Patents

Literature

64results about "V-belt fastenings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

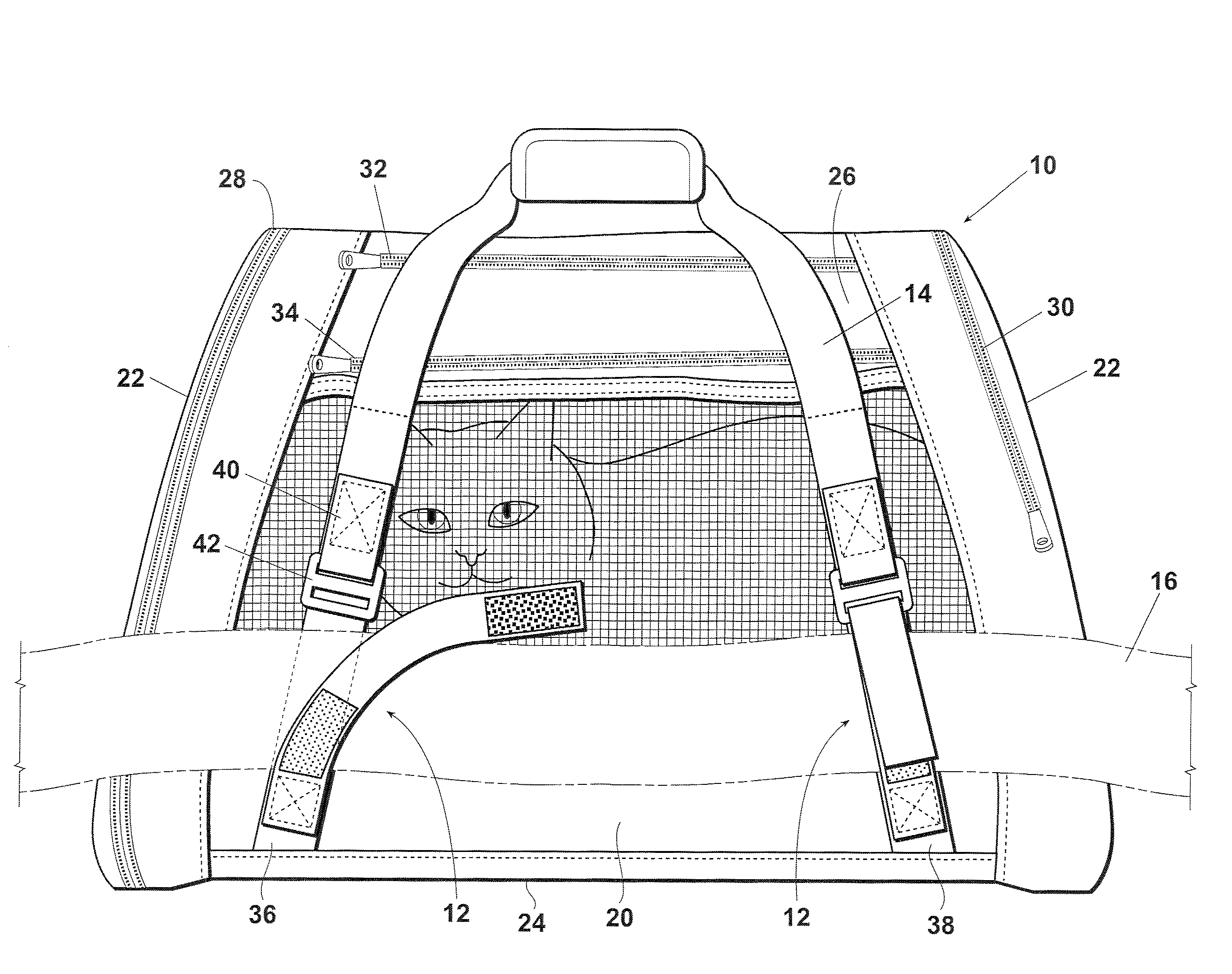

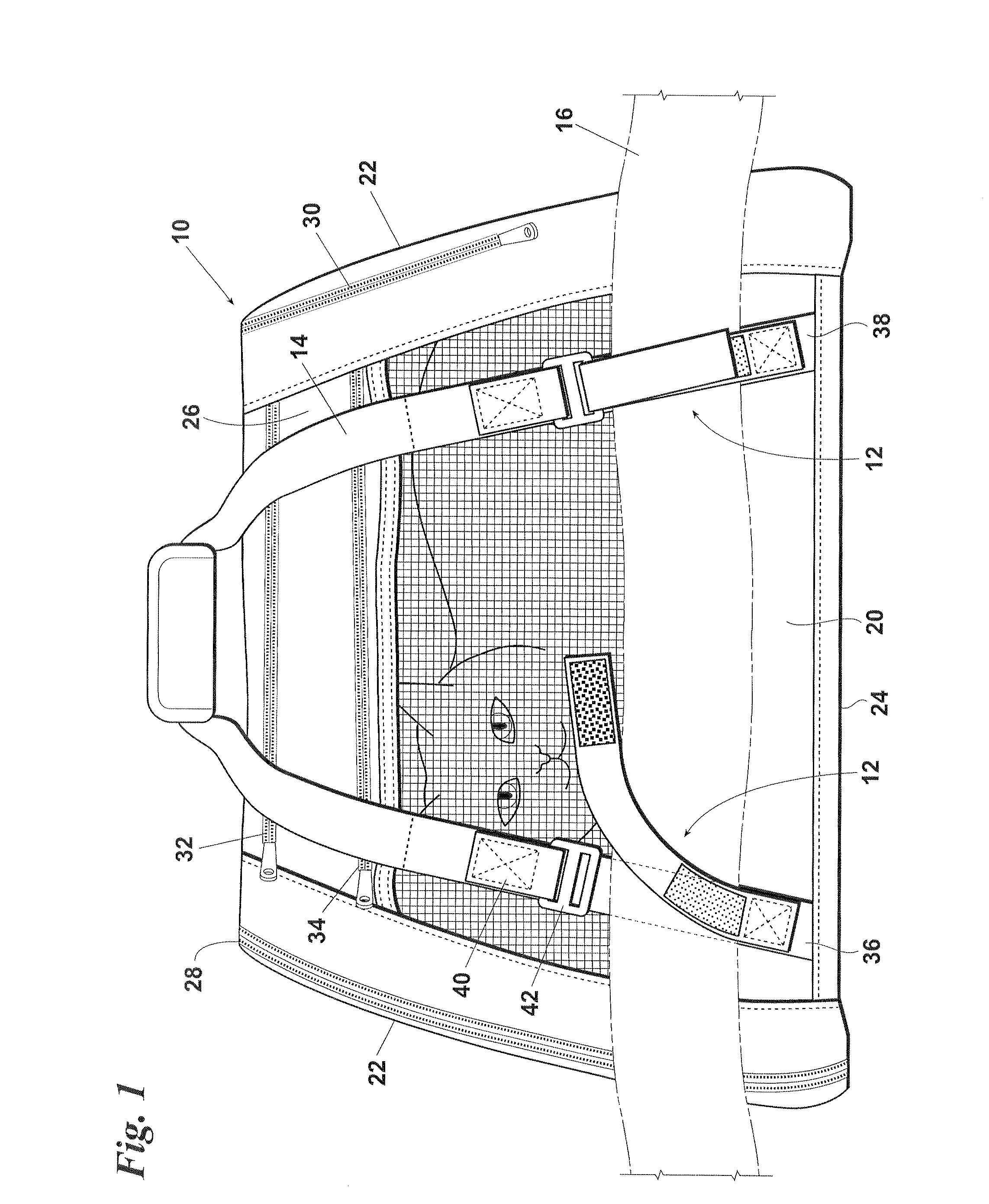

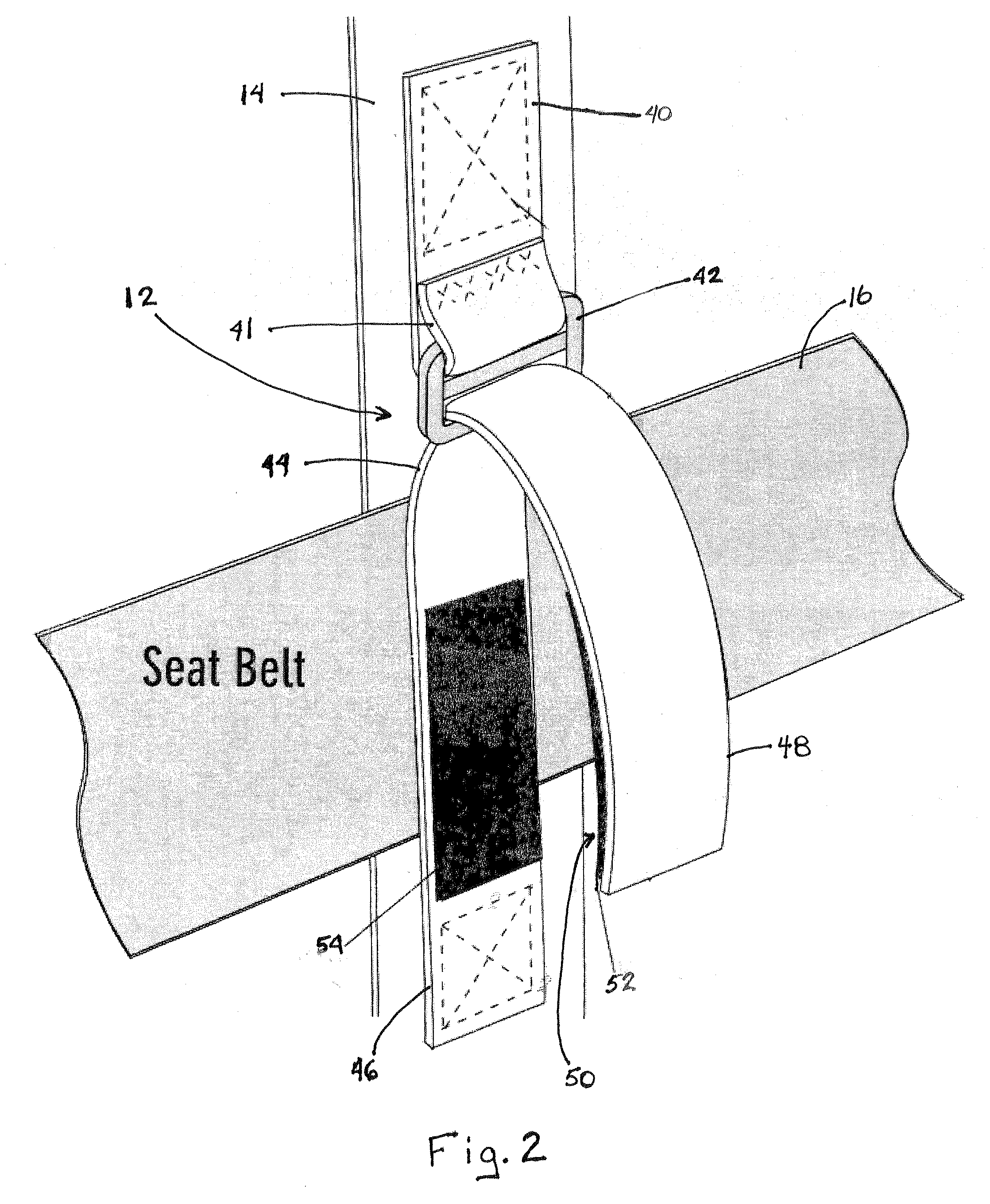

Seat belt loop system for a pet carrier

InactiveUS20100000472A1Prevent movementAvoid playingV-belt fasteningsBelt fasteningsMobile vehicleSeat belt

A seat belt loop system for use with an animal / pet carrier in order to transport an animal in a moving vehicle. The seat belt loop system includes an anchor tab coupled to the pet carrier, a cinch strap coupled to the anchor tab, and cinch strap with a proximal end coupled to the pet carrier and a distal end for insertion through the cinch loop. Once inserted, the distal end is cinched against the cinch loop and then coupled to the cinch strap. A fastening mechanism on the cinch strap is engaged to retain a vehicle seat belt between the pet carrier and the seat belt loop.

Owner:BERGAN

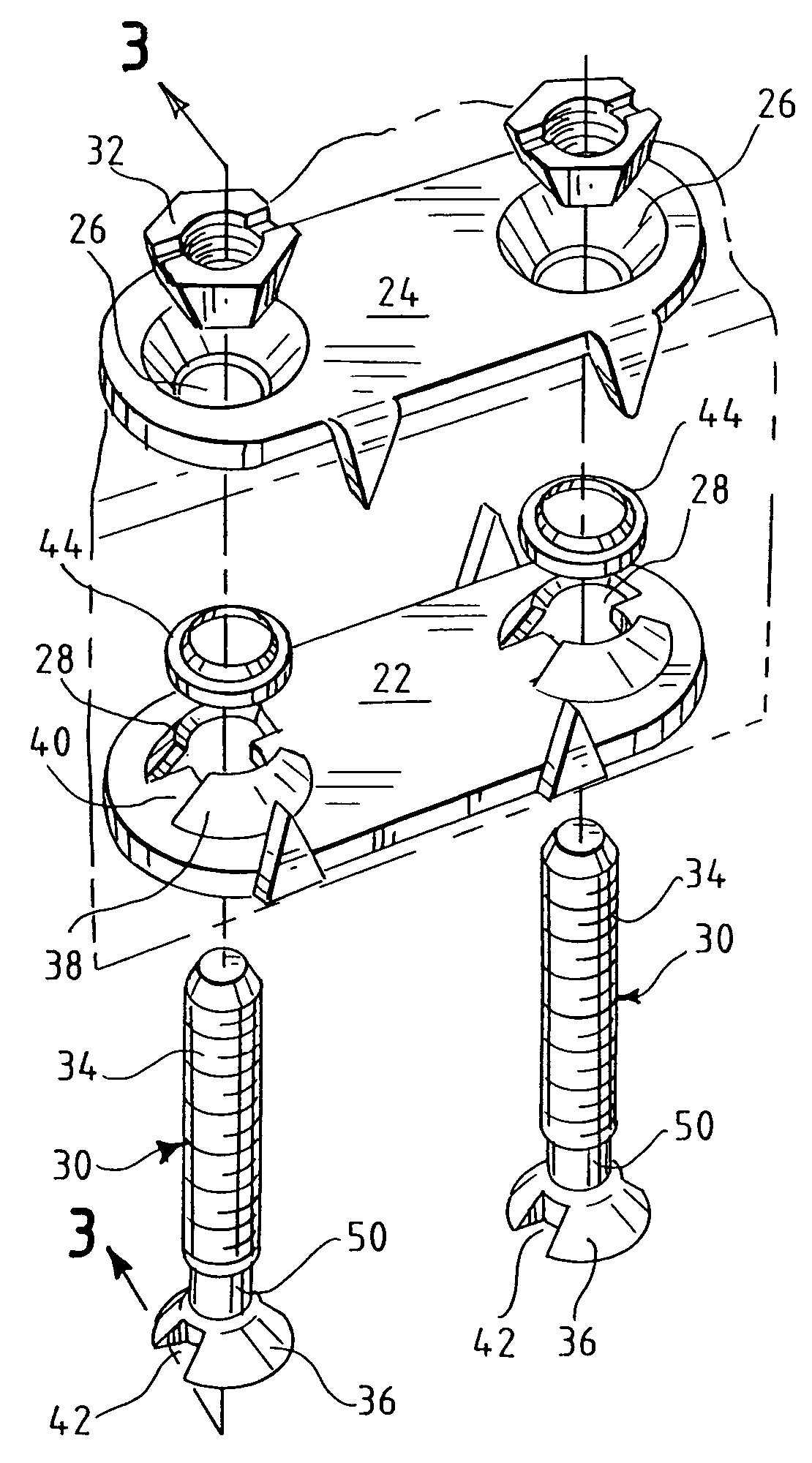

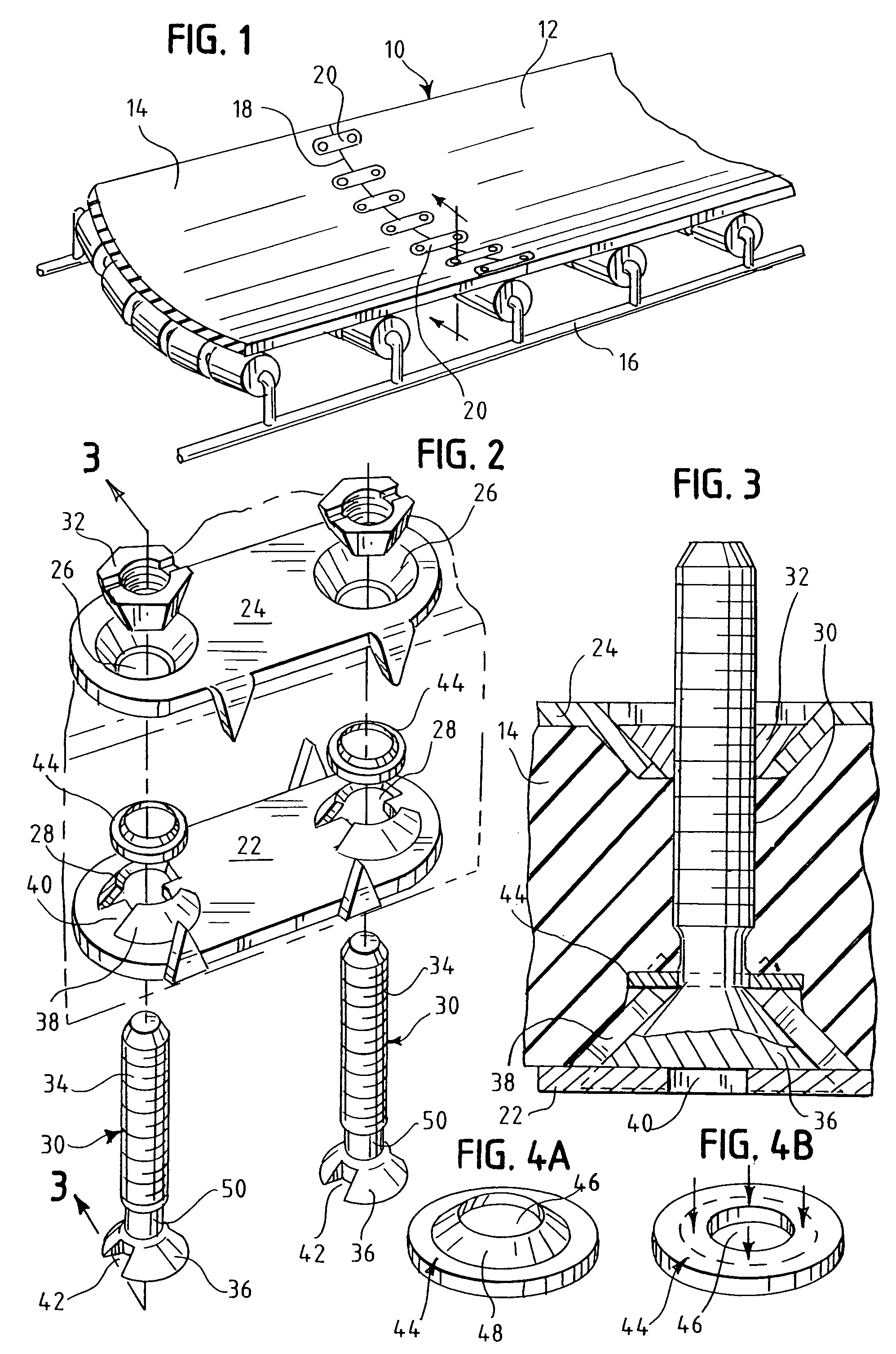

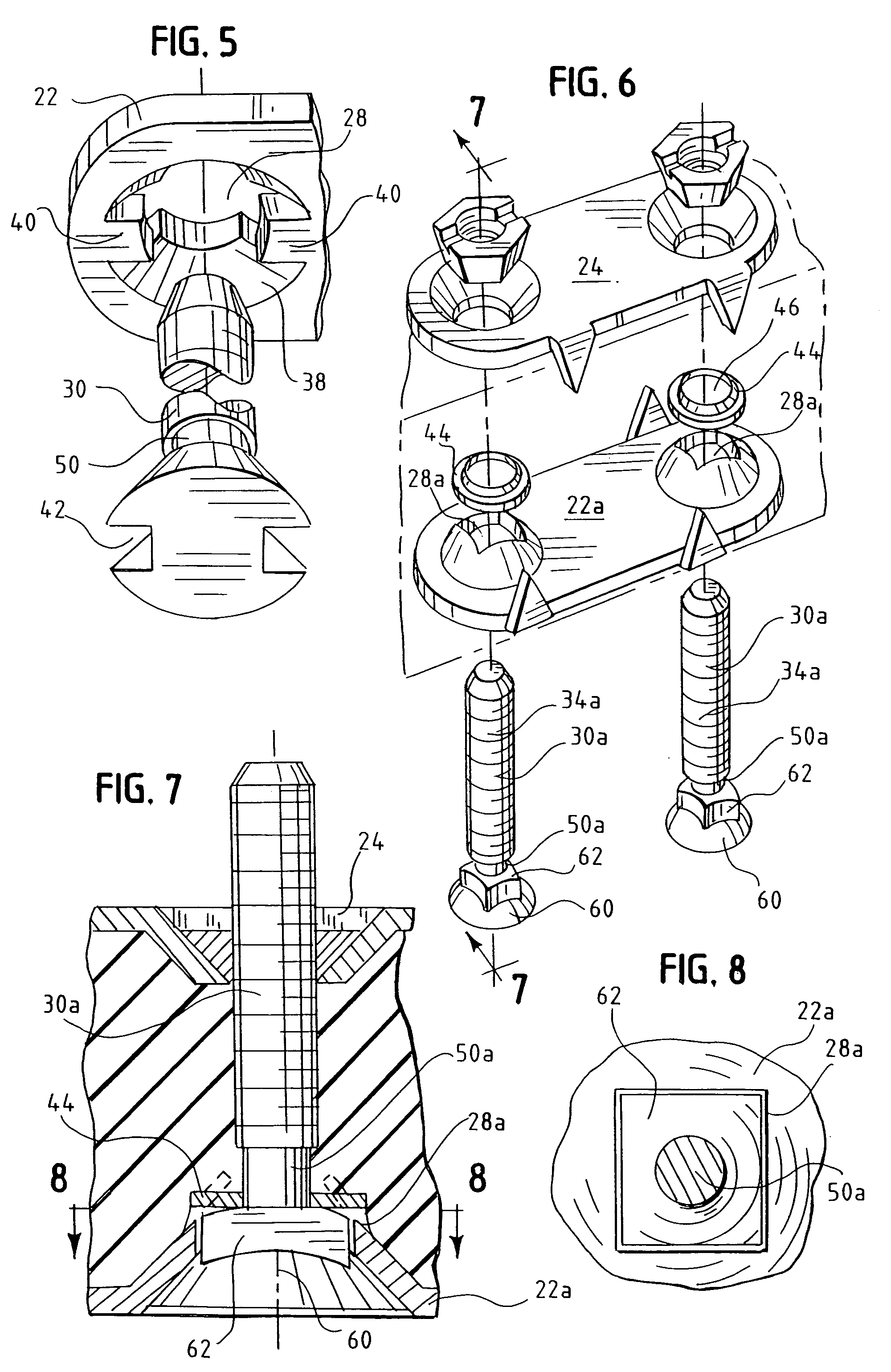

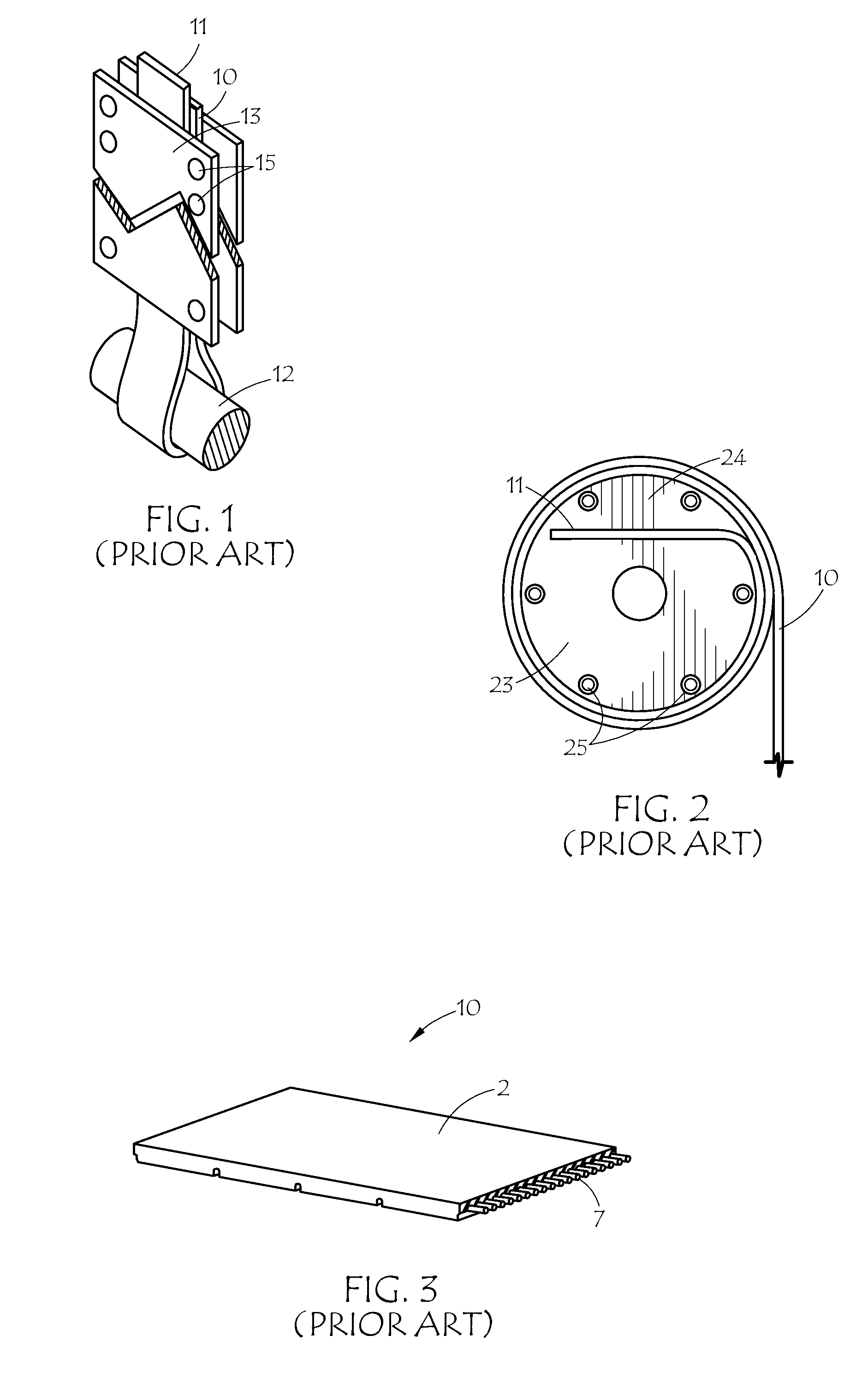

Belt fastener assembly

A belt fastener assembly for fastening belt ends together comprises: first and second retention plates receiving and retaining substantially abutting belt ends between the plates, and defining a plurality of bolt holes. A plurality of threaded bolts each extend through a bolt hole of each of the first and second plates and also extend through portions of the belt positioned between the plates, to retain the first and second plates and the belt ends together, with nuts carried on the bolts. Washers are also carried on the bolts, each having an aperture and having, in an original condition prior to use, a frustoconical inner area surrounding the aperture to enlarge the aperture to a size of at least the outer diameter of the bolt threads. This facilitates placement of the washers on the bolts. Then, the washers may be flattened to decrease the size of the apertures, to retain the bolts in position extending through a retention plate prior to full assembly.

Owner:CONVEYOR ACCESSORIES

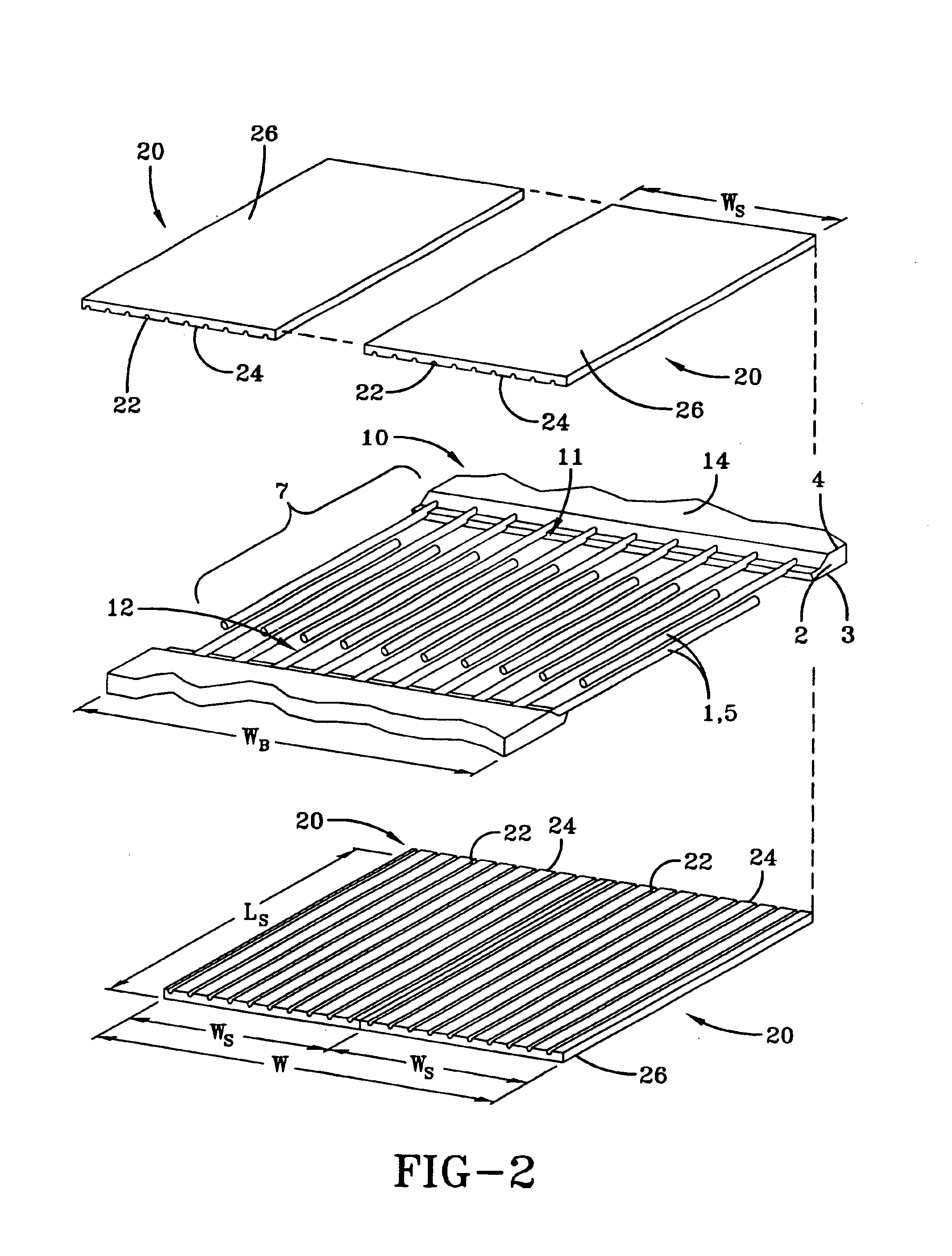

Seamed, conformable belt and method of making

InactiveUS7052426B2Eliminates “ bump ”Easy to replaceV-belt fasteningsV-beltsElectrical and Electronics engineering

