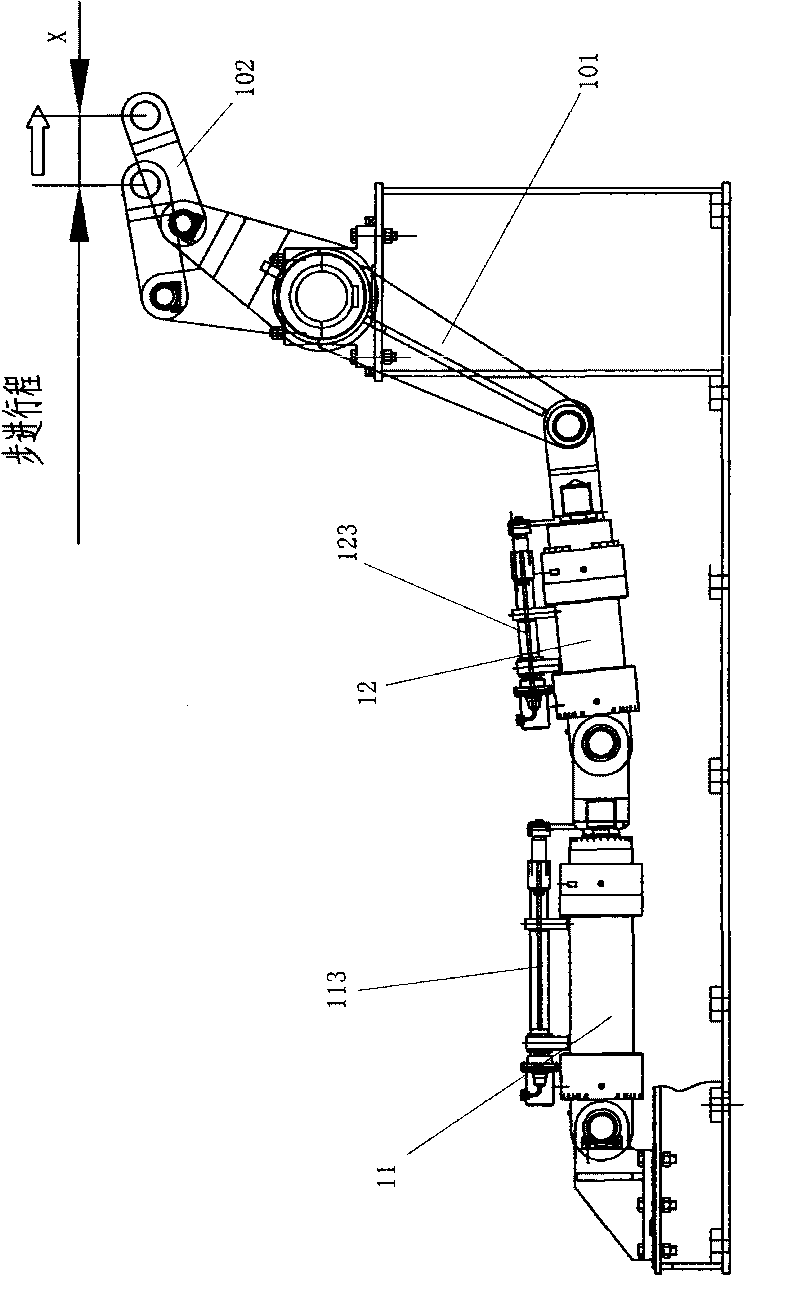

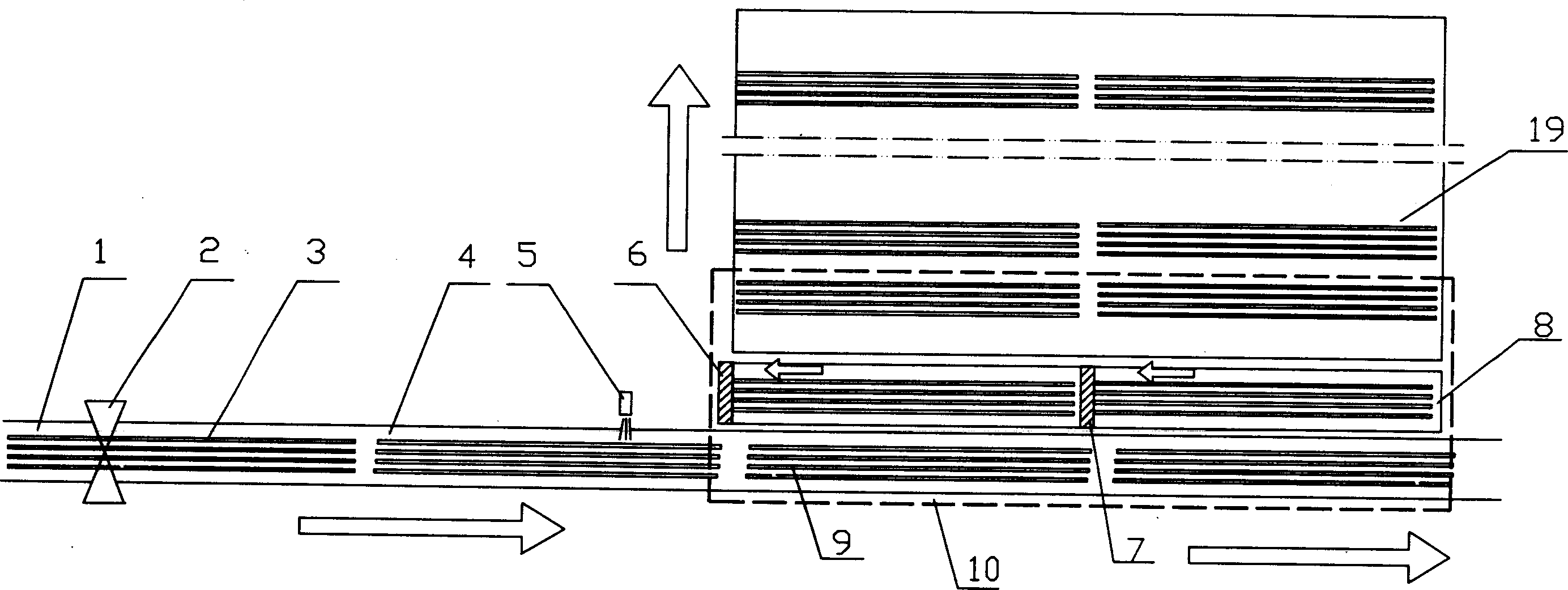

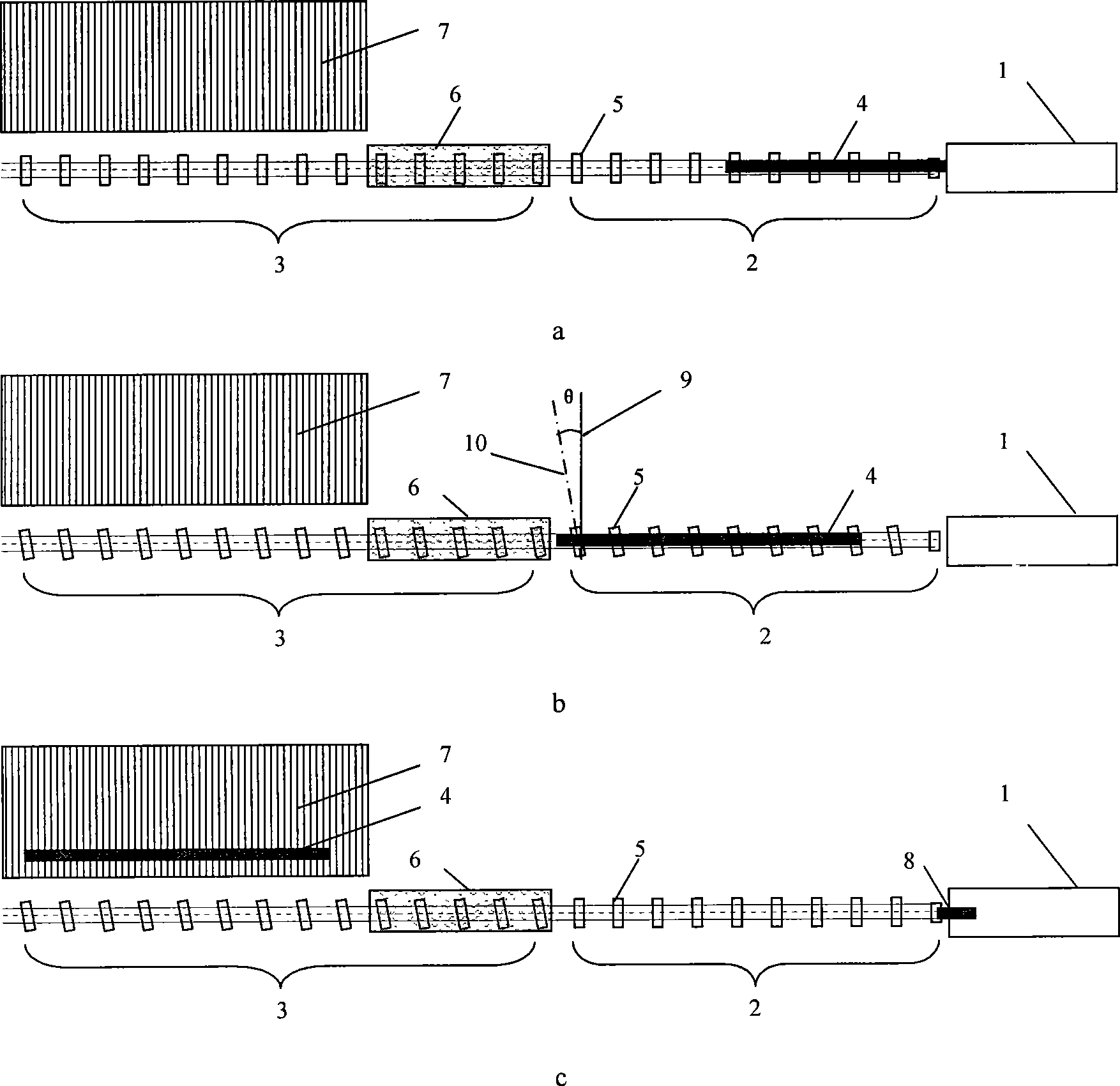

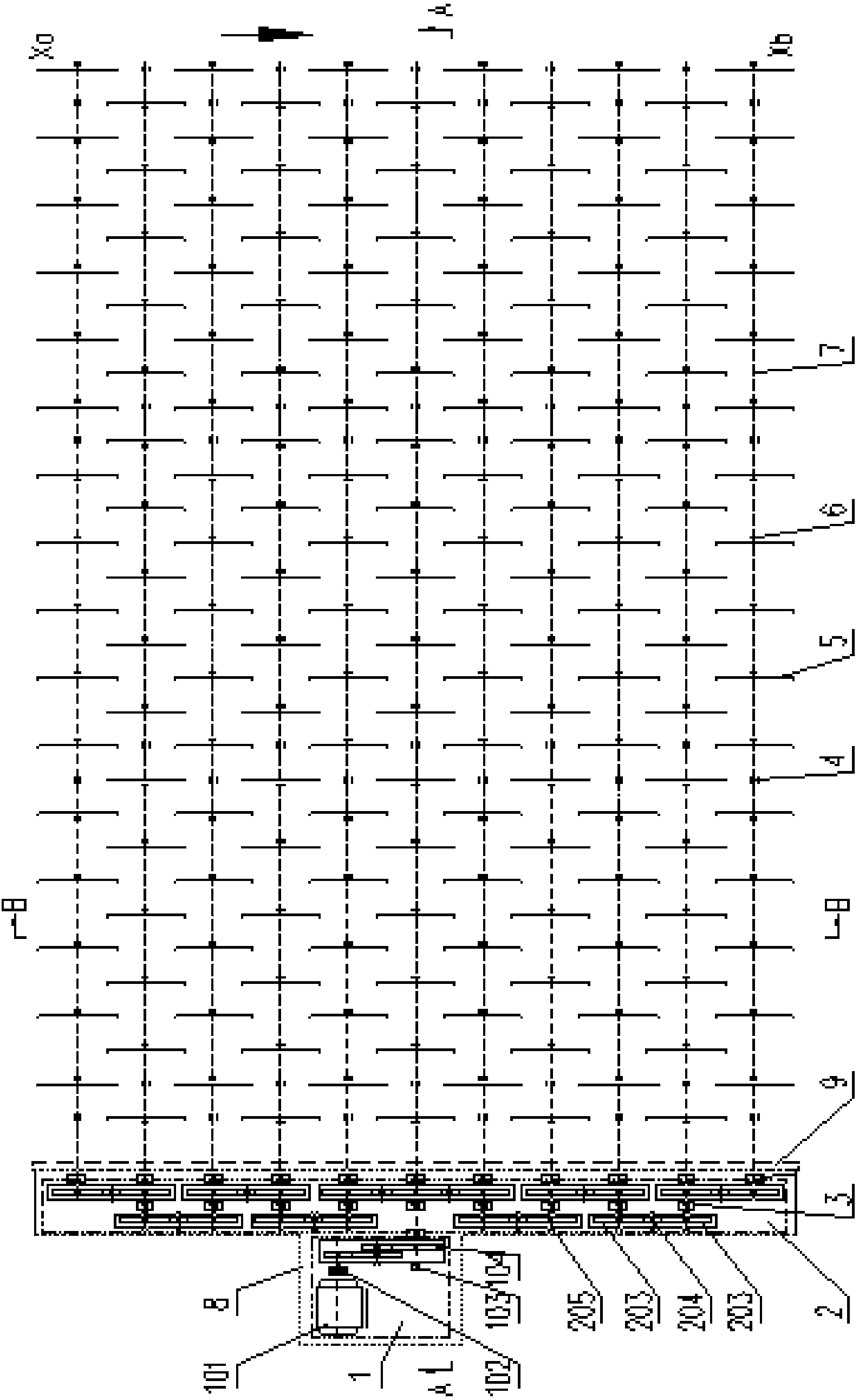

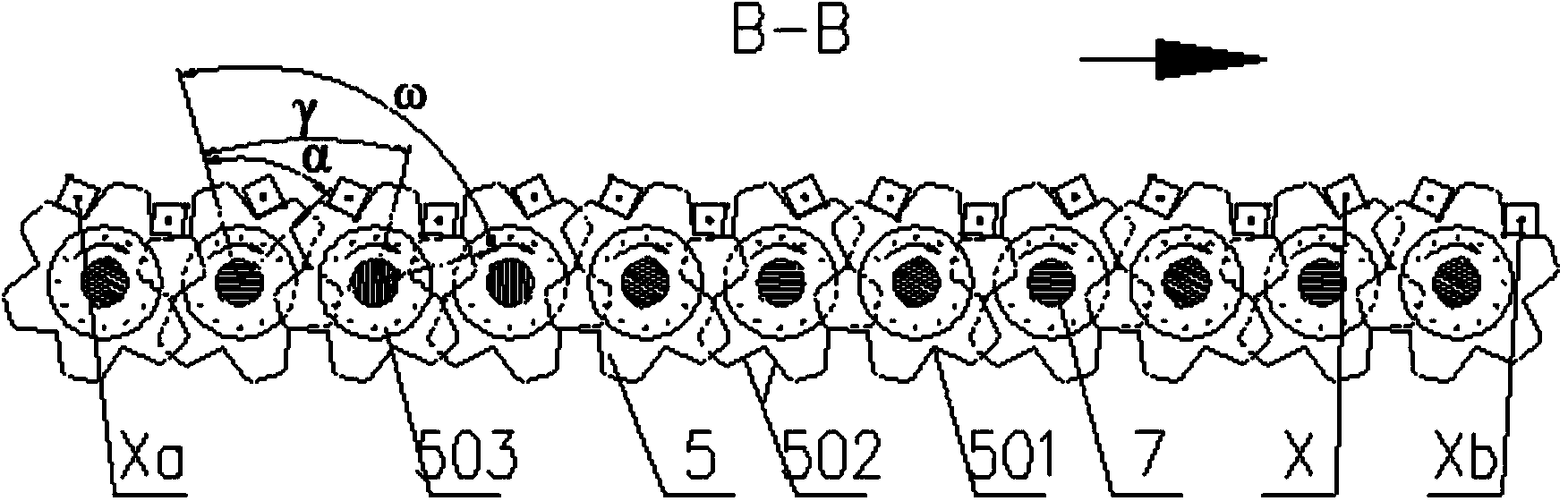

Continuous casting billet hot delivery and offline system

PendingCN109530456AMeet process temperature delivery requirementsImprove heat transfer rateTemperature control deviceCooling bedsProduction lineMetallurgy

