Patents

Literature

118 results about "Shear line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

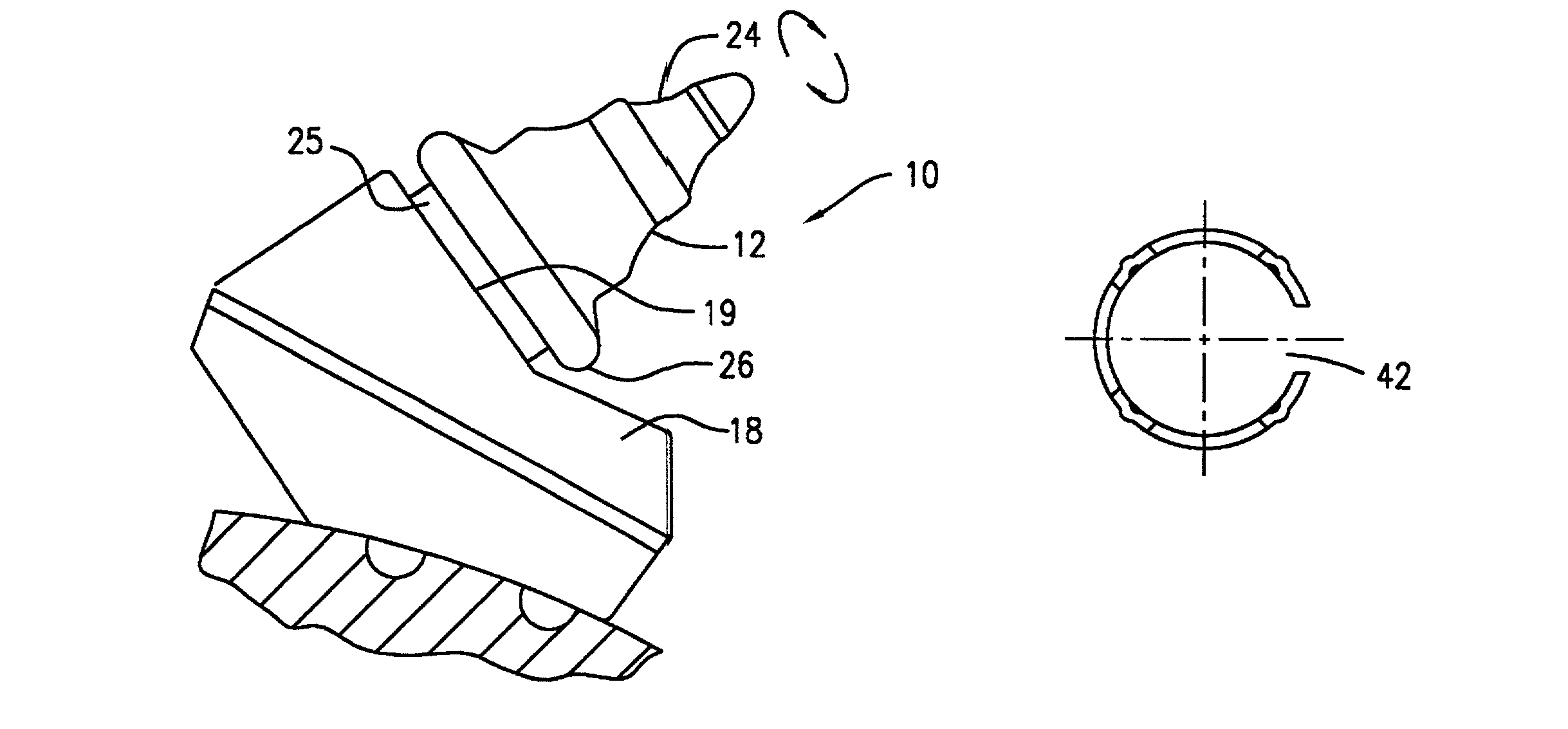

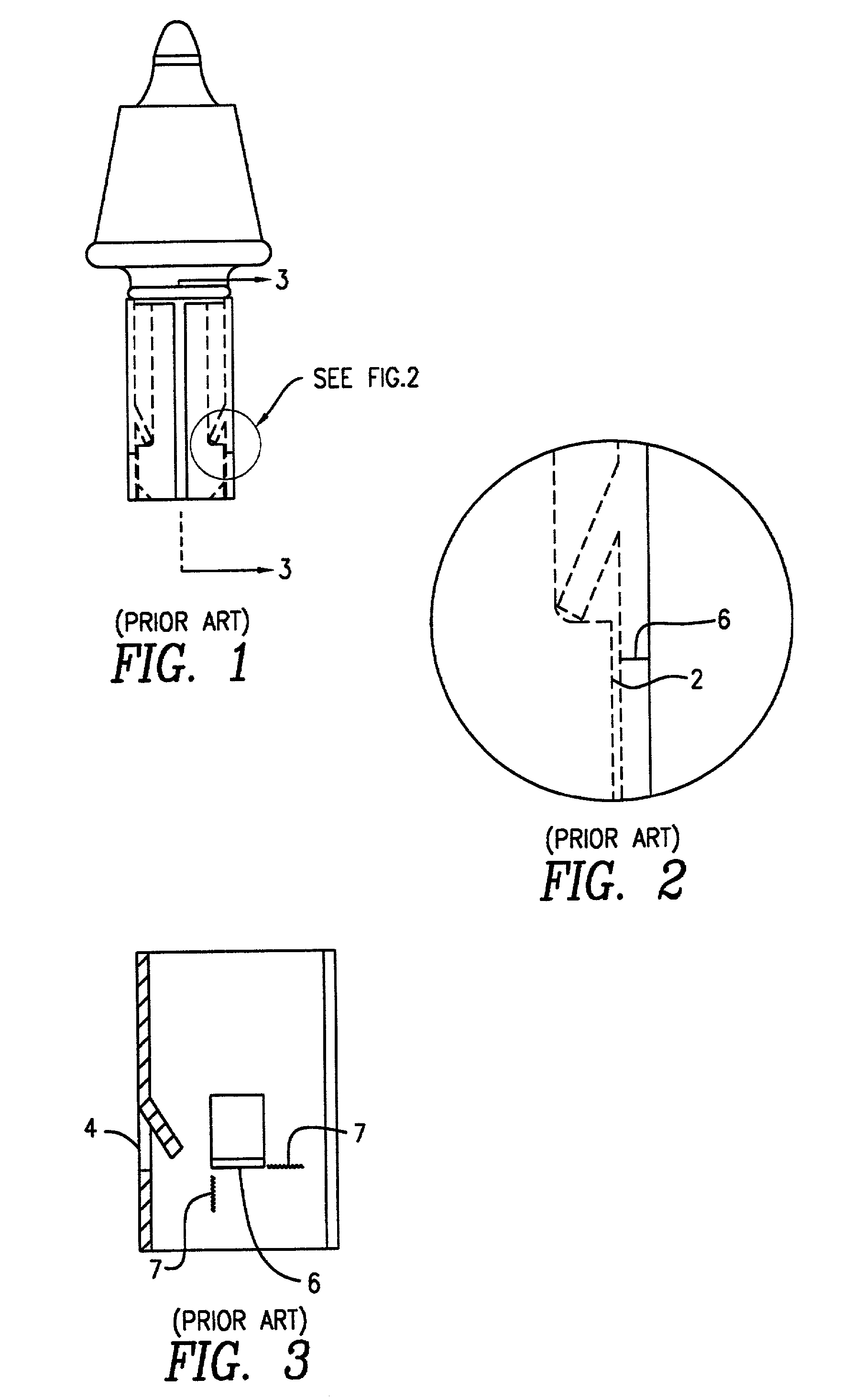

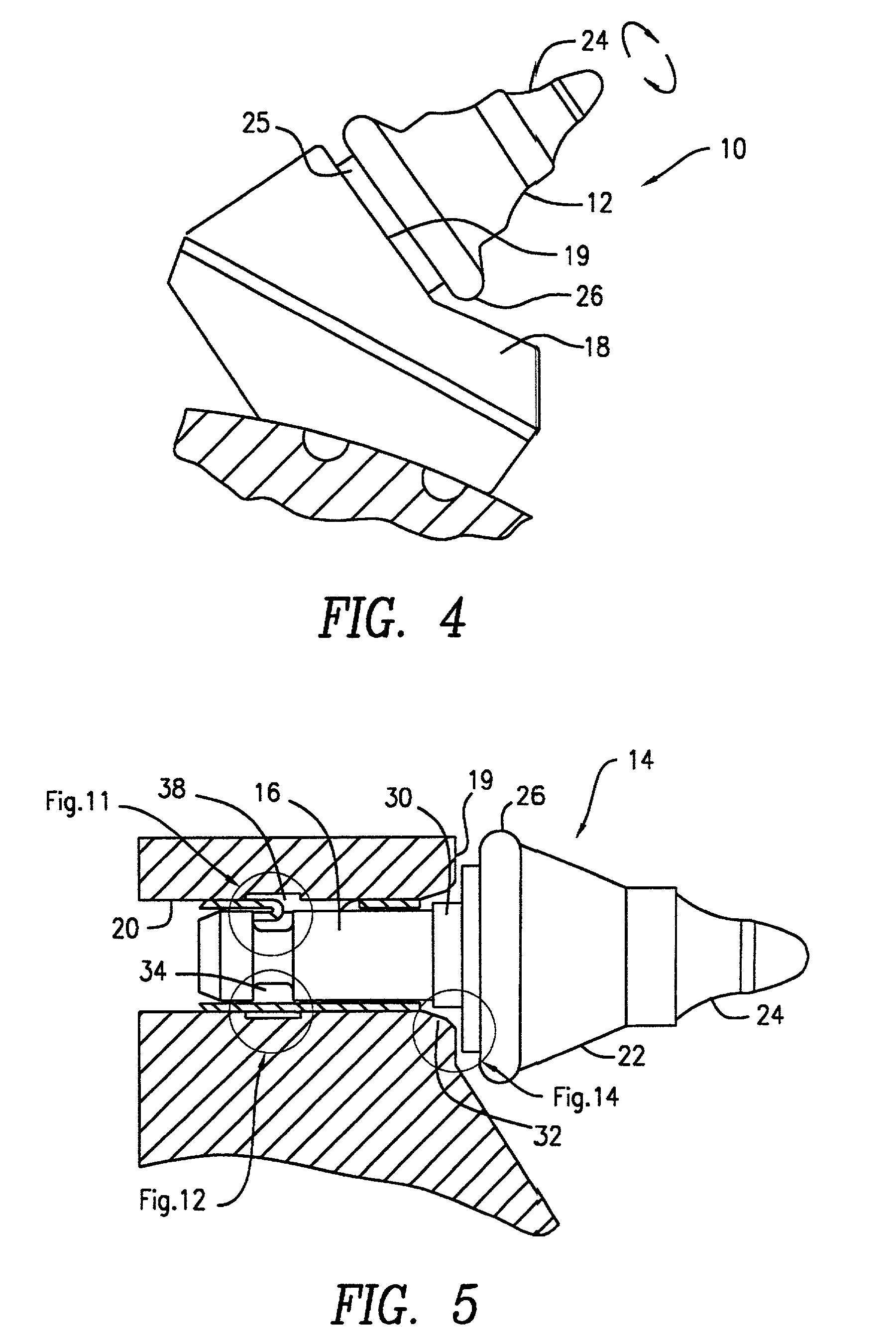

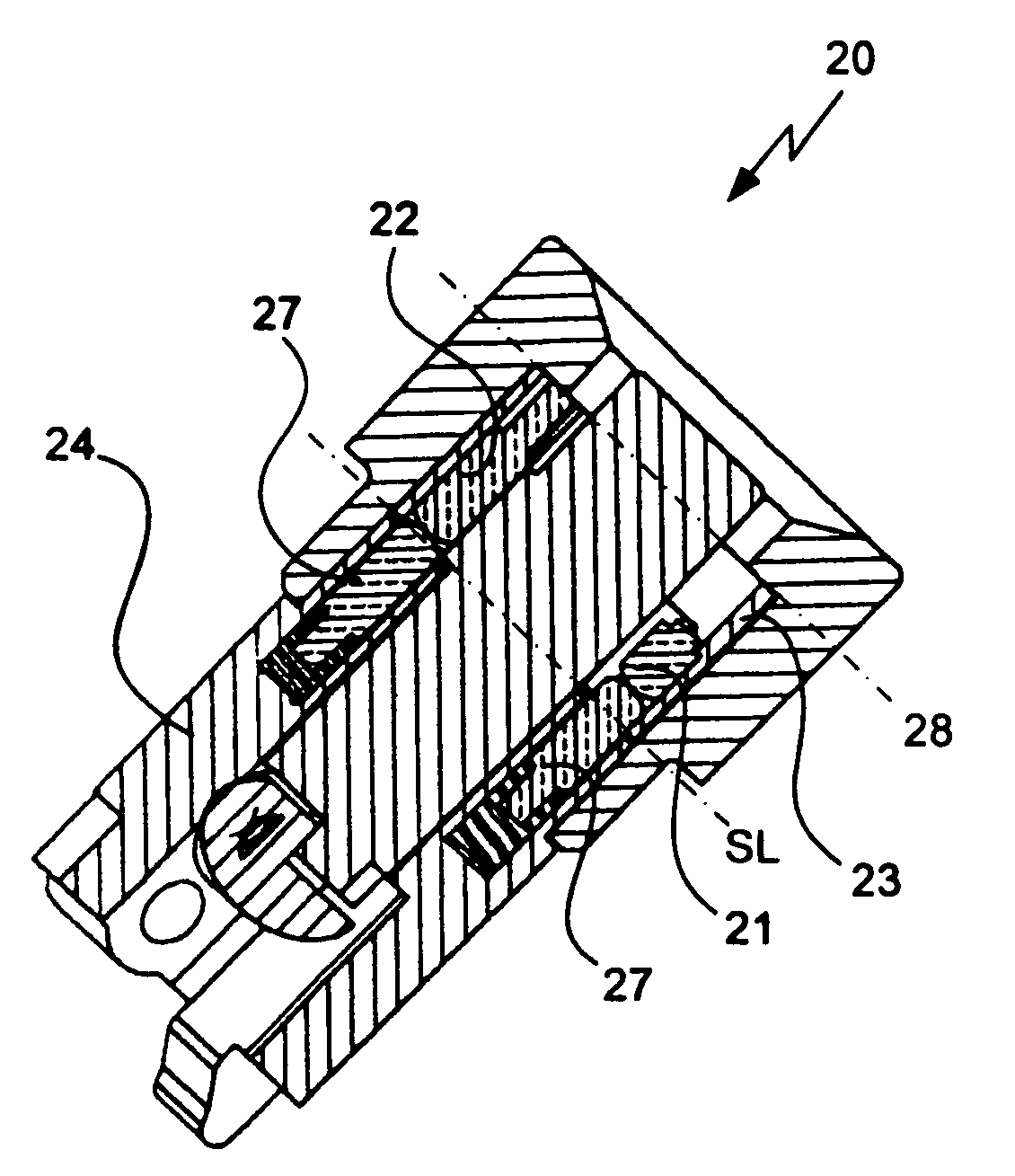

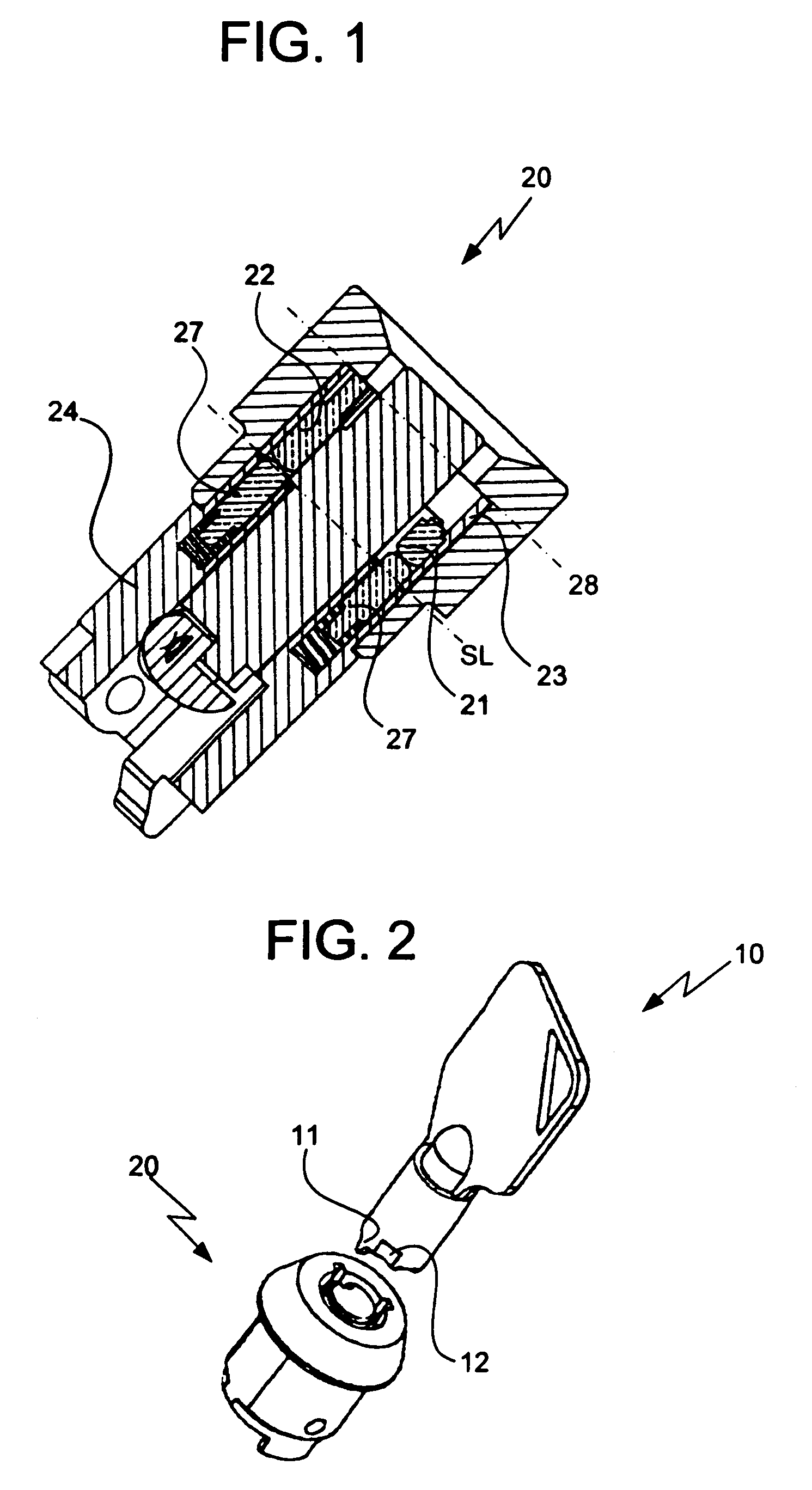

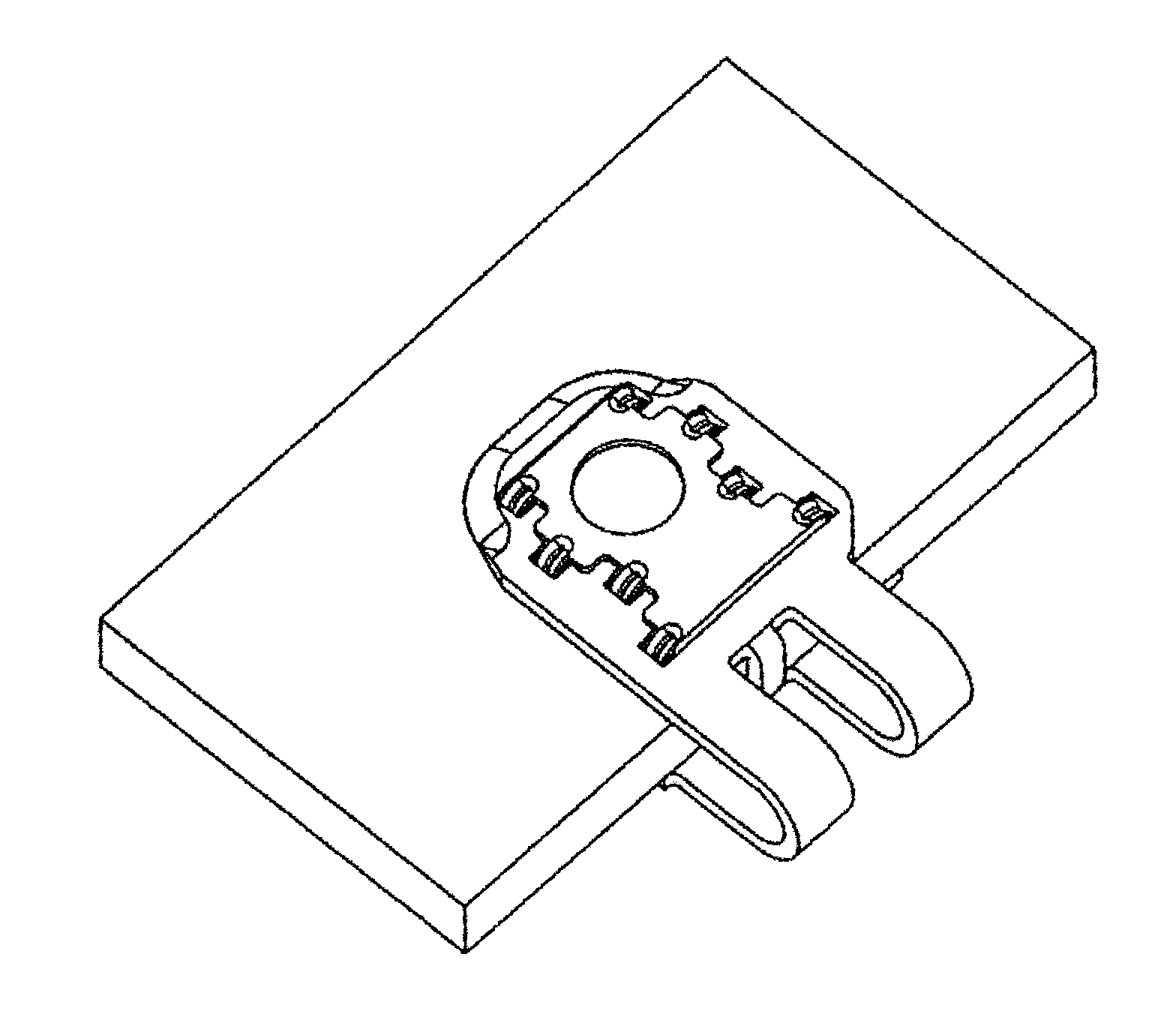

Rotatable cutting tool having retainer with dimples

ActiveUS7380888B2Hinders its propagationAvoid stress concentrationSlitting machinesCutting machinesShear lineEngineering

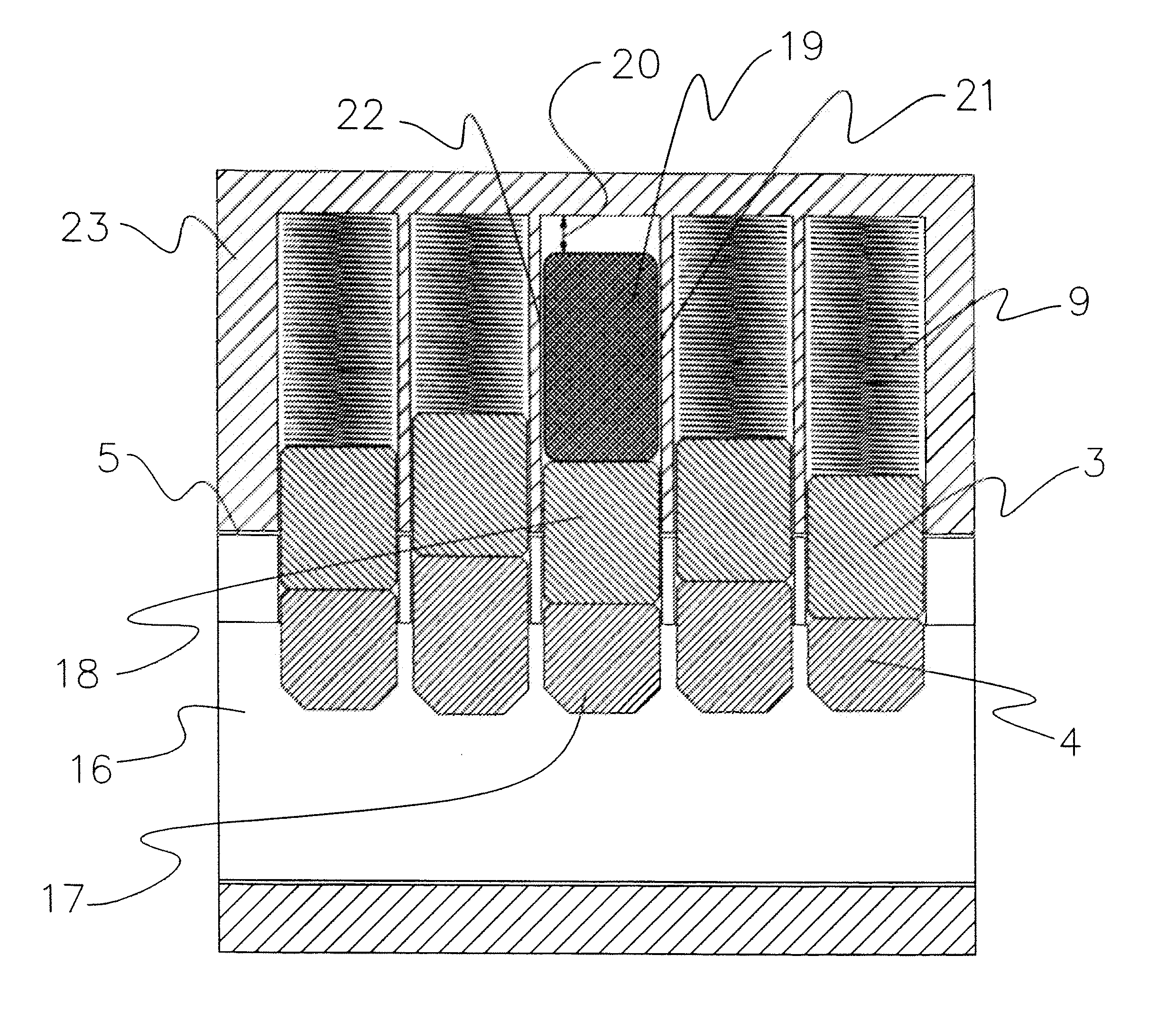

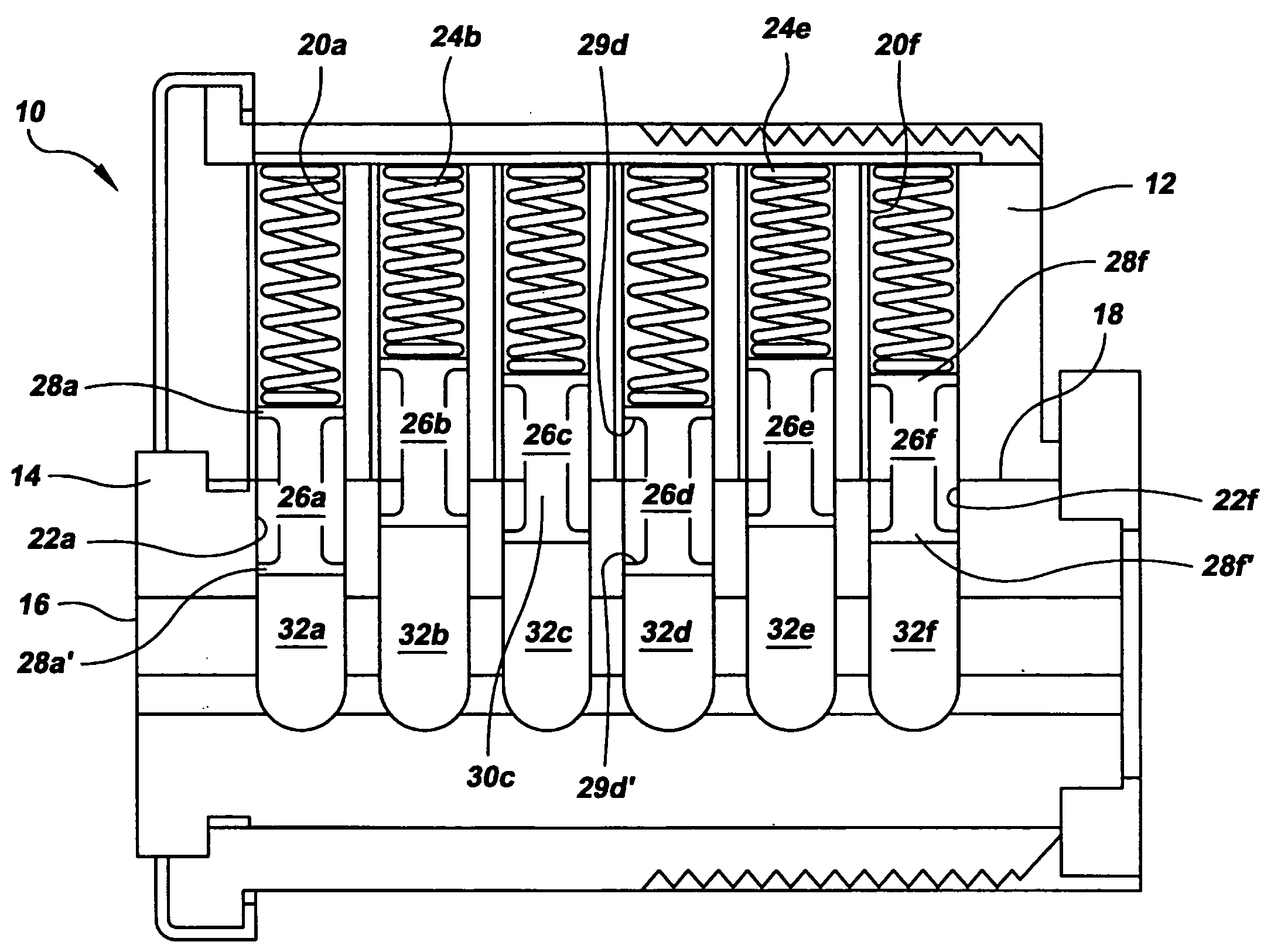

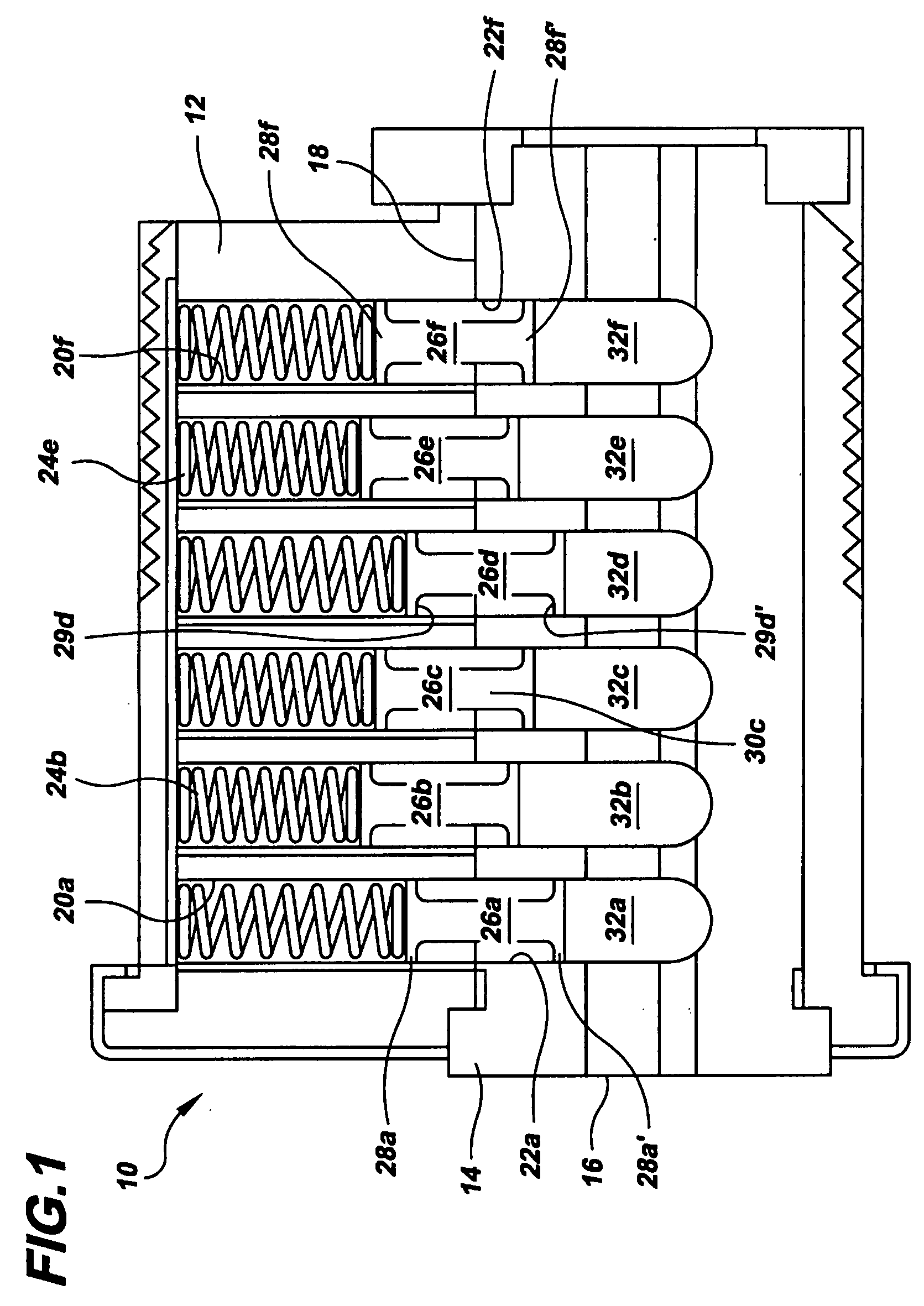

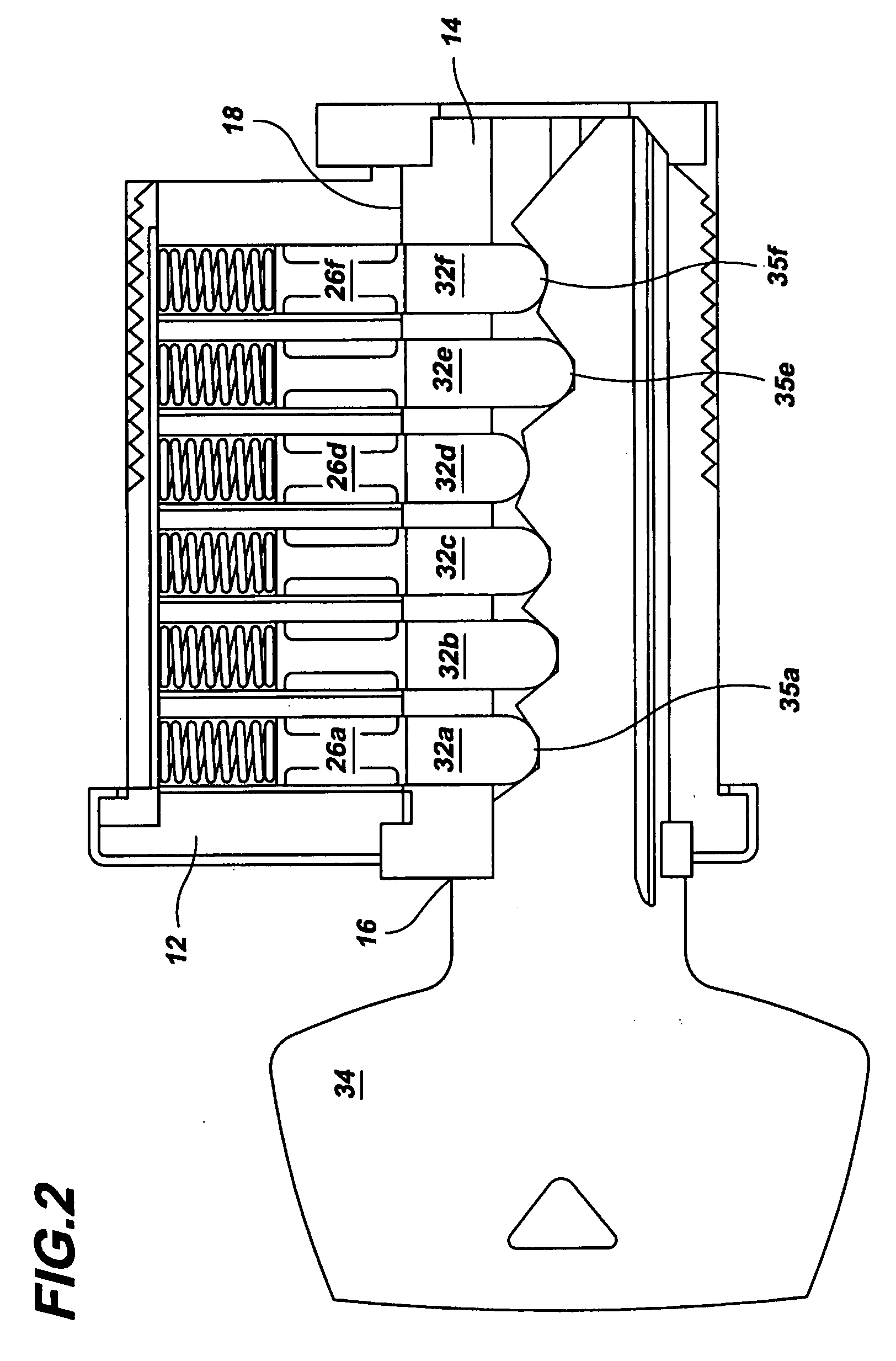

A cutting tool assembly including a cutting bit having a head and a cylindrical shank portion of substantially constant diameter depending from the head as well as a bit holder including a cylindrical bore for receiving the cylindrical shank portion of the cutting bit. The shank portion includes an annular recessed groove. The cutting tool assembly further includes a retainer sleeve disposed between the shank portion of the cutting bit and the bore of the bit holder and which closely conforms about the shank portion while allowing the shank portion to rotate within the bore. The retainer sleeve includes at least one inwardly folded over stop tab that cooperates with the recessed groove to axially position the shank within the retainer. The retainer includes stop tabs that are bent around beyond the shear cut lines of the tab opening so that the hub portions of the shank do not transmit a force against these weakened shear cut areas of the retainer. The shank hub is positioned so that the hub rotates against only those portions of the retainer that are not weakened by shear line openings.