Owner:XEROX CORP

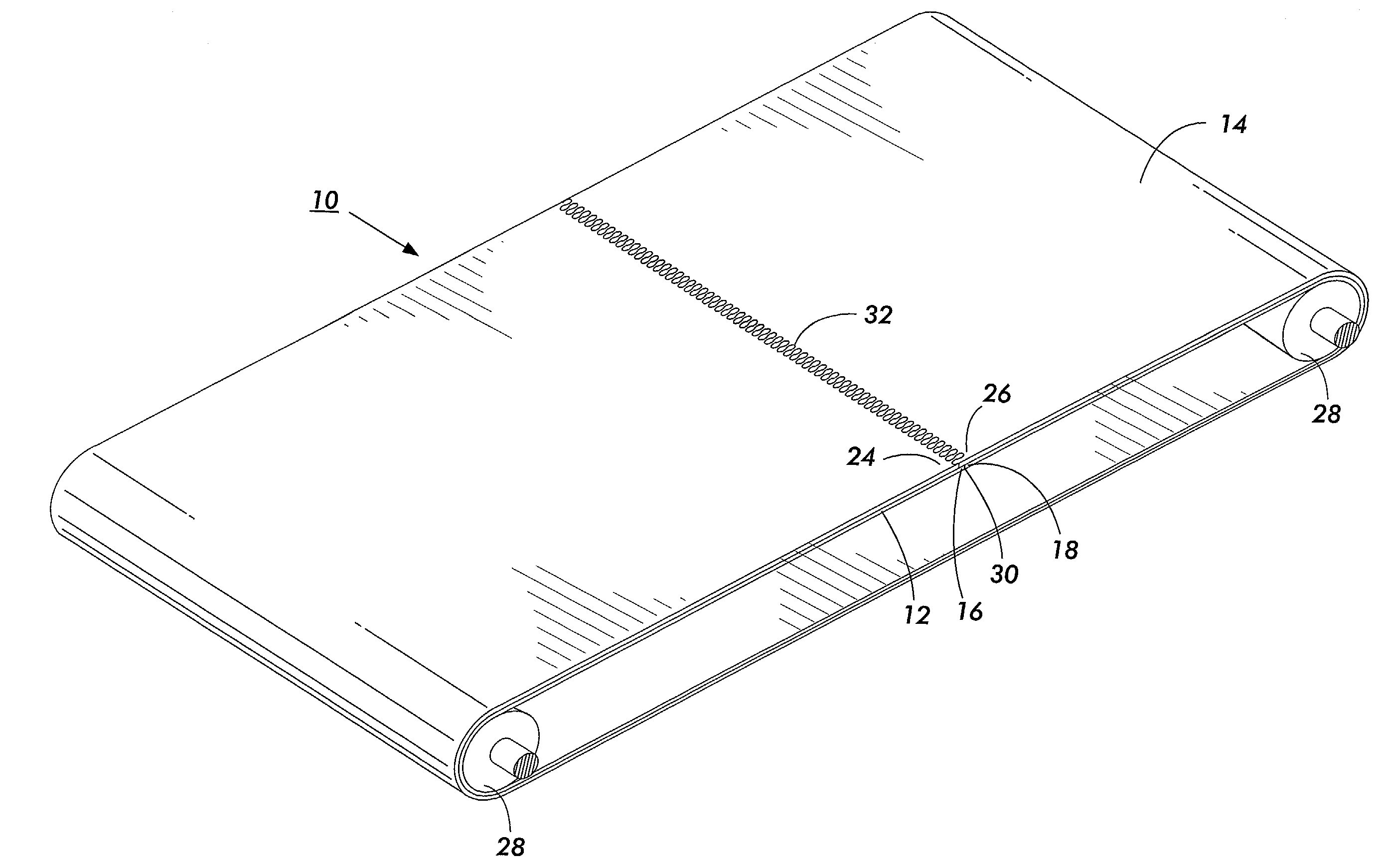

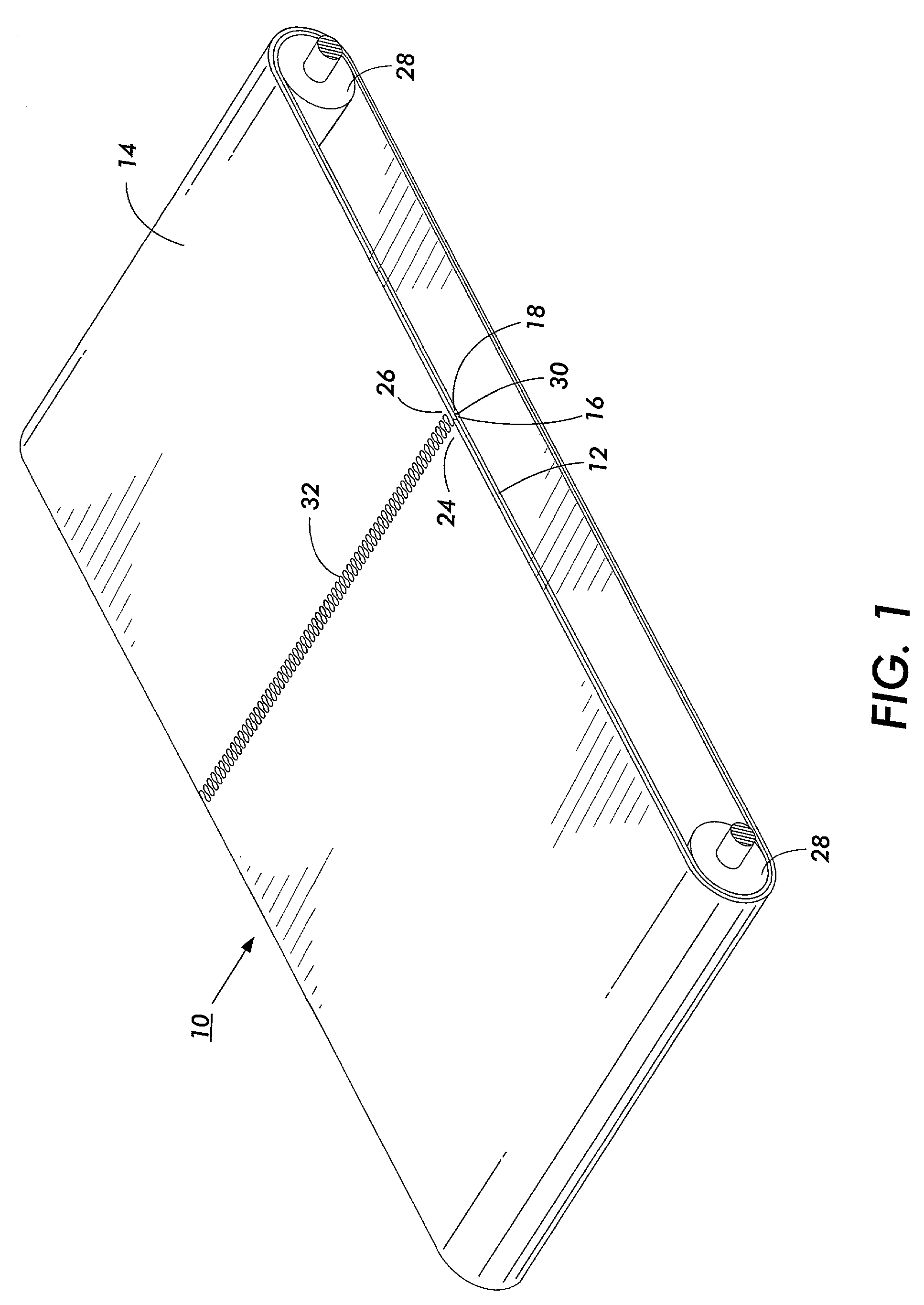

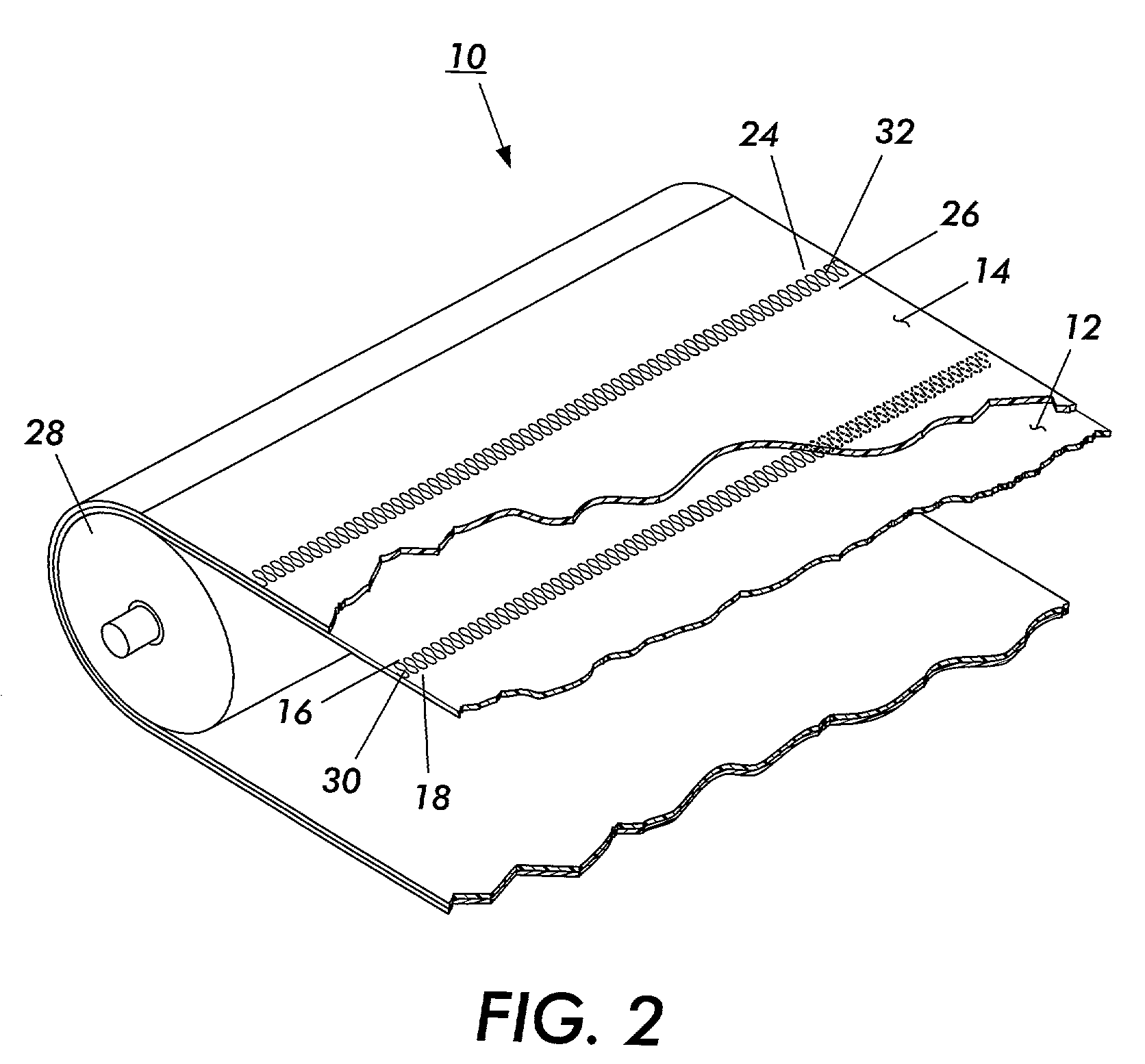

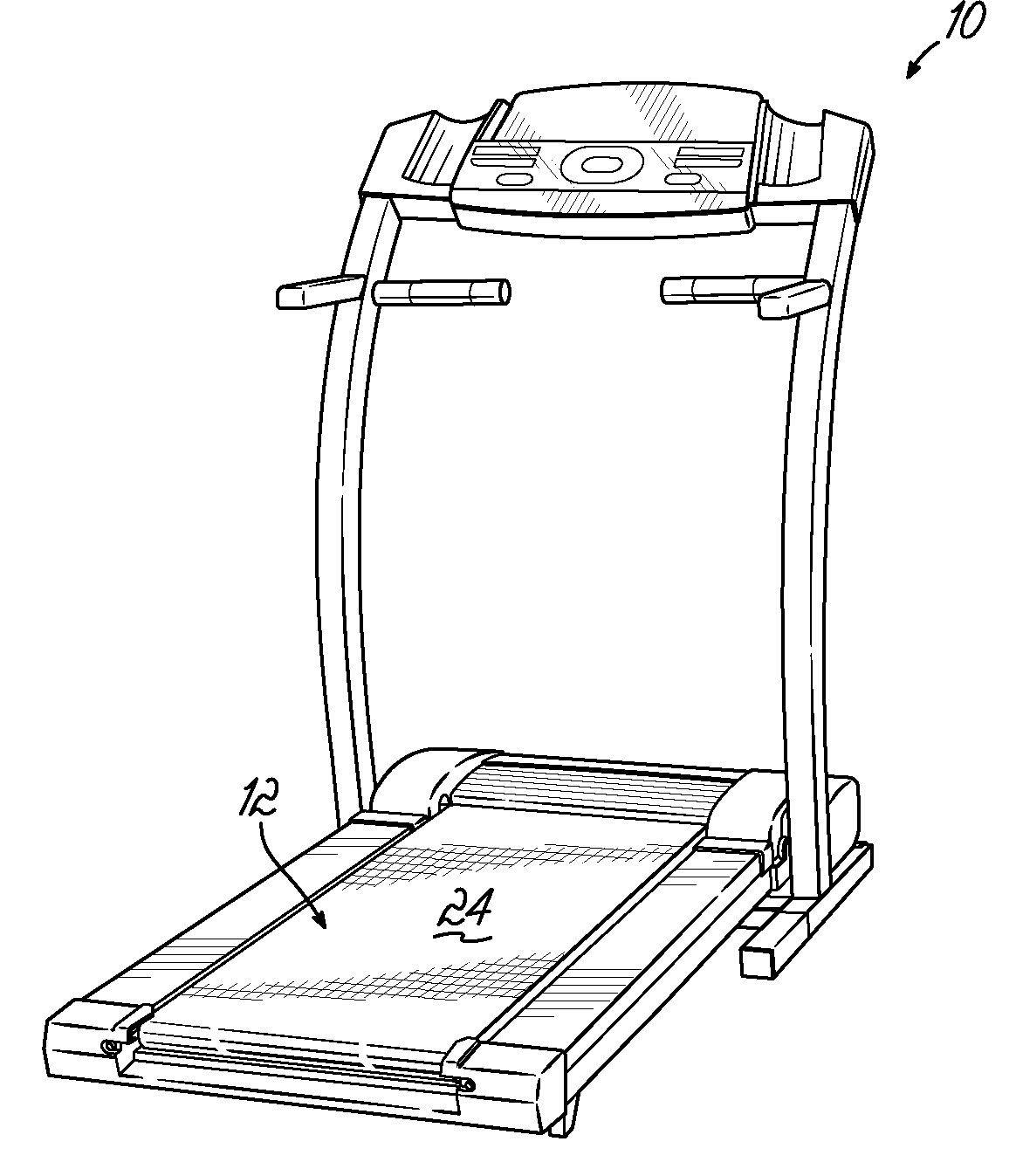

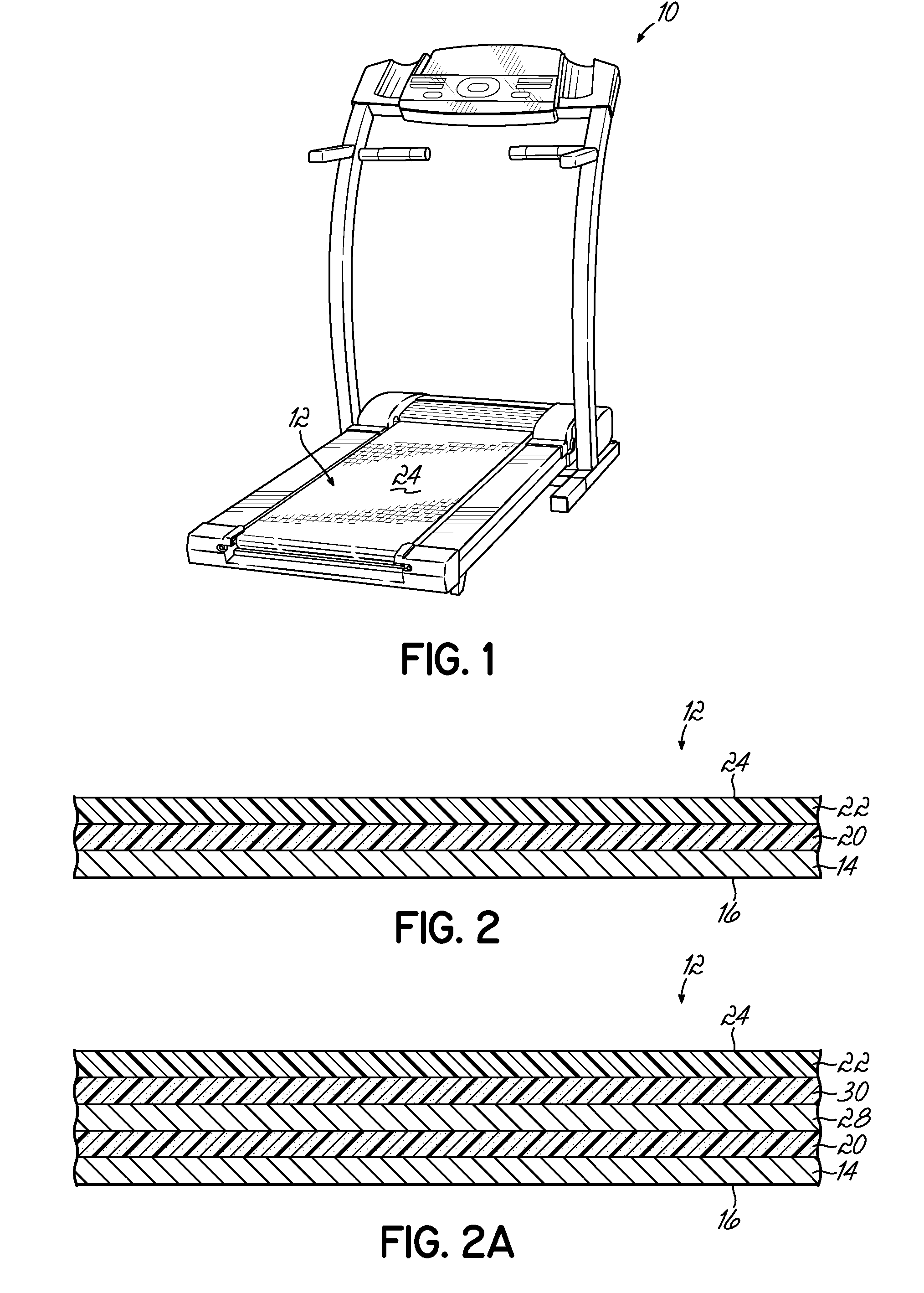

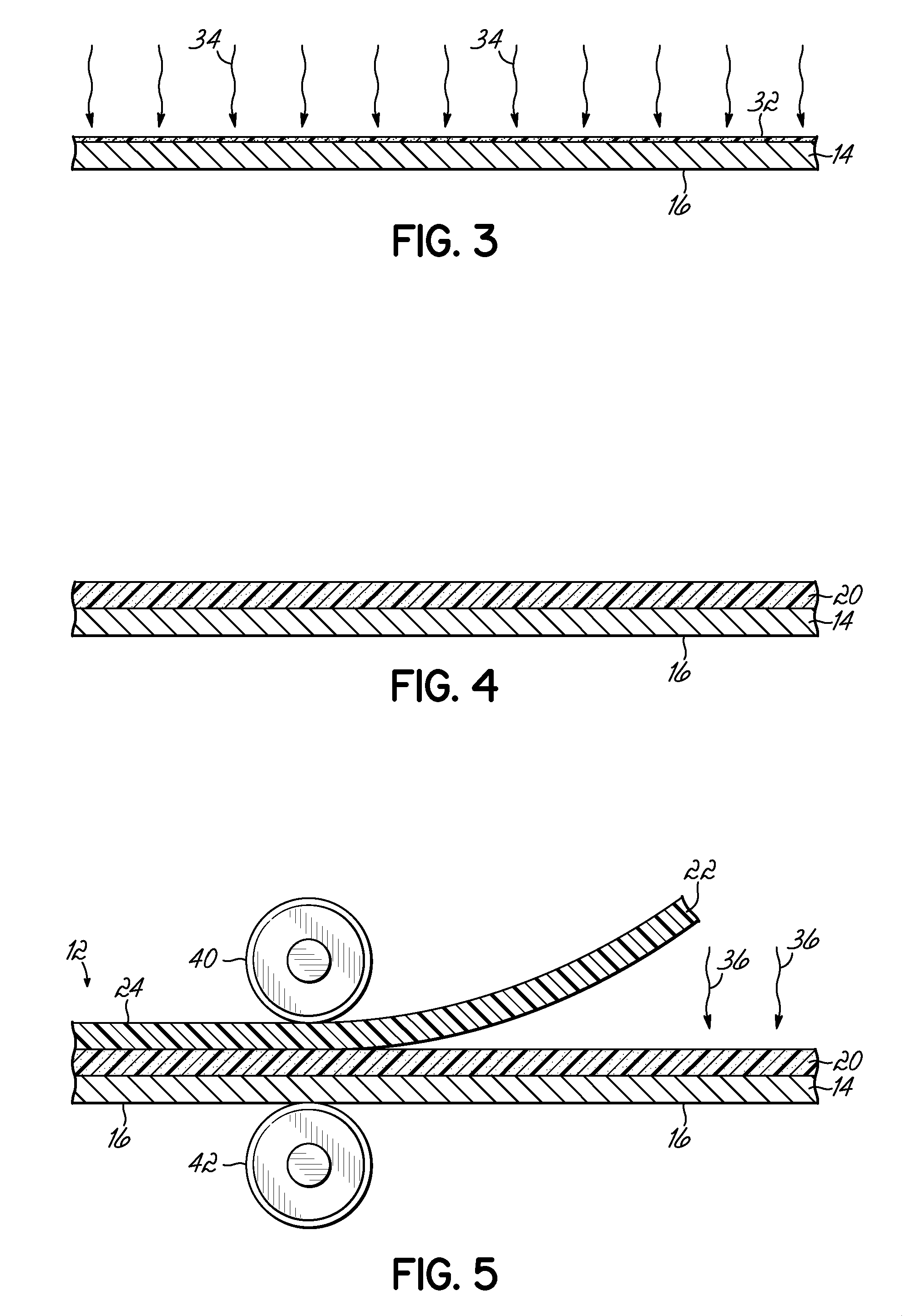

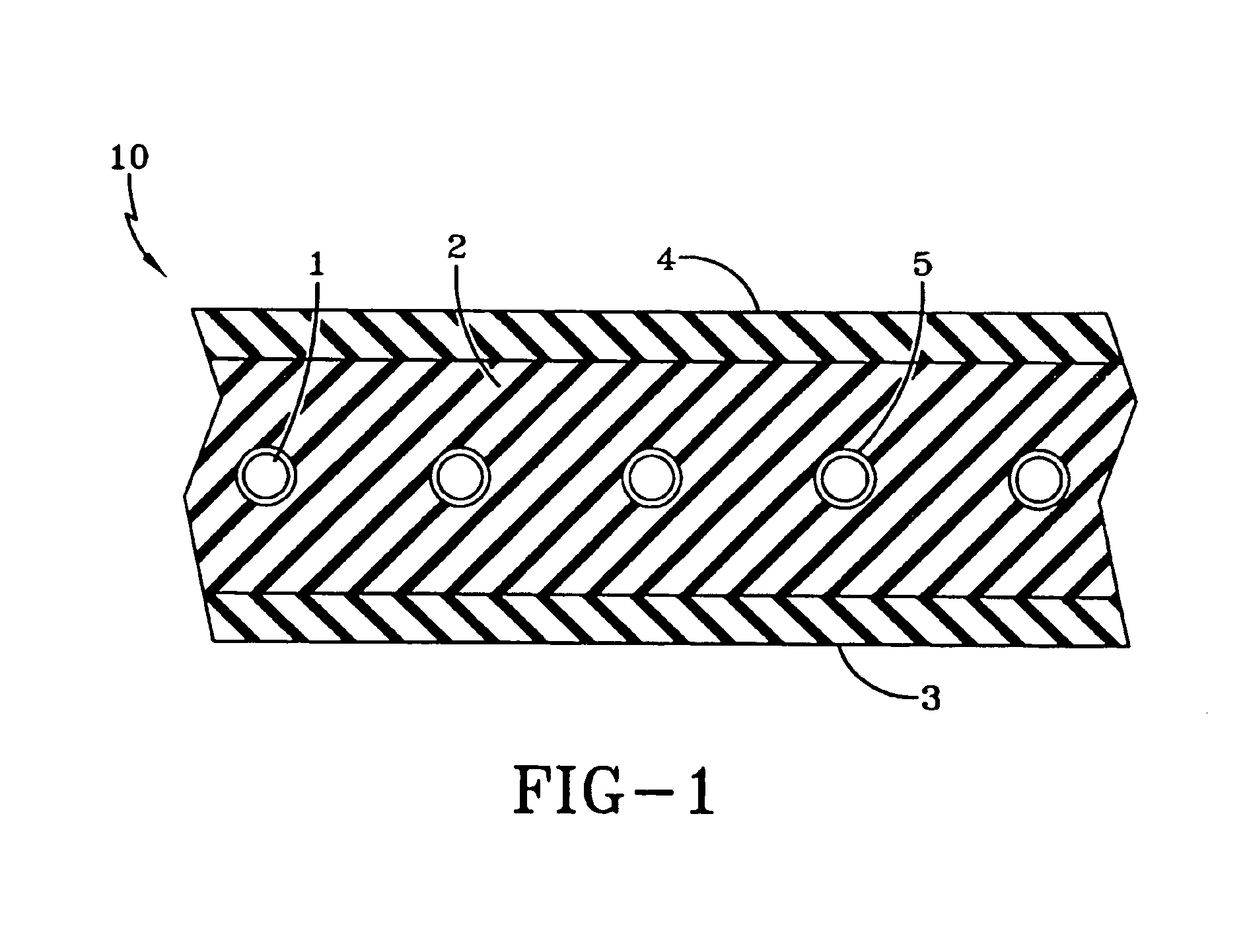

Treadmill belt with foamed cushion layer and method of making

ActiveUS20090176628A1Easy to manufactureAvoid injuryBeltsV-belt fasteningsFoaming agentPolyvinyl chloride

The present invention is directed to a treadmill belt with foamed cushion layer and method of making same. In one embodiment, the treadmill belt includes a fabric base layer and a foamed cushion layer foamed on and integral with the fabric base layer. The foamed cushion layer includes a thermoplastic composition and has a Shore A hardness of about 20 to about 80. In one example, the first foamed cushion layer is from about 0.05 inches to about 0.35 inches thick. The thermoplastic composition, prior to being foamed, includes about 1 part to about 5 parts of a foaming agent, e.g., a chemical foaming agent, based on 100 parts thermoplastic material, e.g., polyvinyl chloride. An outer wear layer is securely adhered on the foamed cushion layer to sandwich the foamed cushion layer between the fabric base layer and outer wear layer thereby defining the treadmill belt.

Owner:CONTITECH USA INC

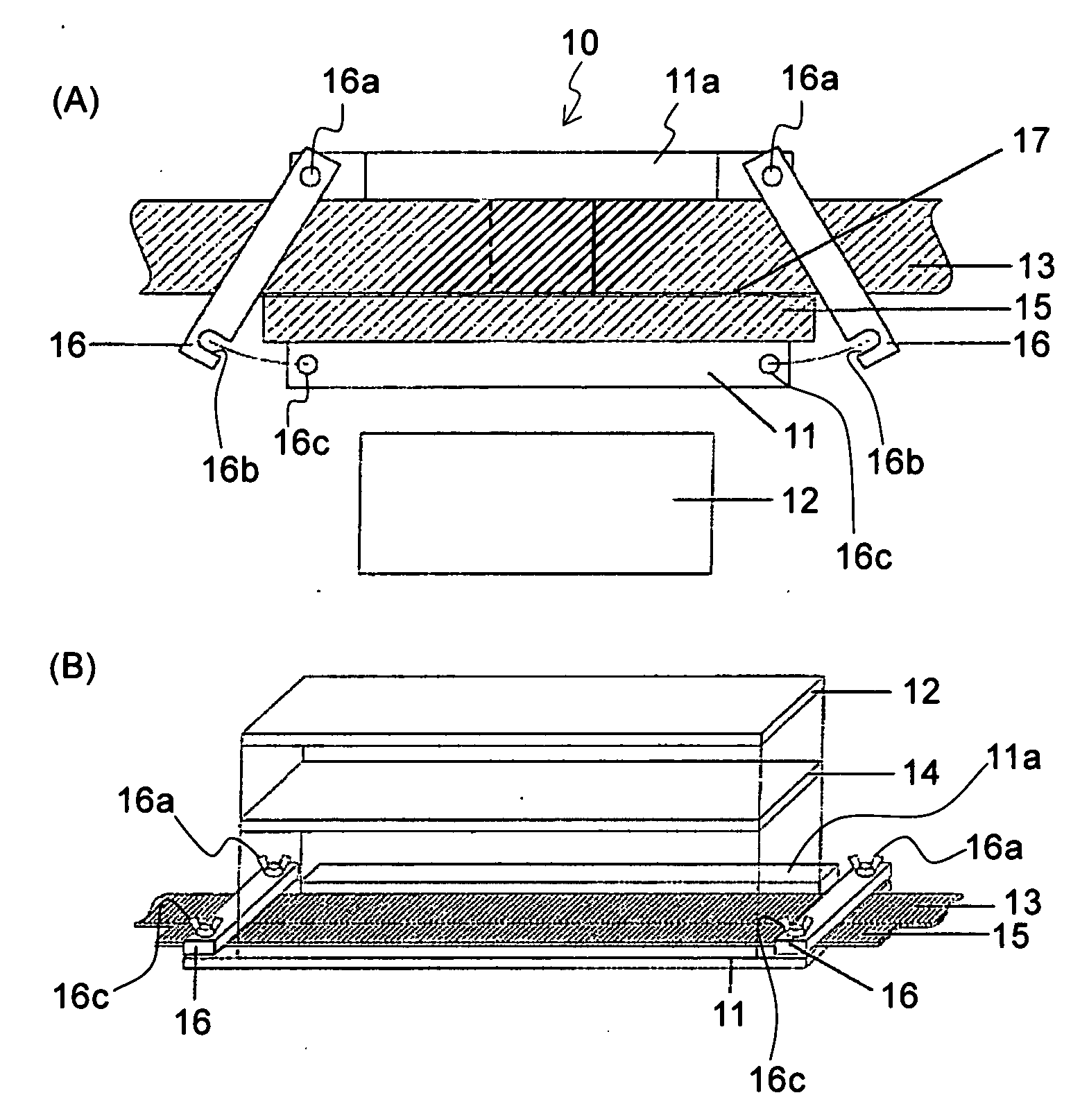

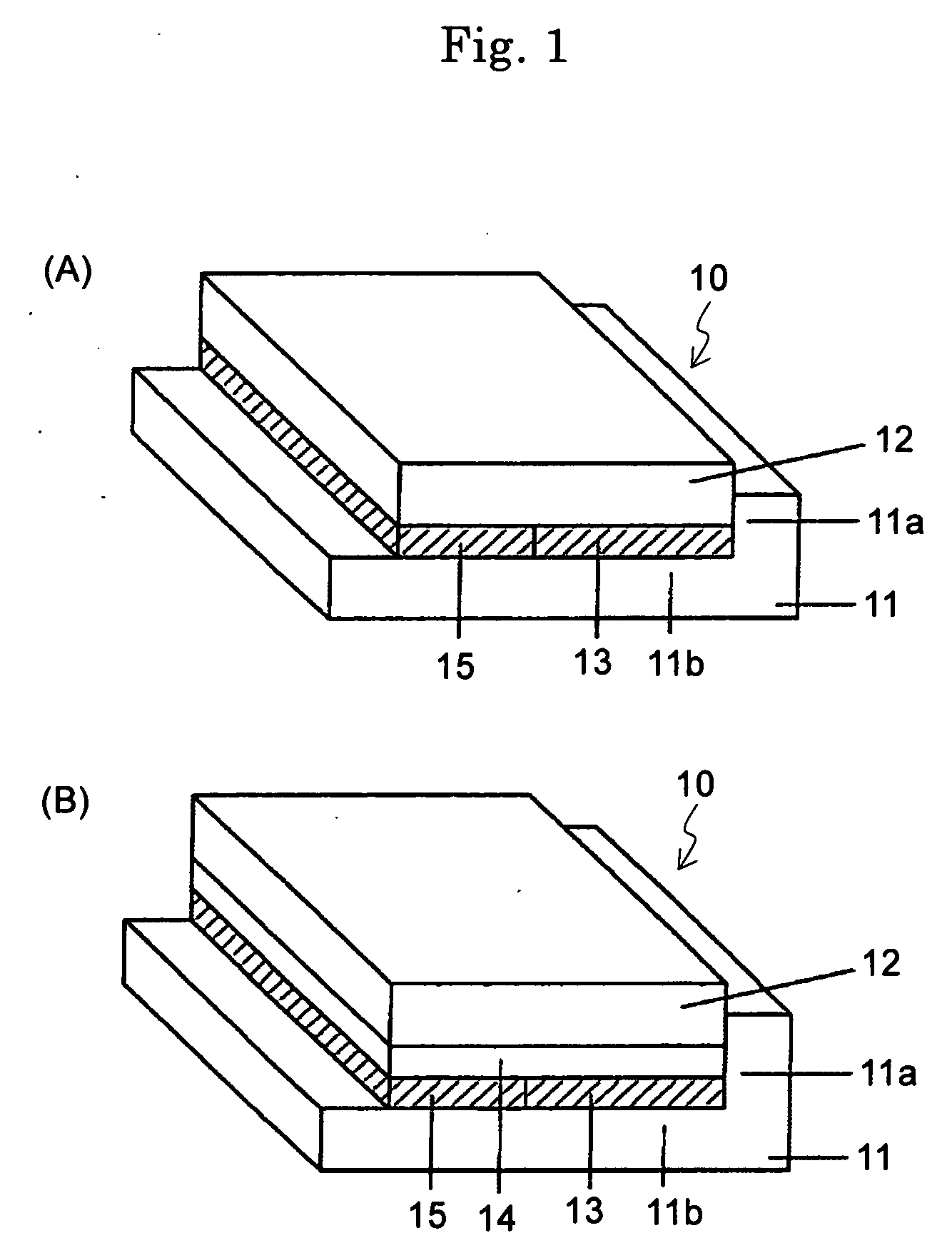

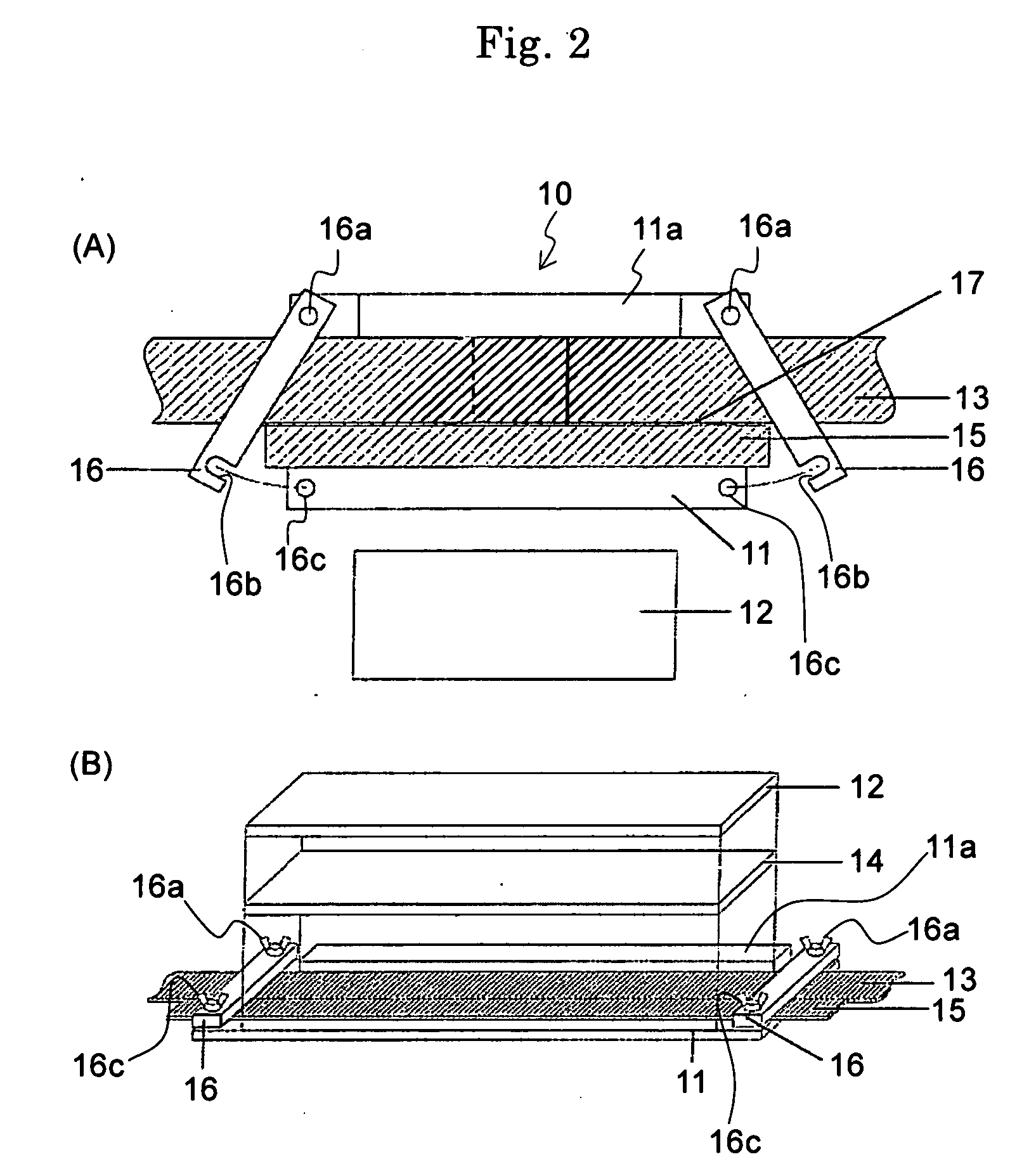

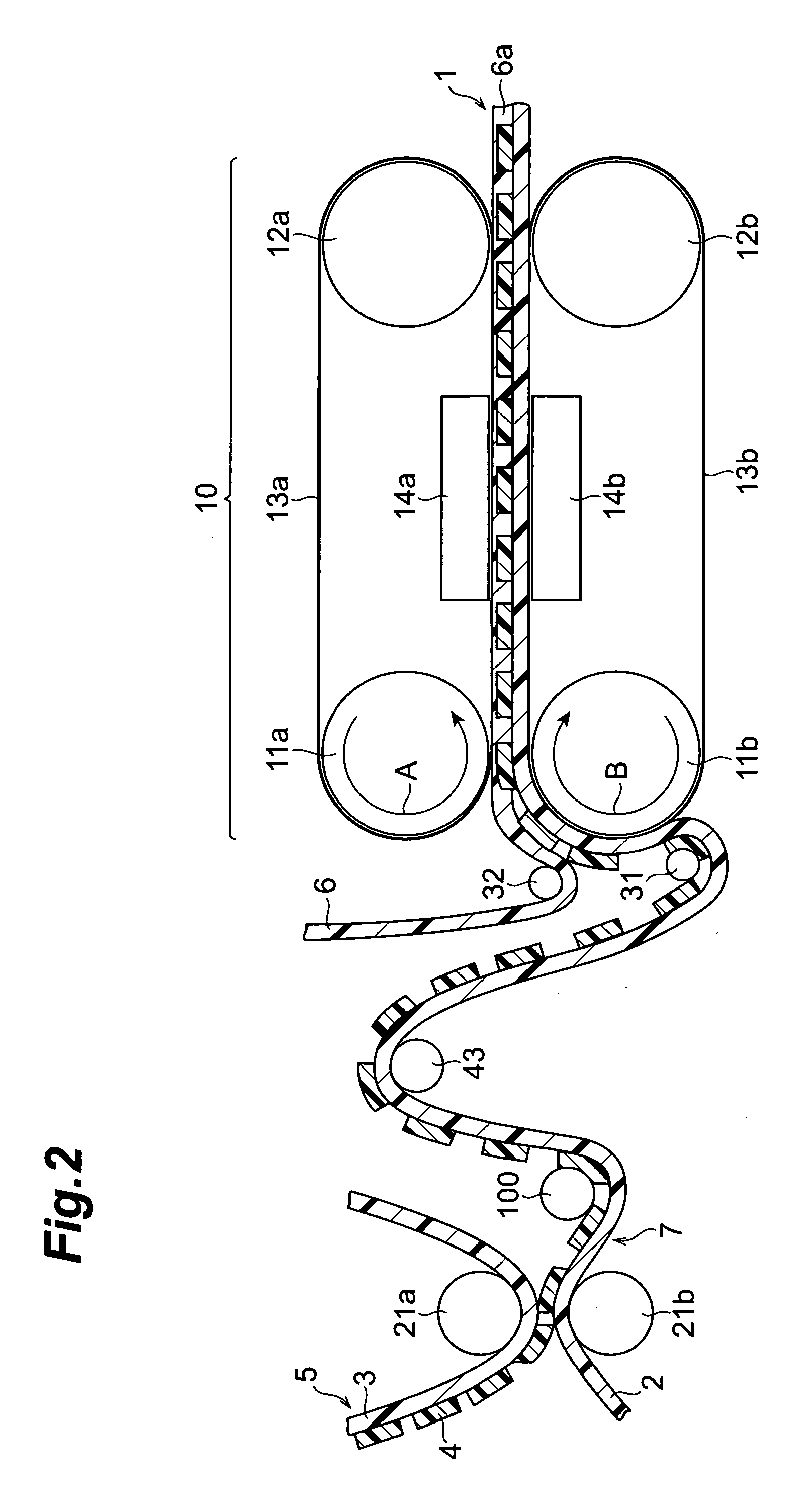

Production method of decorative film

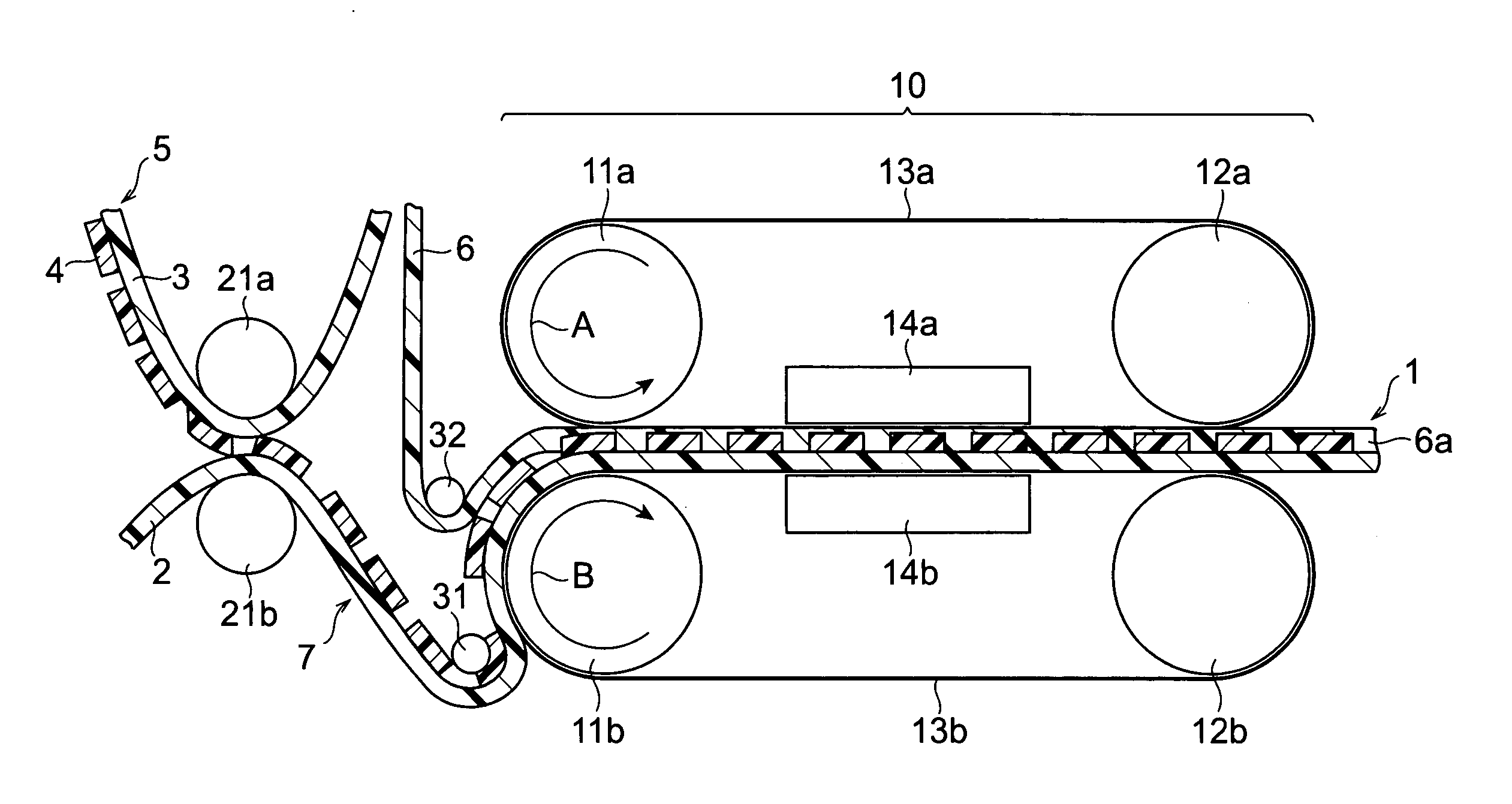

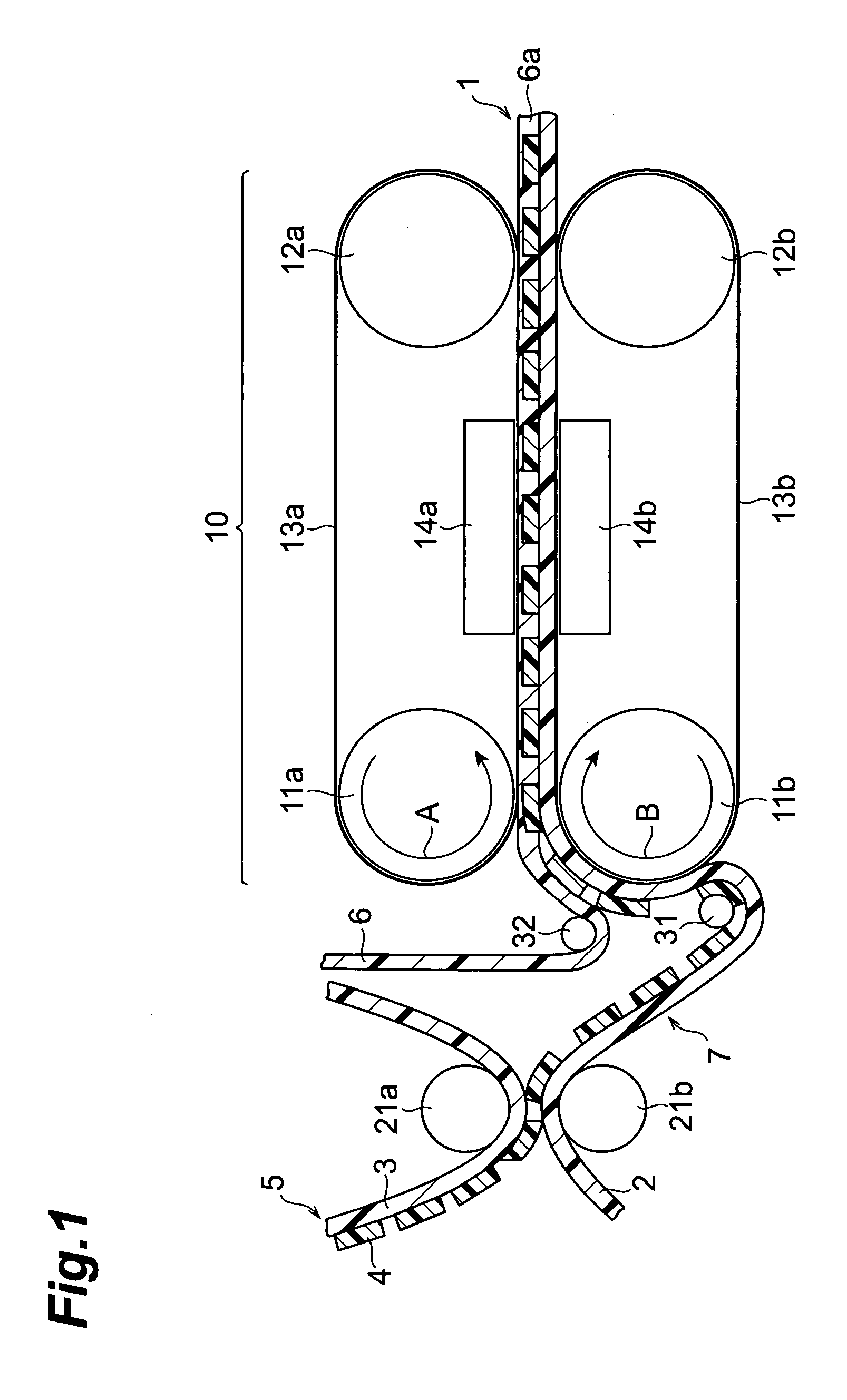

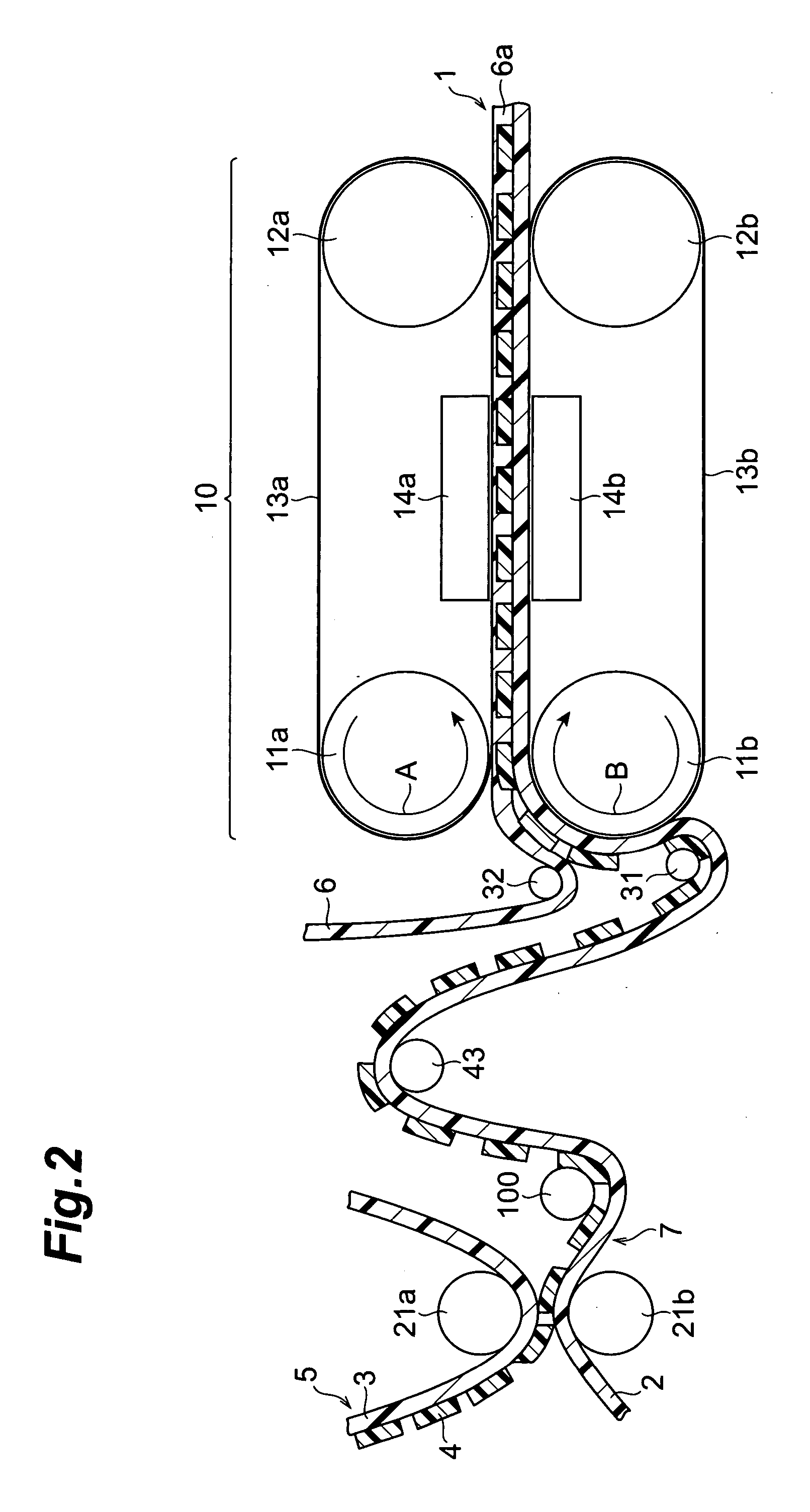

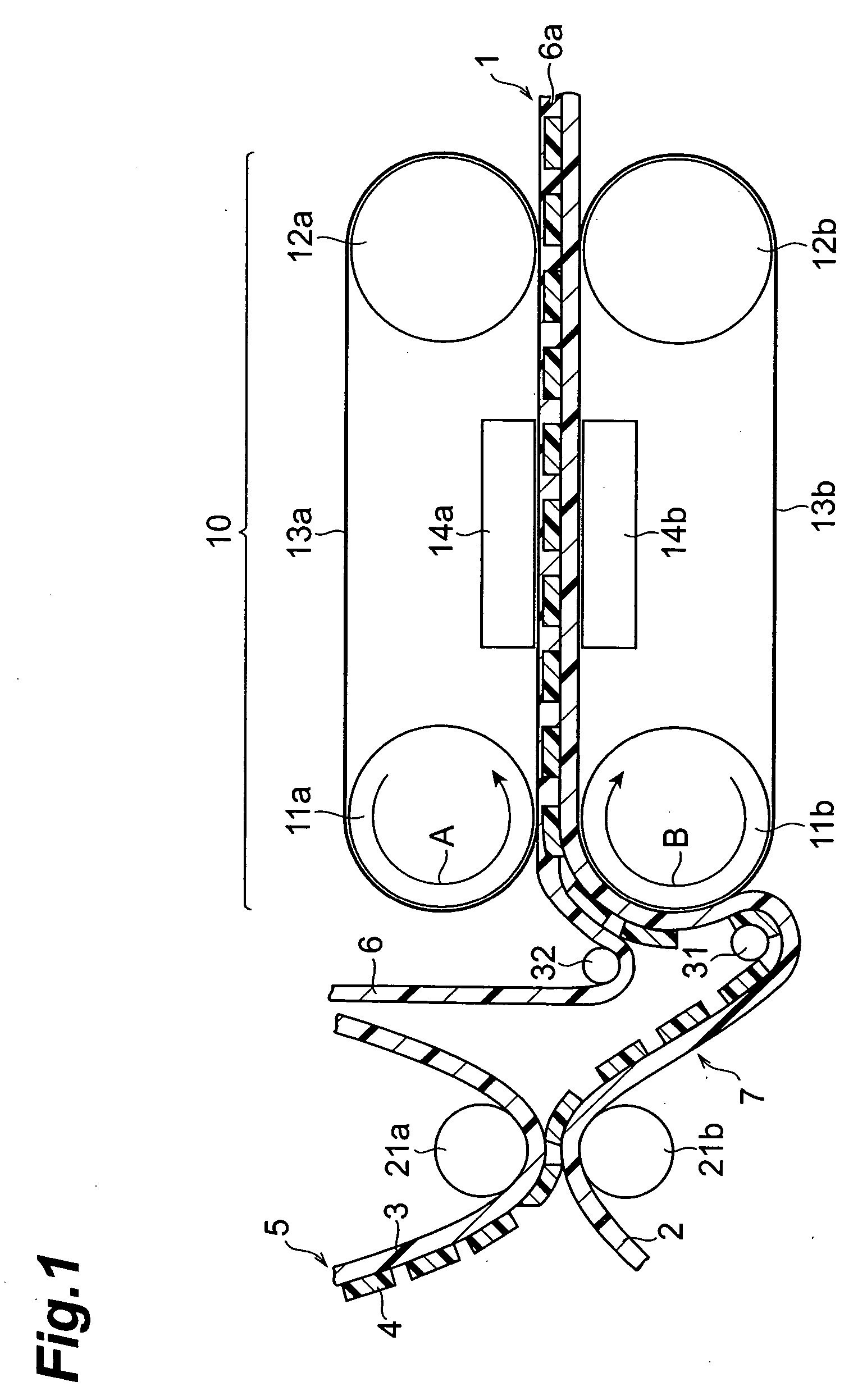

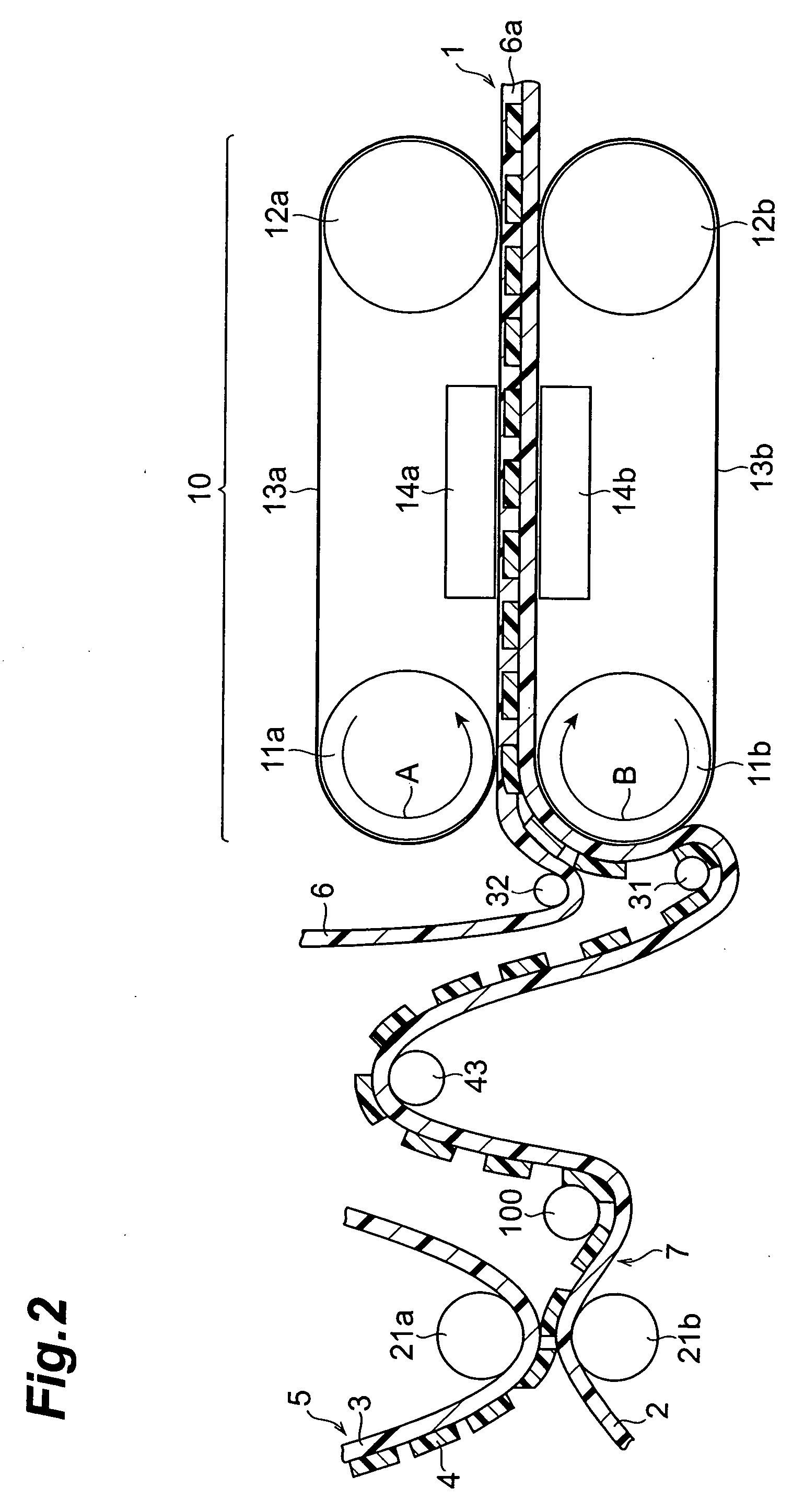

ActiveUS20050211369A1Effective applicationSuppression of surface defectsDecorative surface effectsPretreated surfacesEngineering