The invention discloses a continuous casting billet hot delivery and offline system comprising a continuous casting machine discharging roller (1), a steel casting machine (2), a hot delivery roller (3), a warming roller (4), a casting blank insulation bed (7) and a hot delivery rolled steel roller (10). The steel casting machine (2) can transport casting blanks on the continuous casting machine blanking roller (1) to the hot delivery roller (3) or to the warming roller (4); the warming roller (4) deliveries the casting blanks to the casting blank insulation bed (7), and the casting blanks onthe casting blank insulation bed (7) can be transported to the hot delivery roller (3), and the hot delivery roller (3) transfers the casting blanks to the hot delivery rolled steel roller (10). The continuous casting billet hot-feeding and the offline system can control the surface temperature of the casting blanks between 550 DEC C to 650 DEG C, thereby meeting the requirements of the steel rolling process; in addition, the casting blanks can be temporarily stored in case of the roller change and the small fault on the rolling steel production line. The continuous casting billet hot deliveryand offline system has the functions of improving the casting blank hot delivery and reducing the casting blank offline directly.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

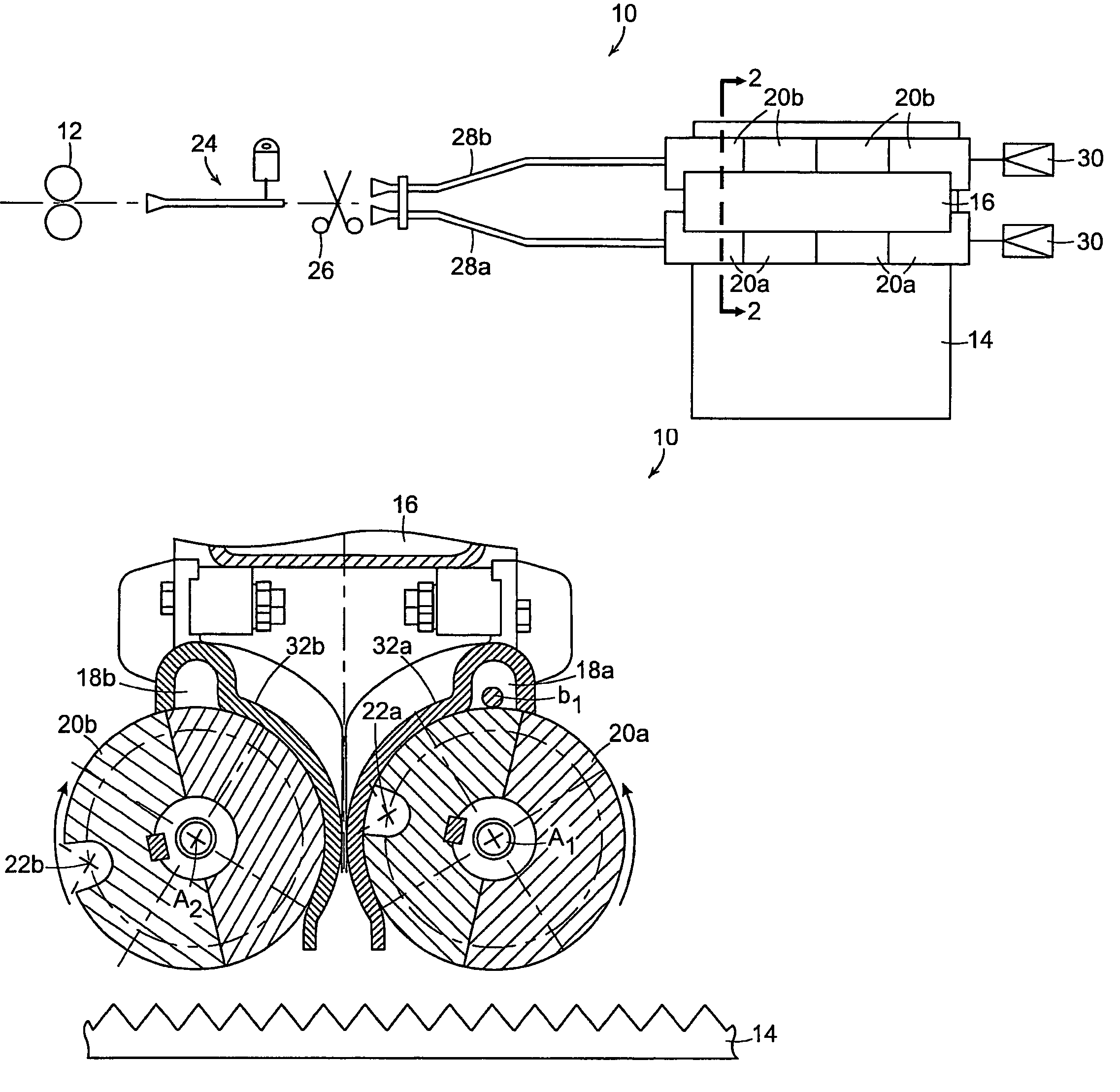

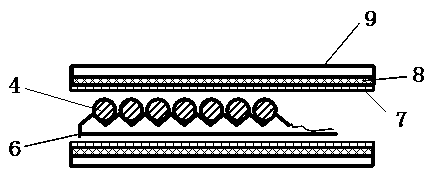

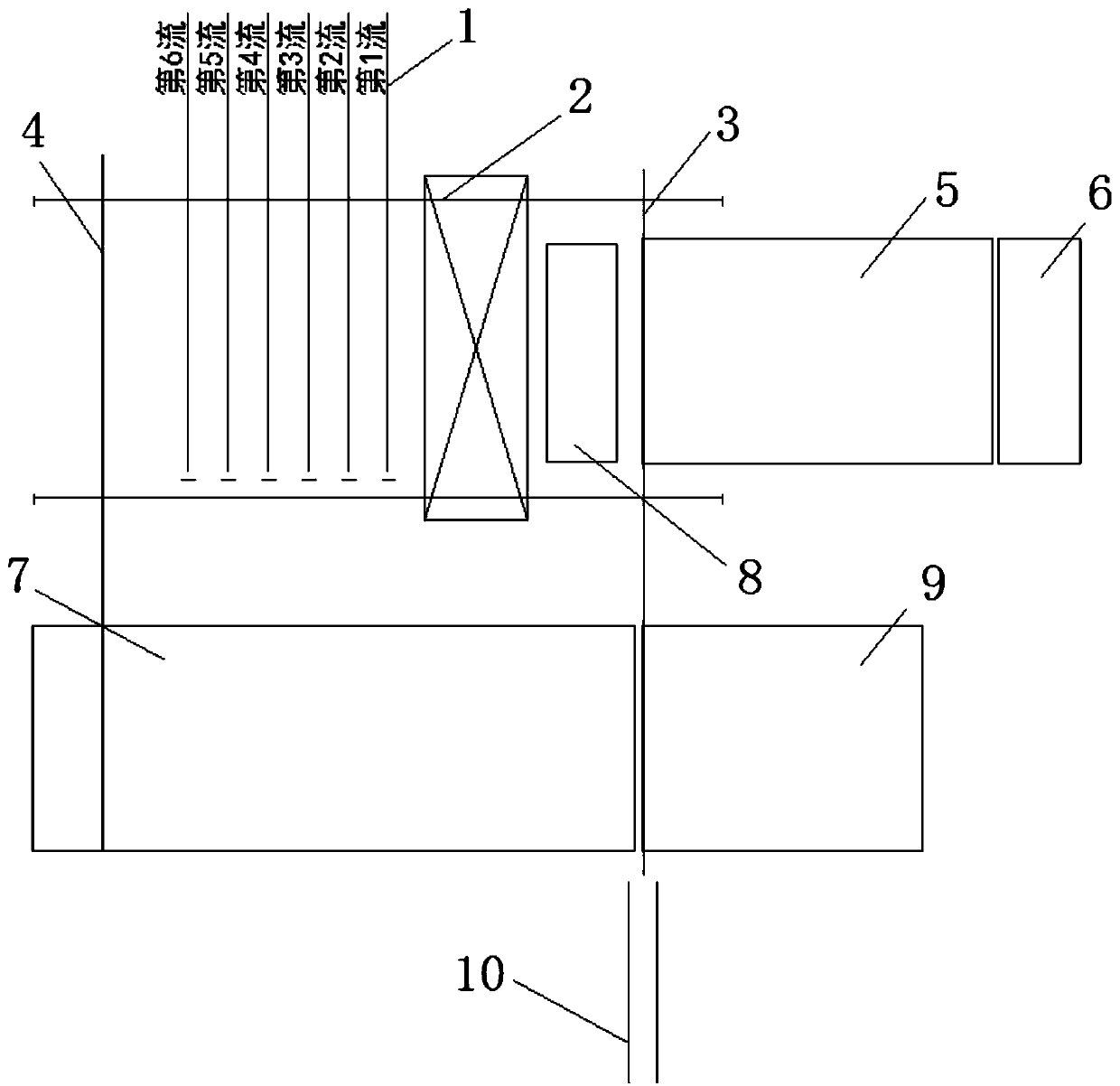

Compound cast-rolling device for metallurgical bonding of liquid aluminum base strip and single metal or alloy strip

InactiveCN103599935ARealize continuous rollingShorten the production cycleWork treatment devicesRollsAlloyLiquid based

The invention discloses a compound cast-rolling device for metallurgical bonding of a liquid aluminum base strip and a single metal or alloy strip. The compound cast-rolling device comprises a cast-rolling machine (7) and a lip device (8) which are fixed onto a board (6). The compound cast-rolling device is characterized by further comprising one or two coiling machines (2), leather-alloy strips (1) are coiled on the coiling machines, are directly led into a compound region at the front end of the cast-rolling machine (7) through a guiding and drawing mechanism and contact with the surfaces of core-liquid base materials fed by the lip device (8), and the leather-alloy strips and the core-liquid base materials are continuously rolled by a roller of the cast-rolling machine to form a metallurgically bonded metal compound strip. The compound cast-rolling device solves the problems that an existing cast-rolling device is large in size, high in investment cost, complicated in compound technology and long in production cycle, and compound interfaces cannot be metallurgically bonded. The compound interfaces of the compound strip can be metallurgically bonded, the production cycle is shortened, production procedures are decreased, production efficiency is improved, production cost is reduced, and post processing quality of the compound strip is ensured.

