Middle thick plate production line and production method

A production method and production line technology, applied in the field of metallurgical steel rolling, can solve problems such as unfavorable and flexible organization of production, affecting the use efficiency of cooling beds, affecting production efficiency, etc., to reduce the average amount of shearing waste, alleviate the influence of constraints, and improve the use efficiency. Effect

Inactive Publication Date: 2017-01-25

CERI TECH +1

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this arrangement, all steel plates entering the shear line from the main rolling line must pass through the cooling bed area, and the main problem is that the length of the rolled piece is affected by the width of the cooling bed (the expansion of the cooling bed width is affected by plant design and investment restrictions), which is not conducive to flexible orga

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

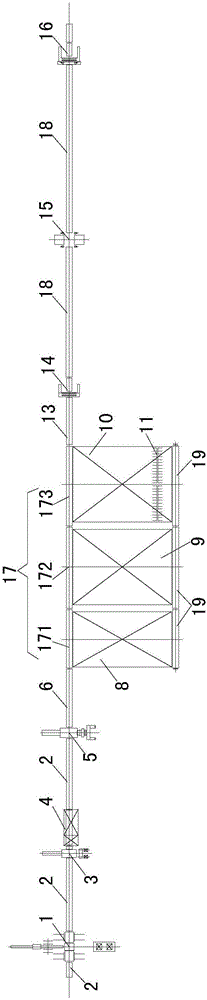

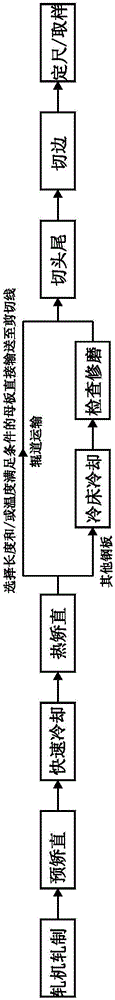

The invention provides a middle thick plate production line and a production method. The middle thick plate production line comprises a main rolling line comprising a main rolling line output roller, a shear line comprising a shear line input roller and a middle roller arranged between the main rolling line and the shear line, and the middle roller is linearly connected with the main rolling line output roller and the shear line input roller respectively. The main rolling line and the shear line are directly connected by virtue of the middle roller, a motherboard produced by the main rolling line can directly pass through the middle roller and enters the shear line to be sheared, the yield can be increased, and the quantity of the motherboards entering a cooling bed component can be reduced, so that the service efficiency of the cooling bed is improved, and the production efficiency of the middle thick plate production line is further improved.

Description

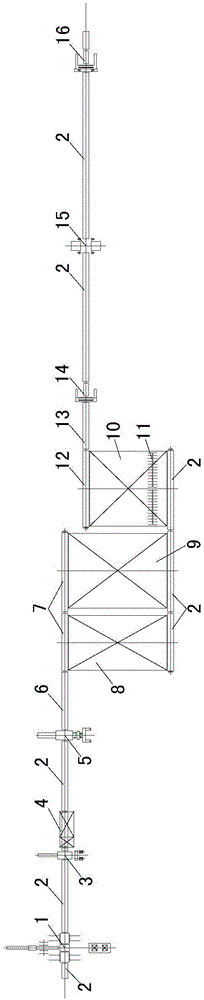

technical field [0001] The invention relates to the technical field of metallurgical steel rolling, in particular to a medium-thick plate production line and a production method. Background technique [0002] The medium and heavy plate rolling workshop is generally composed of plate processing area, main rolling area, cooling bed area, shearing line and finishing area. The steel plate is heated in the plate adding area, and after rolling and other processes are completed in the main rolling area, it enters the cooling bed area to cool as required, and then enters the shearing line to complete the shearing process. Such as figure 1 As shown, the medium and heavy plate rolling workshop in the prior art generally has the following components: a rolling mill 1, a roller table 2, a pre-leveler 3, a rapid cooling device 4, a hot straightener 5, and a main rolling line output roller table 6 ( Hot straightening machine output roller table), cooling bed area input roller table 7, c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B1/22B21B38/00B21B43/04B21B15/00

CPCB21B1/22B21B15/0007B21B38/00B21B43/003B21B43/04

Inventor 曹建宁韩文熊明鲜苏洸

Owner CERI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com