A production method of a decorative film comprises a first step of laying a base film of a thermoplastic resin on a pattern layer of a transfer sheet in which the pattern layer is placed on one surface of a carrier film, thermally transferring the pattern layer onto the base film, and thereafter stripping off the carrier film, thereby obtaining a laminate sheet in which the pattern layer is placed on one surface of the base film; and a second step of, in a state in which a transparent resin film is laid on a surface of the laminate sheet on the pattern layer side, inserting the laminate sheet and the transparent resin film into between a pair of endless belts placed opposite each other, and conveying the laminate sheet and the transparent resin film under heat and pressure, thereby obtaining a decorative film in which a transparent resin layer of the transparent resin film is placed on the surface of the laminate sheet on the pattern layer side.

Owner:SHIN-ETSU POLYMER CO LTD

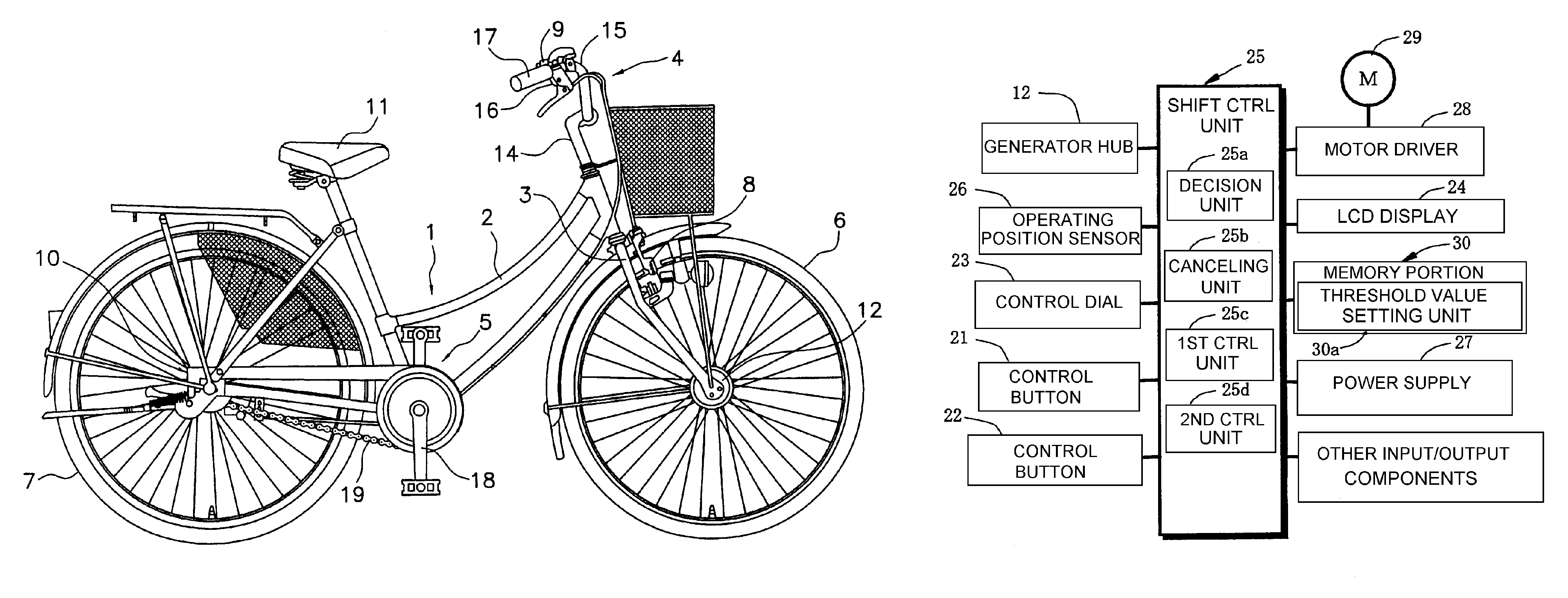

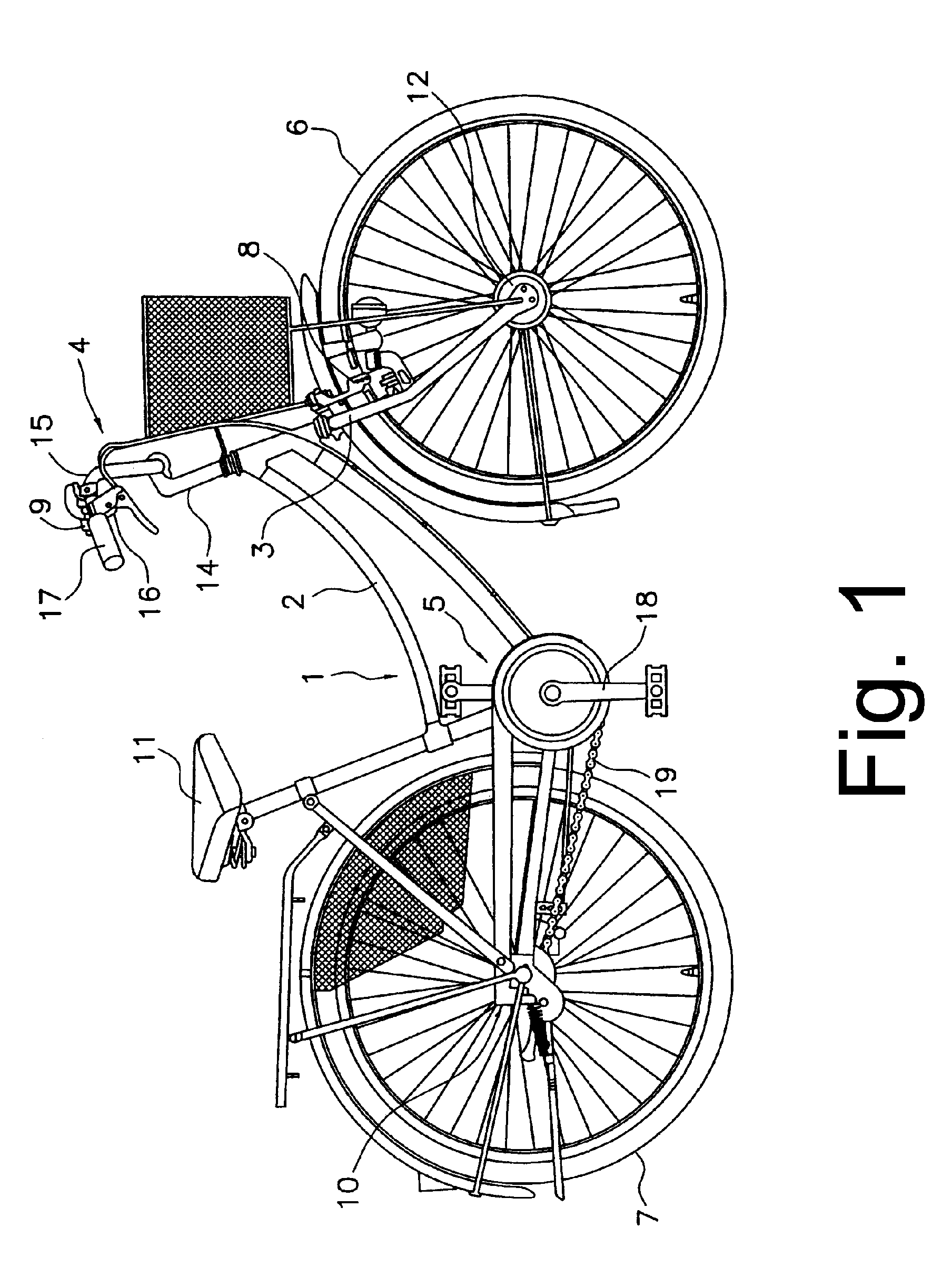

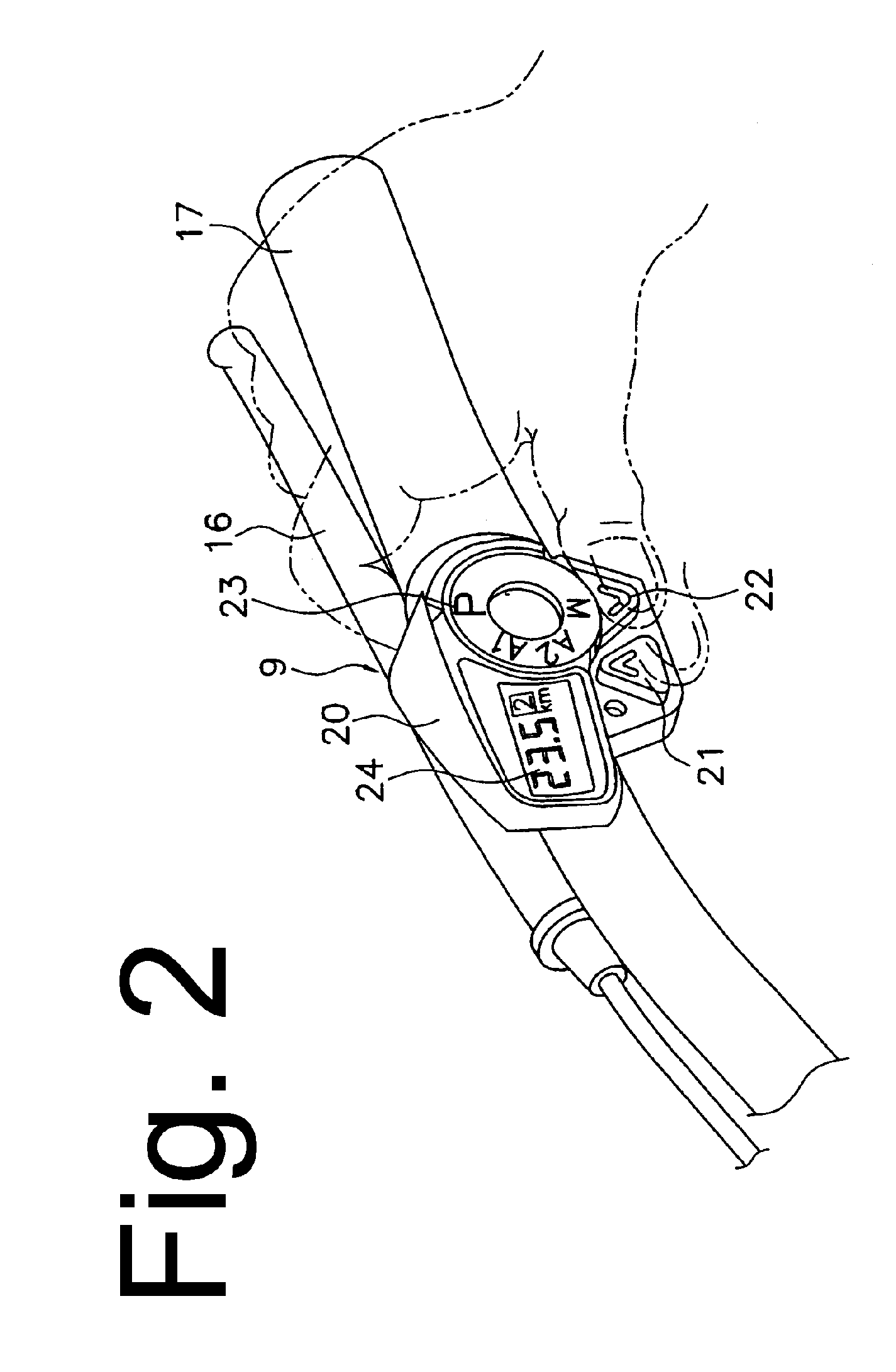

Bicycle shift control apparatus that cancels a tentative shift

A bicycle shift control apparatus comprises a threshold value setting unit that sets a threshold value of a running condition for shifting a bicycle transmission, a decision unit that decides if a current running condition value passes the threshold value, and a tentative shift unit that sets a tentative shift of the bicycle transmission when the decision unit decides that the current running condition value passes the threshold value. A canceling unit cancels the tentative shift if the decision unit decides that the current running condition value varies from a previous running condition value by a determined value.

Owner:SHIMANO INC

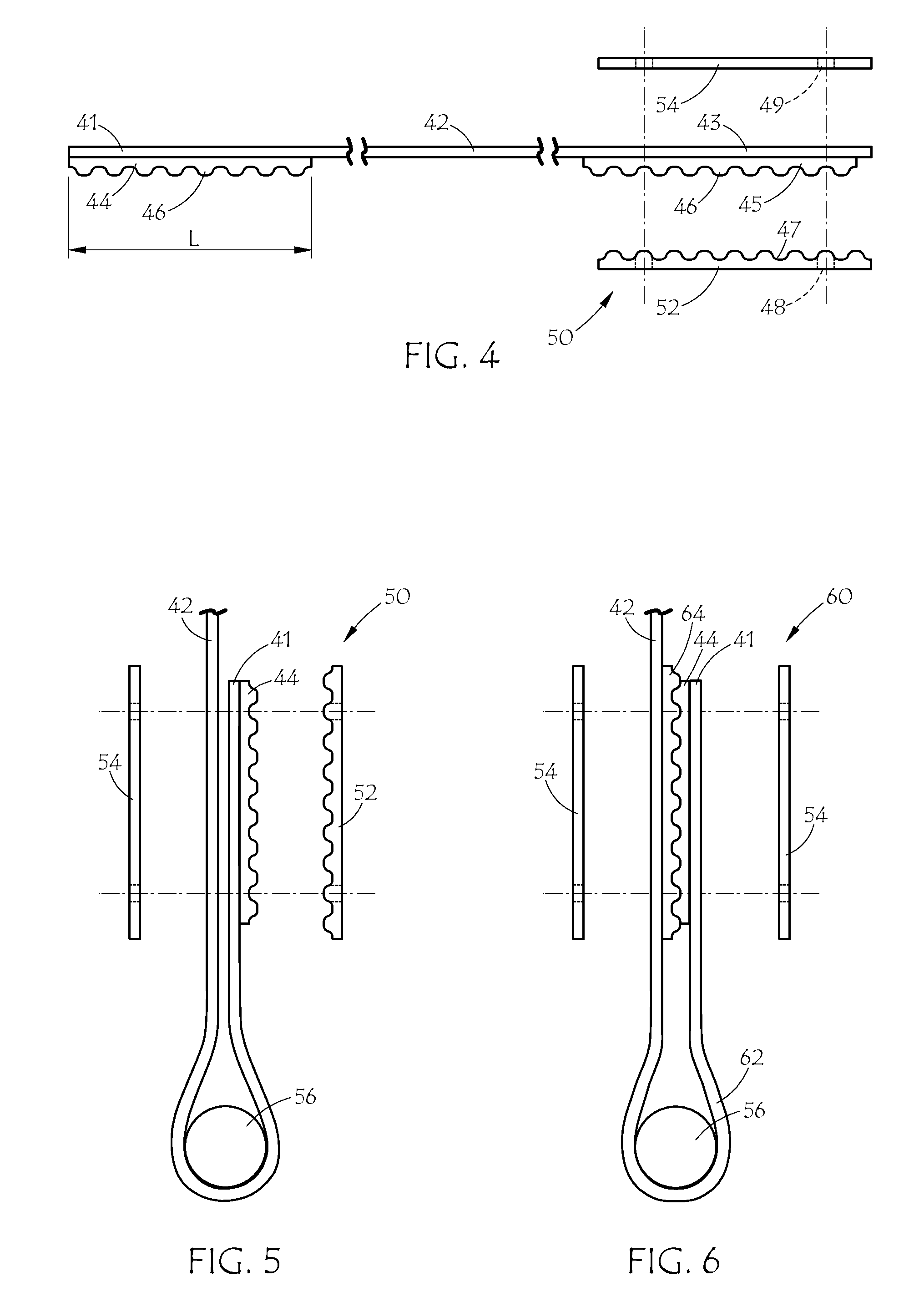

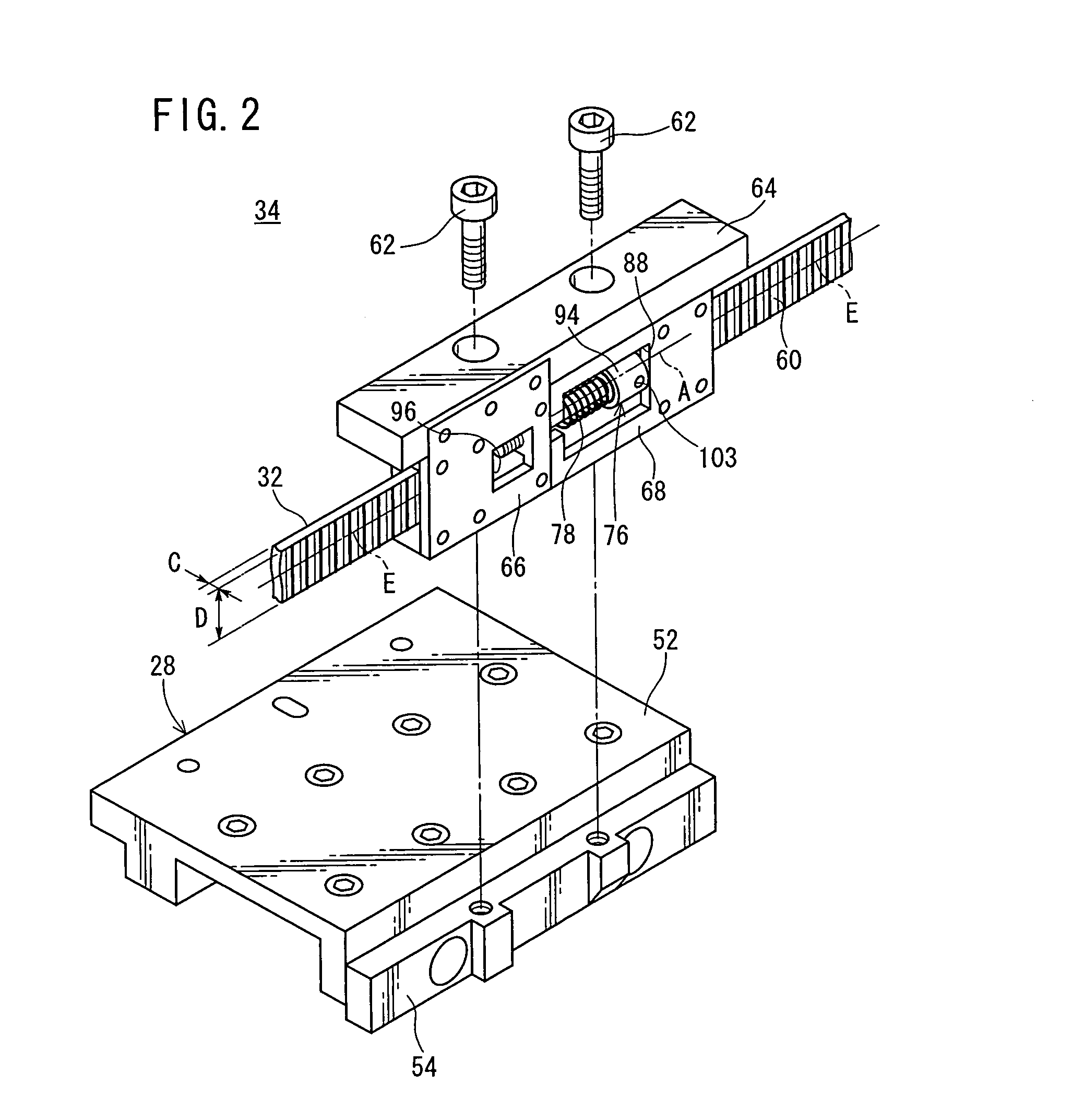

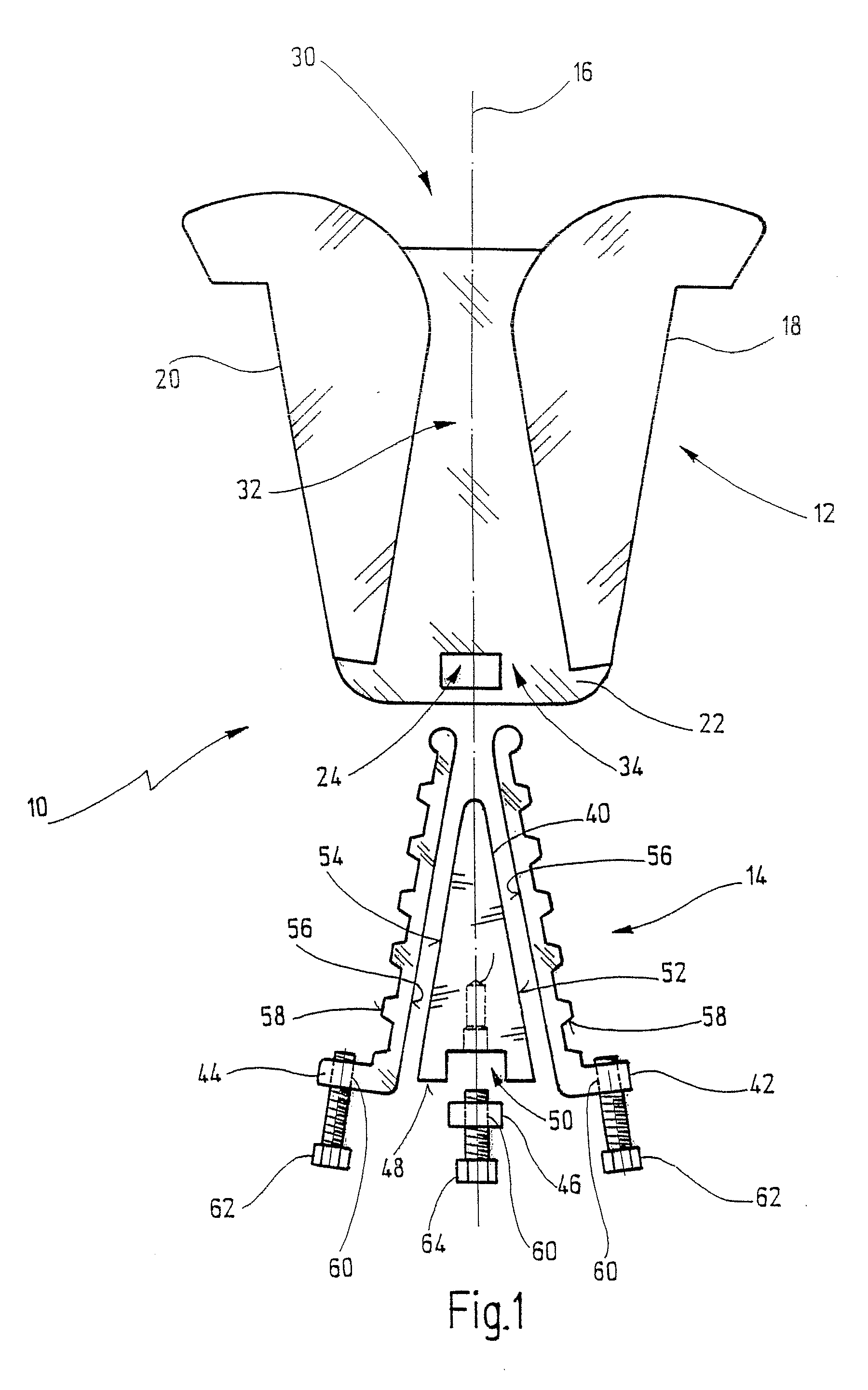

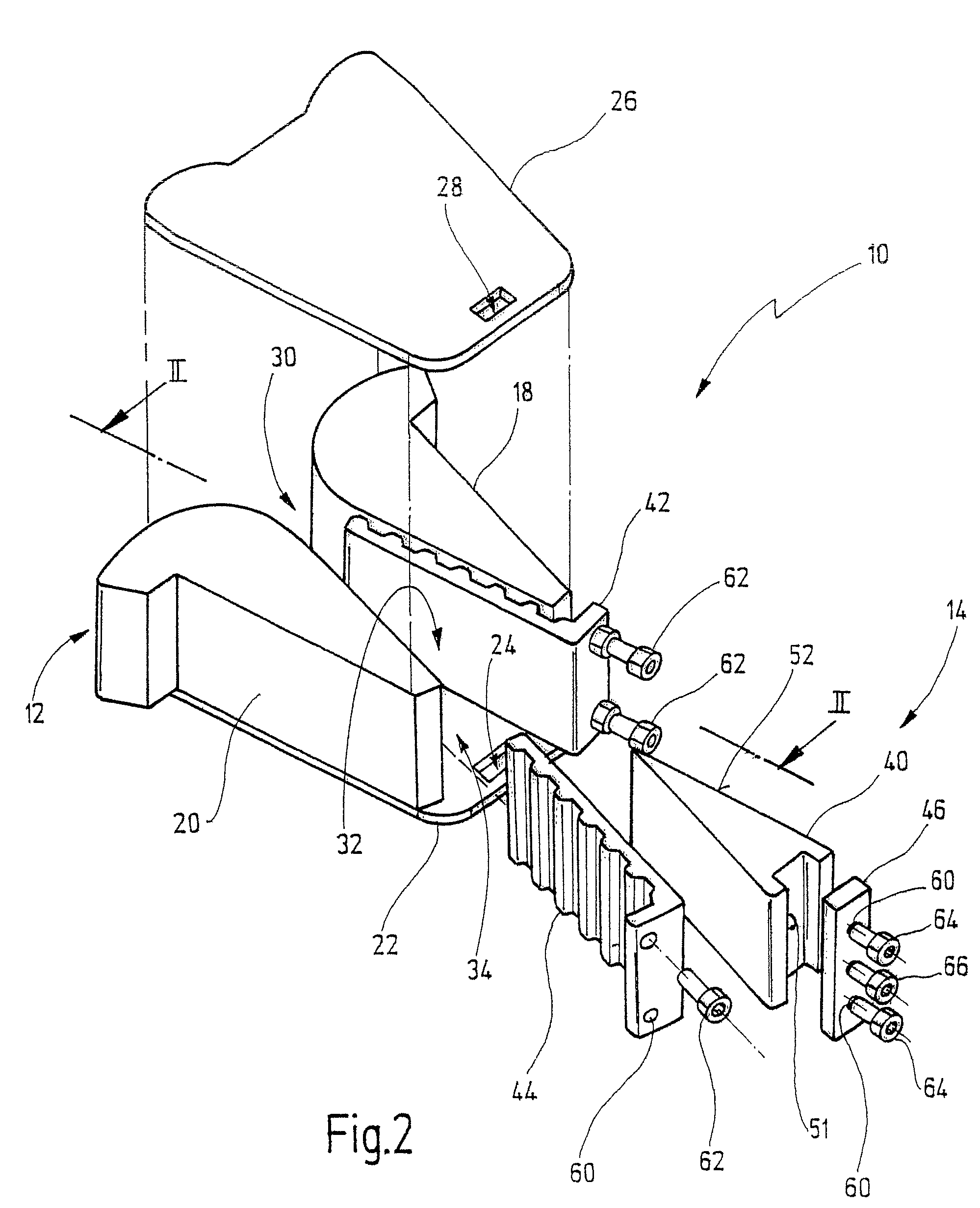

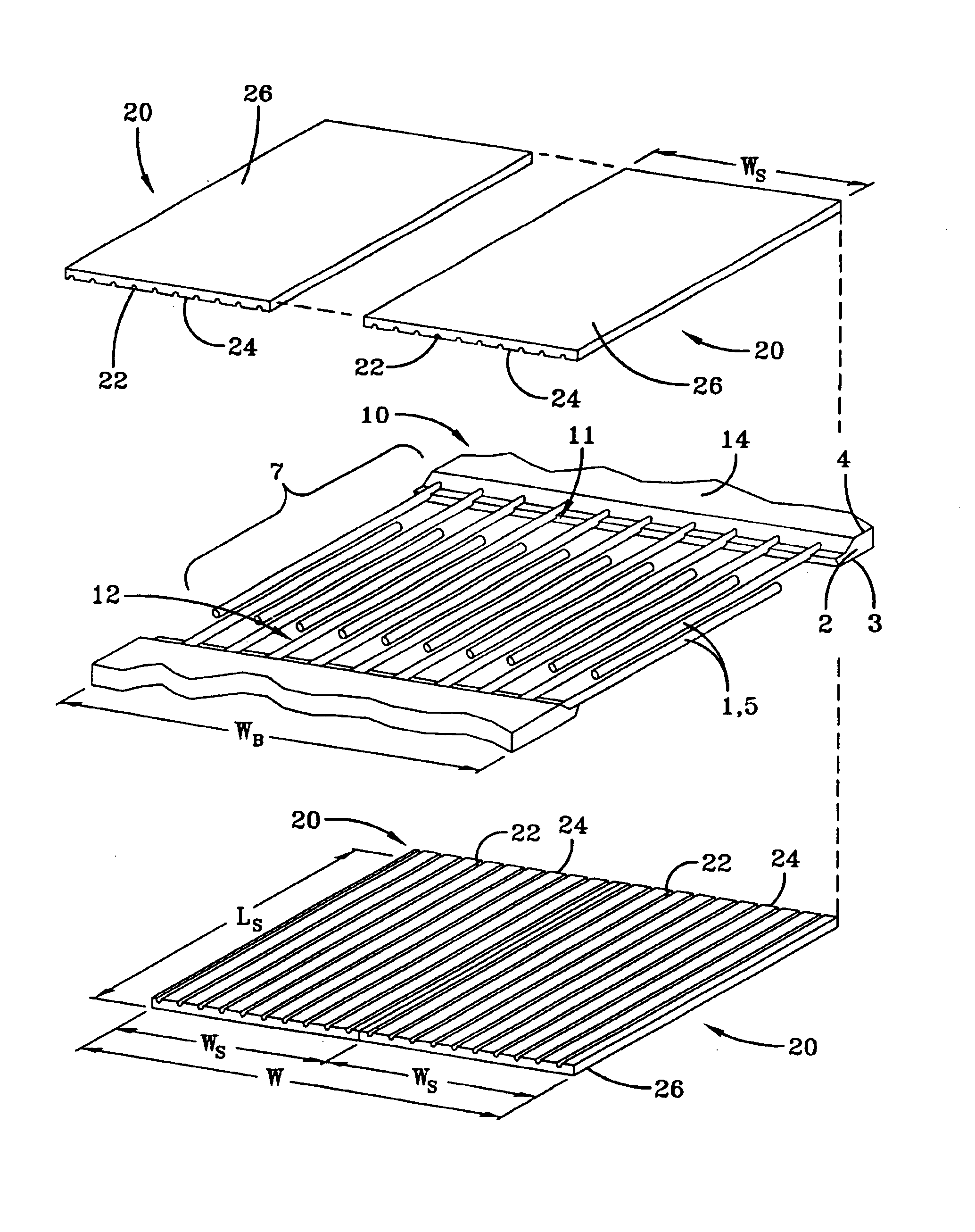

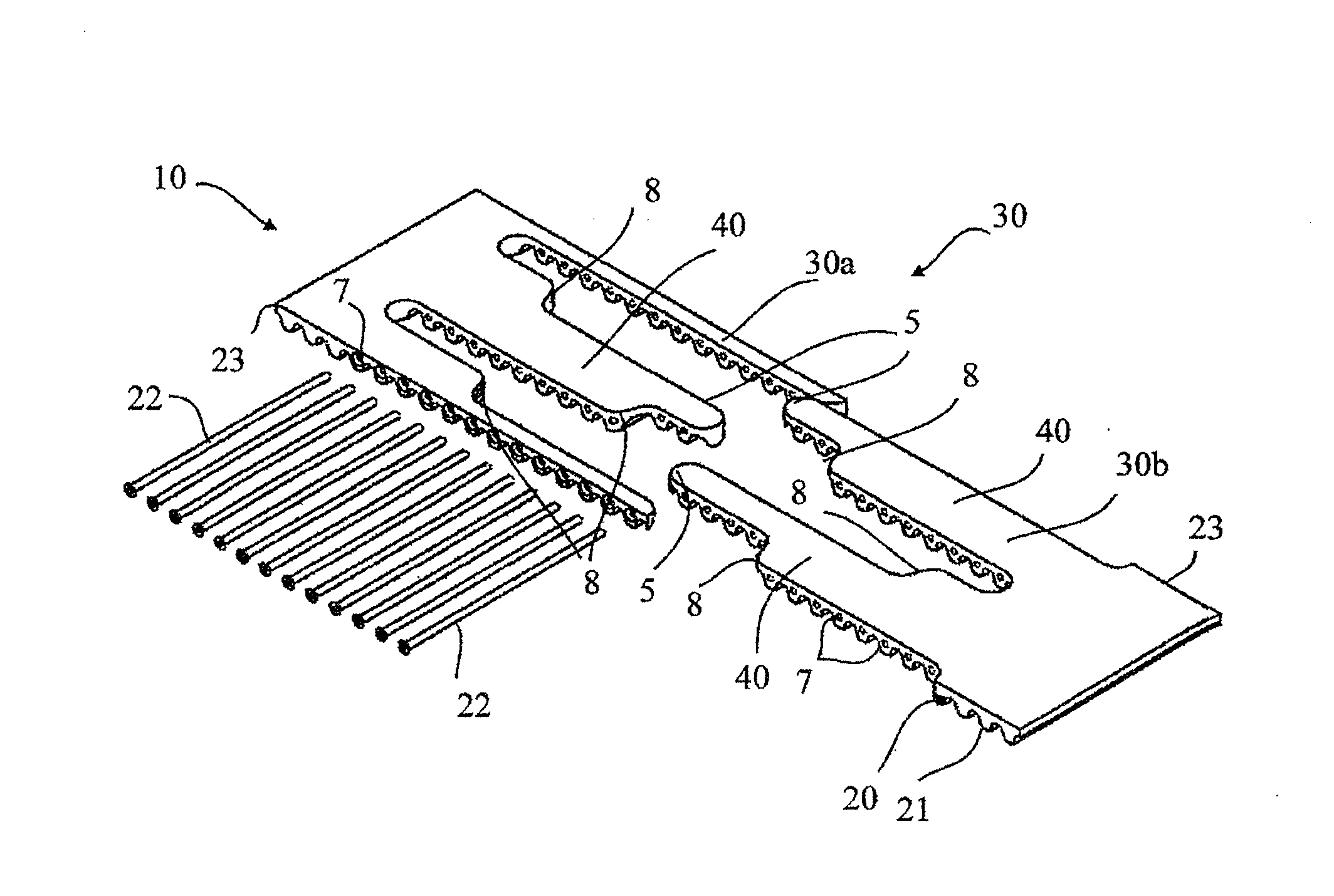

Flat Belt Clamping System and Method

A belt clamping system including an open-ended, flat belt with an end portion having a number of teeth projecting therefrom and a clamping plate with matching tooth profile for use in connecting the belt end to another structure. The flat belt may be reinforced with longitudinally extending cords. The toothed profile may be a standard timing belt profile and may be unreinforced. A length of timing belt profile material may be welded to the flat surface of the open-ended flat belt at or near an end. The length of timing belt profile may include at least 7 tooth pitches. The end portion may be clamped between a flat surface of a flat plate and a grooved surface of a grooved plate having grooves complementary to the timing belt teeth.

