Patents

Literature

70results about How to "Avoid trembling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

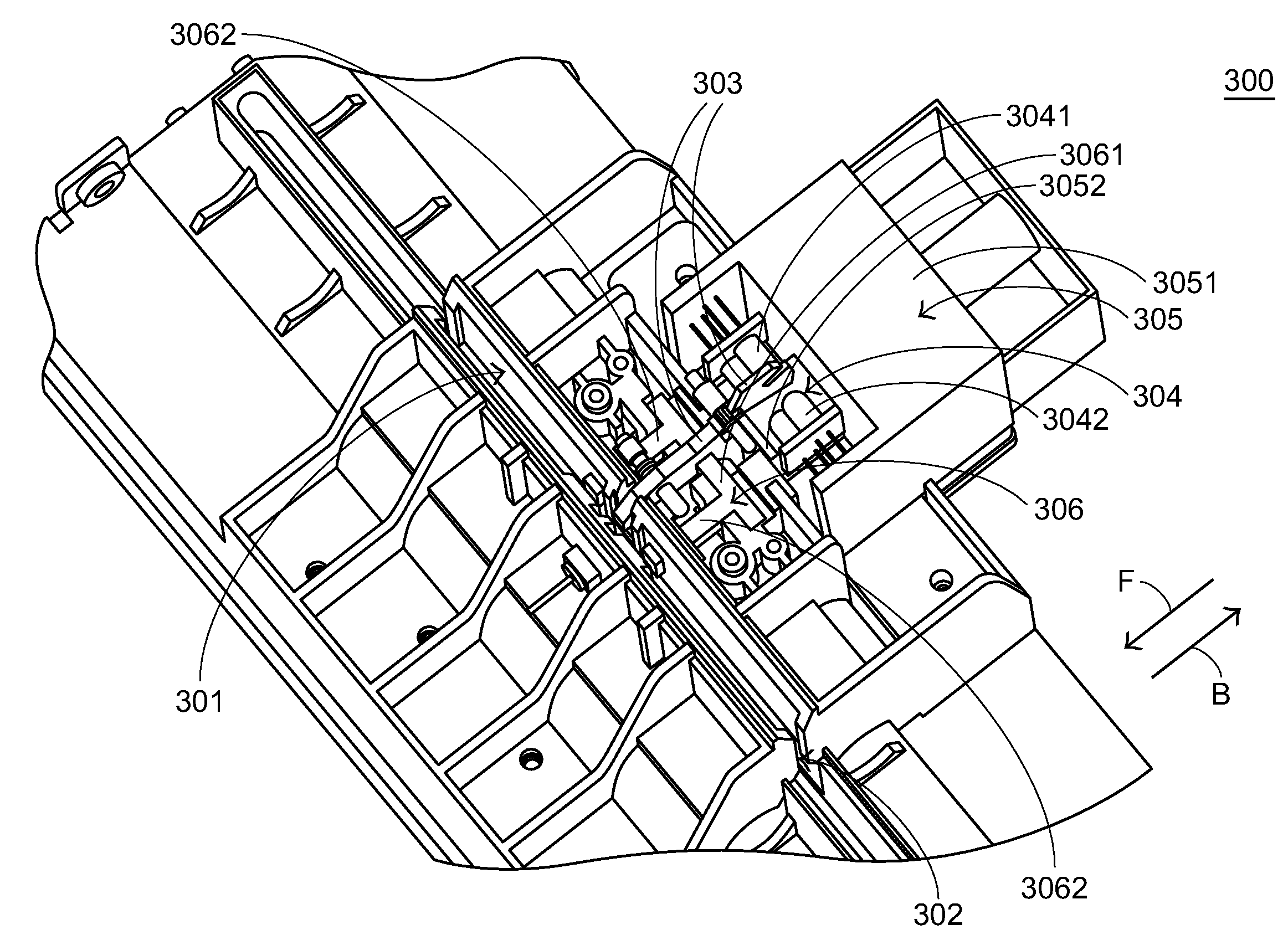

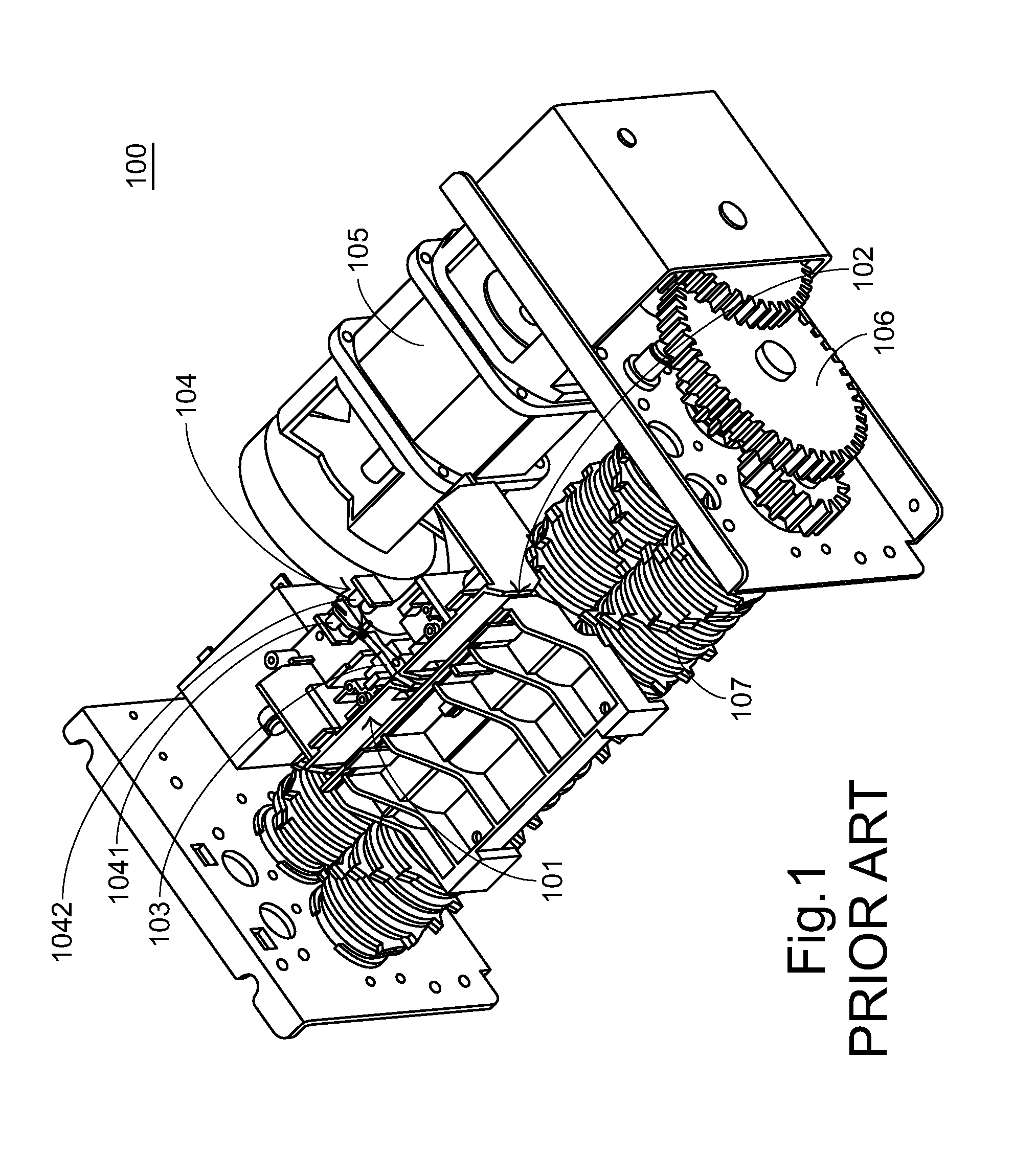

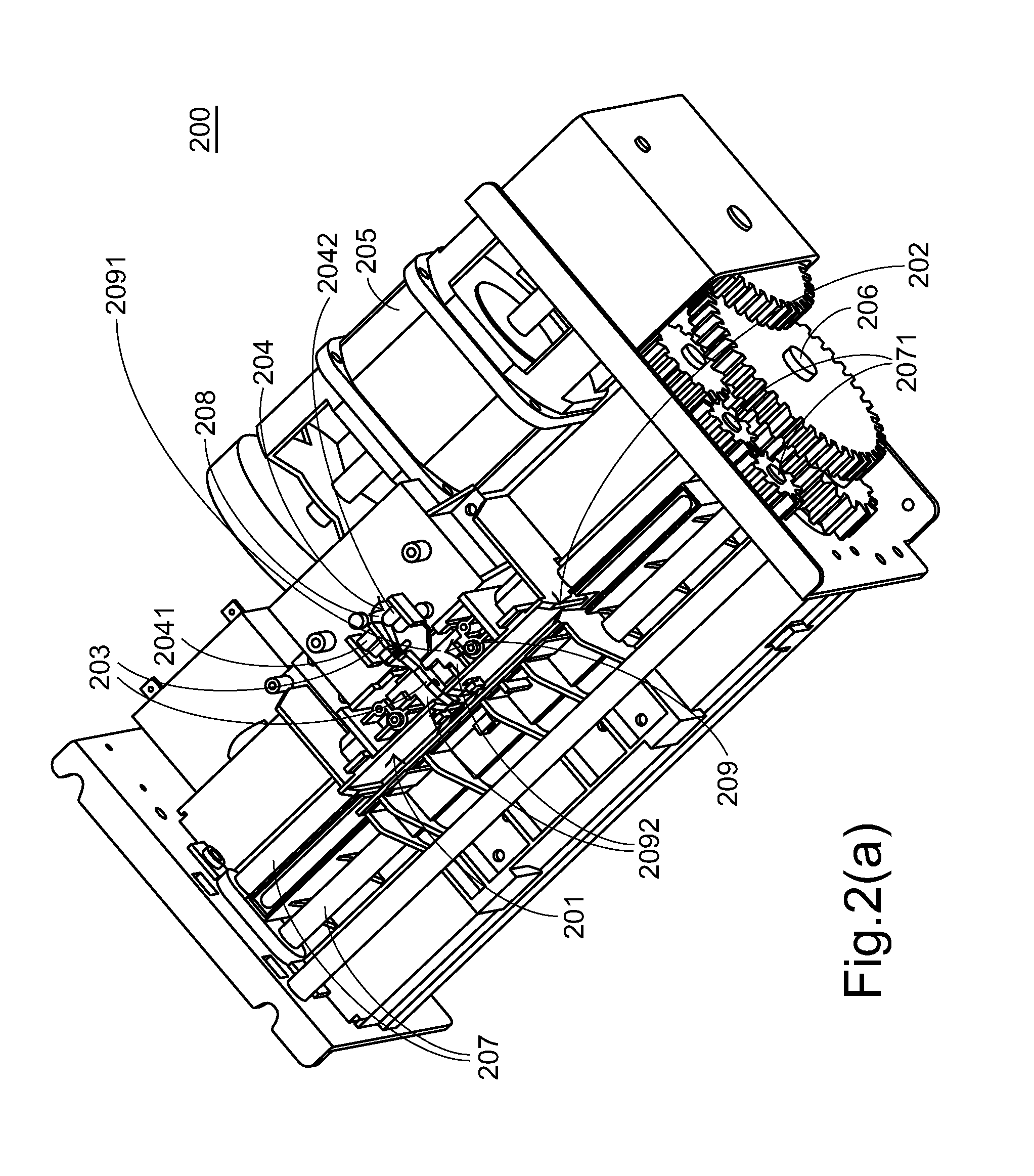

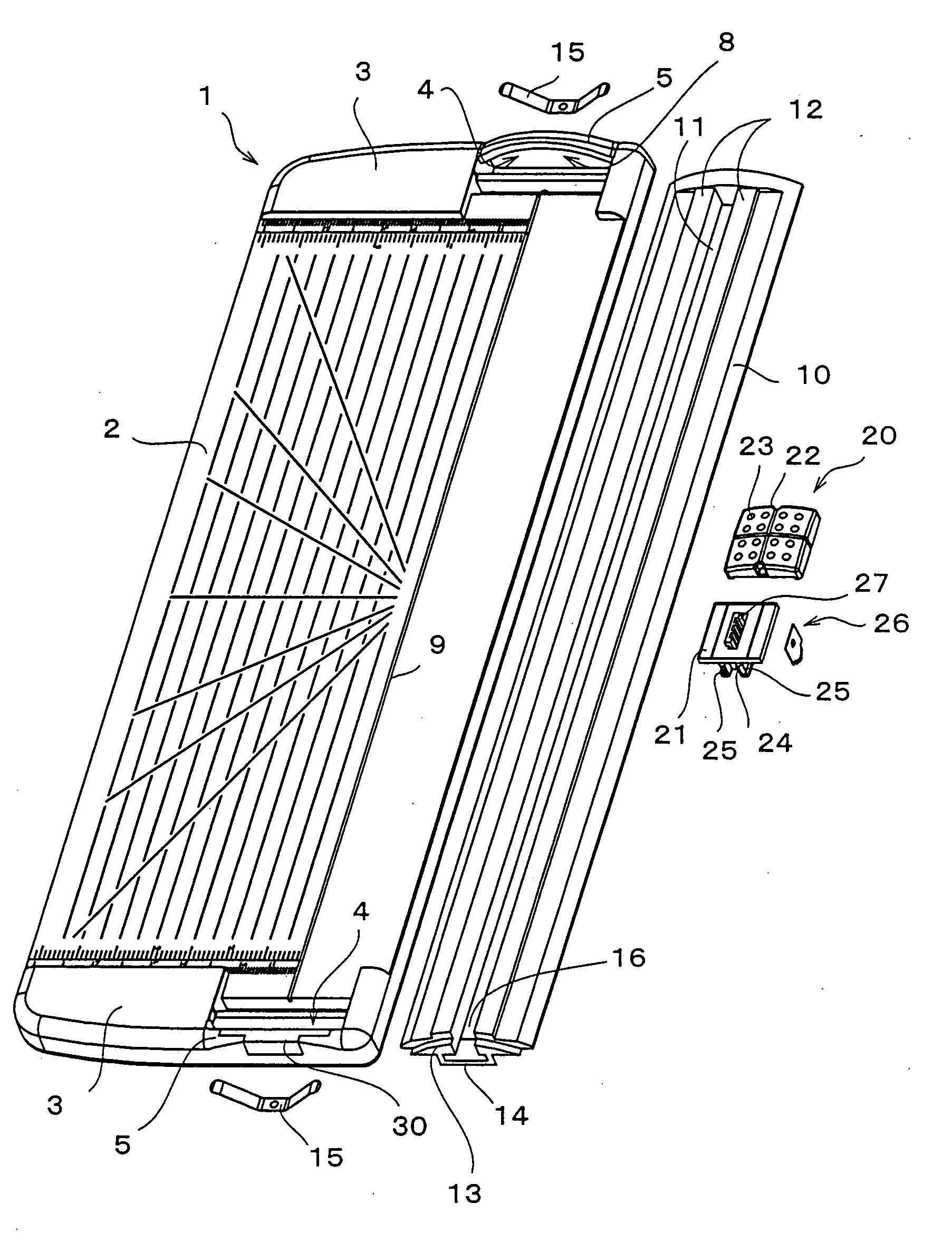

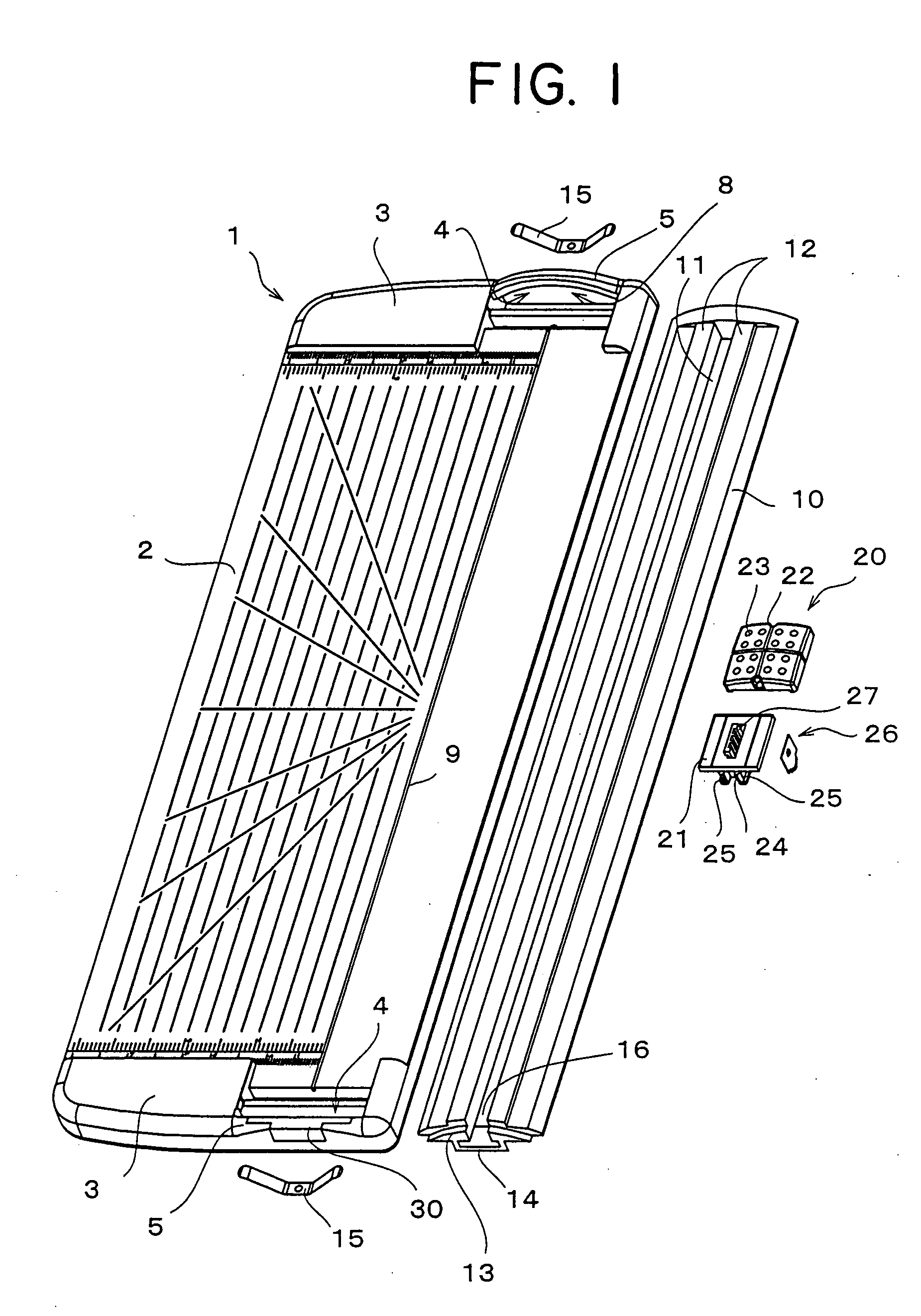

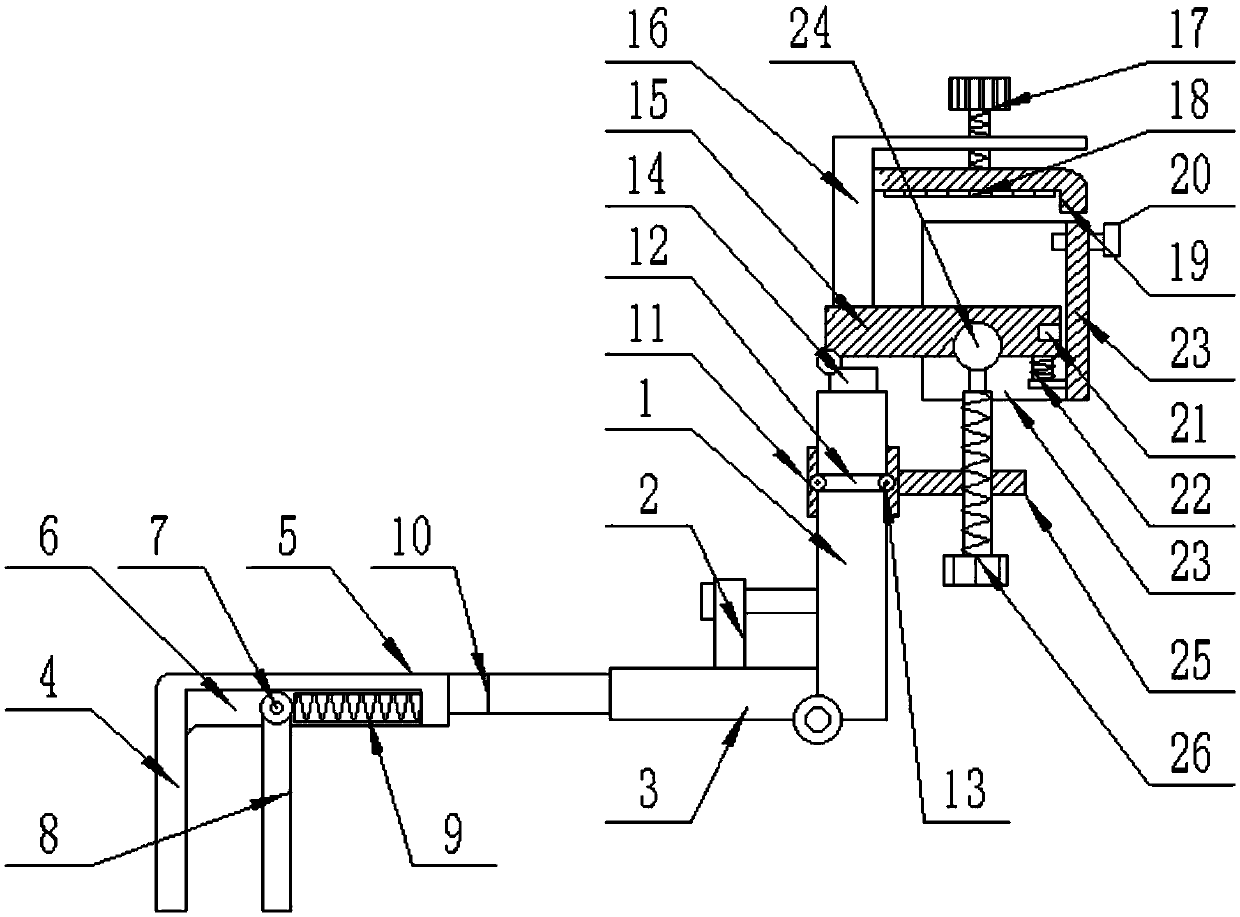

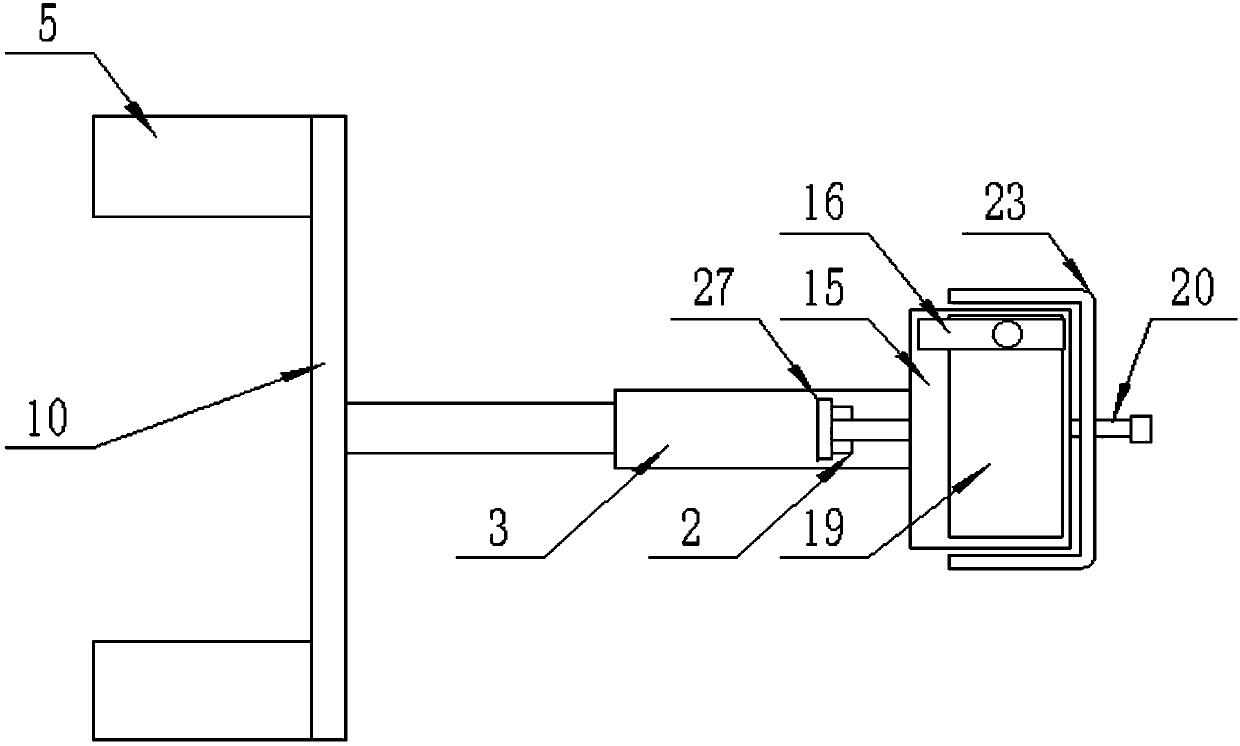

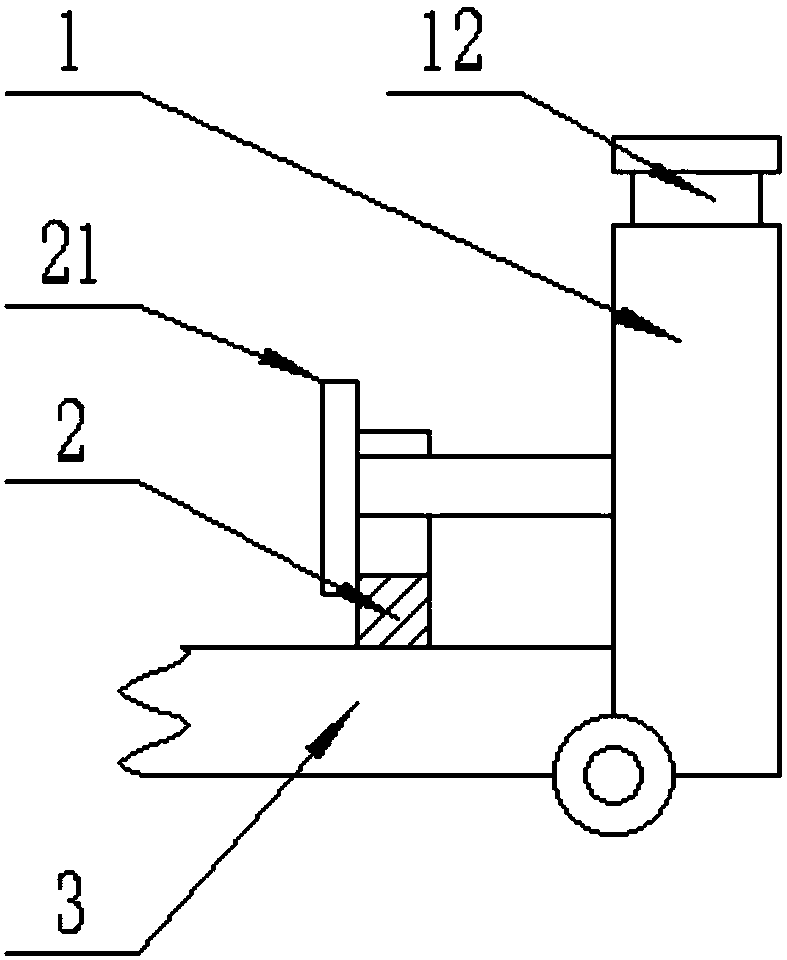

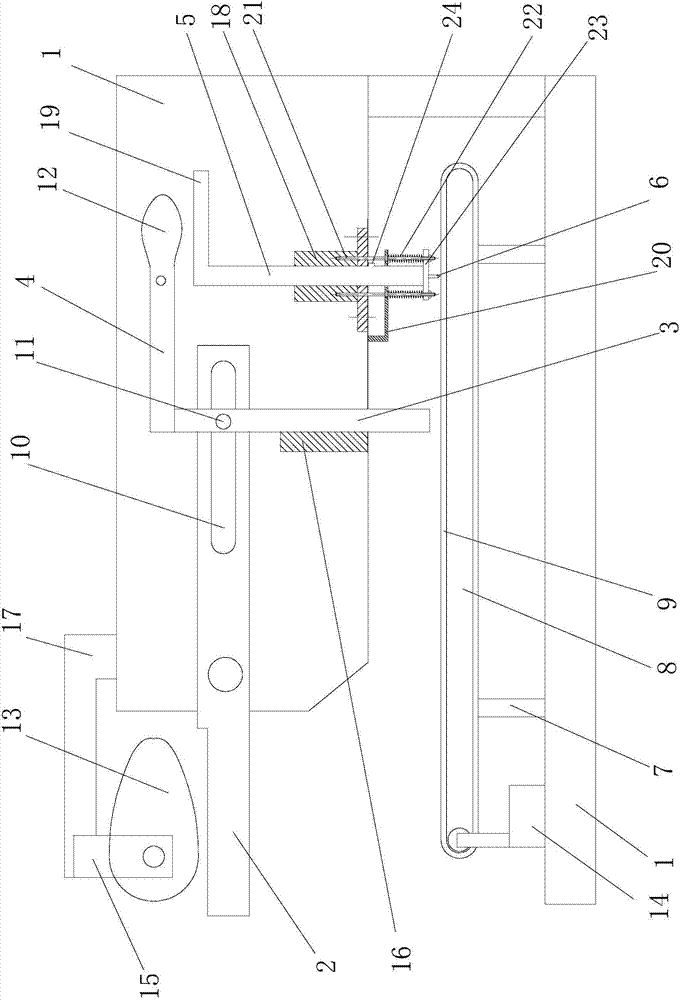

Shredder

The present invention relates to a shredder having a thickness triggering device. During the shredding operation, the trembling of the article is minimized or eliminated by using the shredder. The shredder includes a sustaining mechanism and a driving assembly. Since the sustaining mechanism is sustained against the shredding article, the amplitude of the trembling article is largely reduced. As a consequence, the influence of the shredding article on the thickness triggering device is reduced so as to prevent interruption of the shredder.

Owner:PRIMAX ELECTRONICS LTD

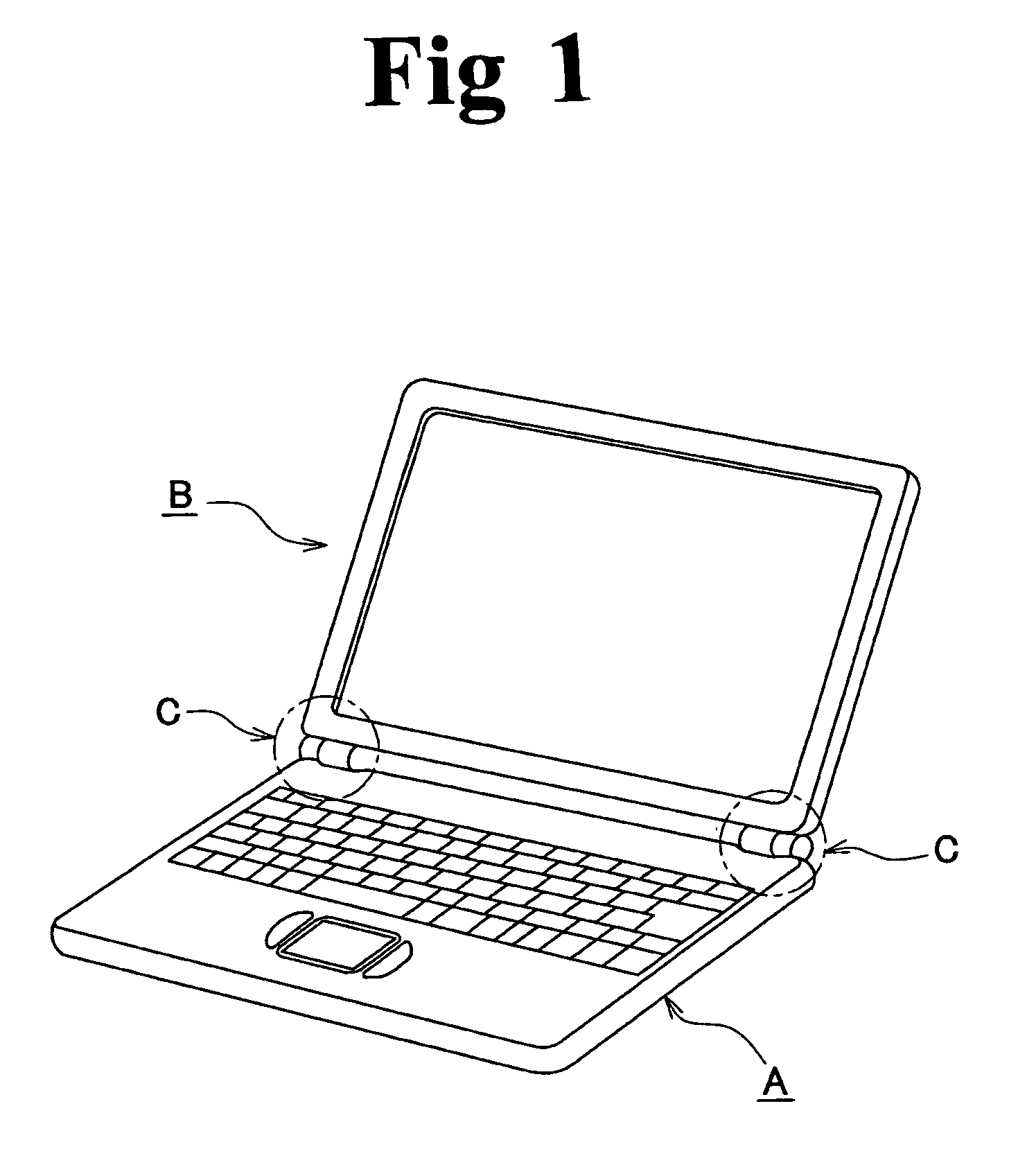

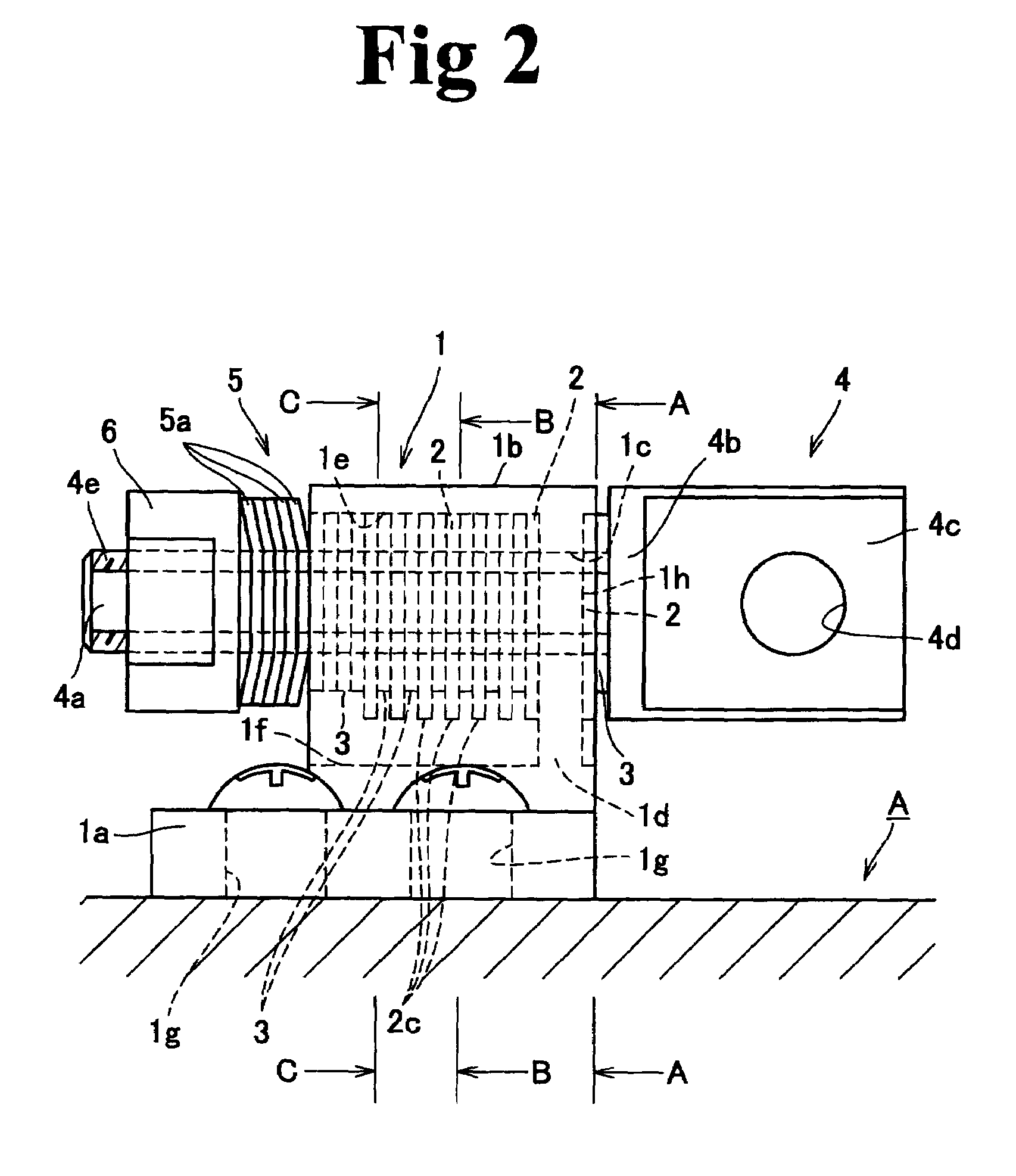

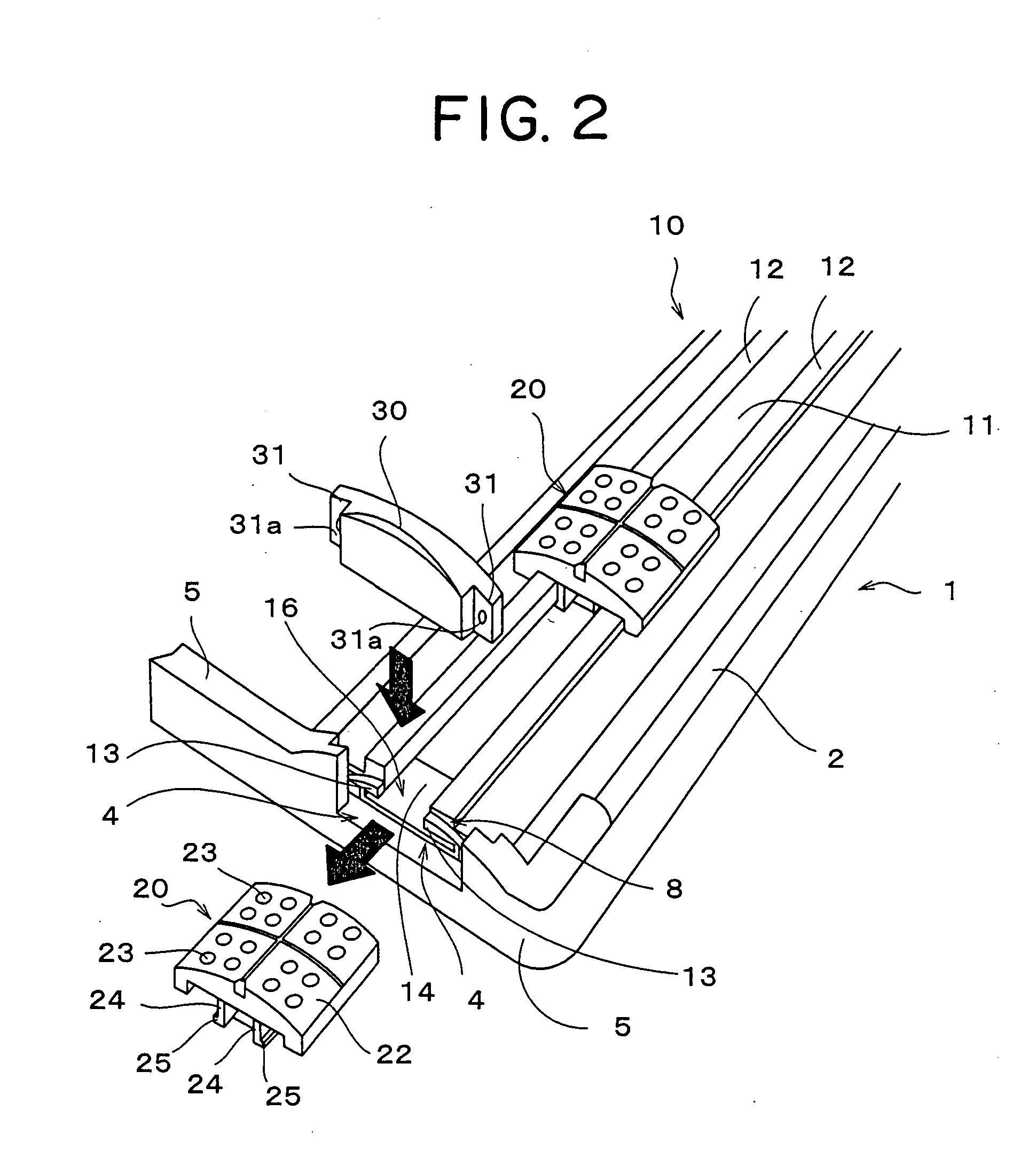

Tilt hinge

InactiveUS6988294B2Avoid tremblingWing fastenersDetails for portable computersHinge angleEngineering

A tilt hinge connecting a first member which constitutes a keyboard base and a second member which constitutes a display device of a small-sized office automation equipment, in which the first member and the second member are opened and closed with respect to each other. The tilt hinge is composed of: a holder attached to either of the first member or the second member; a shaft which is attached to either the other one of the first member and the second member while also attached to the holder so as to be rotatable with respect thereto and to be non-movable in an axial direction; a plurality of first friction disks inserting the shaft rotatably and movably in the axial direction through an insertion hole of each disk and held by the holder; a plurality of second friction disks inserting similarly the shaft through an insertion hole of each disk, being interposed between the first friction disks, restrained its rotation by the shaft and movably in the axial direction; and an elastic means attached to the shaft to cause the first friction disks and the second friction disks to press-contact each other in the axial direction.

