High-speed scanning and overall imaging three-dimensional (3D) measurement method

A technology of overall imaging and three-dimensional measurement, applied in the field of visual inspection, can solve the problems of inability to meet the measurement speed of online production, slow measurement speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

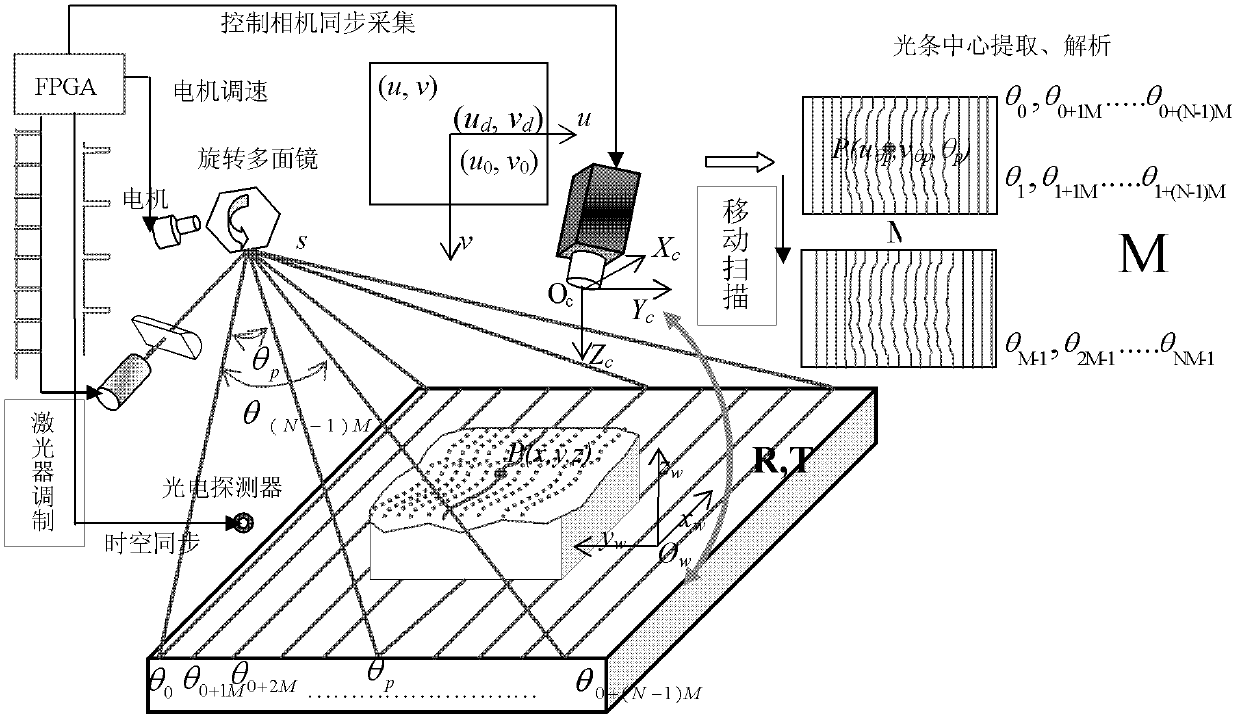

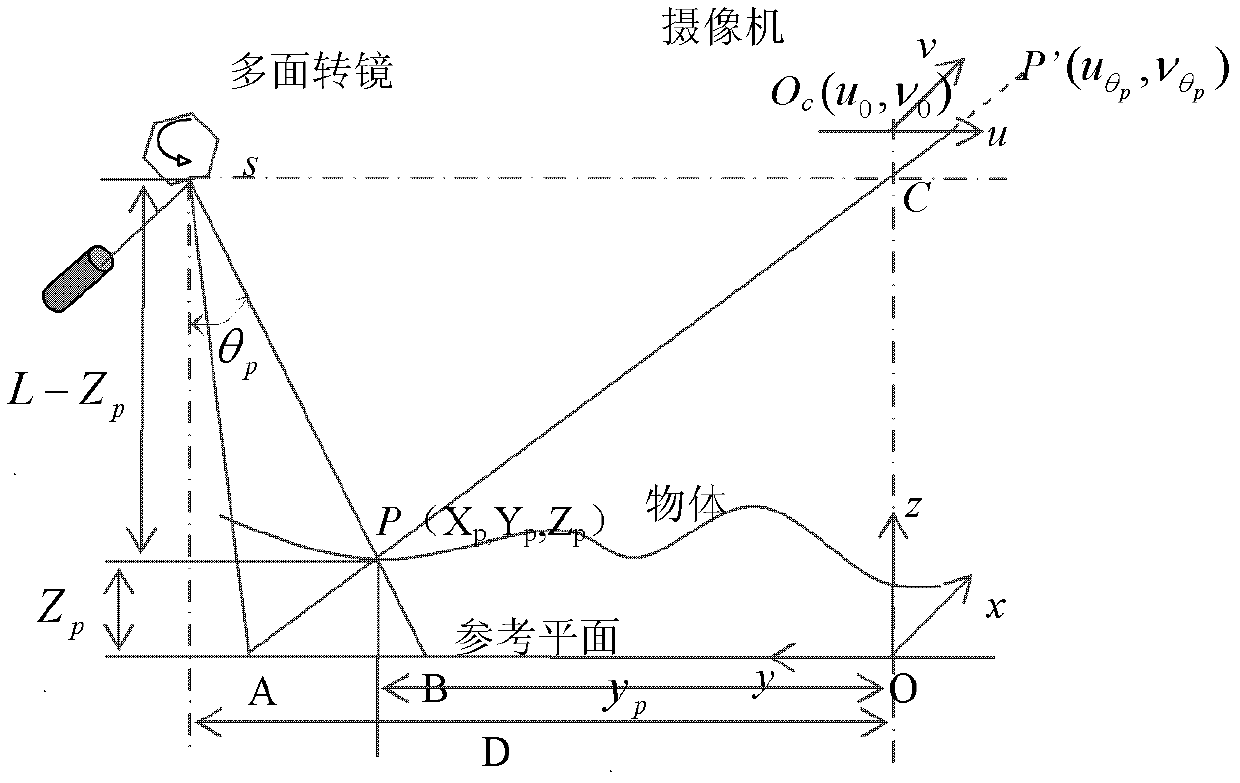

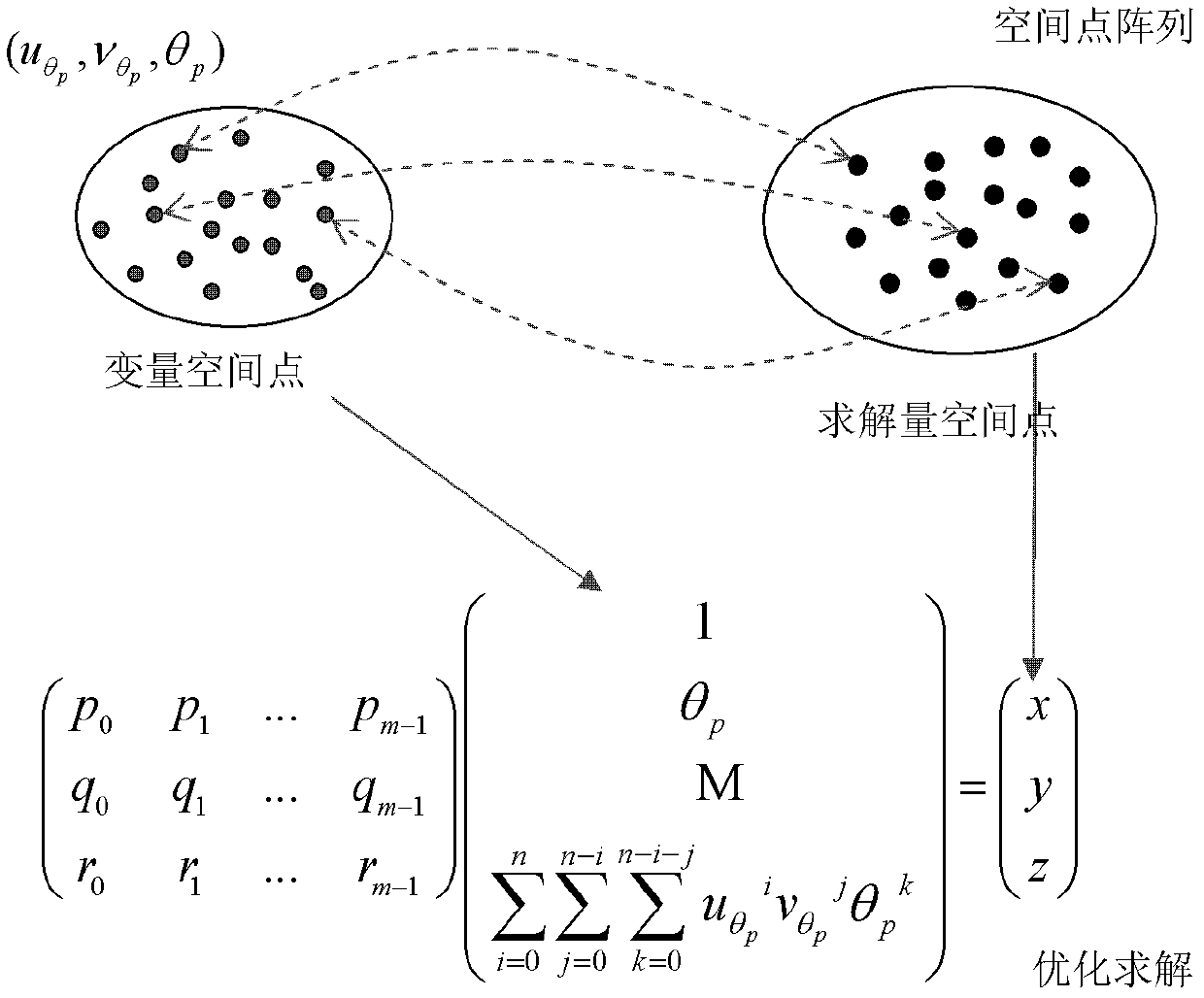

[0045] In order to achieve the research goal of the system's high-speed measurement of the three-dimensional topographical characteristics of the surface of the measured object, the present invention adopts the overall measurement method of high-speed structured light scanning and overall imaging of the area array CCD. The measurement system to be built is attached figure 1 As shown, the whole system consists of a laser, a rotating polygonal prism, an area array CCD, and a photodetector. First, surface structured light is formed by high-speed scanning of line structured light. The output of a word-line laser is controlled by using an external modulation driving power supply of the laser, and the stroboscopic line structured light is output by controlling the modulation frequency of the driving power supply. The polygonal prism rotates under the drive of a high-speed motor, reflecting the line-structured light output by the laser and projecting it onto the surface of the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com