Owner:THE GATES CORP

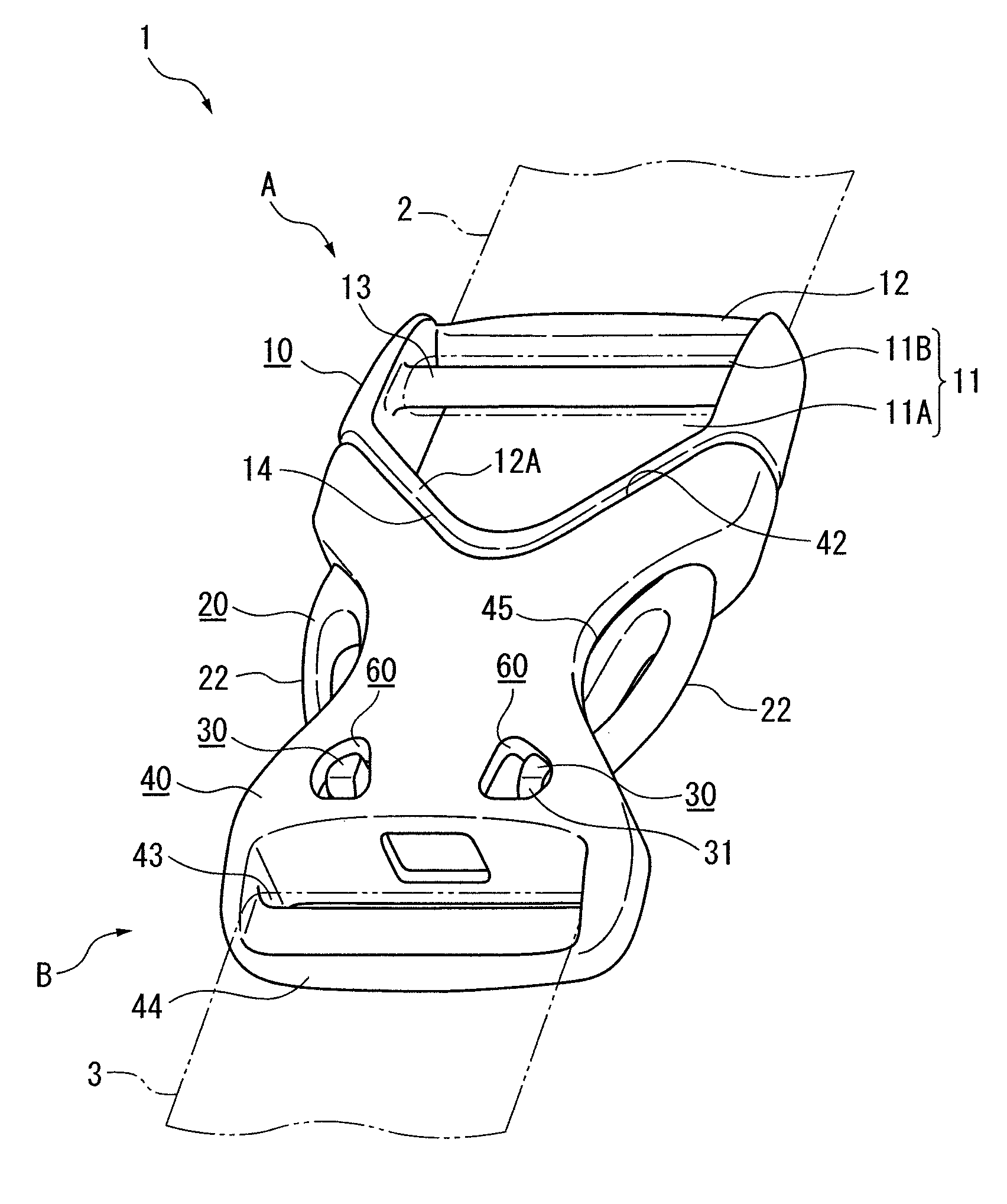

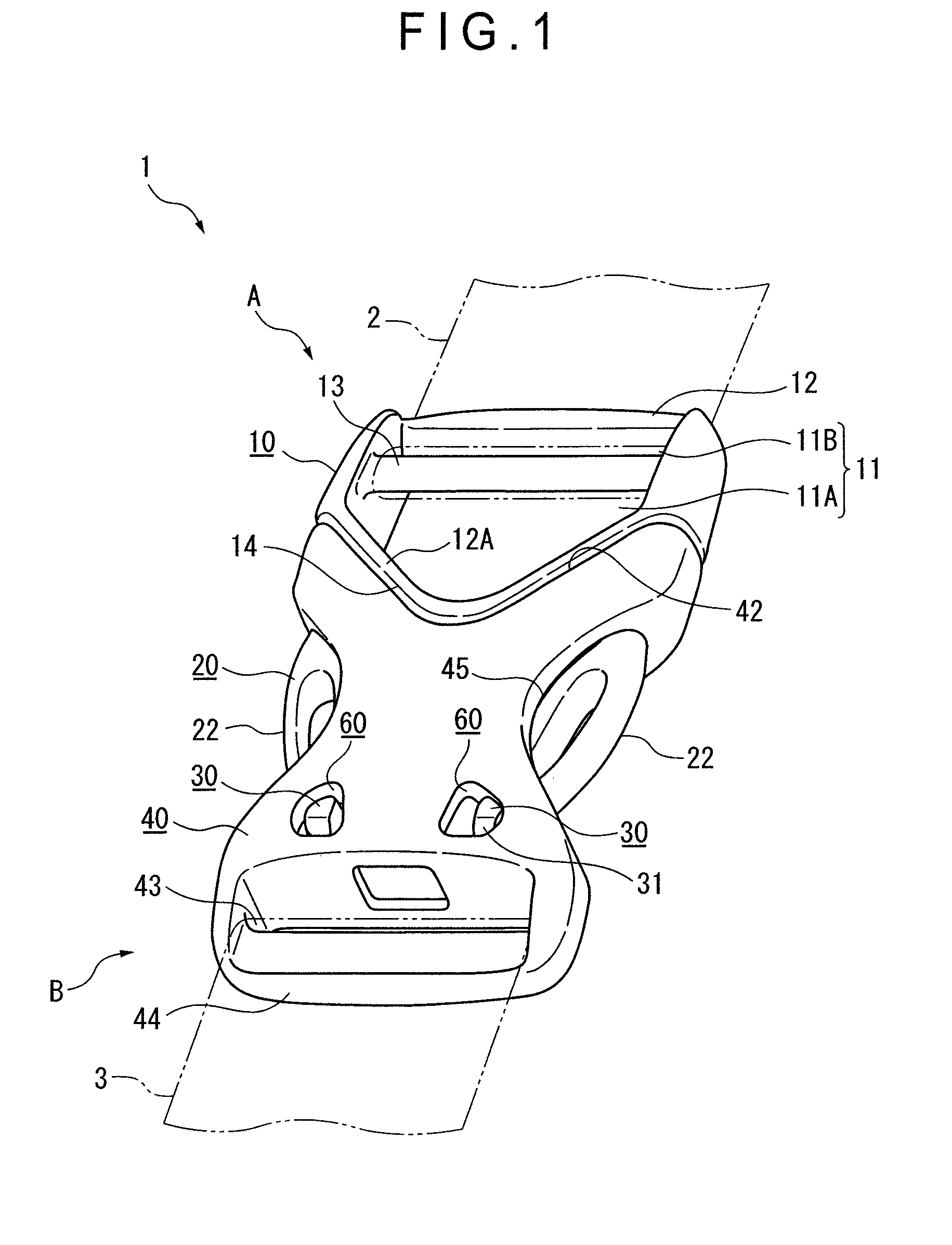

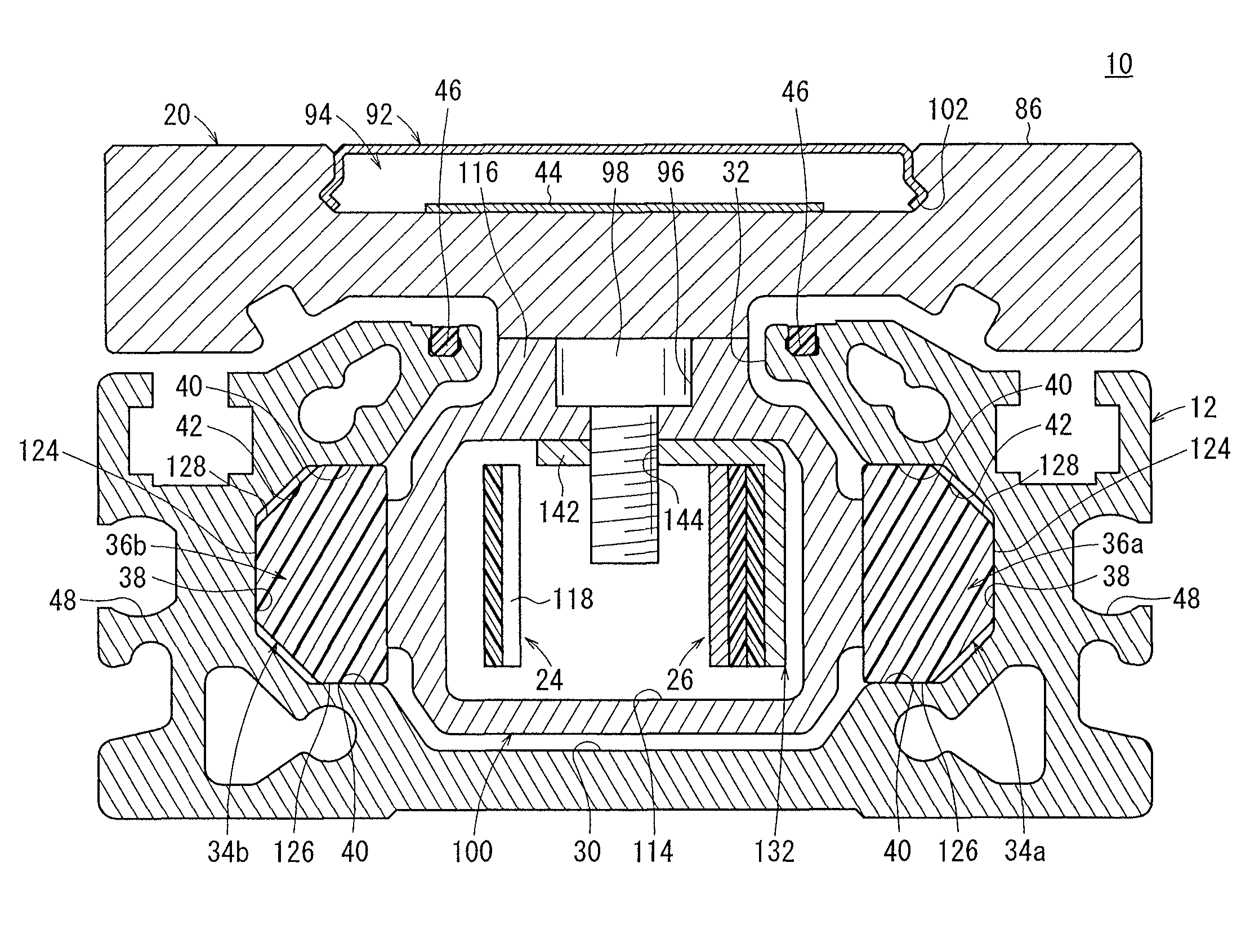

Buckle

A buckle includes a male member and a female member. The male member is provided with a base, a pair of legs and an engaging portion provided on a distal ends of the legs. The female member is provided with an insertion port, a guide that elastically deforms the distal end of each of the legs inserted through the insertion port in a direction in which the distal ends come closer to each other and a pair of engaged portions formed on both sides of a remote side of the guide. Each of the engaged portions displaces each of the engaging portions in the direction in which the engaging portions get apart with each other and is provided by a concave that has an abutment wall on a rear portion in the releasing direction to be abutted by each of engaging portions. Each of the abutment walls is formed as a slant surface that inclines in the direction in which the abutment walls come closer to each other toward the releasing direction of the male member.

Owner:YKK CORP

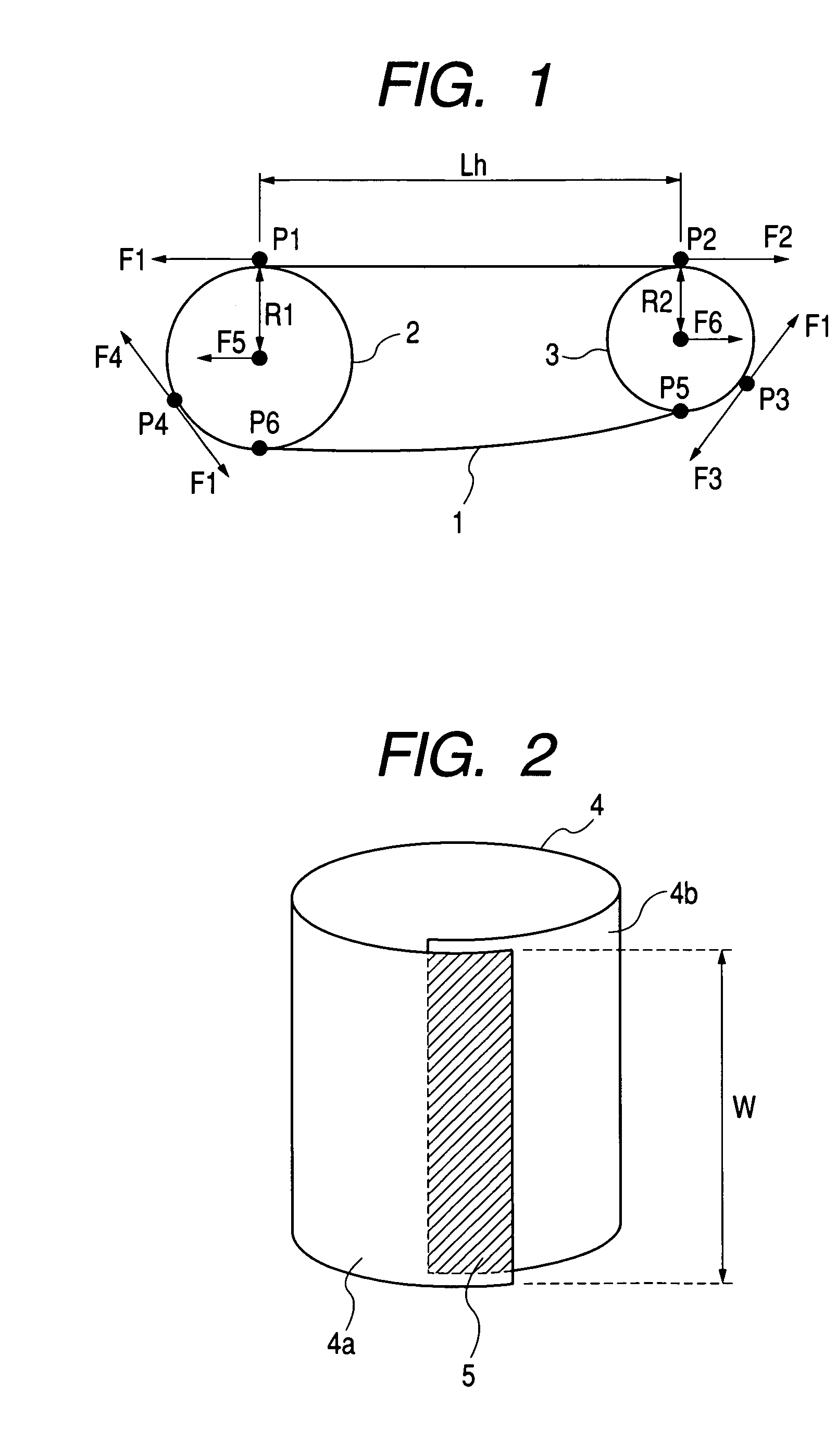

Belt Connecting Method, Presetter, and Belt Connecting Apparatus

ActiveUS20080190745A1Reduce manufacturing costReduce necessityV-belt fasteningsConveyorsLeather beltElectrical and Electronics engineering

Owner:NITTA CORP

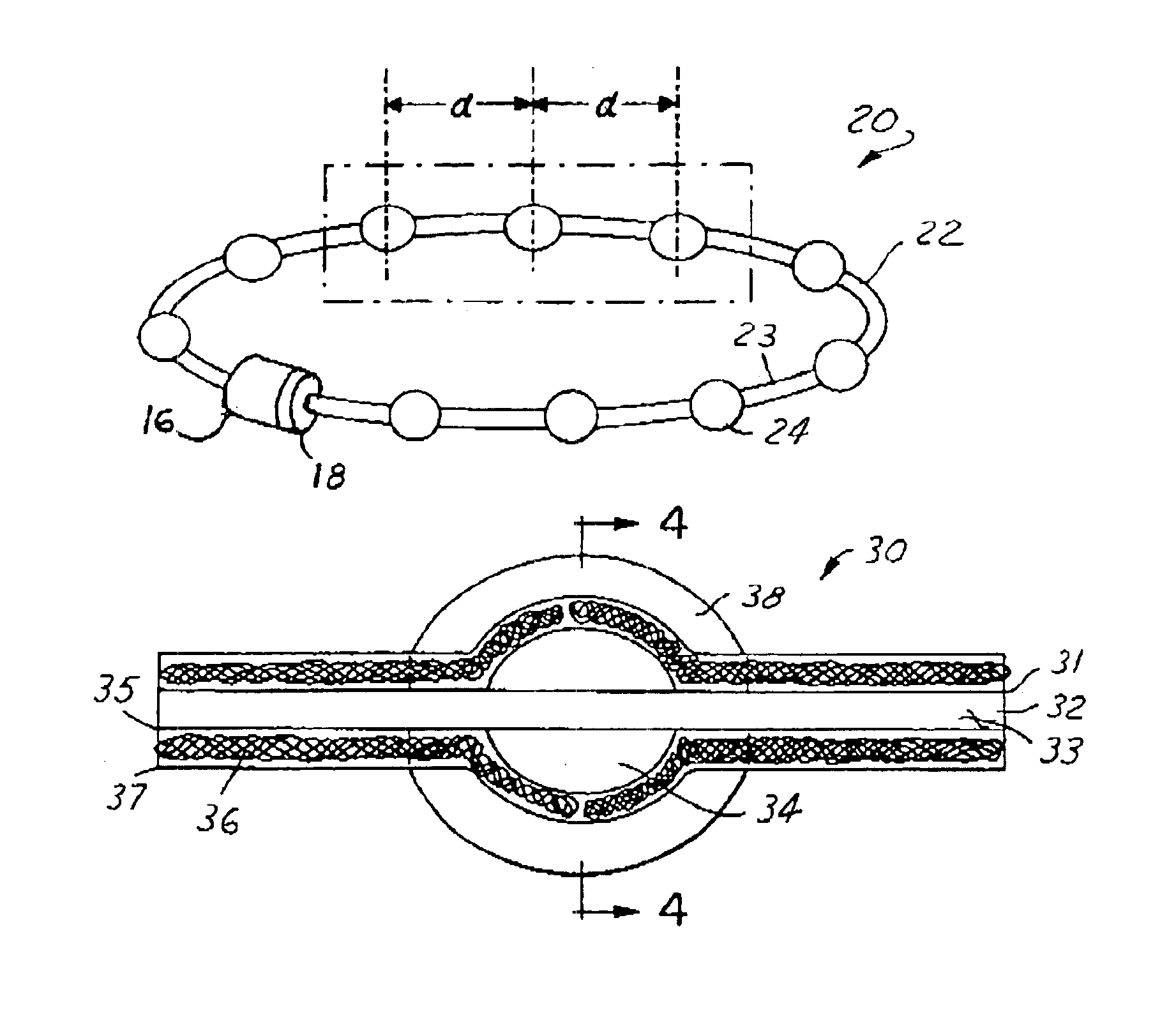

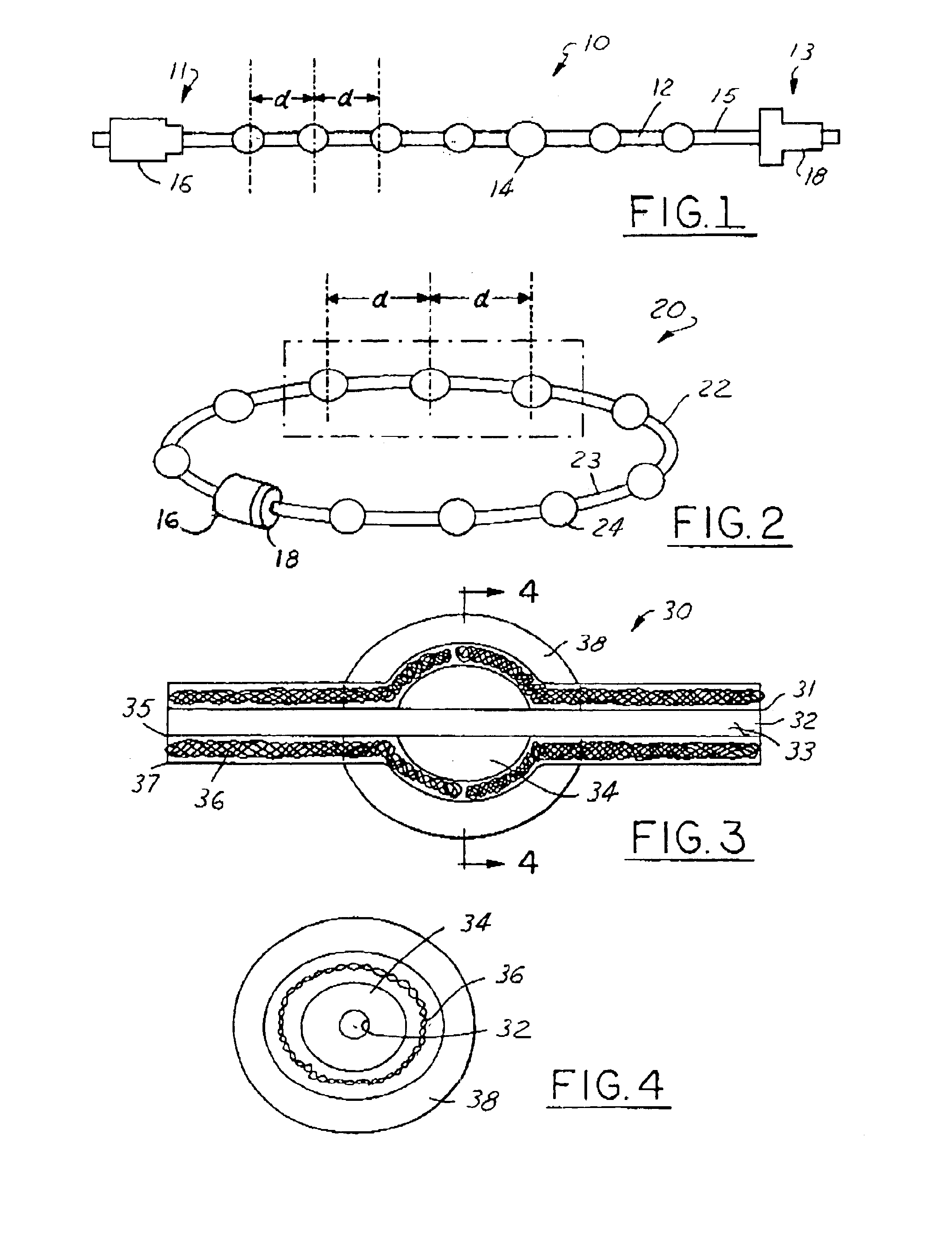

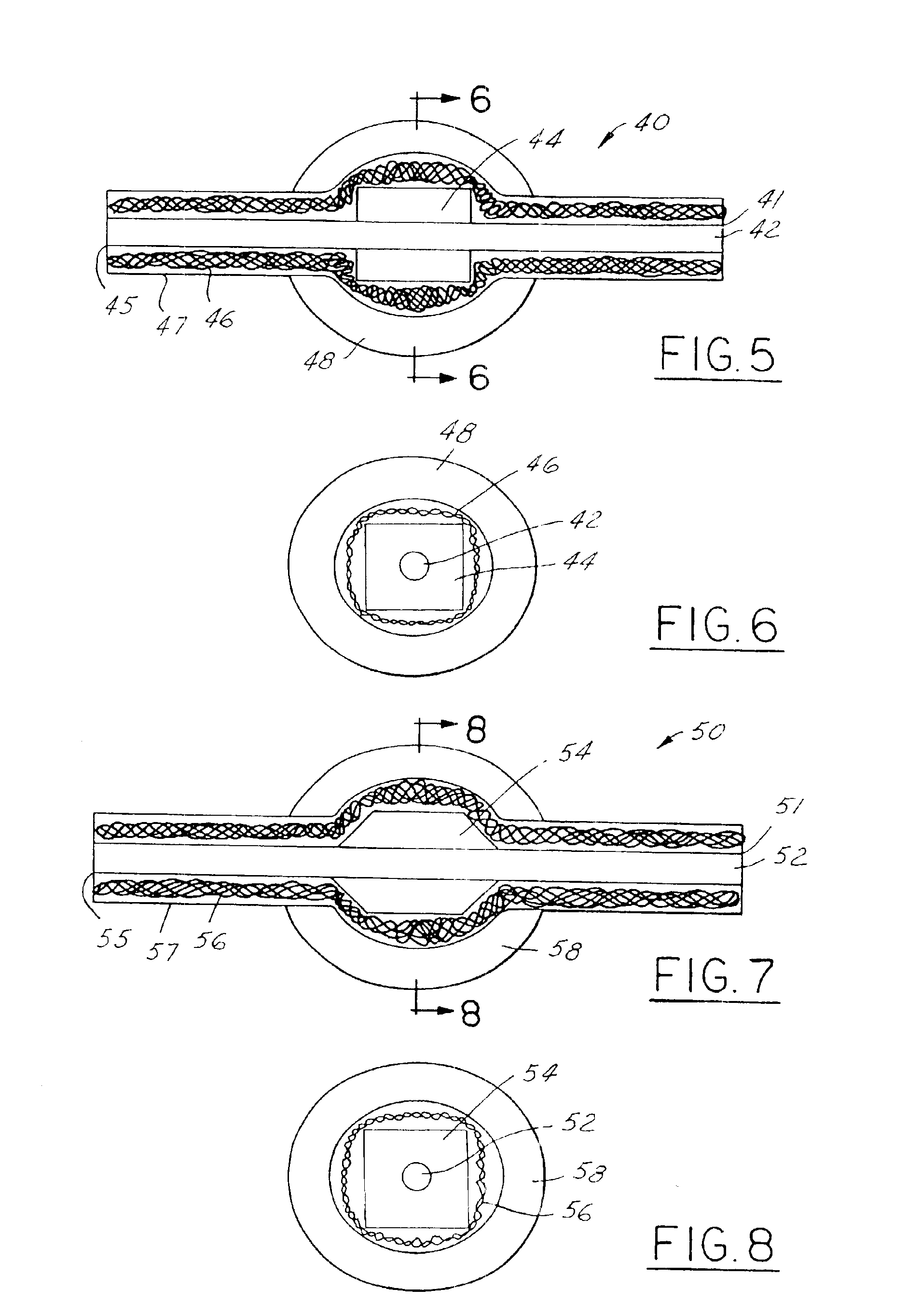

Over-molded beaded cable for driving applications

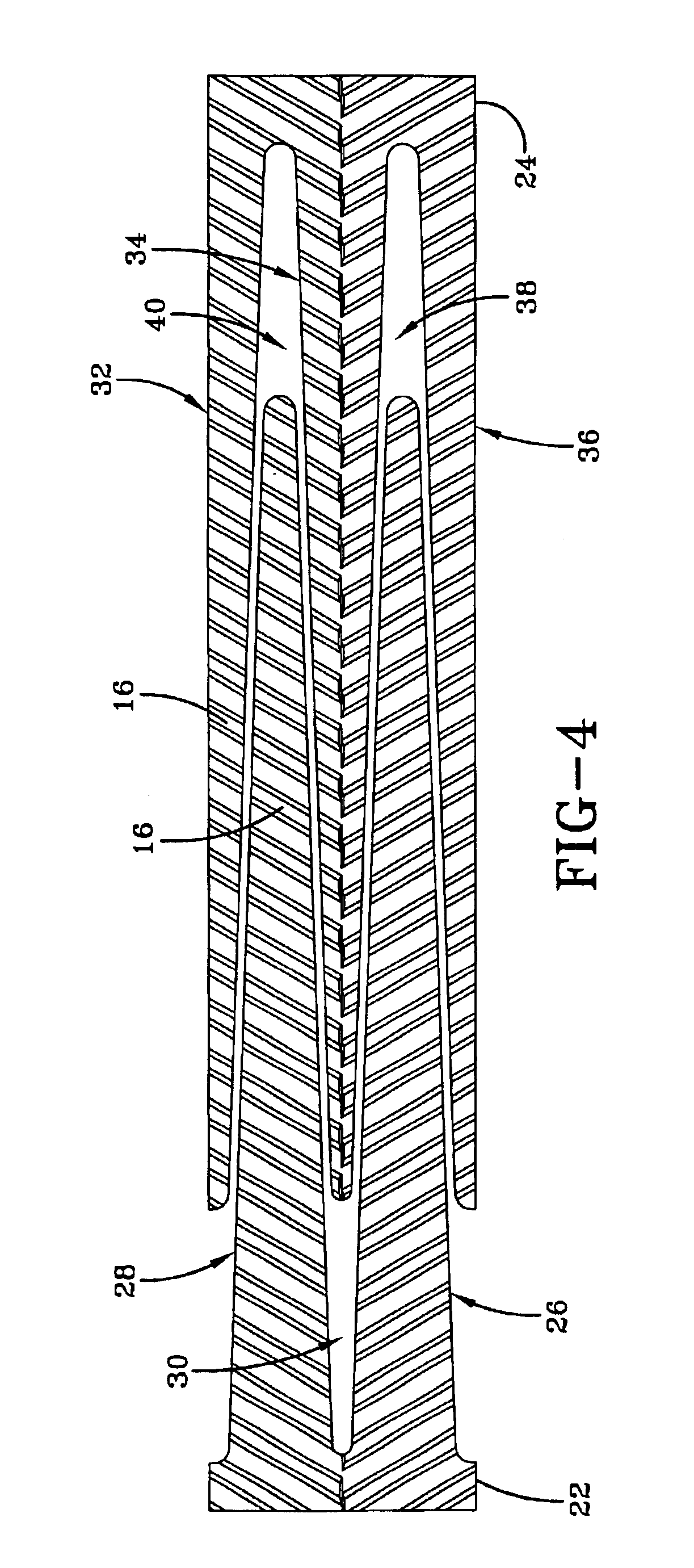

InactiveUS6849016B2Increased strength and flexibilityIncrease load capacityV-belt fasteningsV-beltsClosed loopEngineering

An over-molded beaded driving cable which has an inner core, a plurality of inner core structures. An outer jacket may encompass the inner core and inner core structures. Each of a plurality of outer beads concentrically surrounds an inner core structure. The outer beads are over-molded in this position, forming an interlocking inner core structure and outer bead configuration capable of high load and high flexible performance. An end fitting placed at each end portion of the inner core provides for a driving cable assembly with a variety of end fitting configurations, including a closed loop connection, for automotive and non-automotive applications.

Owner:STRATTEC POWER ACCESS

Buckle

A buckle includes a male member and a female member. The male member is provided with a base, a pair of legs and an engaging portion provided on a distal ends of the legs. The female member is provided with an insertion port, a guide that elastically deforms the distal end of each of the legs inserted through the insertion port in a direction in which the distal ends come closer to each other and a pair of engaged portions formed on both sides of a remote side of the guide. Each of the engaged portions displaces each of the engaging portions in the direction in which the engaging portions get apart with each other and is provided by a concave that has an abutment wall on a rear portion in the releasing direction to be abutted by each of engaging portions. Each of the abutment walls is formed as a slant surface that inclines in the direction in which the abutment walls come closer to each other toward the releasing direction of the male member.

Owner:YKK CORP

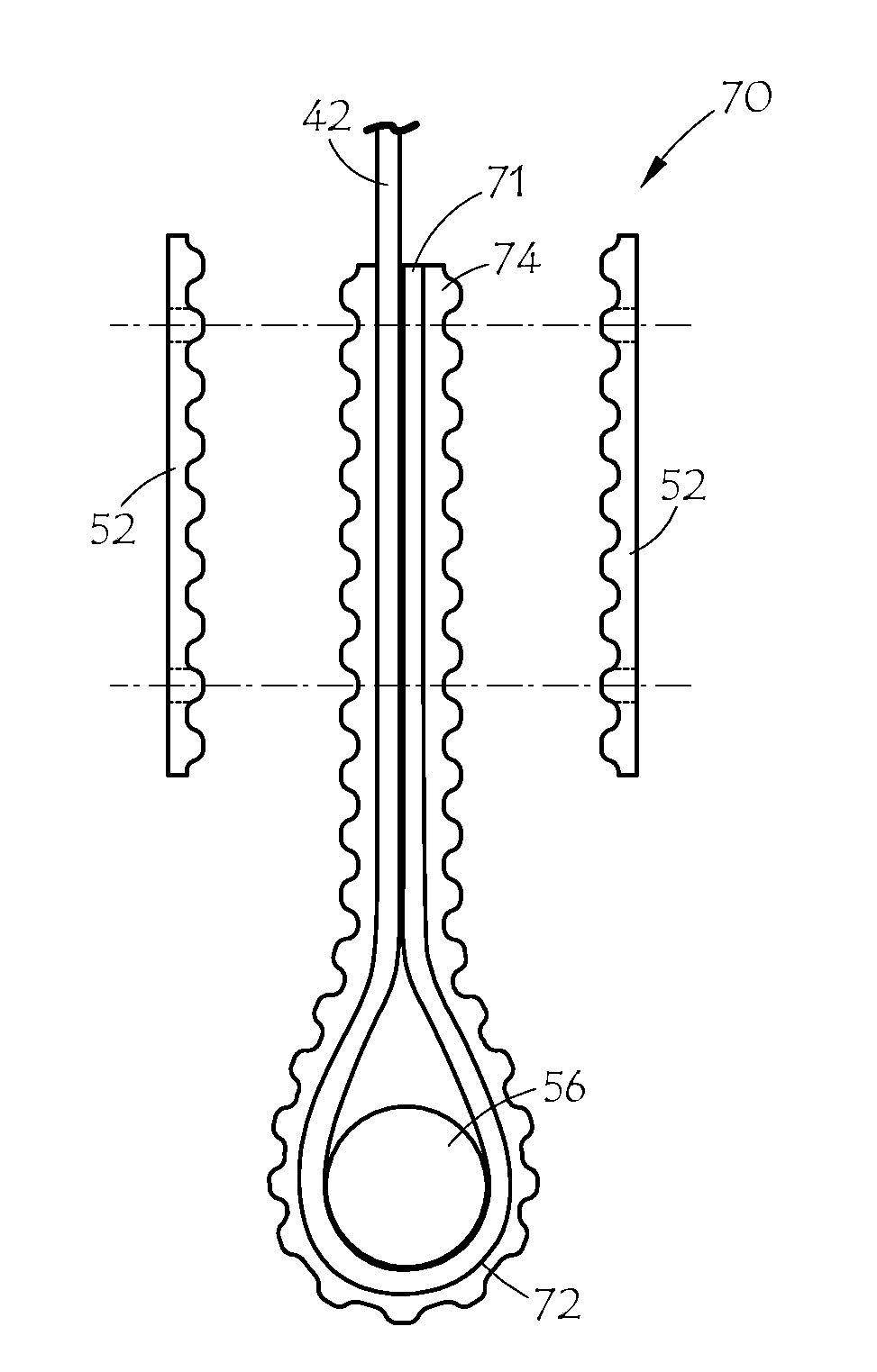

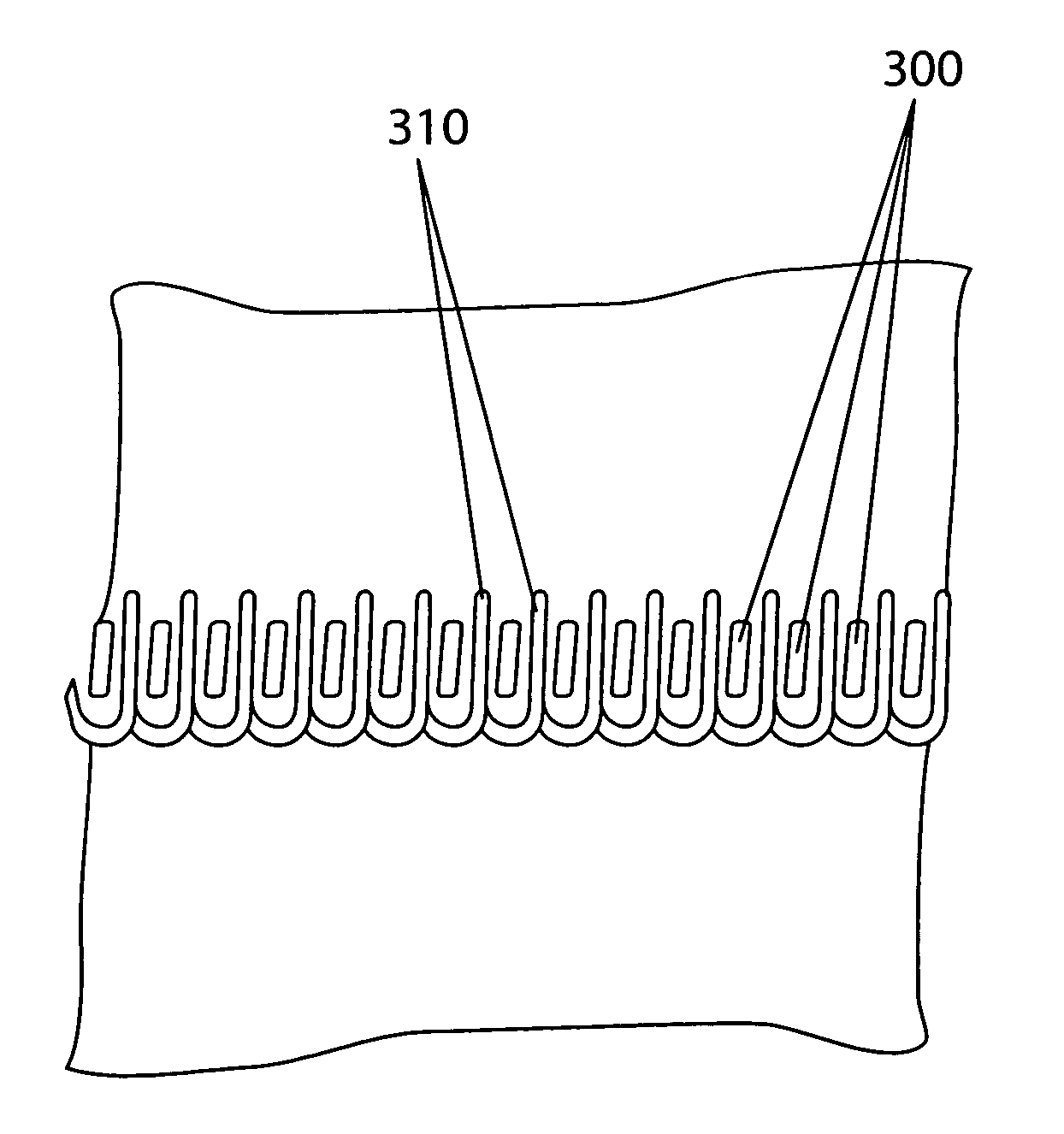

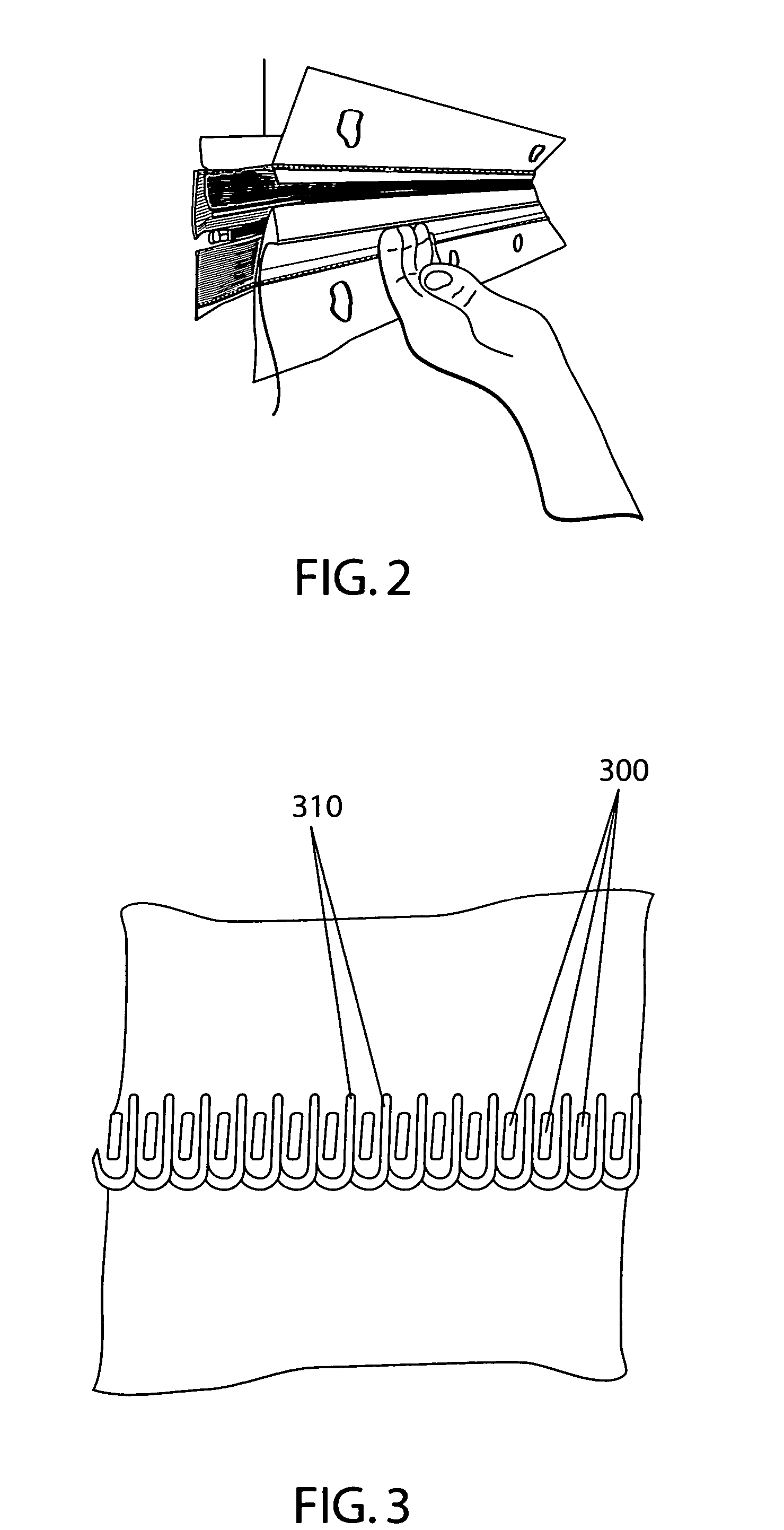

Method and device for stabilizing unseamed loops

ActiveUS7393434B2Easy to connect and seamPrevents torque imbalance and other forcesV-belt fasteningsEngine sealsEngineering

A method of stabilizing the seam loops of a papermaking fabric or other industrial fabric until the fabric is ready to be installed and seamed on a machine. Stabilizing the loops prevents torque imbalance and other forces from distorting the loop alignment over time, thereby making the loops easier to connect and seam when the fabric is ready to be installed.