Owner:洛阳市伟创复合材料科技有限公司 +1

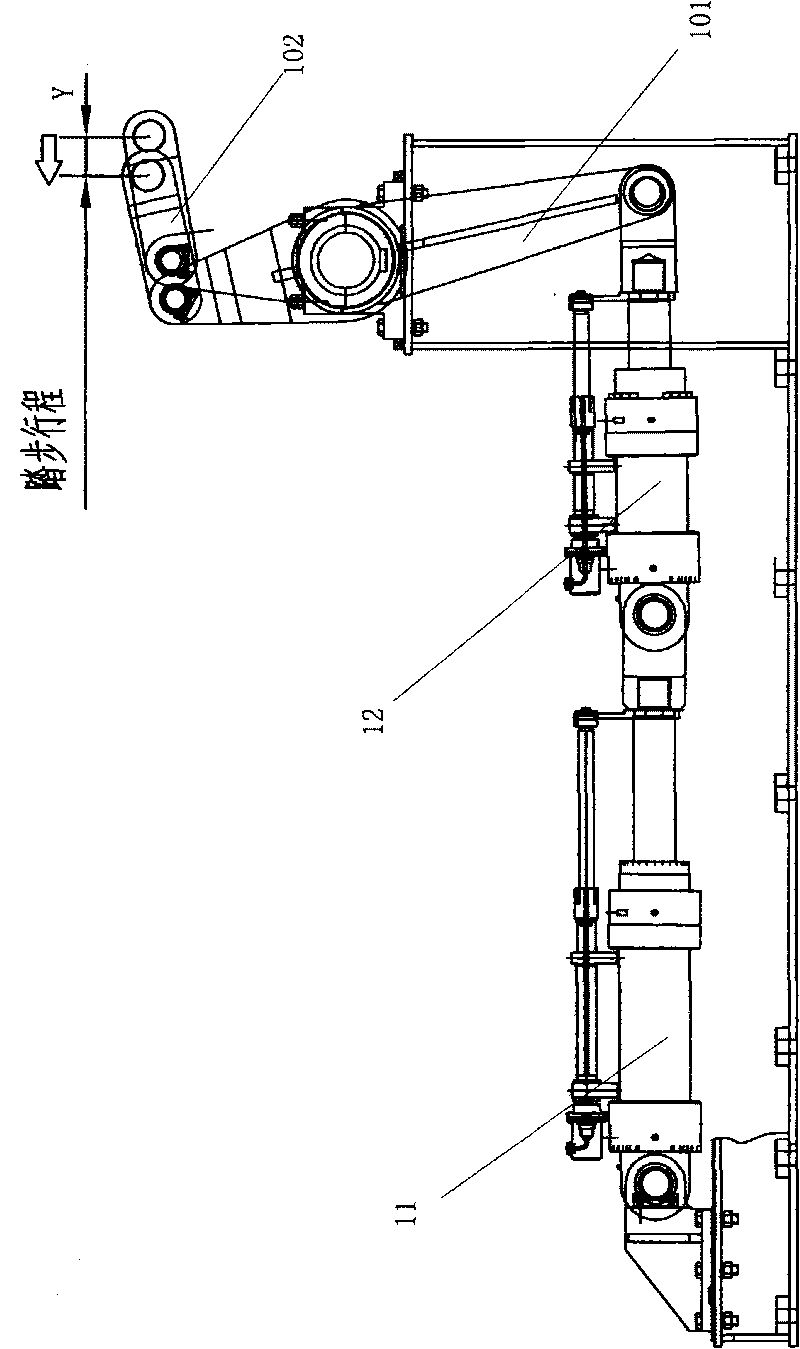

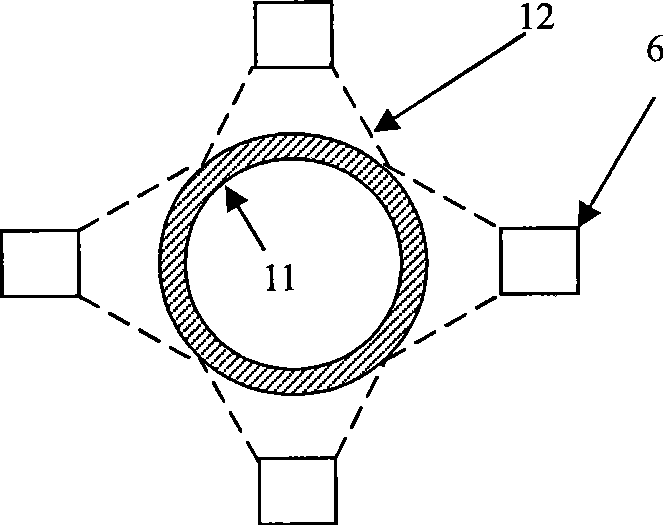

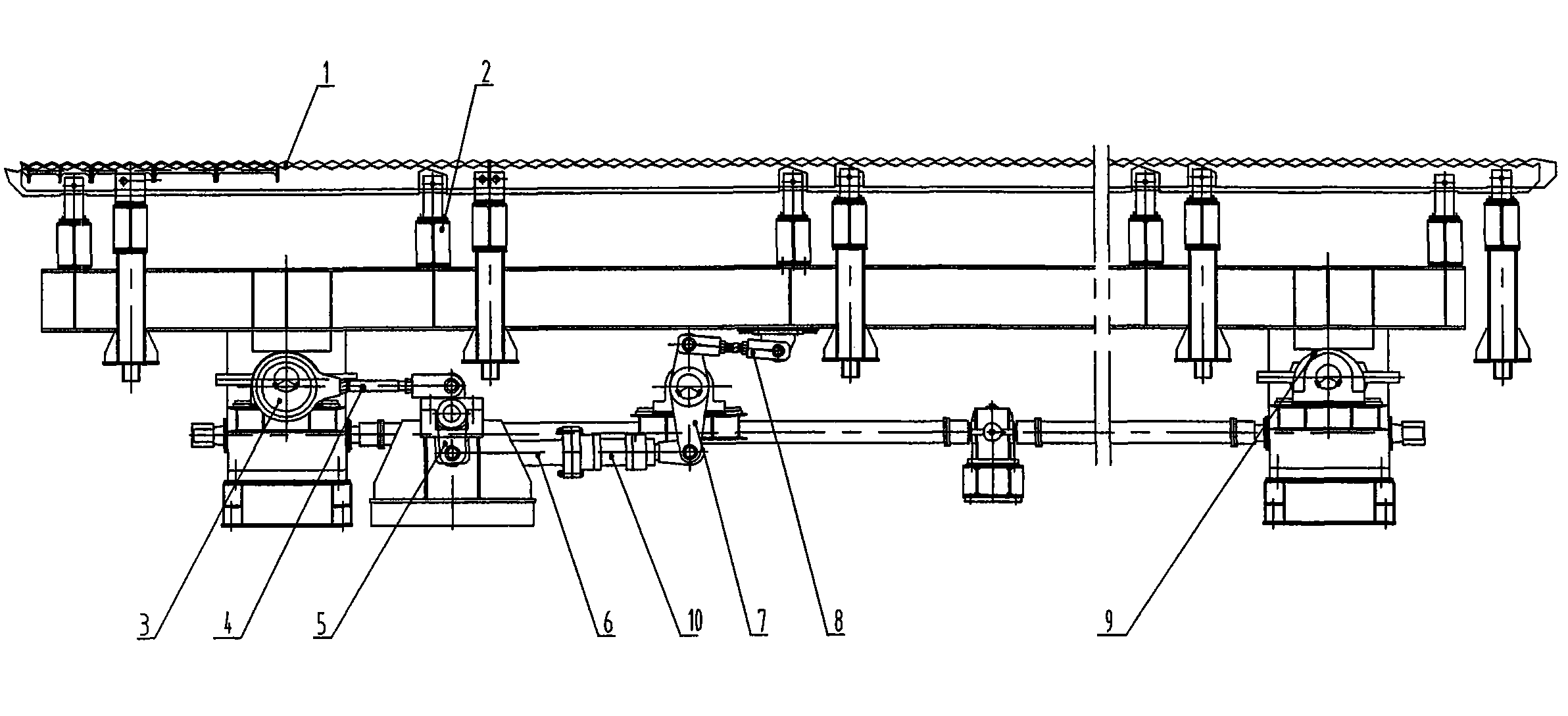

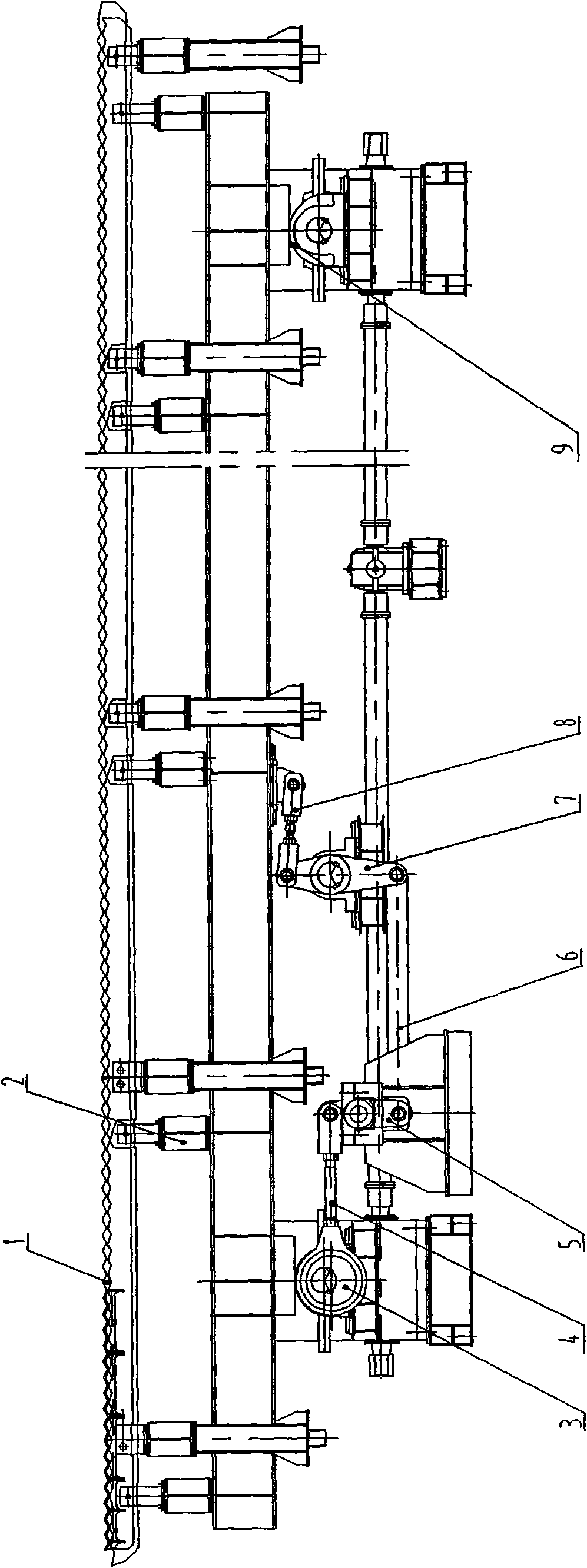

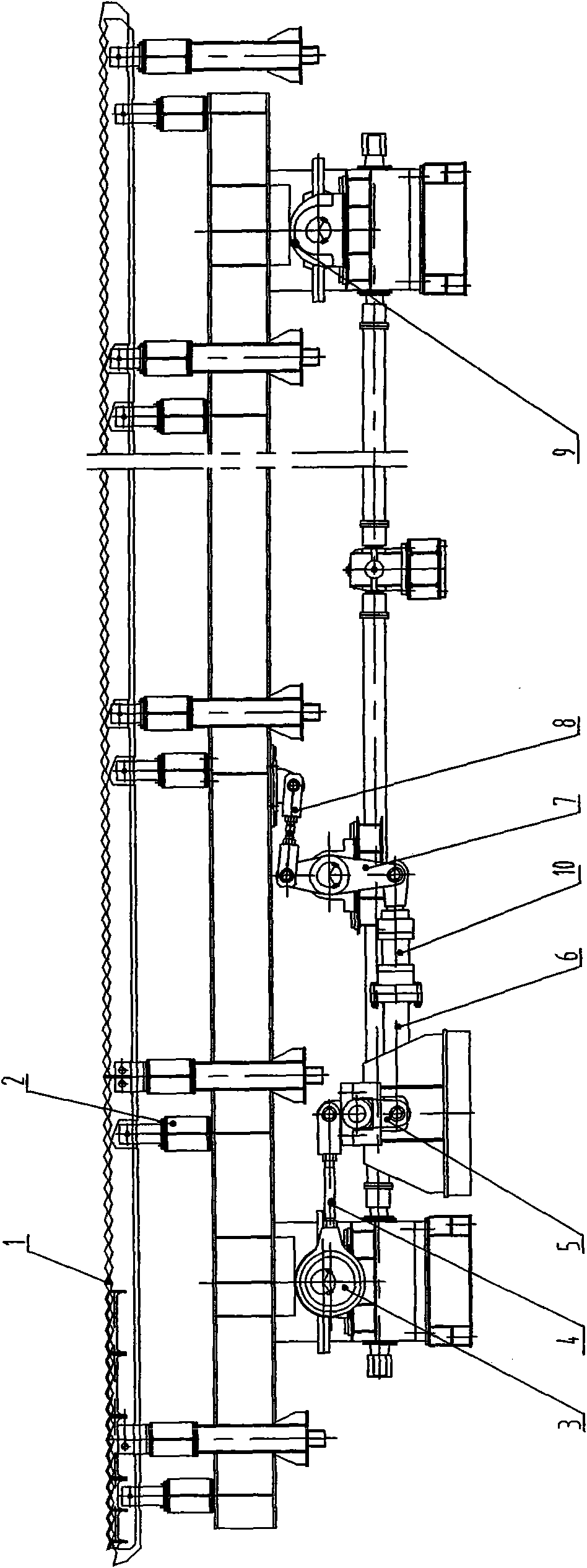

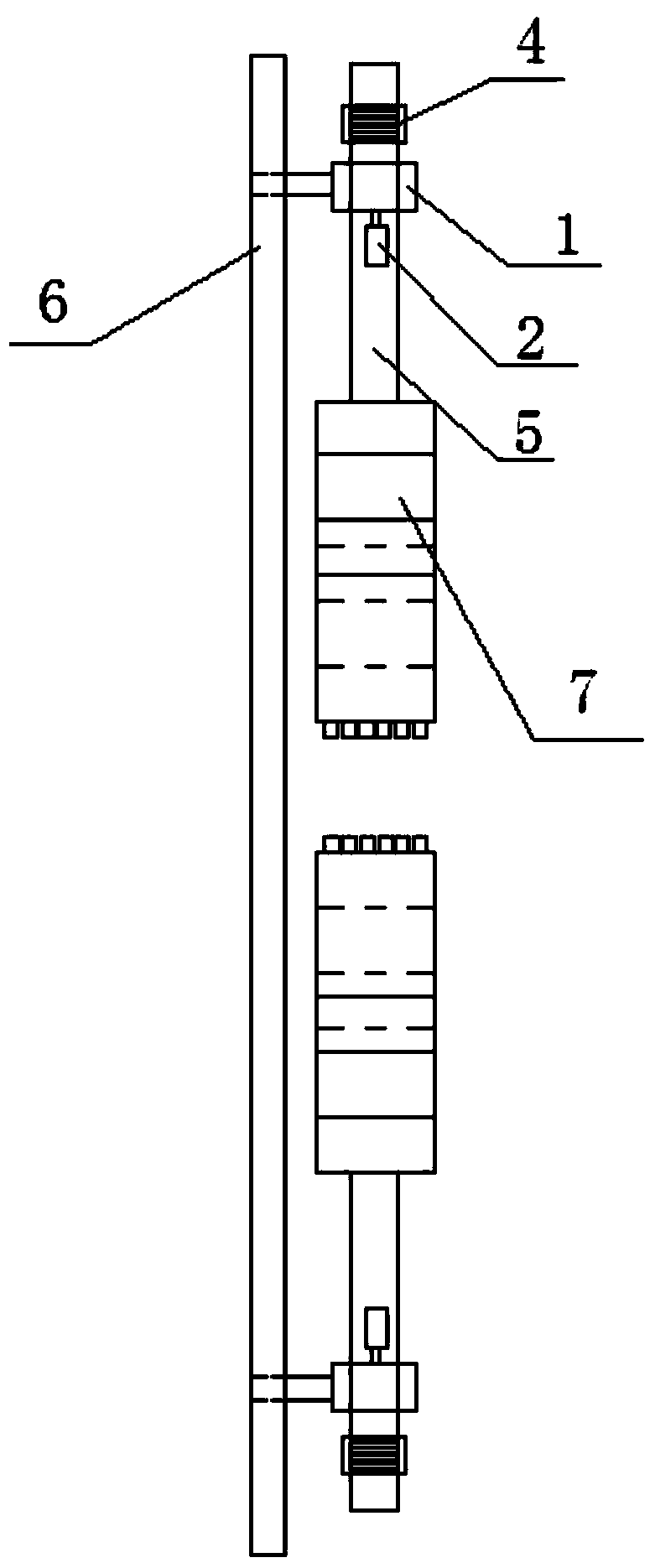

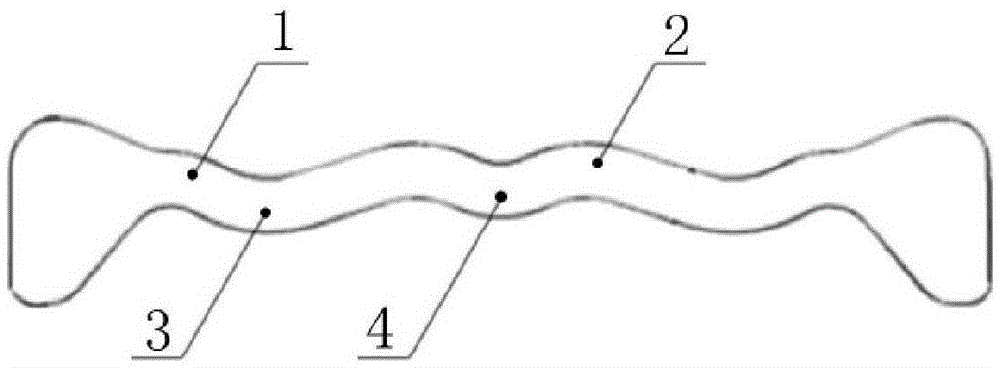

Non-going-forward device for small-pitch stepper cooling bed

The invention discloses a non-going-forward device for a small-pitch stepper cooling bed, and relates to hot-rolled steel pipe cooling equipment. The invention comprises a fixed rack, a movable rack and a transmission mechanism, wherein the movable rack is supported by two groups of No.I eccentric wheels, and a group of No.II eccentric wheels drive the movable rack through a connecting rod, a lever, a pull rod and a rocker; and a group of eccentric wheels of the