Owner:KATOH ELECTRIC MACHINERY +1

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

InactiveCN1740290AAutomatically adjust thicknessOptimizing friction pair clearanceBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

Wet-type multi-plate clutch

InactiveUS20070151822A1Great engagement torque capacityLarge heat capacityFluid actuated clutchesFriction clutchesEngineeringClutch

The present invention provides a wet-type multi-plate clutch subjected to slip control, wherein a first friction material including rich diatom earth at its friction surface acting during the slip control and a second friction material acting at completion of engagement and having great static coefficient of friction are stuck on the same surface of a friction plate of the wet-type multi-plate clutch and wherein the first friction material has an axial thickness greater than that of the second friction material.

Owner:NSK WARNER

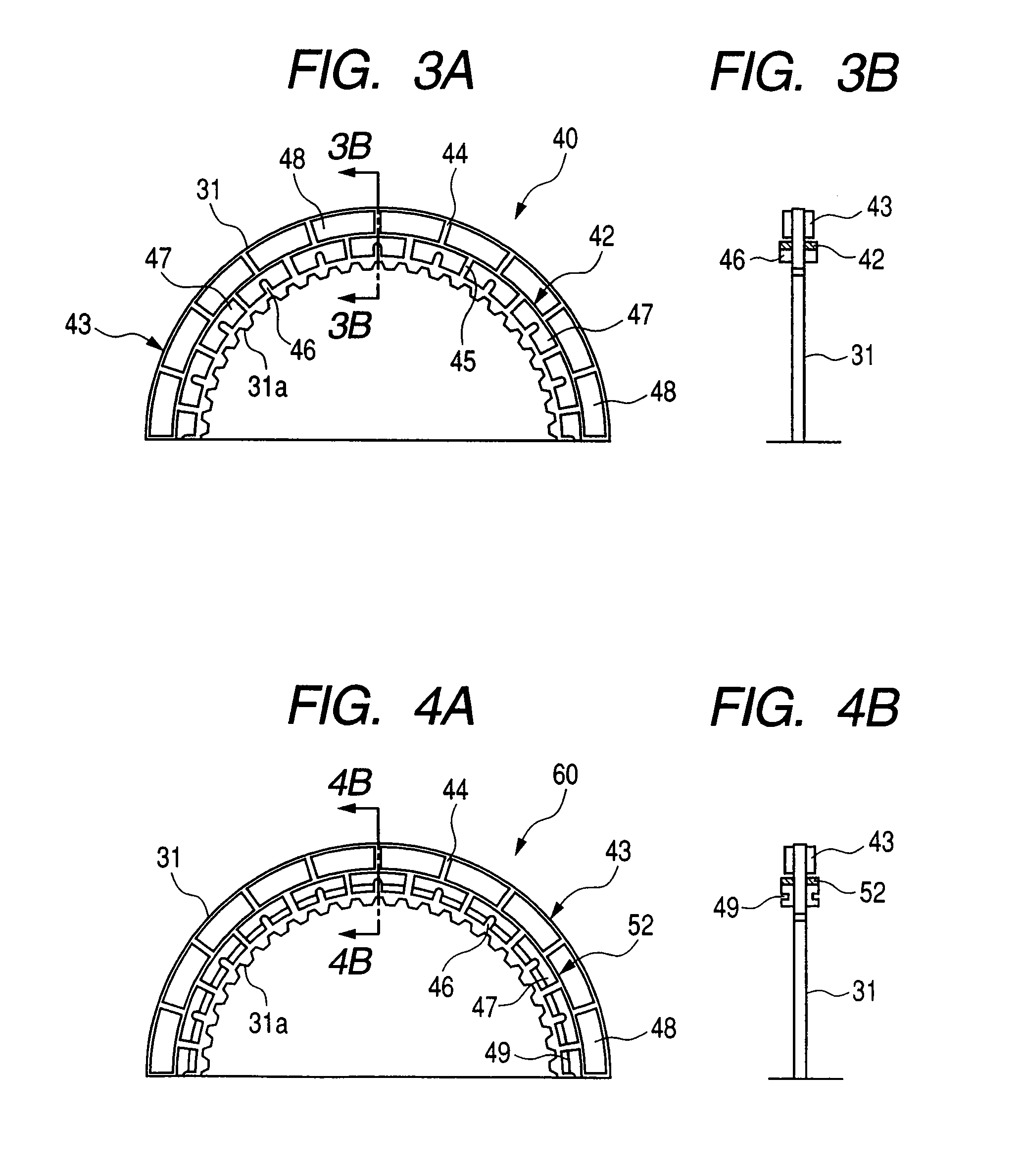

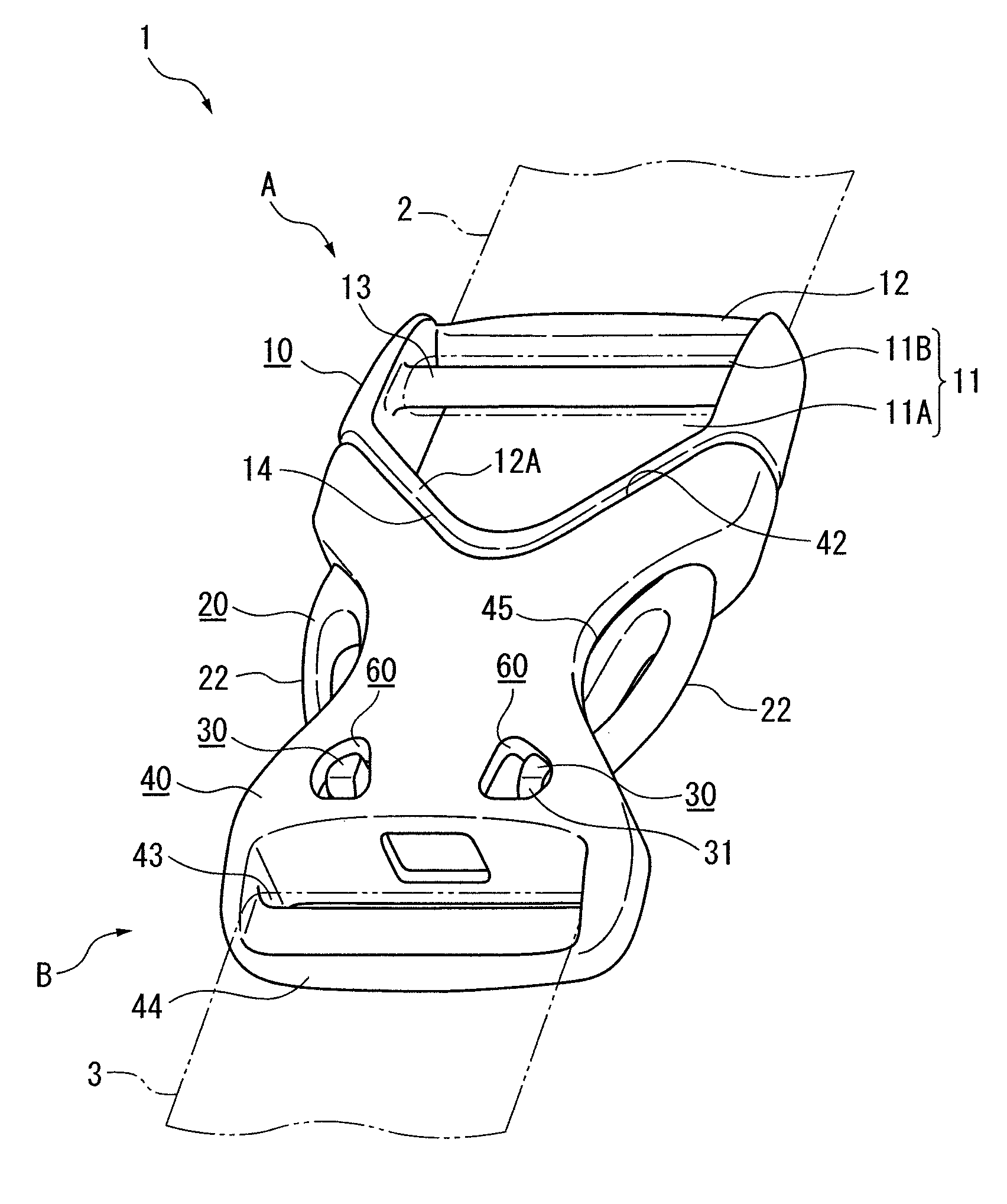

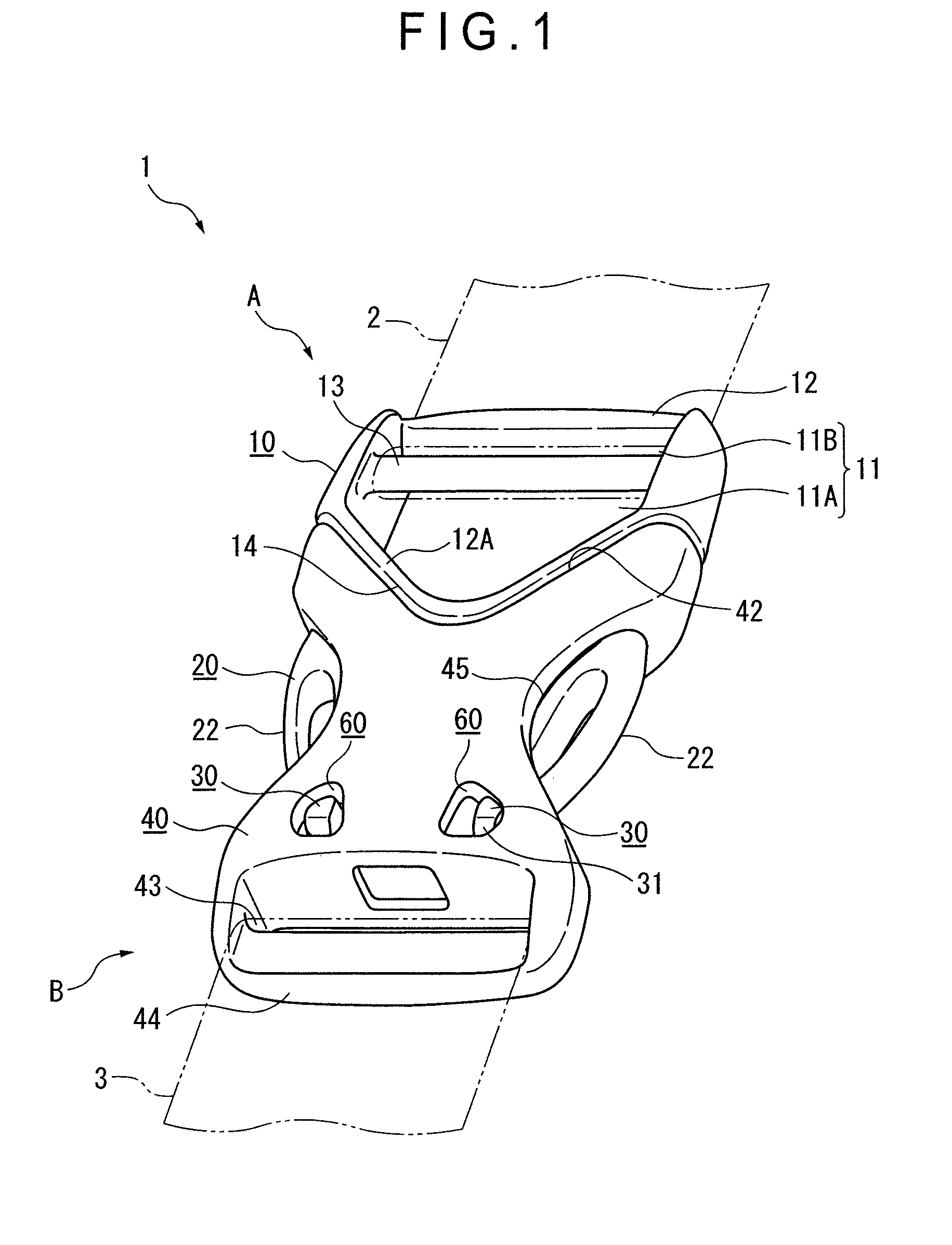

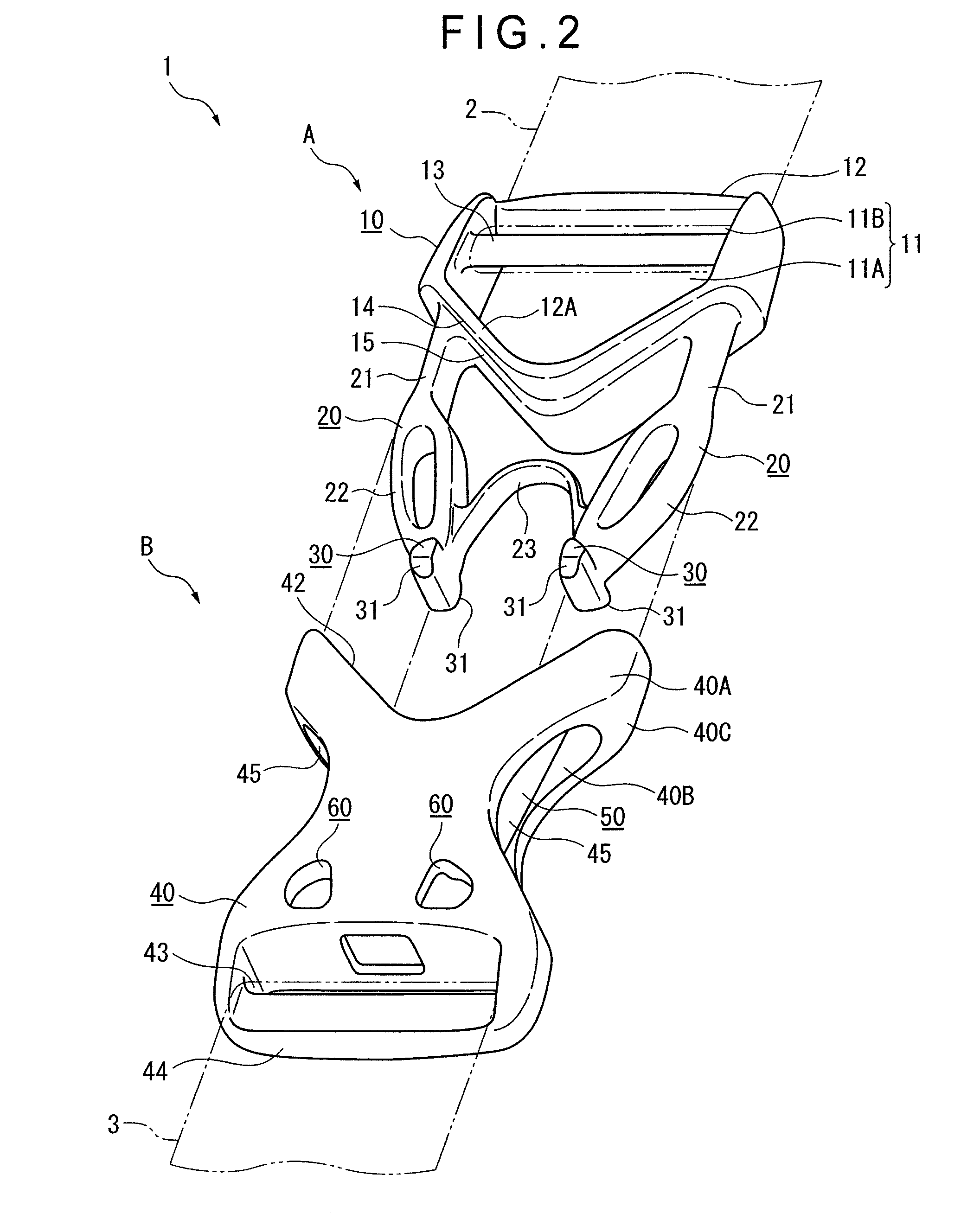

Buckle

A buckle includes a male member and a female member. The male member is provided with a base, a pair of legs and an engaging portion provided on a distal ends of the legs. The female member is provided with an insertion port, a guide that elastically deforms the distal end of each of the legs inserted through the insertion port in a direction in which the distal ends come closer to each other and a pair of engaged portions formed on both sides of a remote side of the guide. Each of the engaged portions displaces each of the engaging portions in the direction in which the engaging portions get apart with each other and is provided by a concave that has an abutment wall on a rear portion in the releasing direction to be abutted by each of engaging portions. Each of the abutment walls is formed as a slant surface that inclines in the direction in which the abutment walls come closer to each other toward the releasing direction of the male member.

Owner:YKK CORP

Buckle

A buckle includes a male member and a female member. The male member is provided with a base, a pair of legs and an engaging portion provided on a distal ends of the legs. The female member is provided with an insertion port, a guide that elastically deforms the distal end of each of the legs inserted through the insertion port in a direction in which the distal ends come closer to each other and a pair of engaged portions formed on both sides of a remote side of the guide. Each of the engaged portions displaces each of the engaging portions in the direction in which the engaging portions get apart with each other and is provided by a concave that has an abutment wall on a rear portion in the releasing direction to be abutted by each of engaging portions. Each of the abutment walls is formed as a slant surface that inclines in the direction in which the abutment walls come closer to each other toward the releasing direction of the male member.