Owner:ALBANY INT CORP

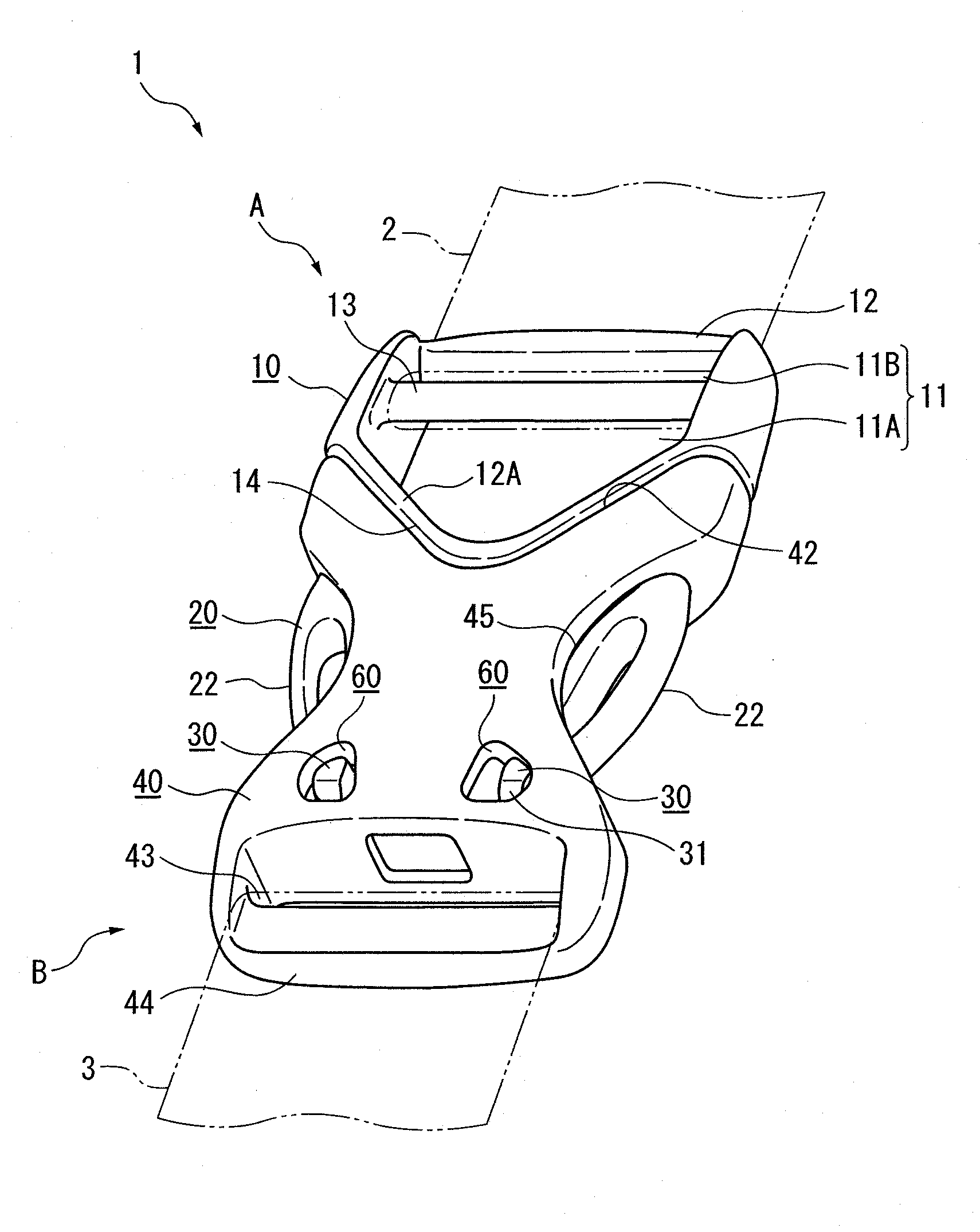

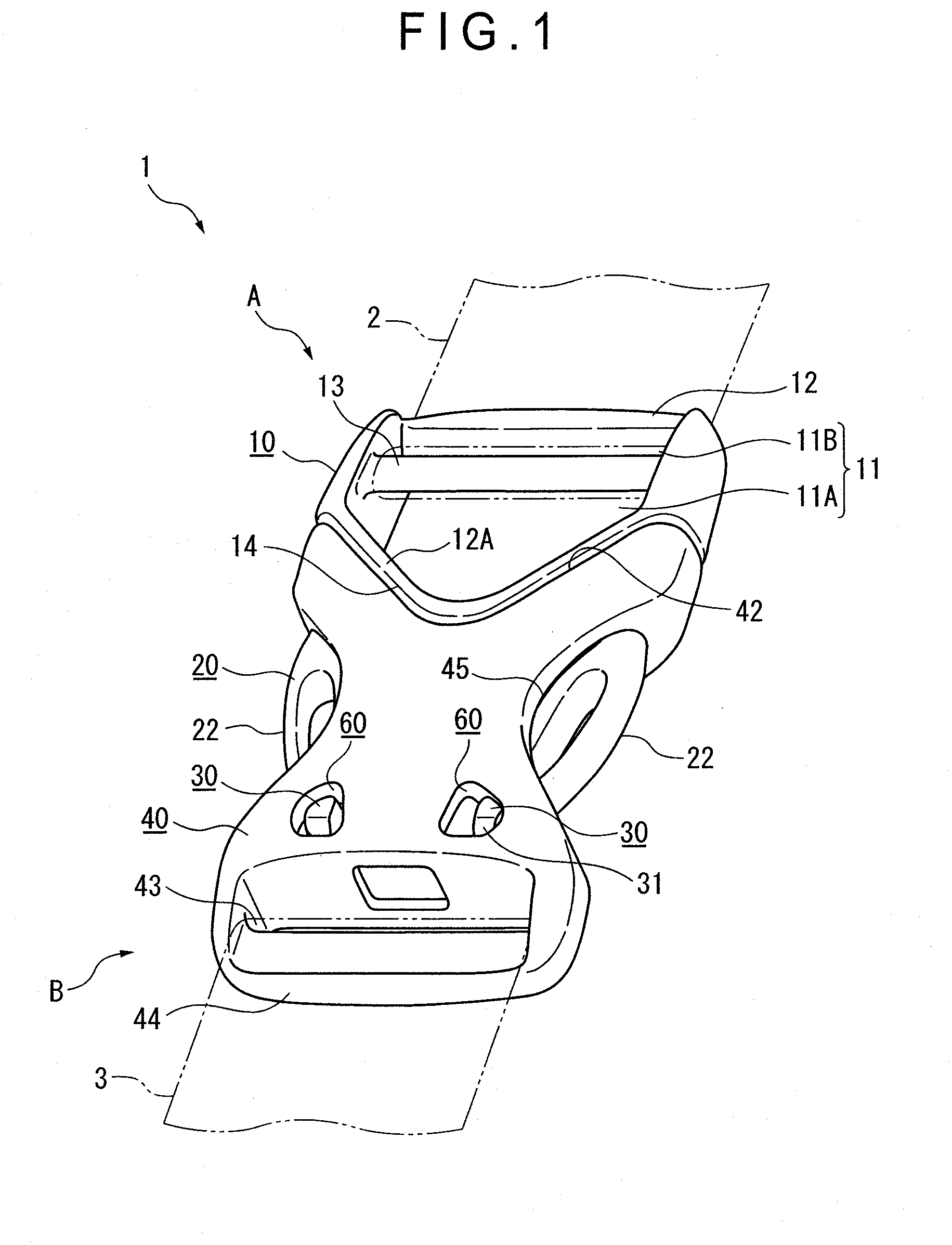

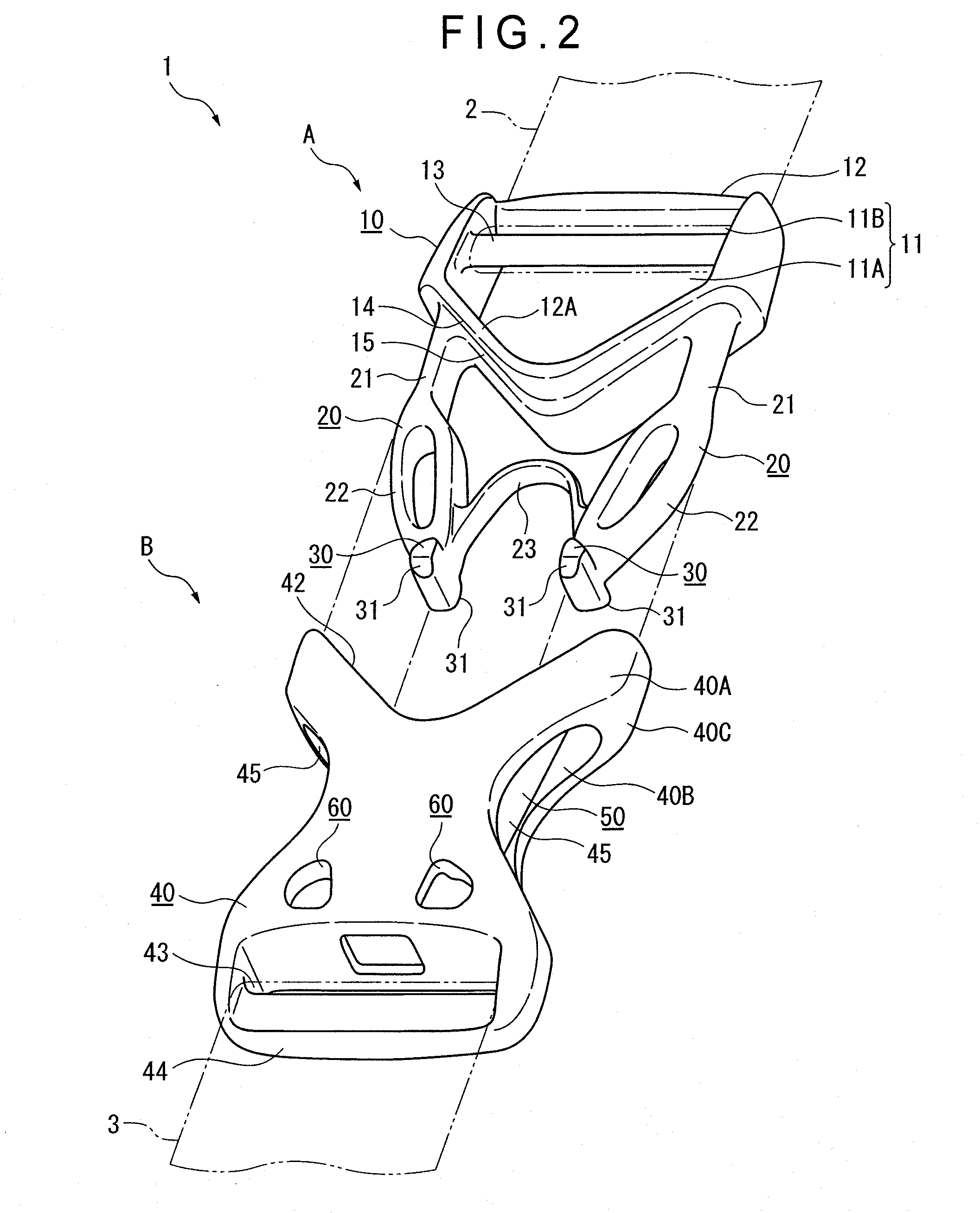

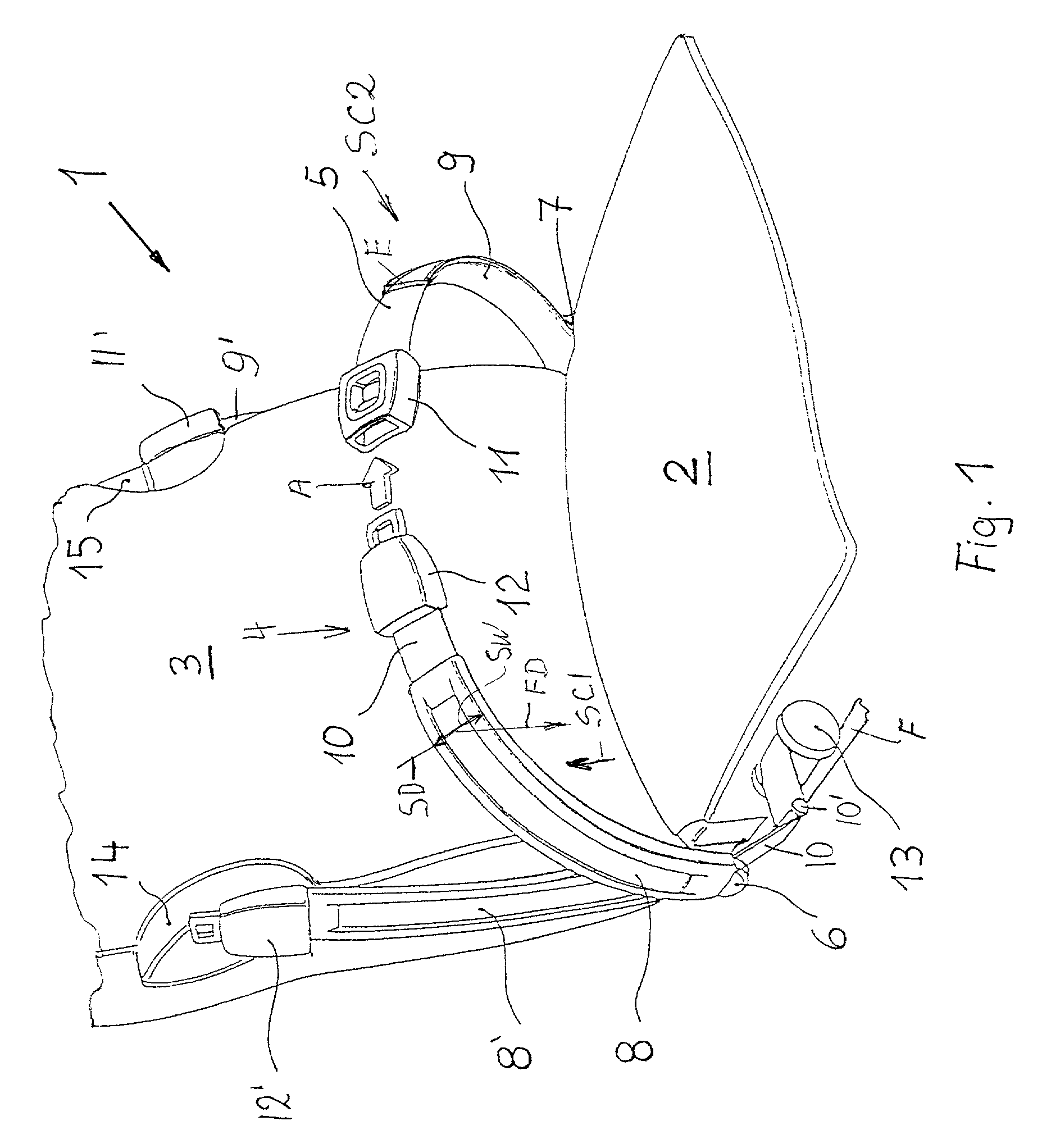

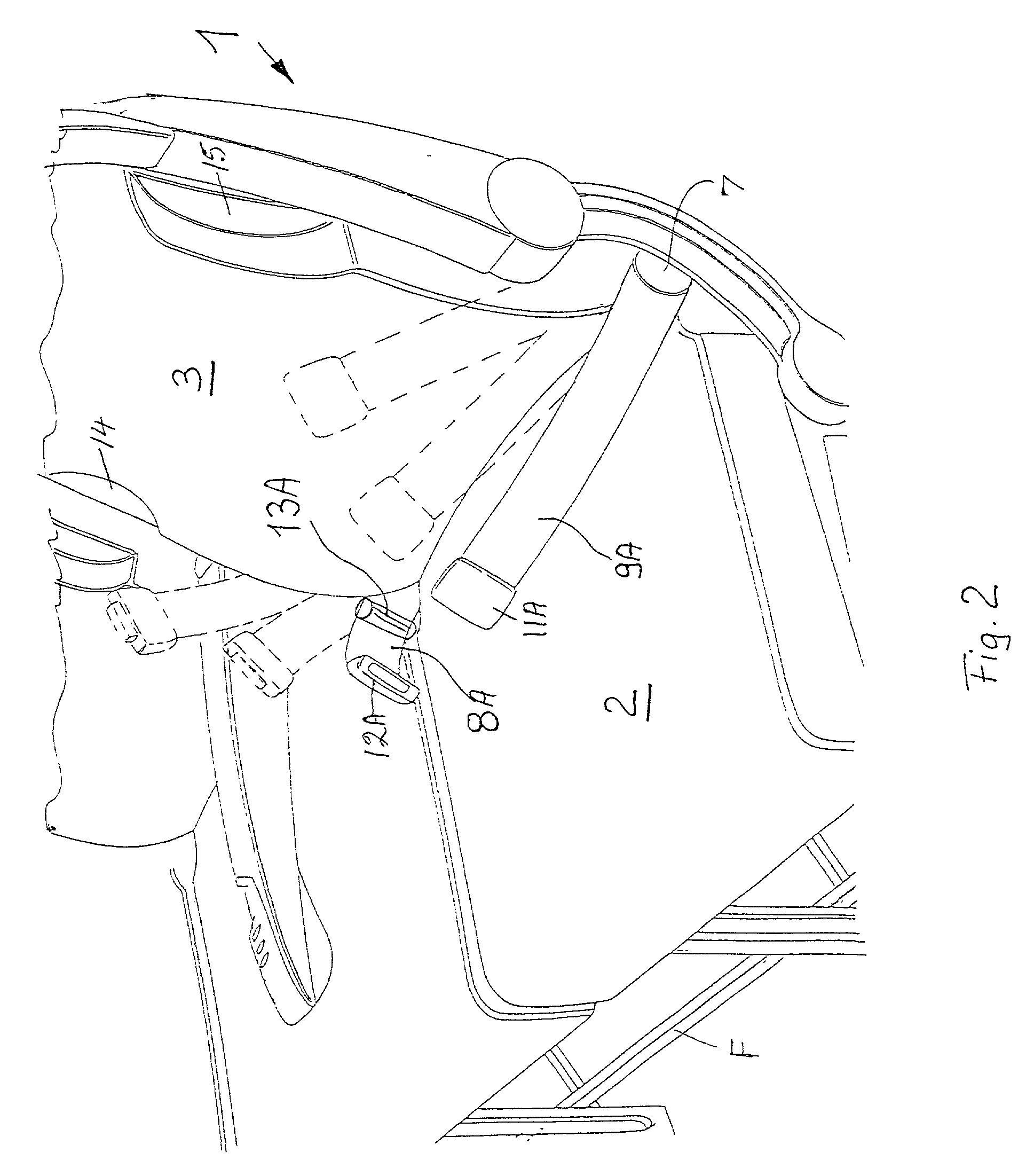

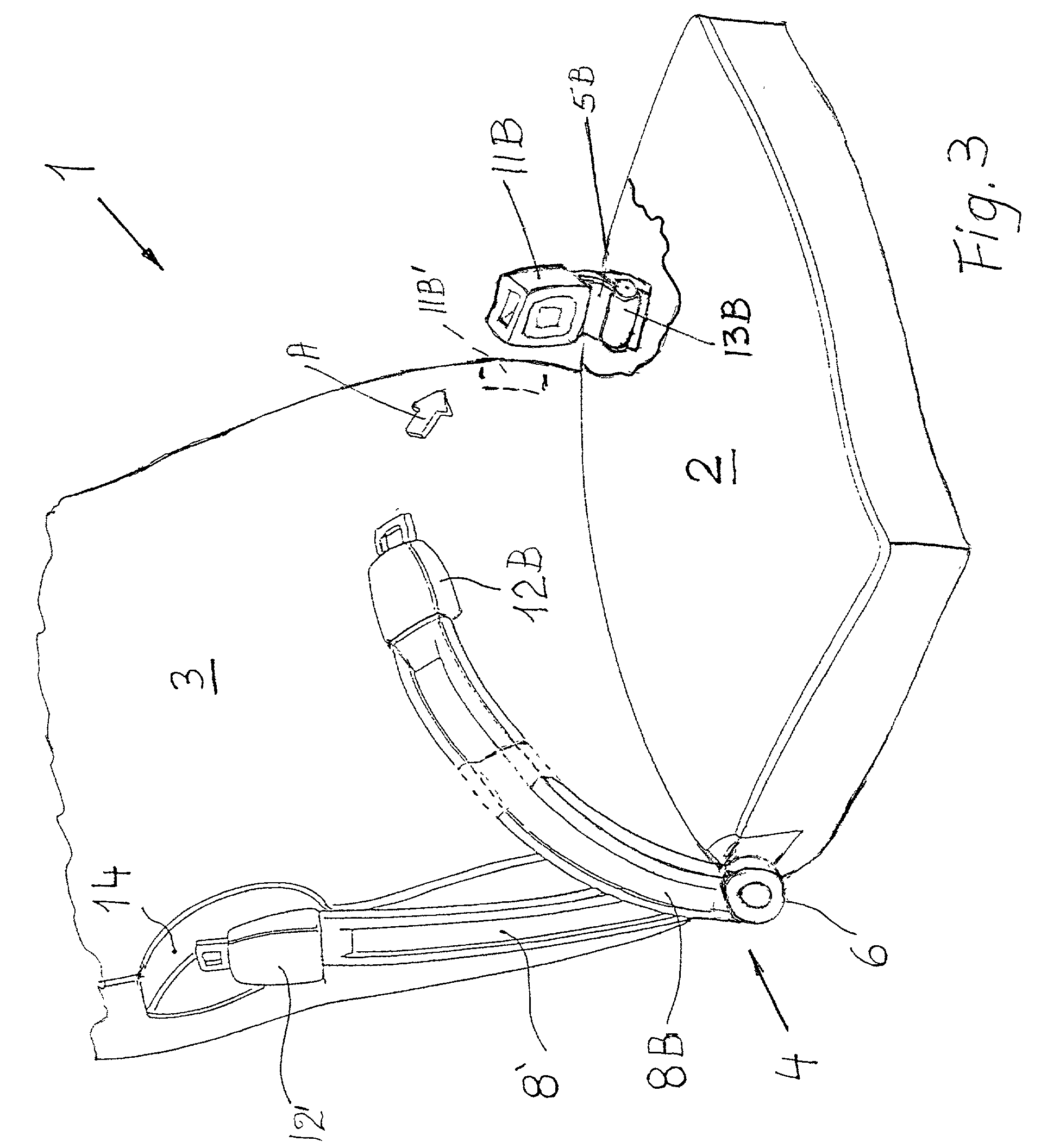

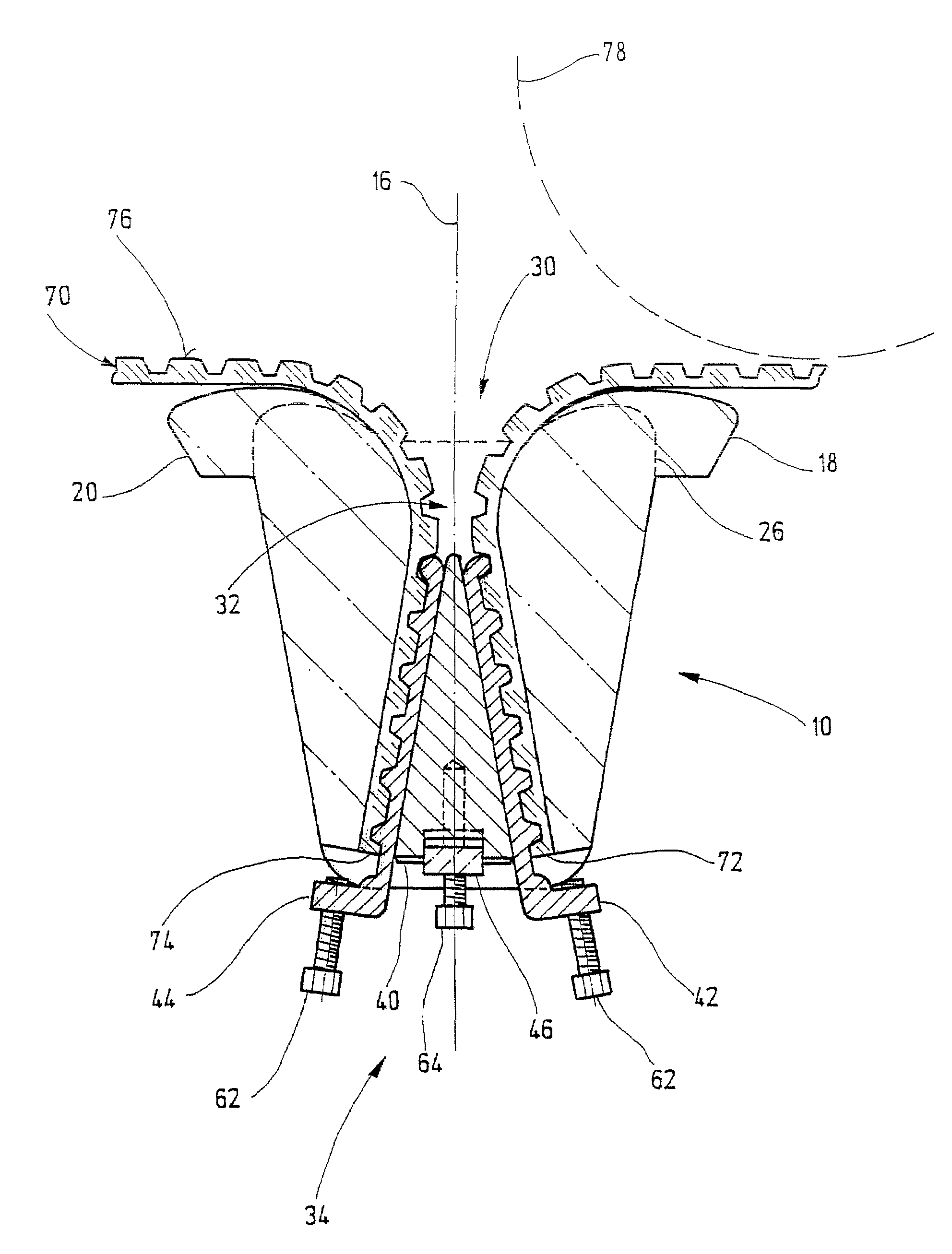

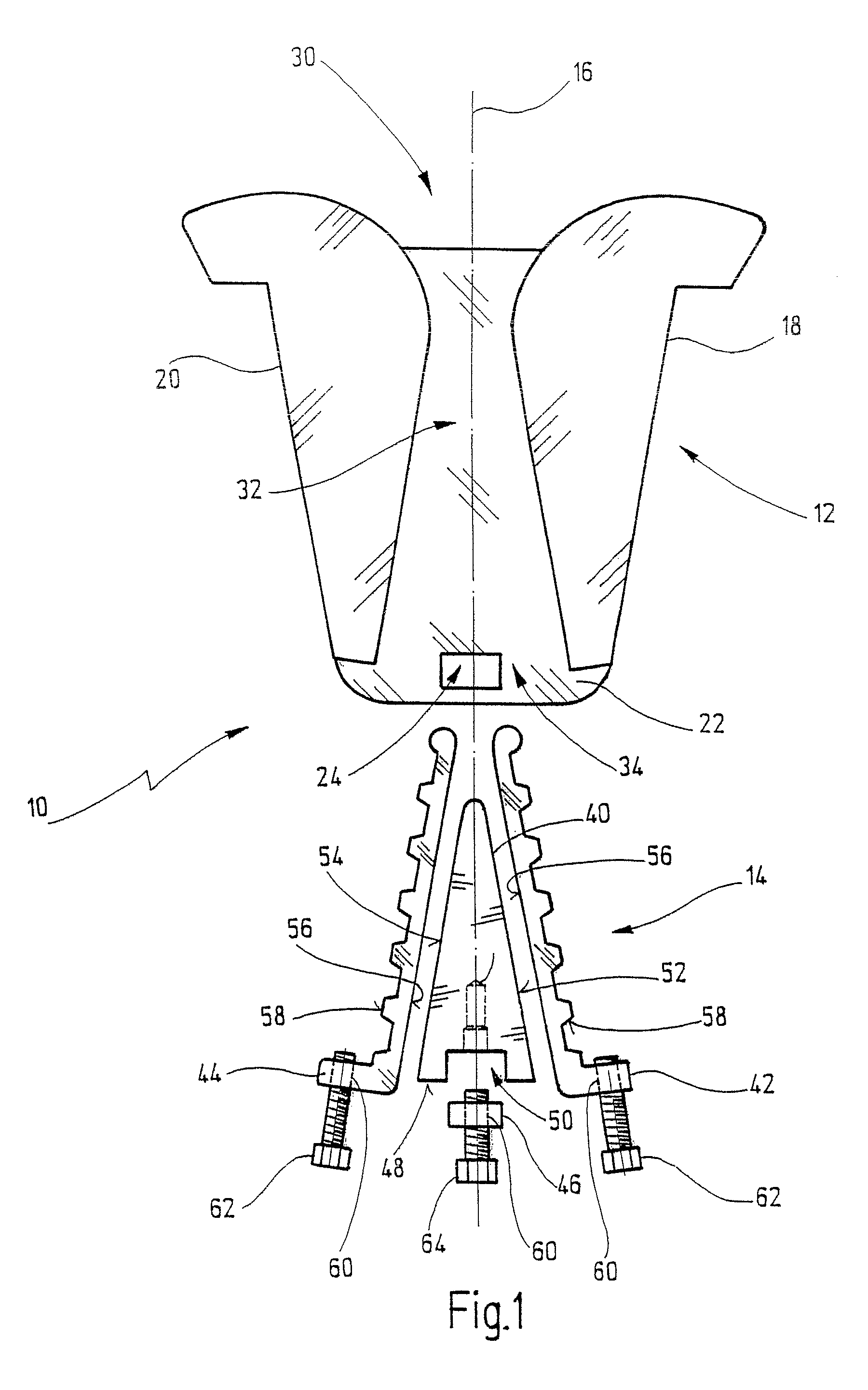

Passenger chair and safety belt system for such a chair

InactiveUS20010025400A1Avoid disadvantagesReduce effortV-belt fasteningsSupports/holding devicesRest positionBack rests

A safety belt system especially for a passenger chair has at least one, preferably two, safety components each of which includes a controlled flexibility. The controlled flexibility is provided by a relatively stiff sheath or whip or belt section. A limp belt member passes through the sheath with the controlled flexibility. In a second embodiment, the controlled rigidity is provided by a flexible belt end section. In both embodiments one end of each safety component is secured to the chair and the other end has a belt lock element for closing the belt system for use. In an open rest position at least one, preferably both, safety components rest against the backrest of the chair. The controlled flexibility provides a spring biasing force that keeps the safety component in the rest position from which the passenger can turn the safety component into a use position and close the system with one hand.

Owner:ROMCA JENS +2

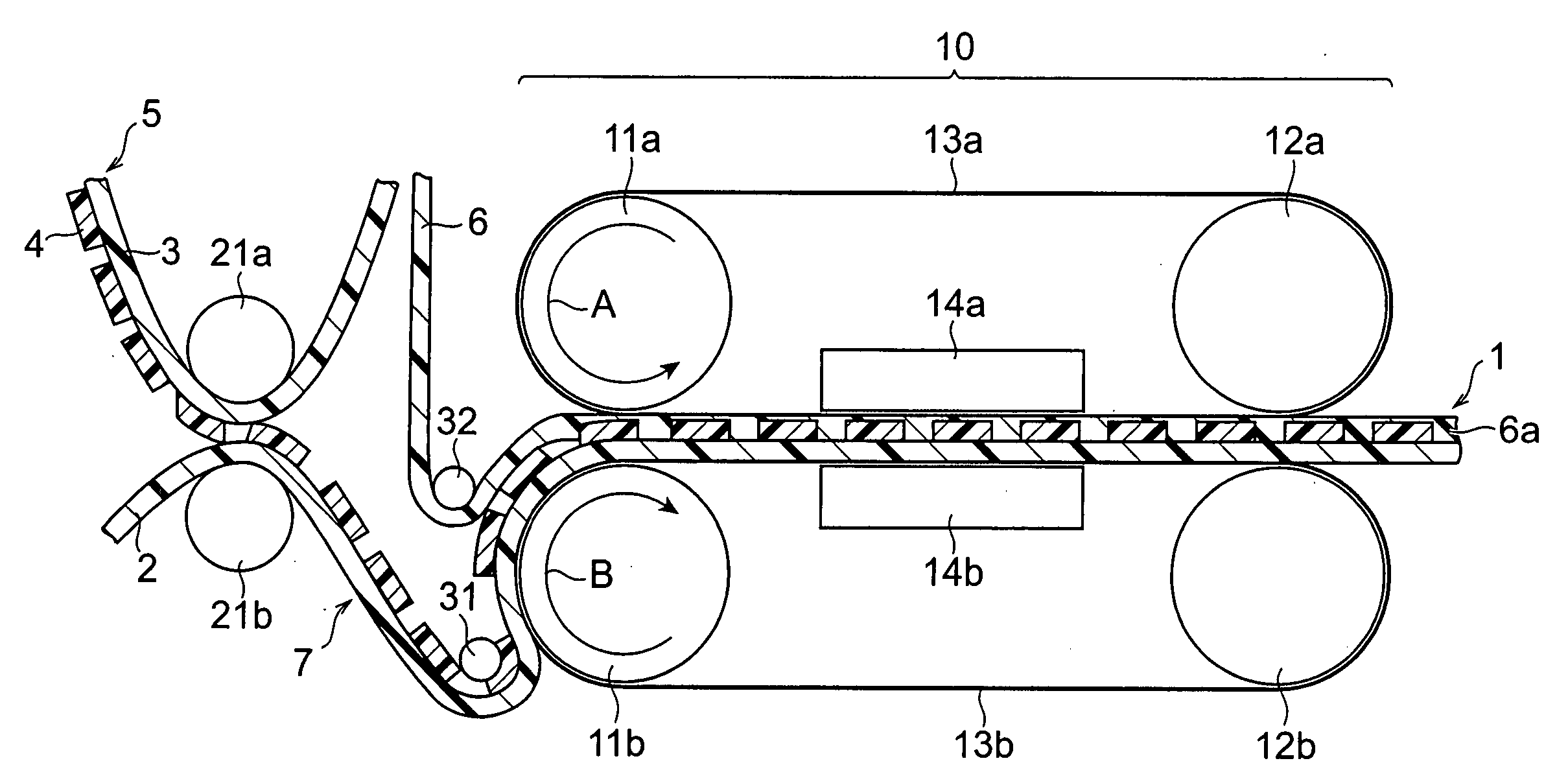

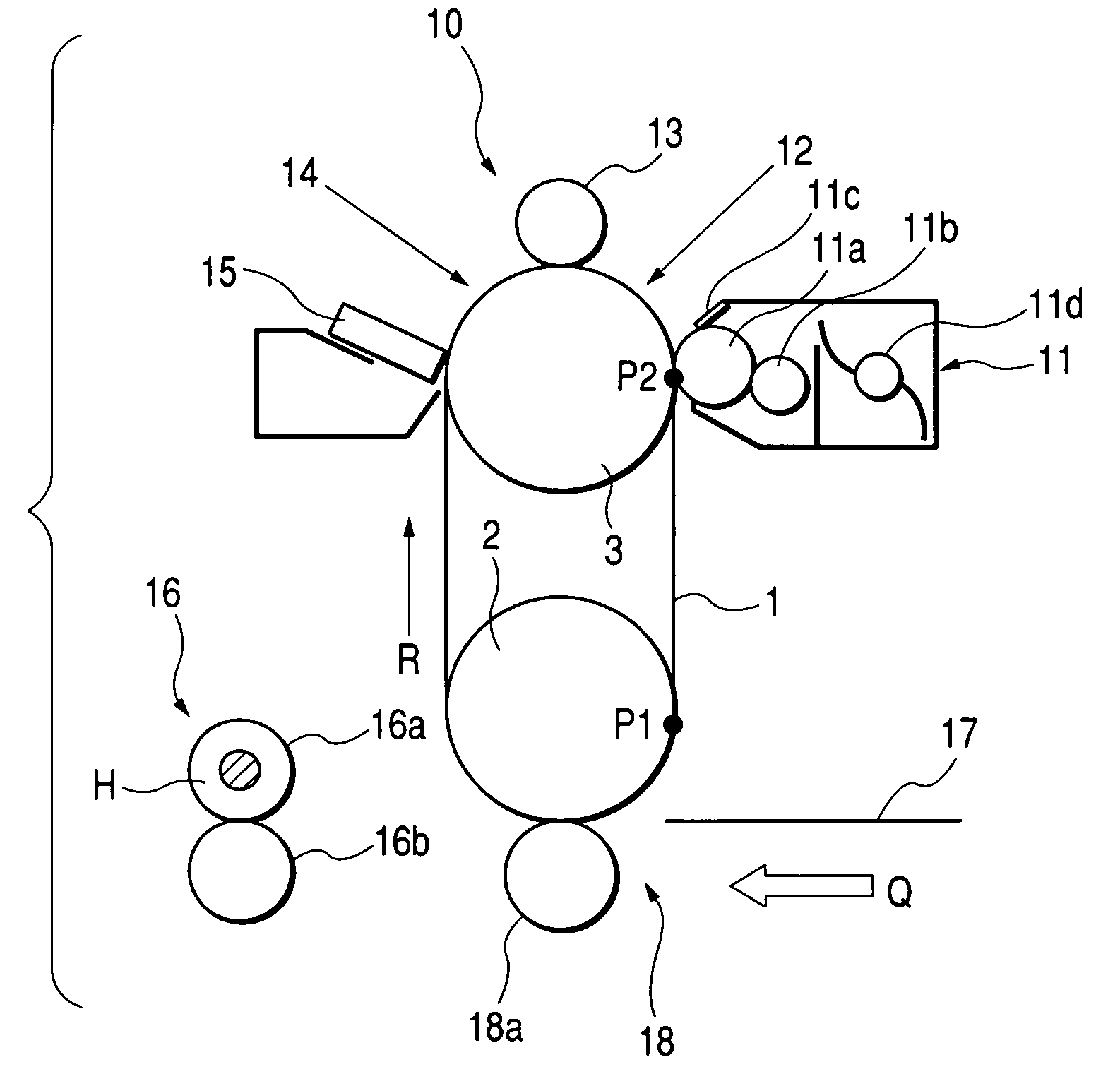

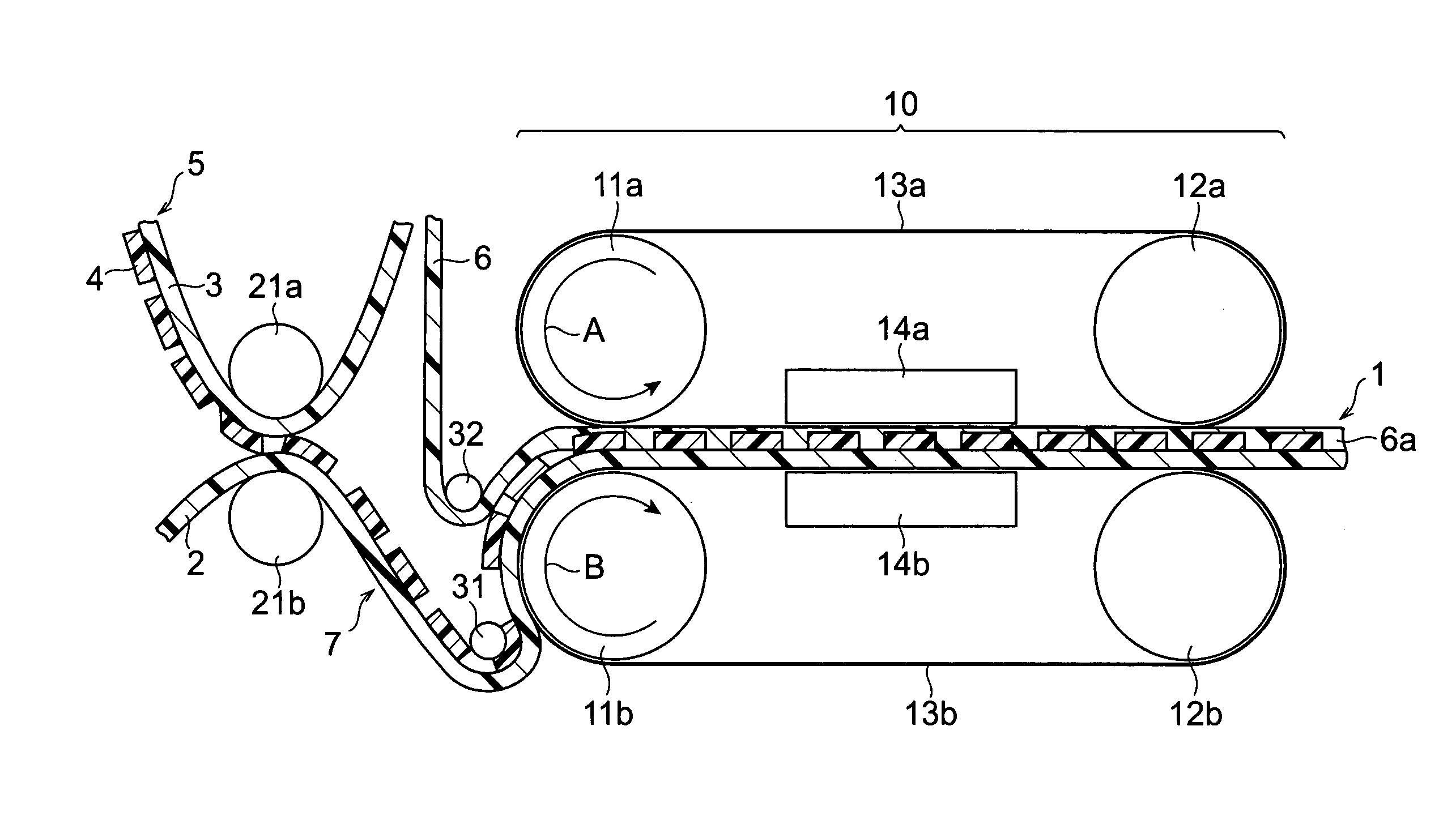

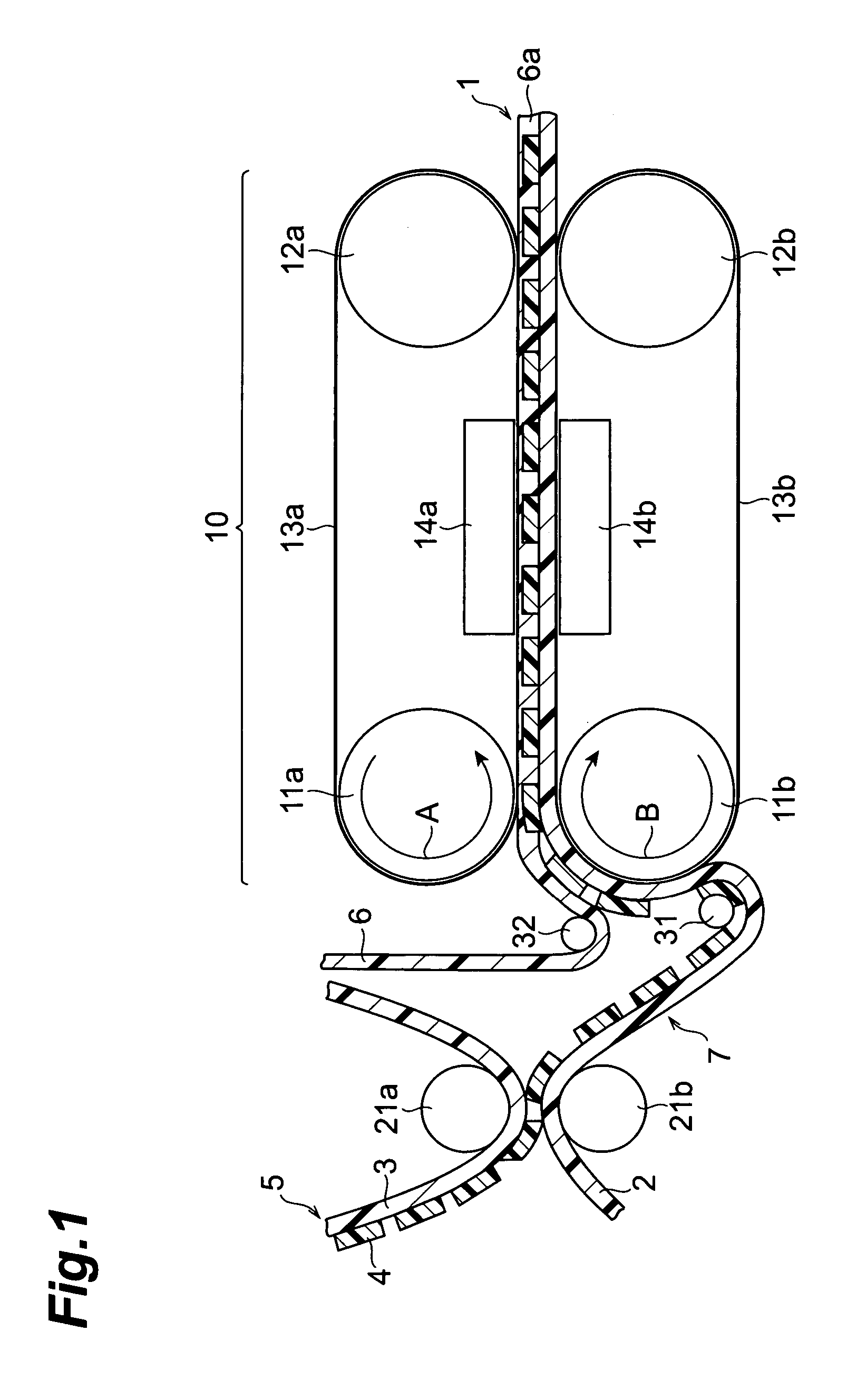

Production method of decorative film

InactiveUS20070051467A1Well formedHigh surface glossAdhesive processesDecorative surface effectsEngineering

A production method of a decorative film comprising a step of, in a state in which a transparent resin film is laid on a surface of a laminate sheet in which a pattern layer is placed on one surface of a base film of a thermoplastic resin, inserting the laminate sheet and the transparent resin film into between a pair of endless belts placed opposite each other, thereby obtaining a decorative film, wherein the transparent resin film is preheated by contact with a peripheral surface of a preheat roll urged toward the endless belt, and the transparent resin film is run so as to constantly contact a peripheral surface of at least one guide roll during a period between departure from the peripheral surface of the preheat roll and contact with the laminate sheet.