two groups of No.I eccentric wheels and the No.II eccentric wheels are coaxial, and a motor is driven by a speed reducer, so that the movable rack moves along the elliptical trajectory. The invention is characterized in that the pull rod between the lever and the rocker is connected with a hydraulic cylinder in series. The invention solves the problems that hot steel pipes bends and deforms to affect the quality of the steel pipes when the steel pipes need to stay on the cooling bed. When the steel pipes stay on the cooling bed, the steel pipes can roll in the rack of the cooling bed and can not go forward, so that the steel pipes can be straightened when being cooled.

Owner:TAIYUAN HEAVY IND

Method and device for improving super-rapid cooling evenness of hot rolled steel plate

The invention discloses a method and device for improving super-rapid cooling evenness of a hot rolled steel plate and belongs to the technical field of metallurgy. The device for improving super-rapid cooling evenness of the hot rolled steel plate comprises a water curtain cooling mechanism, a high-density straight collector cooling mechanism, a super-rapid cooling mechanism and a gas water atomization cooling mechanism. The water curtain cooling mechanism, the high-density straight collector cooling mechanism, the super-rapid cooling mechanism and the gas water atomization cooling mechanism are arranged at the upper end and the lower end of the steel plate respectively. According to the method and device for improving super-rapid cooling evenness of the hot rolled steel plate, a collector is segmented, so that different portions are controlled respectively and cooling evenness is improved.