Owner:YKK CORP

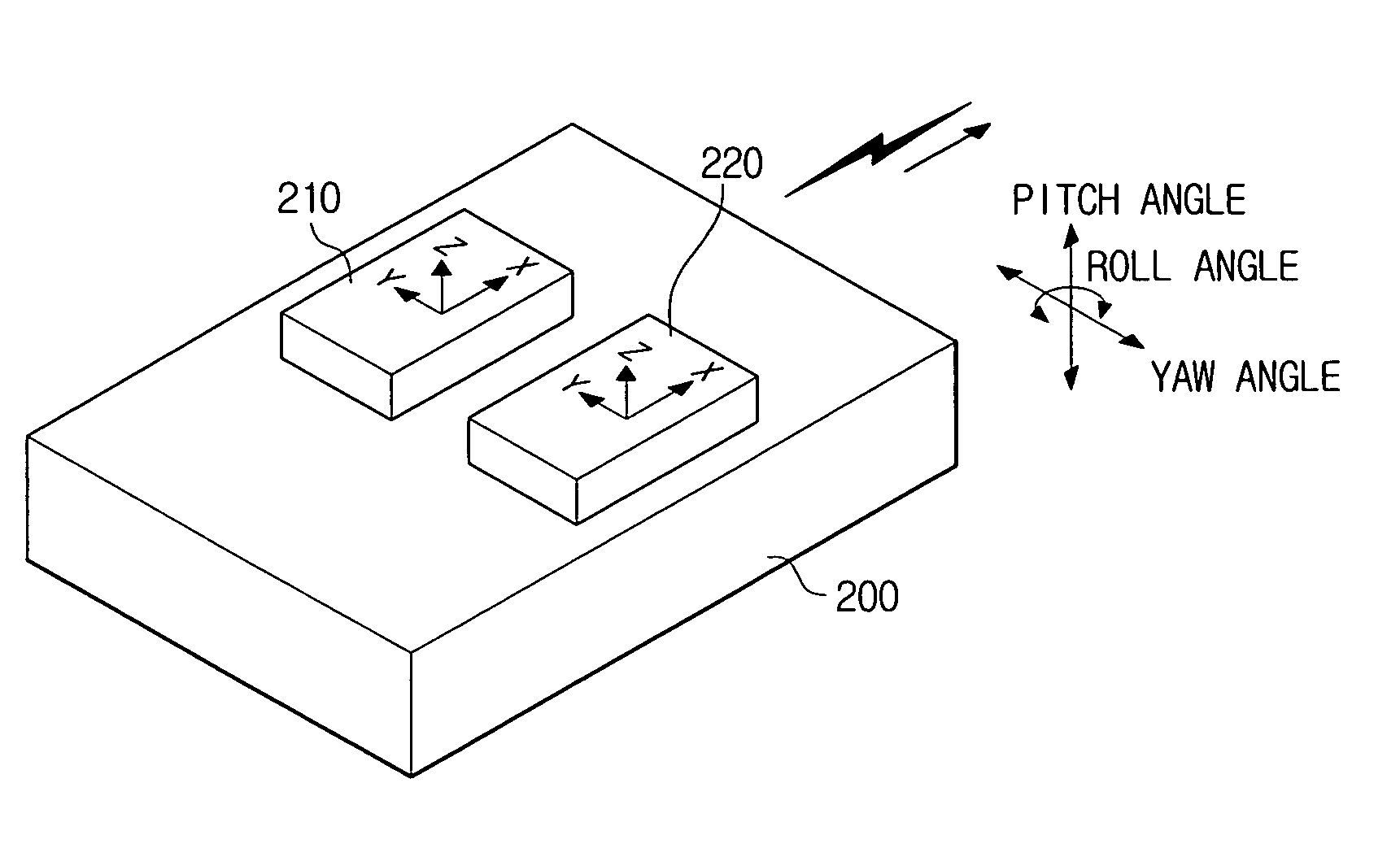

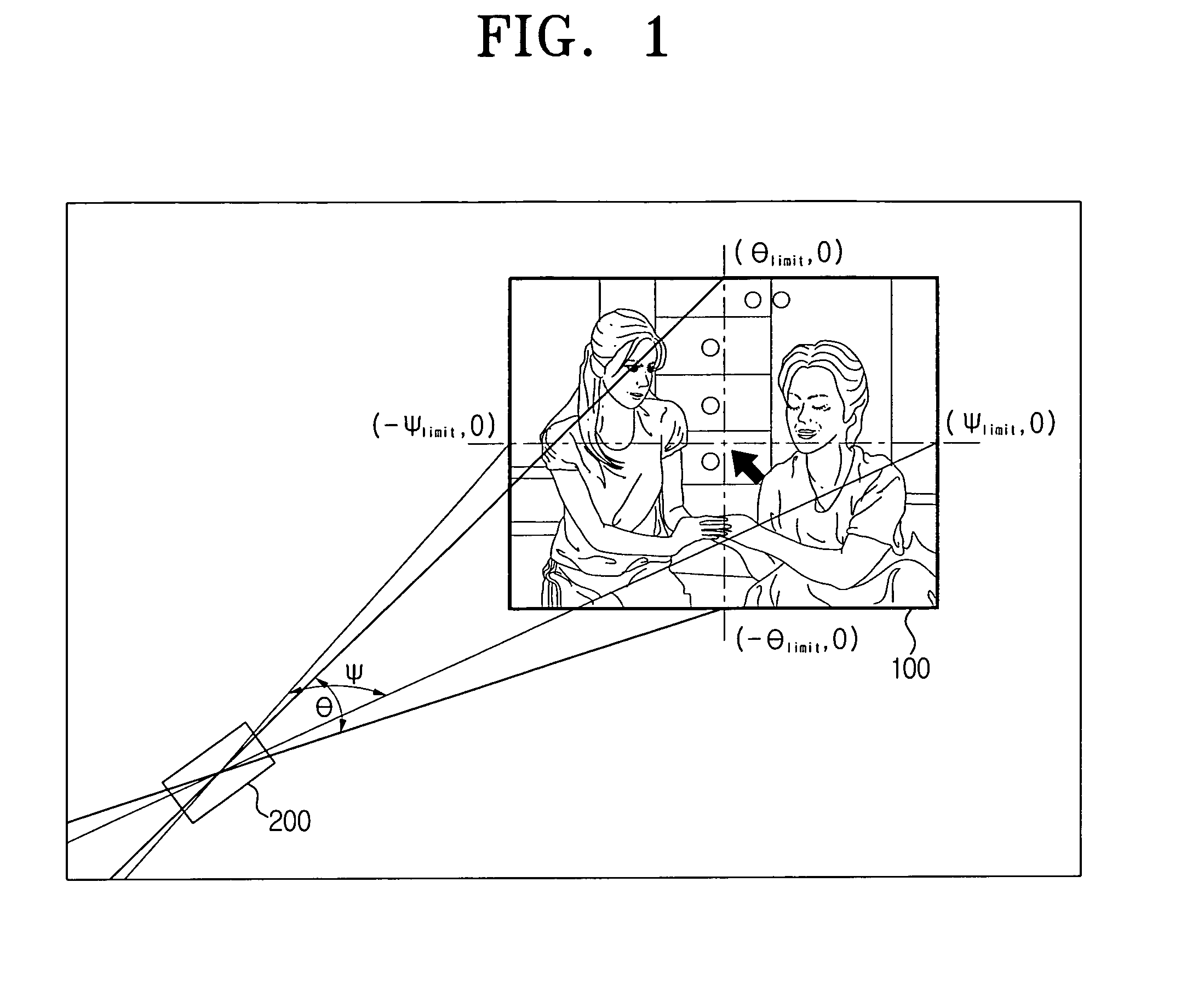

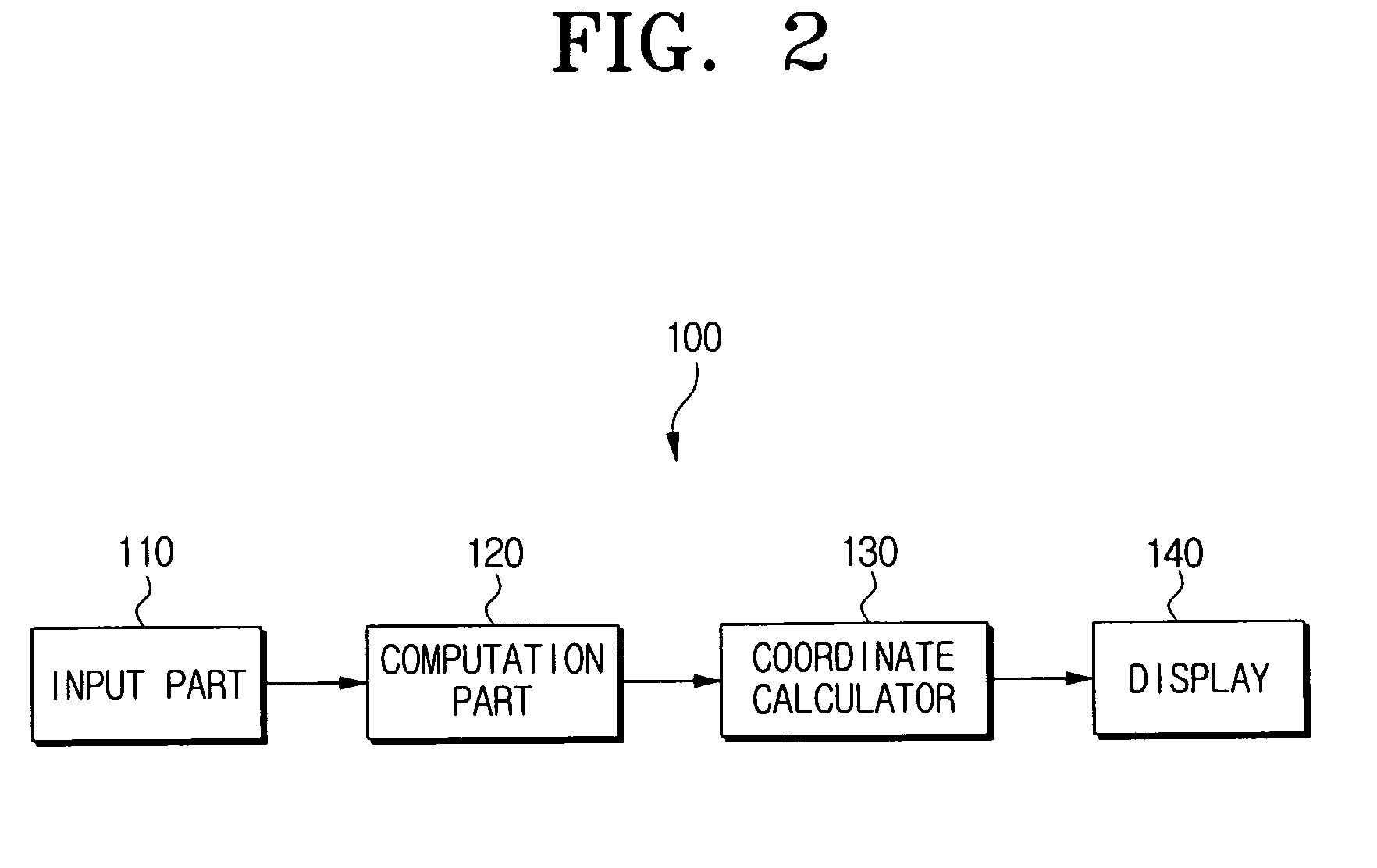

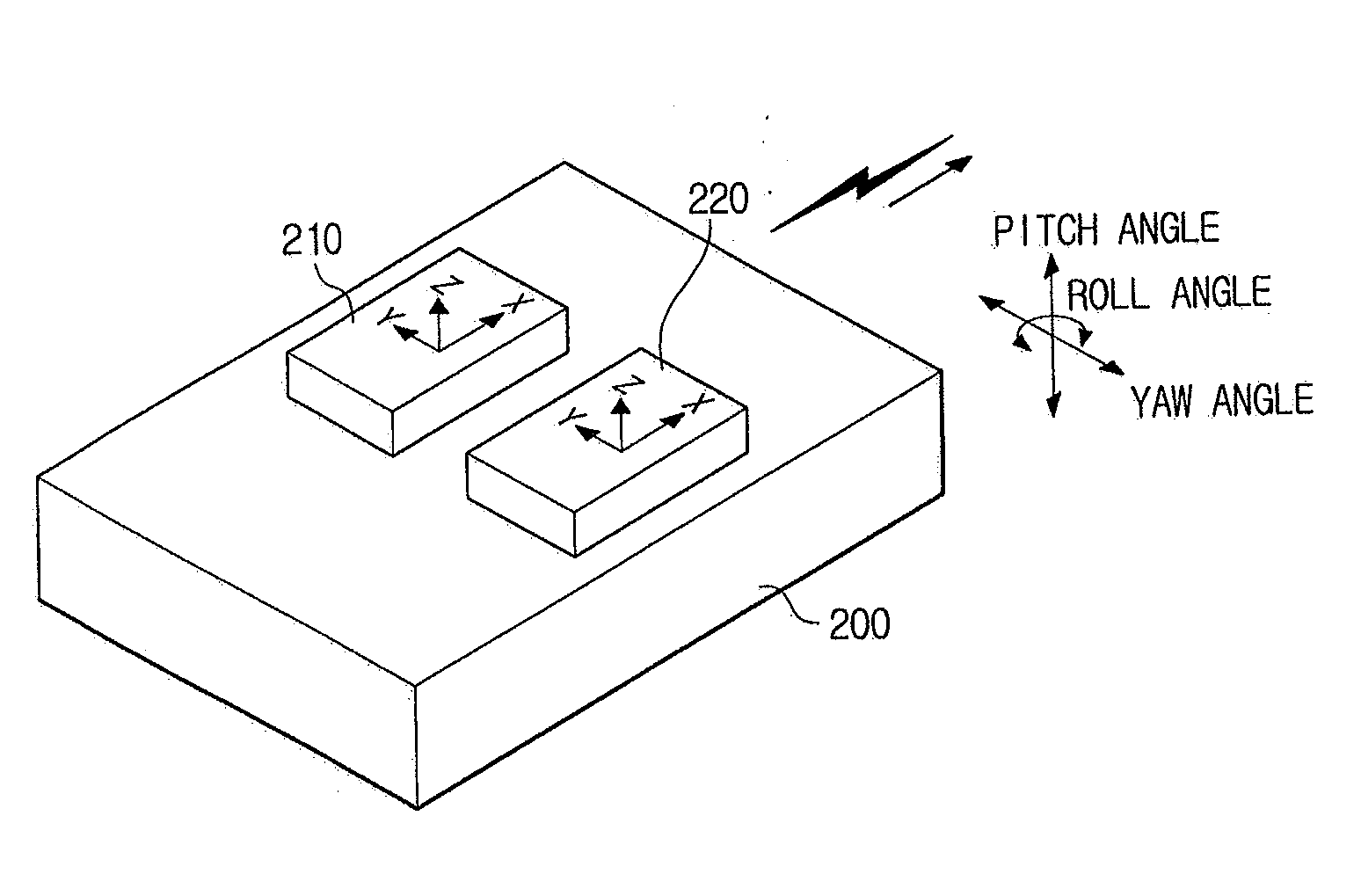

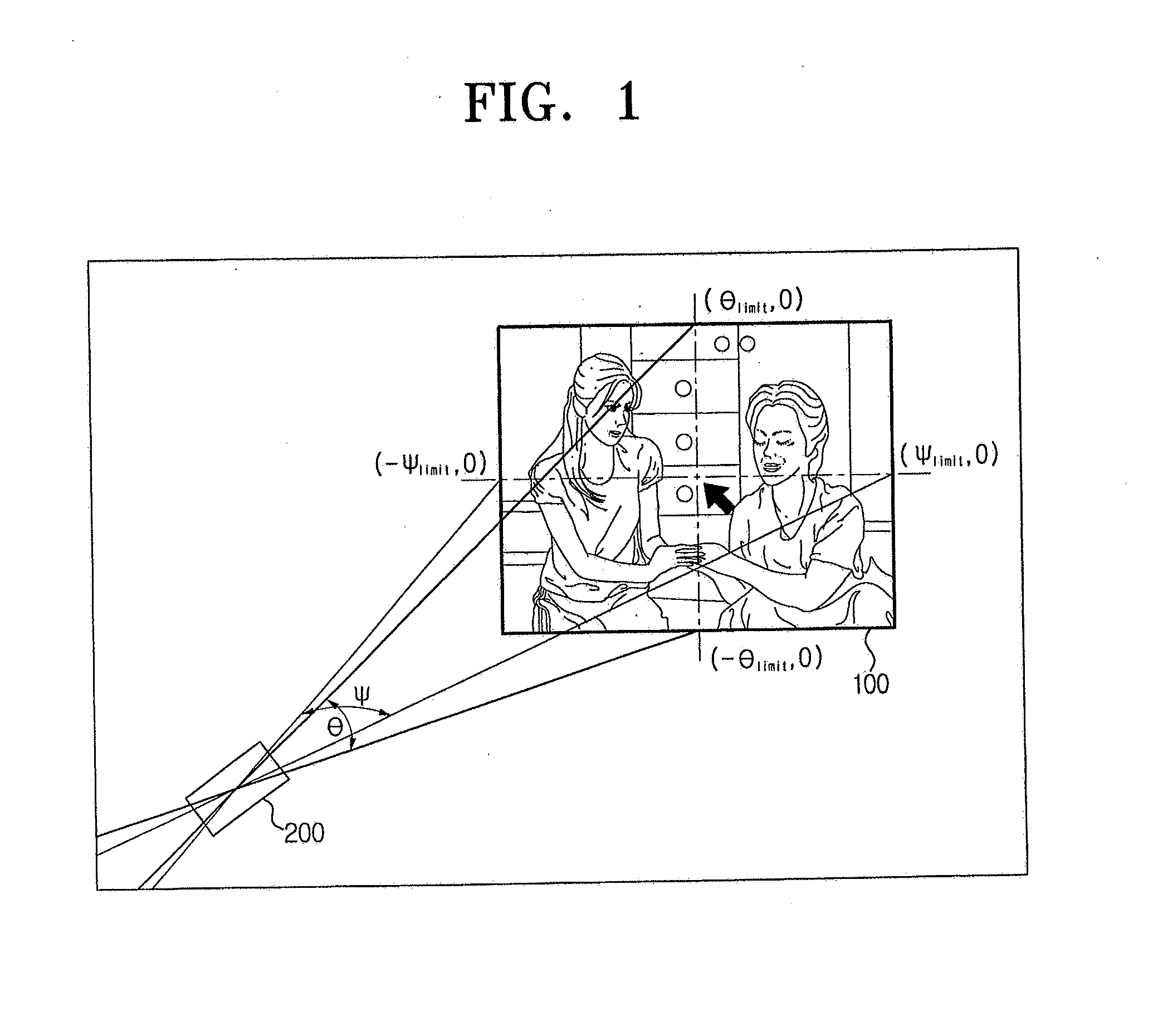

Input device comprising geomagnetic sensor and acceleration sensor, display device for displaying cursor corresponding to motion of input device, and cursor display method thereof

InactiveUS20070290998A1Avoid tremblingAvoid time delayDigital computer detailsCathode-ray tube indicatorsCalculatorInput device

A display device for displaying a cursor according to motion of an input device is provided. The input device comprises an input part which receives pitch angle information and yaw angle information corresponding to motion of an external input device; a computation part which computes a first relative angle corresponding to the information of the pitch angle and a second relative angle corresponding to the information of the yaw angle; a coordinate calculator which calculates a cursor coordinate value which gradually varies according to the changes of the first and second relative angles; and a display which displays a cursor on a position corresponding to the calculated cursor coordinate value. Thus, it is possible to avoid trembling of the cursor caused by noise.