Owner:KENNAMETAL INC

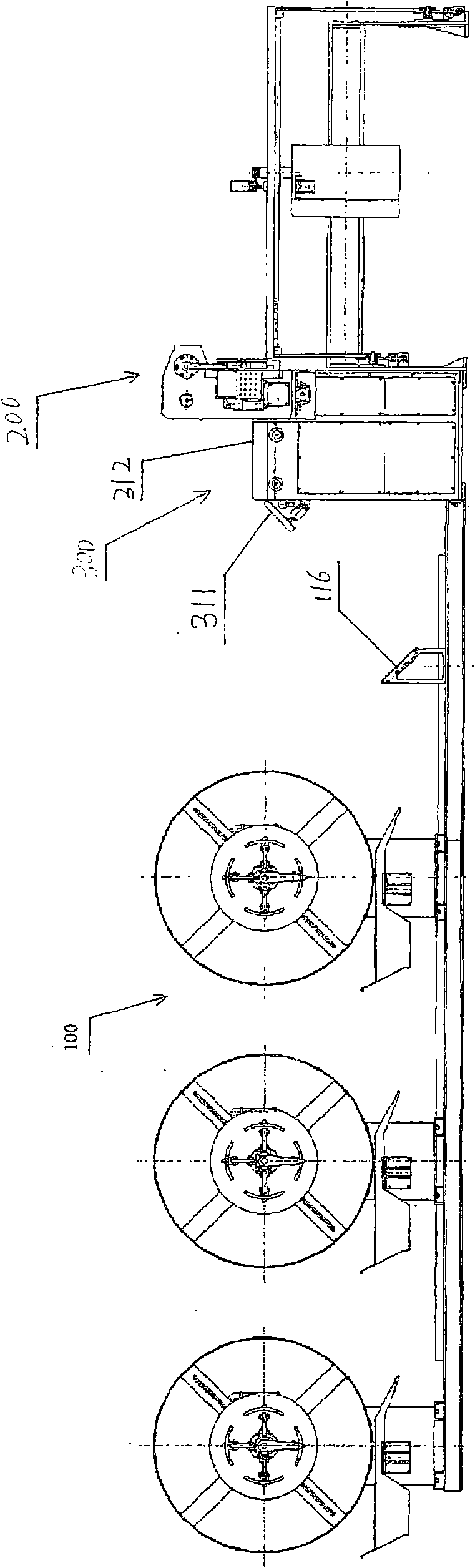

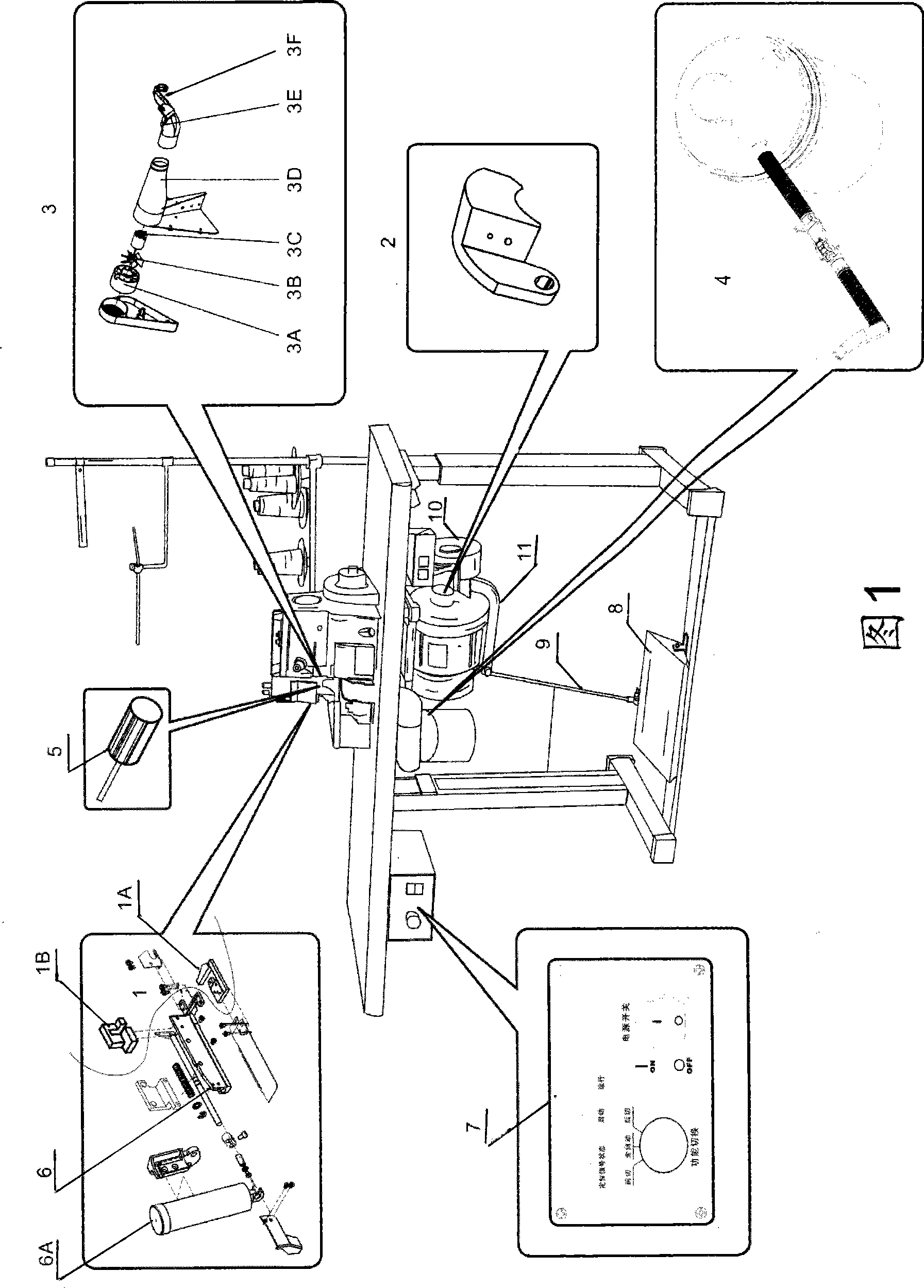

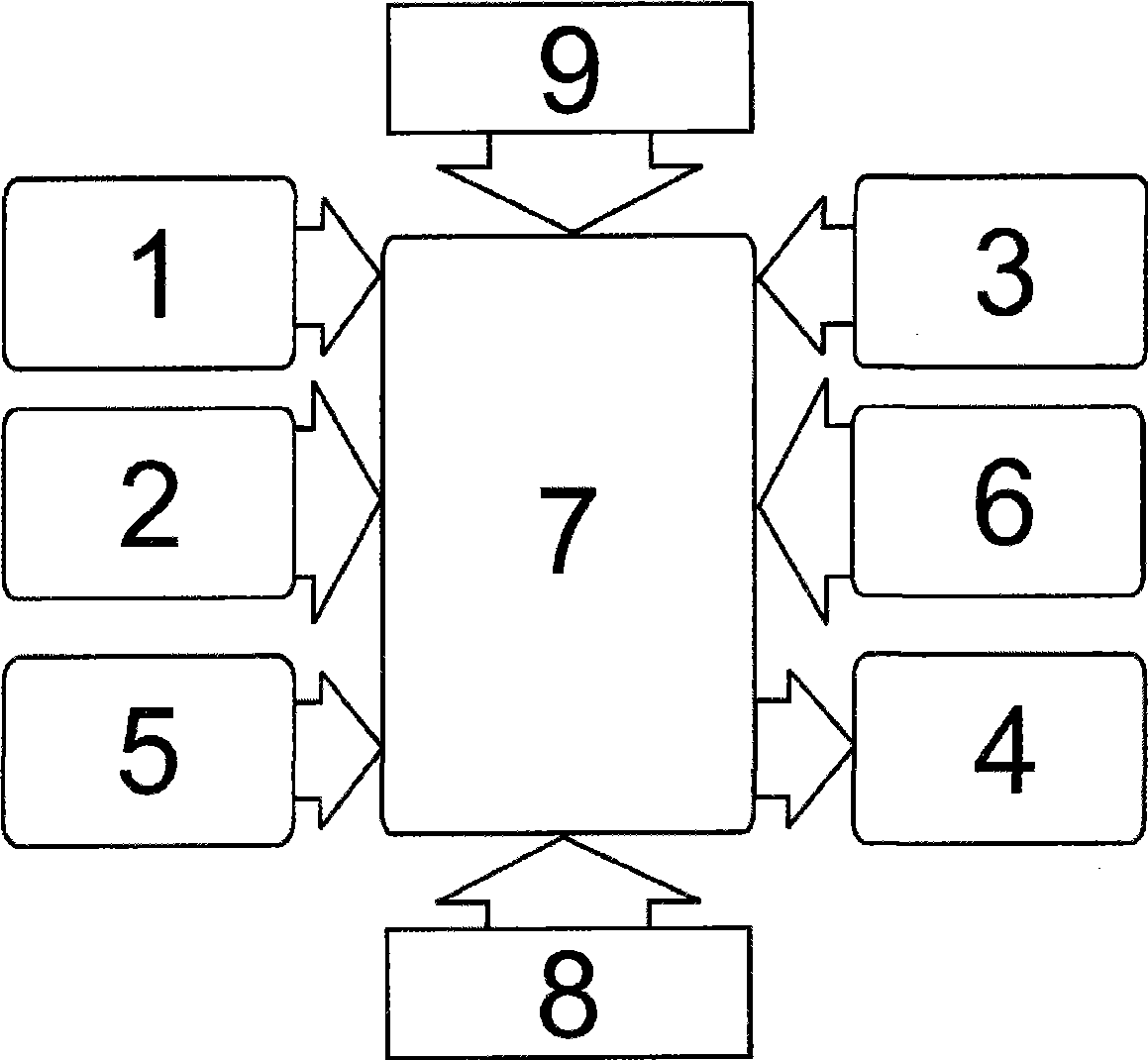

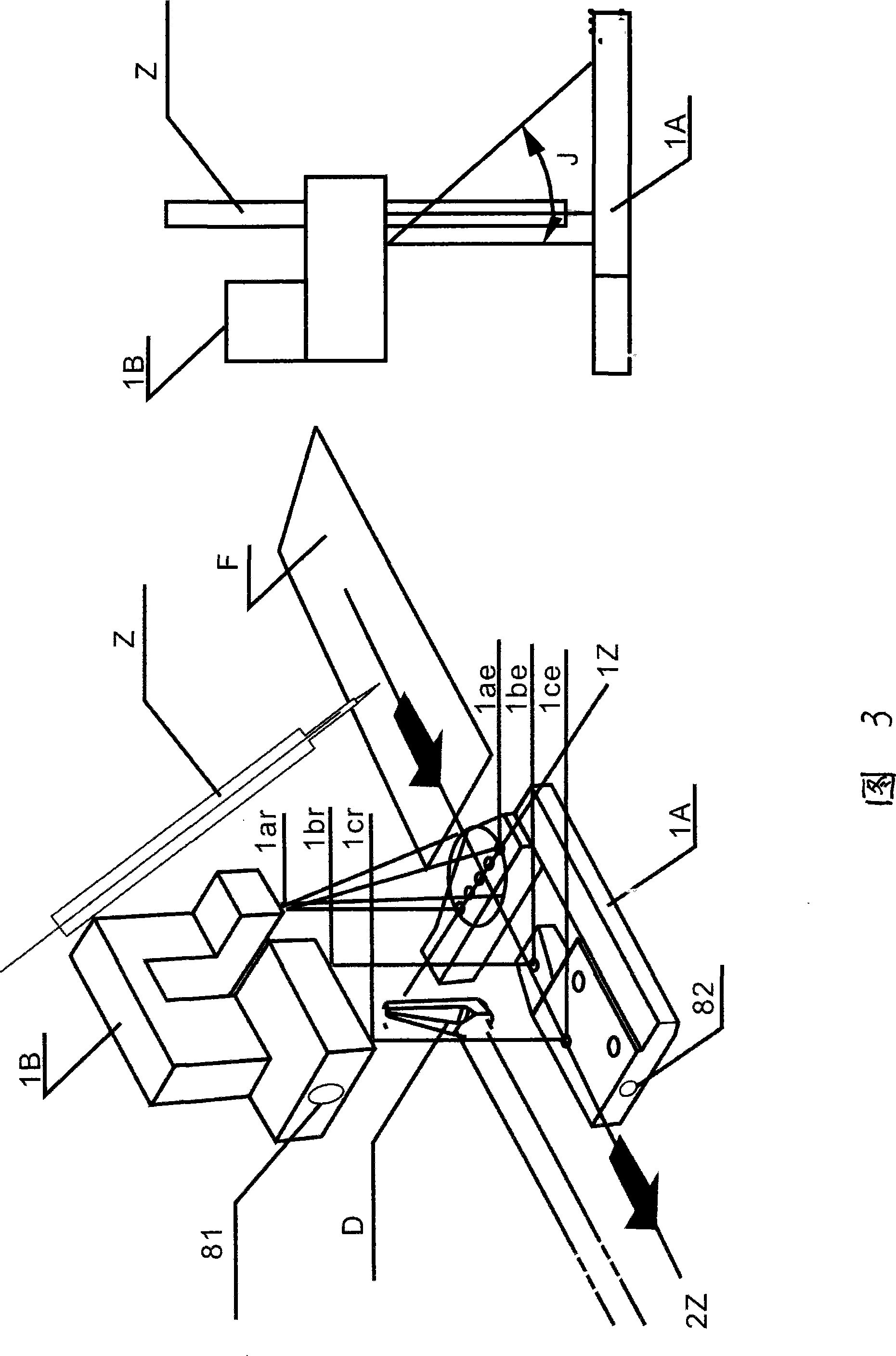

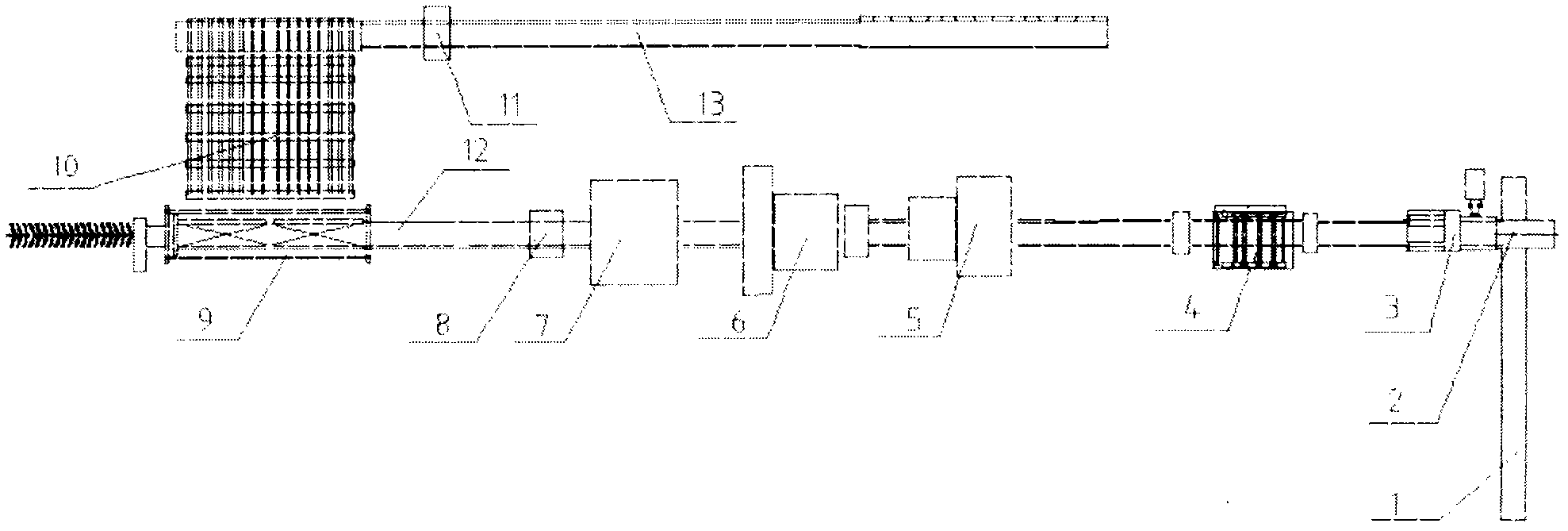

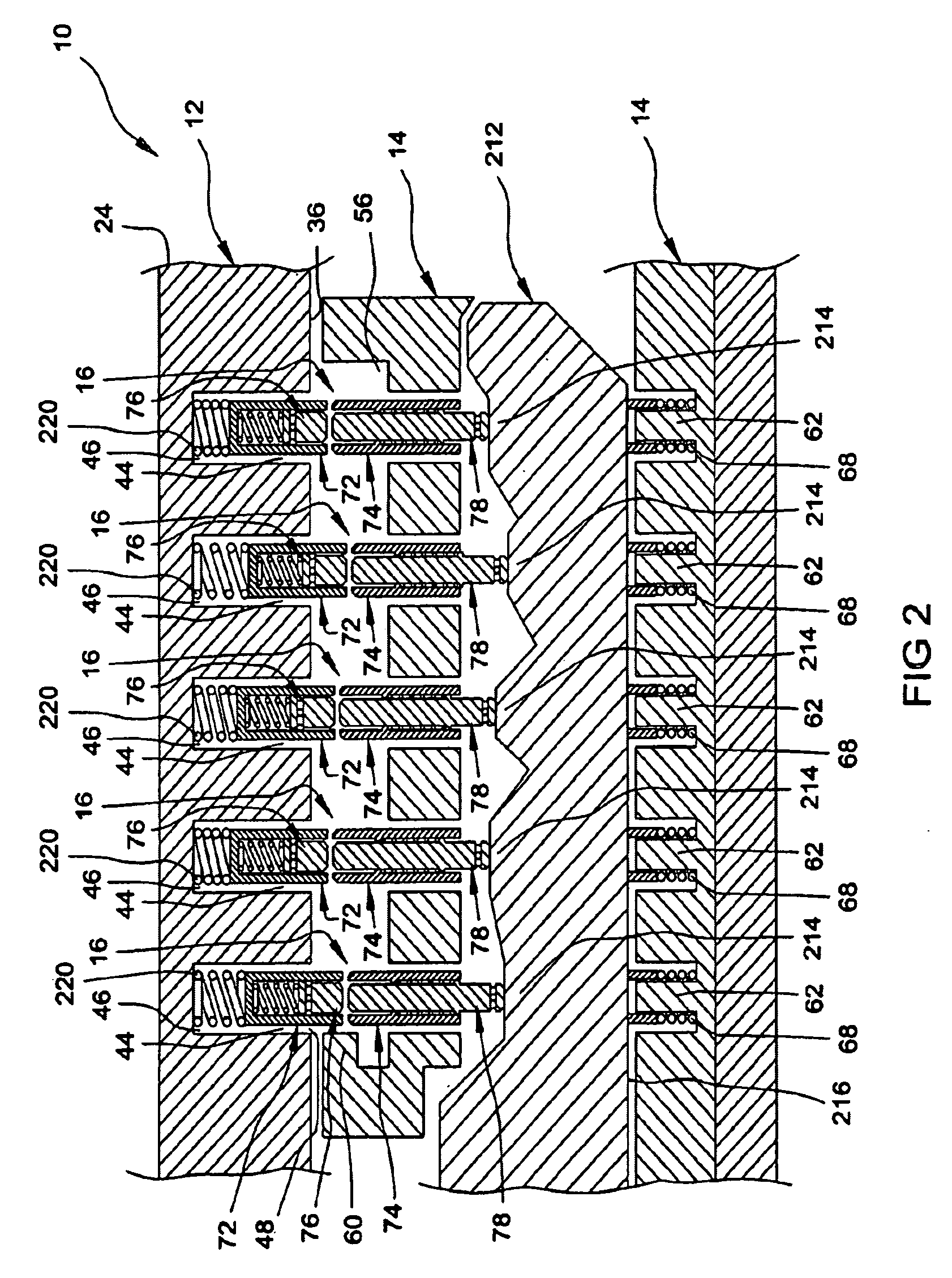

Amorphous alloy strip shear line

ActiveCN101642828AEasy to checkEasy maintenanceMetal-working feeding devicesShearing machinesNumerical controlProgrammable logic controller

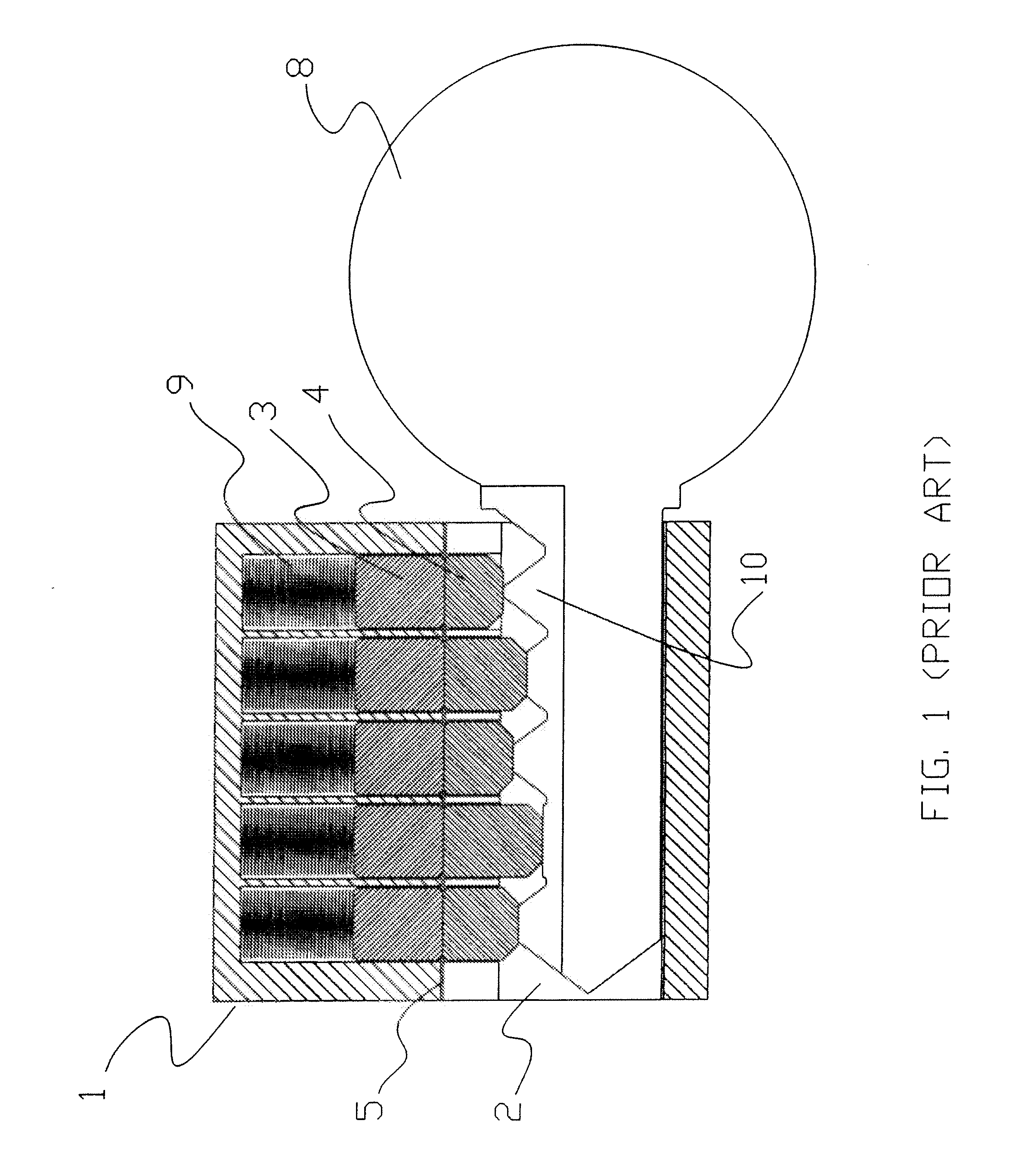

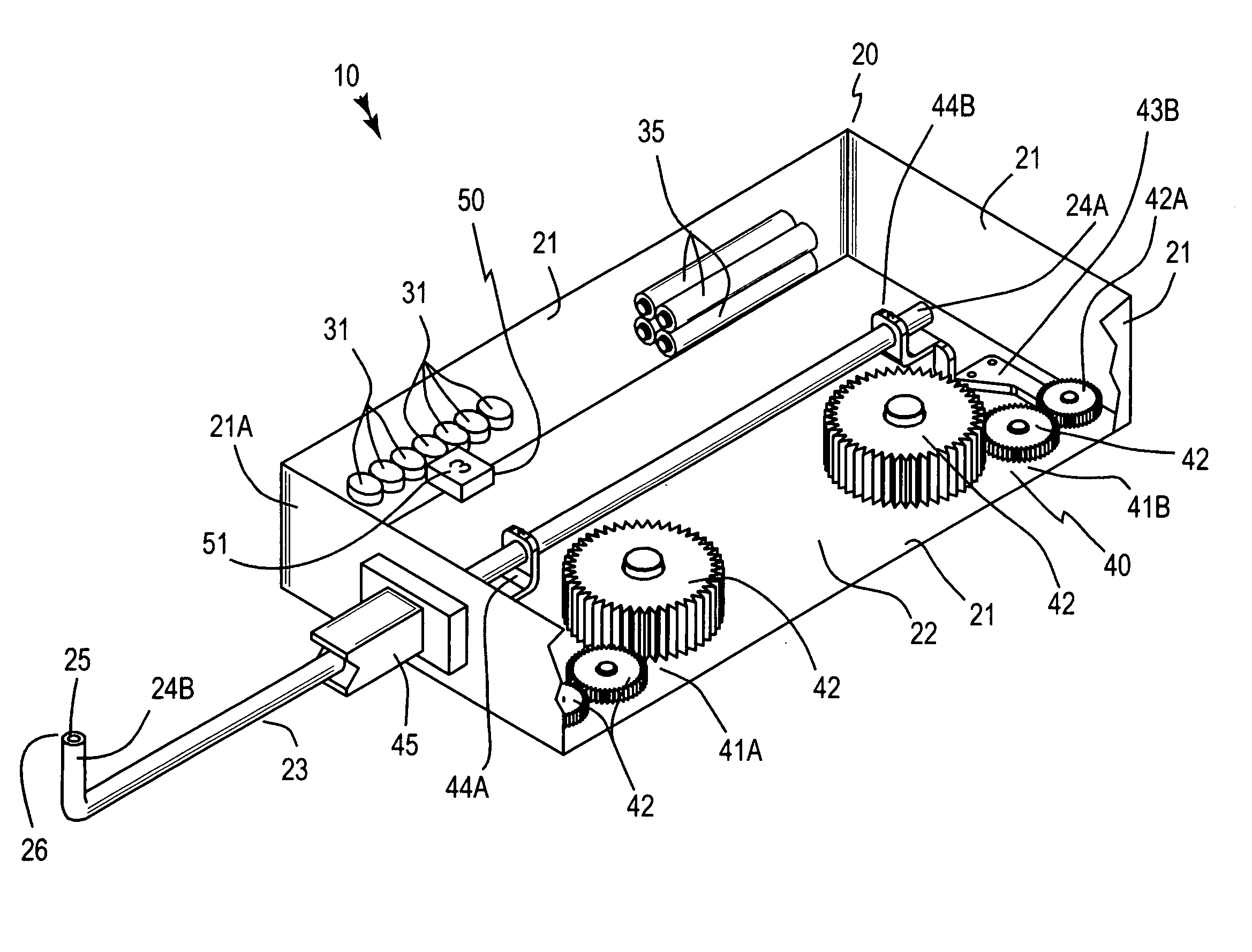

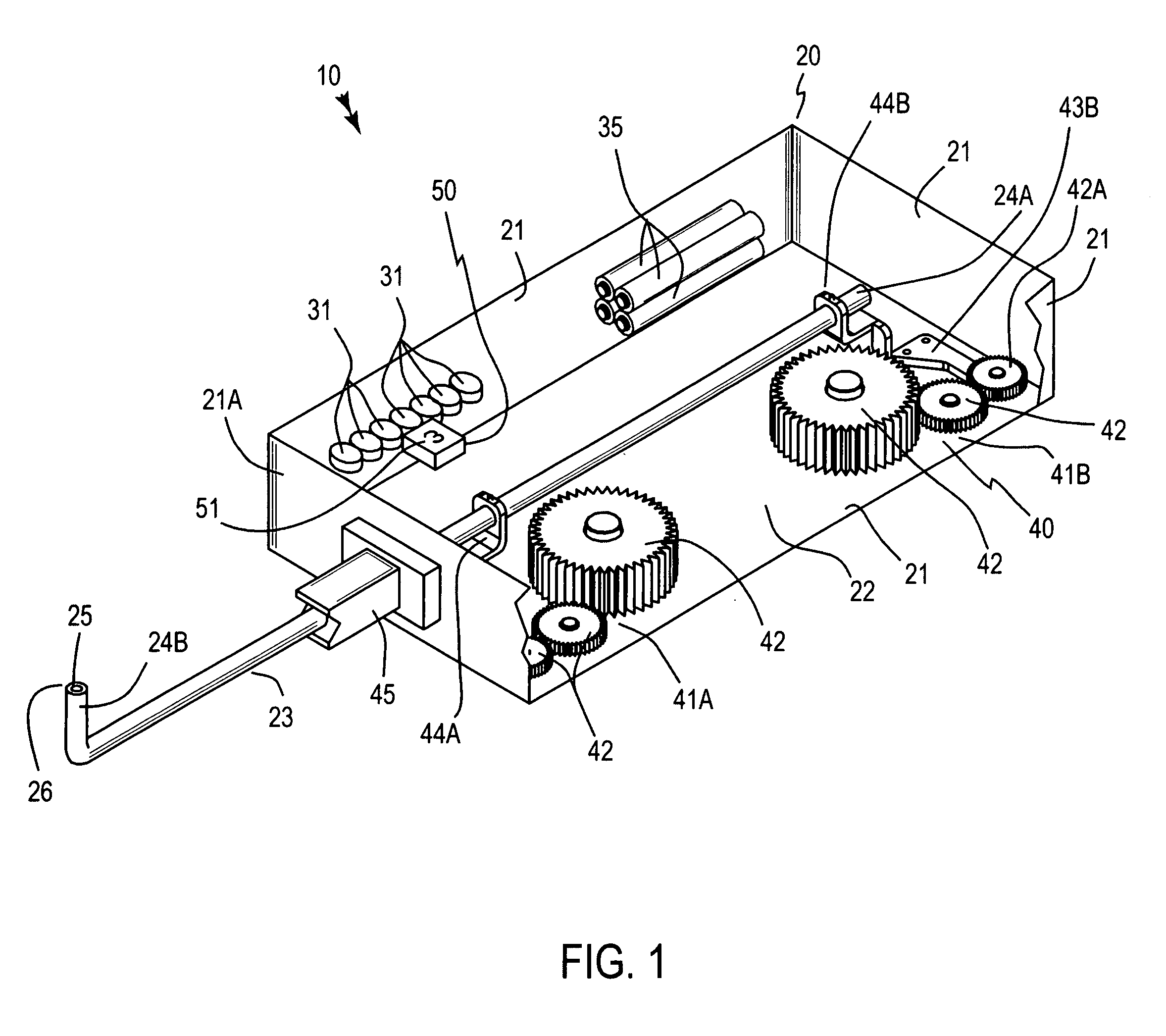

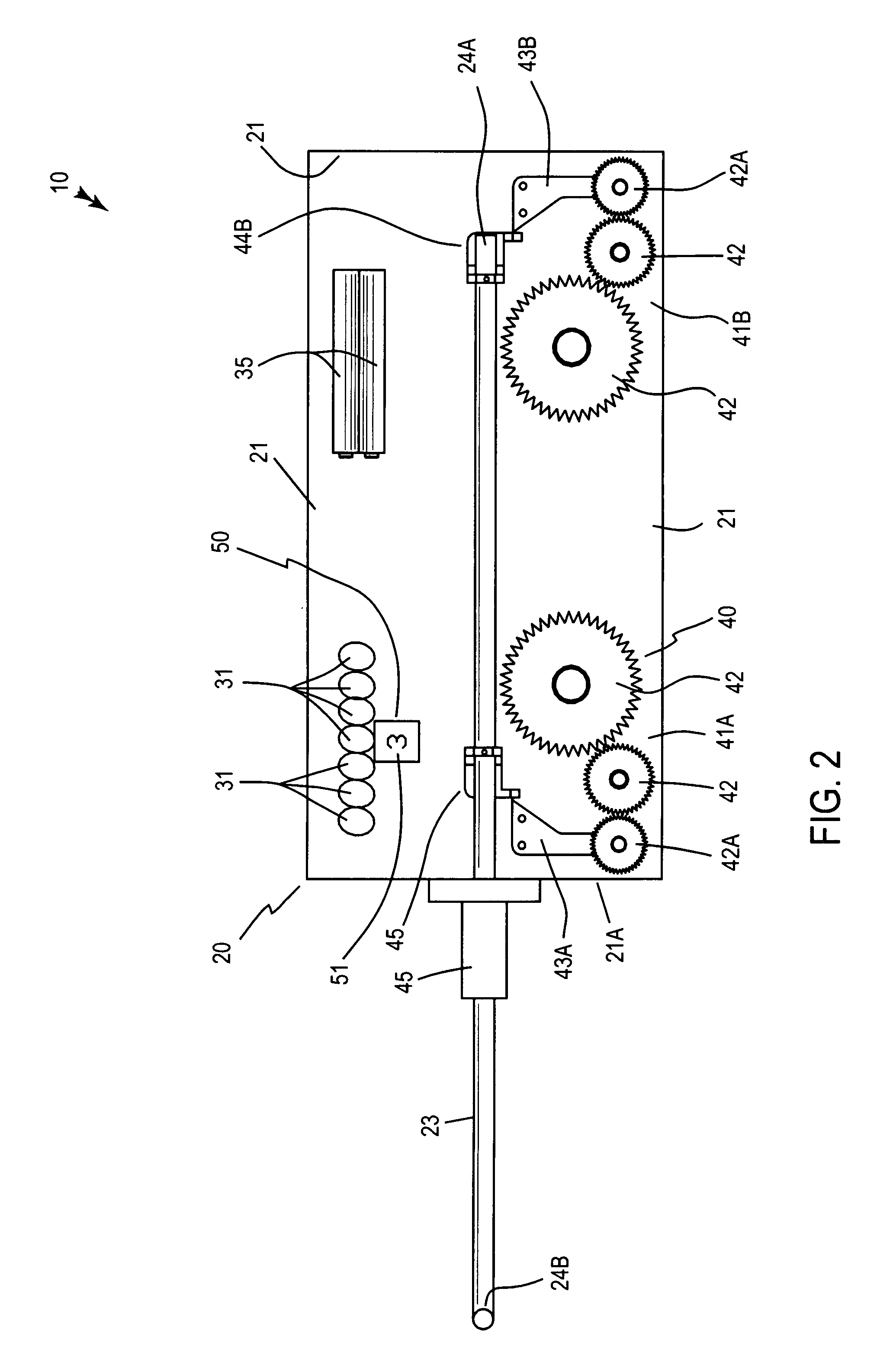

The invention relates to an amorphous alloy strip shear line, comprising monolithic emptying devices which are arranged in sequence, a feeding device and a numerical control (NC) amorphous steel stripshearing machine, wherein, the NC amorphous steel strip shearing machine comprises a programmable logic controller (PLC) and a host shearing machine; the PLC comprises a PLC host and a programming control panel; the PLC host is arranged inside the host shearing machine and the programming control panel is arranged outside the host shearing machine; the emptying device is provided with a pluralityof emptying machines; the feeding device is provided with a vibrator and a charging rack is arranged in the front of the host shearing machine. The shear line can complete emptying, feeding, shearingand laminating of the amorphous alloy strips once, is simple in operation, increases the efficiency and is mainly suitable for producing the amorphous lamination.

