Billet shearing device based on image sensing and shearing method thereof

An image sensor, billet technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

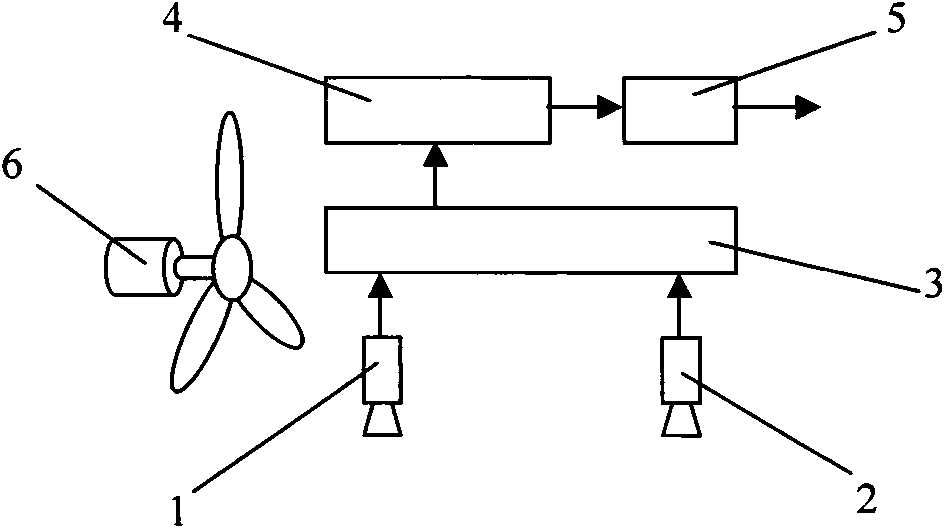

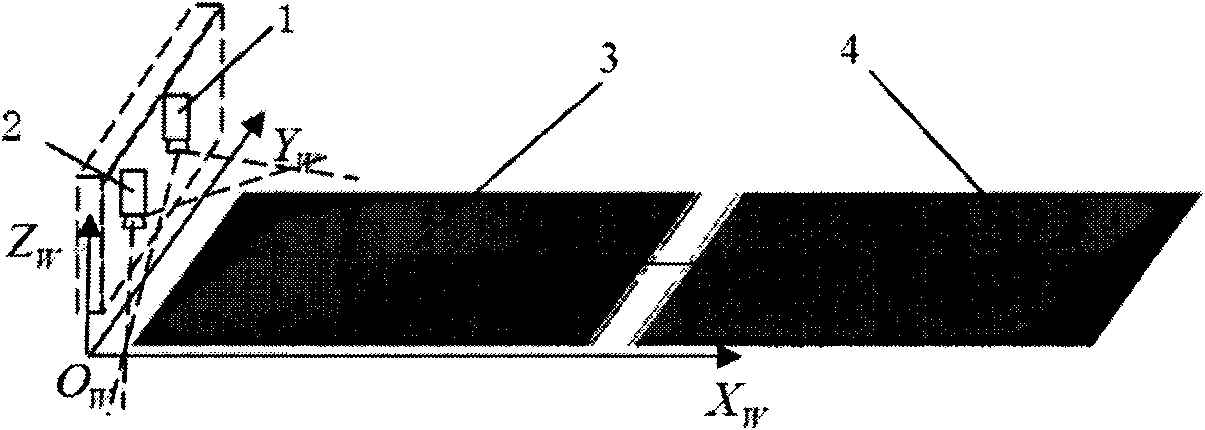

[0074] like figure 1As shown, this embodiment includes: left-eye CCD image sensor 1, right-eye CCD image sensor 2, image processing module 3, image recognition module 4, drive module 5 and cooling mechanism 6, wherein: left-eye CCD image sensor 1 and right-eye CCD image sensor 2. Arranged side by side at the front end 2m of the cutting opening of the thermal bonding shearing machine. The output interfaces of the left-eye CCD image sensor 1 and the right-eye CCD image sensor 2 are connected to the input interface of the image processing module 3, and the output interface of the image processing module 3 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com