Owner:SHIN ETSU POLYMER CO LTD

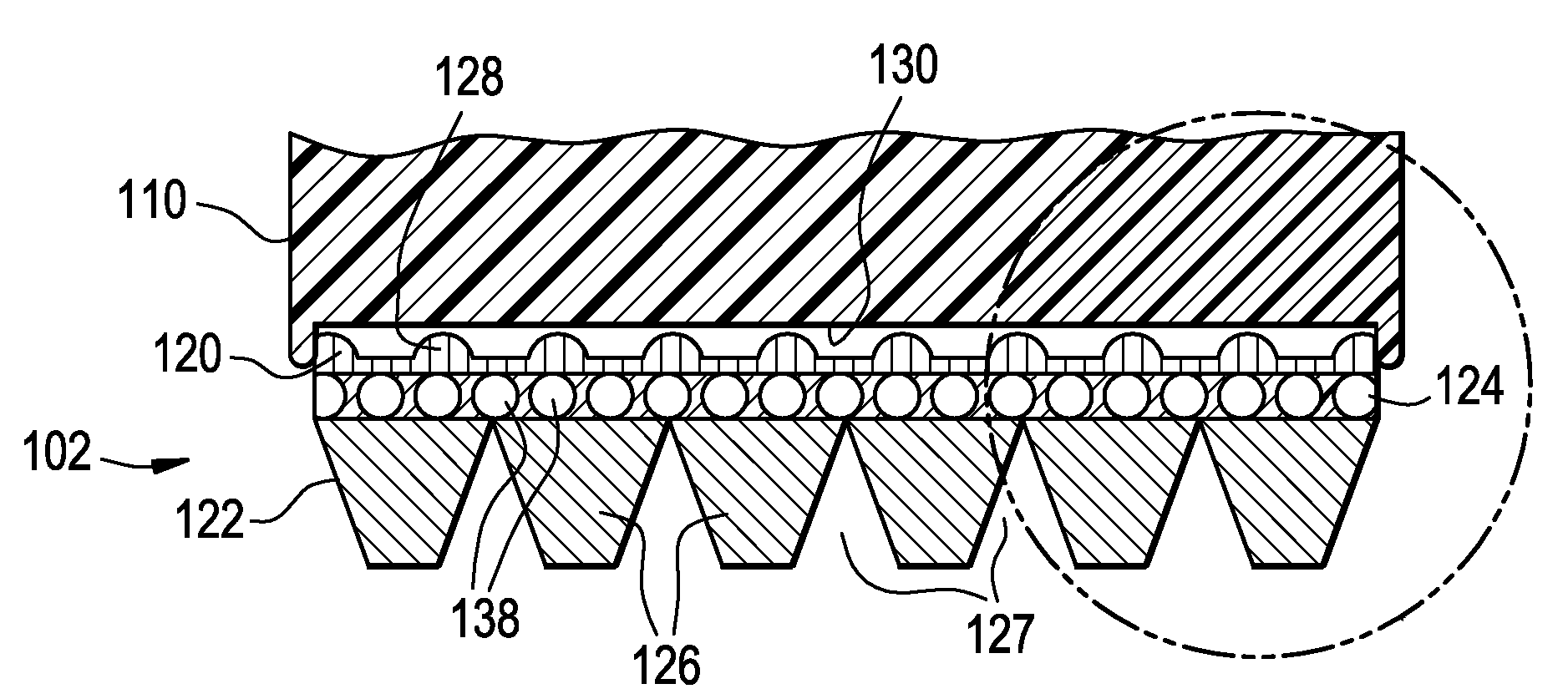

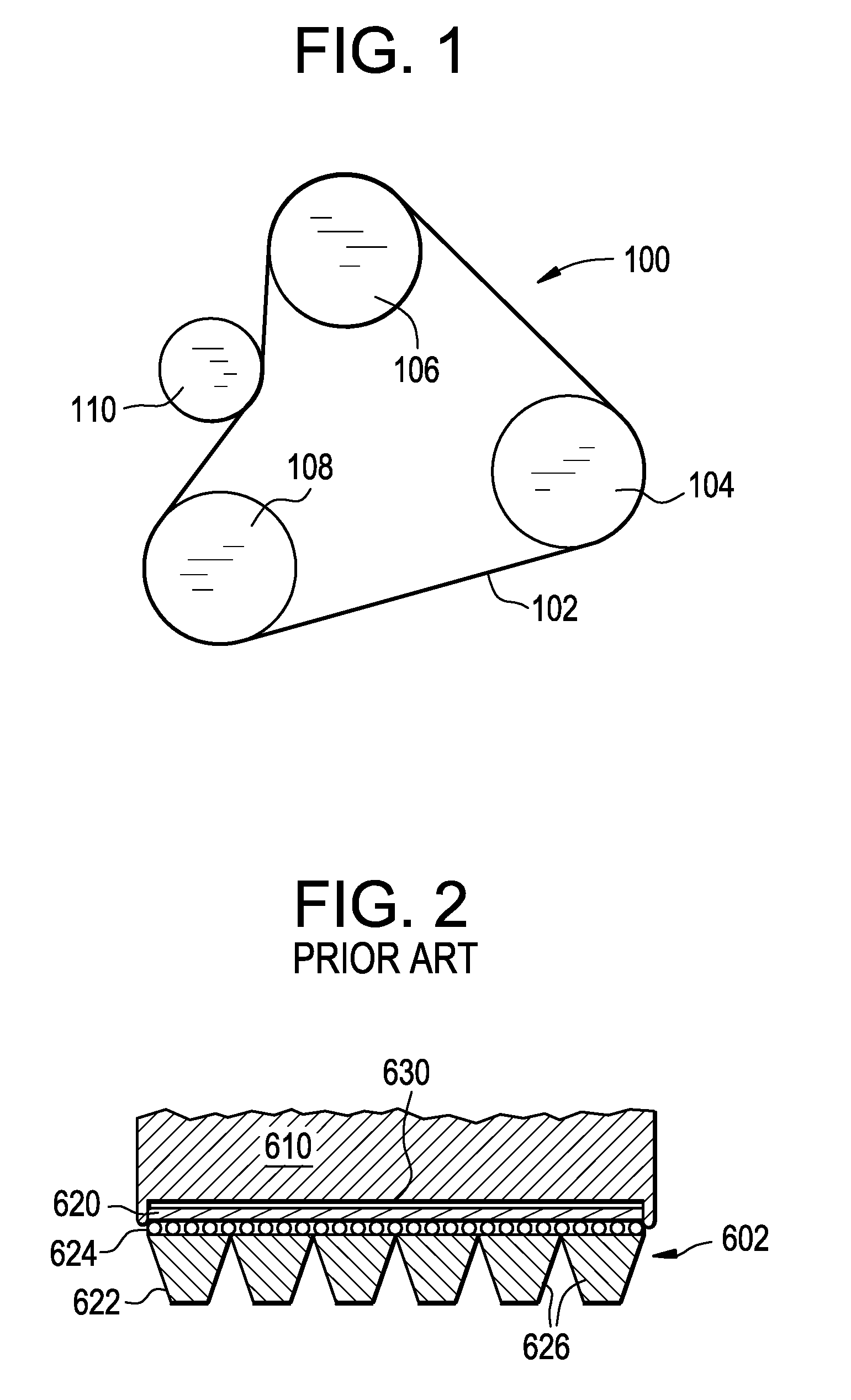

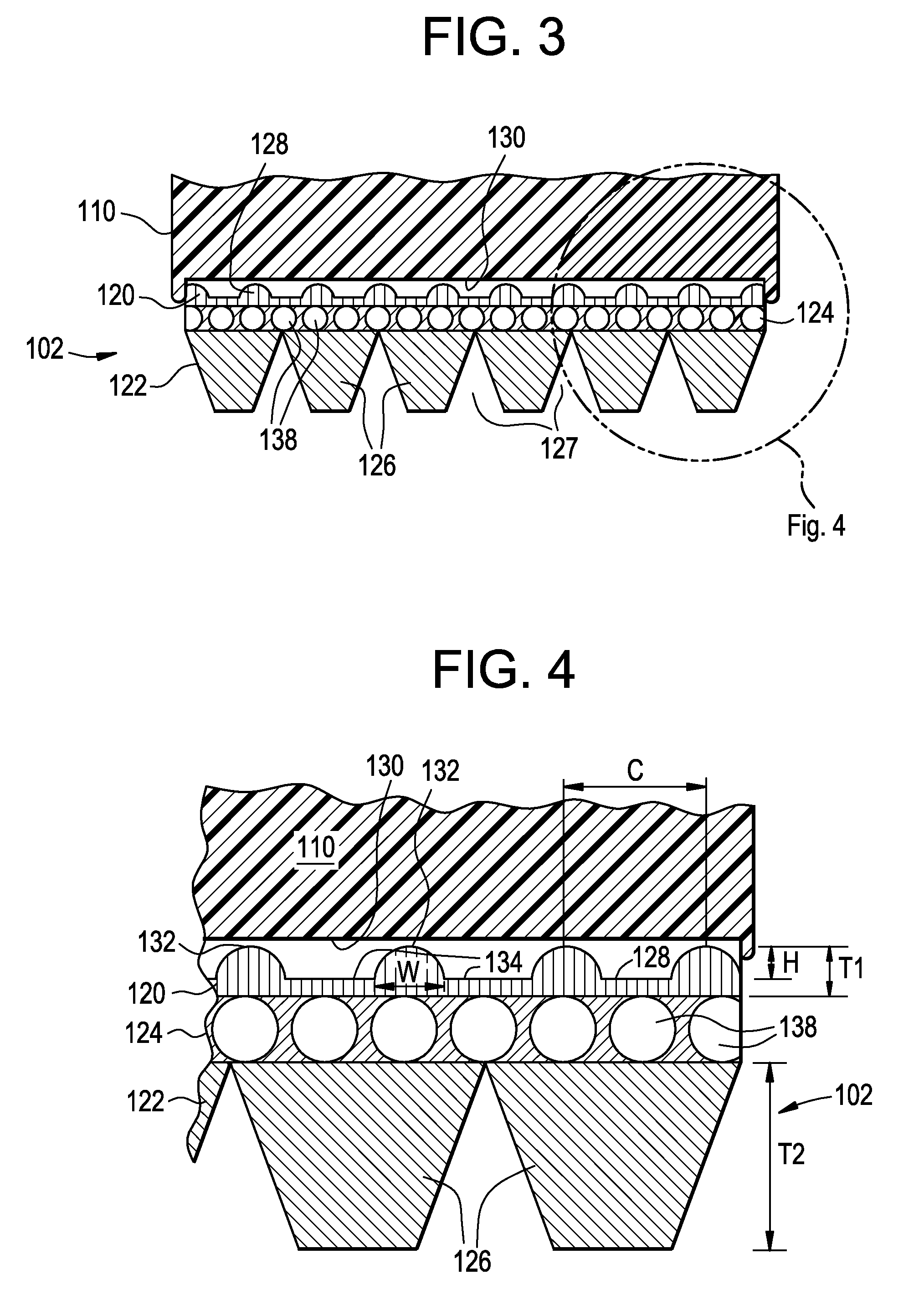

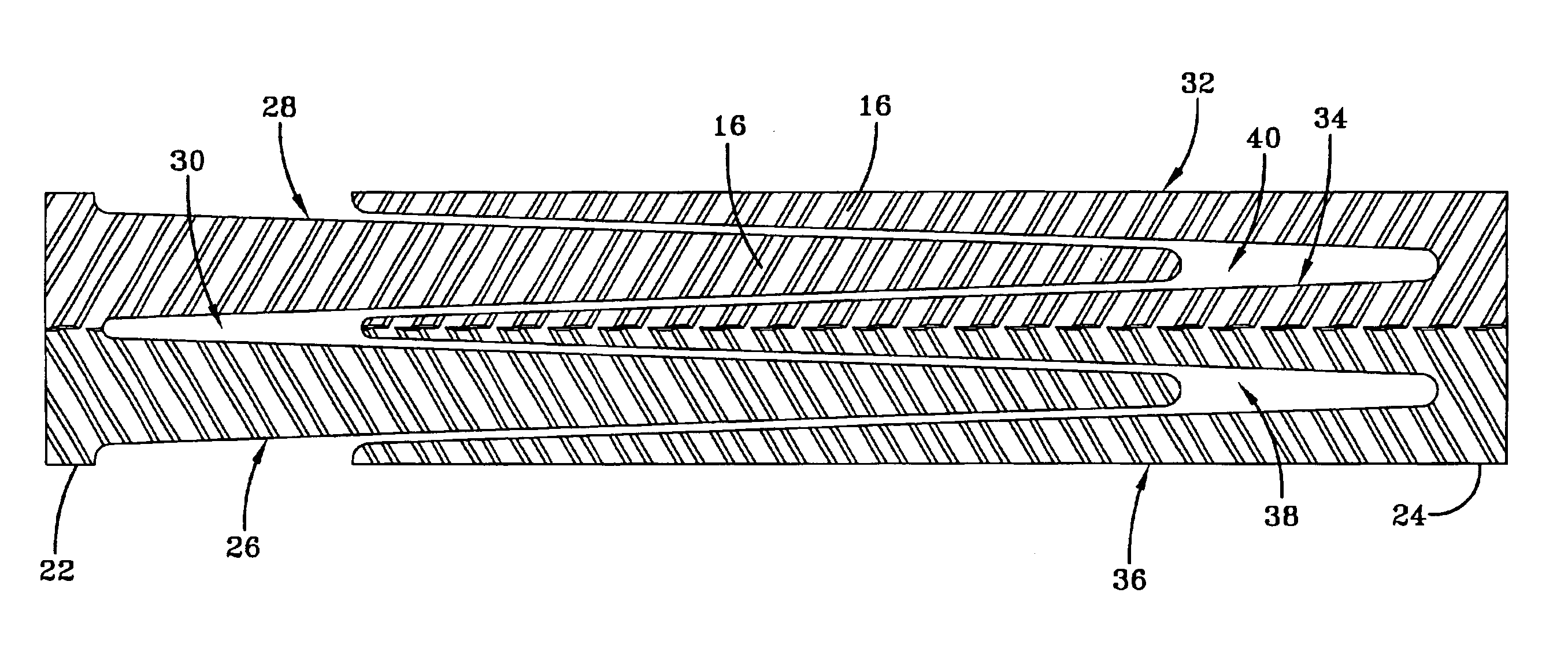

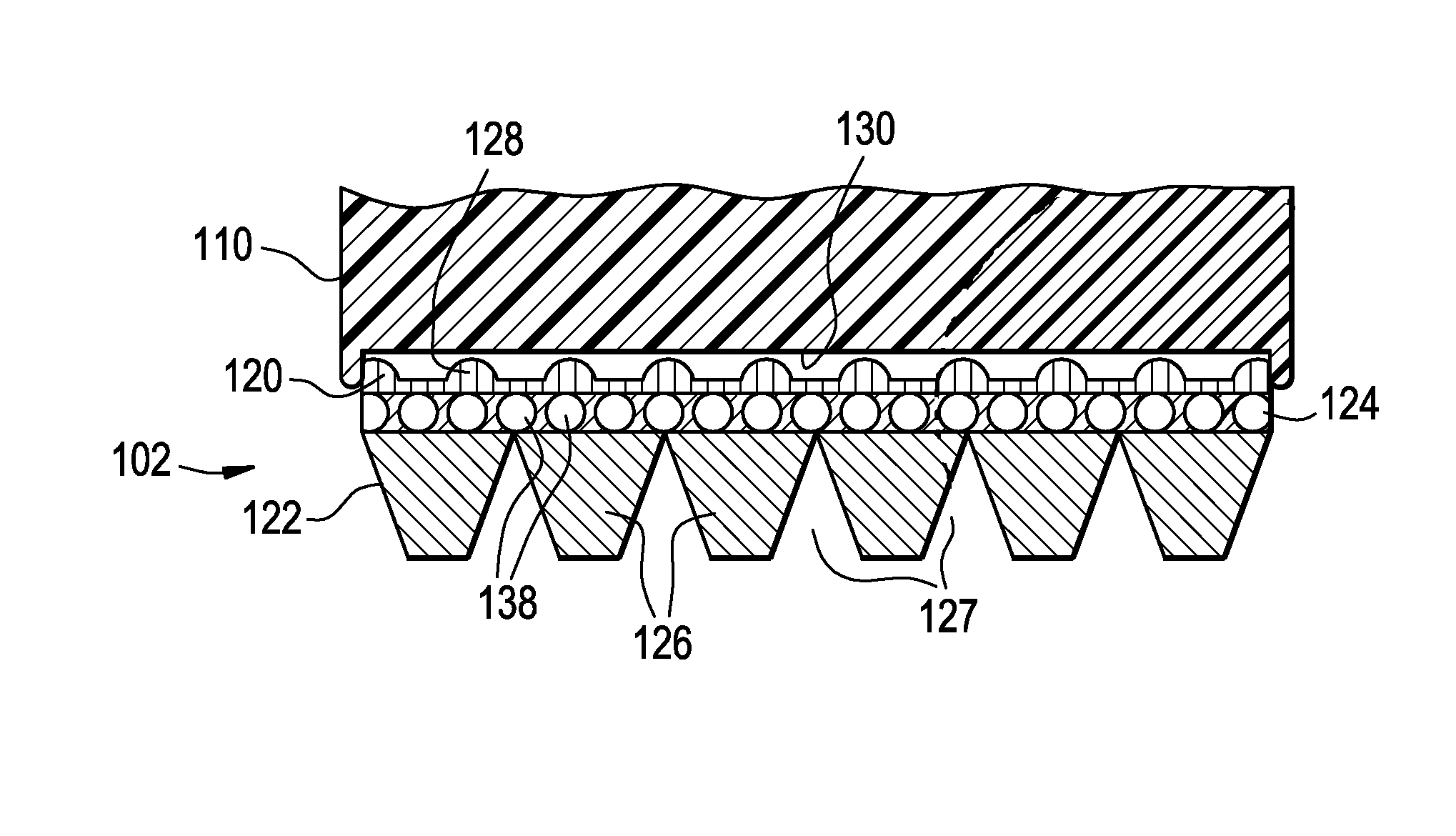

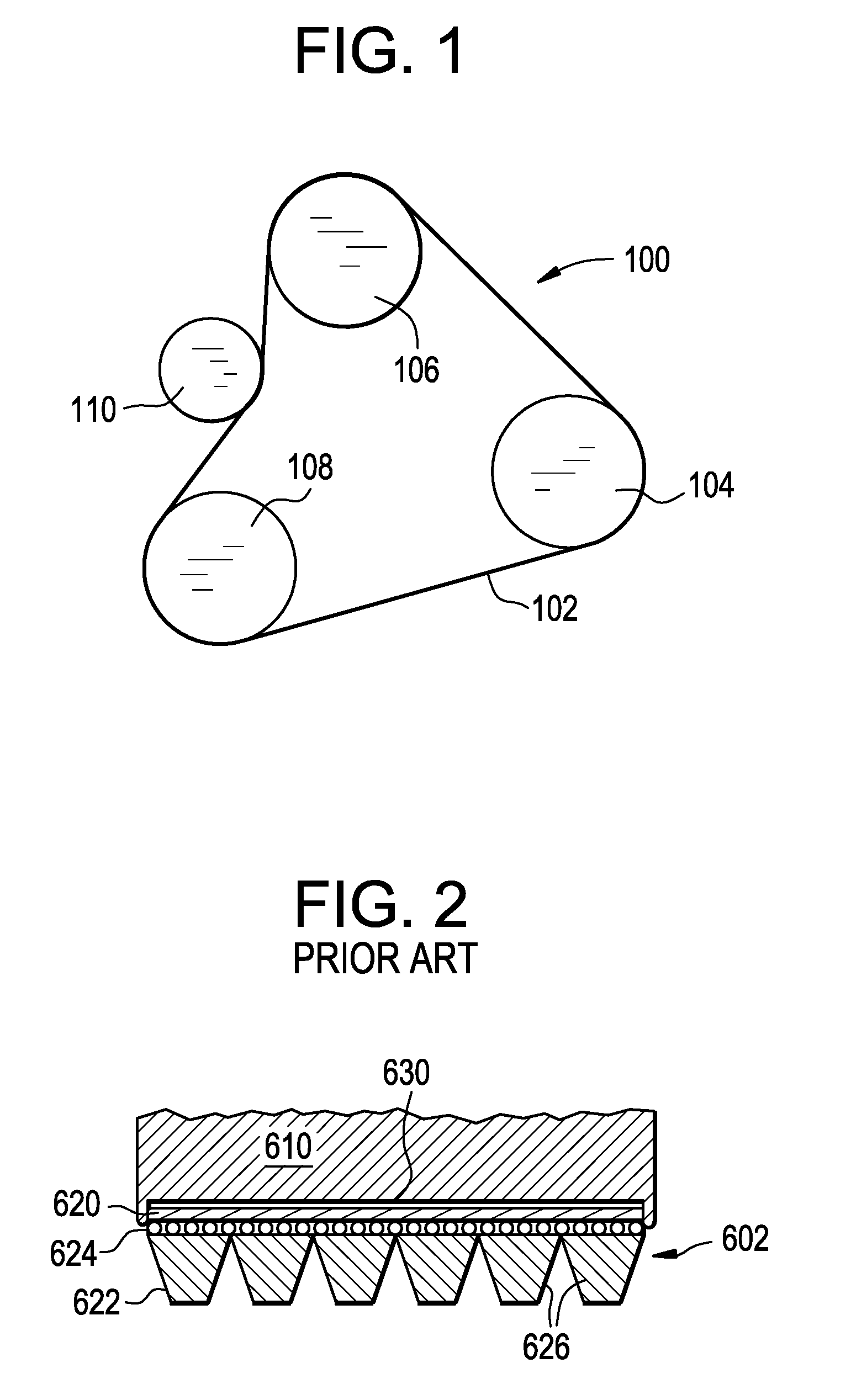

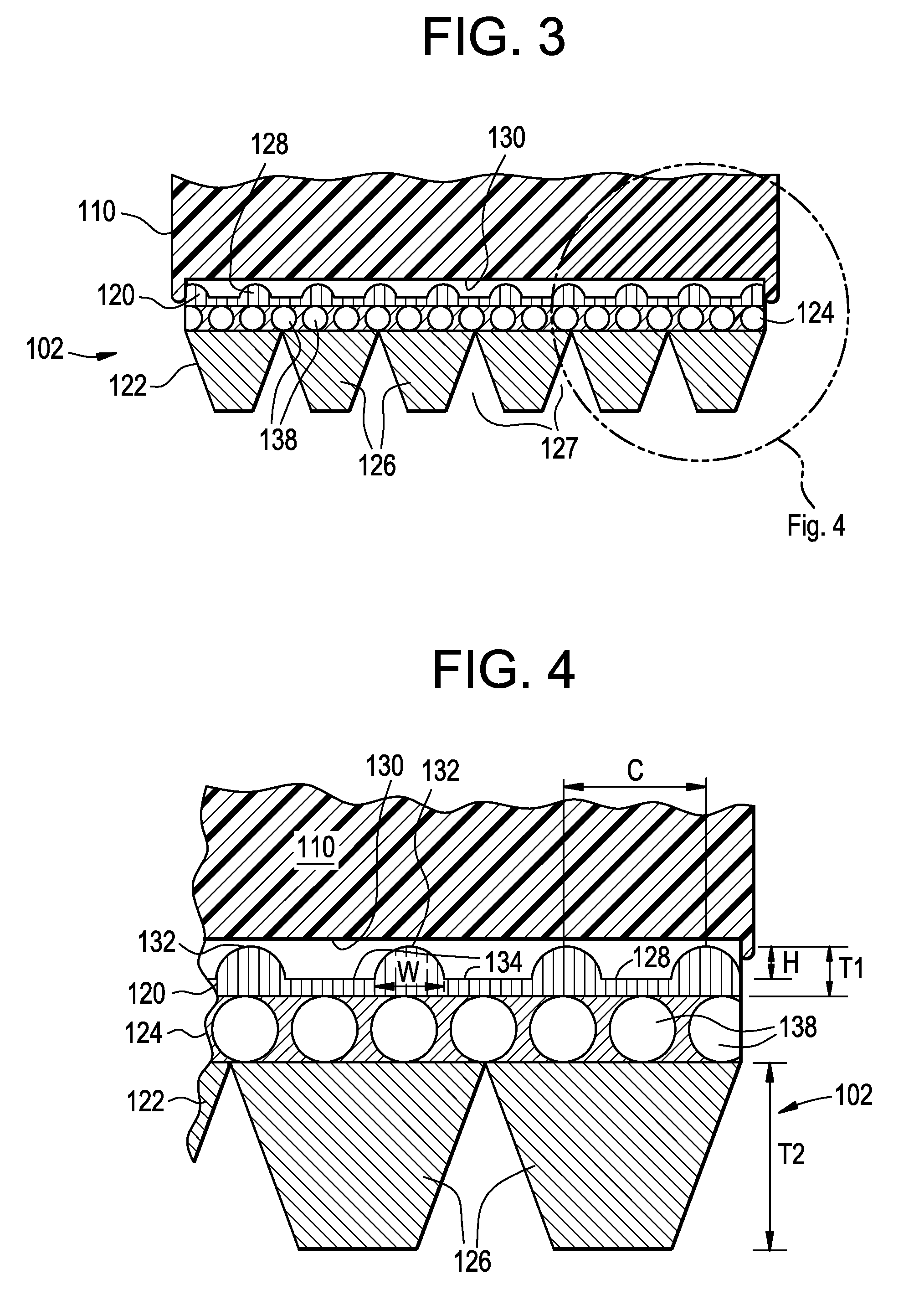

V-ribbed belt having an outer surface with improved coefficient of friction

ActiveUS20100216583A1Increase in friction coefficientReduce noiseV-belt fasteningsV-beltsContact pressureMechanical power transmission

A V-ribbed belt for a mechanical power transmission is disclosed. The V-ribbed belt comprises an outer back-side surface, an inner front-side surface, and a load-carrying section disposed between the front-side and back-side surfaces. The front-side surface includes a plurality of laterally spaced longitudinally extending v-ribs. The back-side surface includes a plurality of raised features that, when running on a flat-faced, back-side pulley, form a contact patch of about 20% to about 50% of that of a traditional flat-faced belt running on a flat-faced pulley. The reduced contact patch provides increased contact pressure which in turn provides an improved effective coefficient of friction between the belt and the pulley.

Owner:DAYCO IP HLDG

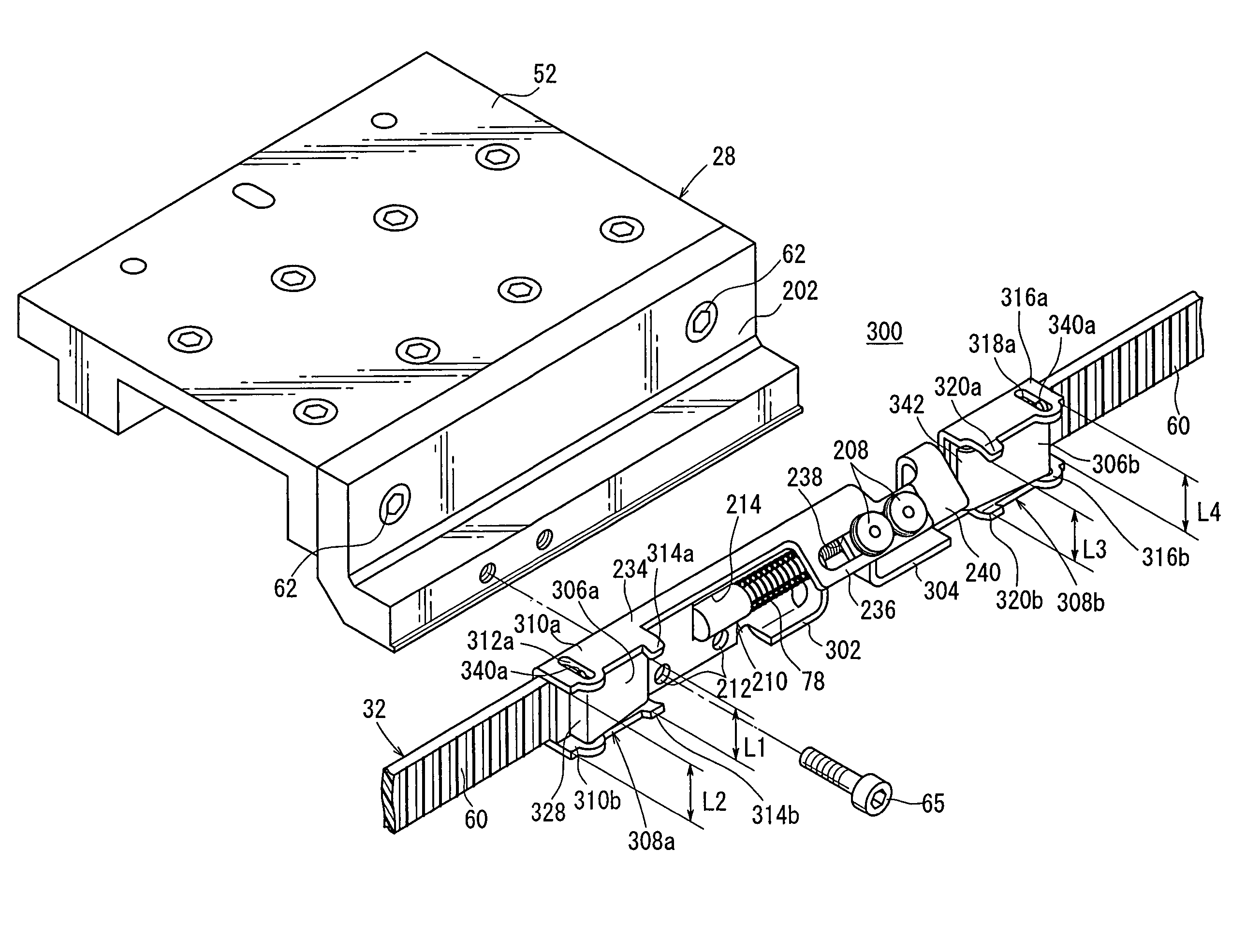

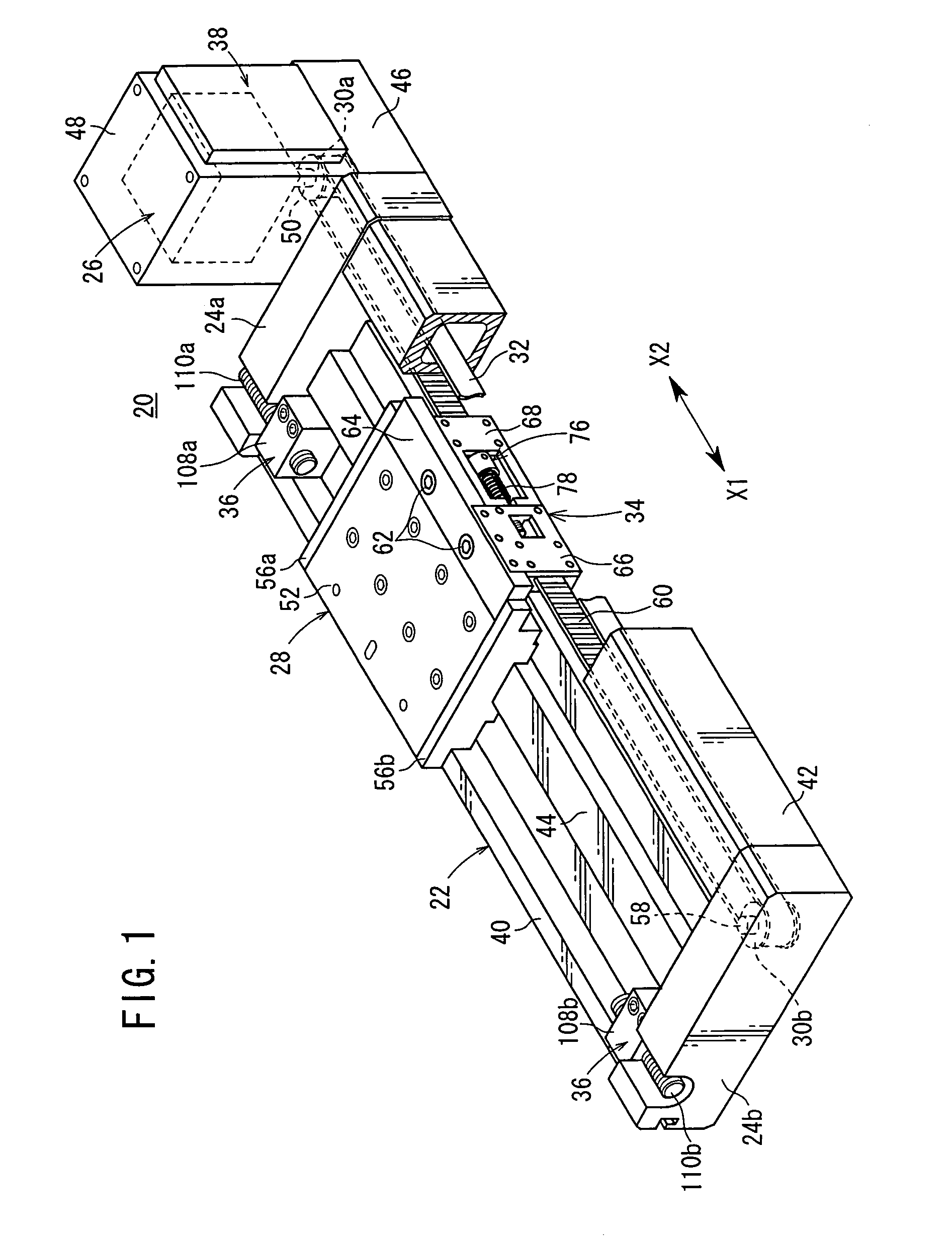

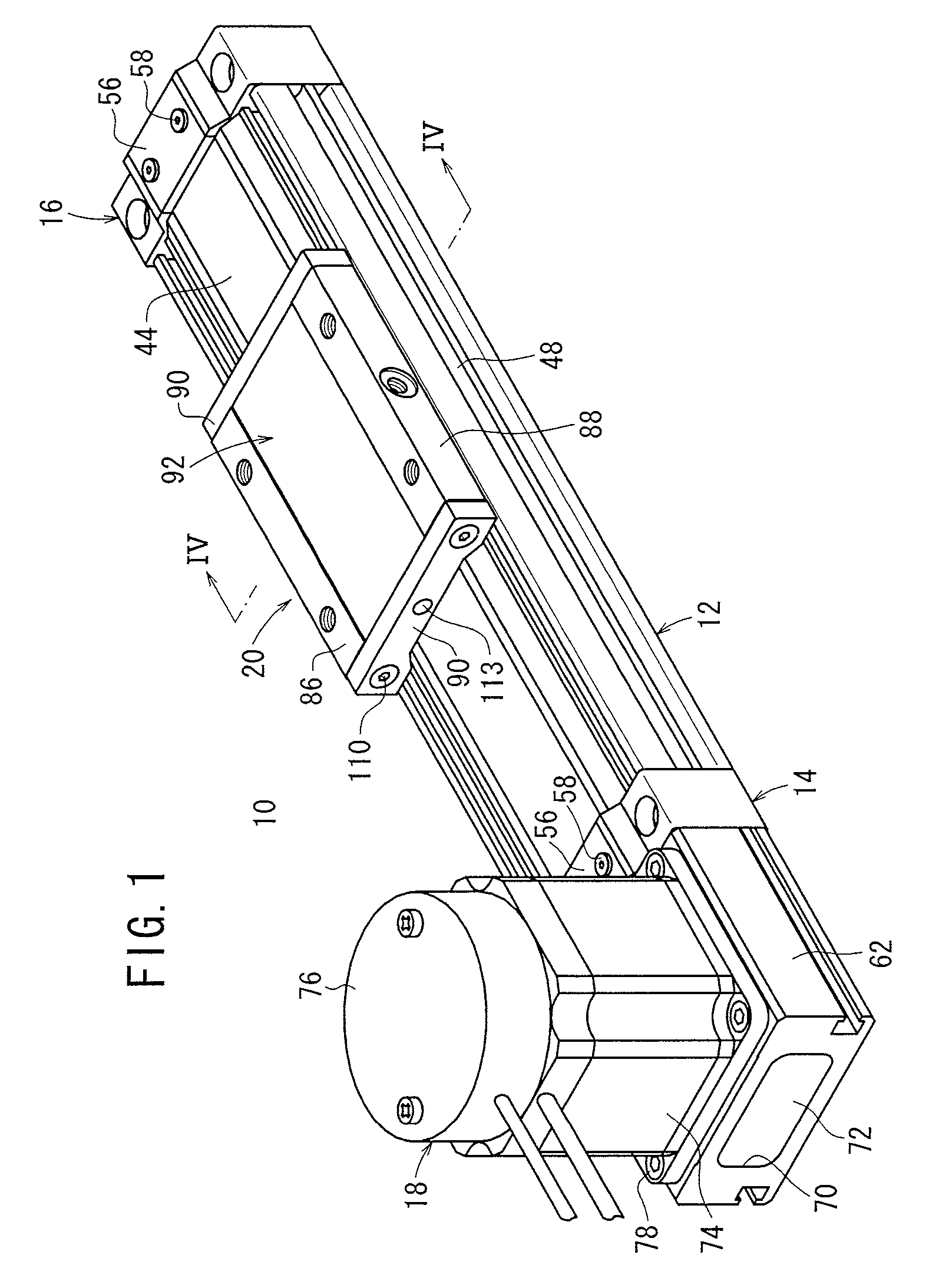

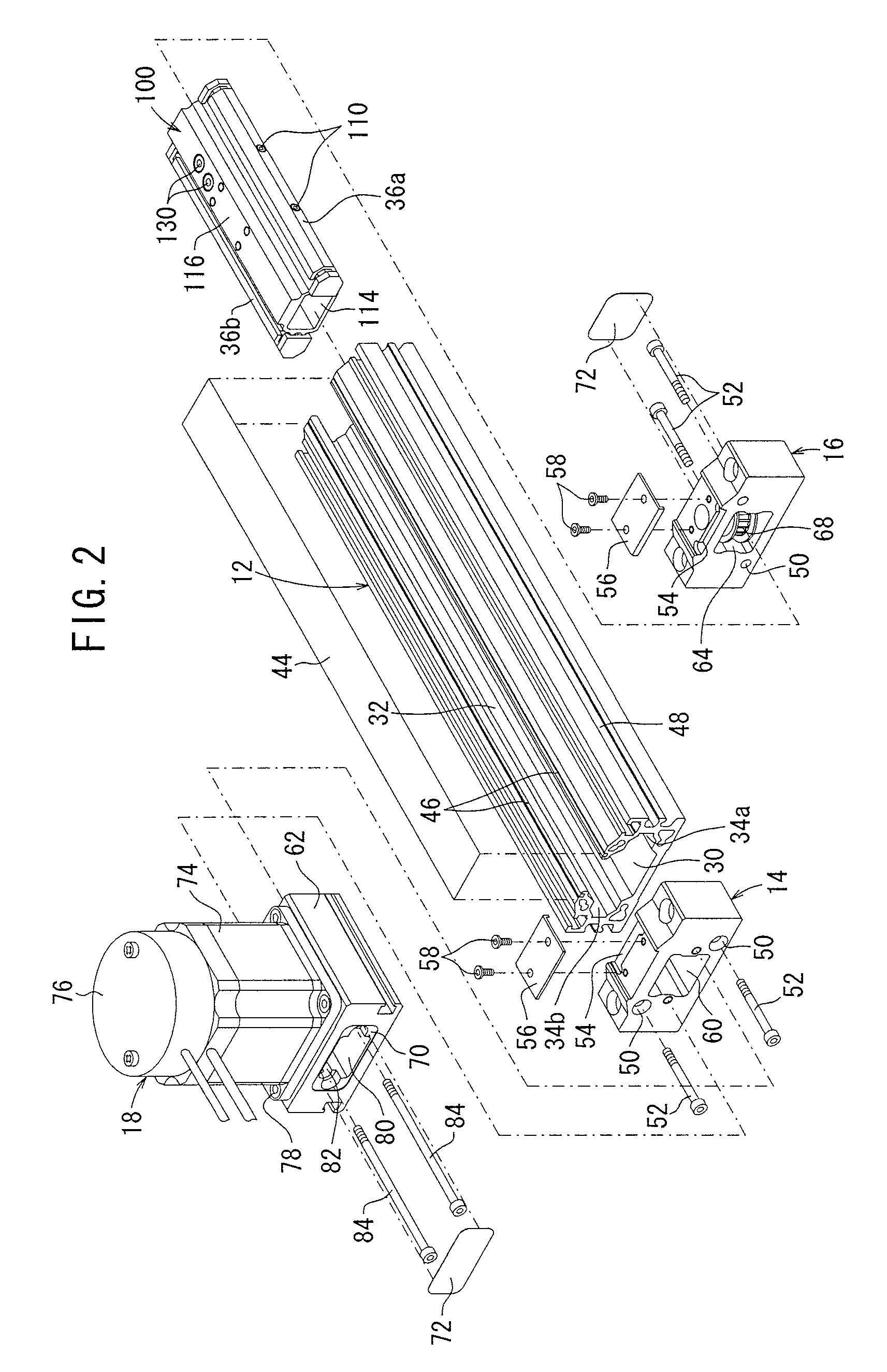

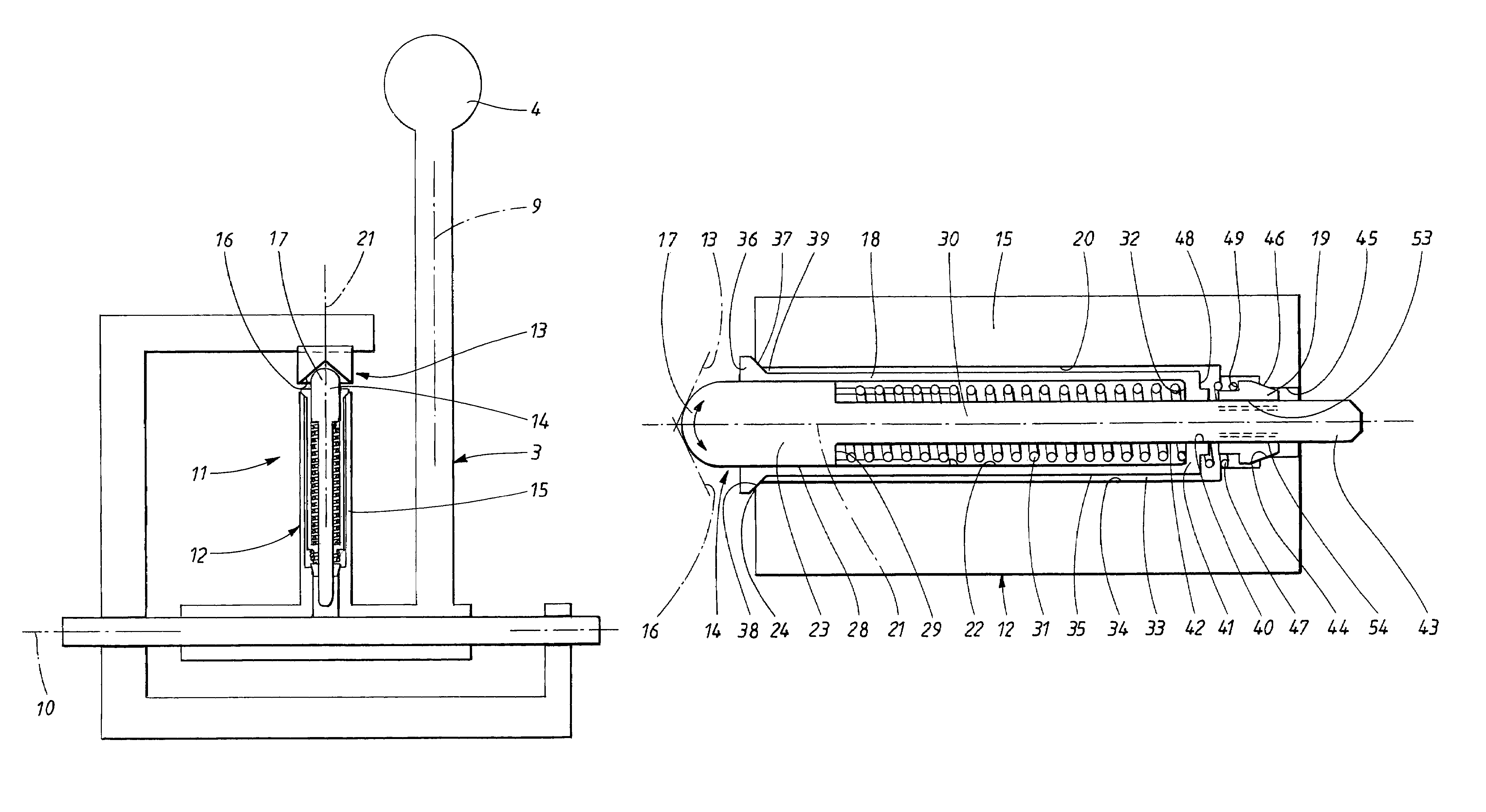

Electric actuator

ActiveUS7220198B2Easily and correctly adjust tensionSimple and reliable processV-belt fasteningsBelt fasteningsEngineeringActuator

An electric actuator comprises a rotary driving source, a timing belt which is circled or orbited under the driving action of the rotary driving source, a slider which is displaced by the timing belt in the axial direction, and a belt-adjusting mechanism which is connected to a side surface of the slider. Both ends of the timing belt are connected to the belt-adjusting mechanism respectively. The tension of the timing belt is adjusted by rotating an adjusting screw of the belt-adjusting mechanism.