Owner:BEIJING ZJLG AMORPHOUS TECH CO LTD +1

Front and rear automatic shear line device of overedger sewing products

InactiveCN101446006AAccuratePrecise positioning in placeNeedle severing devicesSewing-machine control devicesYarnState of art

The invention discloses a front and rear automatic shear line device of overedger sewing products, which consists of a transmission-type synchronous scanning opto-electronic group, a blowing device, an enabling signal sensor, a front cut dust collecting device, a stepping sensor, an electromagnetic or pneumatic shear knife rest (an executing mechanism) and an electrical control box. A full-automatic shear line device which is provided with a front blade and a rear blade of the sewing products that are controlled by photoelectric detection; on the premise of no human intervention, the shear process of freely setting yarn at the front end and the rear end of the sewing products can be completed. As the device is not needed to be stopped for trimming, the sheared thrum is absorbed cleanly at the same time. As the device is not needed to be stopped for trimming, and the sheared thrum is absorbed cleanly at the same time, the working efficiency of the single device is increased by over 30% compared with the prior art; the efficiency and the reliability are high.

Owner:王国秋 +1

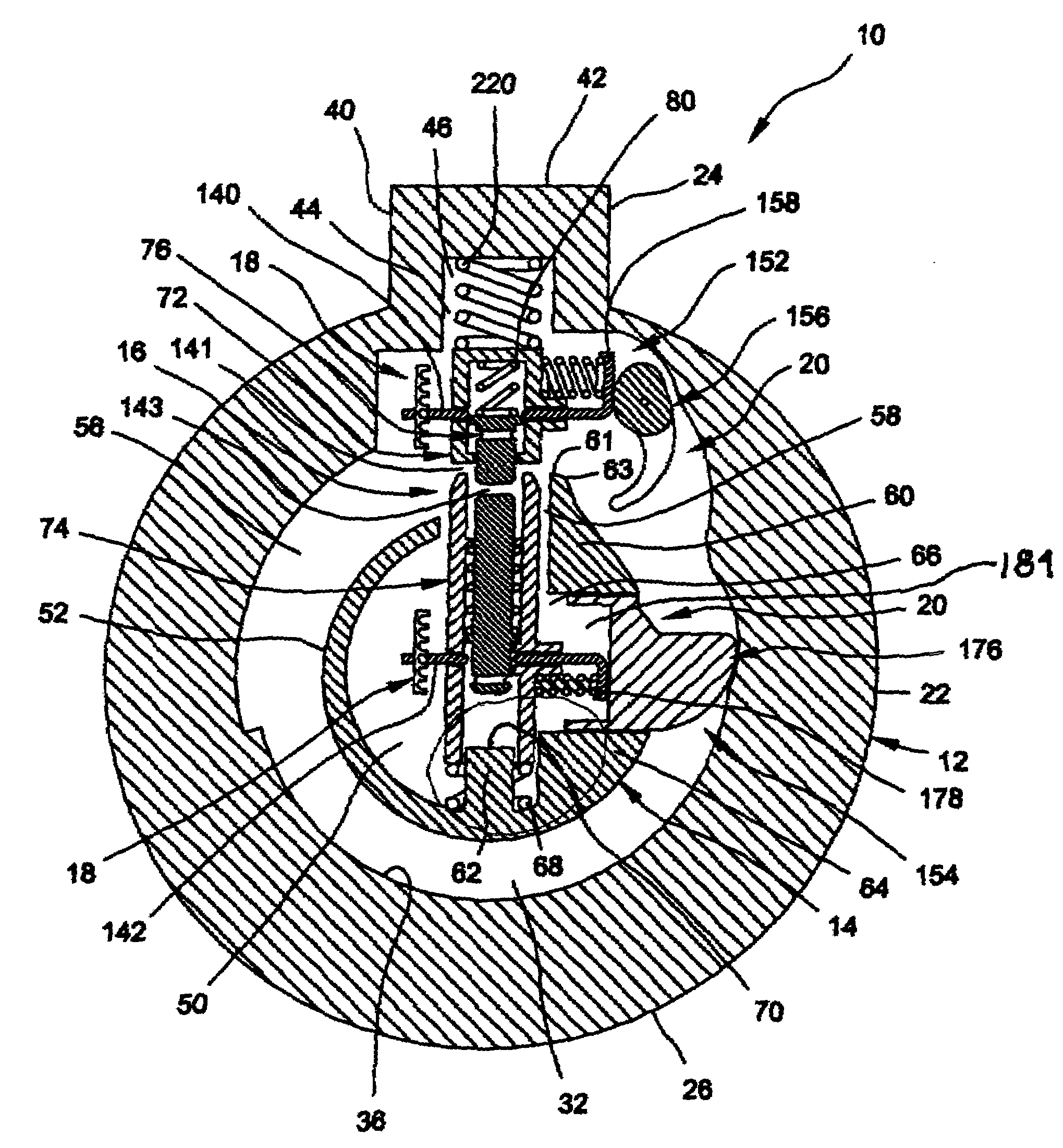

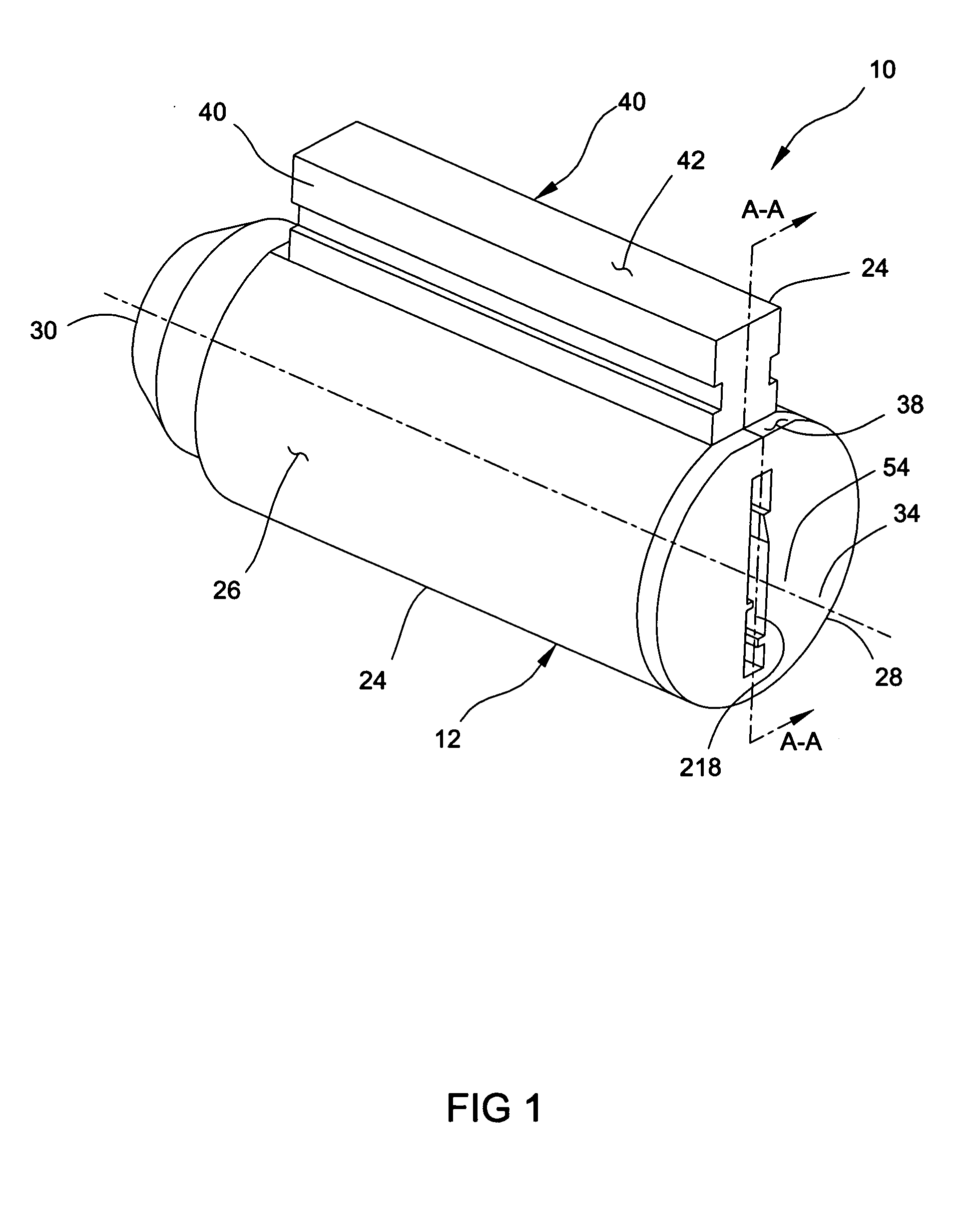

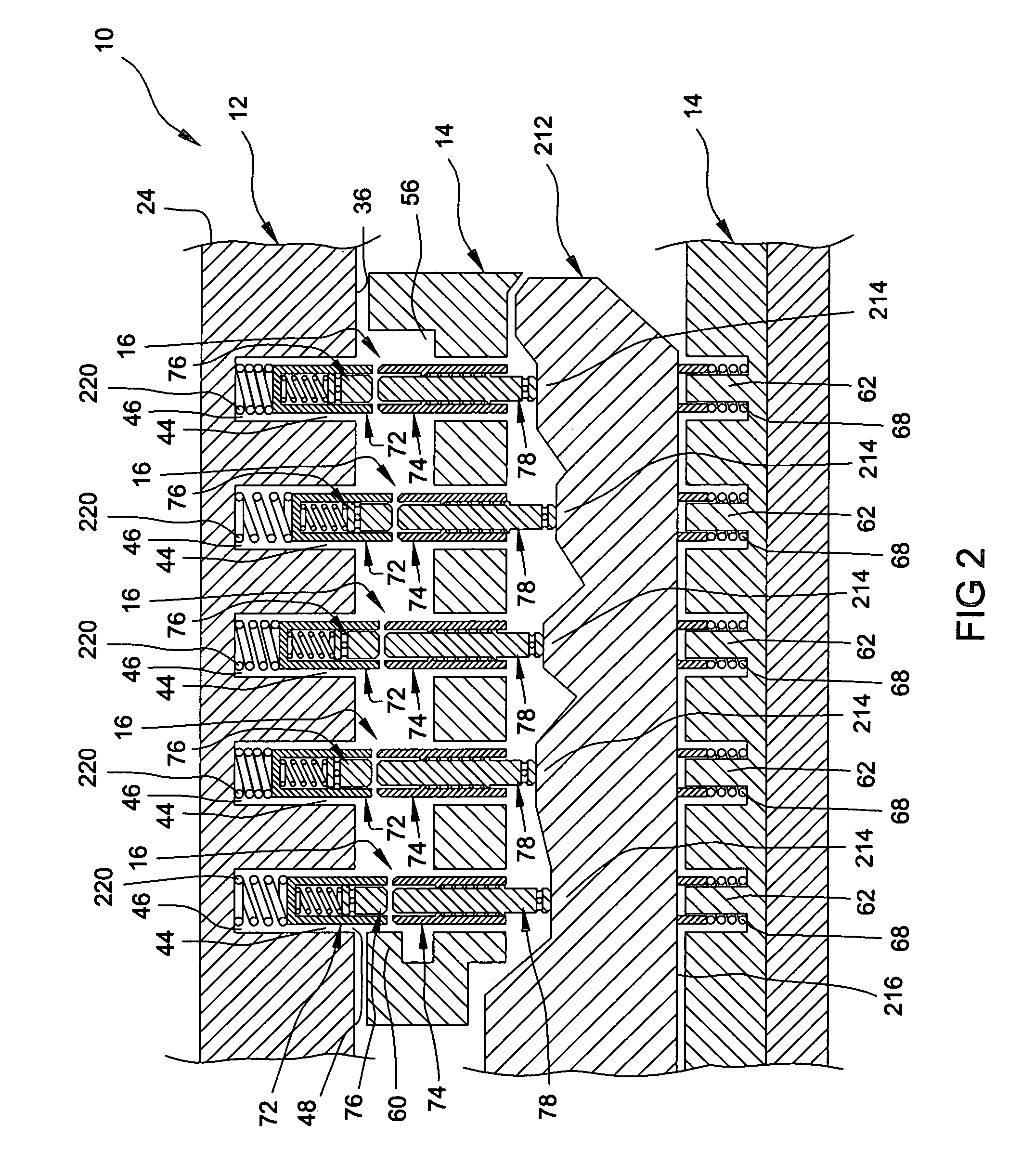

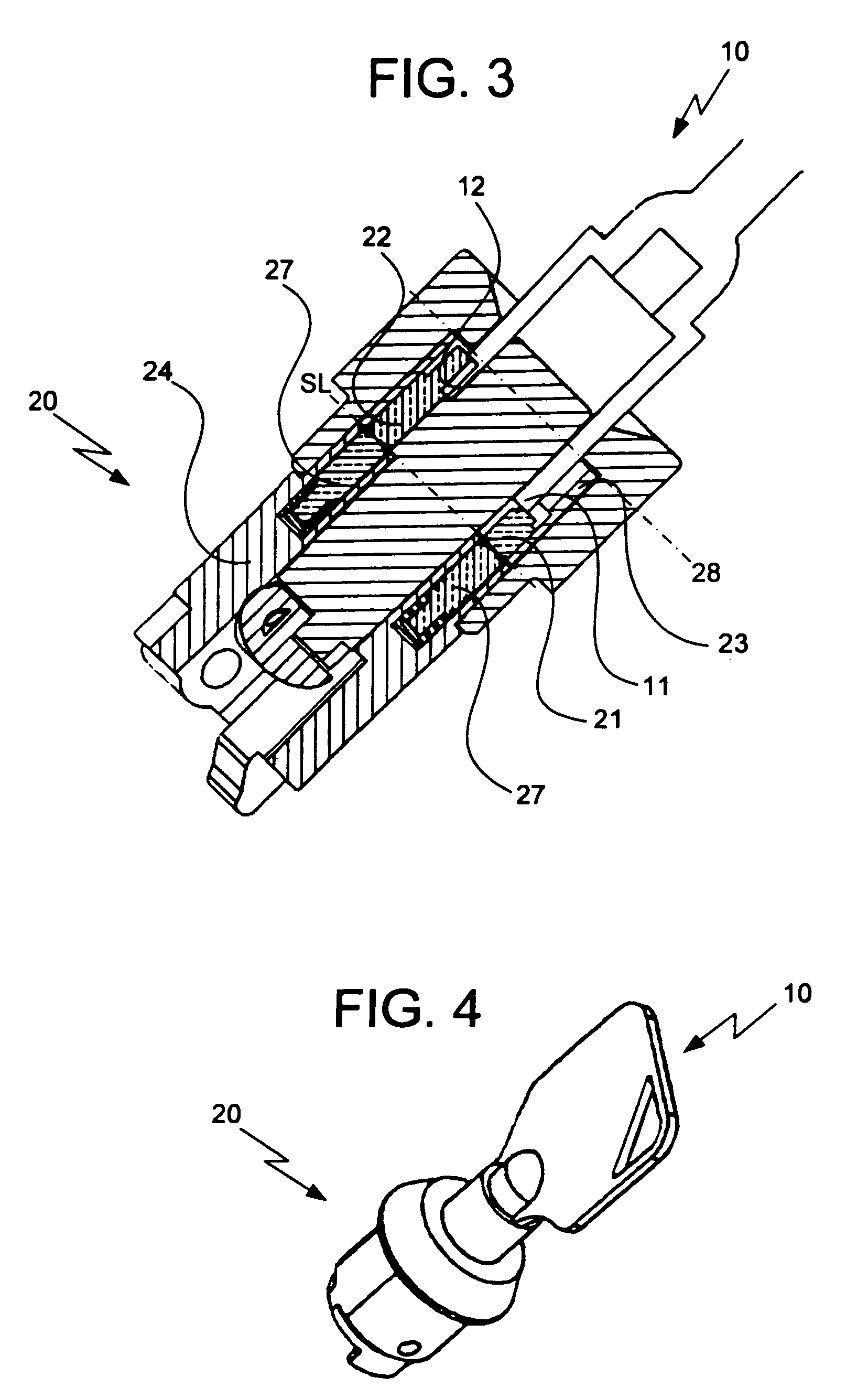

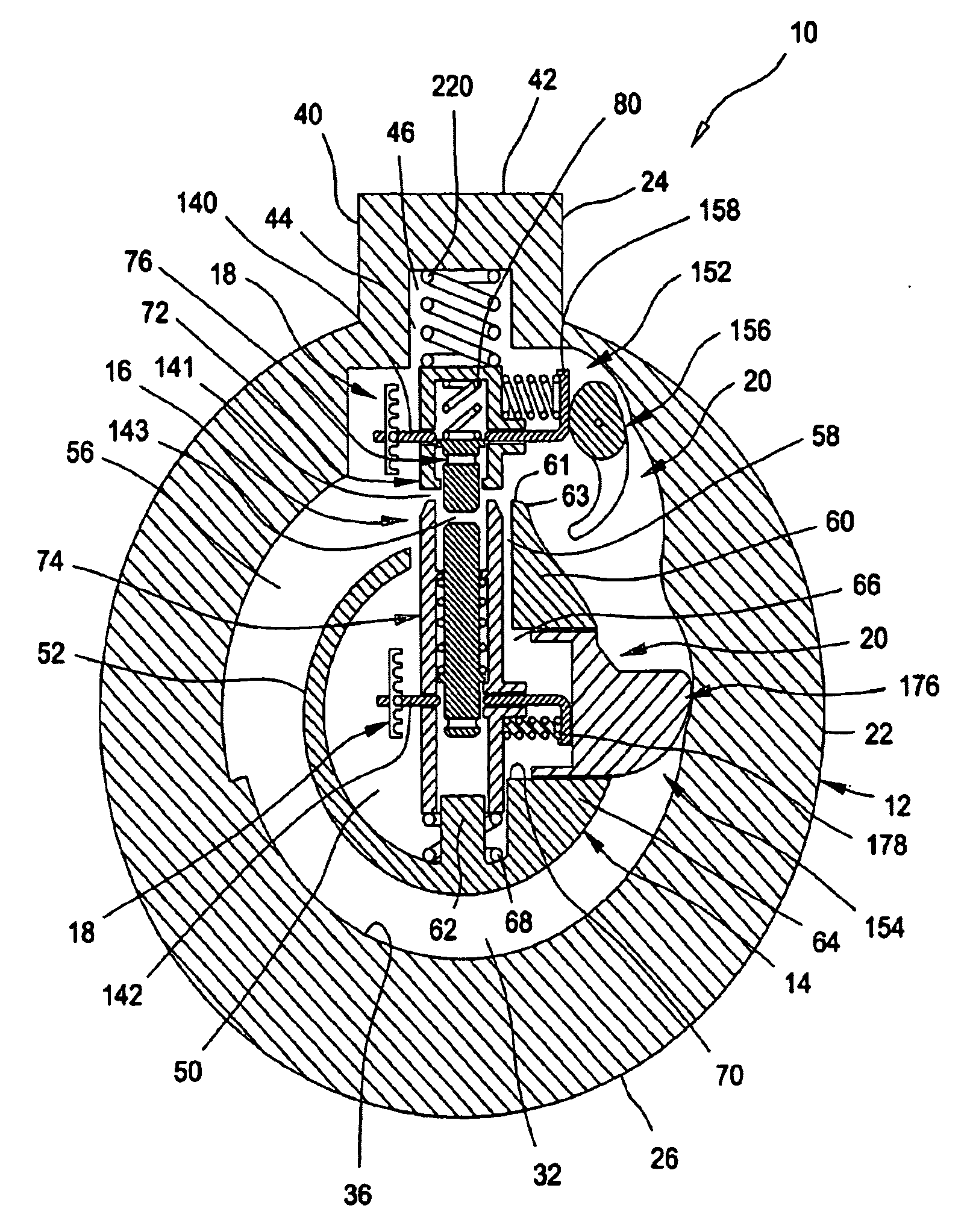