Owner:武汉钢铁有限公司

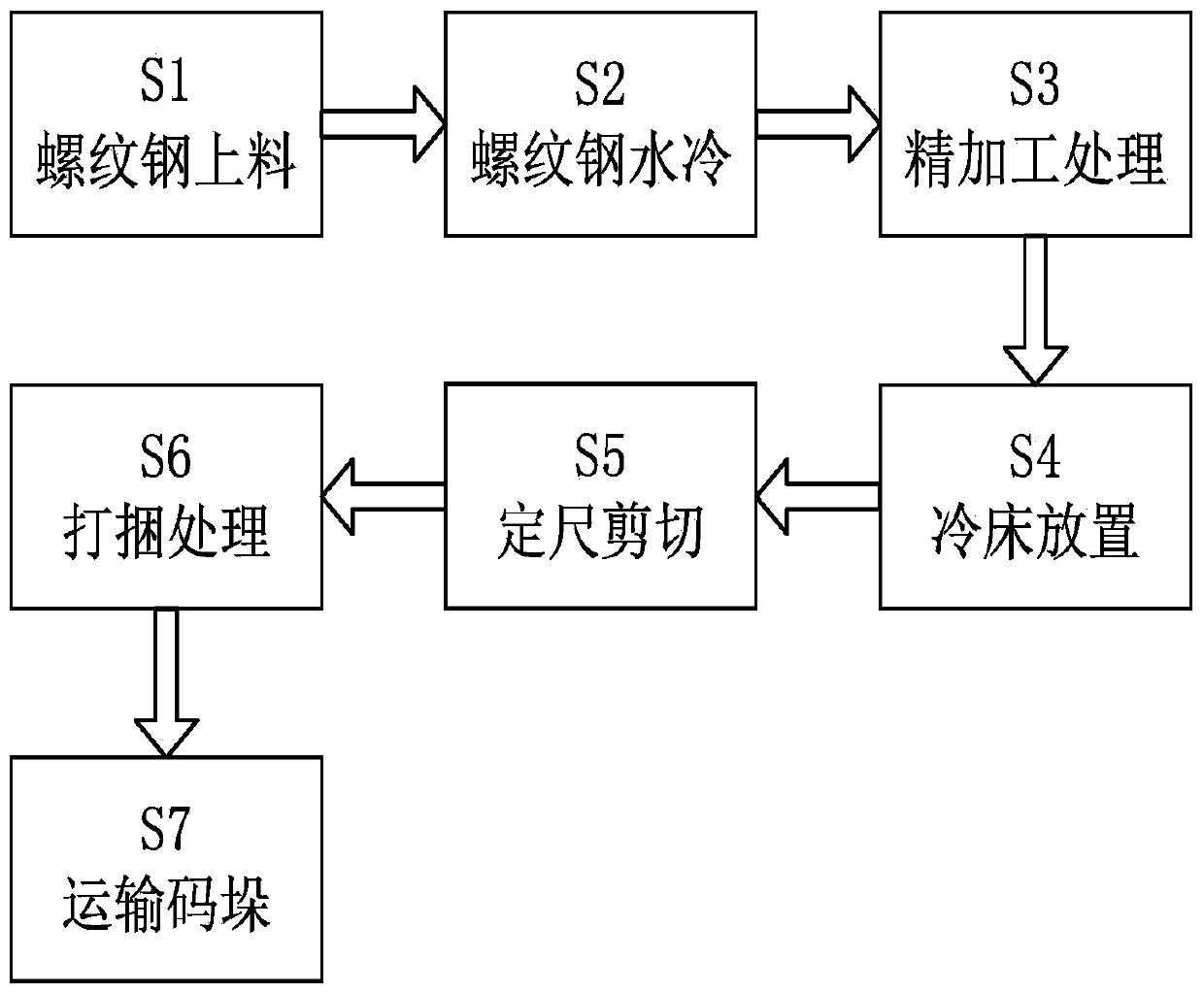

Rolling finish machining method for hot rolled ribbed bar hot rolling manufacturing

ActiveCN110576045ASolve the impact of aestheticsAvoid affecting the appearanceWork treatment devicesCooling bedsEngineeringWater cooling

The invention relates to a rolling finish machining method for hot rolled ribbed bar hot rolling manufacturing. The method is characterized in that a base, a feeding unit, finish machining units and awater cooling device are involved, the feeding unit is mounted at the upper end of the base, the finish machining units are mounted on the inner walls of the left end and the right end of the base, and the water cooling device is mounted at the left end of the base. According to the provided rolling finish machining method for hot rolled ribbed bar hot rolling manufacturing, finish machining treatment of surface lines is carried out on a hot rolled ribbed bar subjected to hot rolling, so that impurities and burrs are removed, the problems that the burrs affect attractiveness, and meanwhile, workers are prone to being scratched and hurt in the using process are solved, a finish machining mechanism is cleaned while the hot rolled ribbed bar is water cooled through the water cooling device,so that the situation that due to the fact that the impurities such as the burrs scratch the surface of the hot rolled ribbed bar, the attractiveness is affected is prevented.

Owner:大冶华鑫实业有限公司

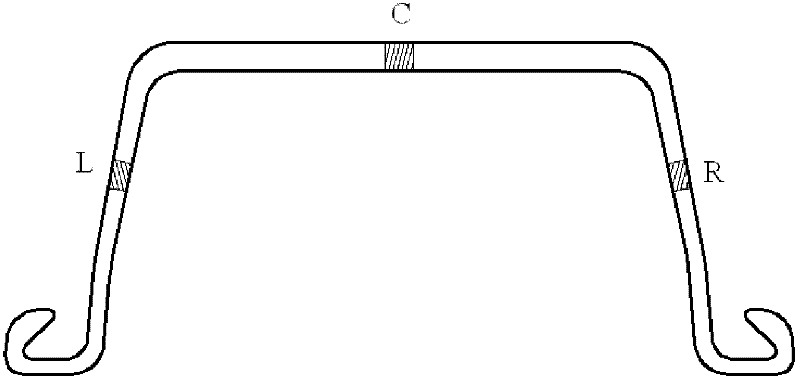

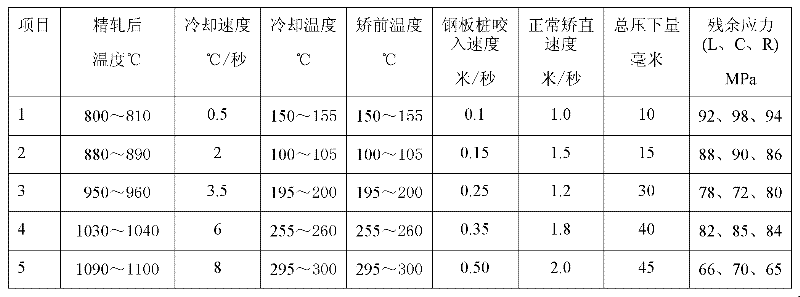

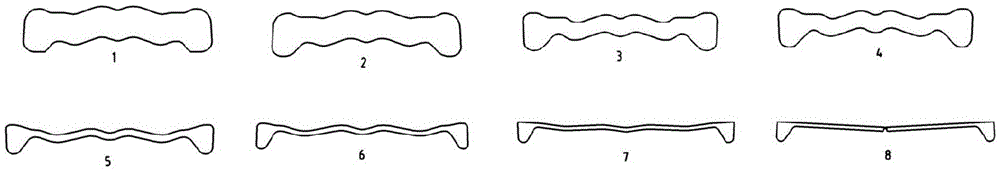

Method for producing hot-rolling U-shaped steel sheet pile with residual stress less than 100 MPa

InactiveCN102240891AControl residual stressIncrease added valueTemperature control deviceCooling bedsSheet pileCooling temperature

The invention relates to a method for producing a hot-rolling U-shaped steel sheet pile with a residual stress less than 100 MPa, which comprises the steps of: carrying out smelting, continuous casting and rolling; conveying to a cooling table for cooling, wherein the cooling speed is controlled within 0.5-8 DEG C / s and the cooling temperature, i.e., the temperature before straightening, is controlled at 100-300 DEG C; and straightening at a temperature of 100-300 DEG C. The method for producing the hot-rolling U-shaped steel sheet pile with the residual stress less than 100 MPa has the characteristics that: through controlling the residual temperature of the steel sheet pile before straightening and adopting a straightening process, the residual stress of the hot-rolling U-shaped steel sheet pile is effectively controlled, and the production cost is lowered, and the residual stress is less than 100 MPa, so that the effect of the hot-rolling U-shaped steel sheet pile used for piling is effectively enhanced; in addition, the method is simple to operate and is beneficial to popularization.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Gear steel banded structure control process

InactiveCN111424149AEvenly distributedImprove distributionTemperature control deviceHeat treatment process controlHeat conservationPearlite