Owner:SAMSUNG ELECTRONICS CO LTD

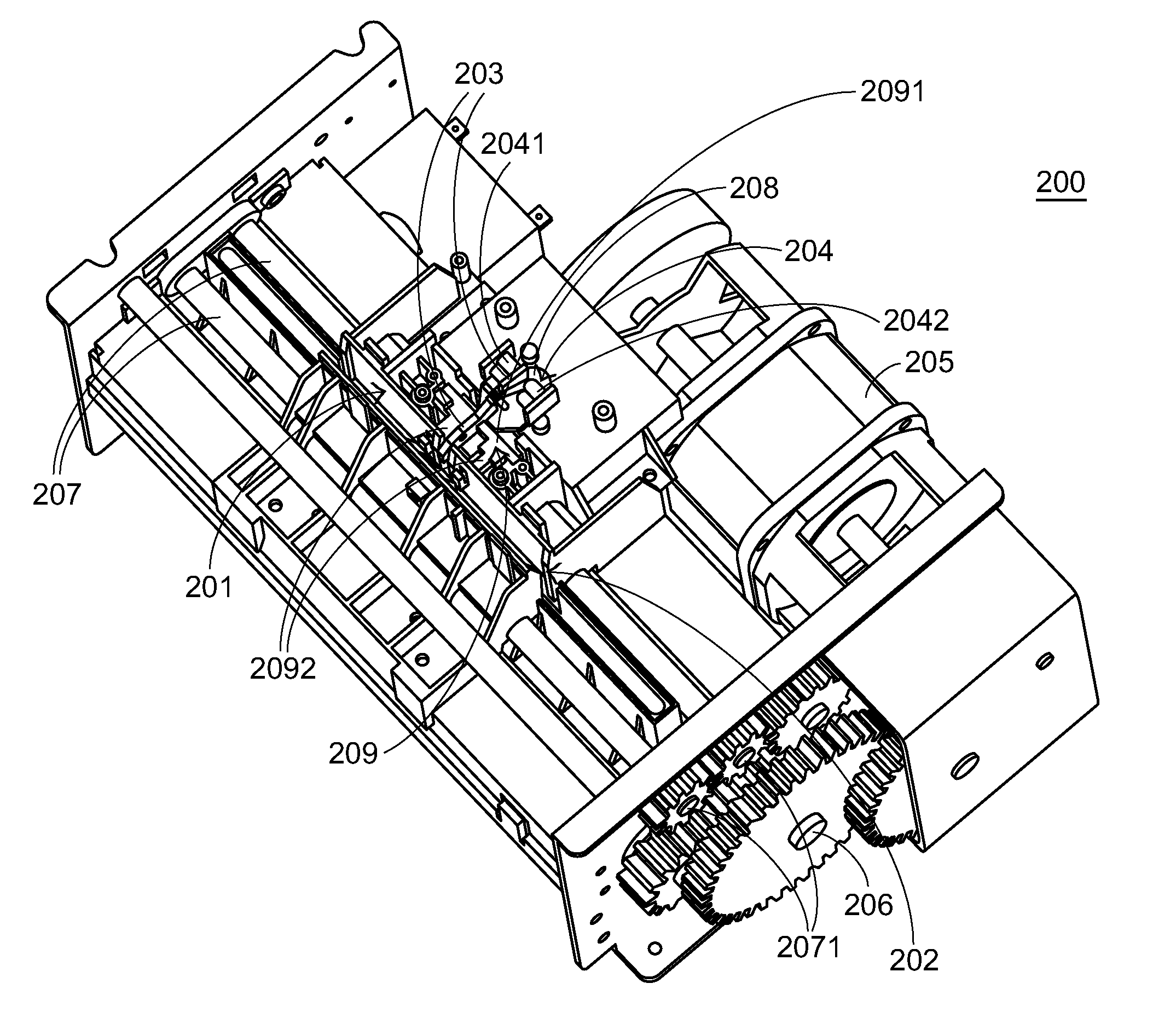

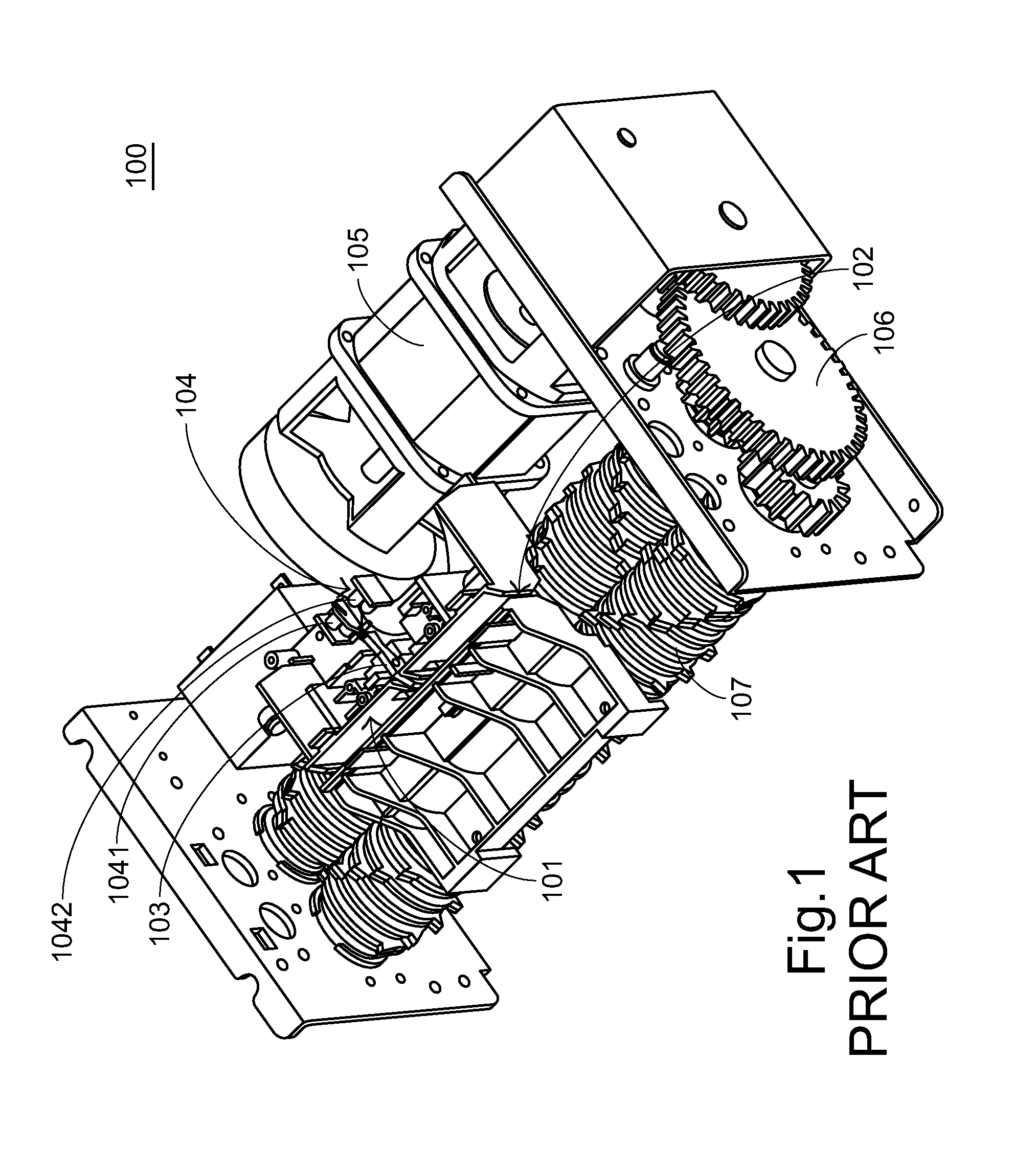

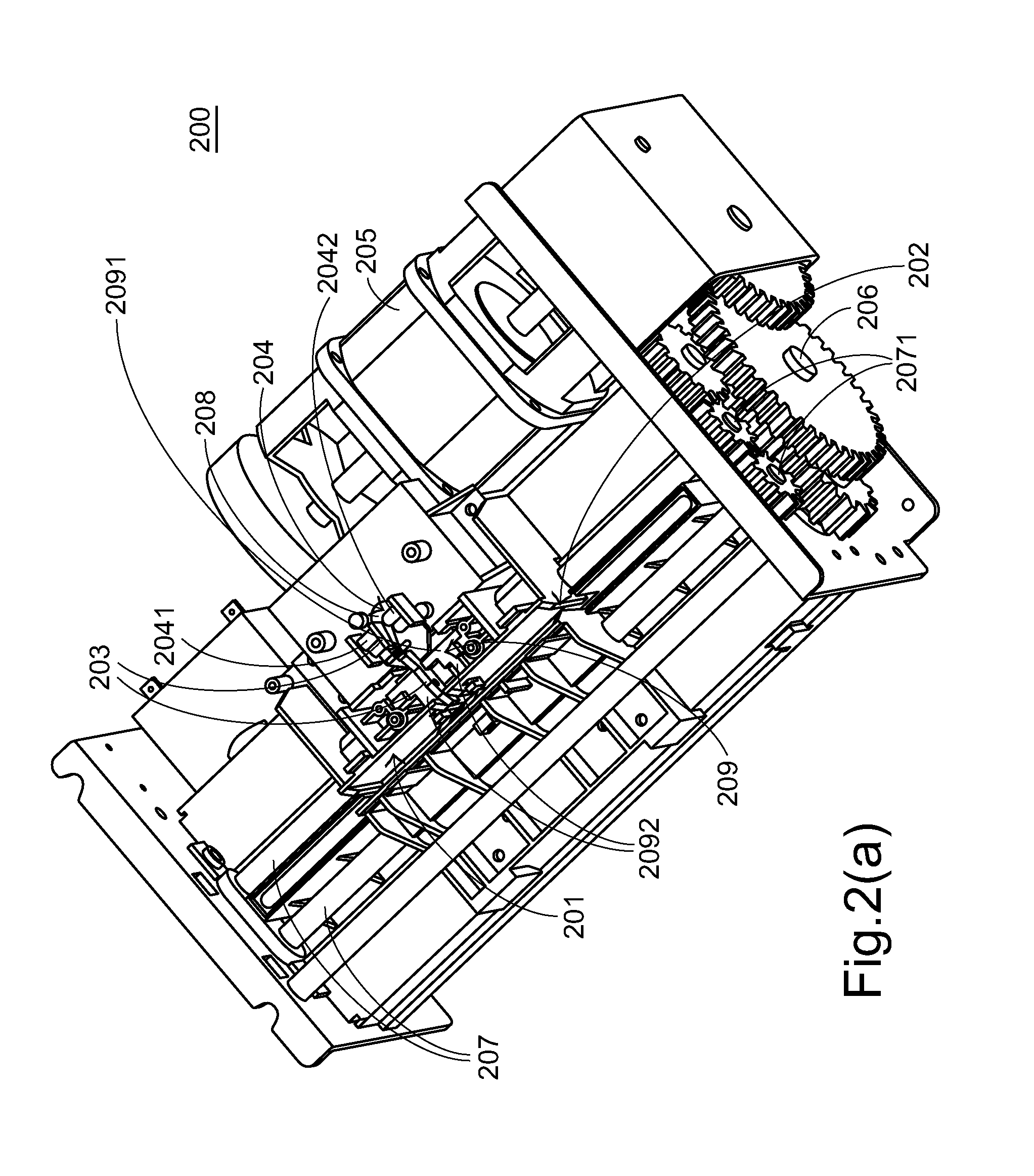

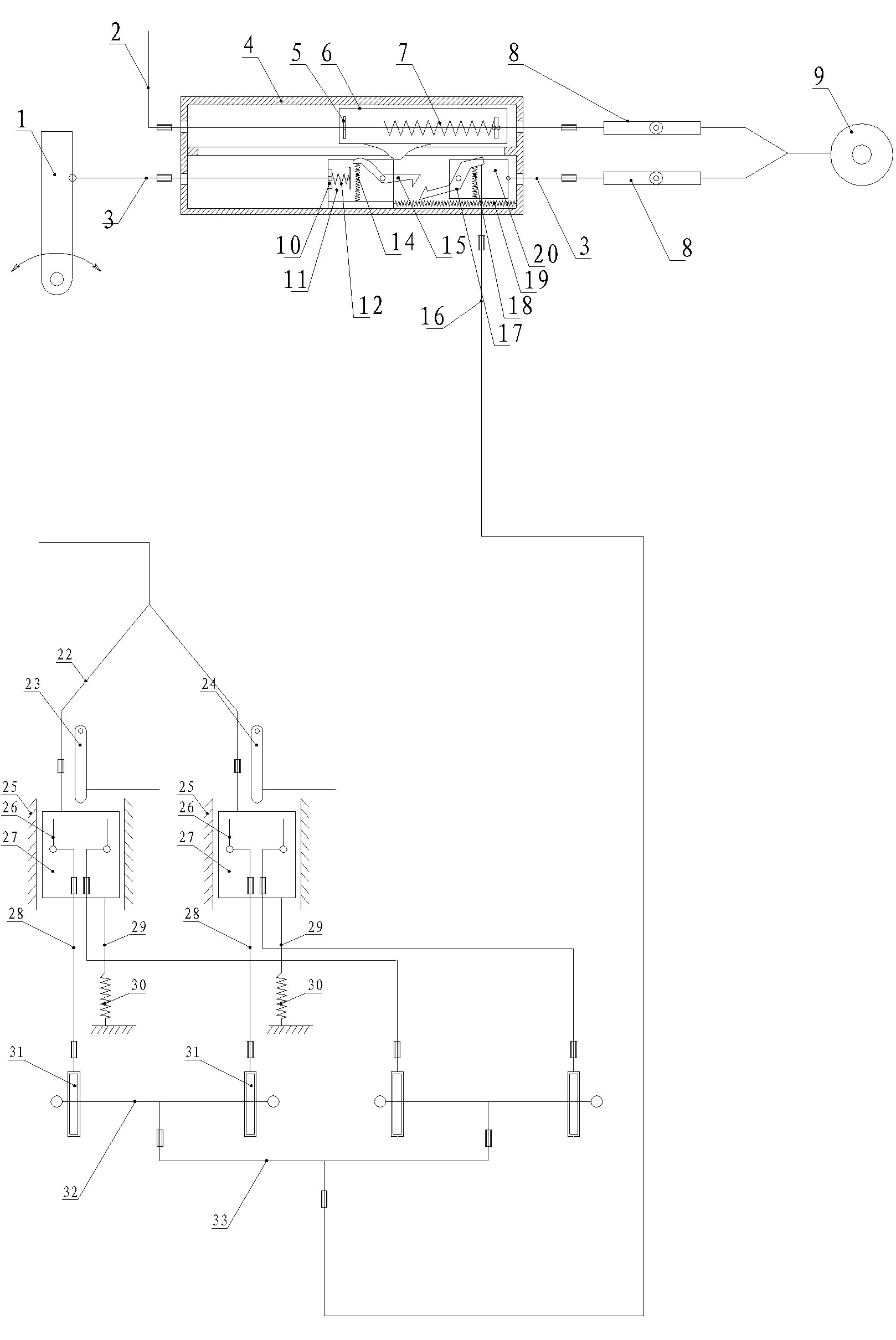

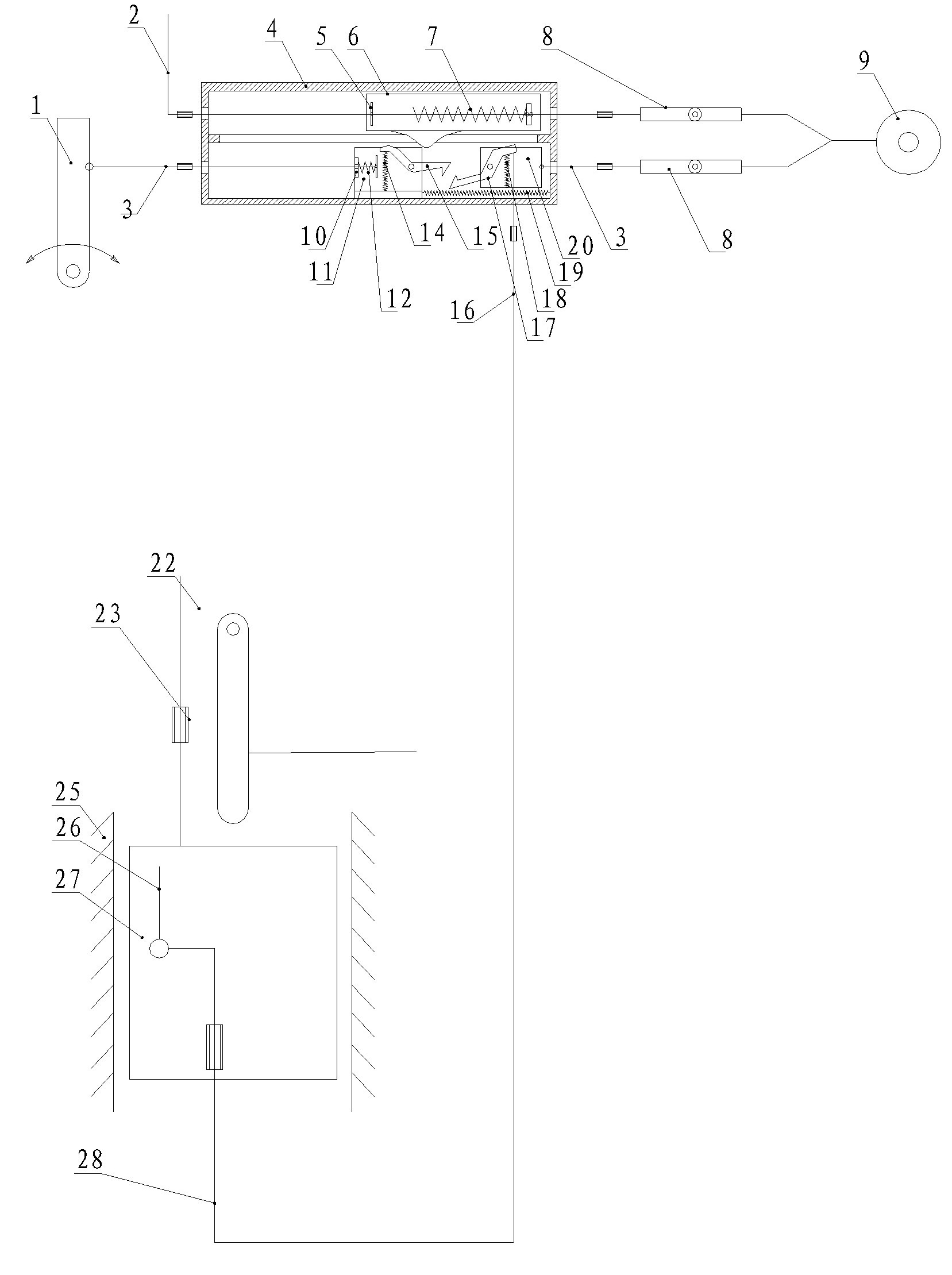

Shredder

The present invention relates to a shredder having a thickness triggering device. During the shredding operation, the trembling of the article is minimized or eliminated by using the shredder. The shredder includes a sustaining mechanism and a driving assembly. Since the sustaining mechanism is sustained against the shredding article, the amplitude of the trembling article is largely reduced. As a consequence, the influence of the shredding article on the thickness triggering device is reduced so as to prevent interruption of the shredder.

