Polyurethane composite thermal insulation board, manufacturing method and application of the same

A composite thermal insulation and manufacturing method technology, applied in thermal insulation, chemical instruments and methods, building structures, etc., can solve the problems of complicated construction procedures, long construction period, toxic smoke, etc., and achieve good thermal insulation performance, thermal insulation Good thermal effect, high fire and flame retardancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

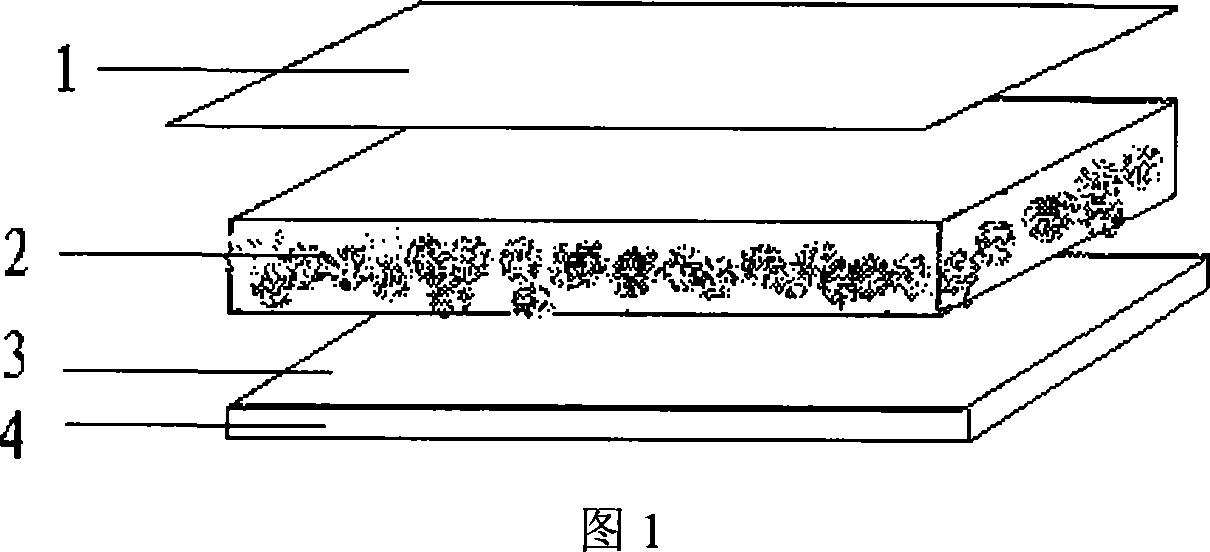

Image

Examples

Embodiment 1

[0028]The calcium silicate board with a thickness of 3mm is used as an inorganic material composite board to be preheated in an oven at 80°C. After preheating, the phenolic polyurethane adhesive is applied. 20mm) poured on it, and enter the composite insulation board continuous production line together with the aluminum foil paper as the protective surface layer for room temperature foaming and curing (Note: A layer of plastic film must be placed under the calcium silicate board when entering the production line for foaming and curing , to prevent the composite material and foam from leaking out), and finally cut into a certain length of composite board according to the specifications and trim it for packaging. This product is used in roof insulation, and the aluminum foil on its upper surface also has a reflective function, which can reflect most of the sunlight back and make the insulation effect better. According to mass ratio, polyether polyol or polyester polyol: catalyst...

Embodiment 2

[0030] The glass magnesium board with a thickness of 5mm is used as an inorganic material composite board to be preheated in an oven at 80°C. After preheating, the phenolic polyurethane adhesive is applied. 50mm) is poured on it, and together with the aluminum foil paper as the protective surface layer, it enters the composite insulation board continuous production line for foaming and curing (note: when entering the production line for foaming and curing, a layer of plastic film must be placed under the glass magnesium board to prevent combination Material and foam leakage), and finally cut into a certain length of composite board according to the specifications and trimmed and packaged. This product is used in roof insulation, and the aluminum foil on its upper surface also has a reflective function, which can reflect most of the sunlight back and make the insulation effect better. According to mass ratio, polyether polyol or polyester polyol: catalyst: surfactant: foaming a...

Embodiment 3

[0032] The 8mm thick magnesite board is used as an inorganic material composite board to be preheated in an oven at 80°C. After preheating, the phenolic polyurethane adhesive is applied. 80mm) is poured on it, and together with the aluminum foil paper as the protective surface layer, it enters the composite insulation board continuous production line for foaming and curing (note: when entering the production line for foaming and curing, a layer of plastic film must be placed under the magnesite board to prevent combination Material and foam leakage), and finally cut into a certain length of composite board according to the specifications and trimmed and packaged. This product is used in roof insulation, and the aluminum foil on its upper surface also has a reflective function, which can reflect most of the sunlight back and make the insulation effect better. According to mass ratio, polyether polyol or polyester polyol: catalyst: surfactant: foaming agent: flame retardant 1: f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com