Material distribution method for cold bed

A technology of cooling bed and cloth, applied in cooling bed, metal processing equipment, metal rolling, etc., to achieve the effect of convenient data management, reduction of human workload, and automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

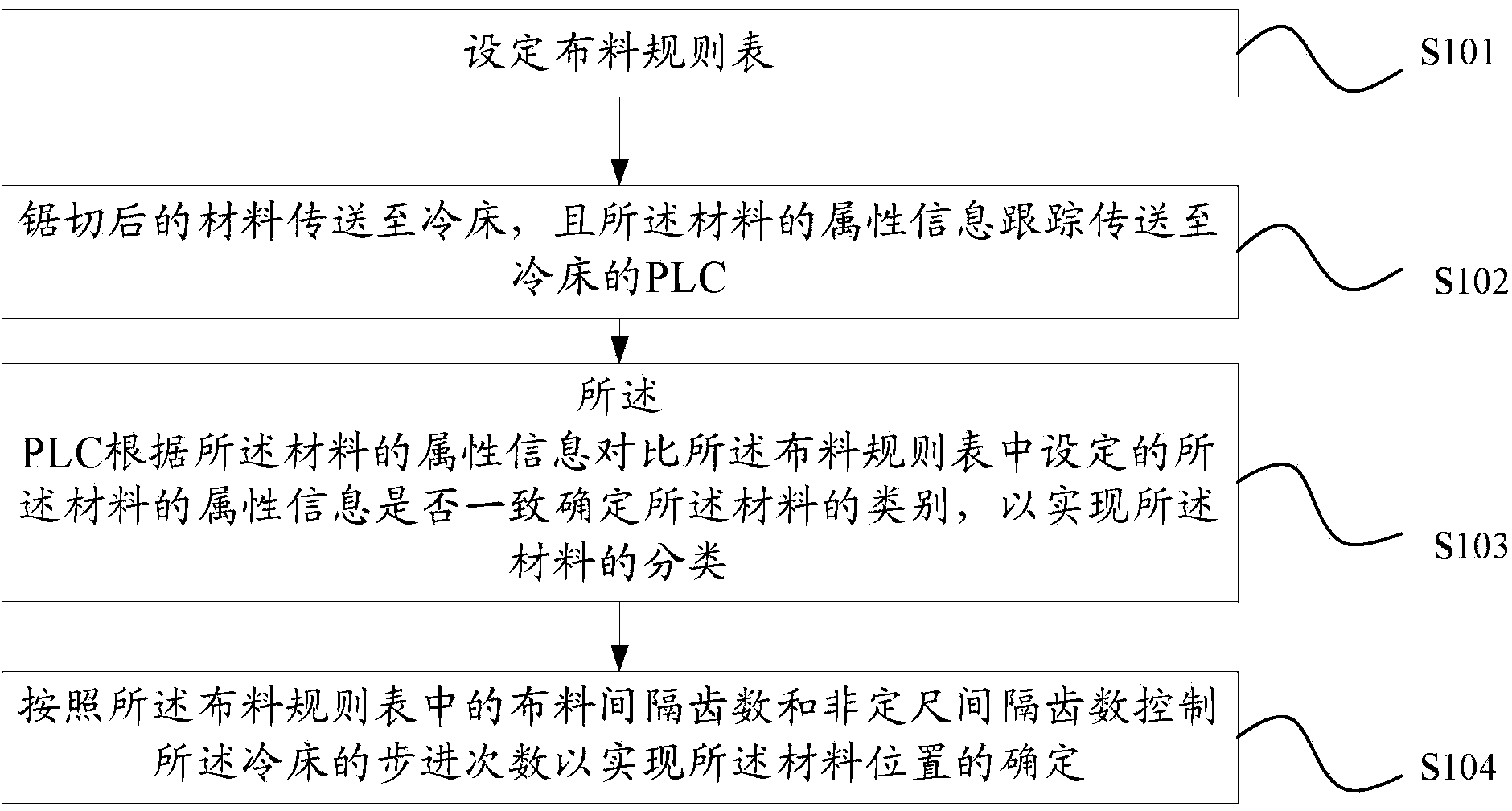

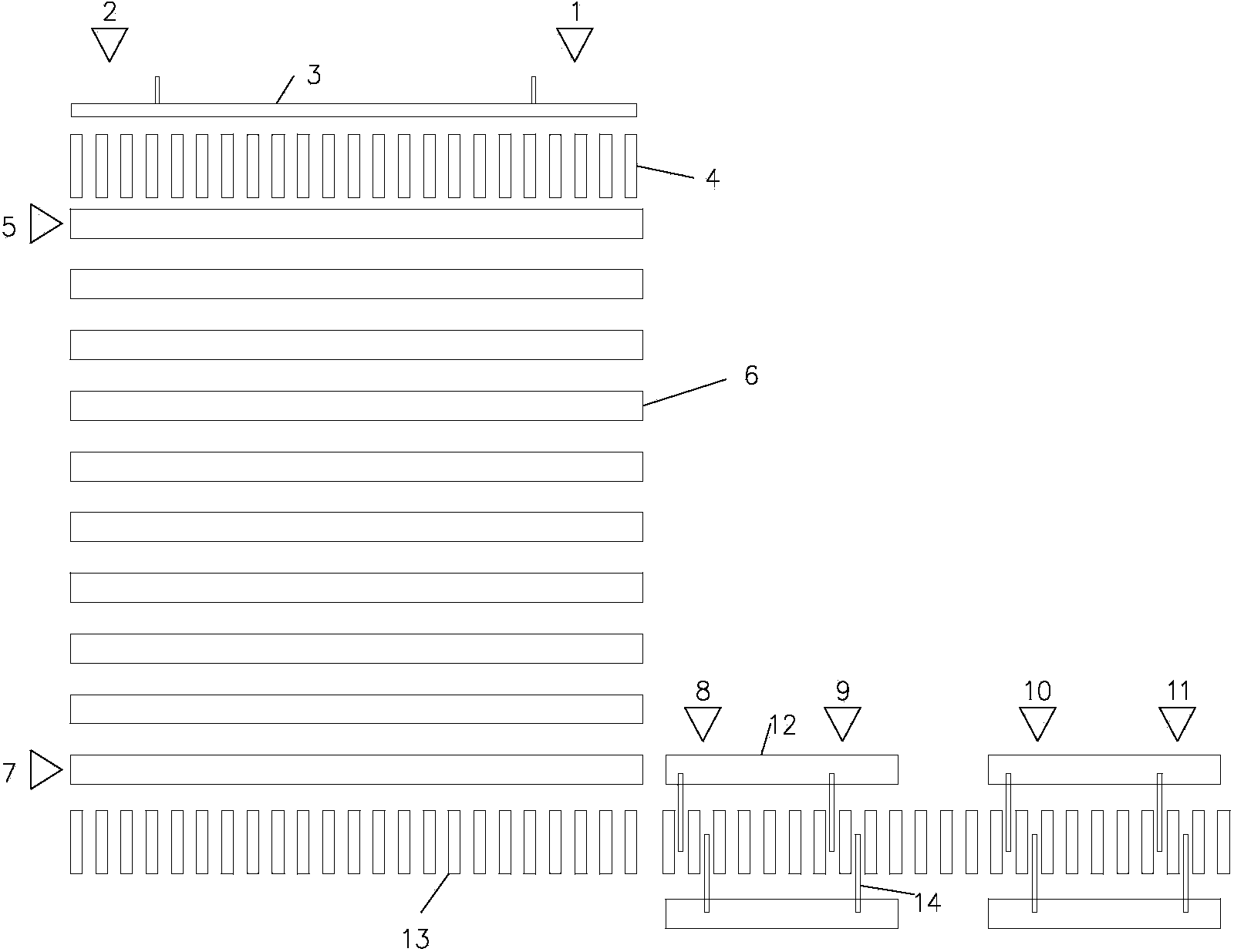

[0014] attached figure 1 It is the general flowchart of the cooling bed cloth method. The cooling bed distribution method according to the present invention includes the following steps: (1) setting the distribution rule table; (2) the sawn material is sent to the cooling bed, and the attribute information of the material is tracked and sent to the PLC of the cooling bed; (3) According to the attribute information of the material, compare whether the attribute information of the material set in the cloth rule table is consistent to determine the category of the material, so as to realize the classification of the material; (4) according to the cloth The number of cloth interval teeth and the number of non-scale interval teeth in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com