Owner:PRIMAX ELECTRONICS LTD

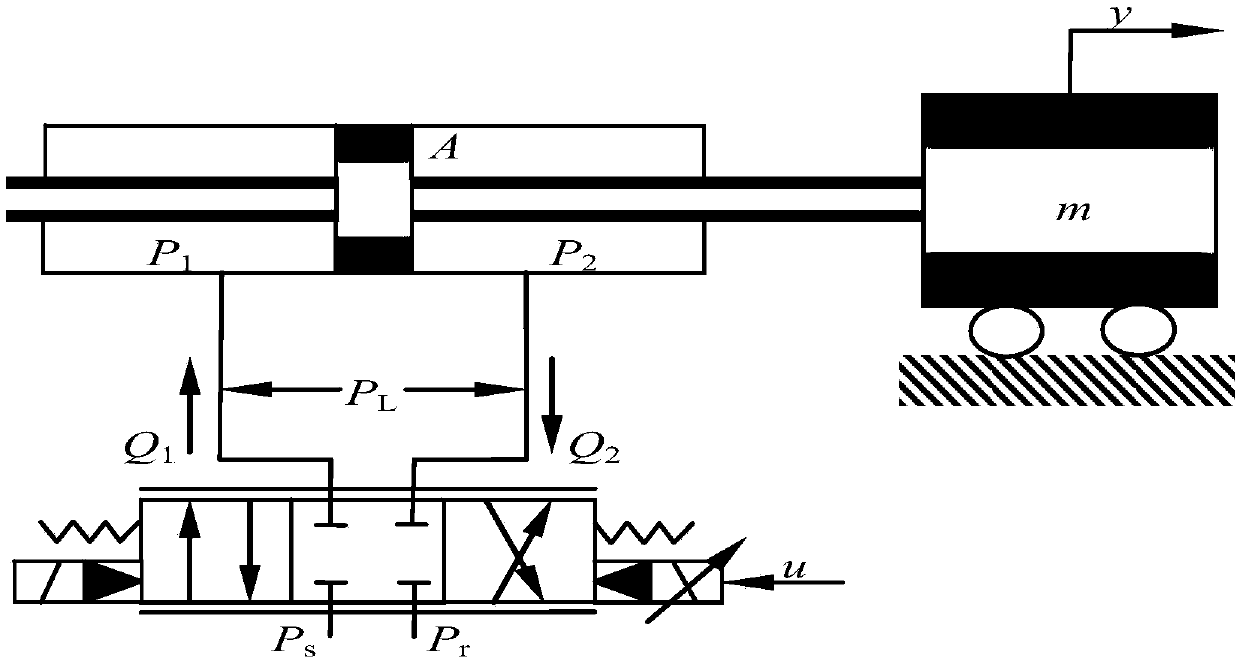

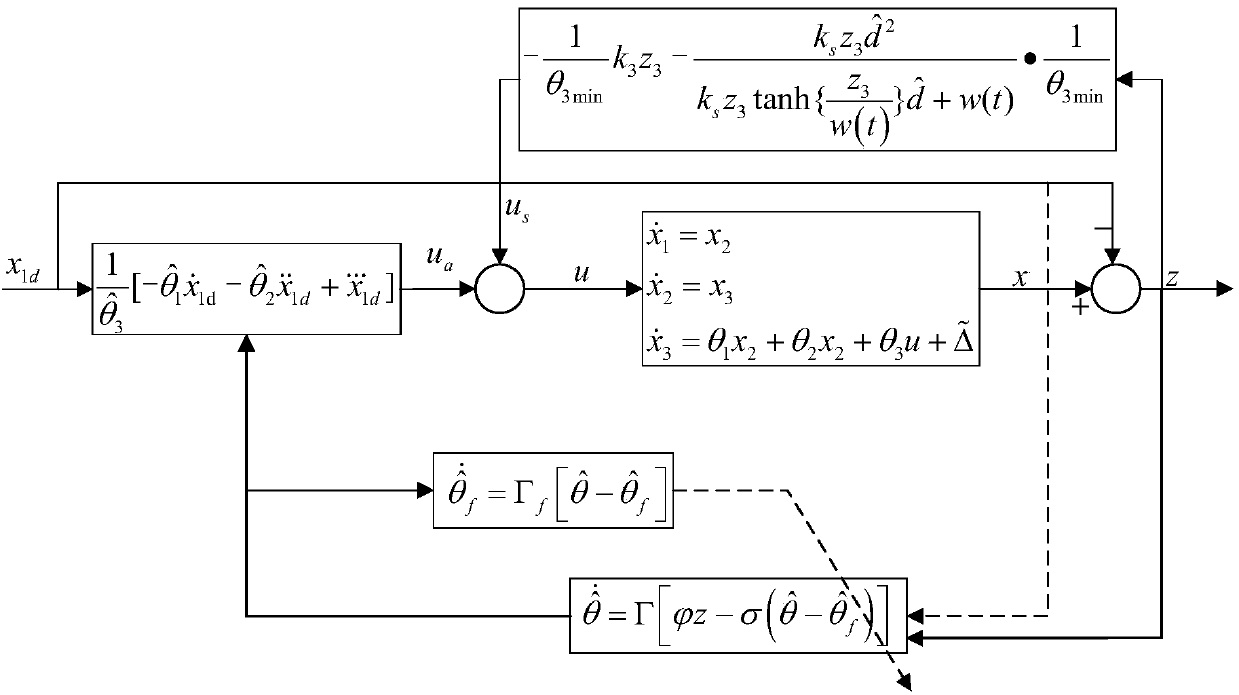

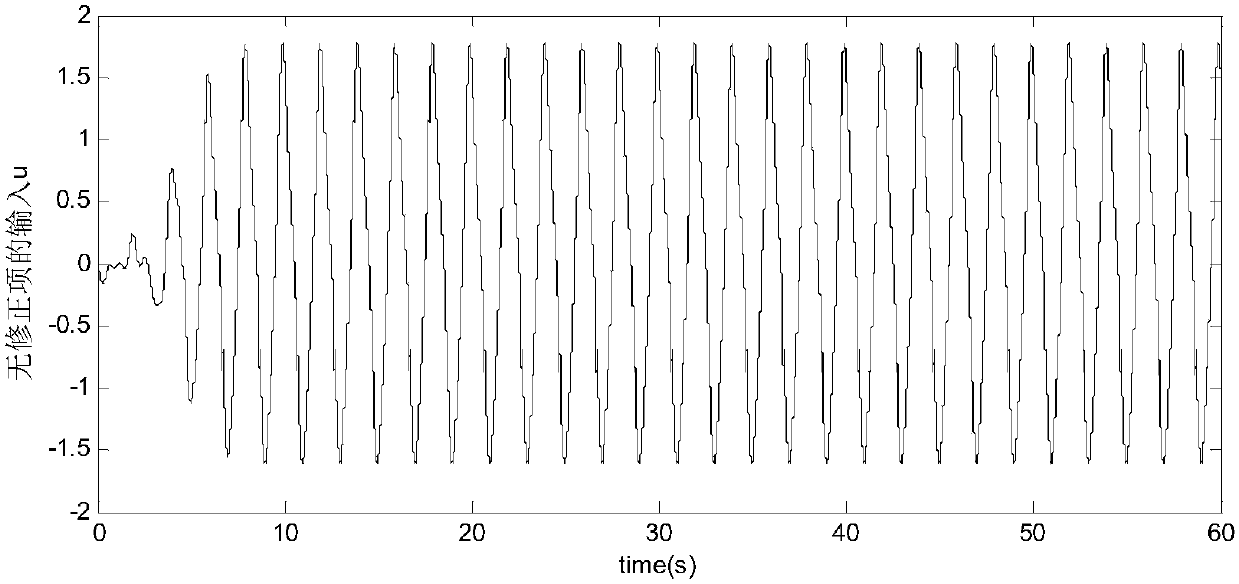

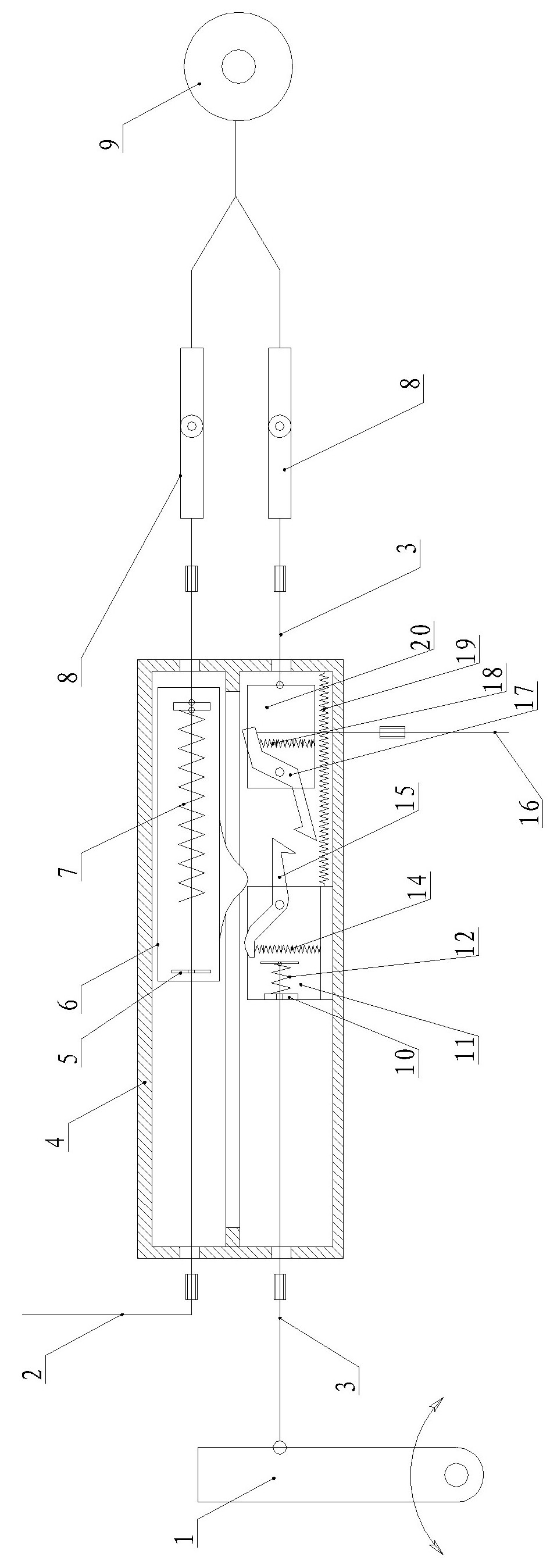

Electro-hydraulic servo system adaptive robust control method based on low-frequency learning

The invention discloses an electro-hydraulic servo system adaptive robust control method based on low-frequency learning. The method comprises a step of establishing a mathematical model of a hydraulic system and making the following assumptions that the total interference of the system is sufficiently smooth such that the total interference exists and is bounded, a desired position trajectory isthree-order derivable and is bounded, the uncertainty change range of parameters is bounded, and decreasing function absolute value and integral about time are smaller than a predetermined value, a step of constructing an adaptive robust low-frequency learning controller, based on a traditional backstepping control method, integrating the ideas of adaptive control and expected compensation, andadding a correction term into a controller parameter self-adjustment law, and a step of proving stability by using the Lyapunov stability theory and obtaining a global asymptotic stability result of the system by using the Barbalat lemma. According to the method, high-frequency tremor caused by a high gain and the influence of measurement noise on the high tracking performance of the system are effectively avoided, and better tracking performance is obtained.

Owner:NANJING UNIV OF SCI & TECH

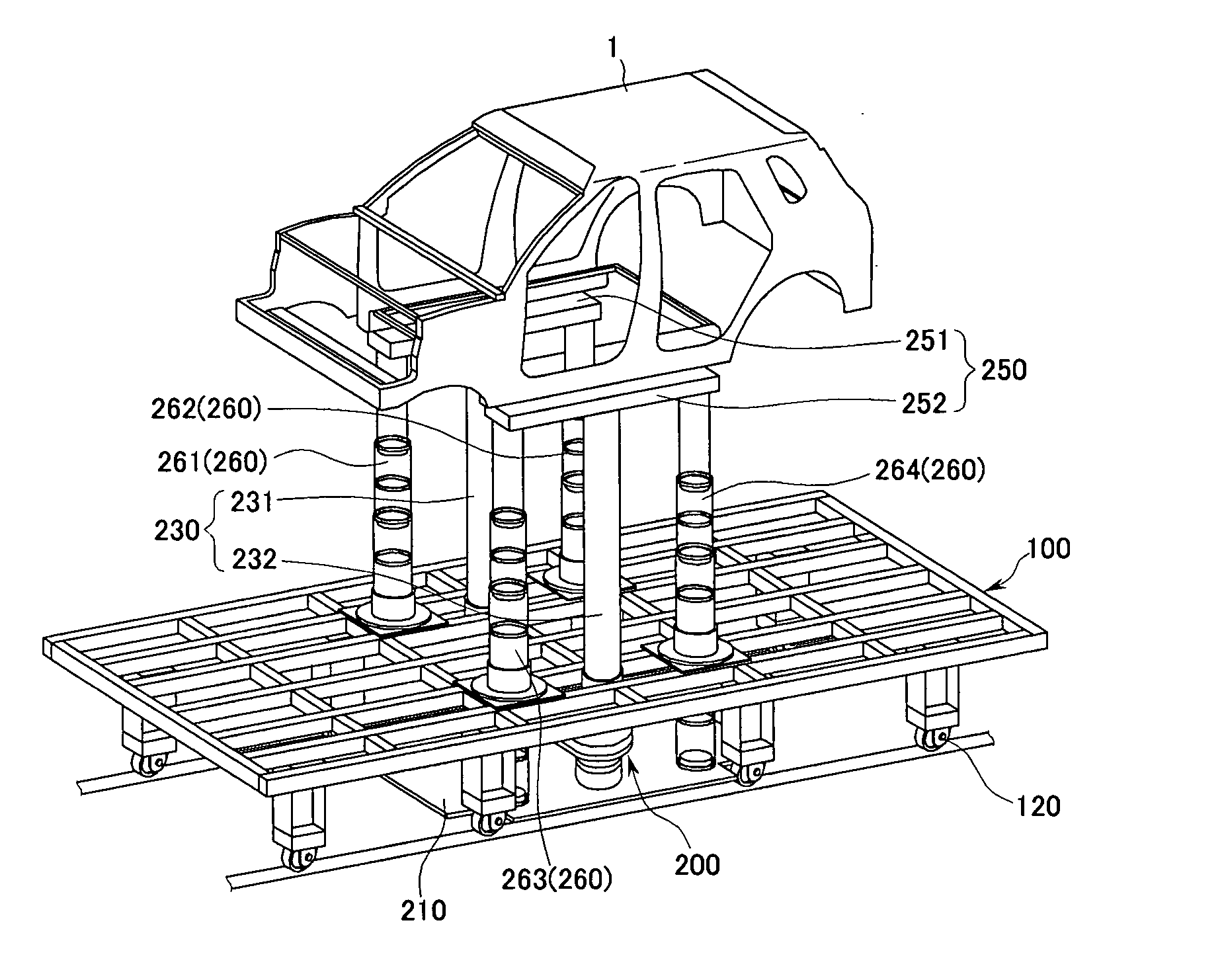

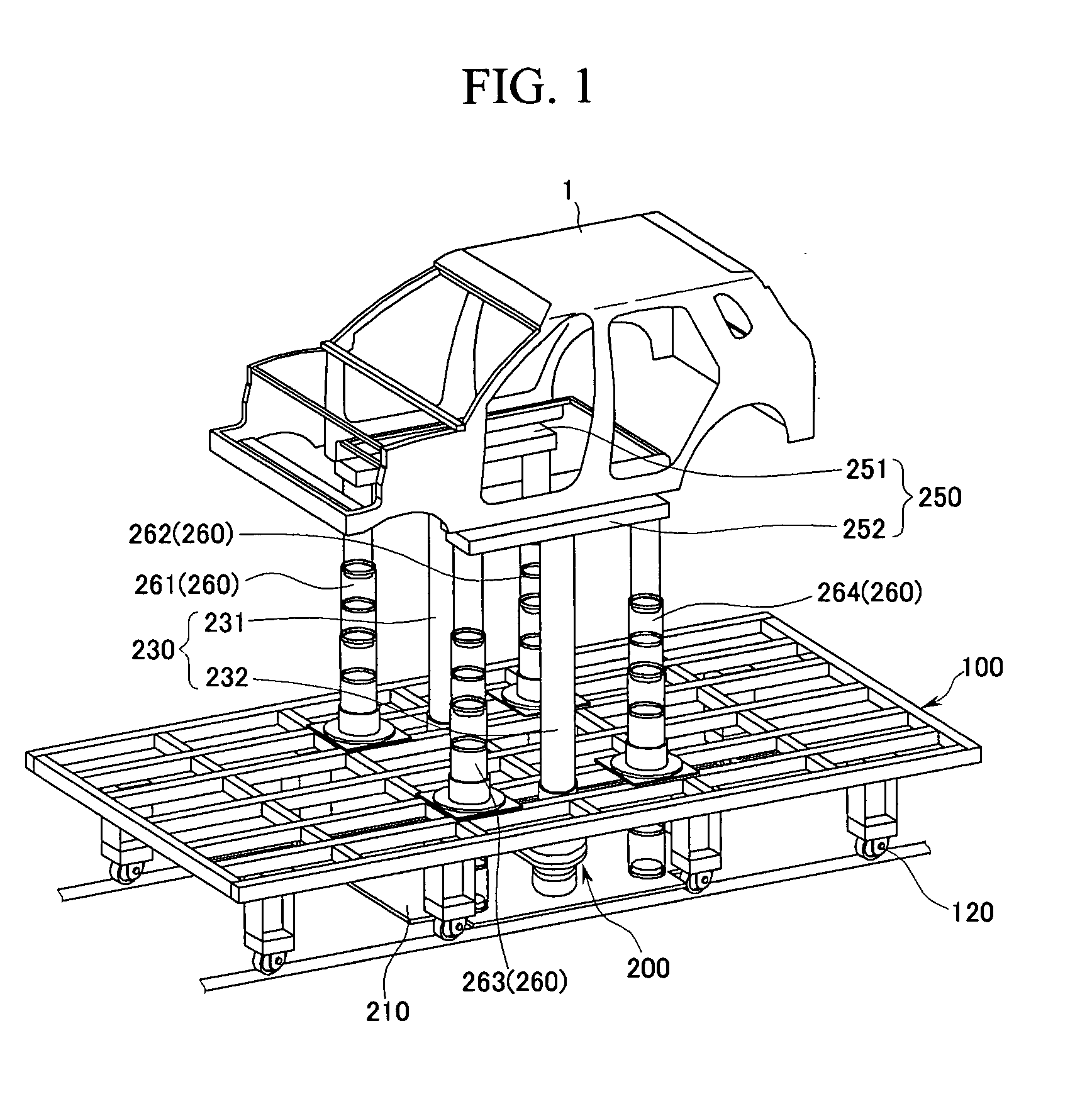

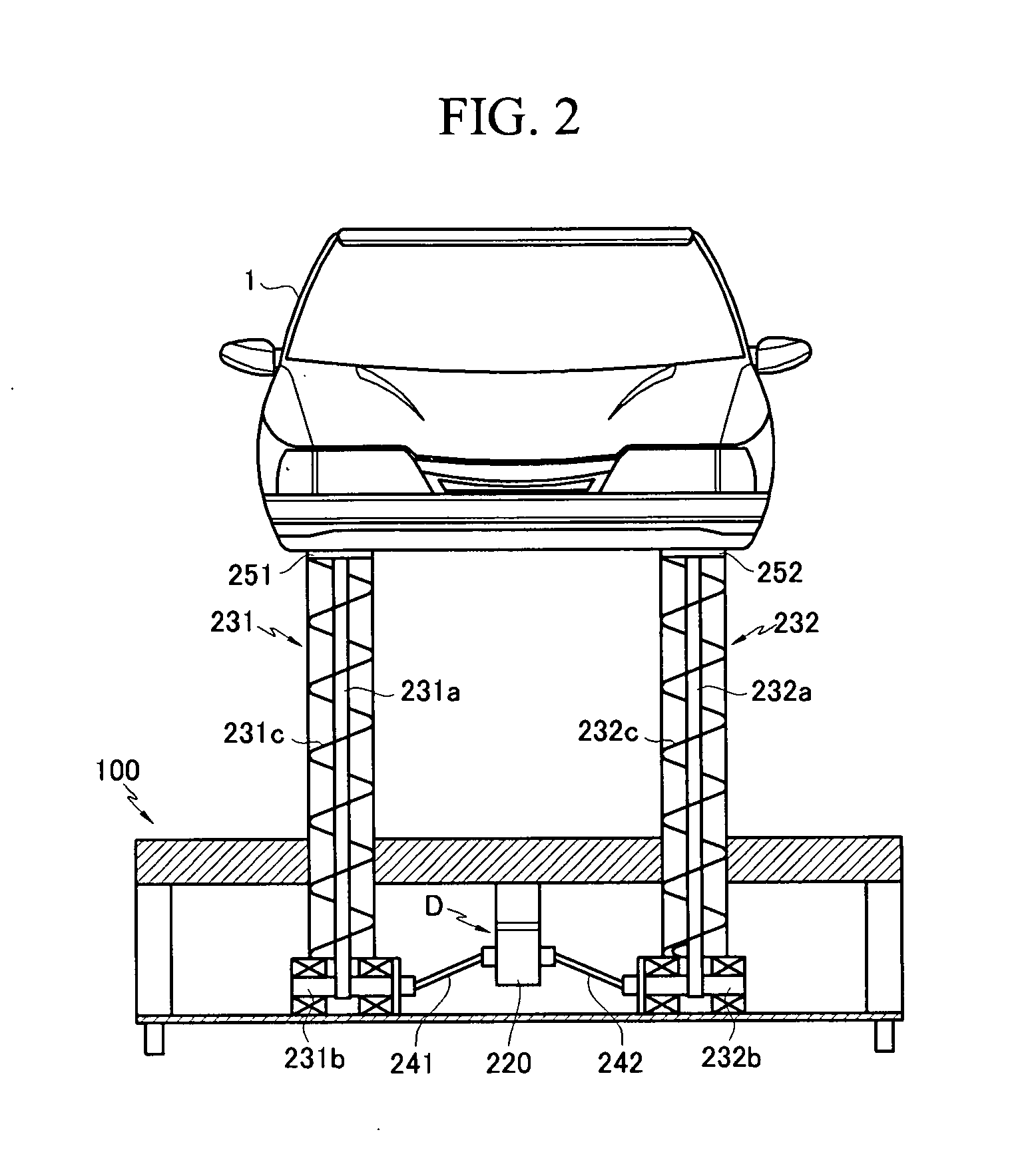

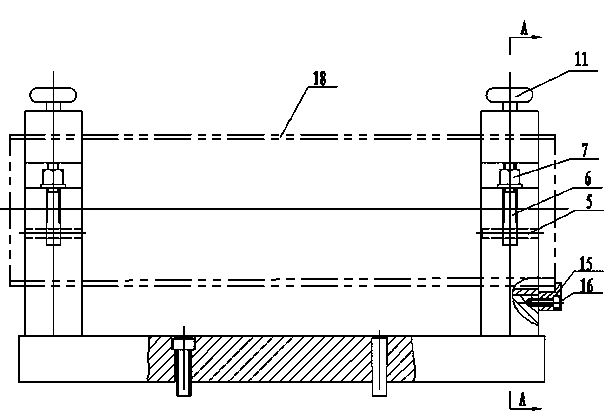

System for transferring vehicle body in vehicle assembling system

A system for transferring a vehicle body according to an embodiment of the present invention includes a stage accommodating the vehicle body and transferring the vehicle body, and a height regulating unit which is disposed on the stage and which regulates height of the vehicle body according to a type of assembly line. The height regulating unit includes a bracket disposed on a lower portion of the stage; at least one lifter, one end of which is disposed on the bracket and the other end of which is disposed on the vehicle body, so as to raise and lower the vehicle body; and a driving part for driving the lifter.

Owner:HYUNDAI MOTOR CO LTD

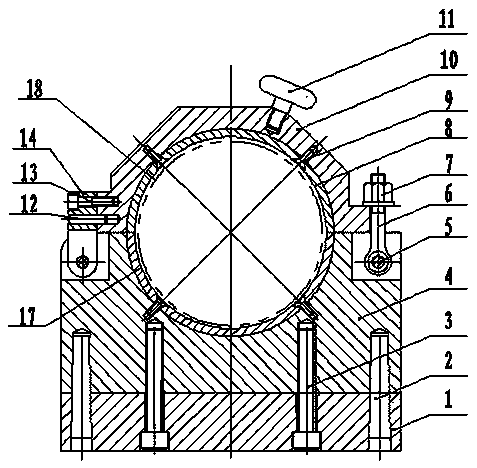

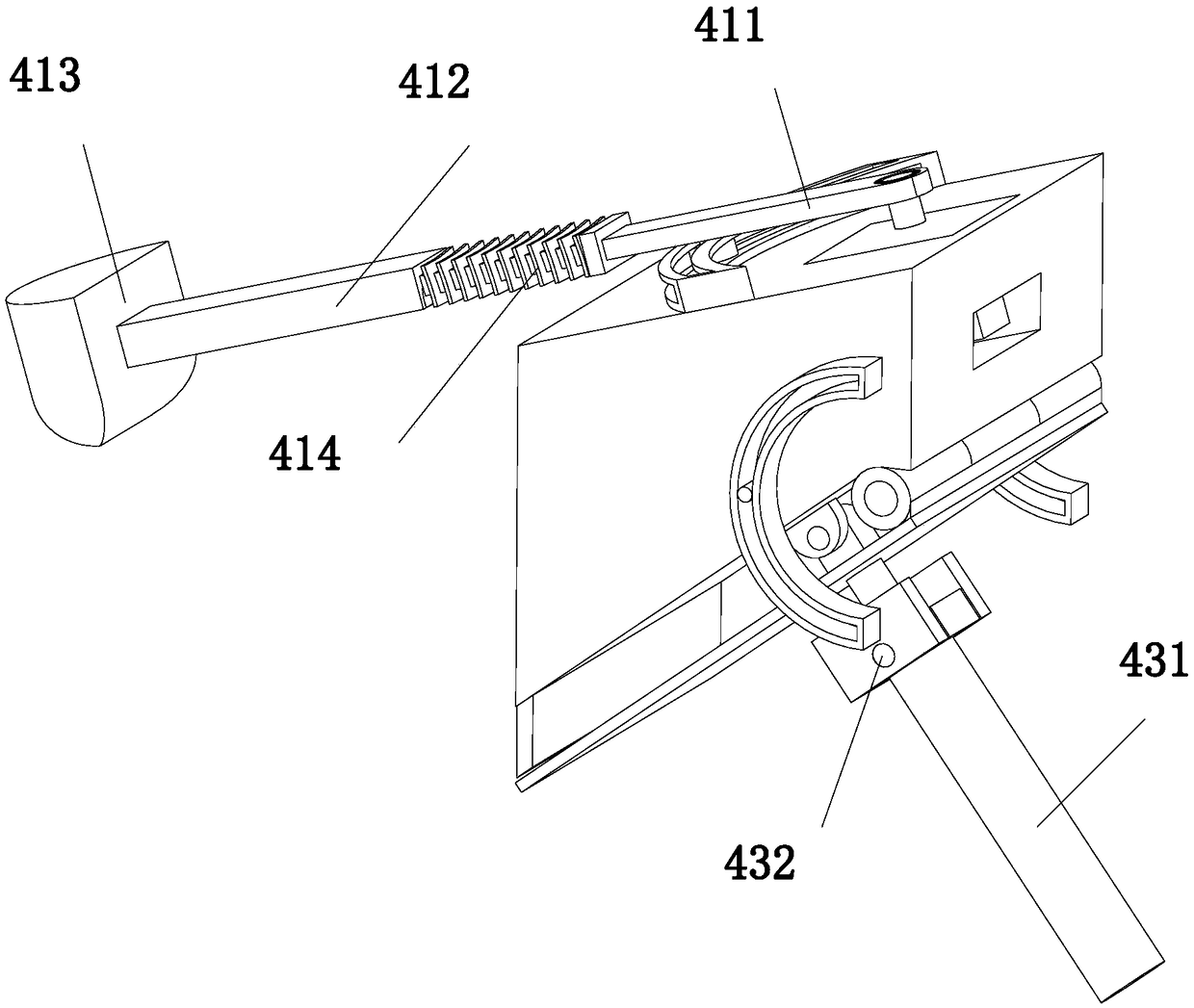

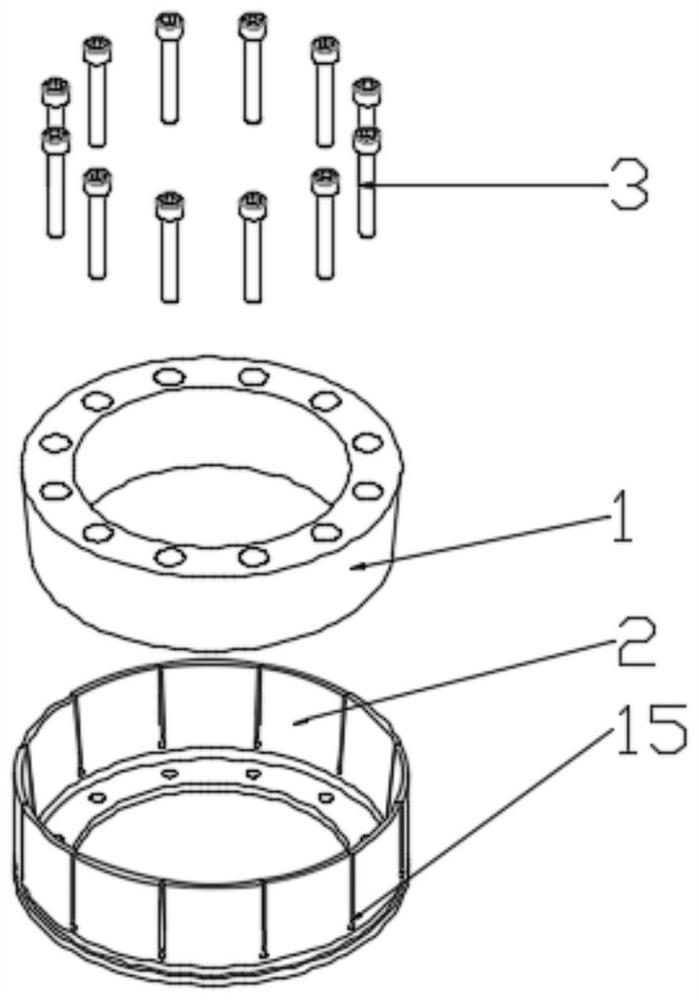

Thin-walled cylindrical part end face machining fixture

ActiveCN104259900AAvoid tremblingEasy to operatePositioning apparatusMetal-working holdersEngineeringMachining process