Owner:SMC CORP

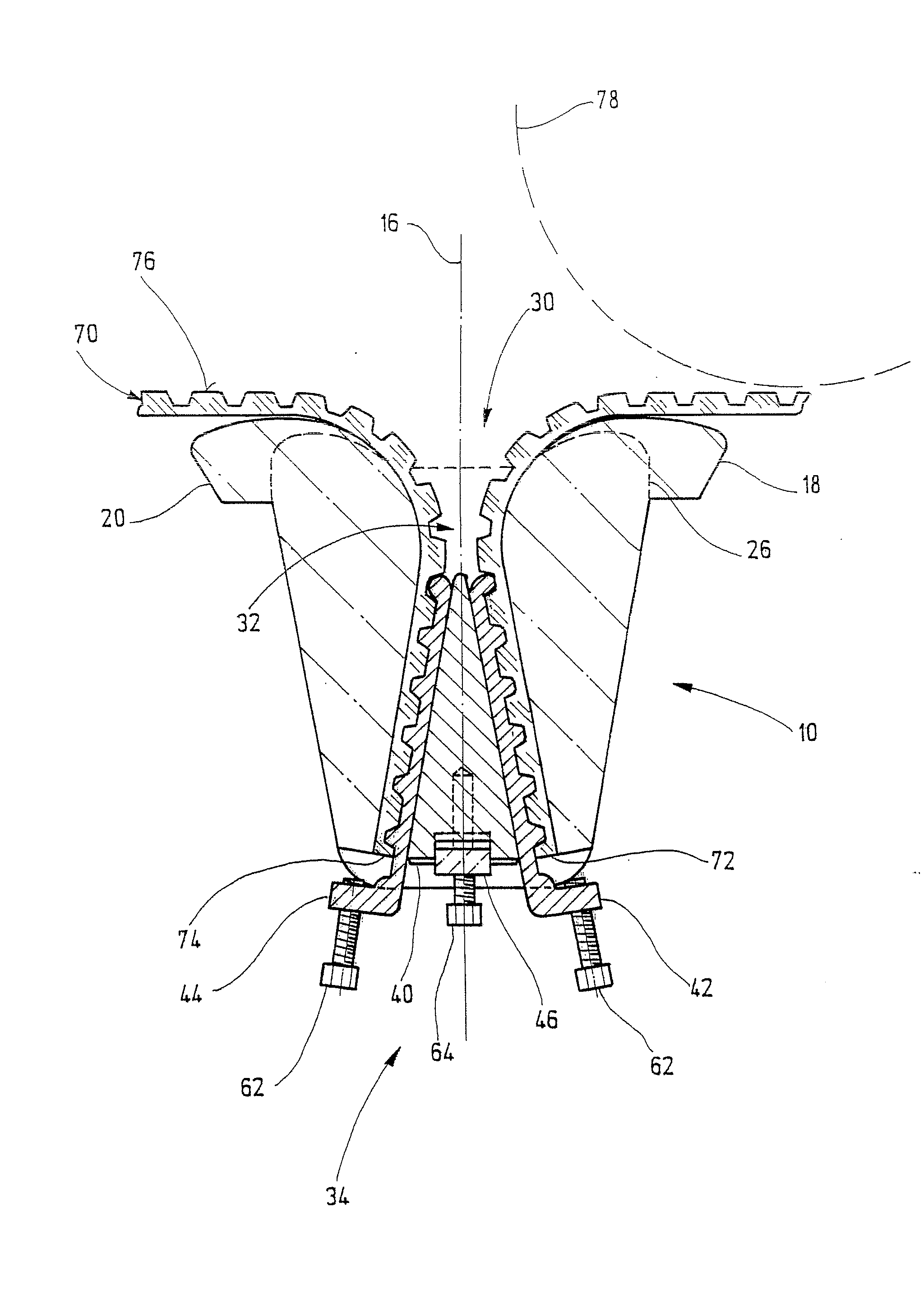

Connecting unit for loose ends of a traction device

InactiveUS20080200295A1Easy to replaceSmooth connectionV-belt fasteningsRopes and cables for vehicles/pulleyEngineeringMechanical engineering

Owner:SSI SCHAEFER PEEM

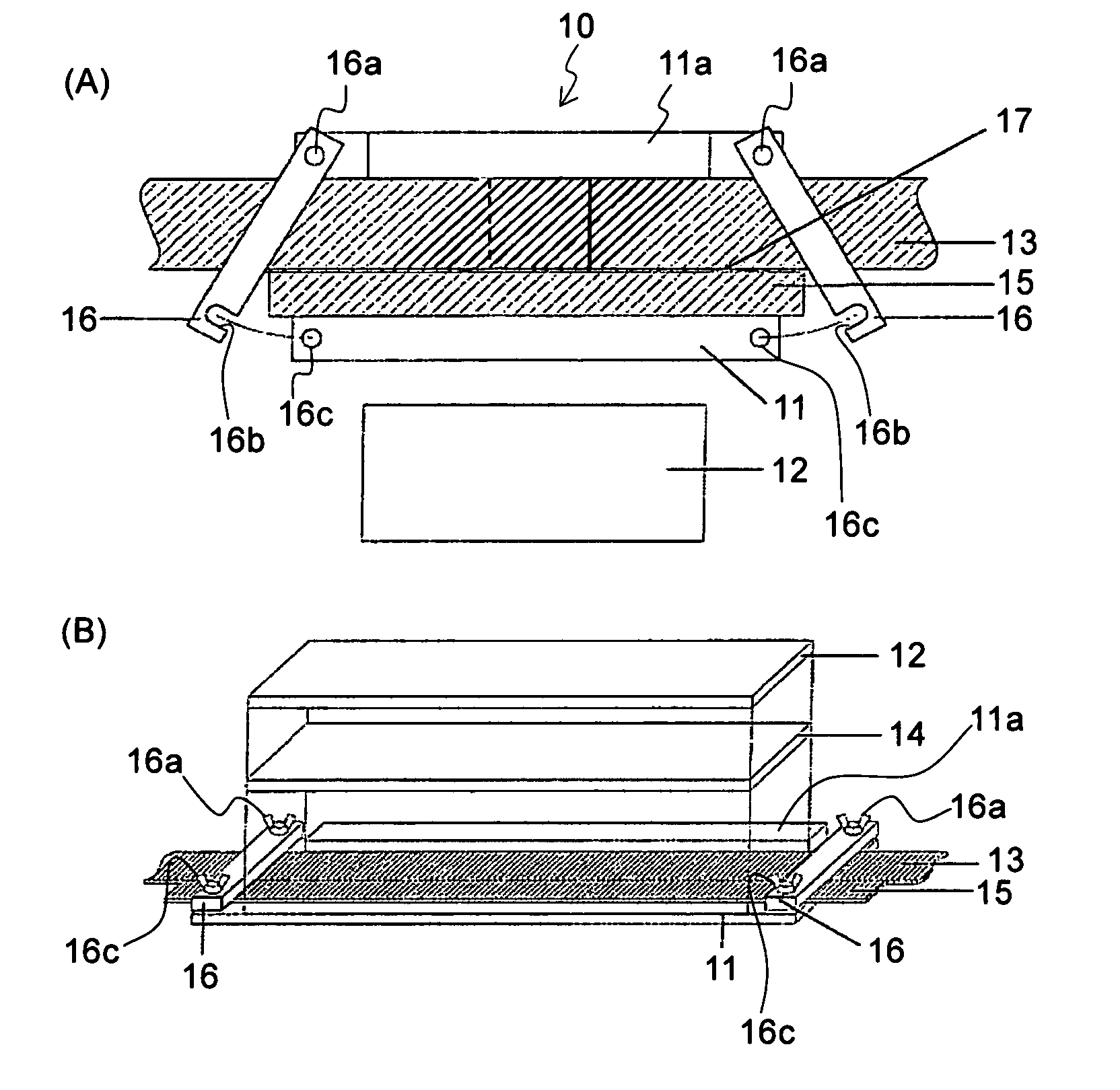

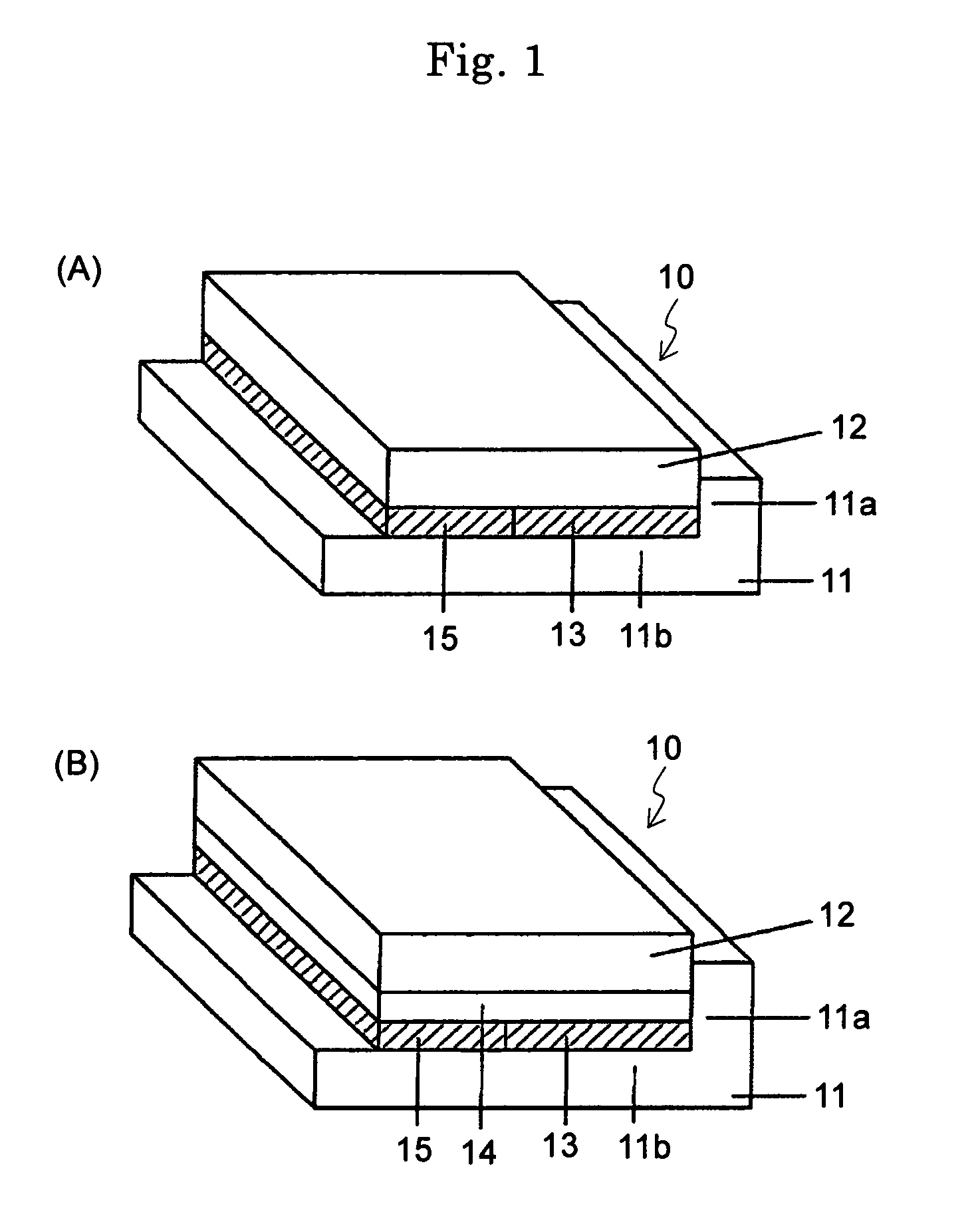

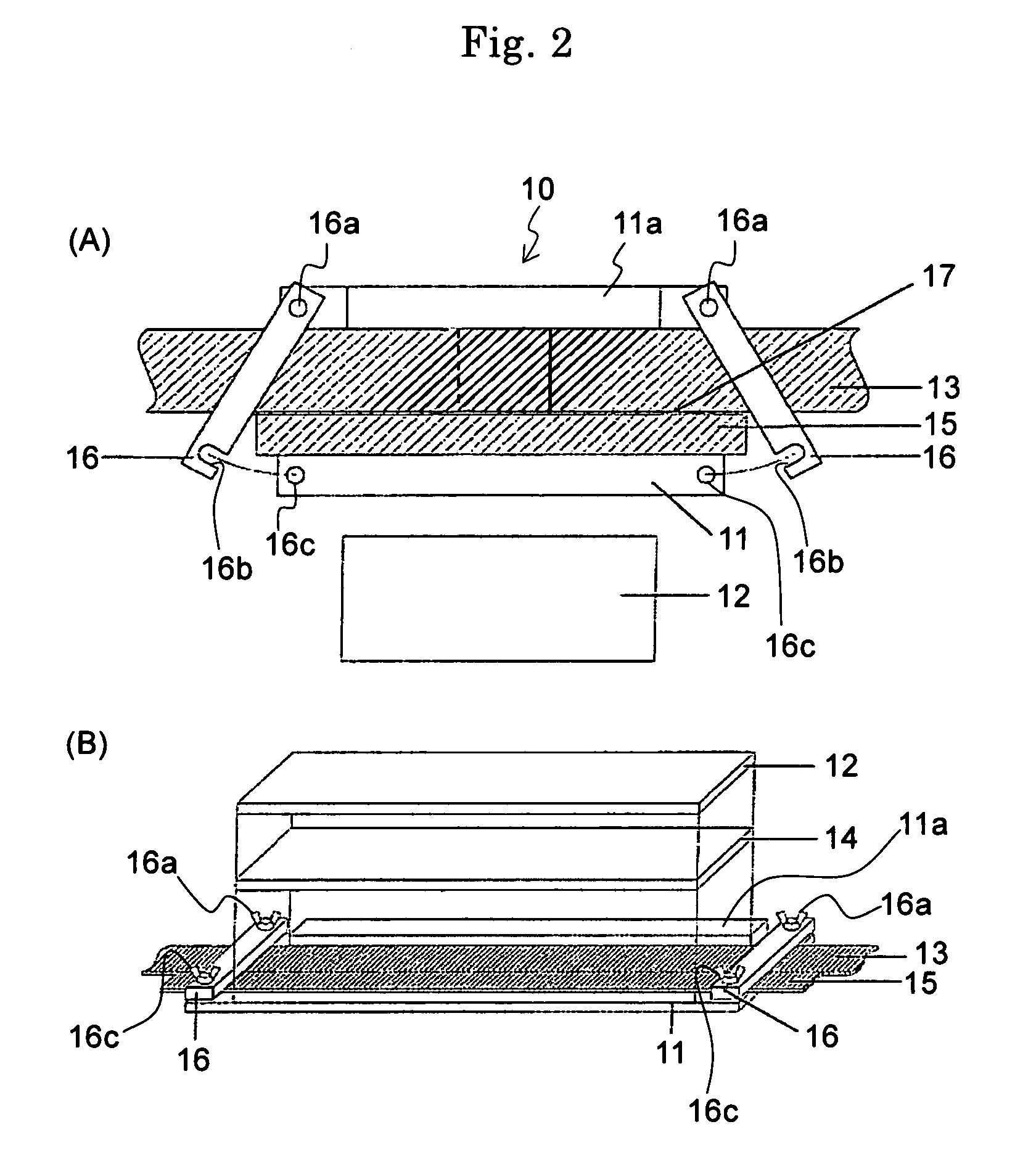

Belt member incorporated in image forming apparatus

InactiveUS6993270B2Avoid damageImproved seam strengthV-belt fasteningsLayered productsImage formationEngineering

Owner:SEIKO EPSON CORP

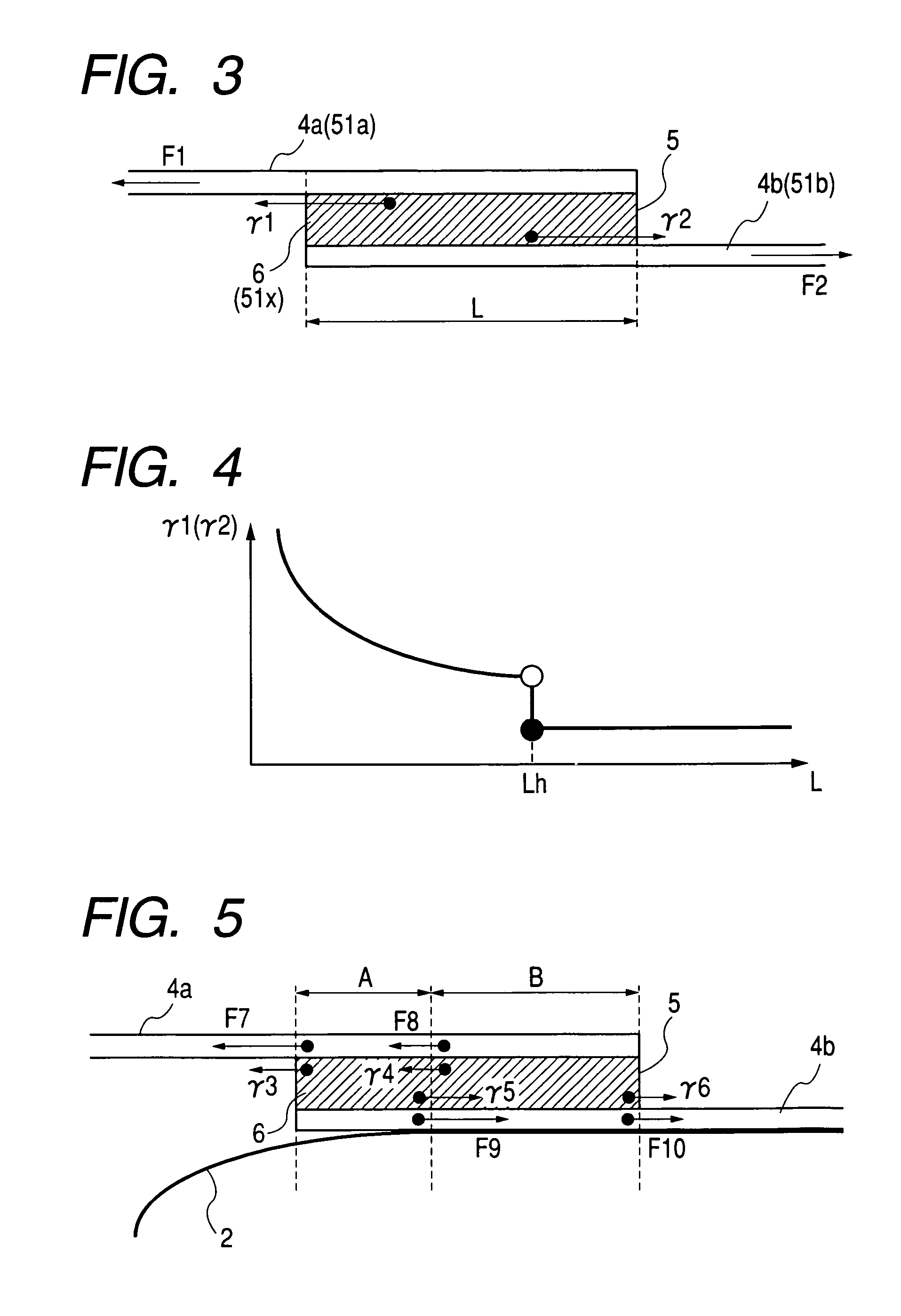

Splicing joint and method for synchronous drive belt

InactiveUS6843744B2Inhibit migrationReduce frictionV-belt fasteningsRopes and cables for vehicles/pulleyEngineeringPulley

A splice joint is for joining first and second synchronous drive belt ends, of the belt type comprising a reinforcement material layer covering a base layer formed from a first thermoplastic material. The joint comprises a fused portion of the base layer of the first and second belt ends that define a splice region. At least one coating layer of thermoplastic material overlaps the reinforcement layer of the end portions in the splice region. The coating layer is comprised of a second elastomeric material intended to melt and penetrate into interstices of the reinforcement material layer while within the mold press. Migration of the base layer material through the reinforcement material layer to the pulley-engaging outer surface is thereby inhibited. The second elastomeric material composing the coating layer may be selected to provide desired frictional and wear characteristics.

Owner:CONTITECH USA INC

Connecting unit for loose ends of a traction device

InactiveUS7707693B2Easy to replaceSmooth connectionV-belt fasteningsRopes and cables for vehicles/pulleyEngineeringMechanical engineering

Owner:SSI SCHAEFER PEEM

V-ribbed belt having an outer surface with improved coefficient of friction

ActiveUS8192315B2Increase frictionEffective coefficient of frictionV-belt fasteningsV-beltsContact pressureMechanical power transmission

A V-ribbed belt for a mechanical power transmission is disclosed. The V-ribbed belt comprises an outer back-side surface, an inner front-side surface, and a load-carrying section disposed between the front-side and back-side surfaces. The front-side surface includes a plurality of laterally spaced longitudinally extending v-ribs. The back-side surface includes a plurality of raised features that, when running on a flat-faced, back-side pulley, form a contact patch of about 20% to about 50% of that of a traditional flat-faced belt running on a flat-faced pulley. The reduced contact patch provides increased contact pressure which in turn provides an improved effective coefficient of friction between the belt and the pulley.

Owner:DAYCO IP HLDG

Method for splicing a conveyor belt

A method is provided for splicing a conveyor belt having vulcanized rubber with steel strands embedded in the vulcanized rubber, comprising the steps of exposing a plurality of strands at two belt ends, and applying a vulcanizable rubber composition to the exposed strands to form a spliced joint between the two belt ends, the vulcanizable rubber composition comprising 100 parts by weight of rubber, and the rubber comprising from about 1 to about 40 parts by weight of a polyoctenamer.

Owner:CONTITECH USA INC

Electric actuator

A hollow yoke is inserted into a bore section of a frame. The yoke is connected to a slider via a slit in the frame. A timing belt is inserted into a belt hole of the yoke. Further, a pair of guide members are provided on both side surfaces of the yoke, which engage with guide grooves of the frame. The yoke is displaced along the guide grooves by the timing belt, under a driving action of a driving section. Accordingly, the slider is displaced in the axial direction along the frame.

Owner:SMC CORP

Belt connecting method, presetter, and belt connecting apparatus

ActiveUS7650987B2Reduce manufacturing costReduce necessityV-belt fasteningsConveyorsEngineeringElectrical and Electronics engineering

Owner:NITTA CORP

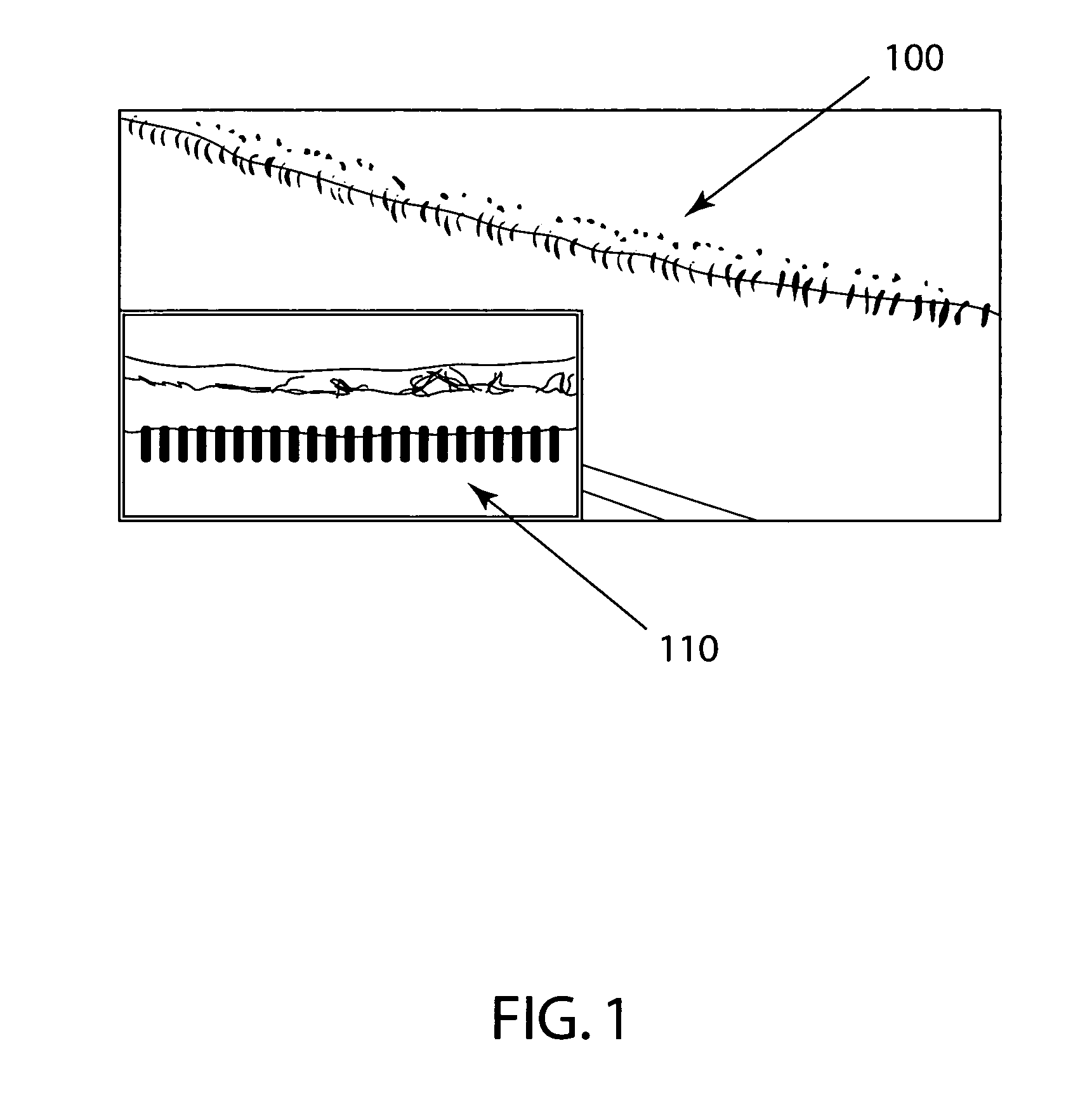

Belt connector and method

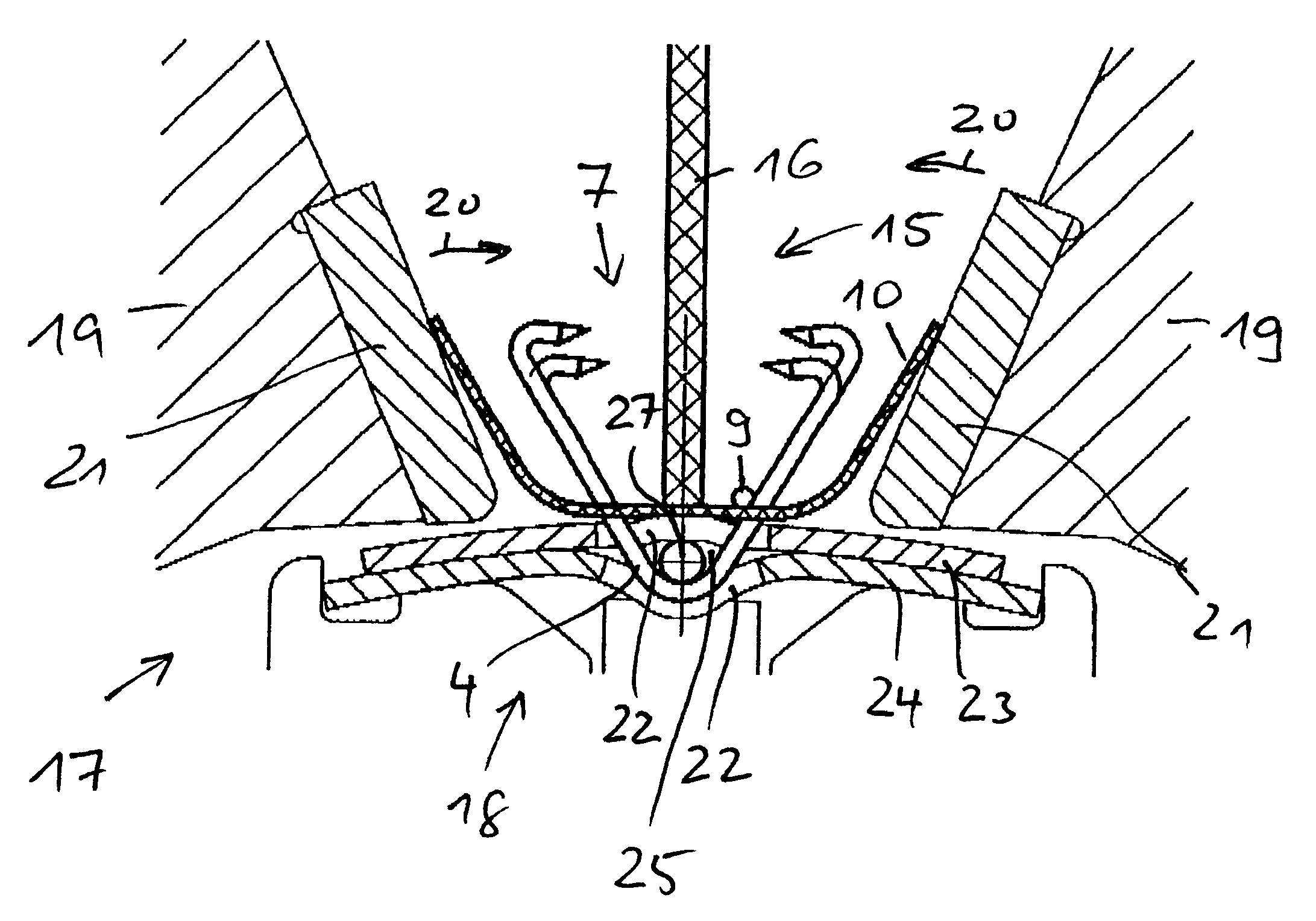

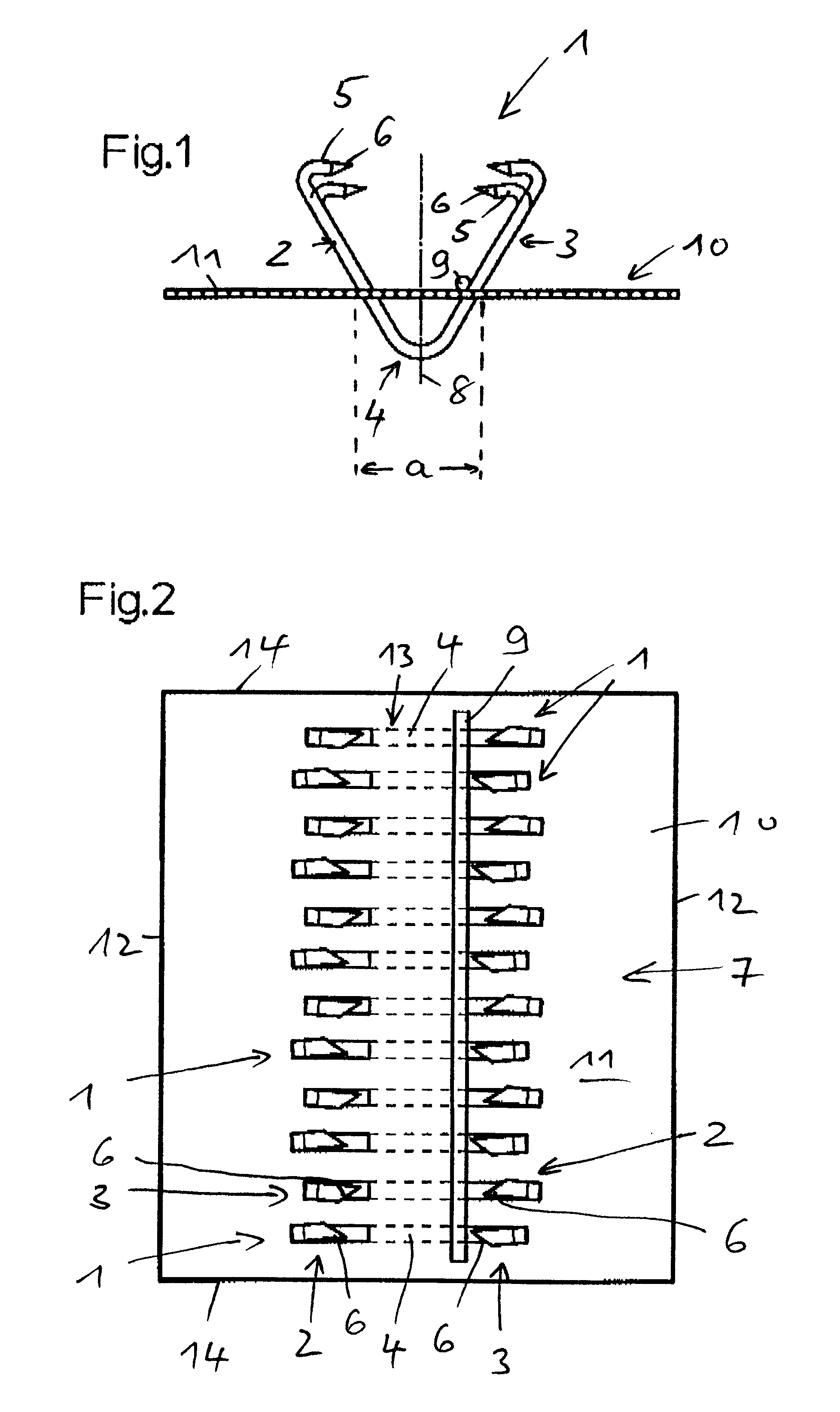

A connector for conveyor belts and the like includes a plurality of connection elements disposed in a side-by-side relationship to extend across the end edge of an associated belt. Each of the connection elements includes outwardly disposed shank portions with free ends shaped for insertion into the opposite faces of the belt, and inwardly disposed loop-shaped center portions arranged to mesh with a like connector on the opposite end of the belt. A generally flat cover element has a central aperture through which the center portions of the connection elements are inserted, and is deformable for folding the cover element over the end edge of the belt and onto the opposite faces of the belt to cover the shank portions of the connection elements on both sides of the belt.