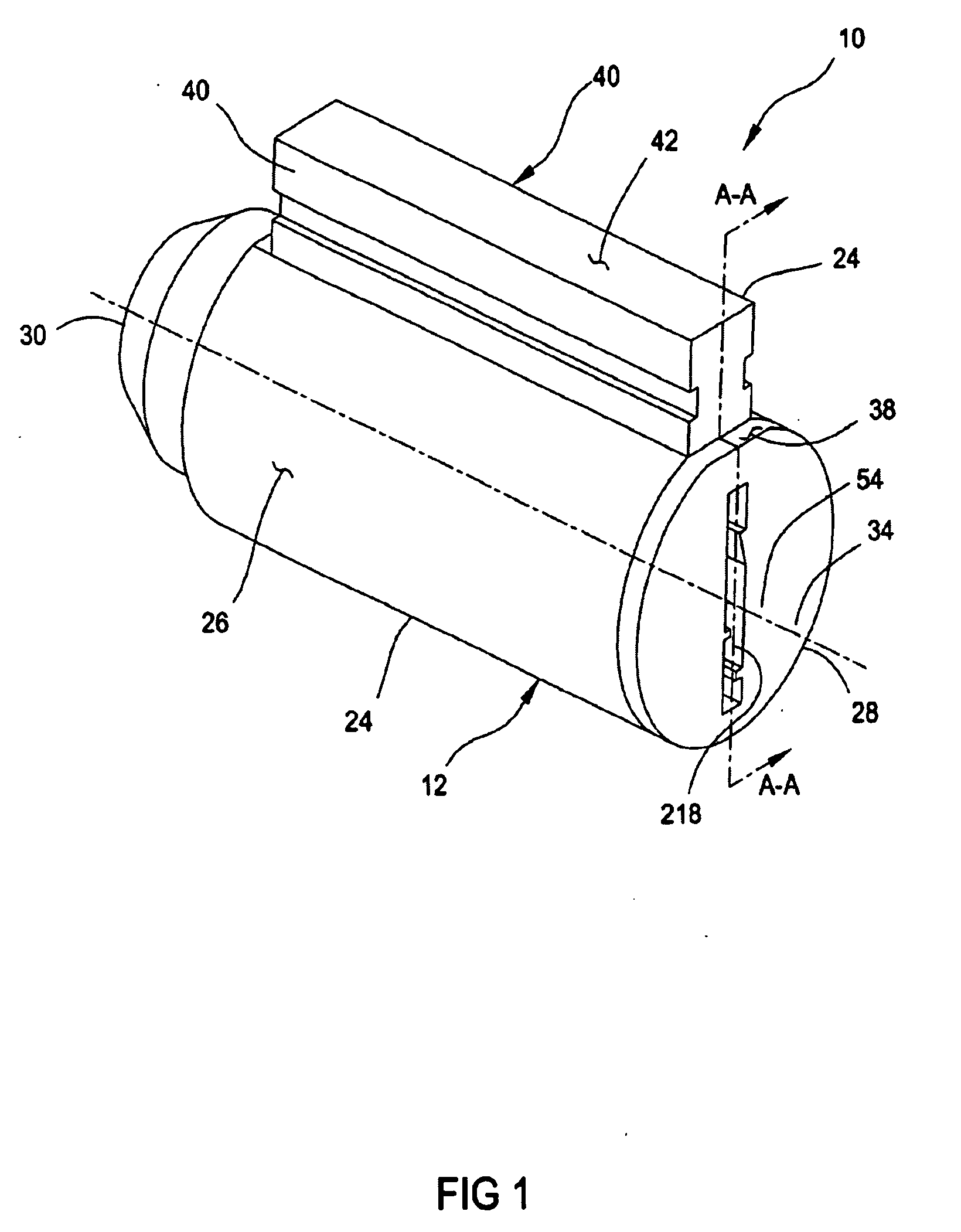

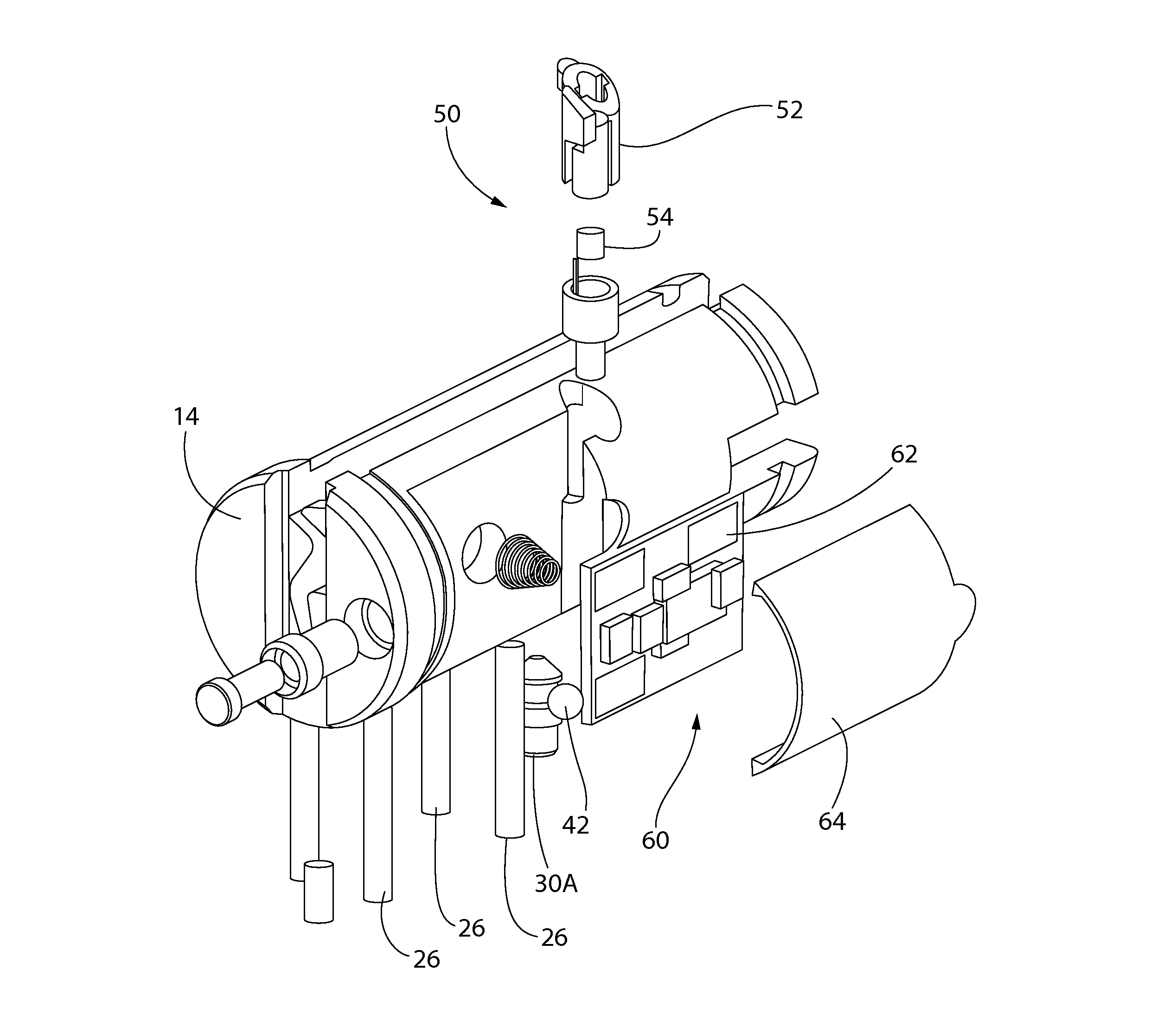

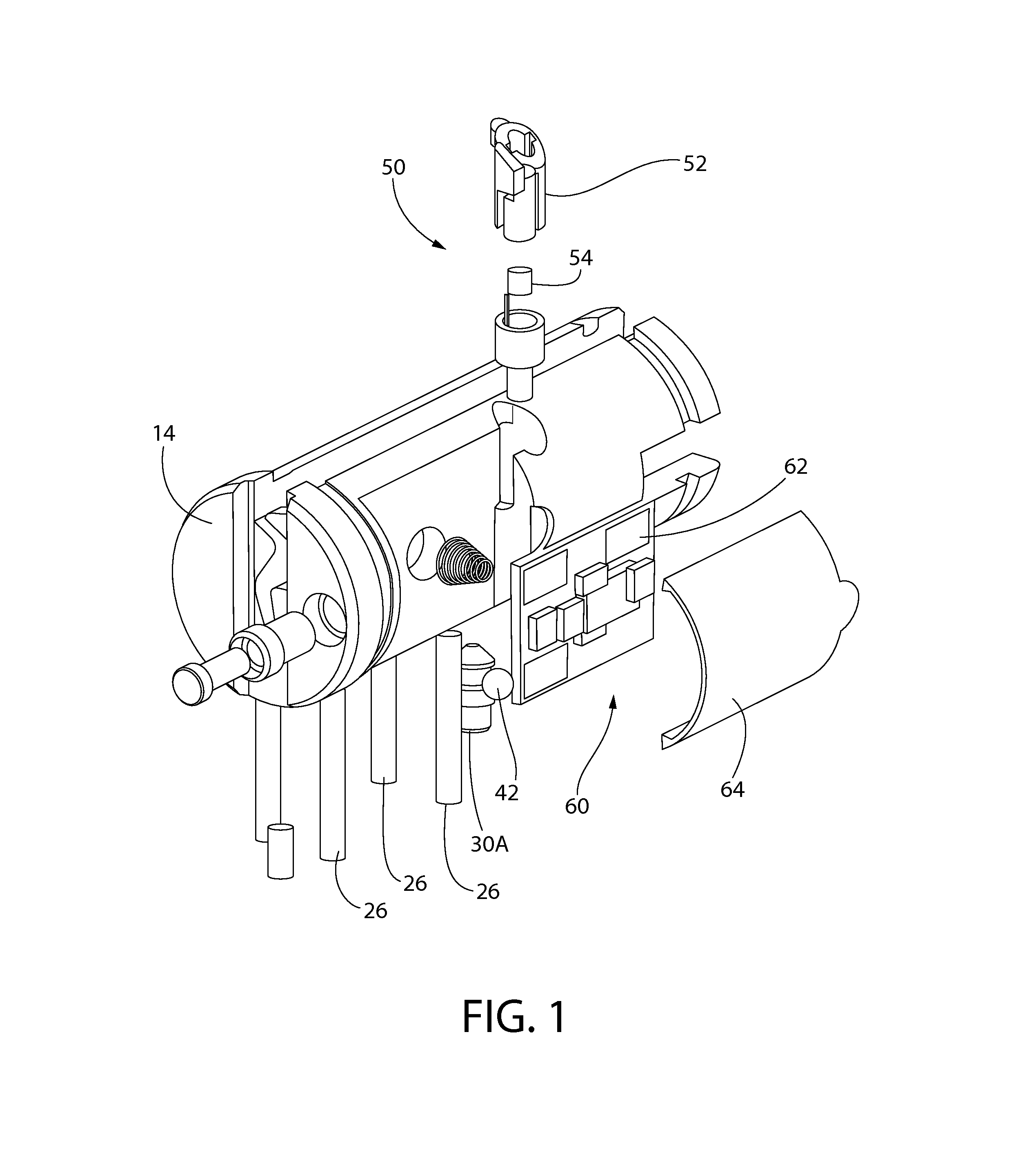

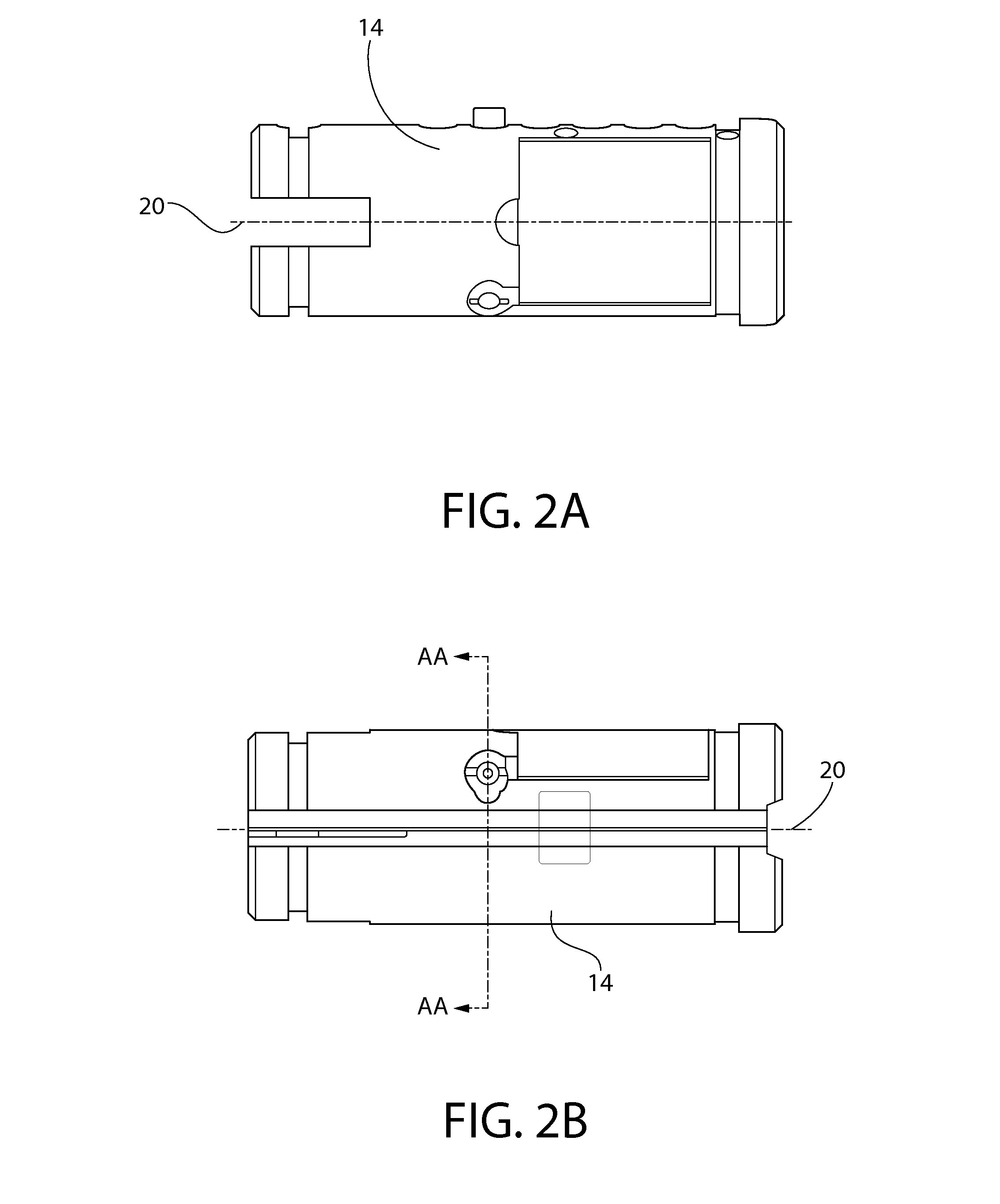

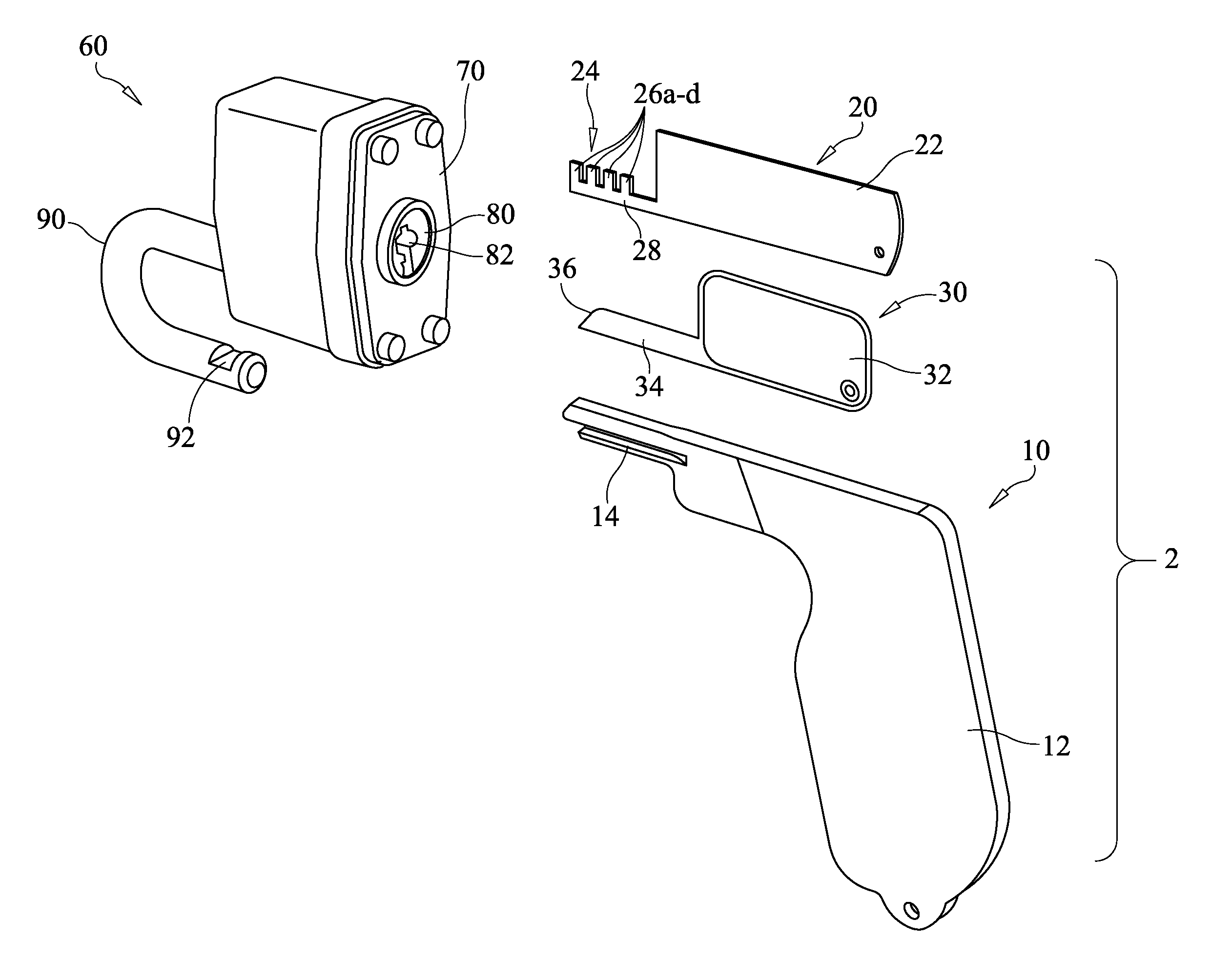

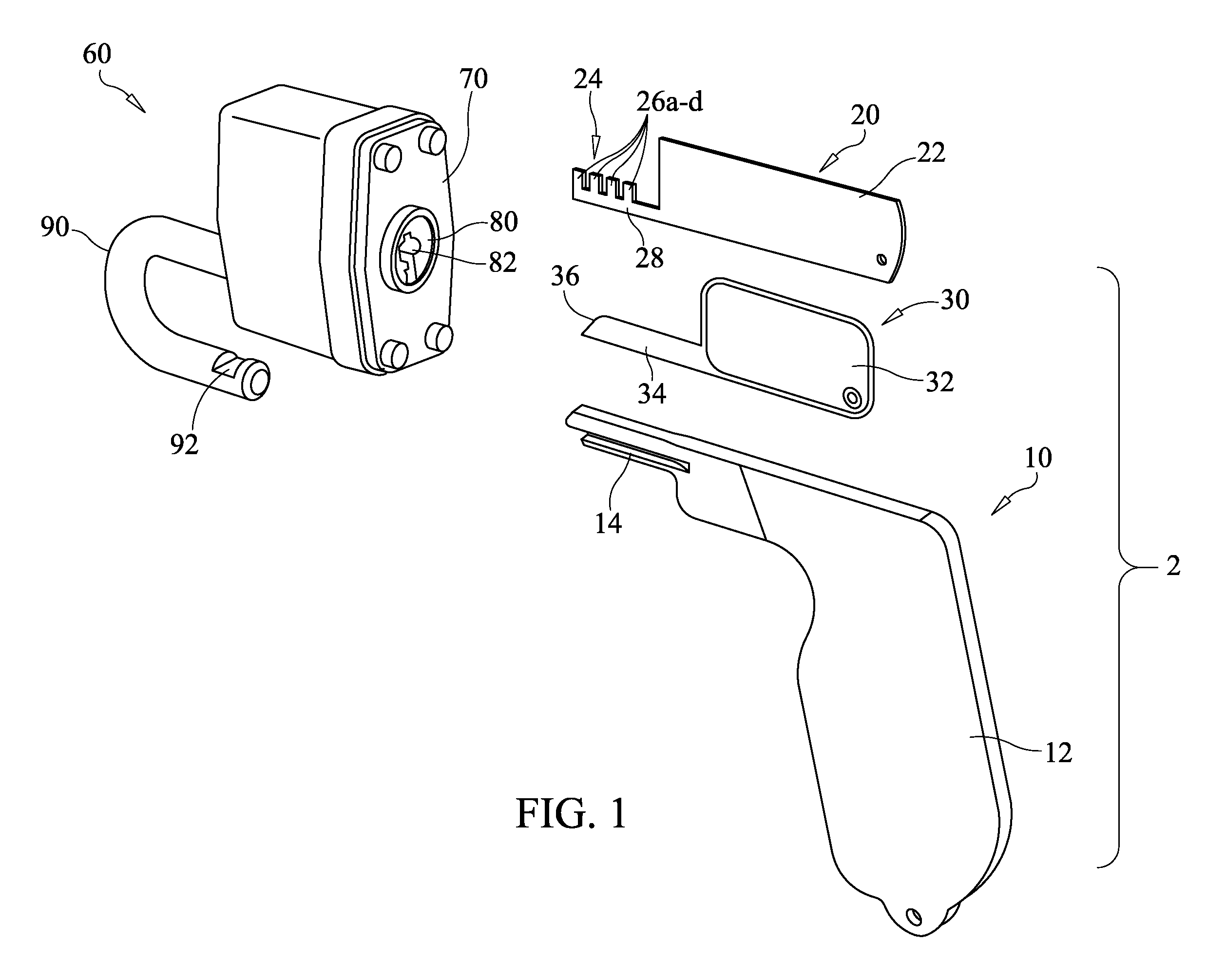

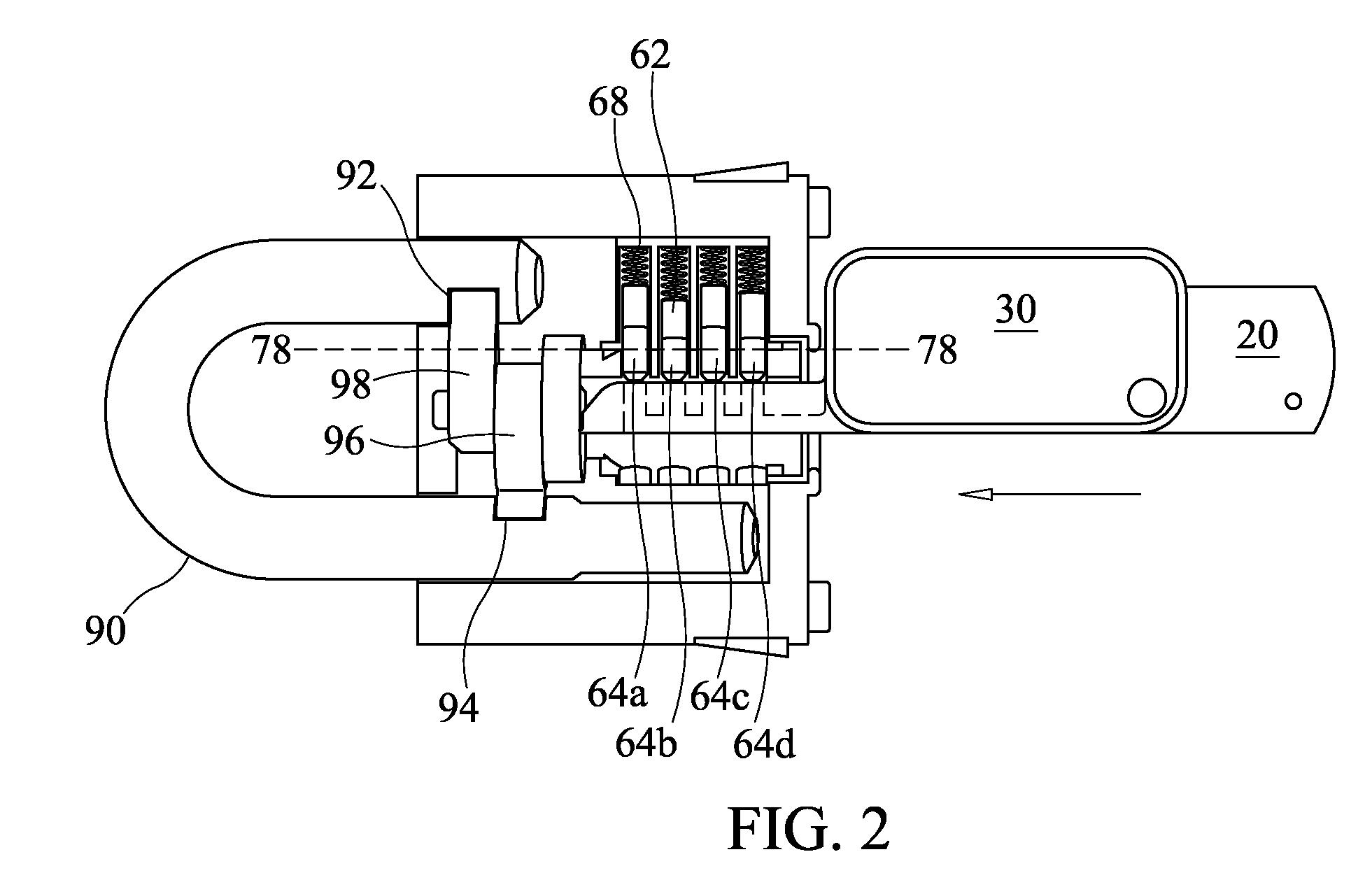

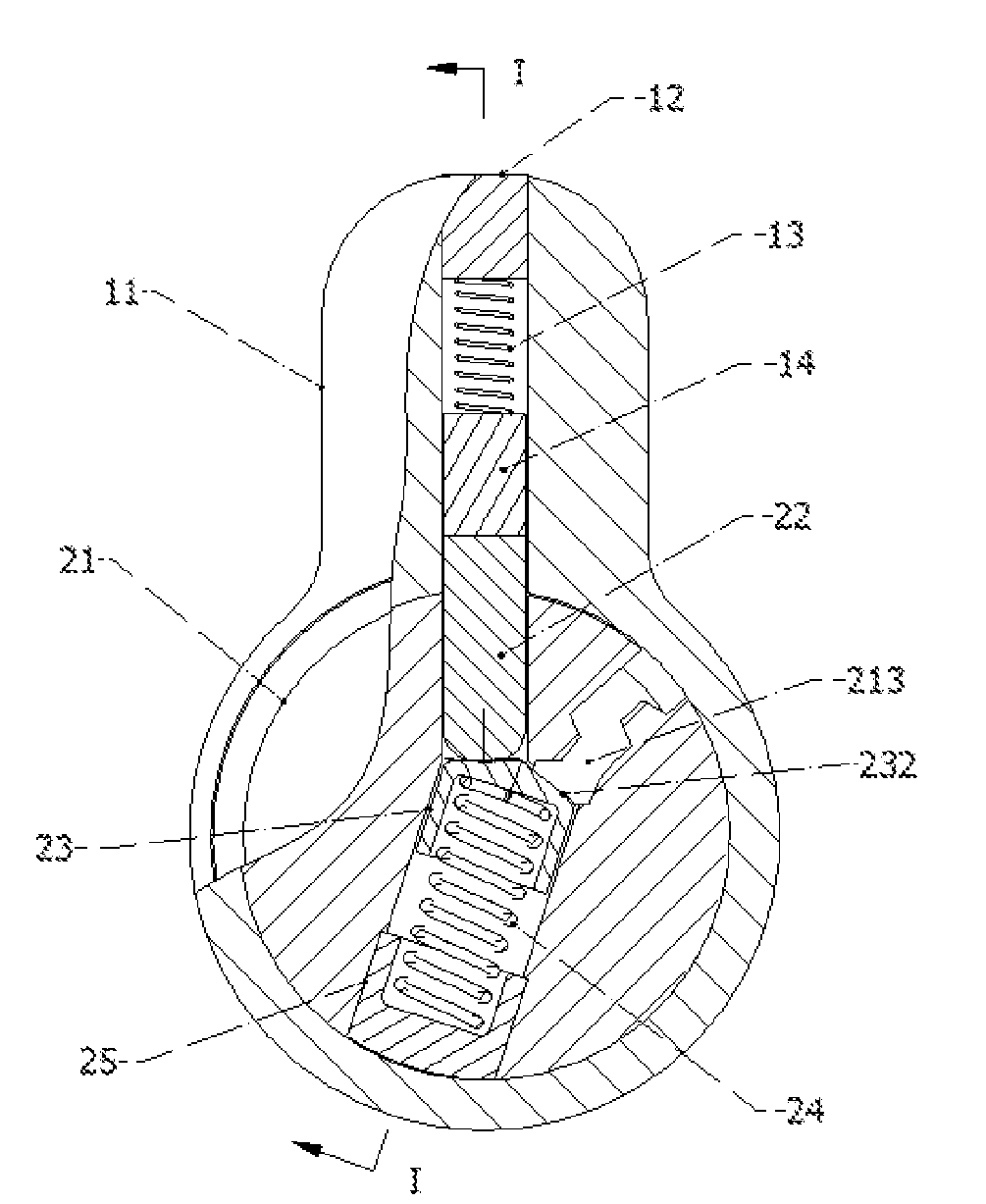

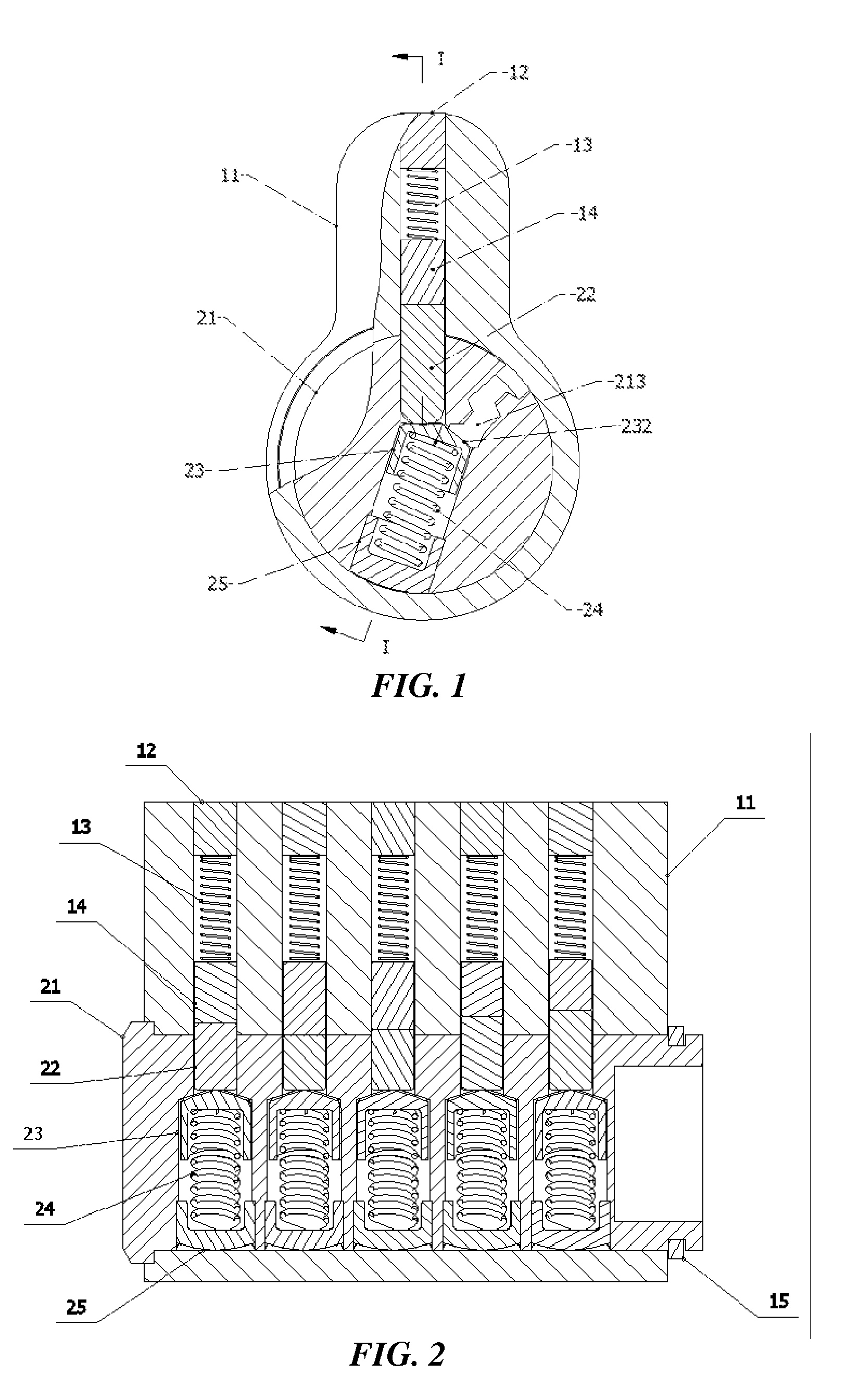

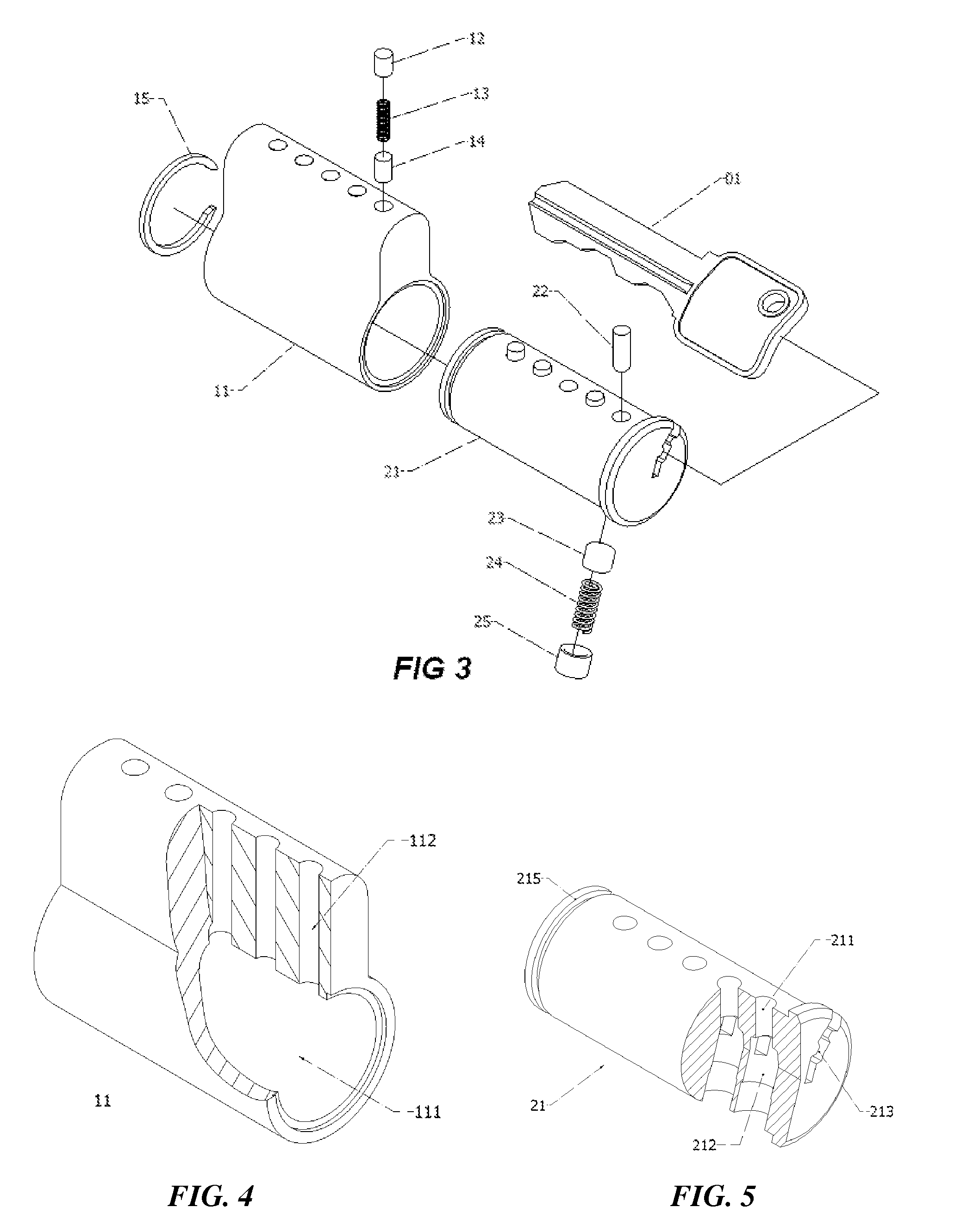

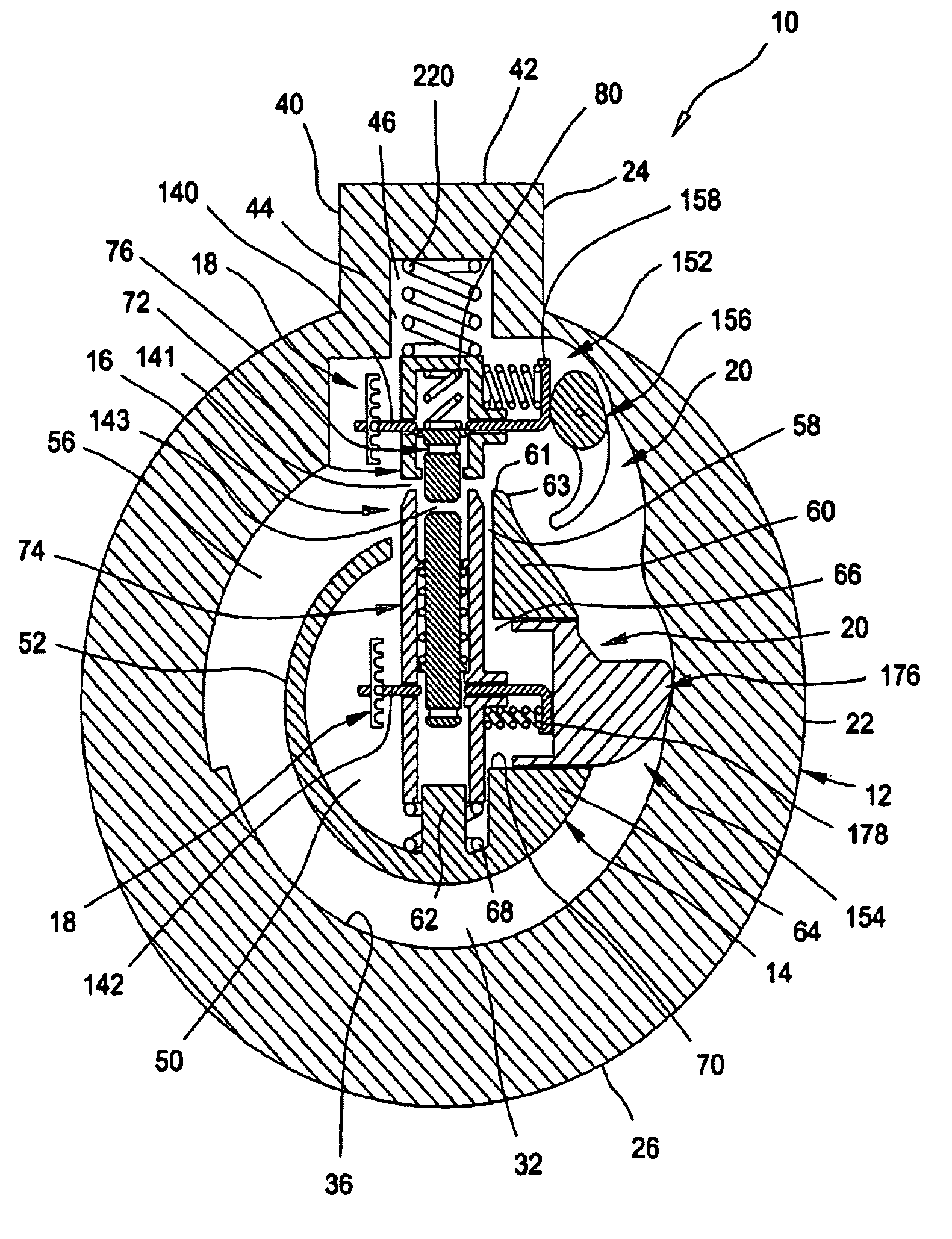

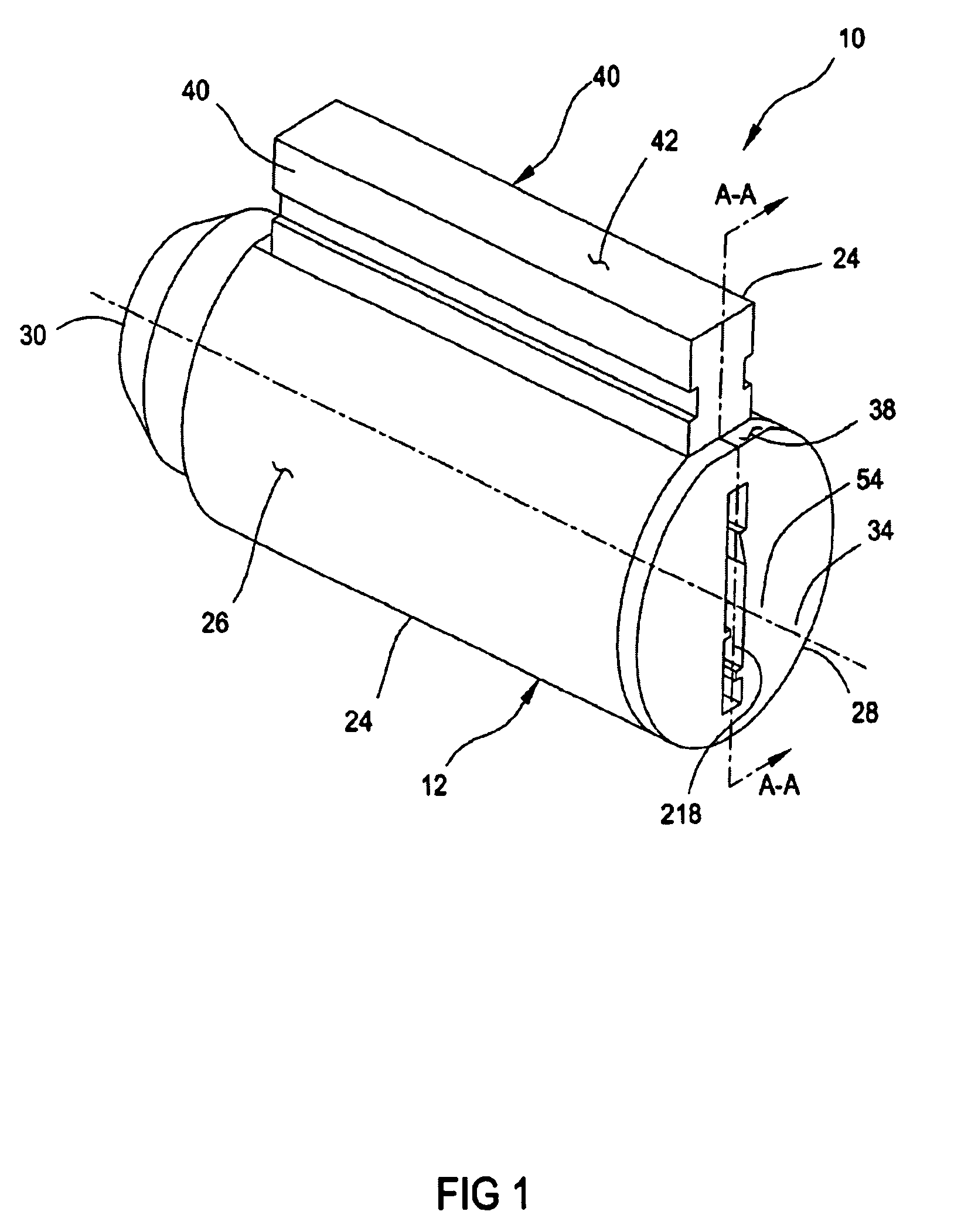

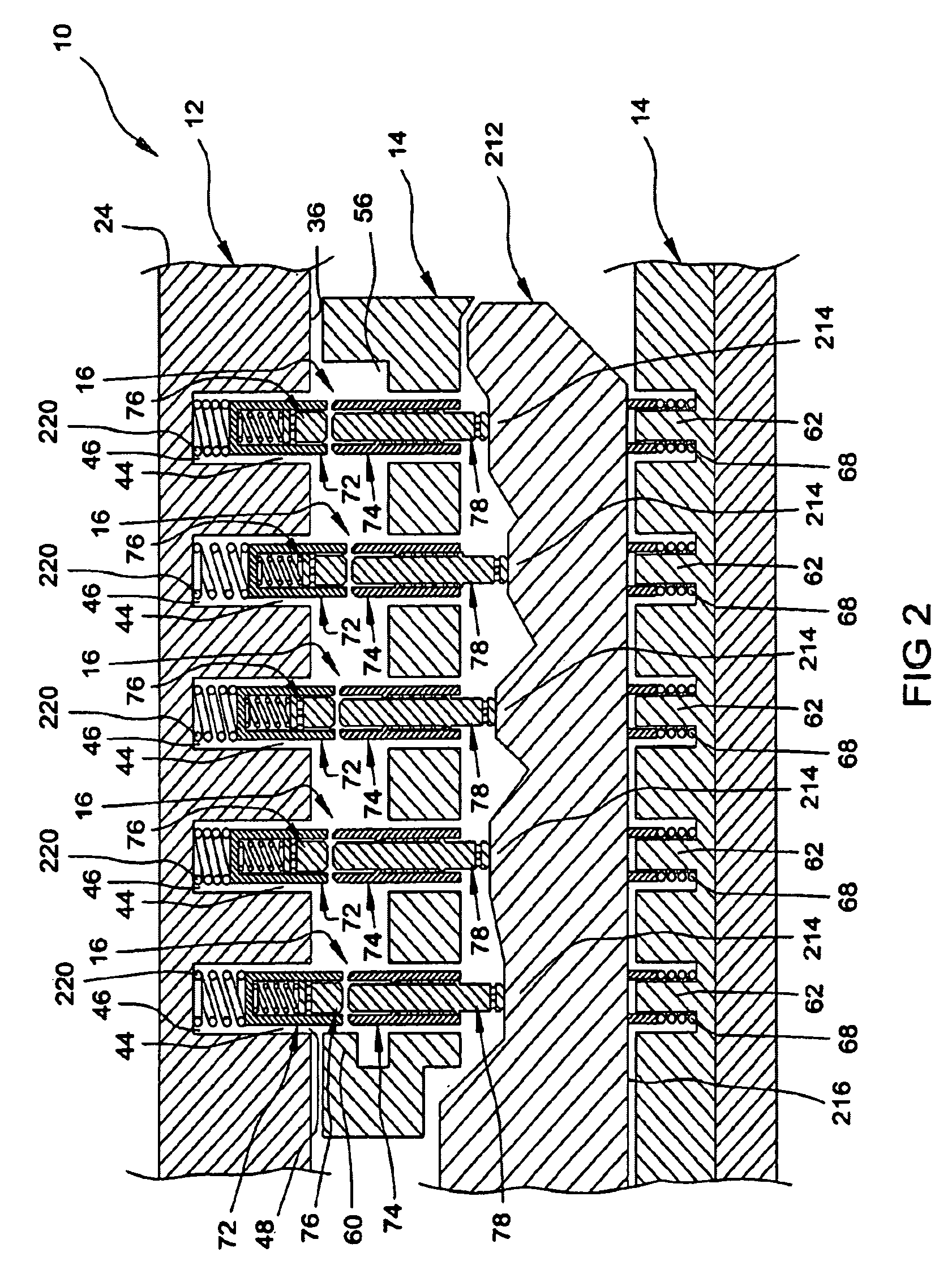

Variable shear line lock cylinder

A lock cylinder is provided and includes an outer cylinder having a bore, an inner cylinder rotatably disposed within the bore, and a pin assembly disposed within the inner and outer cylinders. The pin assembly is operable to selectively lock the inner cylinder relative to the outer cylinder. The pin assembly includes an upper shear cylinder positionable relative to the outer cylinder and a lower shear cylinder positionable relative to the inner cylinder. The upper and lower shear cylinders are movable to define a first shear line therebetween. In addition, the pin assembly includes an upper pin slidable within the upper shear cylinder and a lower pin slidable within the lower shear cylinder, whereby the upper and lower pins define a second shear line therebetween. The lock cylinder is positionable from a locked position to an unlocked position when the first shear line is aligned with the second shear line.