Owner:江苏联峰实业有限公司

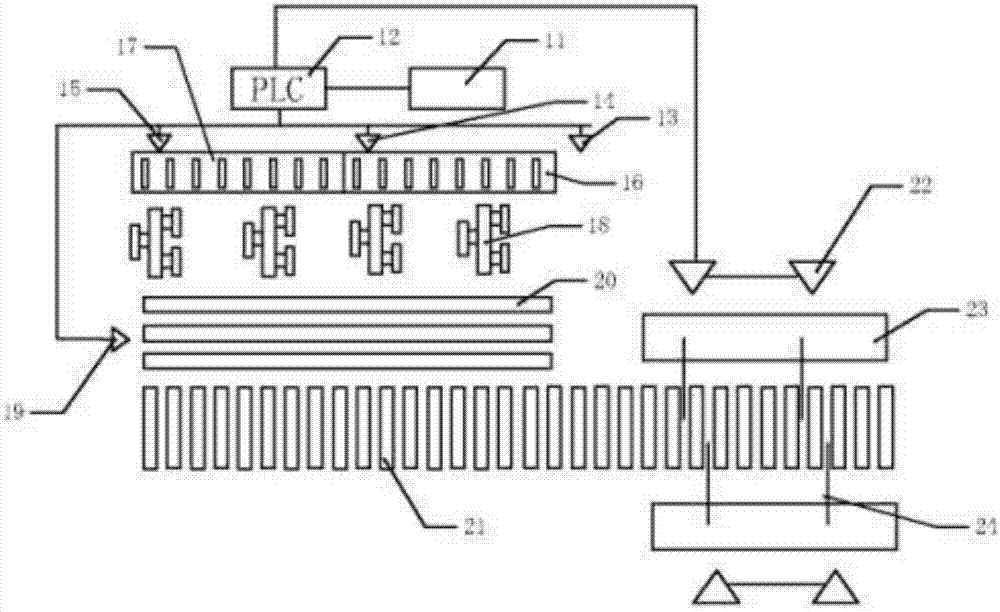

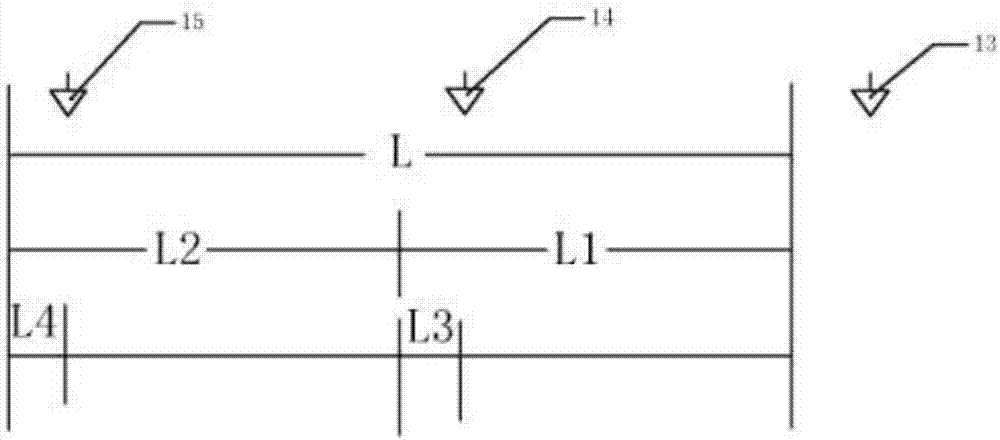

Cooling table charging automatic control device and method

InactiveCN106862286AMaster the length in real timeReasonable use of cooling resourcesCooling bedsMetal working apparatusAutomatic controlControl system

The invention belongs to the technical field of steel rolling machine tool equipment, and relates to a cooling table charging automatic control device and method. A cooling table upper steel roller bed is evenly divided into a first cooling table upper steel roller bed body and a second cooling table upper steel roller bed body. The distance between a first hot metal detector and the head end is equal to the distance between a second hot metal detector and the boundary of the first cooling table upper steel roller bed body and the second cooling table upper steel roller bed body, and is equal to the distance between a third hot metal detector and the tail end of the second cooling table upper steel roller bed body as well. The first hot metal detector, the second hot metal detector and the third hot metal detector are in signal connection with a PLC control system. The PLC control system is connected with an industrial personal computer through wires. An MES system is connected with the industrial personal computer. The PLC control system is connected with a cooling table detection proximity switch through a wire. A pair of finished product collection troughs are arranged on the outer side of a cooling table discharging roller bed. Cool metal detectors are arranged on the outer sides of the finished product collection troughs. The problem that part of zone of a cooling table is not fully utilized when steel plates are distributed in a single row is solved.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Technique for producing rod iron with large diameter for mechanical manufacture

InactiveCN101439347ALess investment in production processImprove organizationTemperature control deviceWork treatment devicesCoiling procedureHeating time

The invention relates to a coil rod production process, in particular to a production process of a major-diameter coil rod for machine manufacturing. The heating time lasts 2.25 hours to 3 hours, and the heating speed ranges from 9 min / cm to 12 min / cm during the heating of a steel billet; the inlet temperature of a No. 0 rolling mill is controlled within the scope ranging from 950 DEG C to 1000 DEG C in a rough rolling procedure; the outlet temperature of a No. 11 rolling mill is controlled within the scope ranging from 1000 DEG C to 1050 DEG C in the medium rolling procedure; the outlet temperature of a No. 13 rolling mill is controlled within the scope ranging from 1050 DEG C to 1100 DEG C in the pre-finish rolling procedure; before the CCR rolling procedure, a rolled piece is led out from the pre-finish rolling procedure and enters a CCR rolling machine after being cooled in No. 4 and No. 5 water tanks, and the inlet temperature of the rolled piece in the CCR rolling machine is lower than 850 DEG C; before the coiling procedure, the rolled piece is cooled in a No. 6 rolling machine after exiting the CCR machine, and the temperature of the rolled piece is lower than 800 DEG C. The major-diameter coil rod for the machine manufacturing can obtain the major-diameter coil rod which has mechanical properties of excellent organization and deep processing, has the advantages of no surface scratch and complete rolling shape and is used for machine manufacturing.

Owner:NANJING NANGANG IND DEV CO LTD

Novel bar material cooling bed steel-feeding transmission mechanism

InactiveCN101412044AEasy to fixImprove carrying capacityCooling bedsMetal rolling arrangementsHydraulic cylinderEngineering

The invention provides a novel steel feeding transmission mechanism of a bar cooling bank. The mechanism completes automatic alignment to a workpiece, and can reduce the manufacturing cost and production cost of a device, reduce the maintenance cost of the device while ensuring normally steel feeding. The mechanism comprises a hydraulic cylinder, a transmission connecting rod, a crank and a lifting apron plate, wherein the crank is connected with the lifting apron plate. The novel steel feeding transmission mechanism is characterized in that the transmission connecting rod is adjustable; a piston rod of the hydraulic cylinder is in axial connection with the transmission connecting rod; the other end of the transmission connecting rod is connected with a pull rod; and the hydraulic cylinder and the transmission connecting rod are arranged rightly under the pull rod.

Owner:无锡雪浪输送机械有限公司

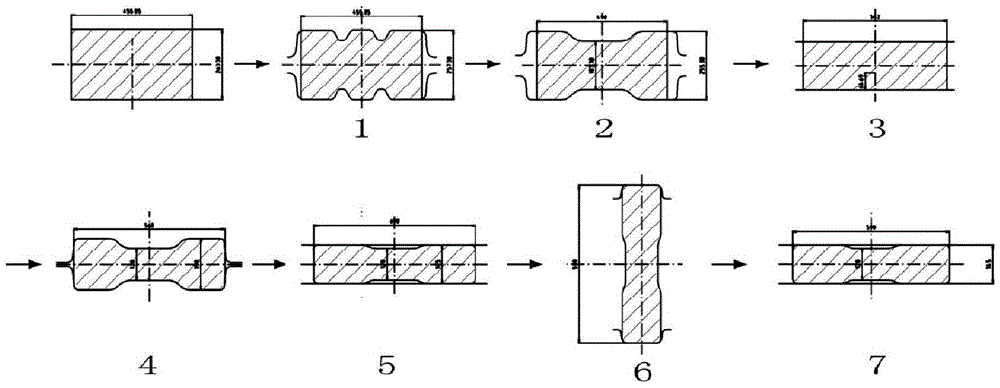

Process for producing flat-bulb steel

ActiveCN105478470AImprove versatilityReduce sizeCooling bedsMetal rolling arrangementsMetalMaterials science

The invention discloses a process for producing flat-bulb steel, belonging to the field of metal rolling. The production process comprises the following steps: (1) BD1 rolling; (2) BD2 rolling; (3) DRDF rolling; (4) primary material cooling; (5) subdividing and straightening for the cooled primary materials. Compared with the prior art, the process has the characteristics of being good in universality of steel billet and rollers, large in size range of final products and good in quality of the final products.

Owner:RIZHAO STEEL HLDG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com