The invention discloses a thin-walled cylindrical part end face machining fixture which comprises a bottom plate. Parallel supporting seats are fixed onto the bottom plate through bottom plate taper pins and bottom plate screws, a connecting ring is hinged to one side of the upper end face of each supporting seat, a pin is arranged on the other side of the upper end face of each supporting seat, each connecting ring is connected with the side wall of a pressing cover through a pressing cover taper pin and a pressing cover screw, hinged bolts sleeve the pins, the pressing covers are pressed on the supporting seats through locking nuts on the hinged bolts, and a lower positioning sleeve and an upper positioning sleeve are fixed into grooves formed by the supporting seats and the pressing covers through screws respectively and combined to form a continuous cylindrical positioning sleeve. A thin-walled cylindrical part is radially positioned by the upper positioning sleeve and the lower positioning sleeve which are parallel, the thin-walled cylindrical part is axially positioned by positioning blocks on the side walls of the supporting seats, the thin-walled cylindrical part end face machining fixture is convenient in clamping operation, high in efficiency and convenient to detach, maintain and replace, shaking of a workpiece to be machined in the machining process is avoided, and rejection rate is reduced.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

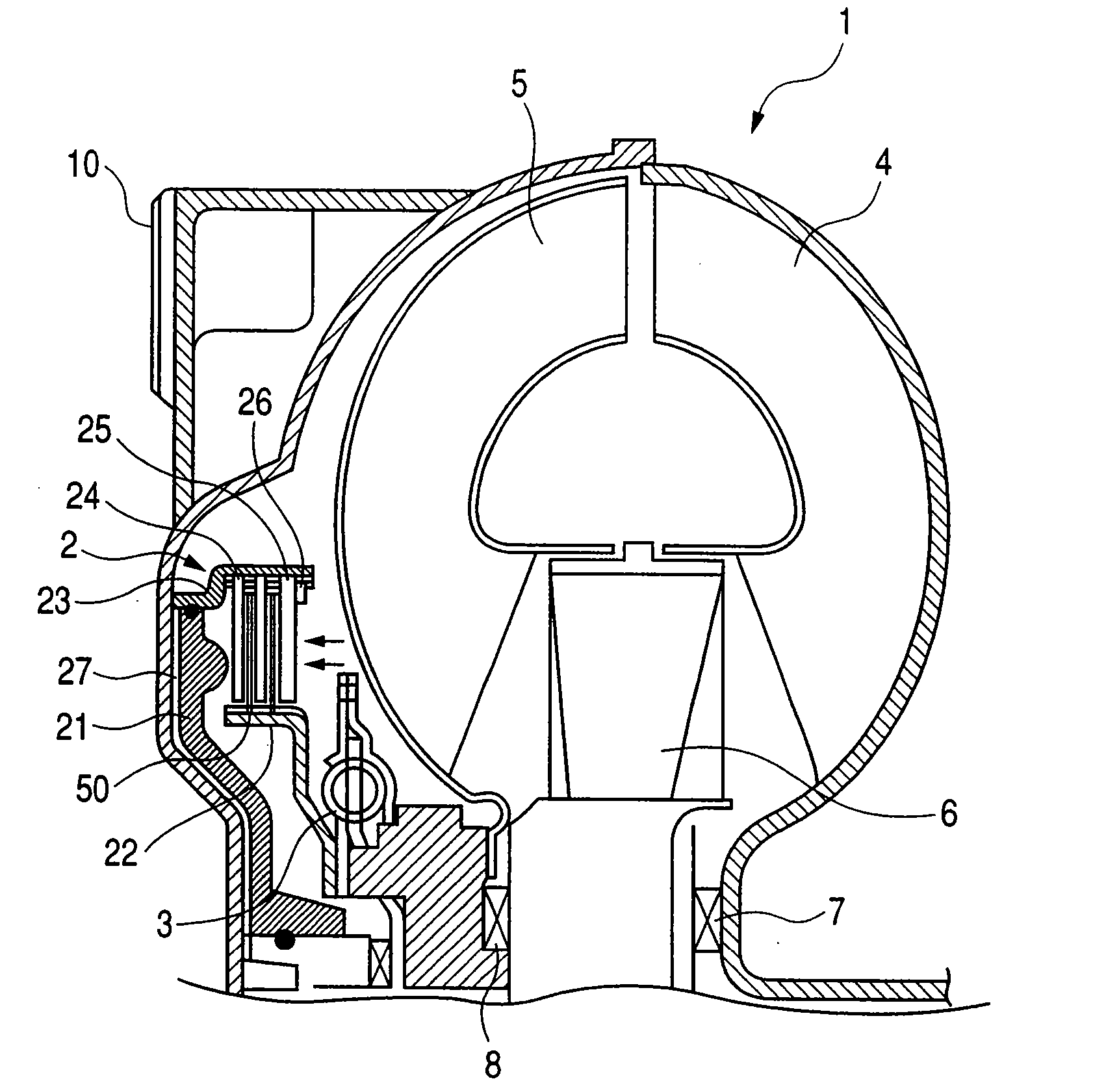