Owner:RAYOVAC CORP

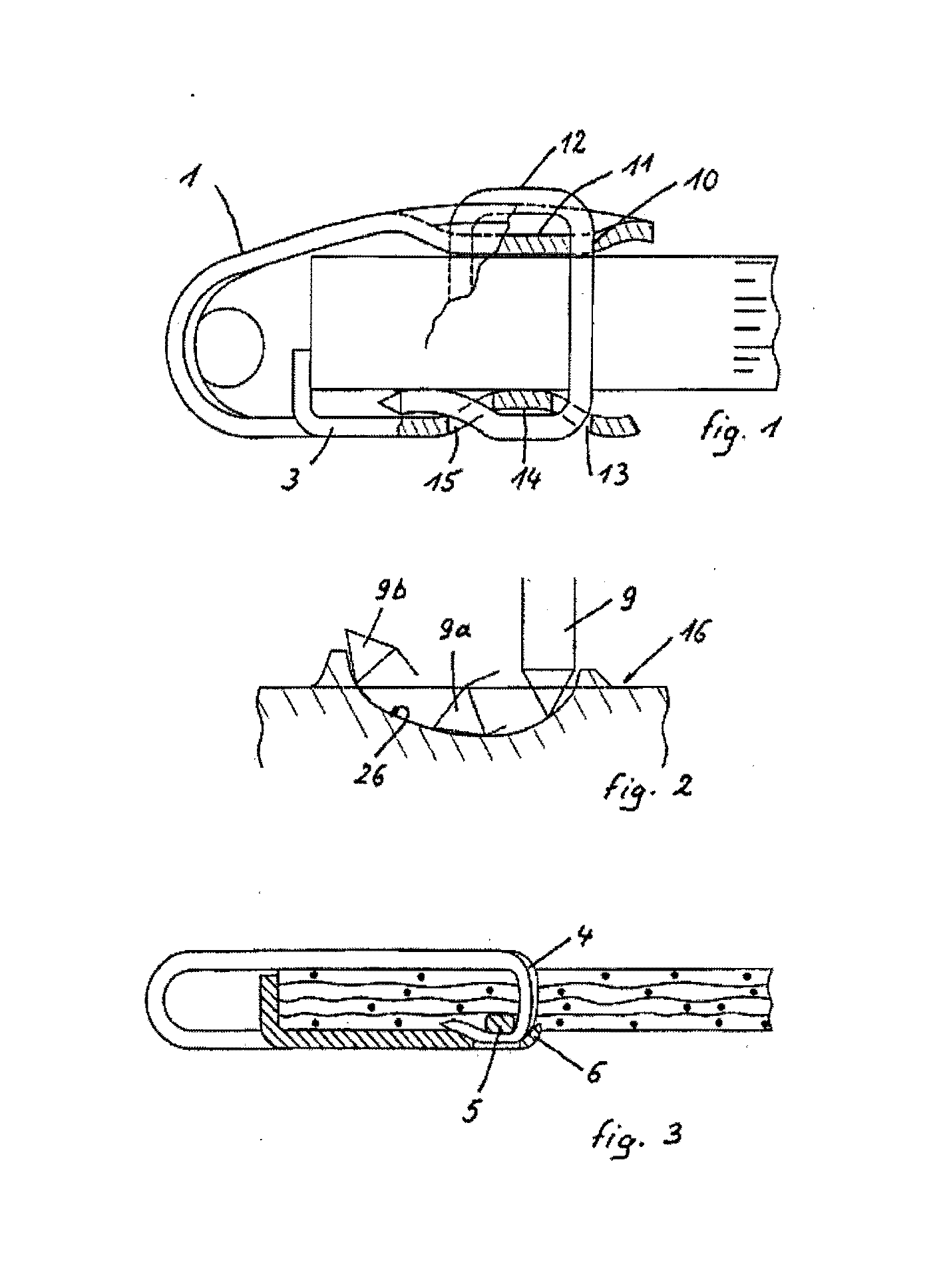

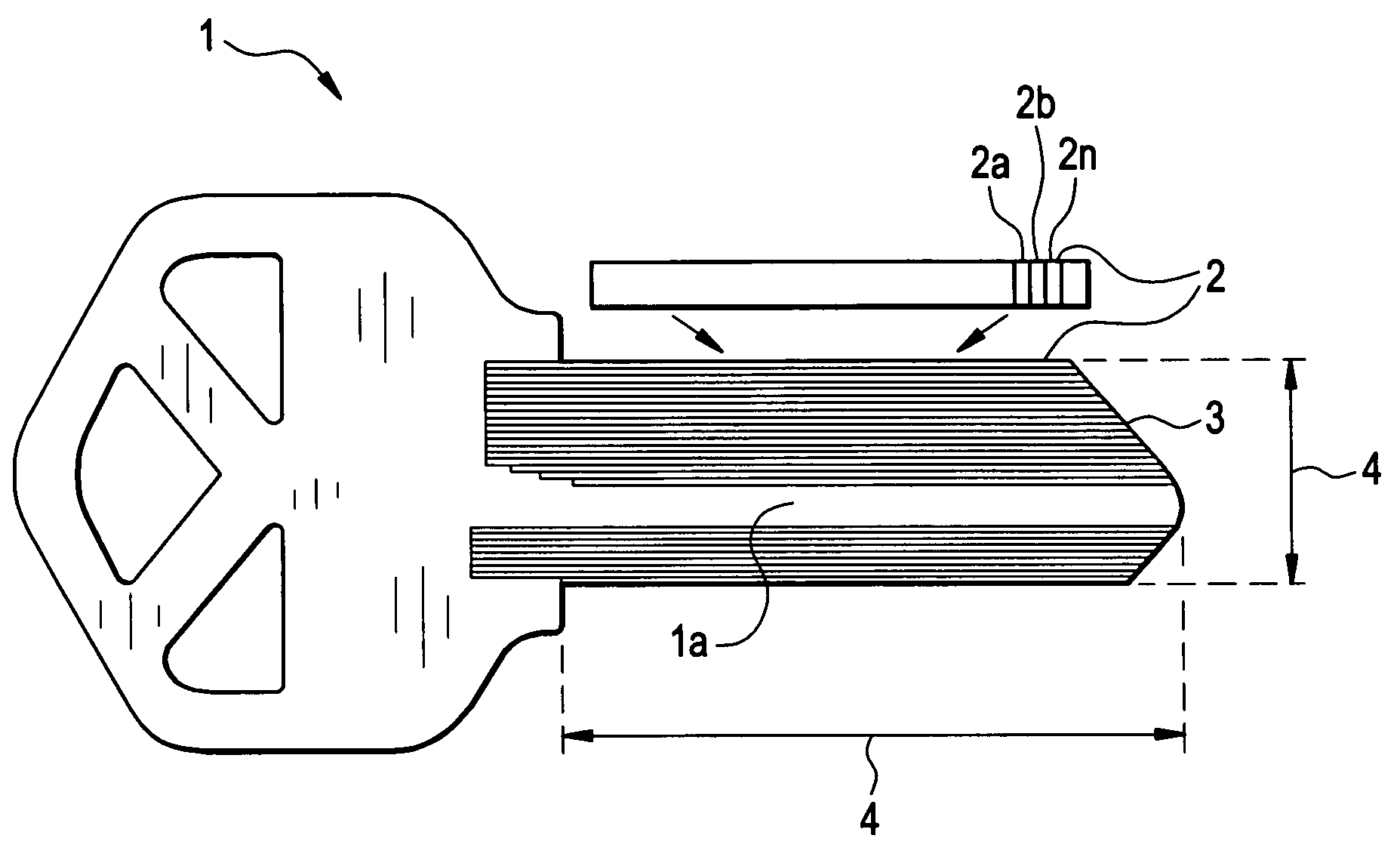

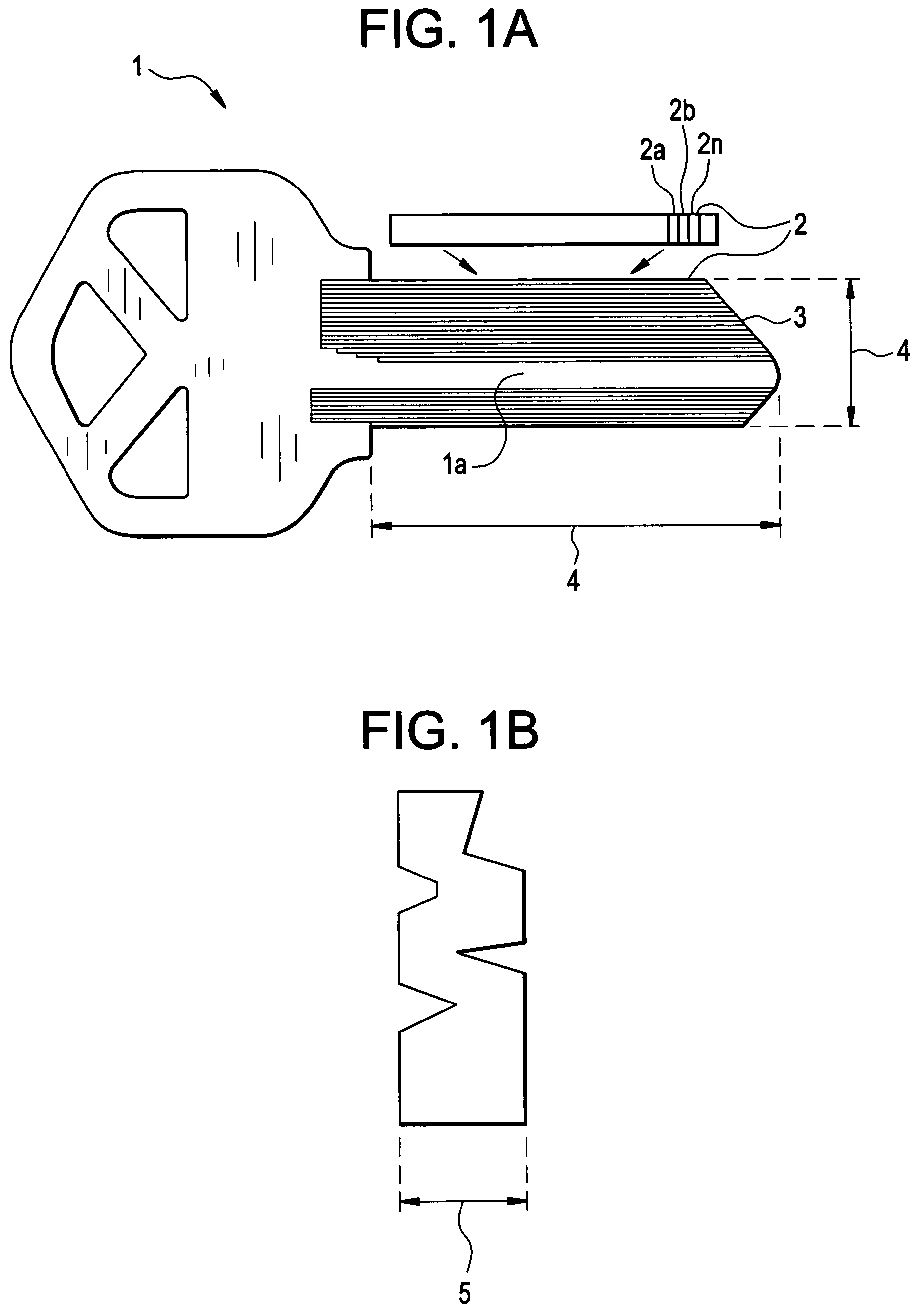

Method and Assembly to Prevent Impact-Driven Lock Manipulation of Cylinder Locks

InactiveUS20090205385A1Avoid manipulationSimple and easily adaptable to all pin tumbler locksCylinder locksLinear displacementShear line

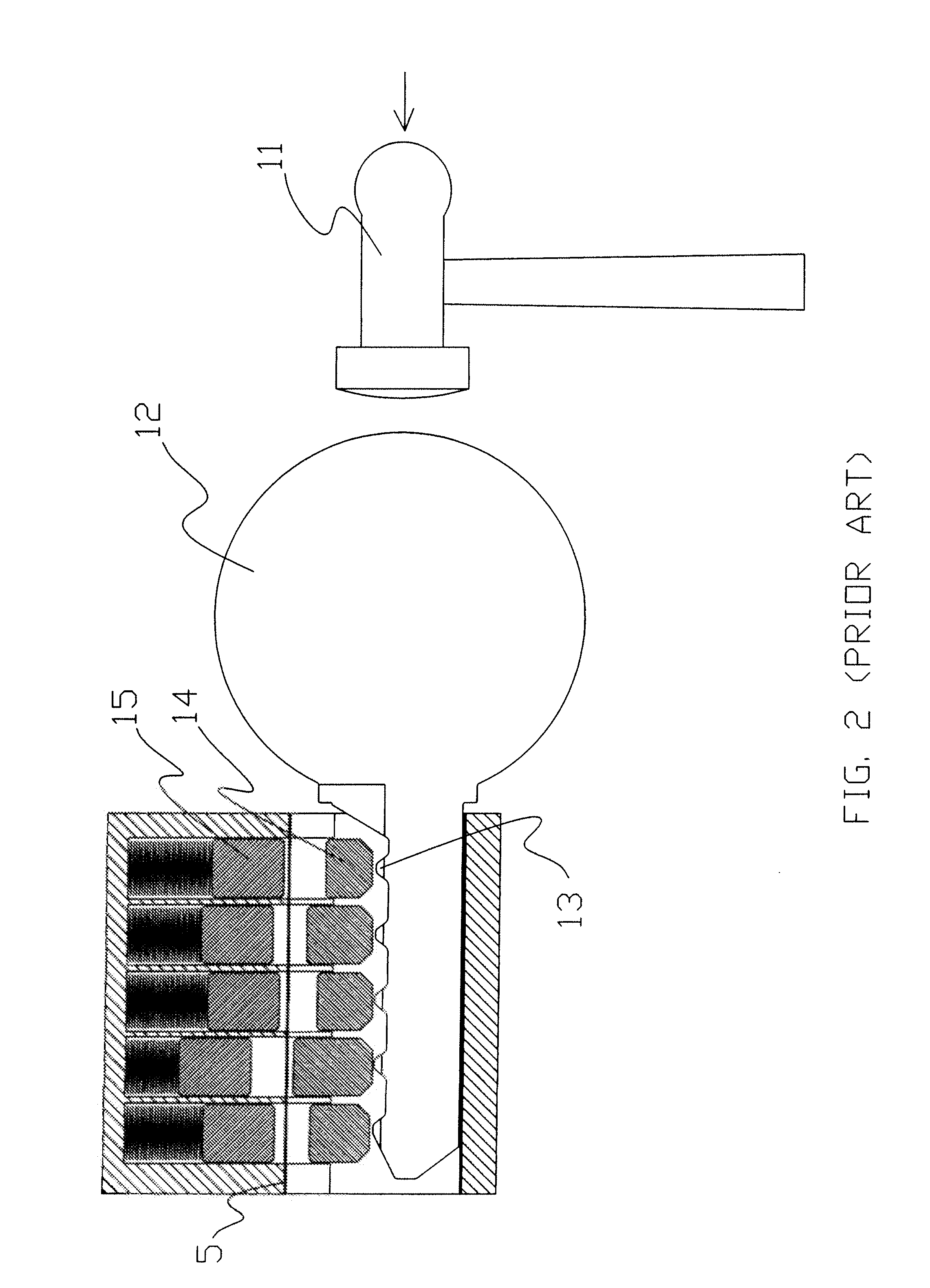

A cylinder lock designed to prevent unauthorized manipulation of the lock using impact-driven methods such as a bump key. The cylinder lock has a plurality of first pin assemblies and at least one second pin assembly, containing a key pin, driver pin, and an elastomer plug, that is adapted so as to alter the linear displacement thereof through the use of the elastomer plug. When an impact-driven blow of a given intensity is applied so as to linearly displace the key and driver pins, the elastomer plug effectively absorbs the energy of the impact and fails to compress sufficiently to allow the key pin to clear the shear line, thus preventing the unauthorized manipulation of the lock.

Owner:COZZOLINO JOHN P

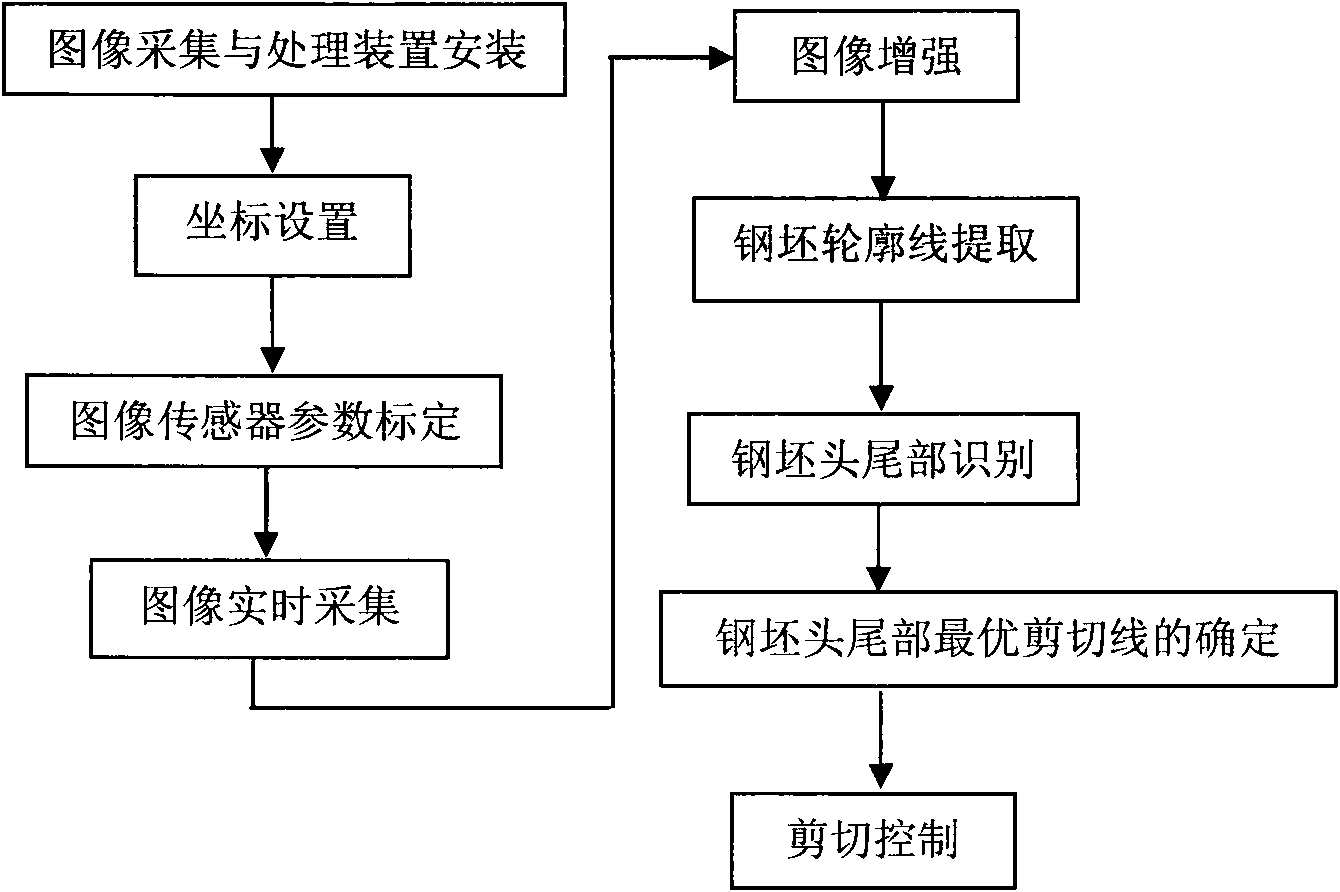

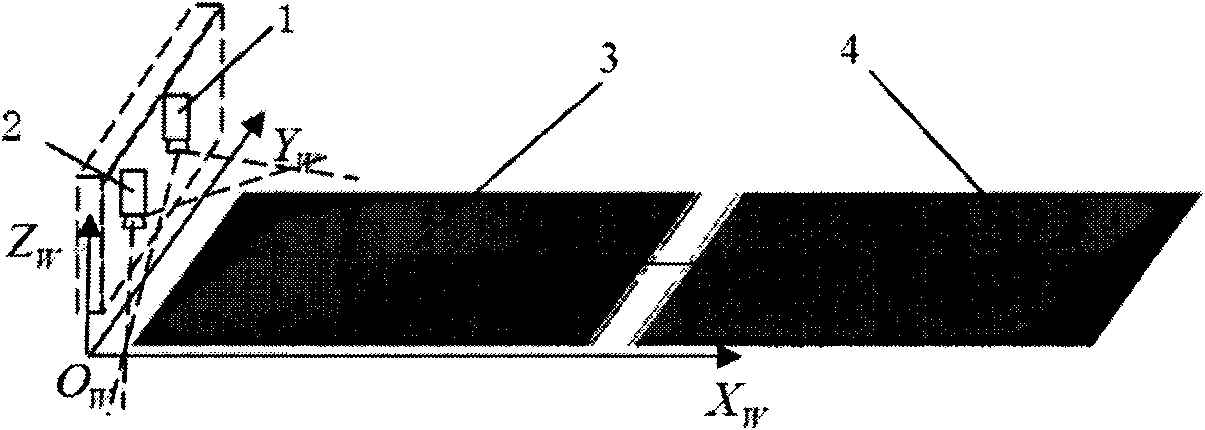

Billet shearing device based on image sensing and shearing method thereof

The invention provides a billet shearing device based on image sensing and a shearing method thereof. The method comprises the following steps: setting a coordinate system by two CCD image sensors, animage processing module, an image identification module and a drive module; performing image acquisition in real time; extracting a billet contour line, identifying a head part and a tail part of thebillet; determining an optimum shearing lines at the head part and the tail part of the billet, obtaining the distance between the endpoint of the billet head part to be sheared and a shearing edge of a shearing machine, and controlling the shearing time of the shearing machine. In the invention, by adopting image acquisition, image processing and identification calculation in the above steps, the optimum shearing lines at the head part and at the tail part of the billet can be finally identified; and operation of a servo mechanism of the shearing machine can be accurately controlled according to the coordinate information of the optimum shearing lines, thus obtaining the best energy and material conservation effect for shearing the billet on a hot rolling production line.

Owner:SHANGHAI JIAO TONG UNIV

Shaped top pin for bump resistant cylinder

ActiveUS20080202180A1Improve impact resistanceEasy to implementCylinder locksShear lineEmbedded system

The present invention provides a pin and tumbler cylinder lock and a retrofitted cylinder lock which minimizes unauthorized openings of the lock by bumping. The cylinder lock utilizes specially designed driver pins which are correlated in size to the largest possible stack height of the tumbler pins with a bump key inserted in the plug portion of the lock and the shear line height of the lock. All the driver pins are about the same height and preferably symmetrical with a lip on each end. The invention also provides a method for retrofitting existing locks by removing at least one of the driver pins and replacing the removed driver pin or pins with the driver pins of the invention.

Owner:SARGENT MANUFACTURING CO INC

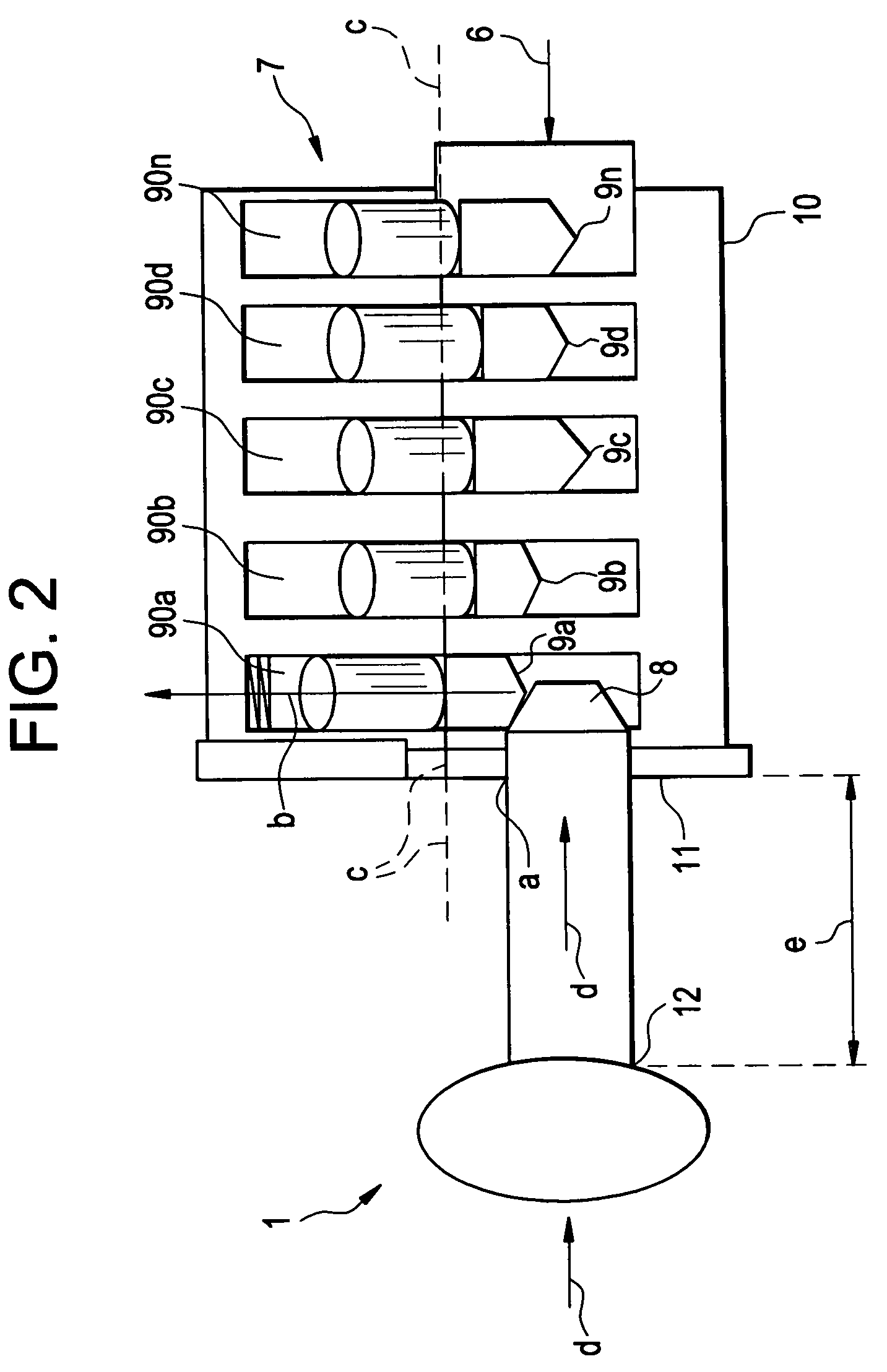

Decoding device for double-sided keys

InactiveUS7243437B1Quick fixConveniently assisting the userMechanical counters/curvatures measurementsKeysShear lineArcuate shape

An electronic device includes a housing and a catheter having a proximal end seated within the housing and a distal end positioned to an exterior thereof. The catheter distal end has an arcuate shape, assisting the user to scan an internal plug cavity, and a cylindrical cross-section provided with a suitable diameter such that the catheter can be probed through a lock plug without contacting pin pairs. A mechanism is included for detecting a point where the pins come together and line up with a shear line. LEDs are coupled to the detecting mechanism and are illuminated when the catheter is displaced along the lower and upper pin pairs. A mechanism is included for automatically adjusting the catheter's position as the point of each of pin pair is detected. A mechanism is included for displaying numeric values on the housing that correspond to the points identified by the detecting mechanism.

Owner:ESTRADA ARMANDO

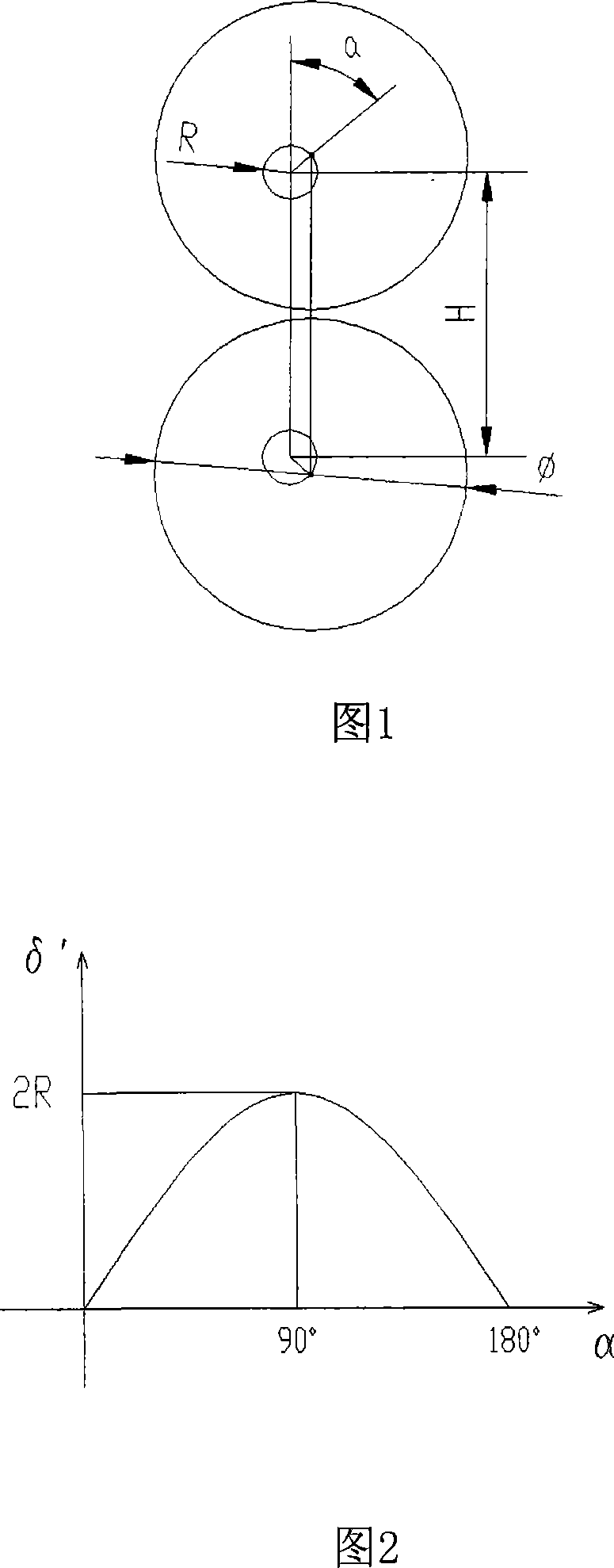

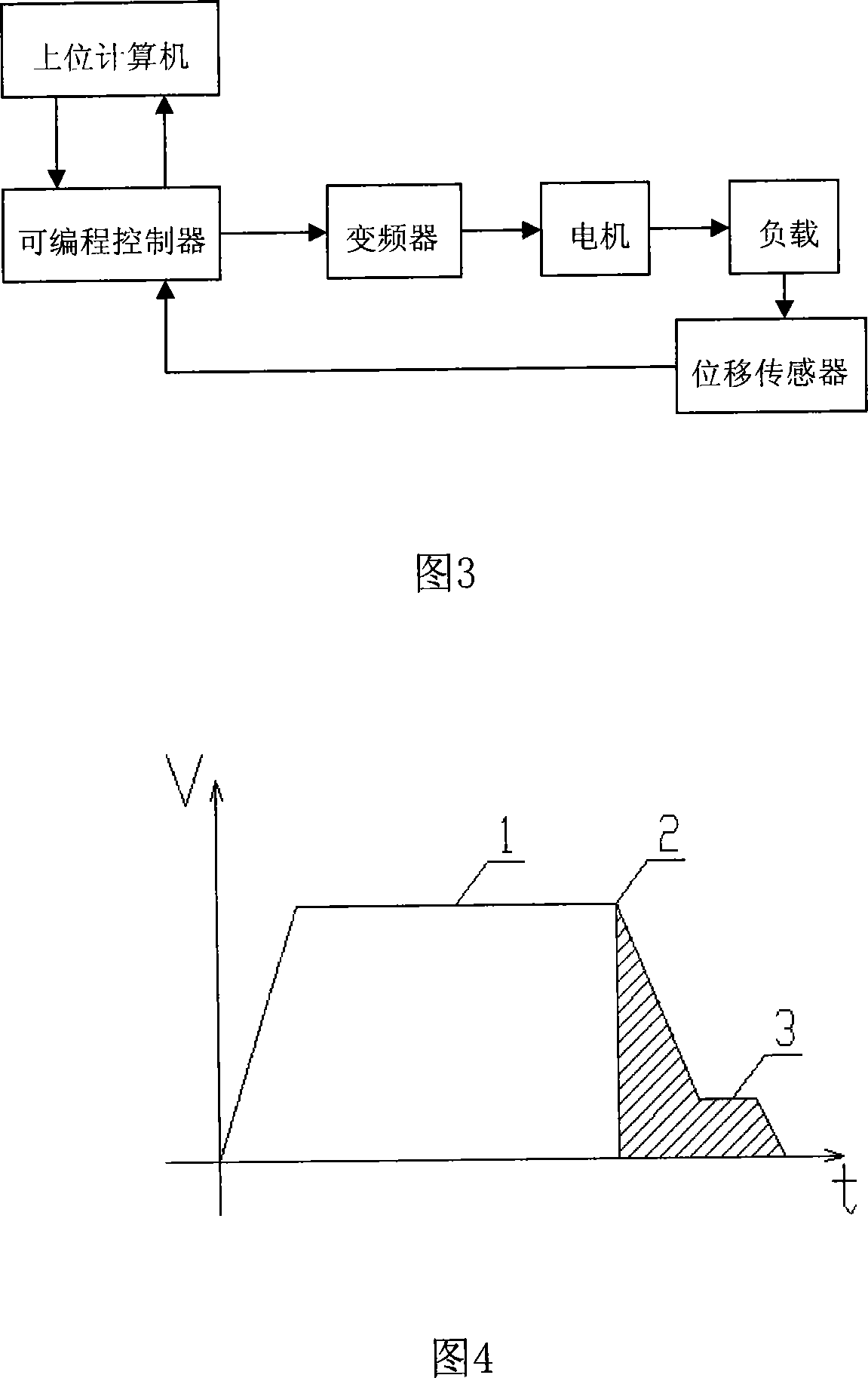

Disc shear cutter head overlap amount regulation control method

InactiveCN101145038AProgramme control in sequence/logic controllersShearing control devicesCircular discFrequency changer

The present invention relates to an adjusting and control method for device in a plate-strip shear line, in particular to an adjusting and control method for the overlapping value of the disk-shaped scissors plate; the present invention uses the frequency conversion and viable speed control system to achieve the control of the overlapping value of the disk-shaped scissors plate; and by the present invention, the absolute value of the difference value between the target value of the overlapping value and the measuring overlapping value of a displacement sensor can be compared with the ahead value L of the motor at the beginning of speeding down; through using the rotating speed of the control motor of the frequency convertor, the absolute value of the difference value between the target value and real overlapping value can be controlled to be equal to or less than 0.02mm. The adjusting and control method for the overlapping value of the disk-shaped scissors plate is time-saving, and has high control accuracy.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

