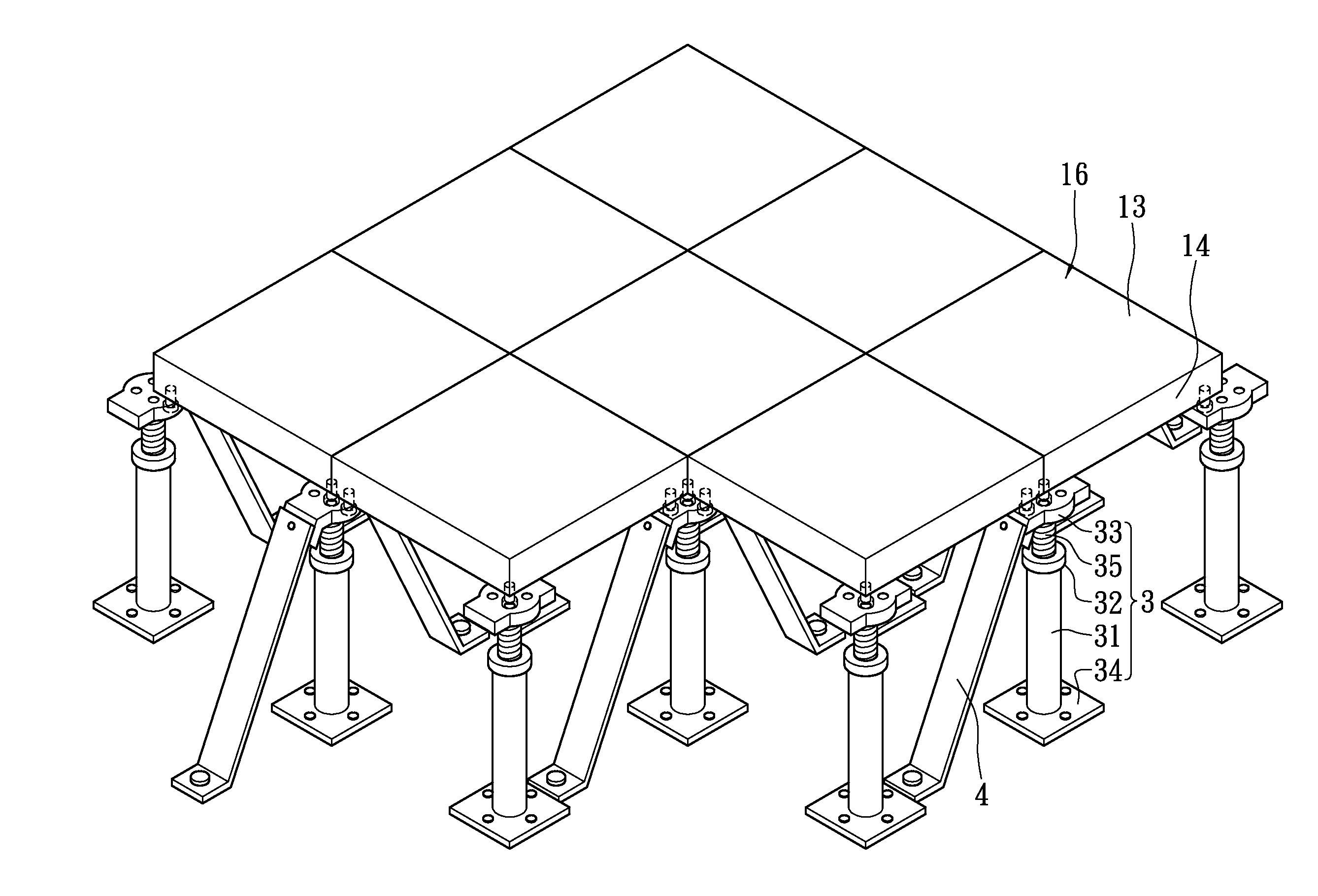

Method for manufacturing a side-folded type elevated floor and a system thereof

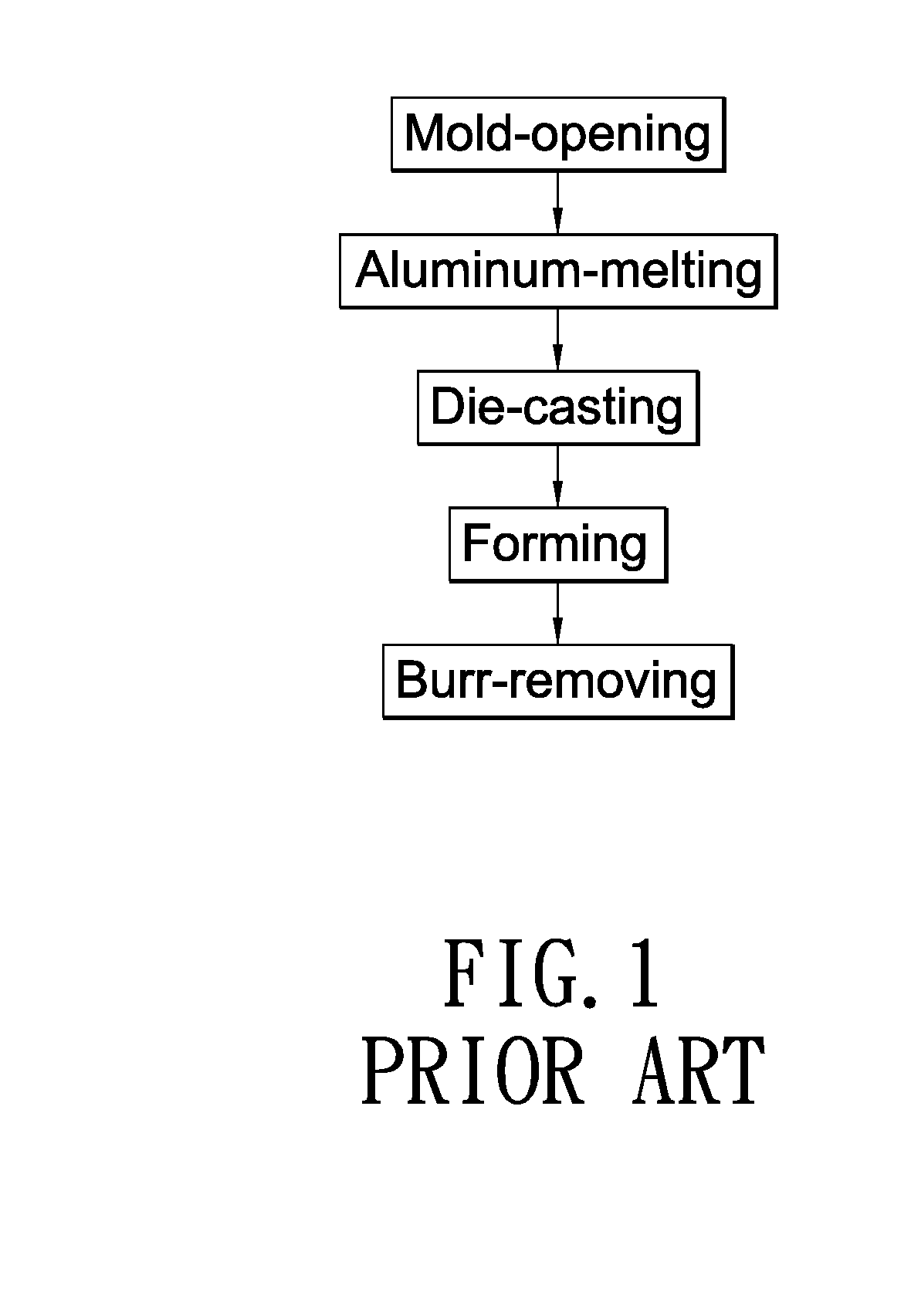

a manufacturing method and elevated floor technology, applied in the field of elevated floors, can solve the problems of uneconomical use of elevated floors made of aluminum alloy, not meeting the requirements of saving energy, and consumption of energy, and achieve the effects of less energy consumption, accurate dimensions, and simple manufacturing method of the present invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