Owner:MATO MASCH & METALLWARENFABRIK CURT MATTHAEI GMBH & CO KG

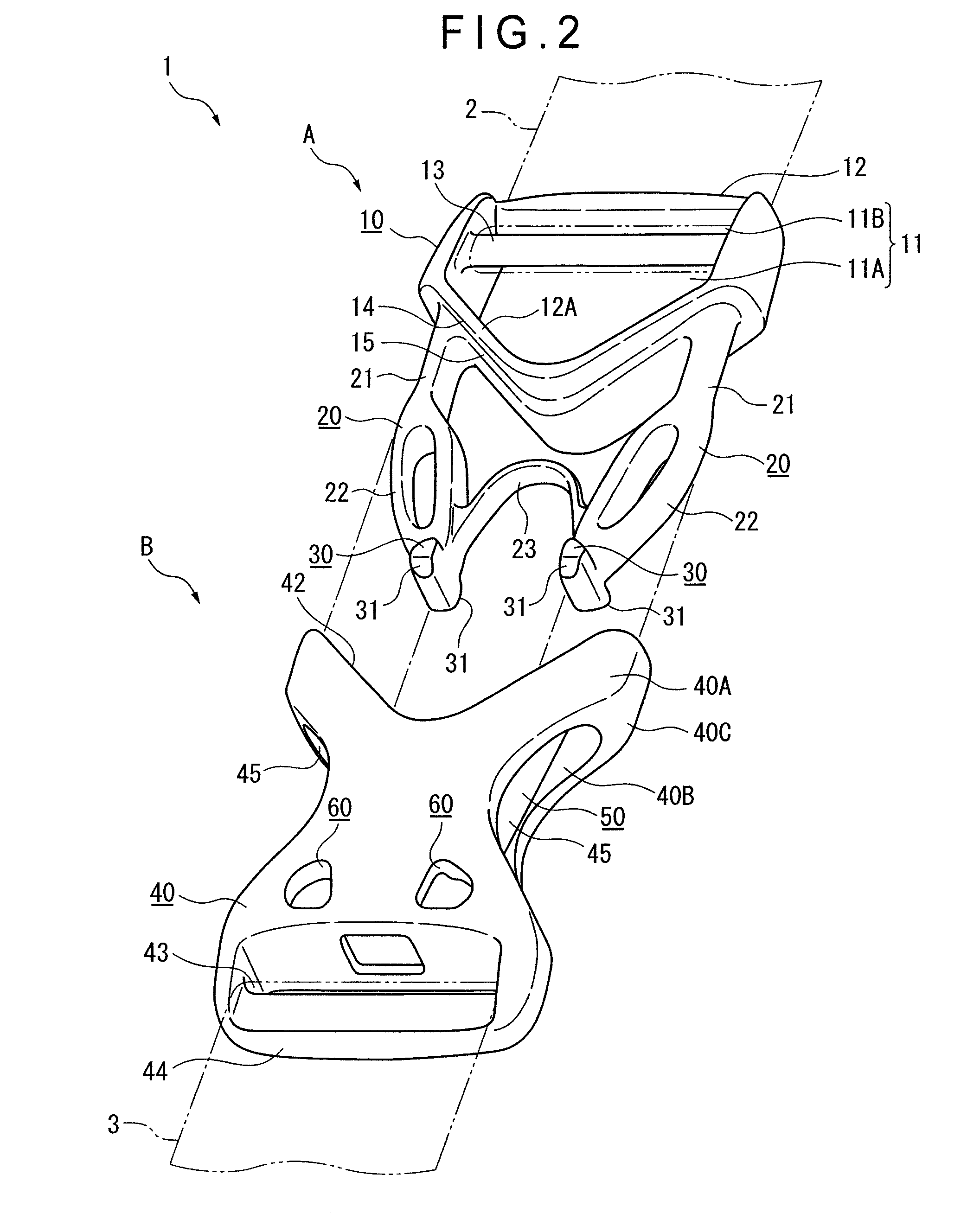

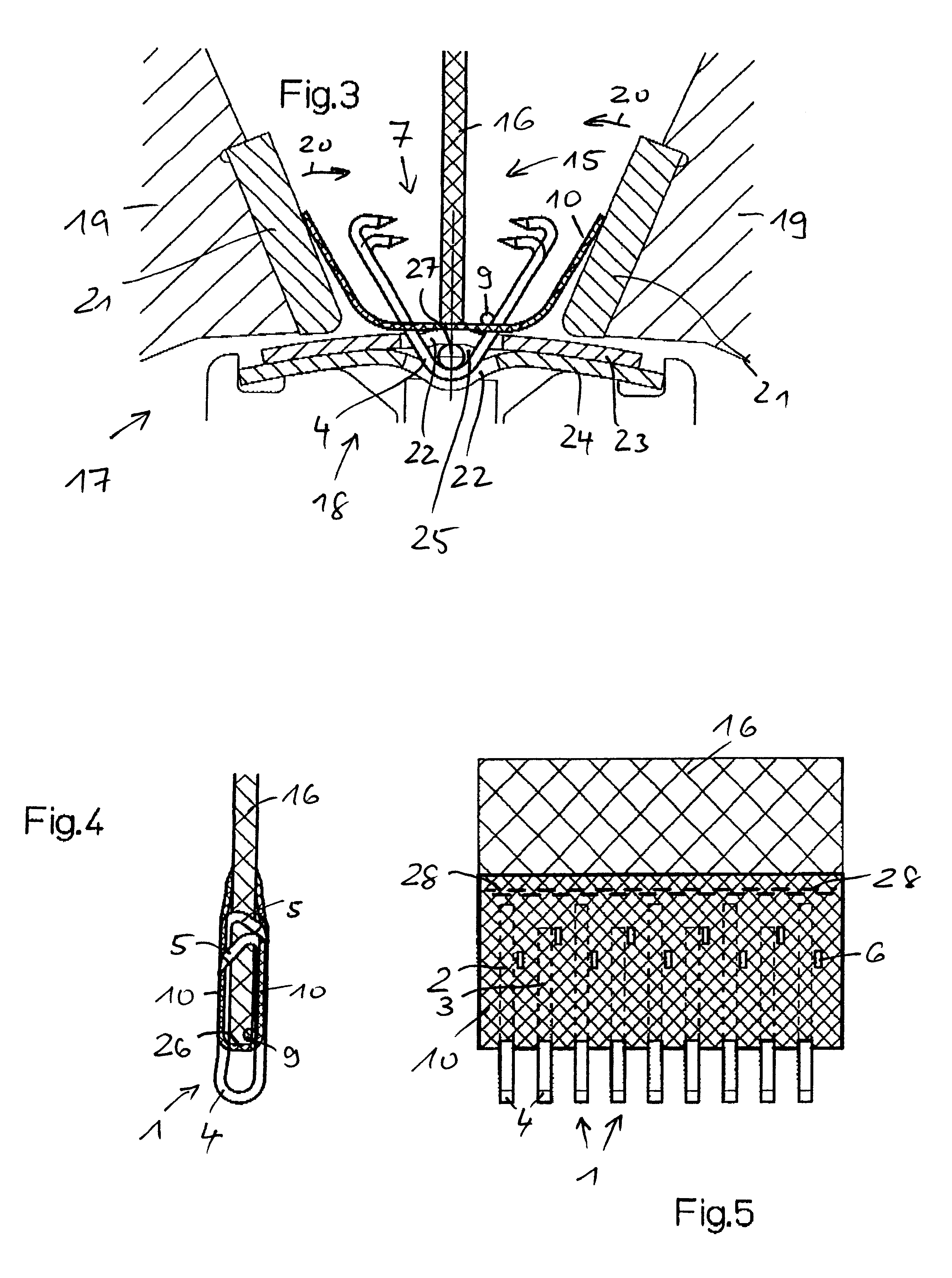

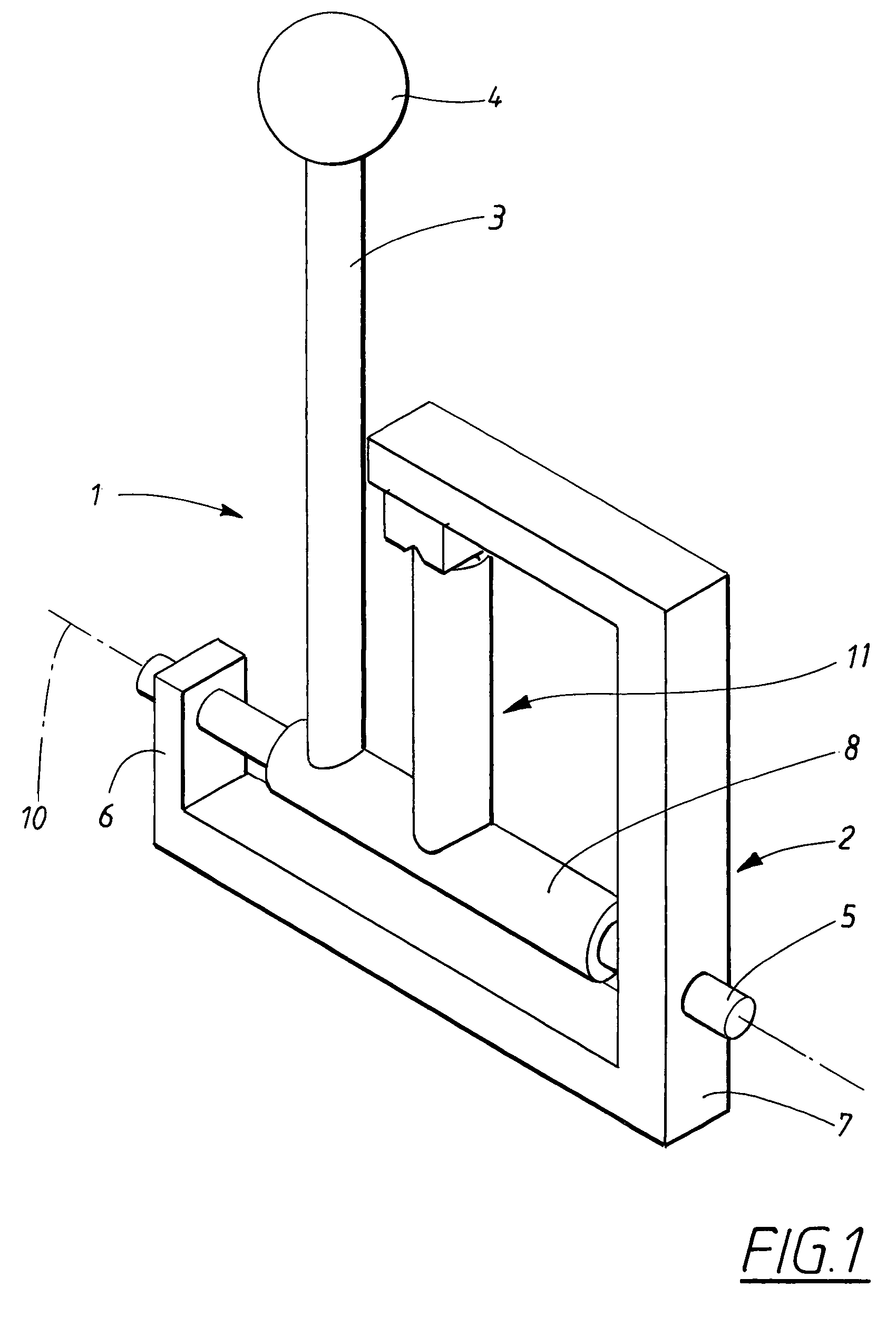

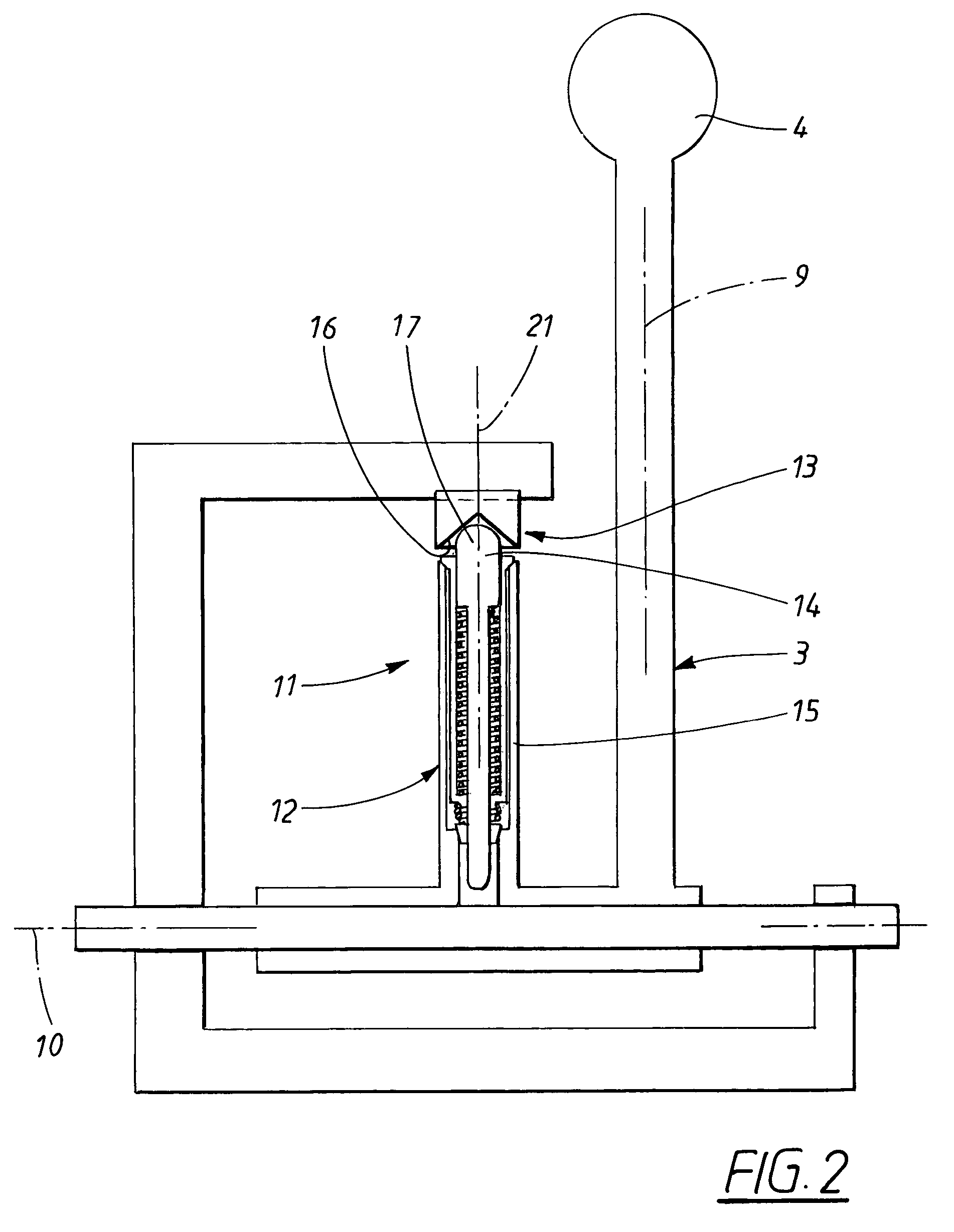

Centering device for longitudinal elements and a resetting device for motor vehicles

InactiveUS7246538B2Low costManual control with multiple controlled membersV-belt fasteningsEngineeringMotorized vehicle

A centering device for elongated elements consisting of a fixed position-retaining part (13) which includes a concave guiding surface (16), and a mobile position-retaining part (12) arranged on the elongated element, or vice versa. The mobile position-retaining part (12) includes a pin (14) which is spring biased for contact against the concave guiding surface. The pin (14) is arranged in at least one casing, and is together with the casing arranged in a cavity (20) in a holder which is fixedly attached to the elongated element with a pin head (23) protruding out of an opening (24) in a front end of both the casing and the holder. The holder (15) includes a seat (38) with a guiding surface for a peripherally conical portion (36) of the casing. This is spring biased in the axial direction so that the conical portion strives to be in contact with the seat of the holder in and for centering of the casing and the pin relative to the longitudinal axis (21) of the holder.

Owner:KONGSBERG AUTOMOTIVE AB (SE)

Production method of decorative film

ActiveUS7135085B2Well formedHigh surface glossDecorative surface effectsPretreated surfacesThin membraneEngineering

A production method of a decorative film comprises a first step of laying a base film of a thermoplastic resin on a pattern layer of a transfer sheet in which the pattern layer is placed on one surface of a carrier film, thermally transferring the pattern layer onto the base film, and thereafter stripping off the carrier film, thereby obtaining a laminate sheet in which the pattern layer is placed on one surface of the base film; and a second step of, in a state in which a transparent resin film is laid on a surface of the laminate sheet on the pattern layer side, inserting the laminate sheet and the transparent resin film into between a pair of endless belts placed opposite each other, and conveying the laminate sheet and the transparent resin film under heat and pressure, thereby obtaining a decorative film in which a transparent resin layer of the transparent resin film is placed on the surface of the laminate sheet on the pattern layer side.

Owner:SHIN-ETSU POLYMER CO LTD

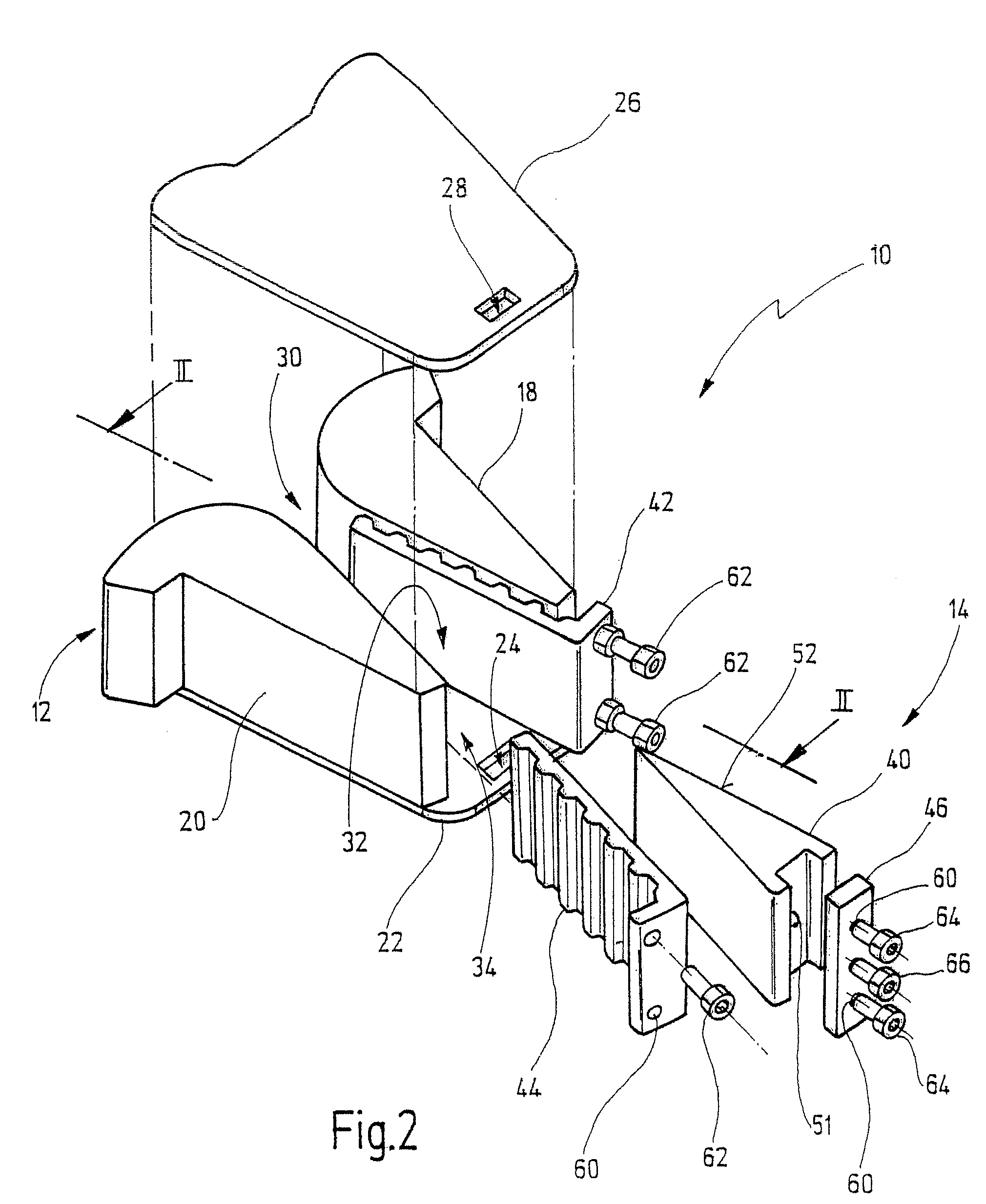

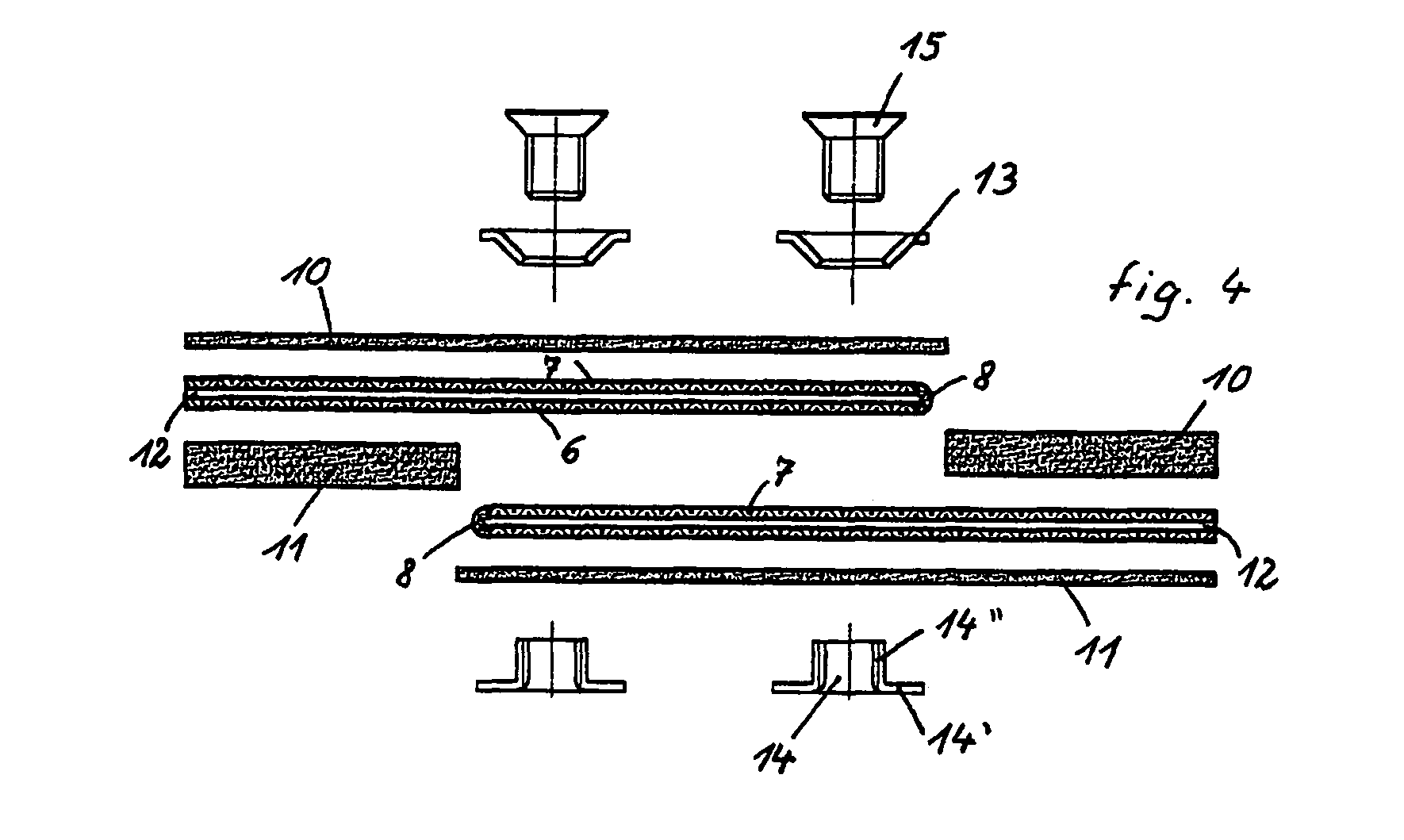

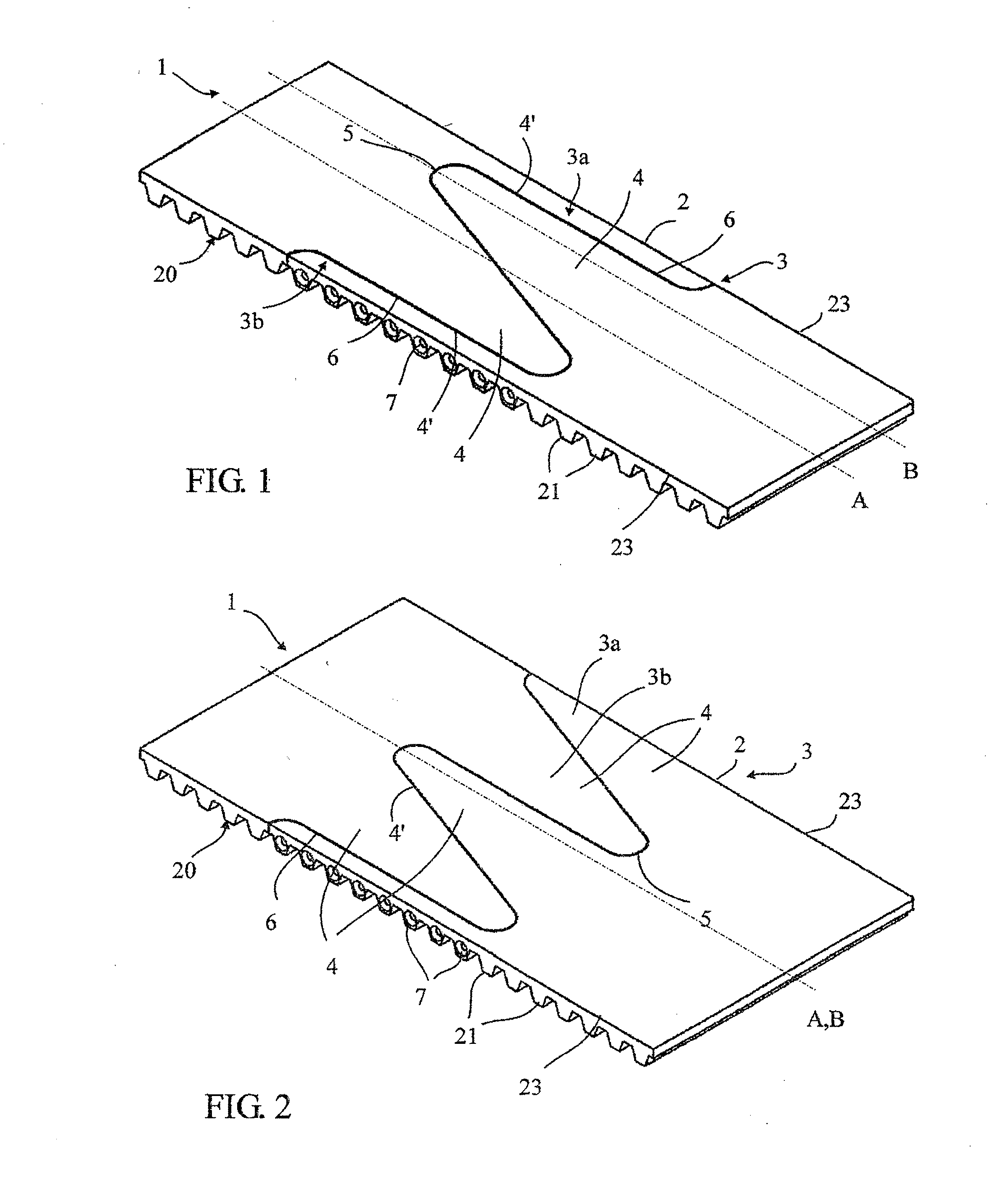

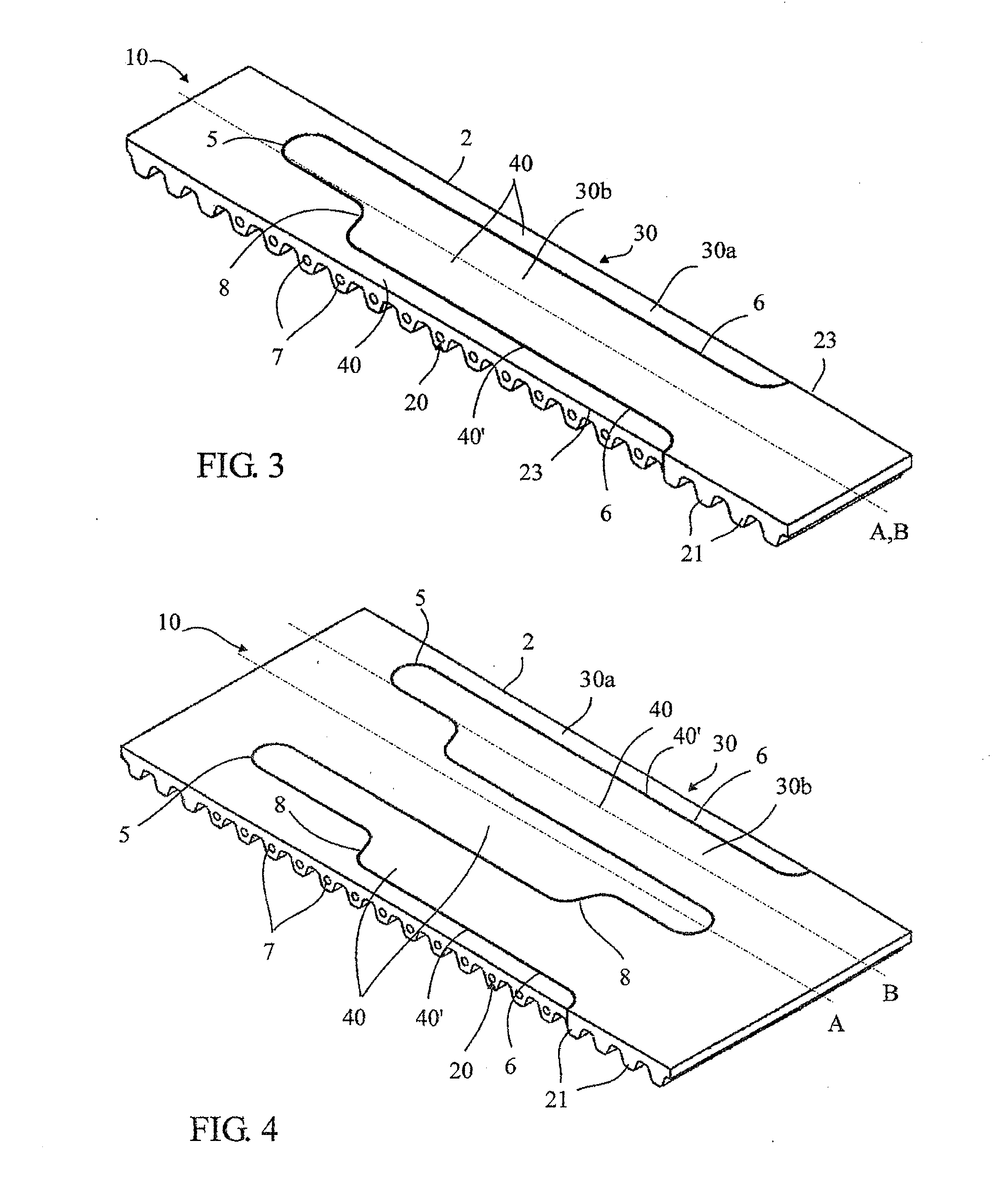

Conveyor belt junction element

A junction for a conveyor belt that includes first and second half-junctions attachable to one end of the conveyor belt. Each of the half-junctions having substantially matching shapes that allow the half-junctions to be interlinked. The half-junctions include a flexible core, and being respectively equipped with cup inserts and bush inserts allowing the passage of an assembly mechanism. Each of the cores extend towards the inside of each half-junction forming a fold at a free edge of each of the half-junctions. The top level of the first half-junction contains the fold and in which a front edge of the bottom level has substantially the same shape as a front edge of the top level, but is shifted towards the rear at least by the distance that separates the front edge of the top level from the cup inserts that are the furthest from the front edge of the top level. The second half-junction has a top level in which the shape of a front edge of the top level matches that of the front edge of the matching first half-junction, and a bottom level containing the fold and the bush inserts. The front edge of the bottom level is shifted towards the front in relation to the front edge of the top level, and its shape matches that of the front edge of the bottom level of the first half-junction. The attachment of the first and second half-junctions with each other is provided by fasteners.

Owner:ASER

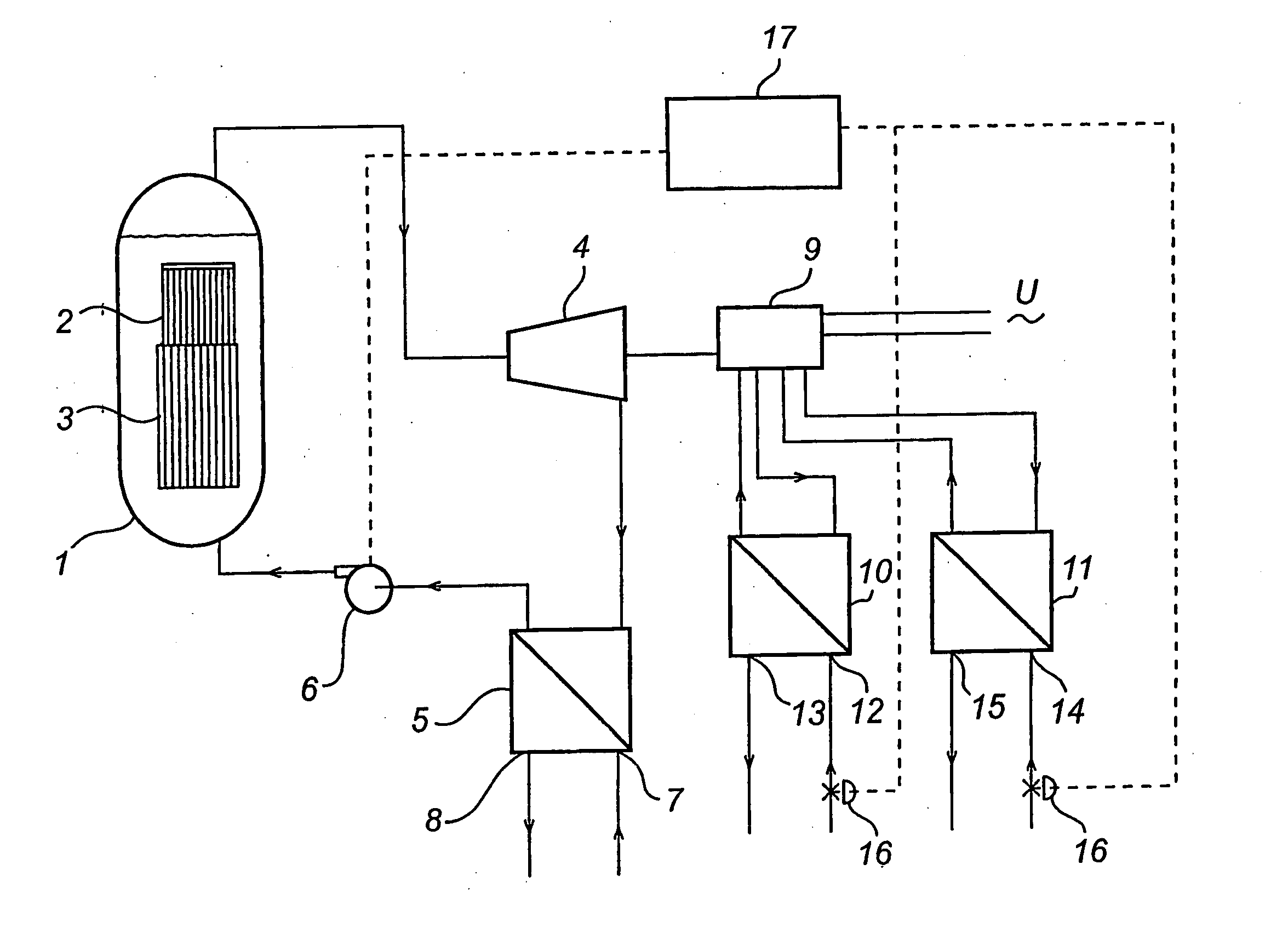

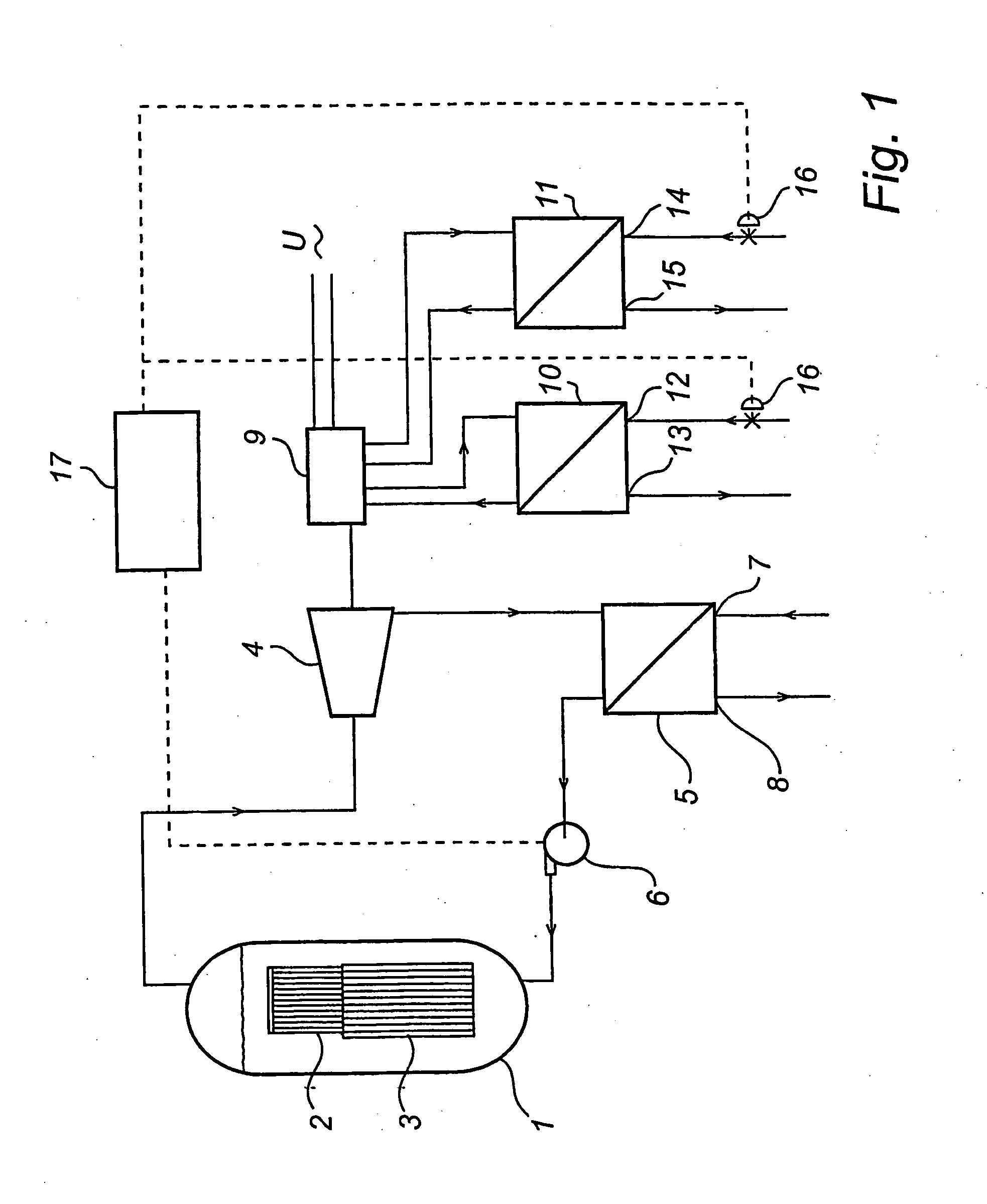

Electric machine

InactiveUS20060038539A1High power outputGreat mean annual power outputLevel controlSleeve-linkElectric machineEngineering

A method and an apparatus are described for monitoring a rotating synchronous electric machine (9), which comprises a rotor winding and a stator having a stator winding. The method comprises the steps of determining the stator winding current, determining the stator winding voltage, determining the rotor winding current, and estimating the temperature in at least two positions in the electric machine (9) using a model of the electric machine and the determined current and voltage values. An apparatus according to the invention is provided for carrying out the method.

Owner:E ON SVERIGE

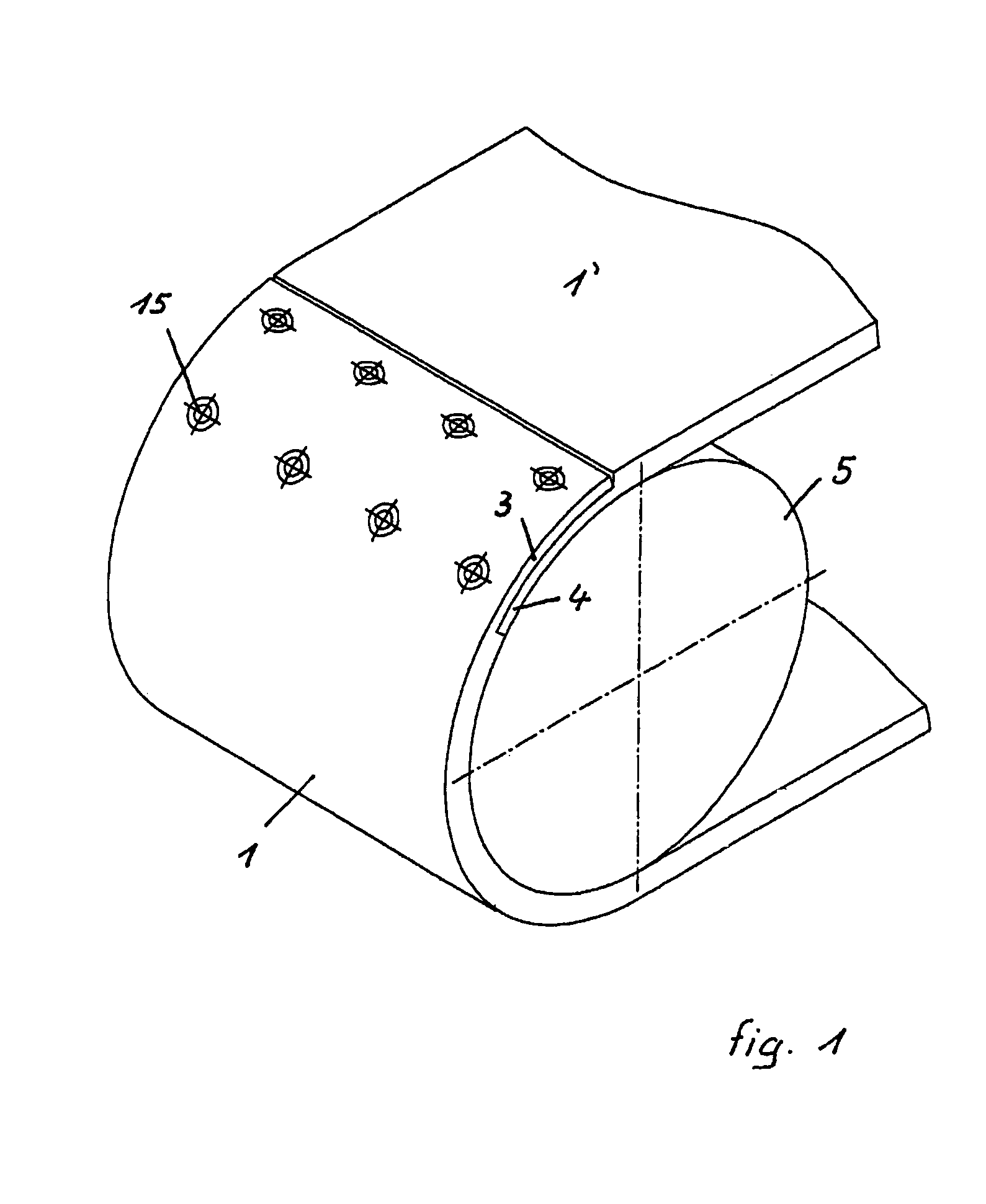

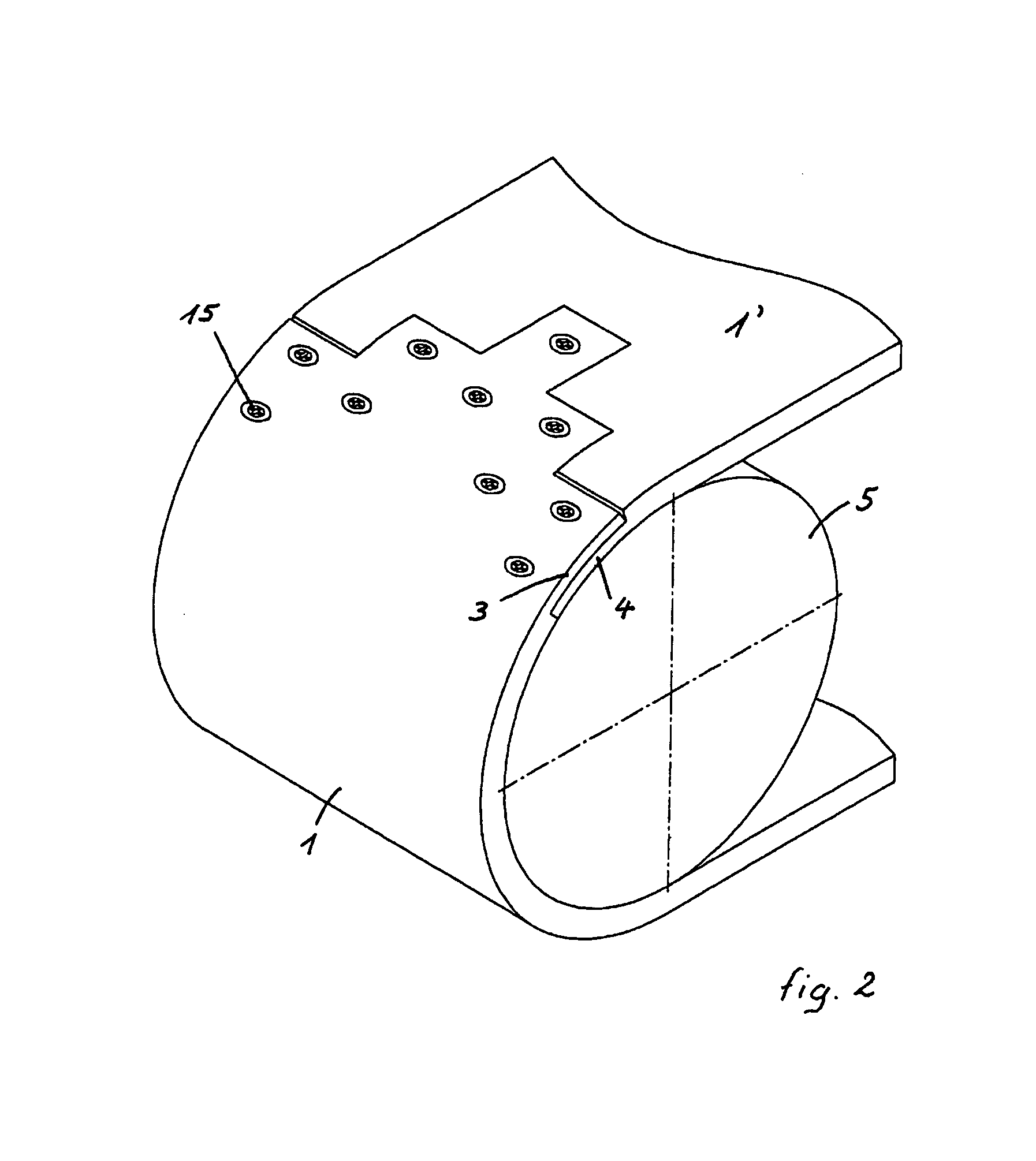

Looped material band provided with a splice

ActiveUS20130062168A1Preserve mechanical resistancePreserve fatigue life propertyV-belt fasteningsConveyorsPulley

Owner:TANALS S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com