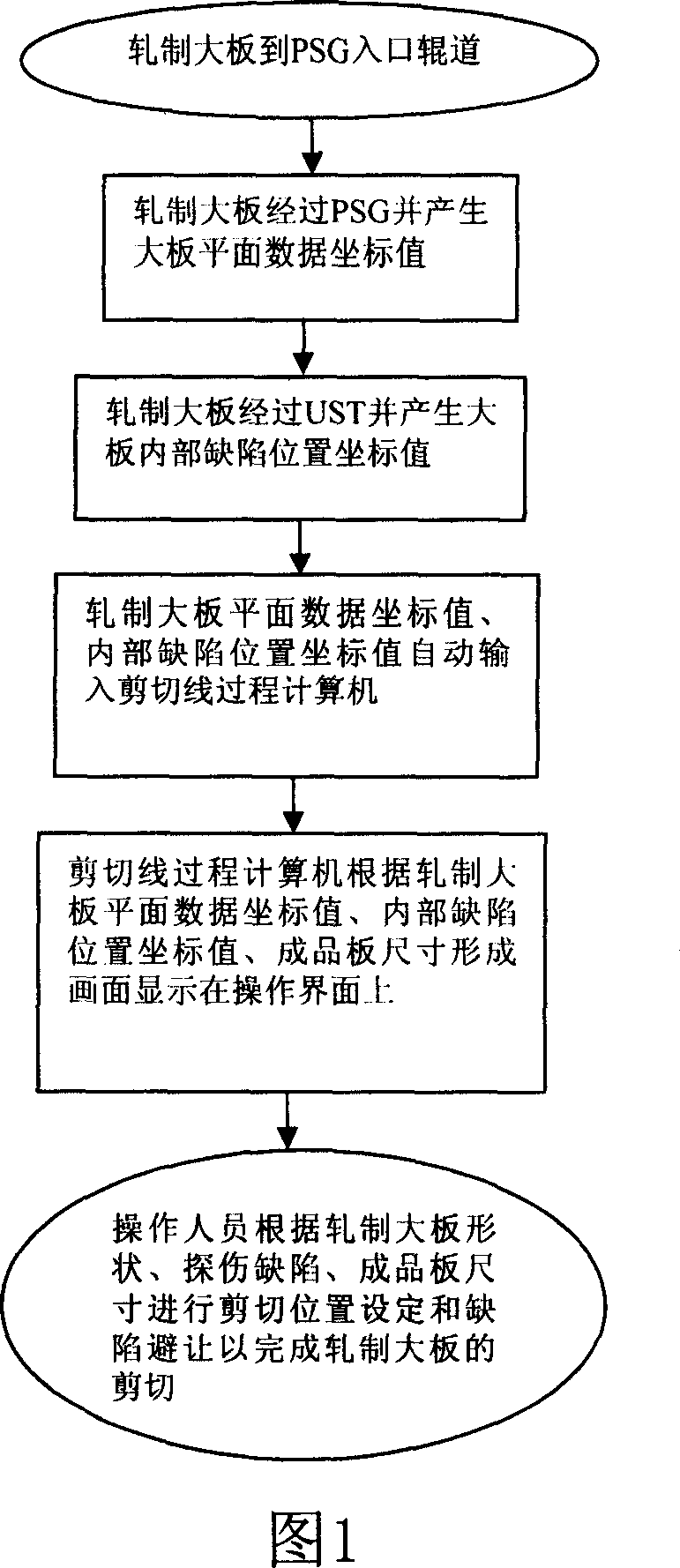

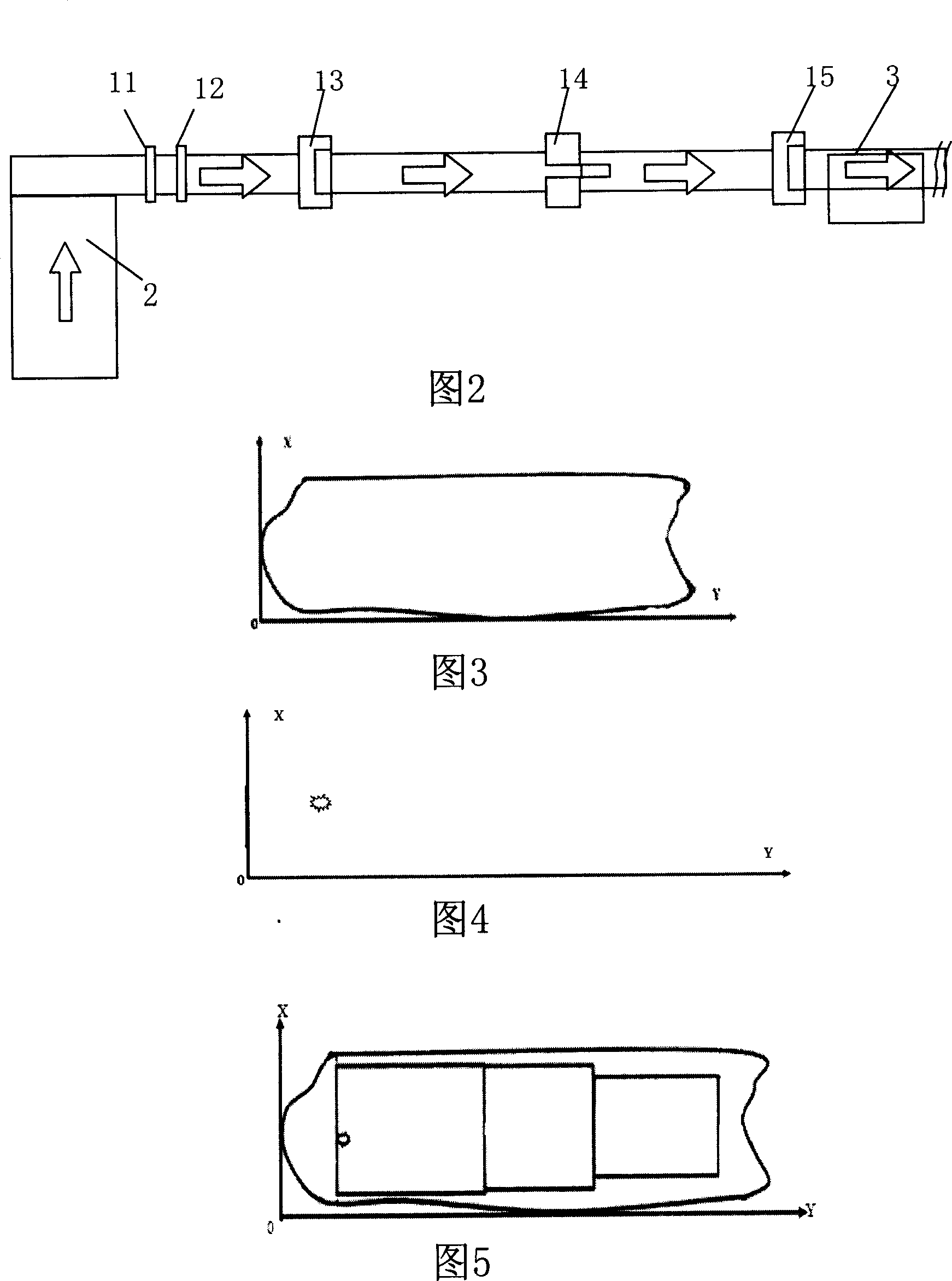

On-line optimizing shearing method of roller milling large plate

ActiveCN101097441AExtension of timeIncrease productionElectric programme controlShearing control devicesShear lineEngineering

The invention discloses a on-line optimizing cutting method of rolling board, it uses flat surface detecting device and on-line ultrasonic detection equipment to roll shape of big board and detect inner defect before snip head, and using cutting line course computer to transform detected shape data of rolling big board and inner defect data to image and displayed on operation interface and setting cutting position and defect avoiding to accomplish cutting of big board. The on-line optimizing cutting method resolves effectively problem that rolling big board with defects on head and trail needs manpower detection or finished board possesses defect of head and trail, it fits for continuous operation, and increasing cutting production capability and steel lumber ratio.

Owner:BAOSHAN IRON & STEEL CO LTD

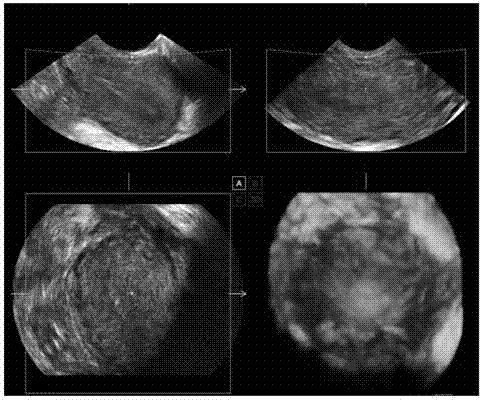

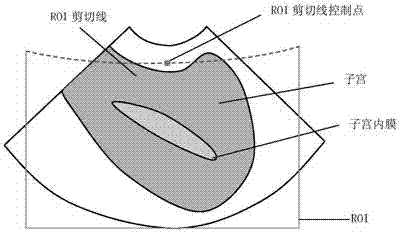

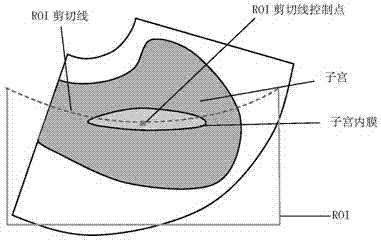

Ultrasonic imaging method and device and ultrasonic equipment thereof

ActiveCN105433980ASave operating timeSimplify operating proceduresUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasound imagingShear line

The invention provides an ultrasonic imaging method used for carrying out 3D imaging on the endometrium. The method includes the steps that a uterus 3D ultrasonic image containing the endometrium is acquired; the ultrasonic image is rotated so that the endometrium part in the ultrasonic image can be rotated to be horizontal; an ROI shear line is adjusted to axially correspond to the endometrium image; an endometrium 3D image extracted according to the adjusted ROI shear line is acquired. The invention further provides a corresponding device and ultrasonic equipment. By the adoption of the method, after a doctor acquires the uterus 3D ultrasonic image containing the endometrium, the ultrasonic image is rotated to make the endometrium image horizontal, then the shear line is adjusted to axially correspond to the endometrium, and thus the endometrium 3D image is automatically acquired; operation time is greatly shortened, and the operation process is simplified.

Owner:SONOSCAPE MEDICAL CORP

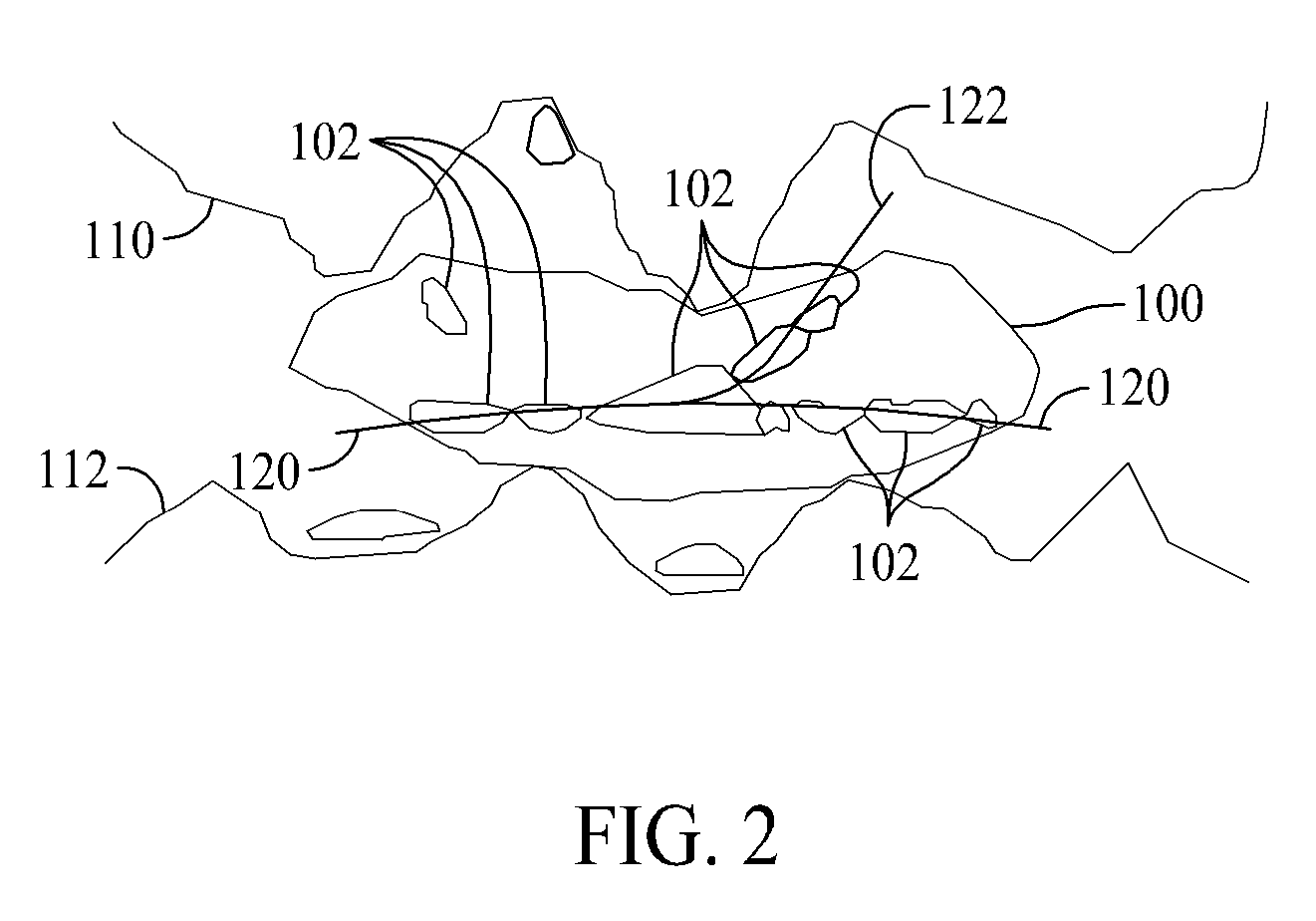

Methods and compositions for reducing wear of surfaces in contact with one another

A method for reducing wear between two surfaces in sliding contact with one another includes introducing nanoparticles between the two surfaces in an amount and having a composition that results in shear lines being generated within at least one agglomerated wear particle that is generated between the two surfaces as a result of the sliding contact, and subjecting the agglomerated wear particles to at least one load, using at least one of the two surfaces, such that the agglomerated wear particles disassemble along the shear lines into multiple smaller wear particles.

Owner:HOWARD UNIVERSITY +1

High security pin tumbler lock

A pin tumbler lock of a first embodiment includes a shell containing top pins; and a plug, rotatable within the shell, containing standard bottom pins, and a shorter bottom pin, set back from the face of the plug. A tubular key has bitings corresponding to the standard bottom pins, and a projection corresponding to the short bottom pin. When the key is inserted, the bitings and the projection press all the bottom pins to the shear line. In a second embodiment, a lock includes a shell containing top pins and a depression; and a plug, rotatable within the shell, containing bottom pins. The depression is configured and dimensioned to receive one of the bottom pins. The depression may be opposite one of the bottom pins, and there may be one more bottom pin than top pins. When the key is inserted, the bottom pins are moved to the shear line.

Owner:ACCO BRANDS USA LLC

Method for machining metal protective cover

The invention relates to a method for machining a metal protective cover, which comprises the following steps of: selecting a rectangular steel plate of which the shape and the size are consistent with those of the unfolded protective cover; drawing broken lines on the middle part of the steel plate; machining required holes inside the broken lines; cutting the periphery of the steel plate by taking the intersection points of the broken lines as vertexes; folding the periphery of the steel plate towards the same direction along the broken lines, so that two adjacent shear lines coincide with each other; and welding the four pairs of adjacent shear lines together to finish machining the protective cover. When the batches of the protective cover are few, the machining period can be shortened and the machining cost can be reduced by the method.

Owner:JIANGSU BAIXUE ELECTRIC APPLIANCES

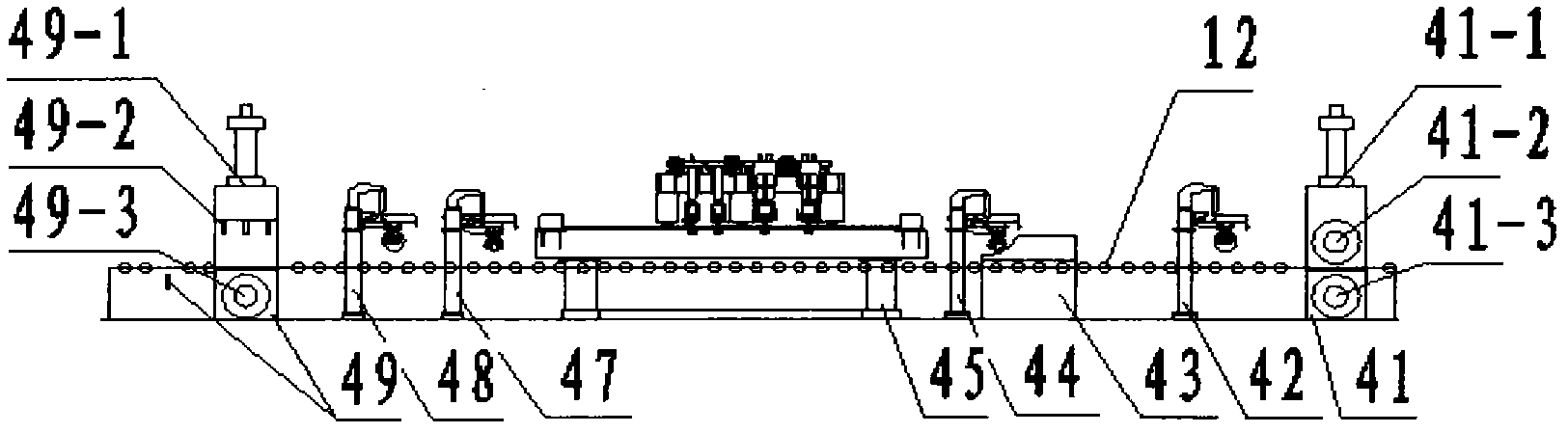

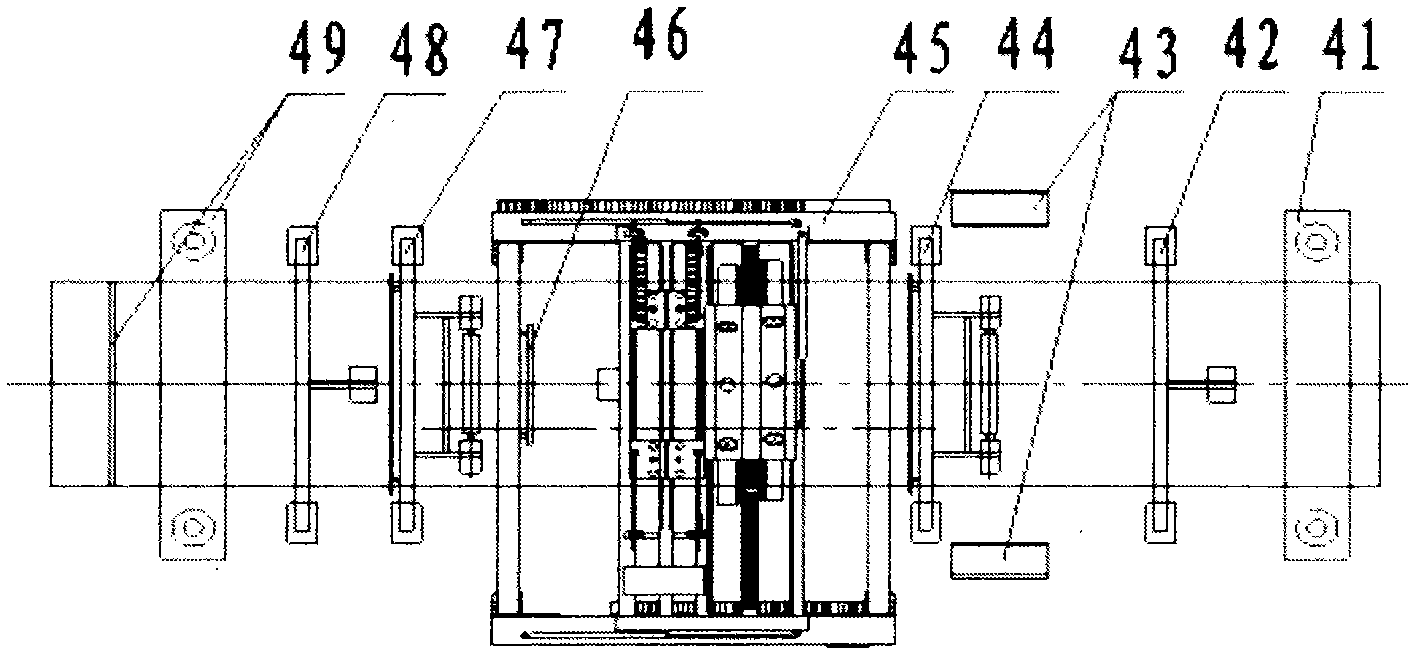

Hot rolled steel coil transversely shearing line online flaw detecting device and method

ActiveCN102078890AGuaranteed uptimeEasy to wearAnalysing solids using sonic/ultrasonic/infrasonic wavesMetal working apparatusProduction lineProduction rate

The invention discloses a hot rolled steel coil transversely shearing line online flaw detecting device and method, belonging to a device for testing flaws existing in a solid by utilizing ultrasonic waves, in particular relating to a hot rolled steel coil transversely shearing line online flaw detecting device and method. The hot rolled steel coil transversely shearing line online flaw detectingdevice is characterized by being arranged between a steel coil straightener of a transversely shearing line and a flying shear; an ultrasonic flaw detecting device is formed by sequentially connecting a pinch roll, an entrance length measuring mechanism, a width measuring mechanism, an entrance water retaining mechanism, a flaw detecting mechanism, a water scraping plate, an exit water retaining mechanism, an exit length measuring mechanism and an exit blowing mechanism in sequence; flaw detecting electric control instruments and meters are arranged inside an operating room or electric room at a production line side. Detecting flaws by uncoiling firstly and then shearing are realized. The invention has the advantages of novel conception, compact structure and reasonable process. Flaw detecting and transverse shearing are synchronously carried out, a production line operates smoothly, and the working efficiency and the production rate are increased. A probe is in contact with band steel all the time, the detecting dead zone is greatly reduced, the abrasion of the probe is greatly reduced, the service life is prolonged, the consumption of spare parts is lowered, and the production cost is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

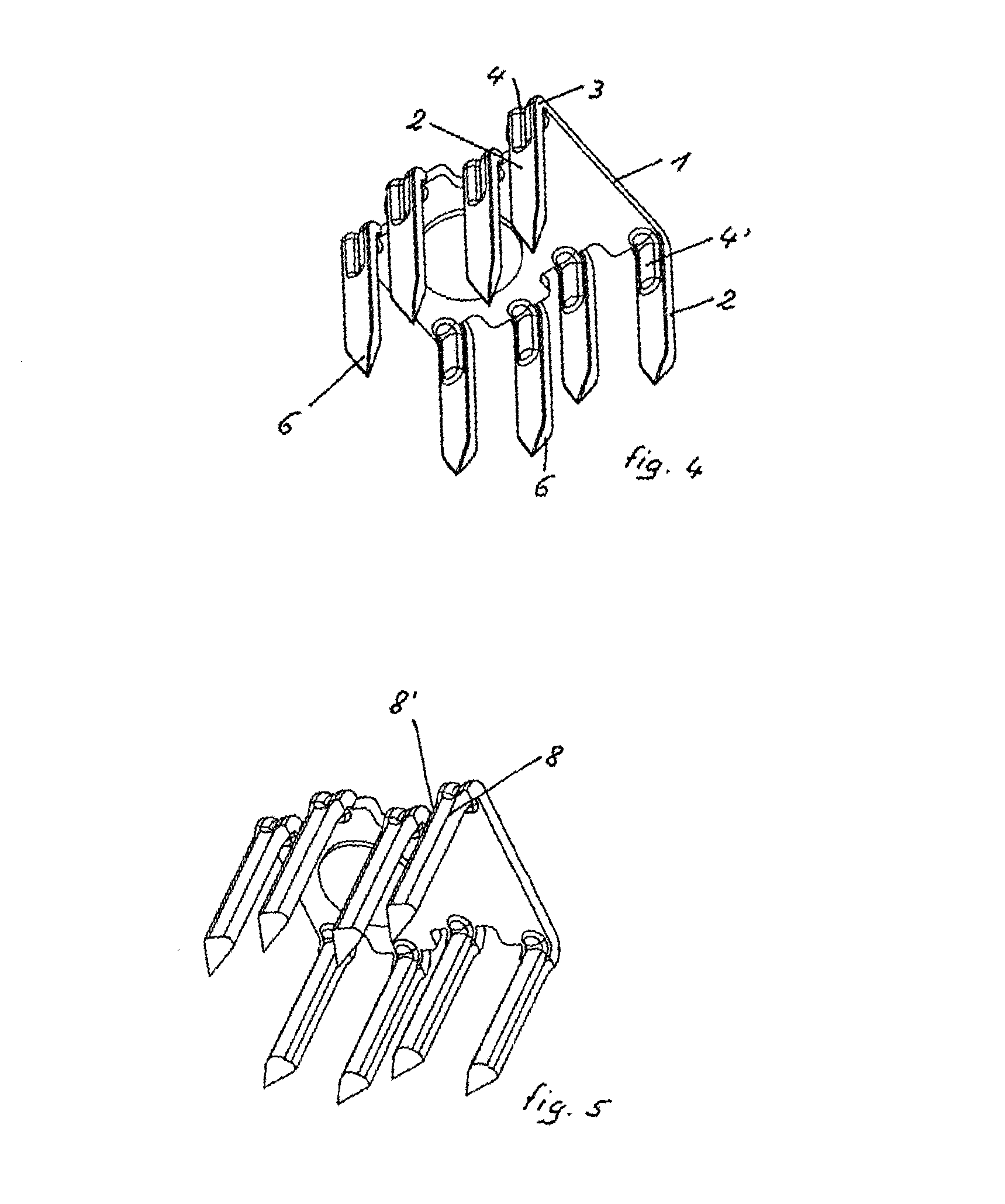

Clips for attaching staples for joining conveyor belt ends, staples for joining conveyor belt ends and clip-staple assemblies

ActiveUS20140182089A1Easy to implementRobustness in useV-belt fasteningsBelt fasteningsVertical alignmentShear line

A conveyor belt joining staple including upper and lower staple plates situated at different levels joined by knuckles. The upper staple plate has through-holes for passage of staple attaching clip claws and the lower staple plate has bridges that form a recess between a bar of the bridge and an upper surface of the lower plate. The lower staple plate has two shearing lines corresponding to the recess of the bridge, and inlet and outlet toboggans that each have a curved tab. The toboggans are symmetrical with respect to the longitudinal axis of the bridge. Each toboggan has a boss that has an upper round portion and base rounded portions. A portion of the boss is connected to a portion of the tap. Each inlet toboggan-boss is situated in vertical alignment with a corresponding hole of the upper plate for the passage of the clip claws.

Owner:ASER

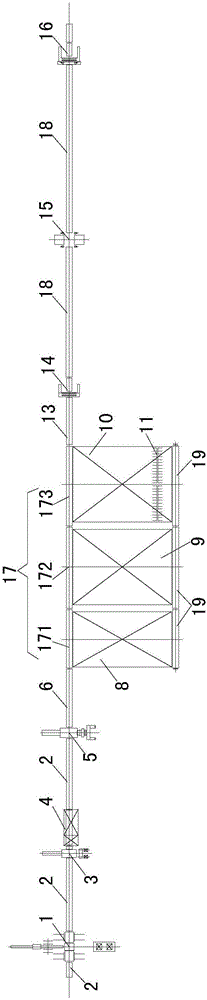

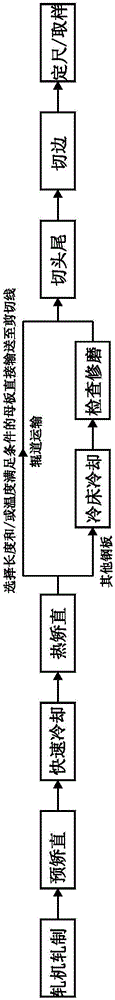

Straightening method preventing steel plates from buckling

ActiveCN103433334AAvoid bowingImproving the pass rate of one-time straightening plate shapeSheet steelShear line

The invention relates to a straightening method preventing steel plates from buckling. The method includes the following steps that (1) a bending roller adjusting scheme of a hot straightening model is carried out; (2) hot straightening is carried out on the steel plates with final cooling temperature of 400-650 DEG C for three passes, and the steel plates enter a cooling bed for cooling through a roller way; (3) the hot straightening is carried out on the steel plates with final cooling temperature of 250-400 DEG C for five passes, and the steel plates enter a shear line for rapid shearing; (4) for the steel plates sheared and processed rapidly, the four edges of the upper surface of the steel plates are grinded block by block; (5) the steel plates enter a cold straightening machine for straightening. Compared with the prior art, the straightening method preventing the steel plates from buckling has the advantages that according to the controlled cooling steel plates straightened through the method, nonuniformity of temperature of all parts of the steel plates can be greatly reduced, new internal stress of the steel plates can be prevented from being generated in the hot straightening process, besides, original internal stress can be effectively released, buckling, caused by internal stress release, of the steel plates in the slow cooling process is avoided, and the one-time straightening plate shape qualified rate of the controlled cooling steel plates is improved.

Owner:ANGANG STEEL CO LTD

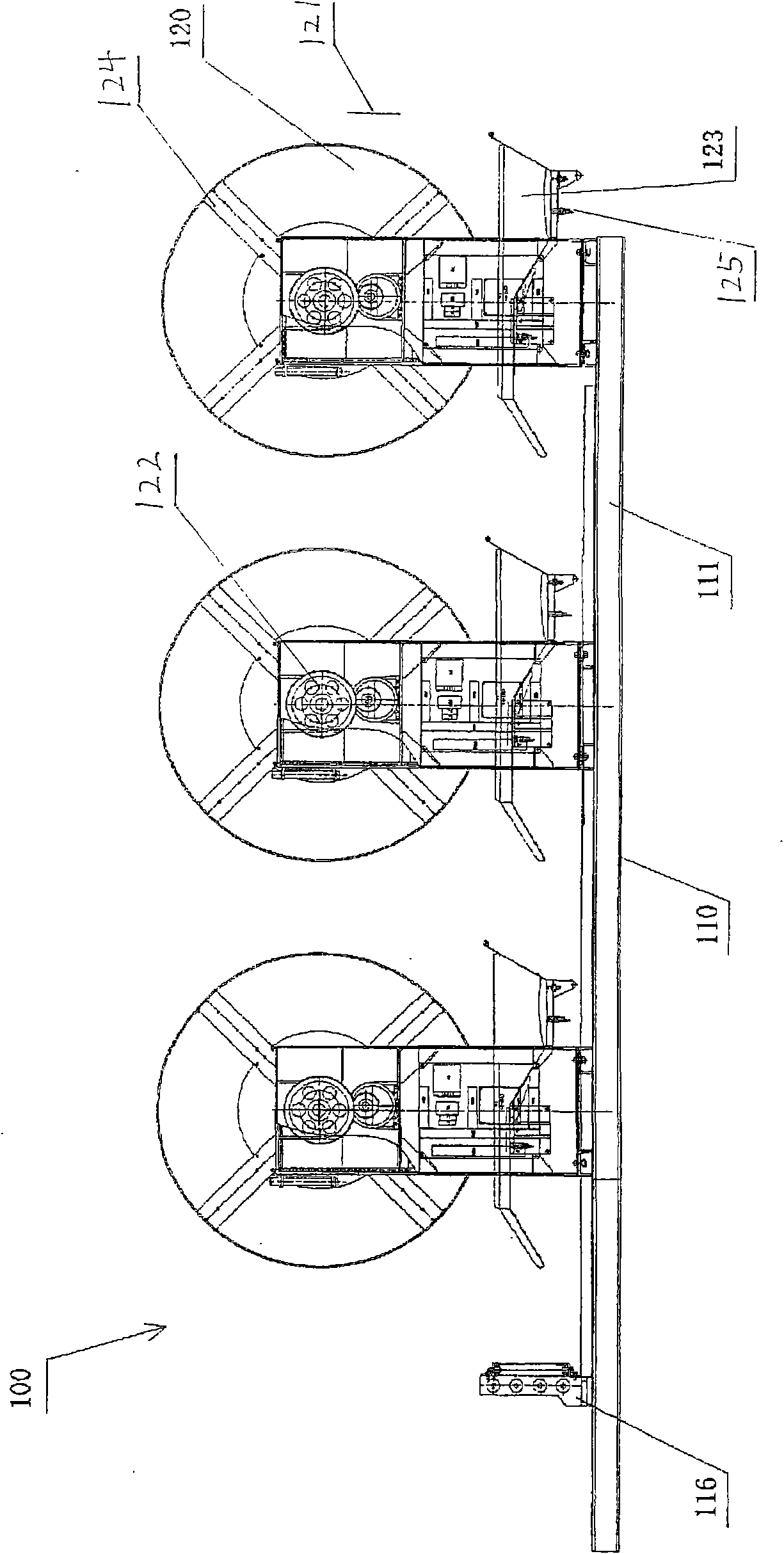

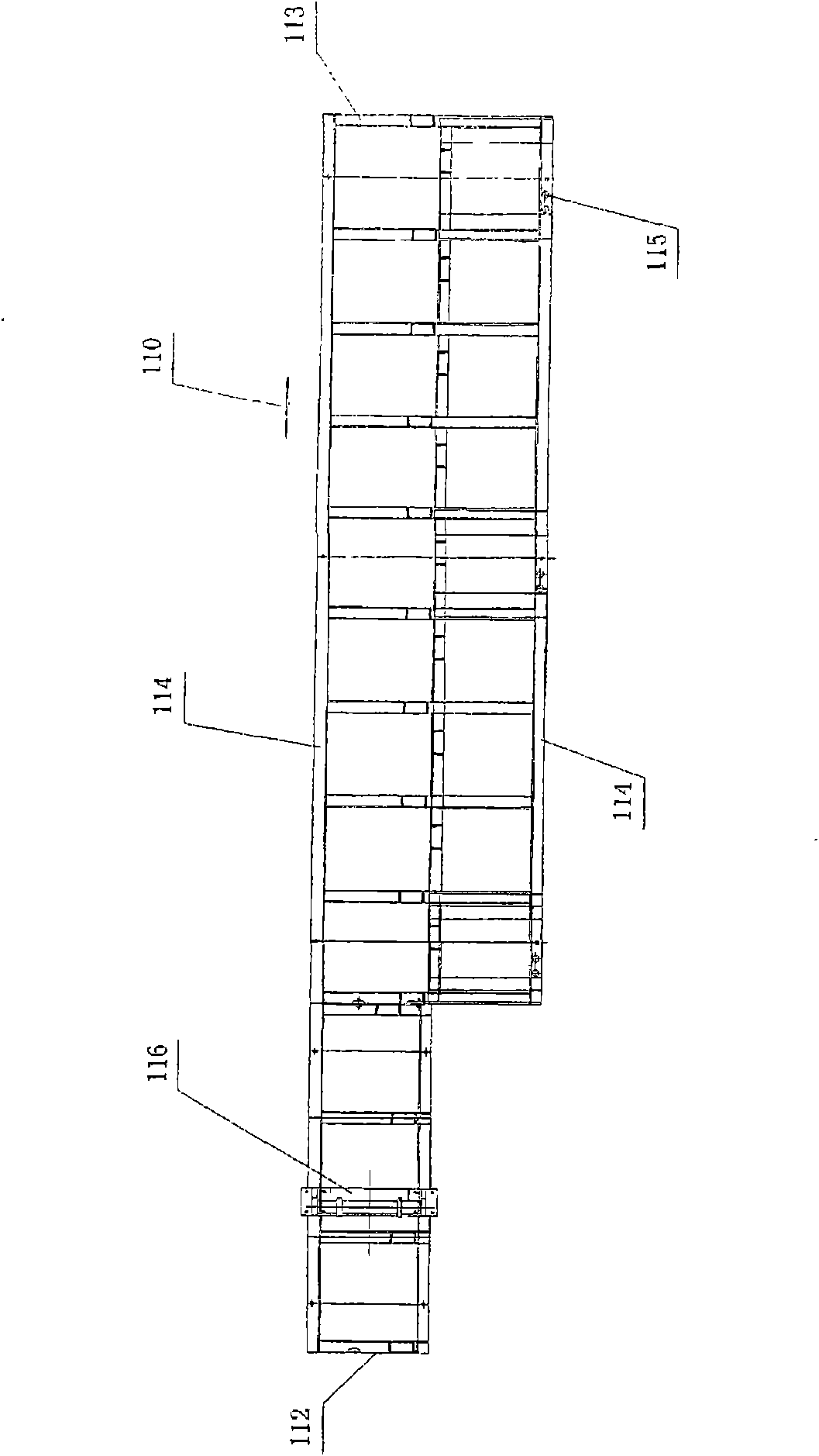

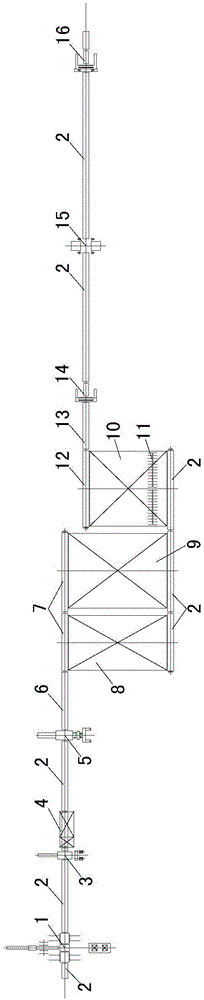

Middle thick plate production line and production method

InactiveCN106345807AThe overall thickness is thinReduce the temperatureMeasuring devicesCooling bedsShear lineManufacturing engineering

Owner:CERI TECH +1

Variable shear line lock cylinder

A lock cylinder is provided and includes an outer cylinder having a bore, an inner cylinder rotatably disposed within the bore, and a pin assembly disposed within the inner and outer cylinders. The pin assembly is operable to selectively lock the inner cylinder relative to the outer cylinder. The pin assembly includes an upper shear cylinder positionable relative to the outer cylinder and a lower shear cylinder positionable relative to the inner cylinder. The upper and lower shear cylinders are movable to define a first shear line therebetween. In addition, the pin assembly includes an upper pin slidable within the upper shear cylinder and a lower pin slidable within the lower shear cylinder, whereby the upper and lower pins define a second shear line therebetween. The lock cylinder is positionable from a locked position to an unlocked position when the first shear line is aligned with the second shear line.

