Novel bar material cooling bed steel-feeding transmission mechanism

A transmission mechanism and bar technology, applied in cooling beds, metal processing equipment, metal rolling, etc., can solve problems such as many hidden dangers, transmission damage, and inability to complete, reduce the factors that cause accidents, and reduce technical difficulty. , the effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

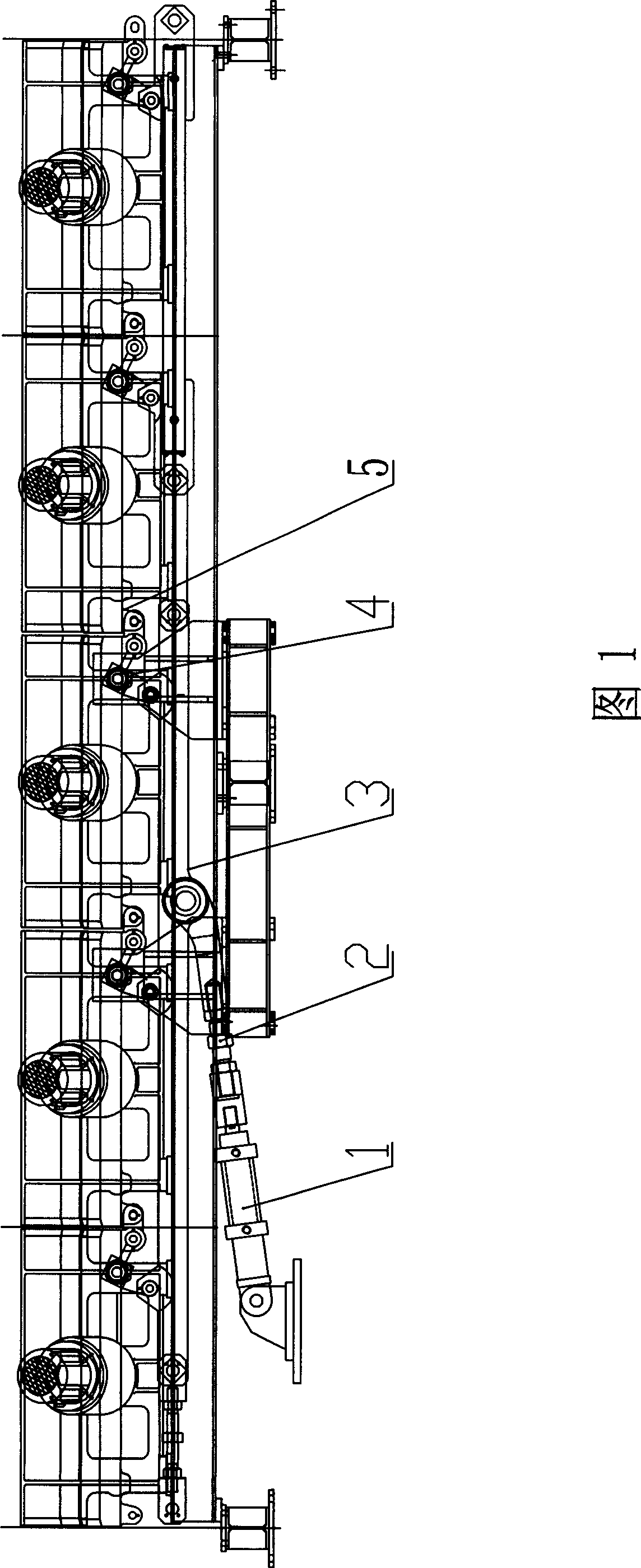

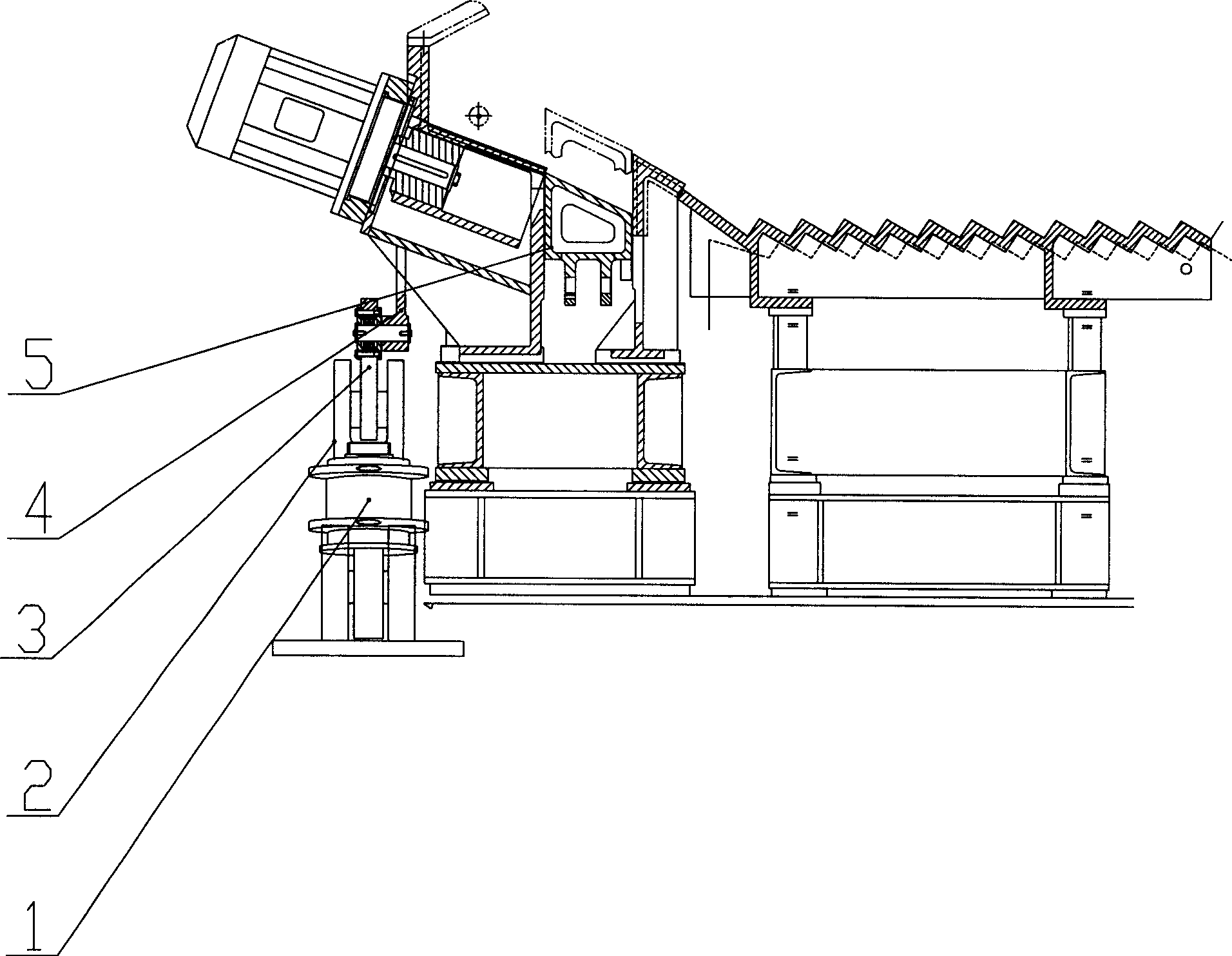

[0009] see picture 1, figure 2 , the present invention includes a hydraulic cylinder 1, a transmission connecting rod 2, a bell crank 4, a lifting skirt 5, the bell crank 4 is connected to the lifting skirt 5, the transmission connecting rod 2 is an adjustable transmission connecting rod, and the piston rod of the hydraulic cylinder 1 It is connected to the transmission connecting rod 2, the other end of the transmission connecting rod 2 is connected to the pull rod 3, the pull rod 3 is connected to one end of the crank throw 4, the other end of the crank throw 4 is connected to the lifting skirt 5, the hydraulic cylinder 1 is installed on the base and passes through the ground The foot bolts are fixed, the hydraulic cylinder 1 and the transmission connecting rod 2 are located directly below the pull rod 3, and the hydraulic cylinder 1 adopts a hydraulic synchronous circuit to make its actions completely consistent. The device contains at least two hydraulic cylinders 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com