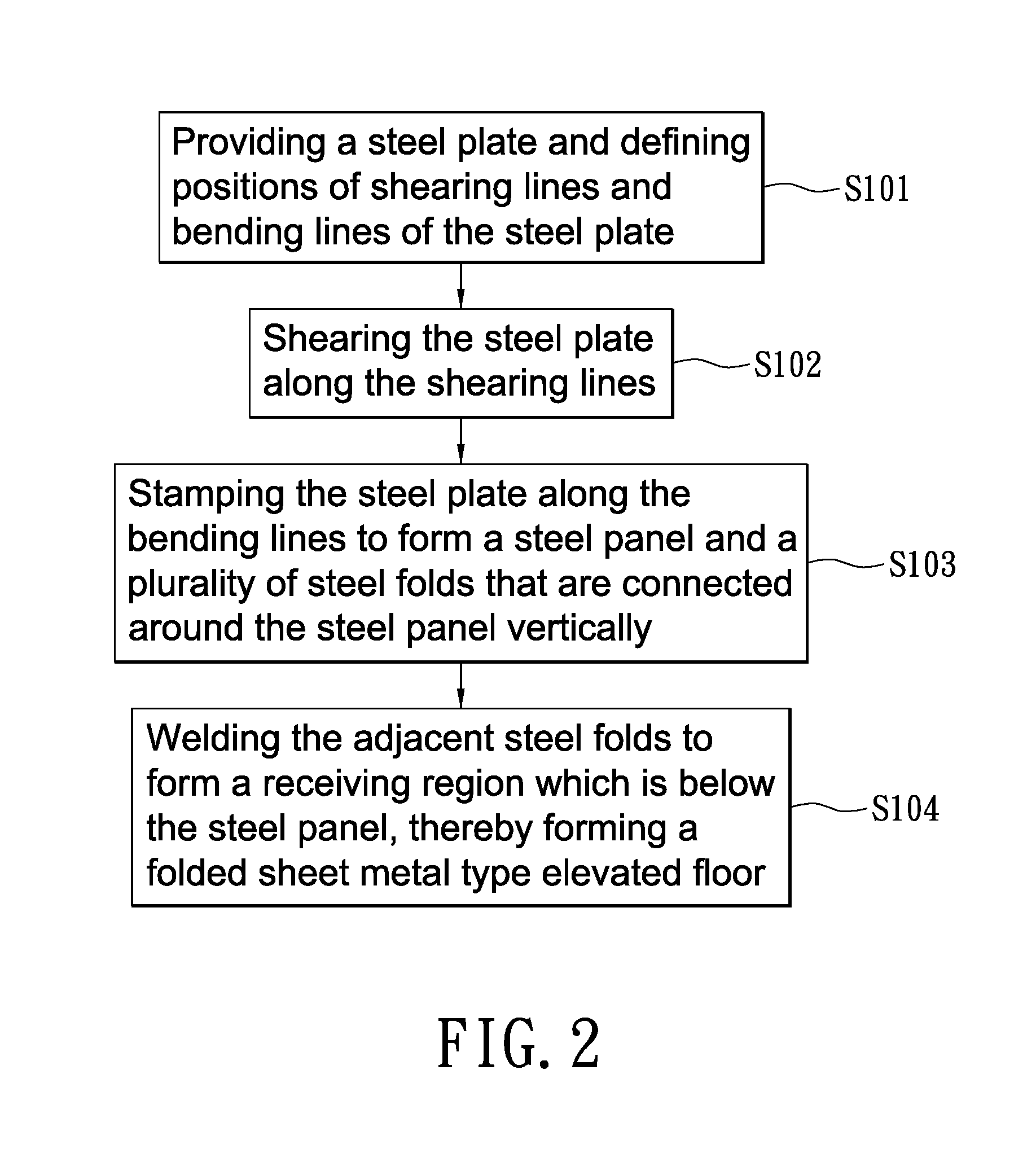

[0021]Please refer to FIGS. 2 to 5. The present invention is to provide a method for manufacturing a side-folded type elevated floor, which includes the steps of S101 to S104.

[0022]In the step S101, a square steel plate 1 is provided, and the positions of shearing lines 11 and bending lines 12 are defined (FIG. 3). In the present embodiment, there are four shearing lines 11 and four bending lines 12. Each of the bending lines 12 is separated from one side of the steel plate 1 by a distance respectively and these bending lines 12 are parallel to each other. One end of each shearing line 11 is connected to the intersection of the respective bending lines 12, while the other end is perpendicular to one side of the steel plate 1.

[0023]In the step S102, the steel plate 1 is sheared along the shearing lines 11.

[0024]In the step S103, the steel plate 1 is stamped along the bending lines 12, thereby forming a steel panel 13 and a plurality of steel folds 14 that are connected around the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com