Hot rolled steel coil transversely shearing line online flaw detecting device and method

A technology for flaw detection devices and hot-rolled steel coils, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, and can solve the problems of no data acquisition and automatic control devices, difficulty in covering the steel plate surface, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

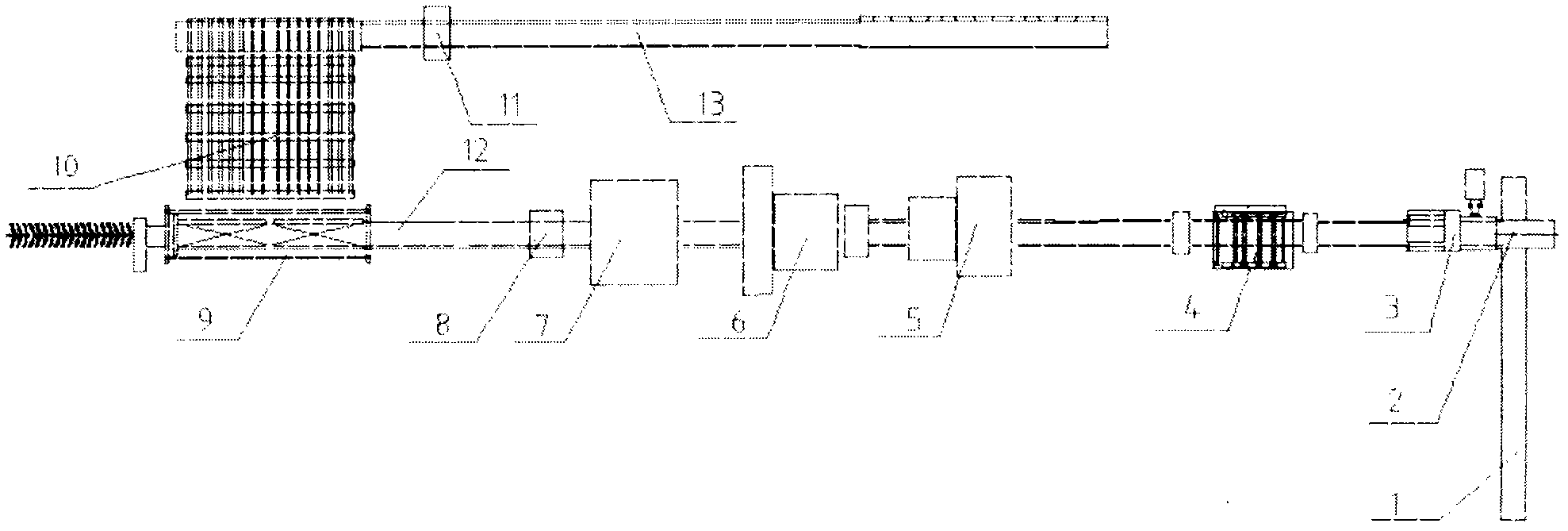

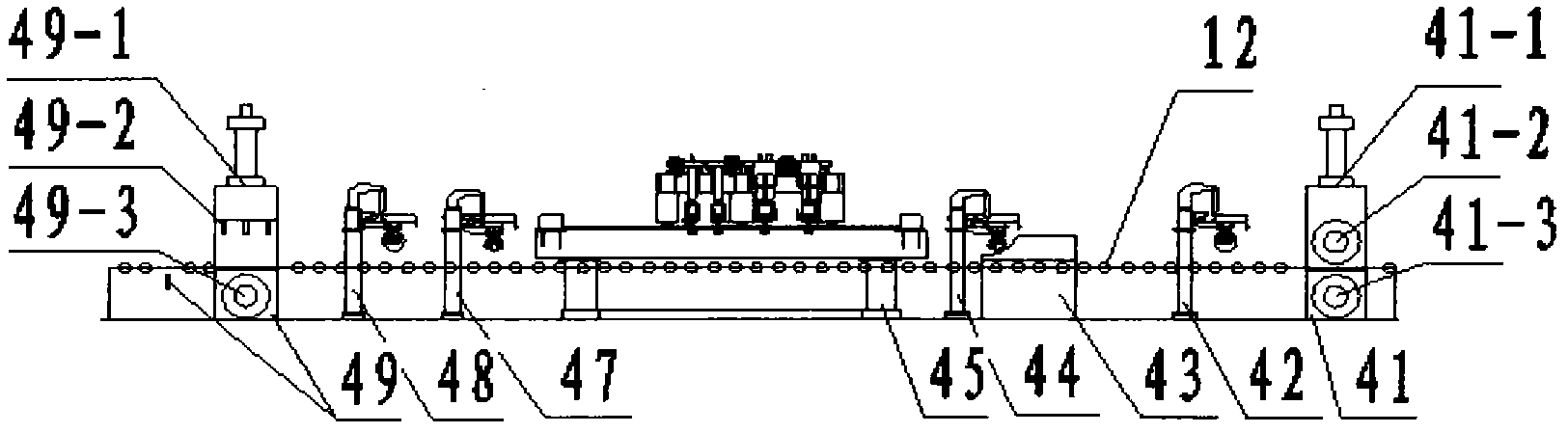

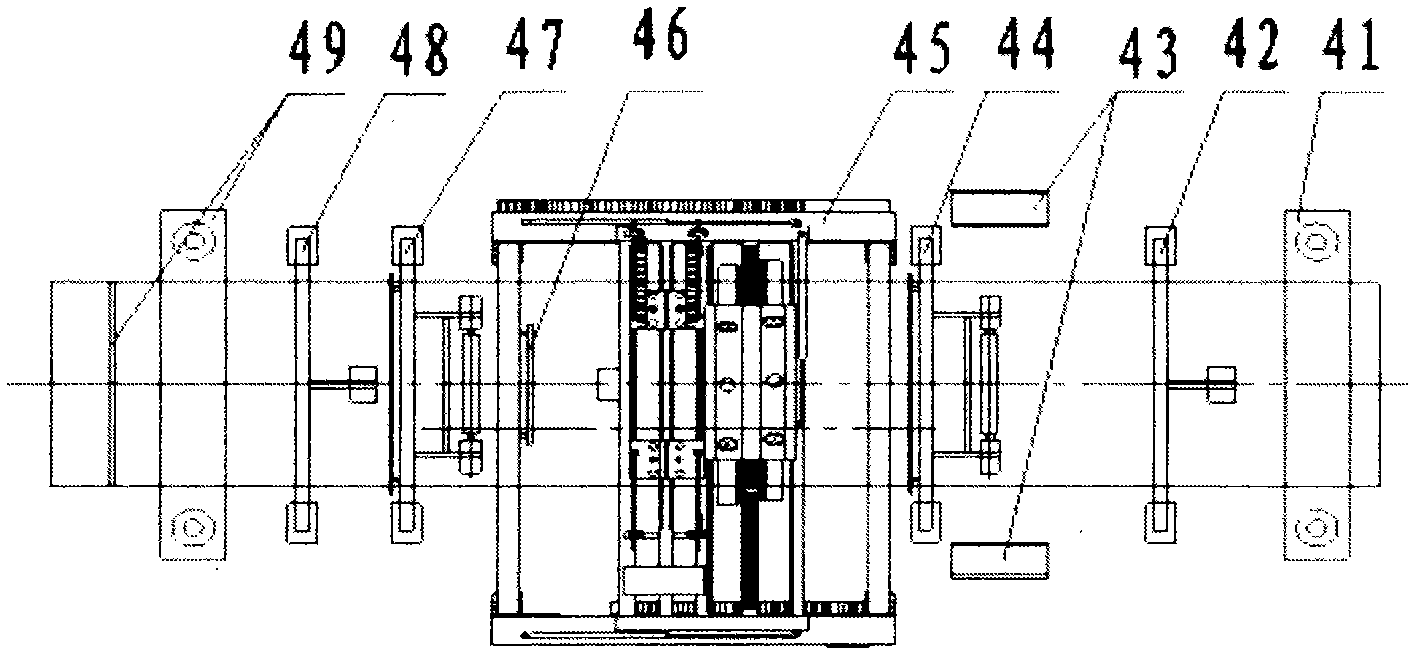

[0073] Depend on figure 1 , figure 2 , image 3 It can be seen that the on-line flaw detection device for the cross-cutting line of hot-rolled steel coils consists of a walking beam 1, an uncoiler 2, a coil straightening machine 3, an ultrasonic flaw detection device 4, a disc shear 5, a flying shear 6, and a steel plate straightening machine 7 , inkjet printing machine 8, stacking table 9, plate stacking conveyor 10, and strapping machine 11 are sequentially connected through conveying roller table 12 and unloading conveying roller table 13 to form a hot rolling crosscutting line. The pinch roller 41 above the transport roller table 12, the entrance length measuring mechanism 42, the width measuring mechanism 43, the entrance water retaining mechanism 44, the flaw detection mechanism 45, the wiper blade 46, the exit water retaining mechanism 47, the exit length measuring mechanism 48 and the exit The purging mechanism 49 is connected sequentially.

[0074] Depend on fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com