Owner:RAYOVAC CORP

Locking device

InactiveUS20160017636A1Reduce power consumptionExtend battery lifeNon-mechanical controlsKeysShear lineLinear actuator

A locking device and system are disclosed. The locking device includes a barrel within which sets a plug. A plurality of pins sit in pin pathways that extend partially through the barrel and plug and the pins prevent rotation of the barrel within the plug when the ends of the pins are not aligned with a shear line. One of the pins has a recess formed therein within which a locking ball can sit. The engagement or otherwise of the locking ball in the recess is controlled by a linear actuator. When the linear actuator allows the locking ball to disengage the recess the pin with the recess in can engage the key and a line the end of the pin with the shear line.

Owner:HENRY SQUIRE & SONS

Pin tumbler lock releasing system

A pin tumbler lock releasing system includes keyway insertible and universally configured lift, key and shim devices that cooperatively work to raise the pin stacks within a pin tumbler lock to just above the pin tumbler lock's shear line so that its plug element may be rotated within its outer casing in order to disengage its locking mechanism.

Owner:BLACK CARL

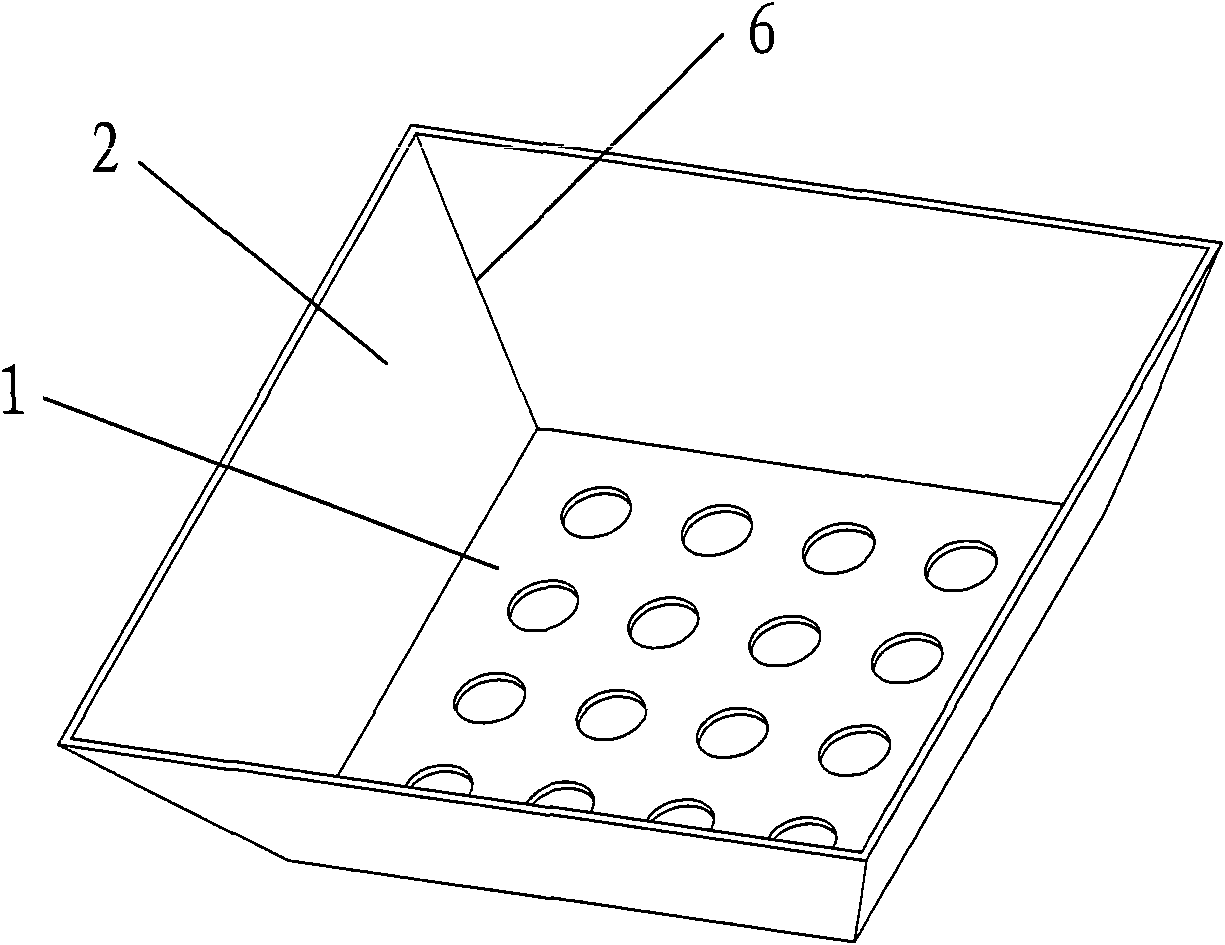

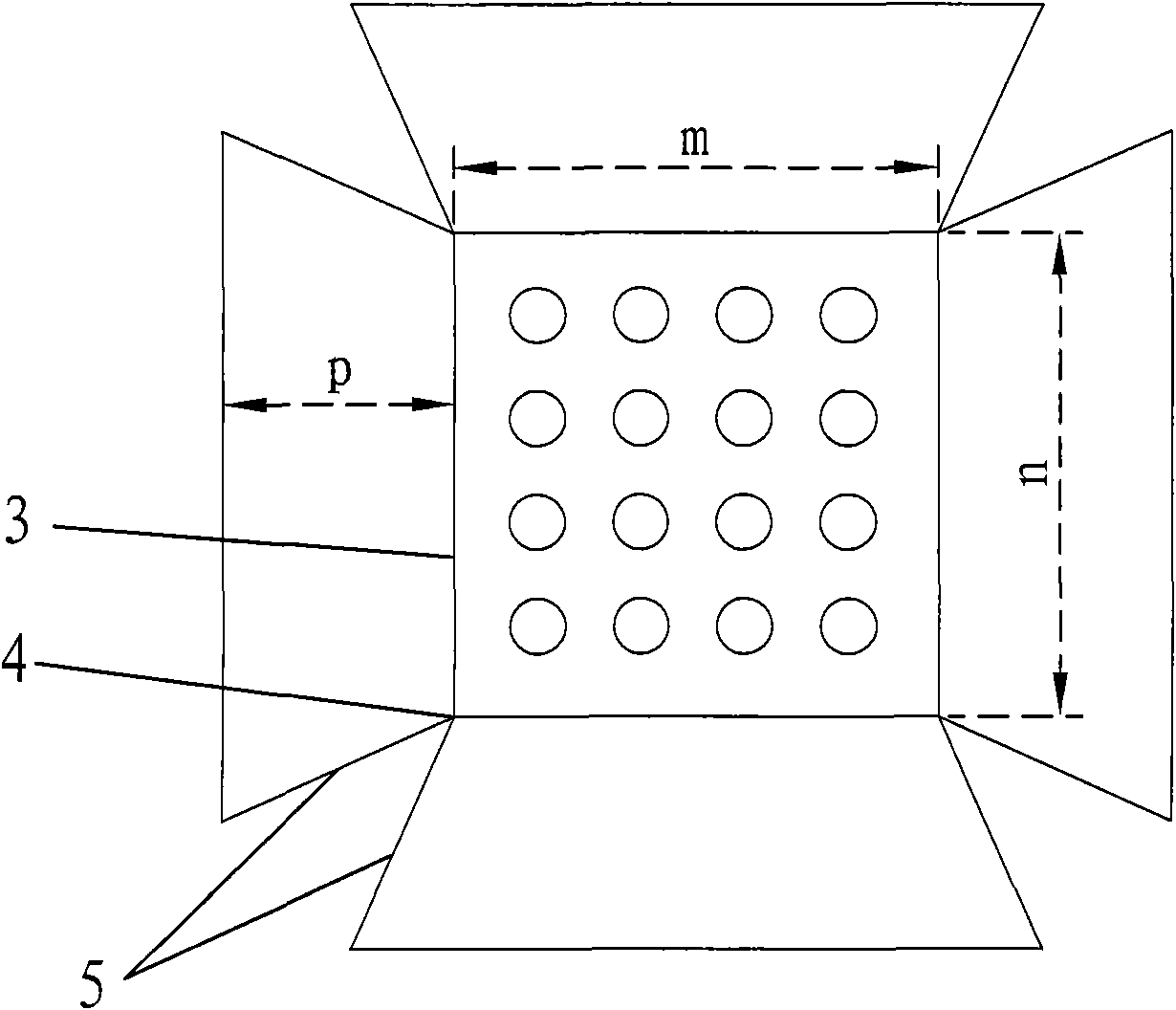

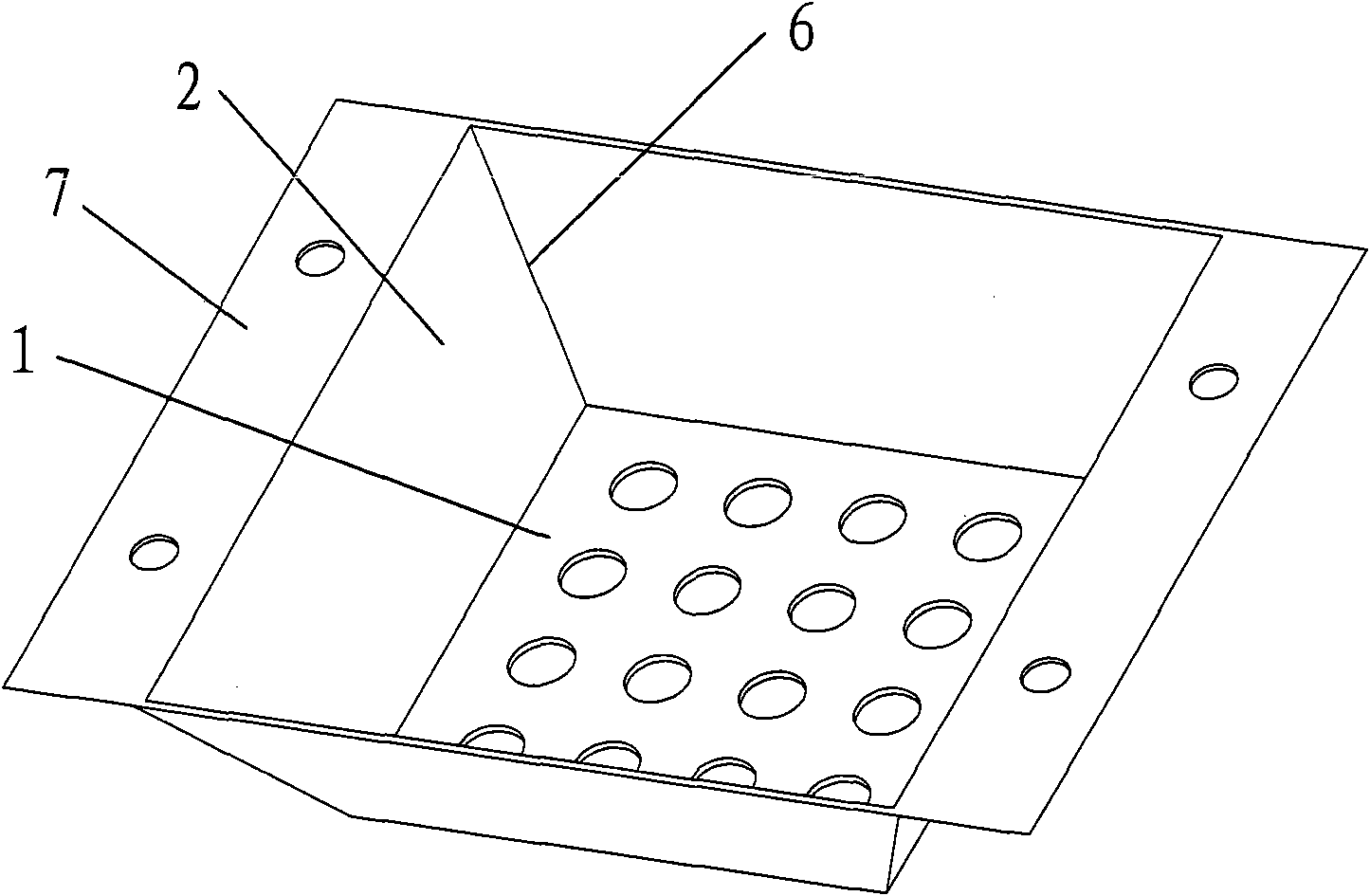

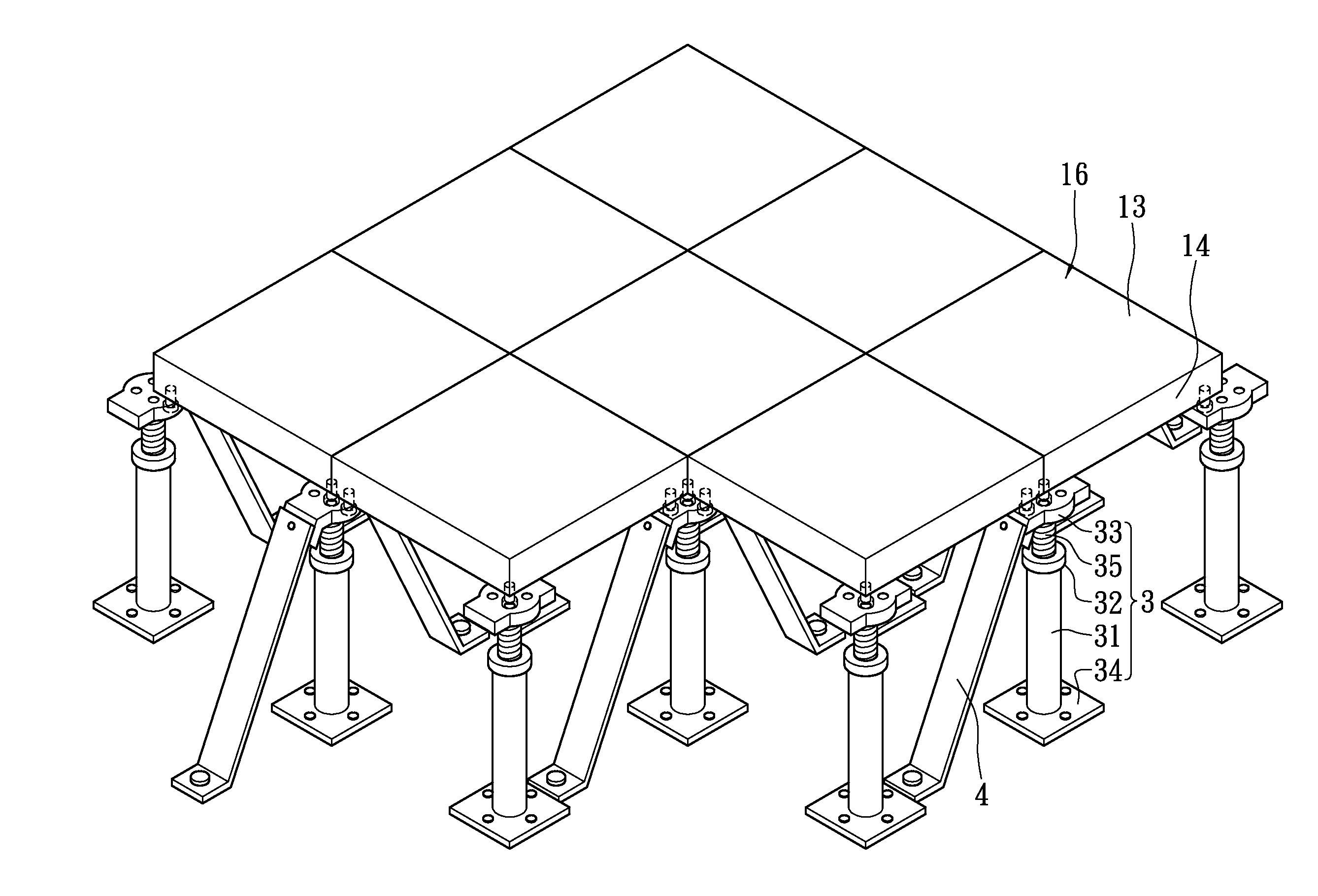

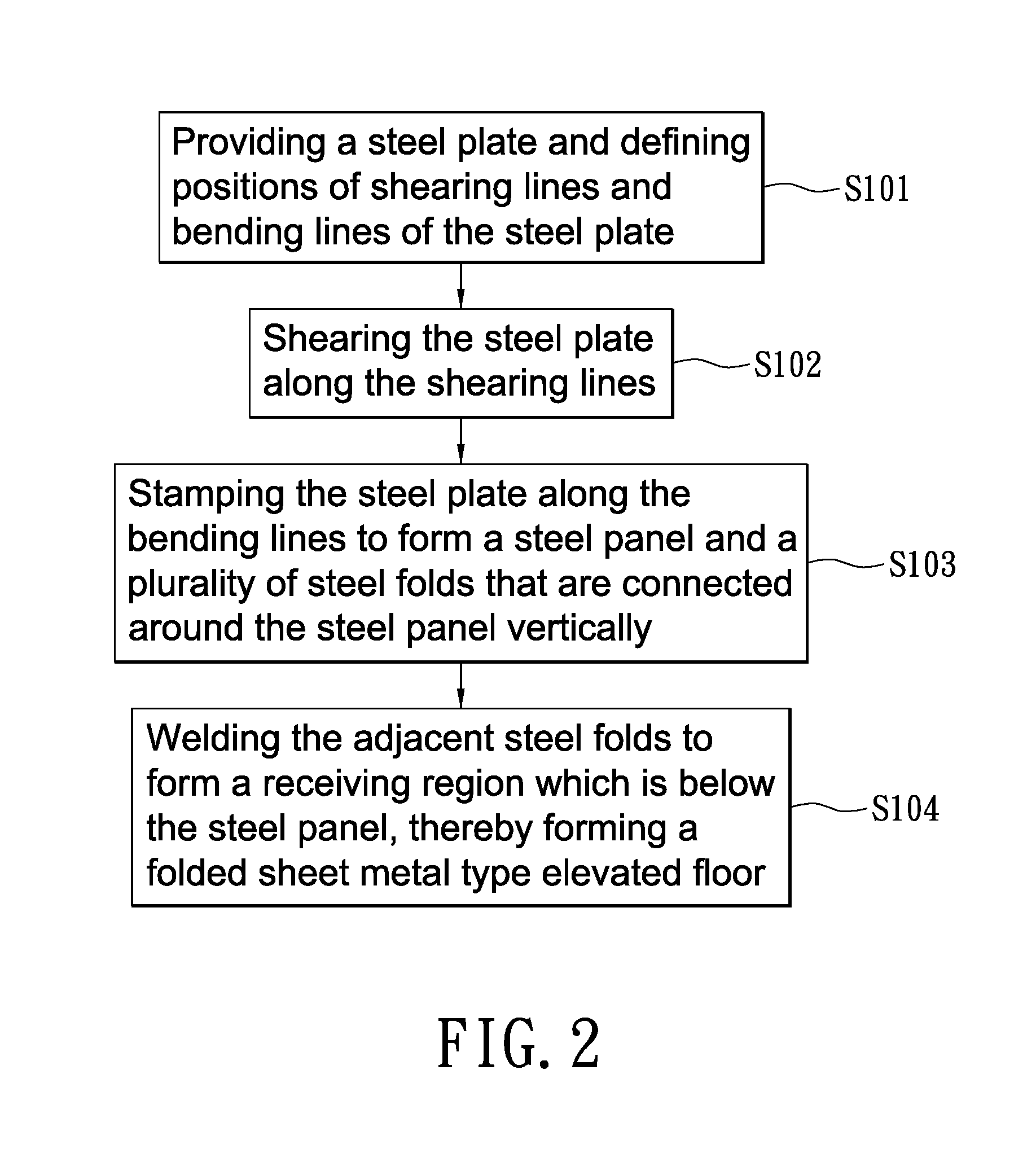

Method for manufacturing a side-folded type elevated floor and a system thereof

A method for manufacturing a side-folded type elevated floor includes the steps of: providing a steel plate and defining positions of shearing lines and bending lines of the steel plate; shearing the steel plate along the shearing lines; stamping the steel plate along the bending lines to form a steel panel with a plurality of steel folds that are bendingly connected around the steel panel; and welding the adjacent steel folds to form an accommodating region; thereby a side-folded type elevated floor is formed. In this way, the amount of energy consumed in manufacturing the elevated floor can be reduced greatly, thereby conforming to the requirement for saving energy. A side-folded type elevated floor system is further provided.

Owner:UNITED INTEGRATED SERVICES

High Security Cylinder Lock

InactiveUS20100024499A1Cost efficientEasy to assembleNon-mechanical controlsCylinder locksShear lineEngineering

A high security cylinder lock includes a housing comprising a plurality of driver pin bores for disposing spring loaded driver pins; a plug rotatable within the housing comprising a plurality of balancing pin bores for disposing spring loaded balancing pins and a plurality of combination pin bores for disposing combination pins. Each combination pin is sandwiched between a driver pin and a balancing pin. The extension force of the balancing spring at its pre-load length is greater than the extension force of the driver spring at its fully-load length. The compound force causes at least one combination pin partially extended into a corresponding driver pin bore in the housing when the plug is at its first rotational orientation in case of no key engaged. The key profile pushes the balancing pins to move to such position that all mating surfaces of the combination pins and the driver pins to lies onto the shear line of the lock. The balancing pin, balancing spring and balancing spring seal set may be substituted by magnetic balancing pin and magnetic seal pin set.

Owner:XU FORREST +1

Methods and devices for decoding locks

The decoding of a lock, such as a pin tumbler type of lock, is completed by utilizing a method that includes the insertion of a key blank or other material with one or more reference indicators on a modifiable surface, into a keyway of the lock. The key blank is inserted until a stopping resistance is detected. Such a resistance occurs when a pin of the lock reaches a shear line position. After such a position is reached a marking is made on the key blank and a measurement is made. The measurement is compared to markings on a novel decoding template to determine the depth of a cut that should be made on an uncut key.

Owner:UTTARO MICHAEL THOMAS

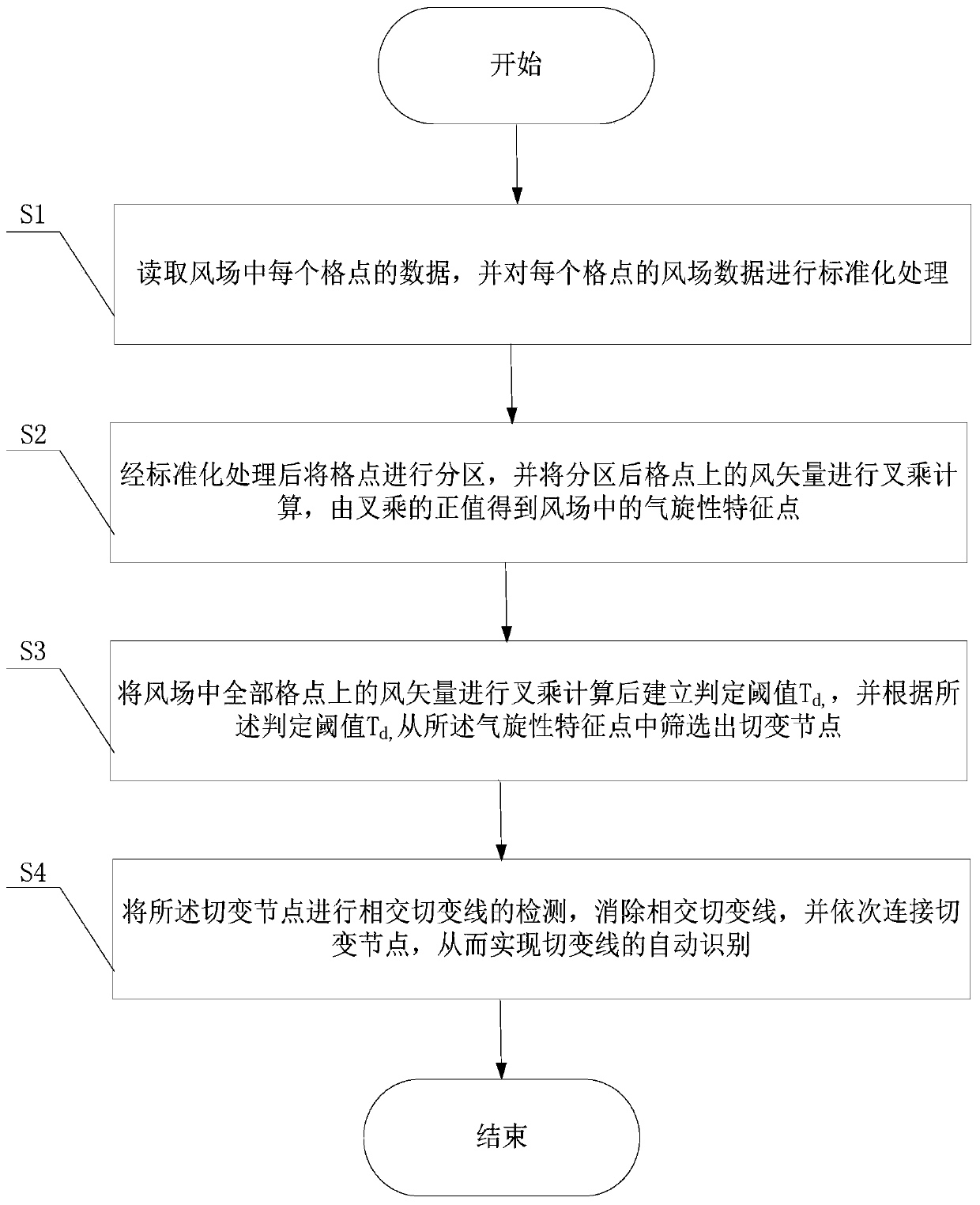

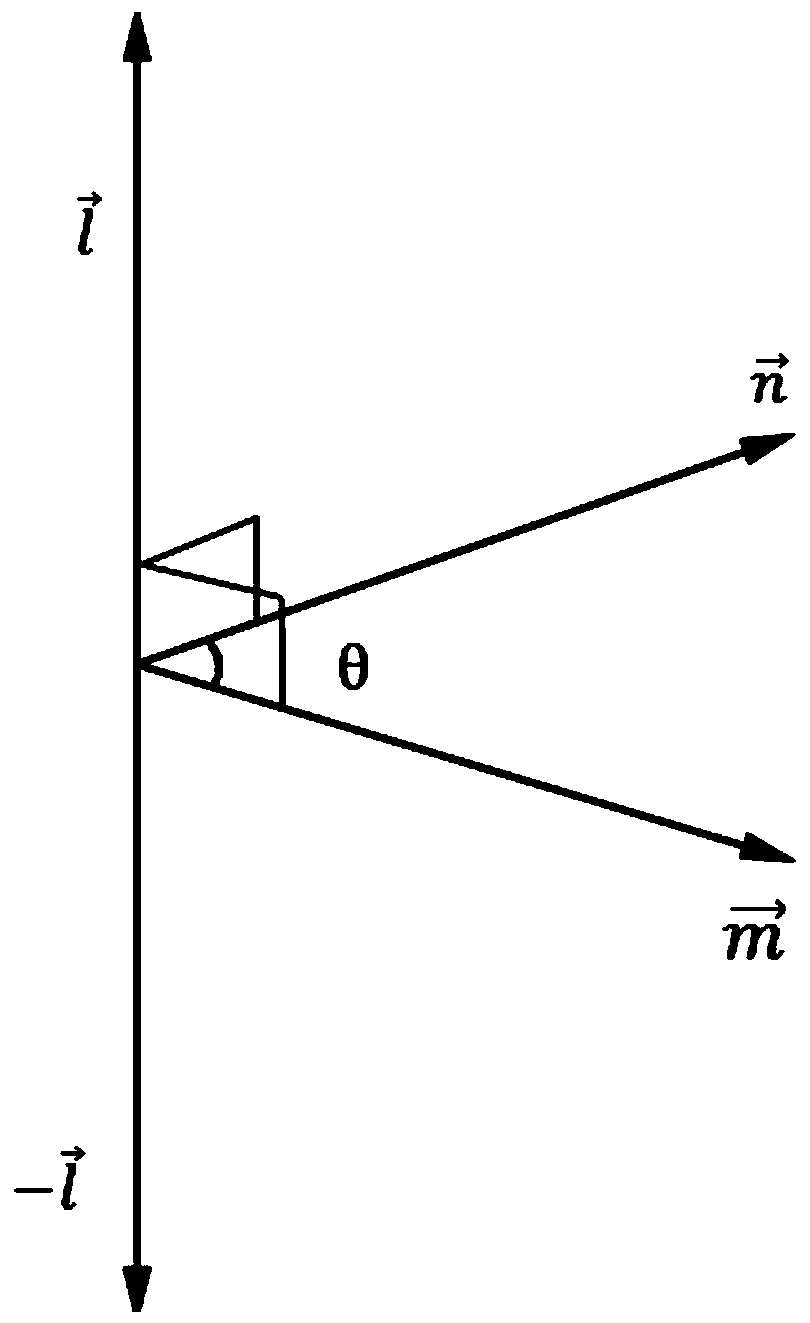

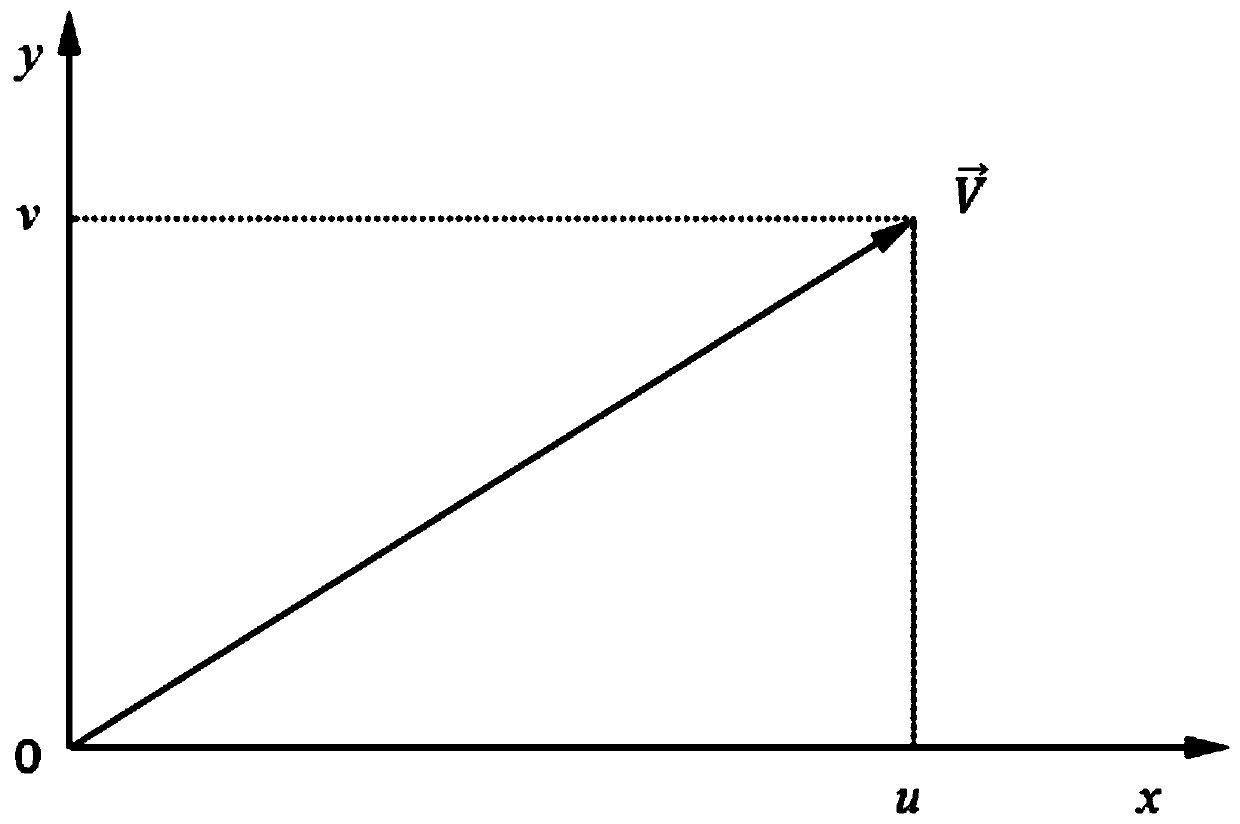

Method for automatically recognizing shear line

ActiveCN110221359AImprove the efficiency of forecast analysisFacilitating Smart Weather ForecastingWeather condition predictionApplications of artificial intelligenceSimulation

The invention provides a method for automatically recognizing a shear line. The method comprises the following steps: performing standardized processing on a wind field; partitioning lattice points and performing multiplication cross computation on the wind vectors on the lattice points after partitioning, and obtaining cyclonic characteristic points in the wind field through a multiplication cross positive value; taking an establishment judgment threshold of the maximum multiplication cross positive value, and screening out shear nodes from the cyclonic characteristic points; eliminating intersected shear lines according to a shear node analysis method, and then constructing the shear line by connecting the shear nodes in groups. The possible shear of the judgement and screening can be performed by utilizing the two-dimensional vector multiplication cross result, and the shear nodes are finally connected to form the shear line, thereby reaching an aim of automatically recognizing andpositioning the shear line. The shear line analysis in the current meteorological service still uses the human-machine interaction way, the disadvantage problem that the forecast personnel performs manual operation according to the own experience is solved, thereby laying a solid foundation for realizing the automatic analysis forecast and artificial intelligence in the weather service.

Owner:CHENGDU UNIV OF INFORMATION TECH

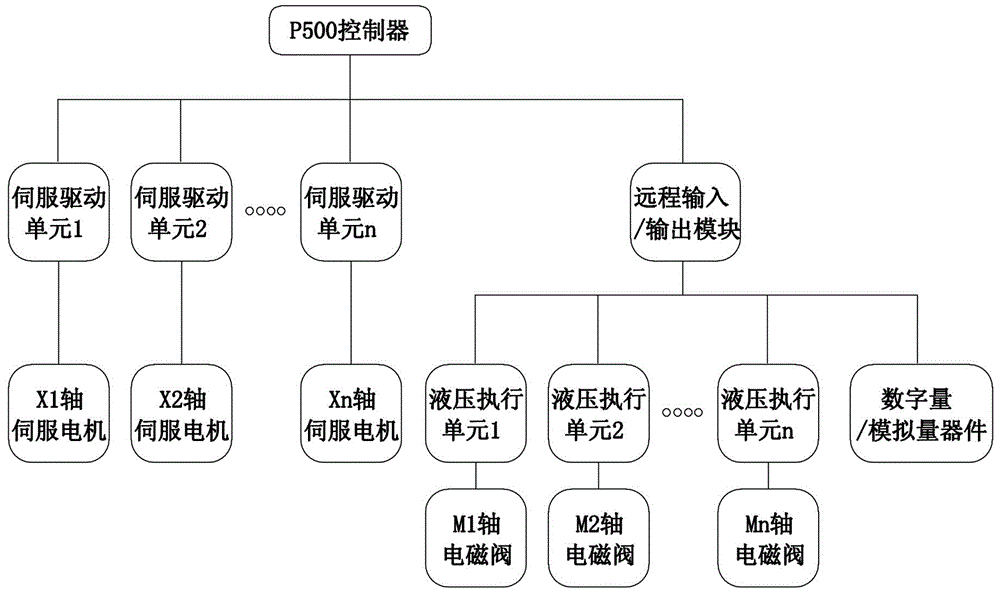

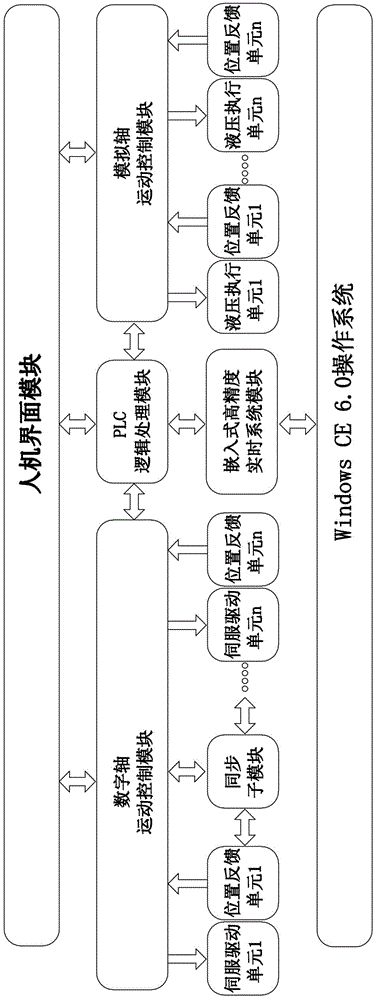

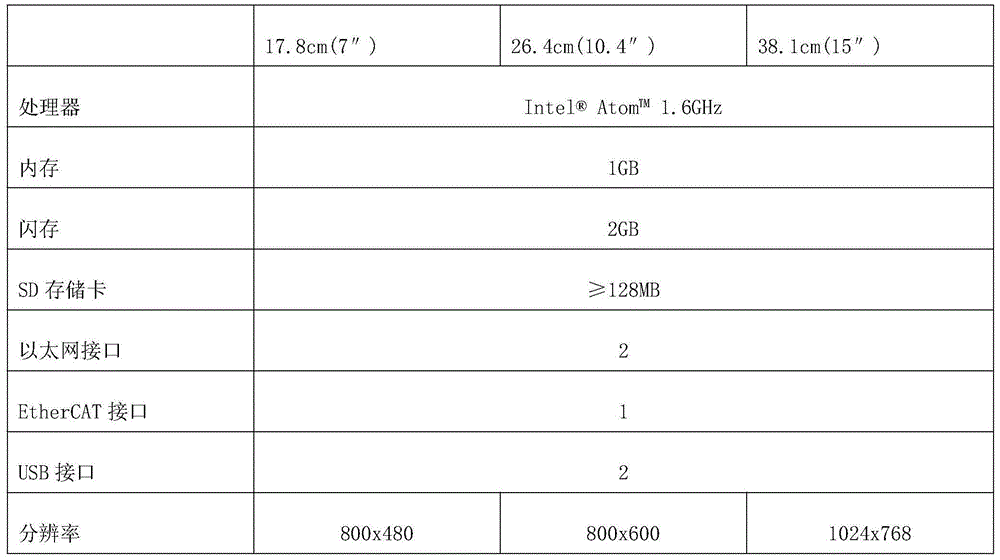

Shear-line multi-axis numerical control system based on P500 controller

ActiveCN104898574ALarge storage capacityEasy to replaceNumerical controlHuman–machine interfaceData acquisition

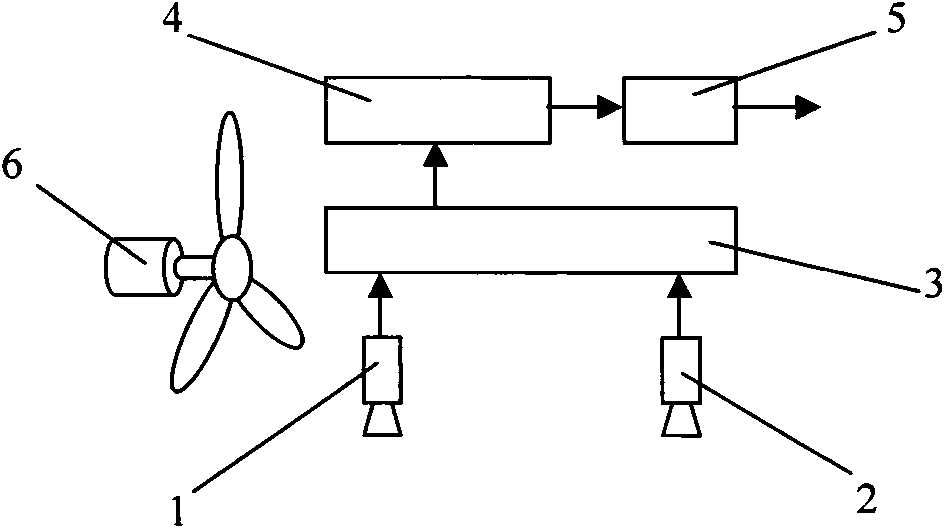

A shear-line multi-axis numerical control system based on a P500 controller has a P500 controller, which serves as a hardware carrier of the shear-line multi-axis numerical control system and communicates respectively with a remote input / output module and at least three servo driving units in a high speed through EtherCAT on-site buses. The servo driving units corresponding drive servo motors. The remote input / output module is in communication connection with a digital quantity / analog quantity device and at least three hydraulic execution units to complete data acquisition and accurately positioning of numerical control shafts of a shear line during a production process. The shear-line multi-axis numerical control system comprises a man-machine interface module, a PLC logic processing module, an embedded high-precision real-time system module, a digital shaft motion control module, a synchronous sub-module and a simulated shaft motion control module. The shear-line multi-axis numerical control system has high performance-price ratio, flexible functions and excellent data interaction performance. Precise positioning and process synchronization of a plurality of numerical control shafts on a shear line are realized, and centralized control is achieved.

Owner:HUALI BRANCH CORP HUBEI SANHUAN METALFORMING EQUIP

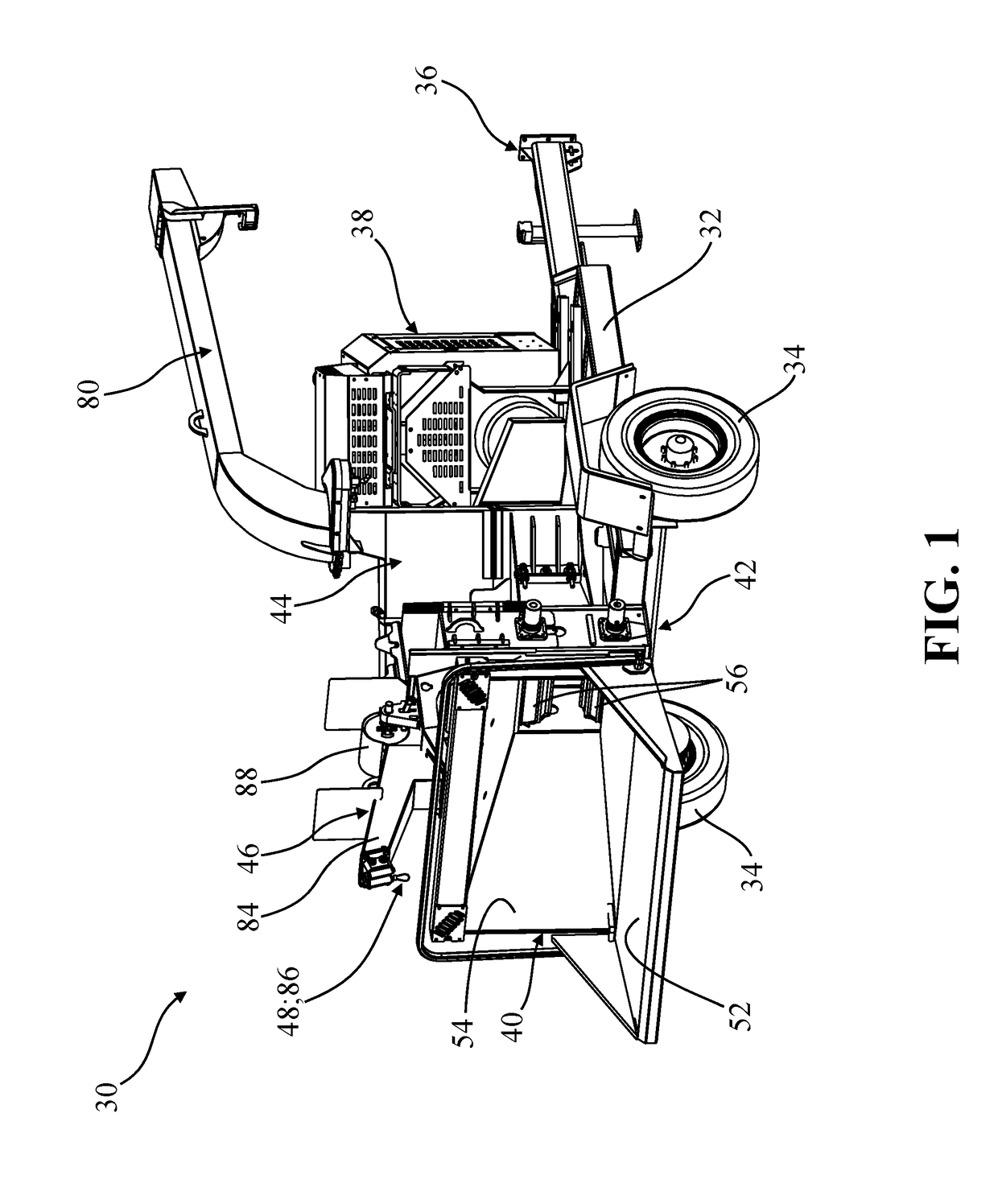

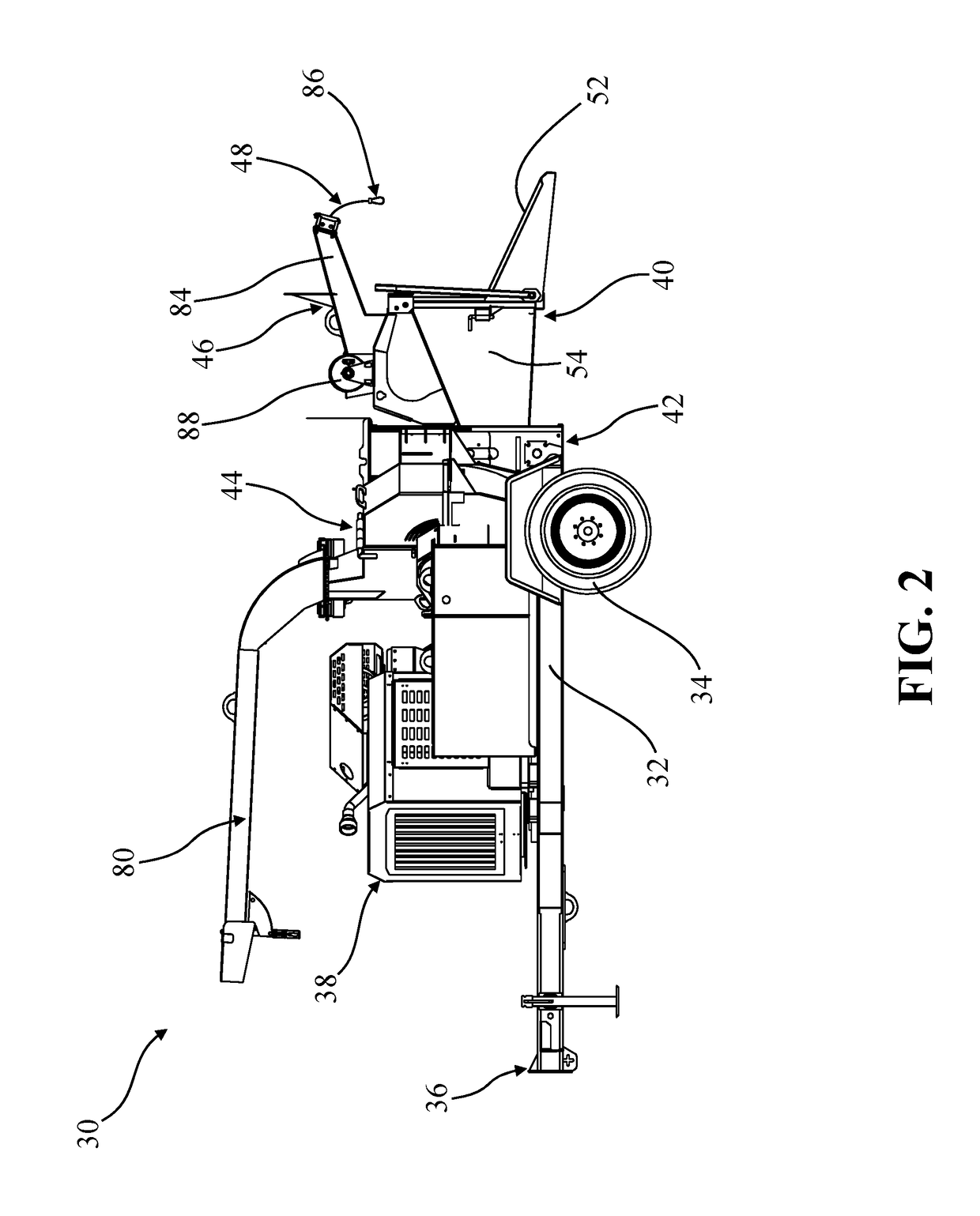

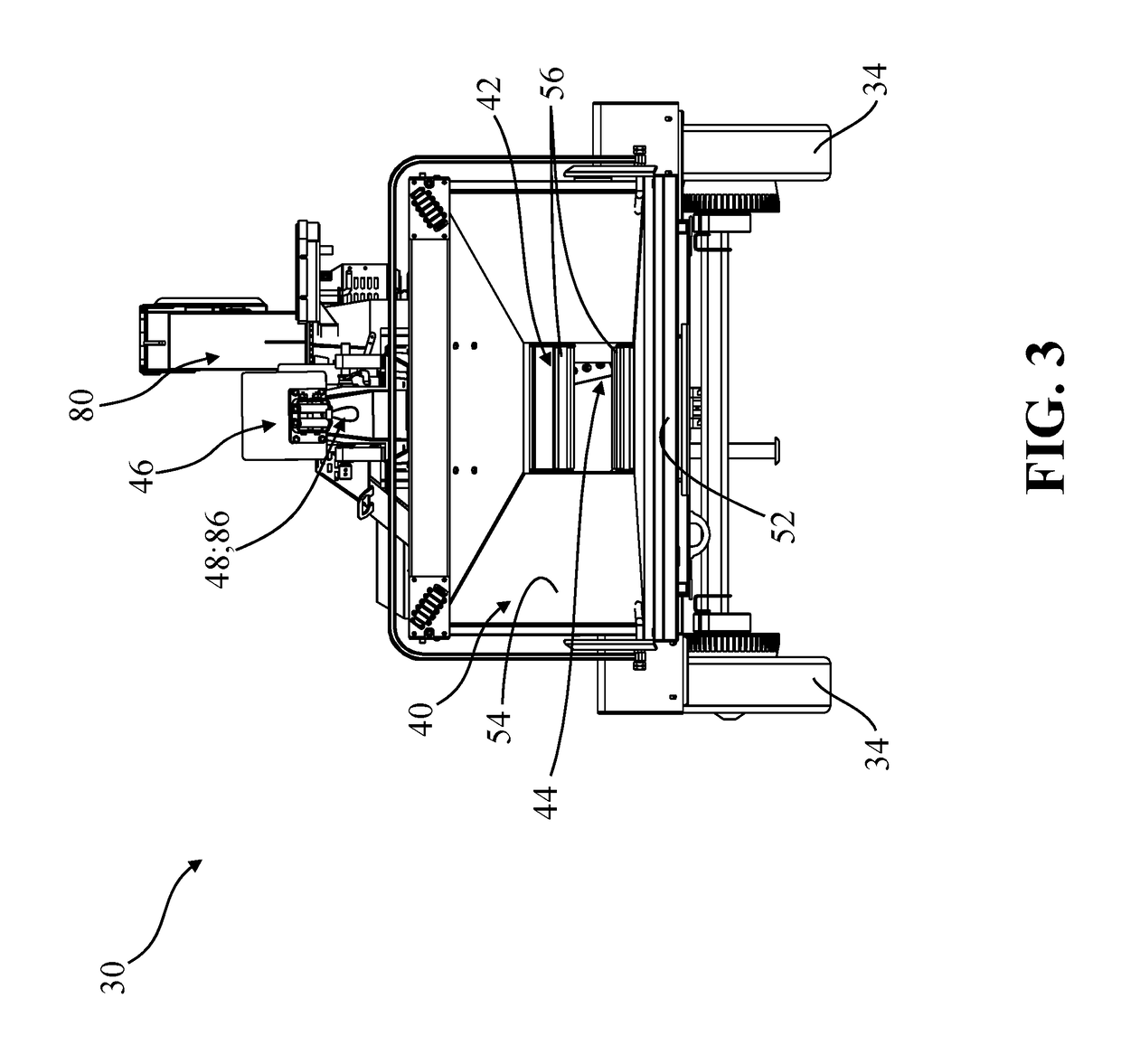

Waste Processing Machine Safety Device

ActiveUS20190046990A1Reduce decreaseReduce wasteGrain treatmentsWood working safety devicesWaste processingShear line

A waste processing machine for reducing waste material and having a safety device for shearing lines. A housing defines a cutting chamber and an intake opening in communication with the cutting chamber for receiving waste material. A disc is disposed in the cutting chamber, rotates about an axis, and has an axial surface facing the intake opening. A cutting member is fixed to the disc for revolution about the axis concurrent with rotation of the disc for reducing waste material. A cutting anvil is coupled to the housing adjacent to the intake opening and faces the axial surface of the disc for reducing waste material between the cutting anvil and the cutting member. A line shear element is attached to the housing, extends into the cutting chamber toward the axial surface of the disc, and is spaced from the cutting anvil for shearing lines caught by the rotating disc.

Owner:BANDIT IND

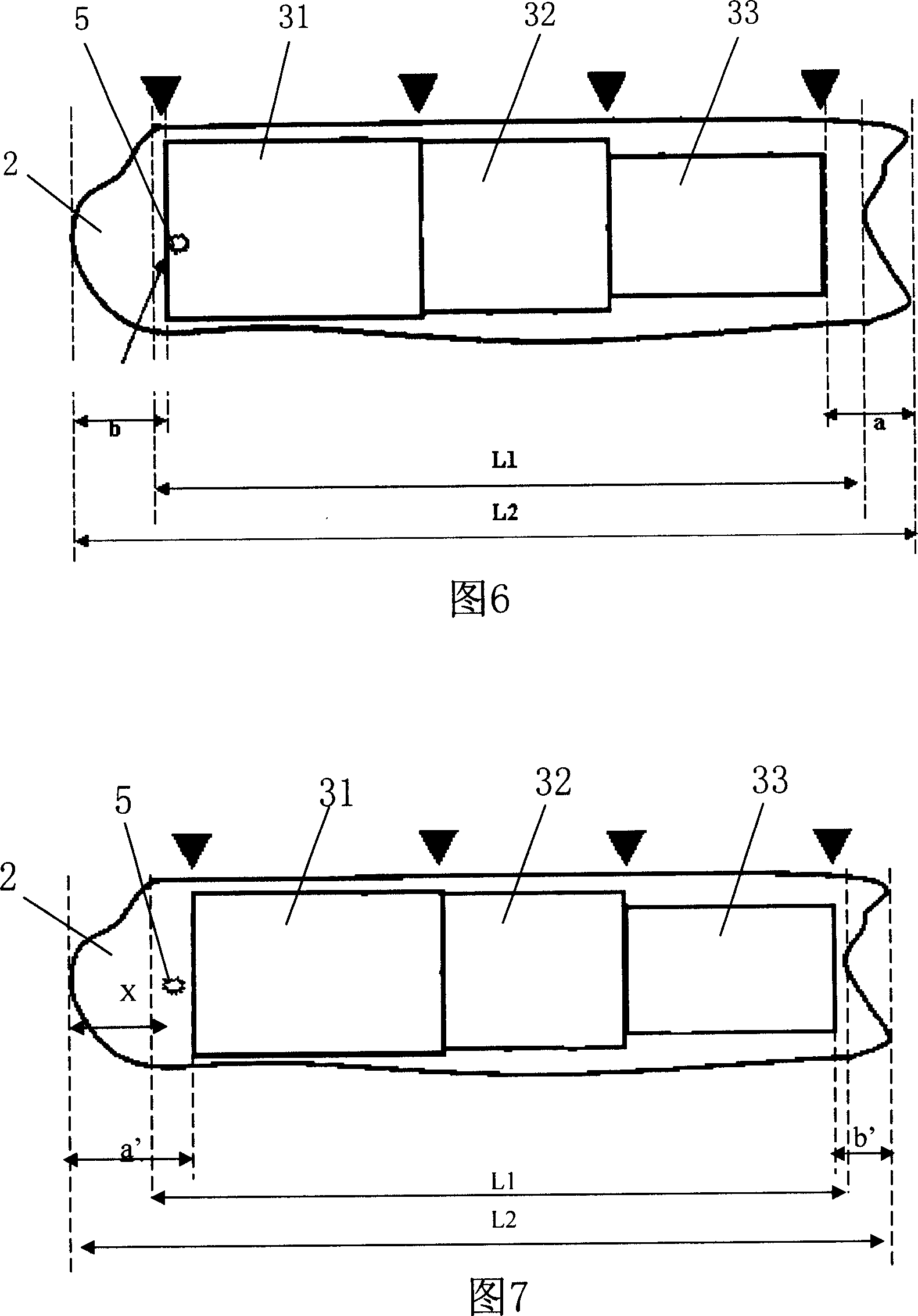

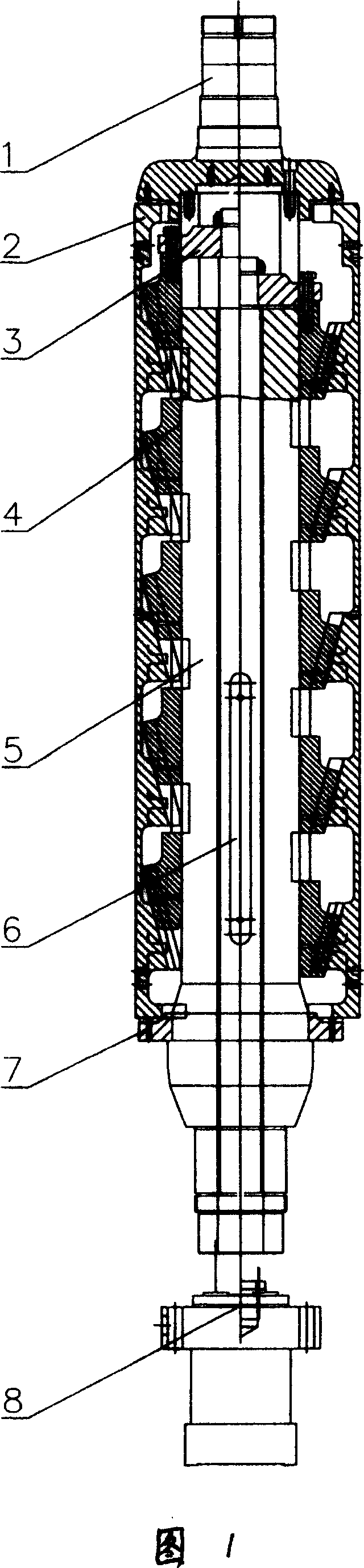

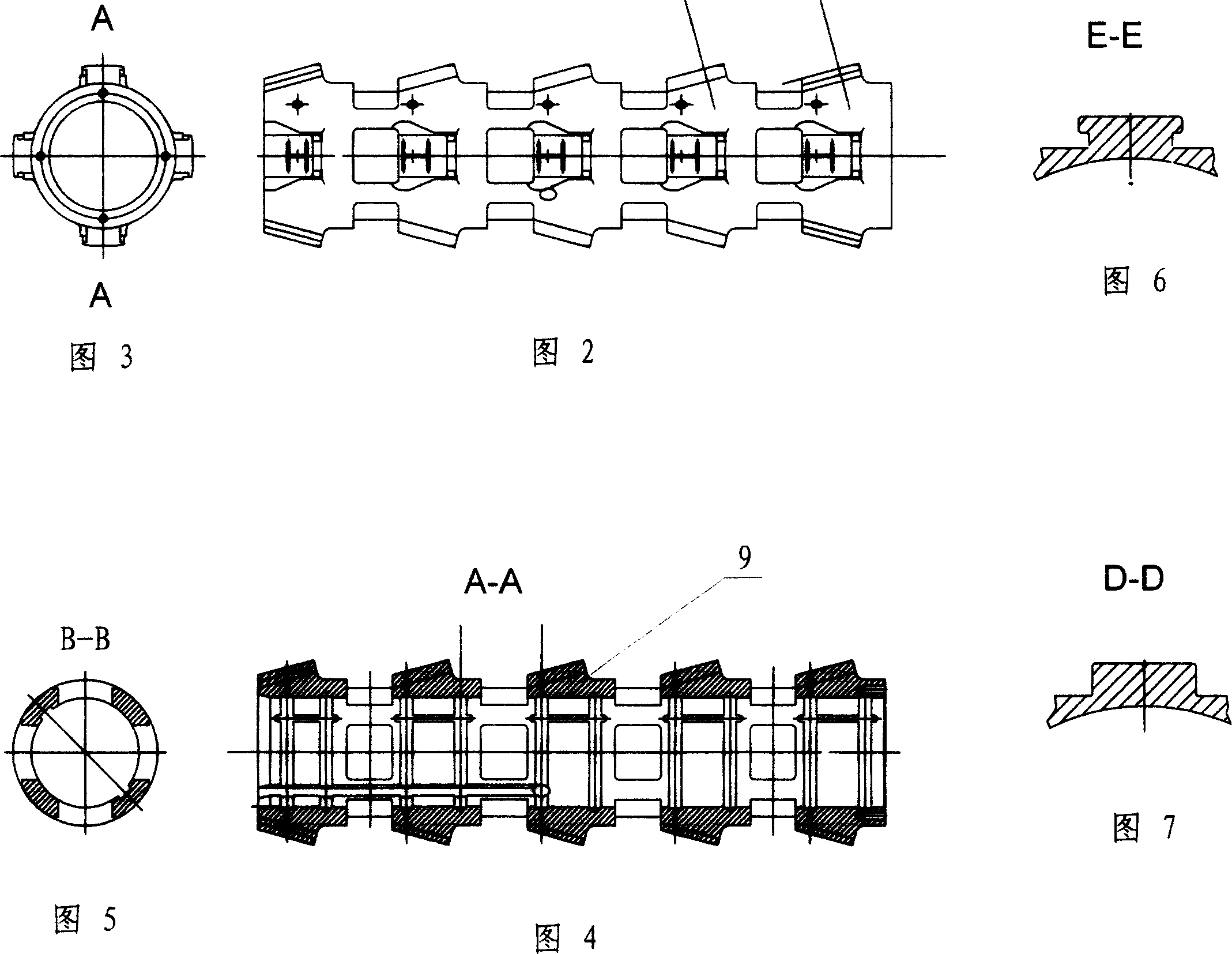

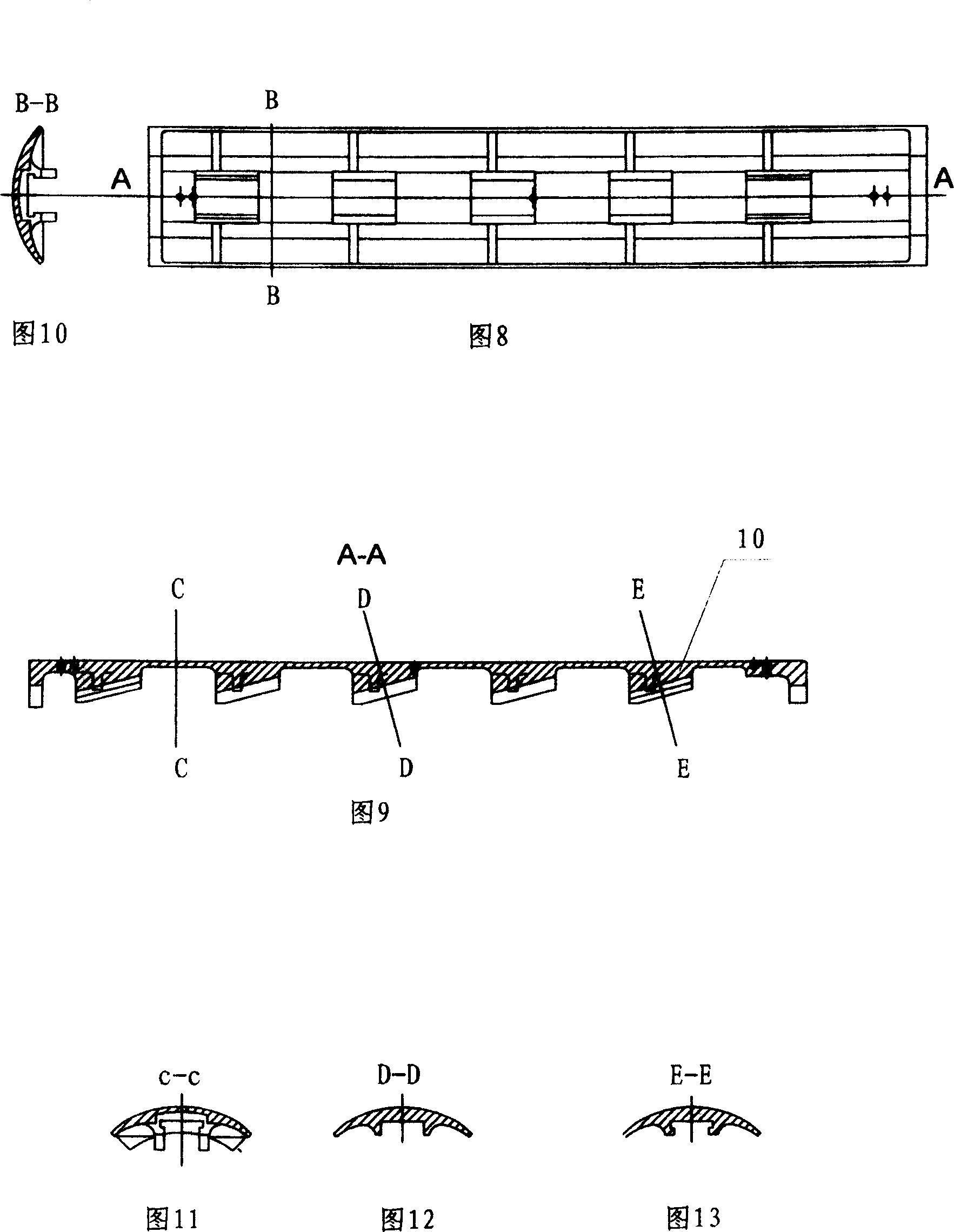

Oblique wedge type barrel arbor decoiler on flying shear line

Sloping Wedge sleeve barrel arbor decoiler on flying shear line, the invention involves cantilever axle of the transmission equipment. The sloping Wedge sleeve barrel arbor decoiler on flying shear line in the invention includes main axle, draft bar, cross cover and fixed ring, the main axle is equipped with axle sleeve, the out surface of axle sleeve is two or more conical bench installed axially or sloping wedges within same physical dimension and installed radially and uniformly, two or more bow plates in the same axle with axle sleeve cover the sloping wedges of axle sleeve, the inner surfaces of bow plates are equipped with sloping wedges corresponding with axle sleeve sloping wedges. The invention improves the original assembly sliding basement of main axle into whole sloping wedge sleeve, thereby extends main axle and can carry big tonnage roll bending. Because of extended main axle, the faying face of bow plate and inner barrel of spool is increased to forming whole face contacting, so can ensure the roll bending not torsional and distortion under the condition of self-strength is not enough in the last loops.

Owner:JIANGSU YAWEI MACHINE TOOL

Variable shear line lock cylinder

A lock cylinder is provided and includes an outer cylinder having a bore, an inner cylinder rotatably disposed within the bore, and a pin assembly disposed within the inner and outer cylinders. The pin assembly is operable to selectively lock the inner cylinder relative to the outer cylinder. The pin assembly includes an upper shear cylinder positionable relative to the outer cylinder and a lower shear cylinder positionable relative to the inner cylinder. The upper and lower shear cylinders are movable to define a first shear line therebetween. In addition, the pin assembly includes an upper pin slidable within the upper shear cylinder and a lower pin slidable within the lower shear cylinder, whereby the upper and lower pins define a second shear line therebetween. The lock cylinder is positionable from a locked position to an unlocked position when the first shear line is aligned with the second shear line.

Owner:SPECTRUM BRANDS INC

Rice and flour packaging bag

The invention discloses a rice and flour packaging bag, which comprises a bag body, lifting lugs and handle buckles, wherein the lifting lugs protrude out of the two side faces of the upper end of the bag body; the handle buckles are embedded into the central positions of the lifting lugs; a shear line is marked in the middle of a sealing port in the upper end of the bag body; and the two inner side faces of the bag body close to the lower side of the sealing port are provided with a convex clamping head and a concave clamping groove respectively. After the rice and flour packaging bag is opened along a sealing-off line, an original packaging bag is utilized to the maximum extent, resources can be saved and environmental pollution can be lowered to the maximum extent, and environmental protection is facilitated.

Owner:江苏华商企业管理咨询服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com