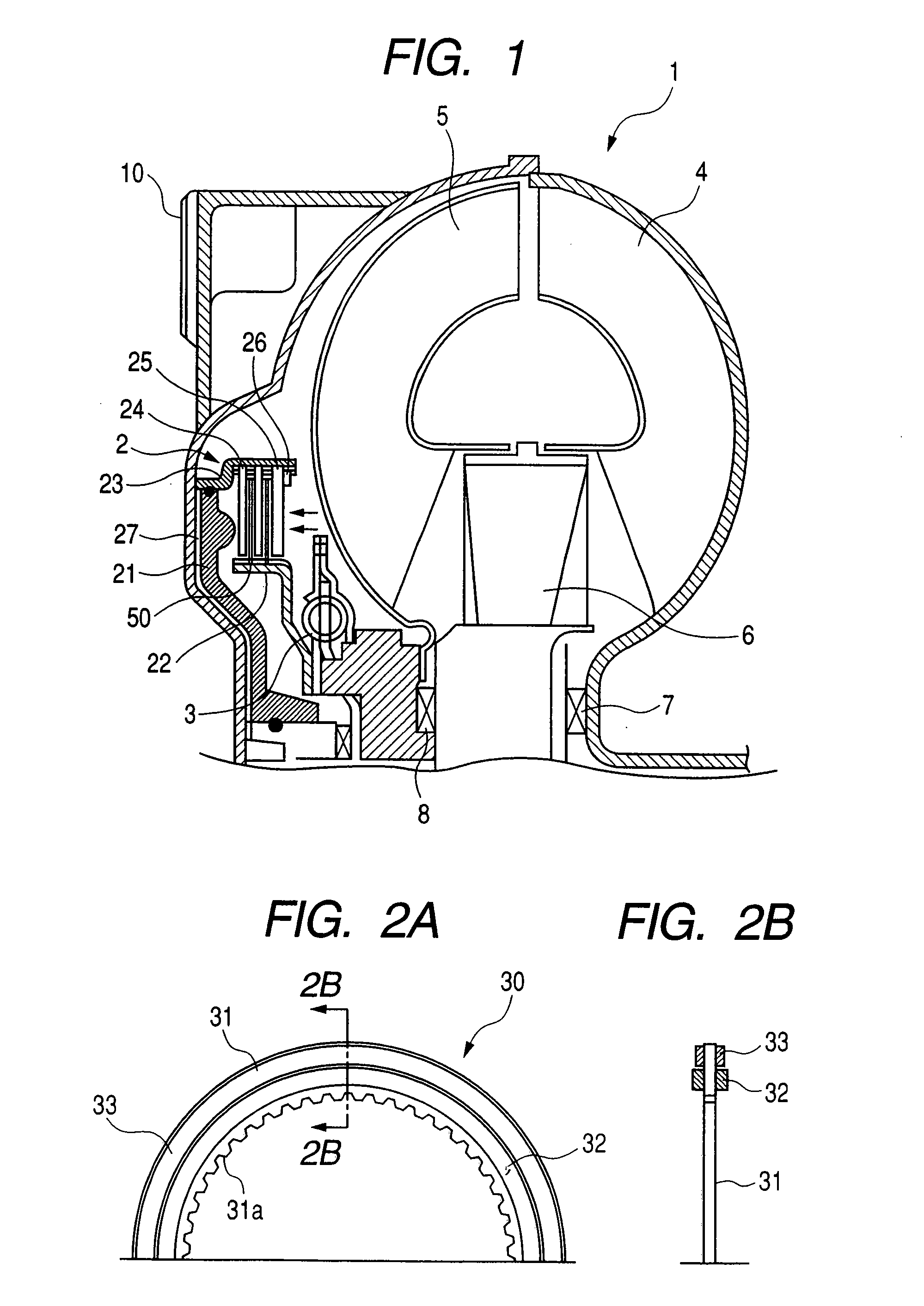

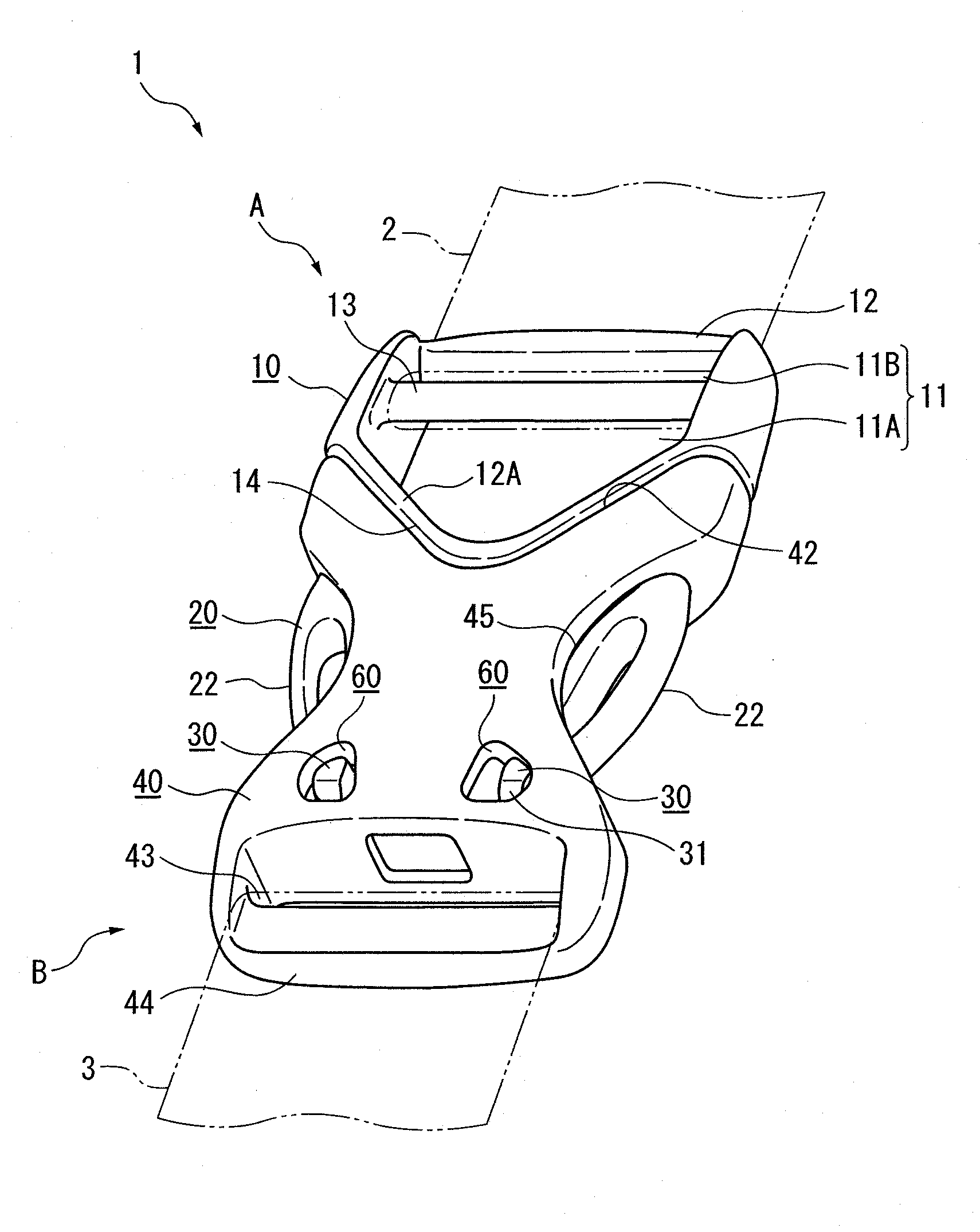

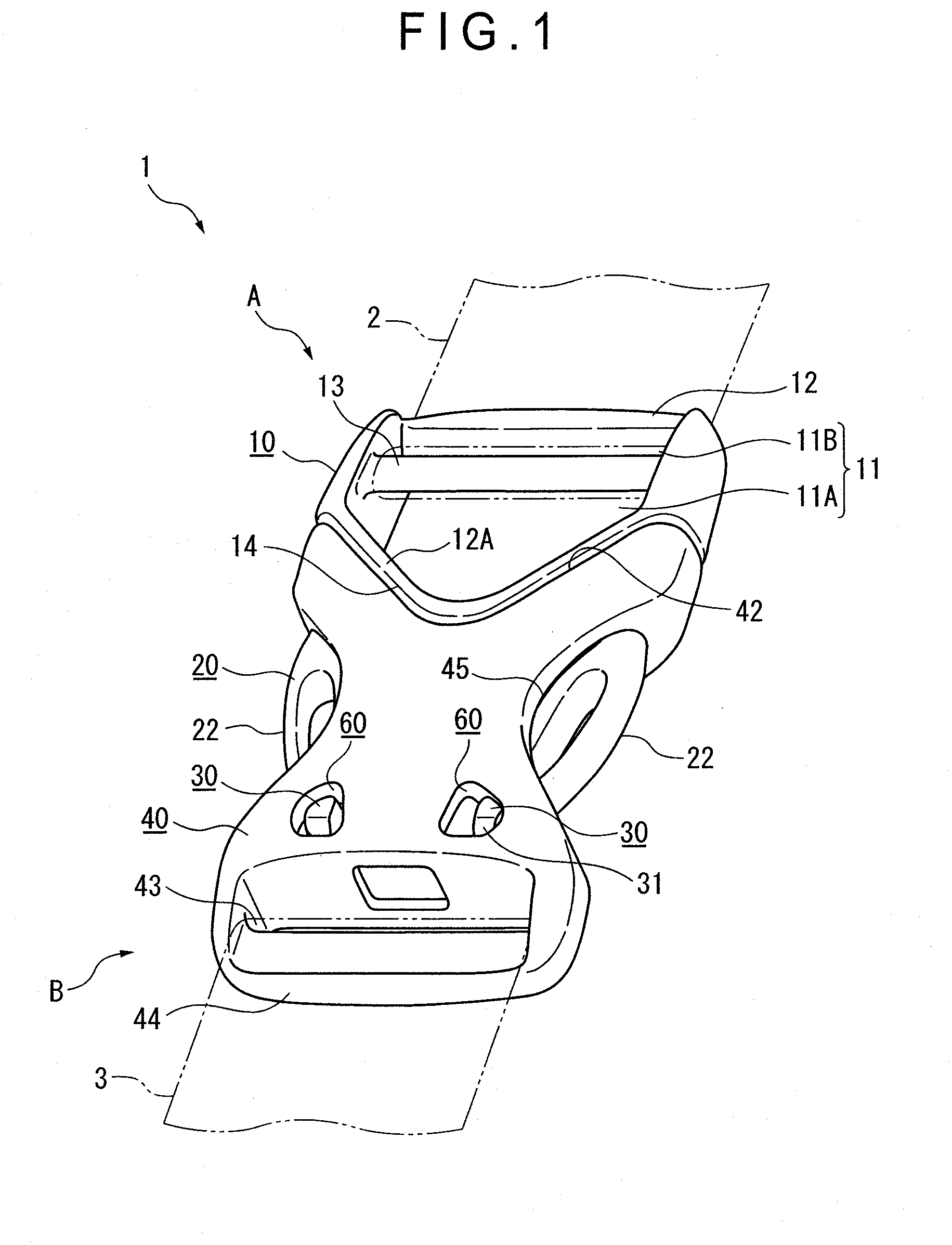

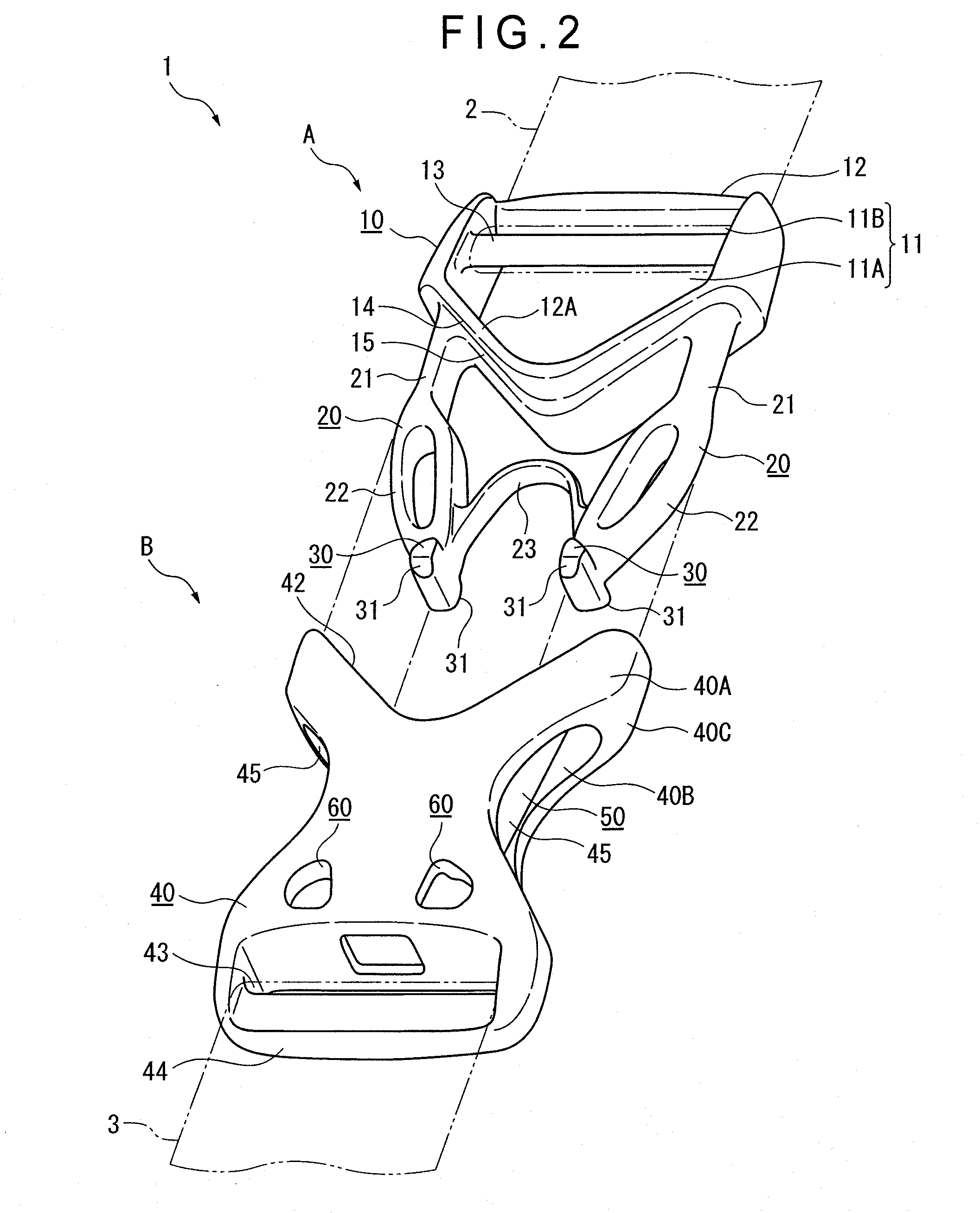

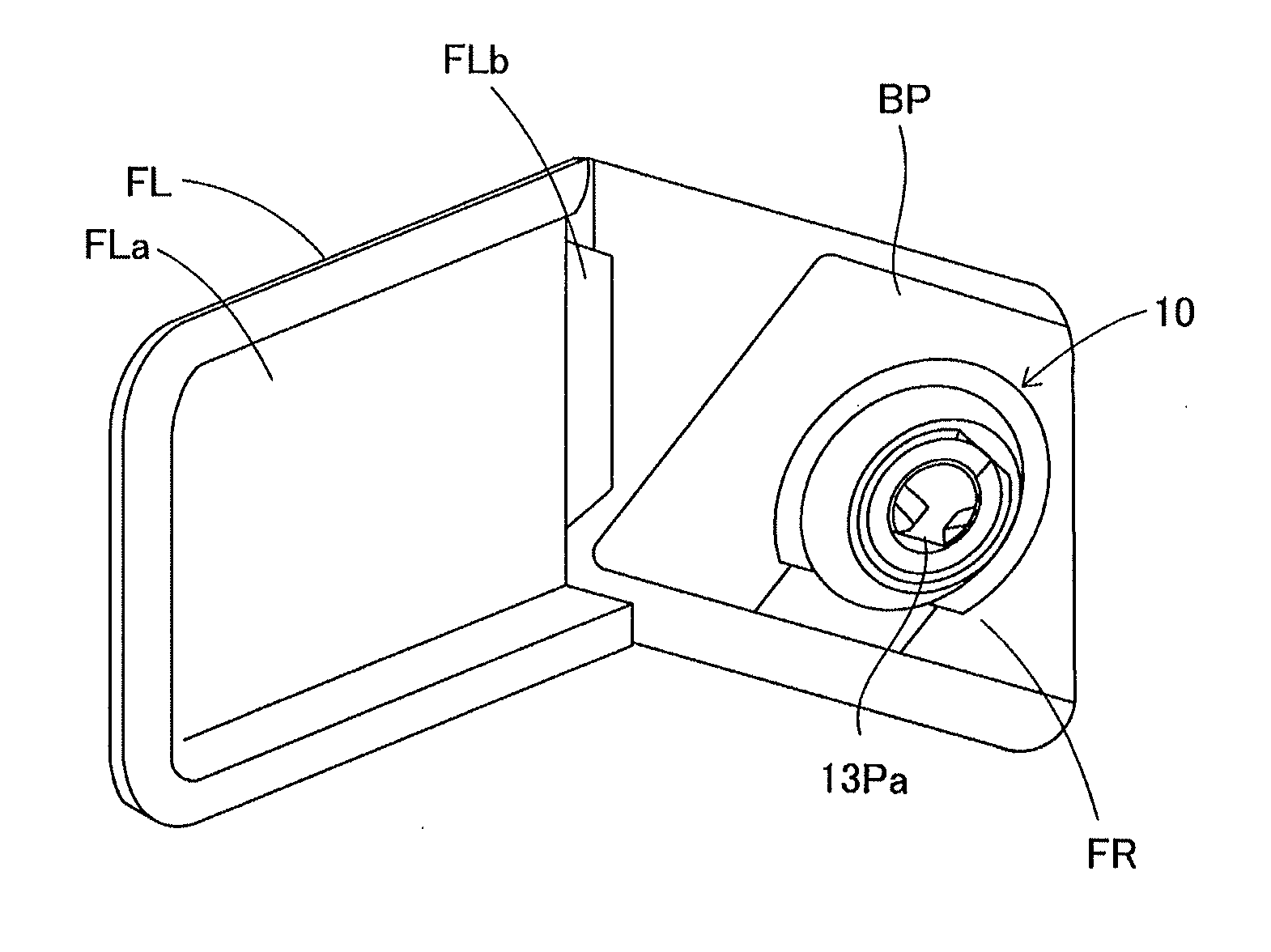

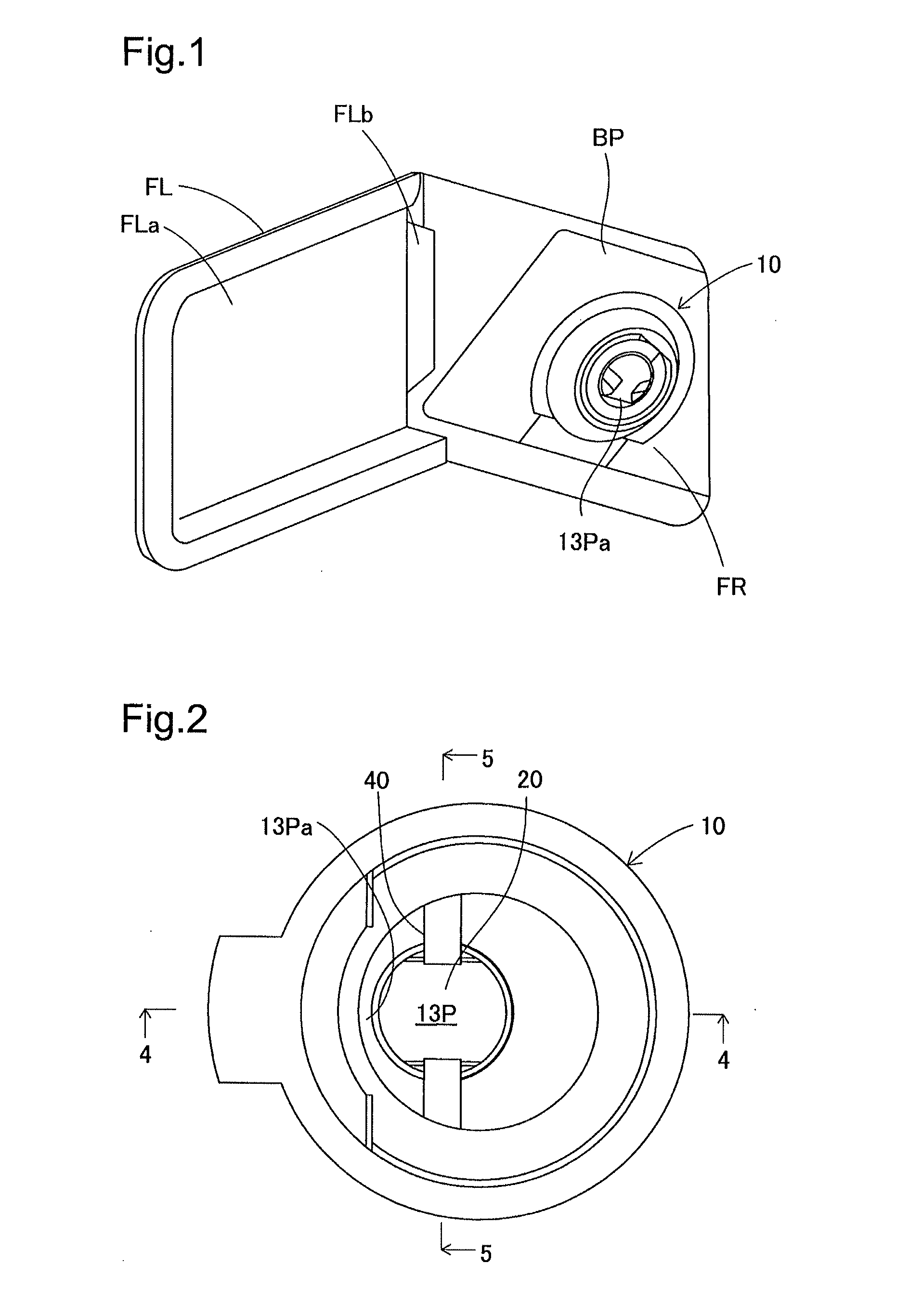

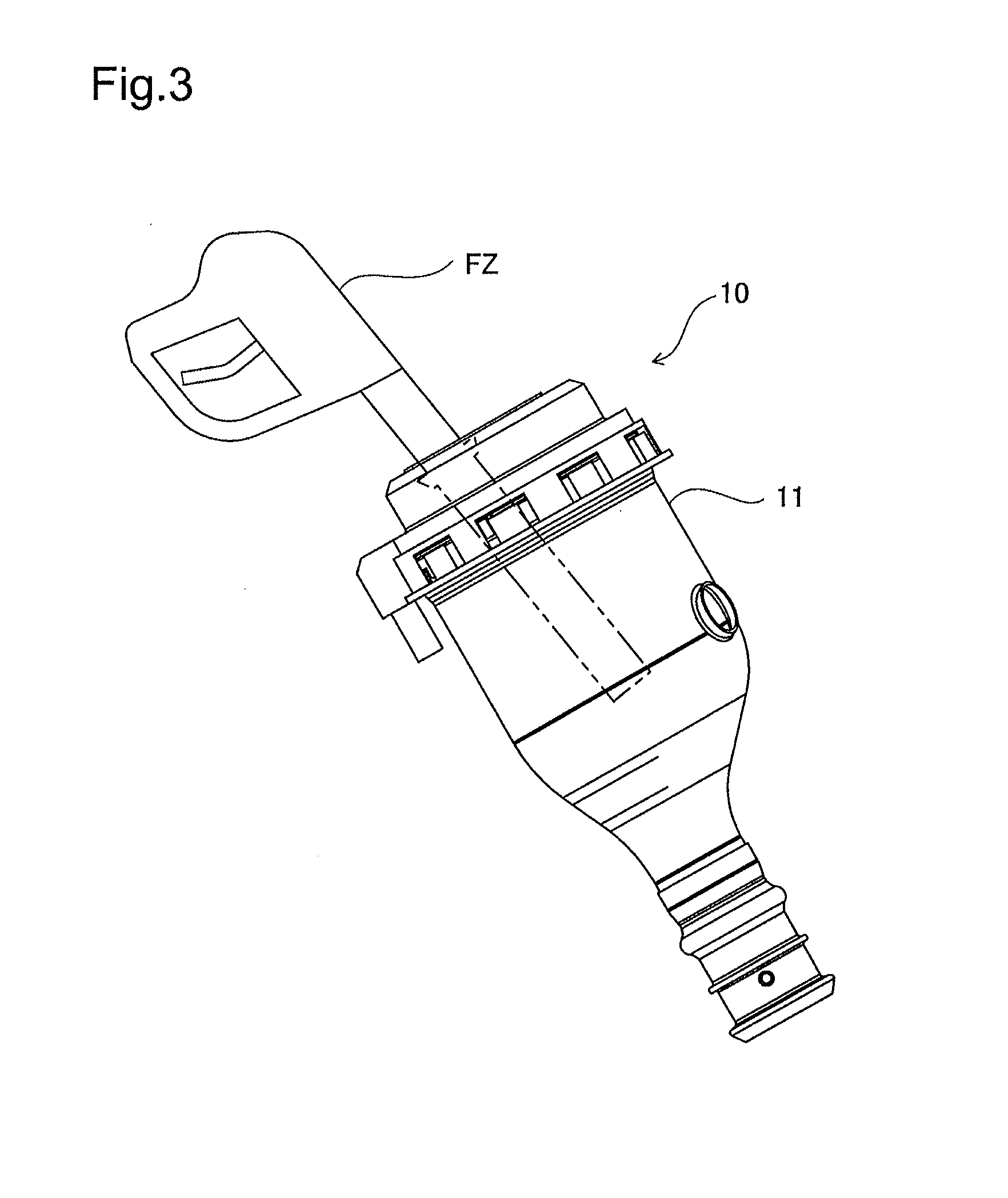

Fuel tank opening and closing device

InactiveUS20110240640A1Easy to chargeReliable removalSolid materialClosures to prevent refillingFuel tankEngineering

A fuel tank opening and closing device is equipped with a flap valve mechanism having an opening and closing member for opening and closing an inlet inside a tank opening forming member. The nozzle positioning guide mechanism has a first support mechanism of an opening peripheral edge of an introduction port of an insertion path of a tank opening forming member, a second support mechanism having an introduction guide surface formed on the top surface of the pressing member of the opening and closing member, and a positioning ridge line that has a curvature almost the same but slightly larger than the outer diameter of the fueling nozzle and which touches by line contact on the outer peripheral surface of the fueling nozzle at the insertion completion position, and a third support mechanism having a valve positioning member which regulates the degree of openness of the opening and closing member by touching the inner wall of the tank opening forming member.

Owner:TOYODA GOSEI CO LTD

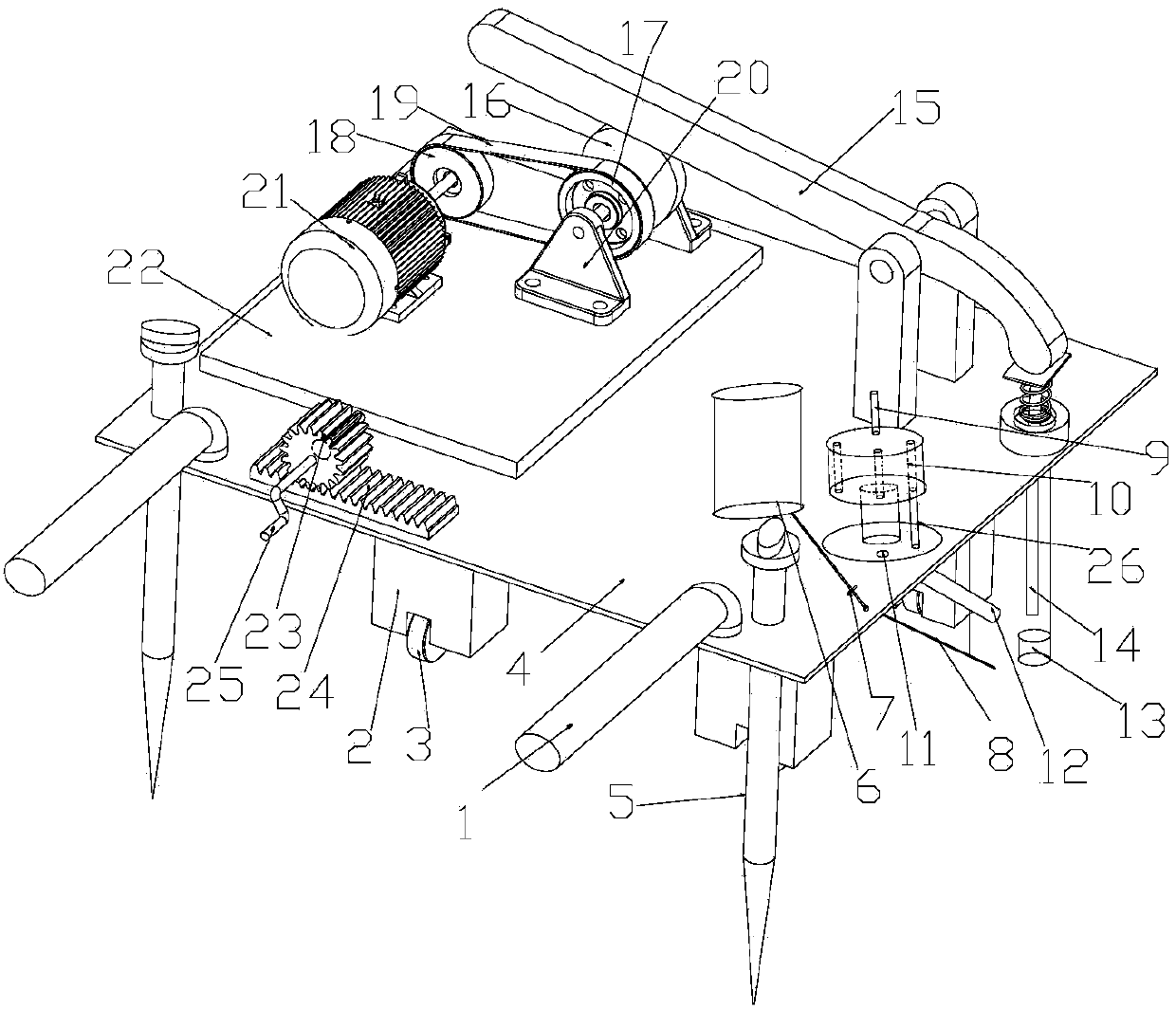

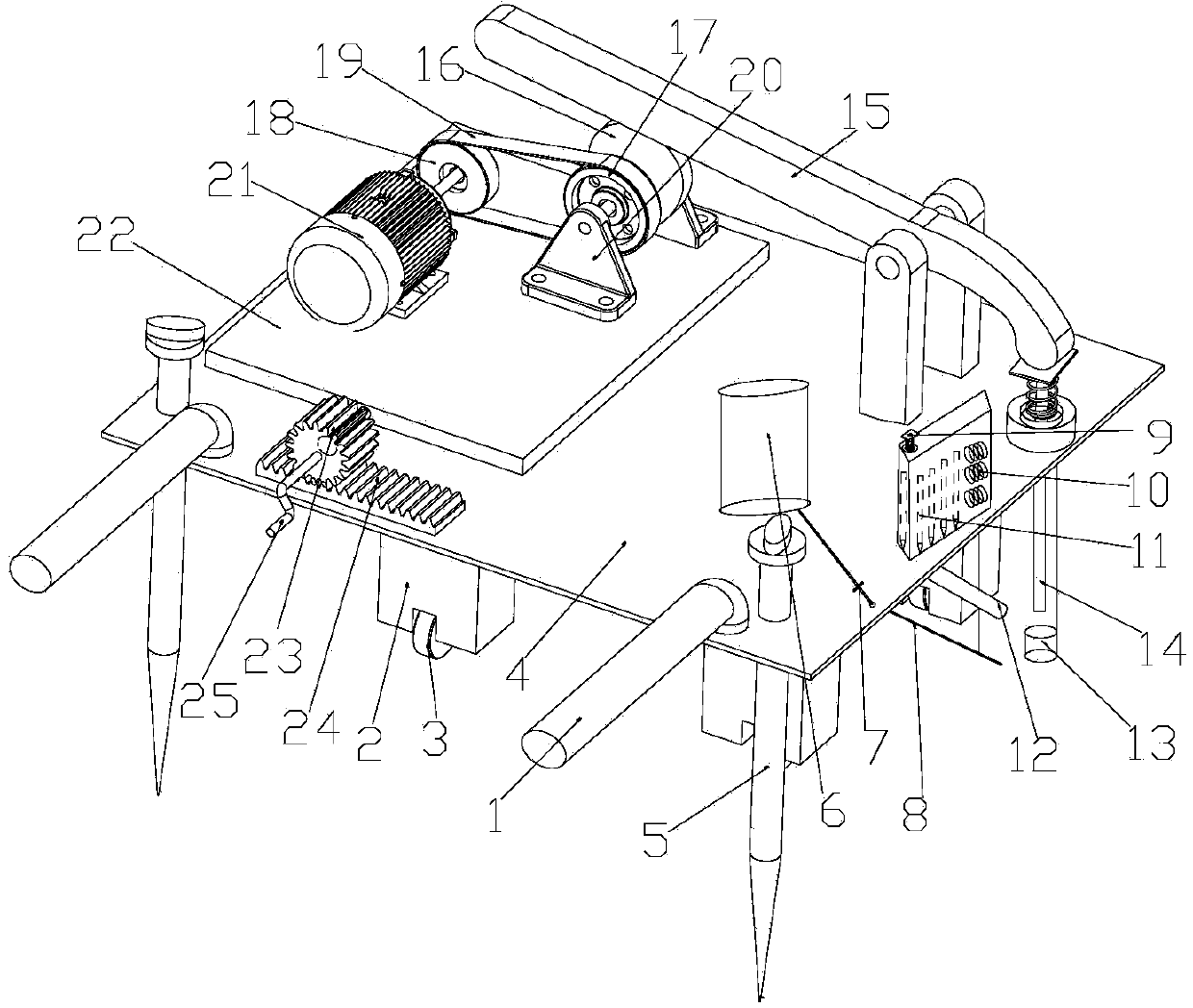

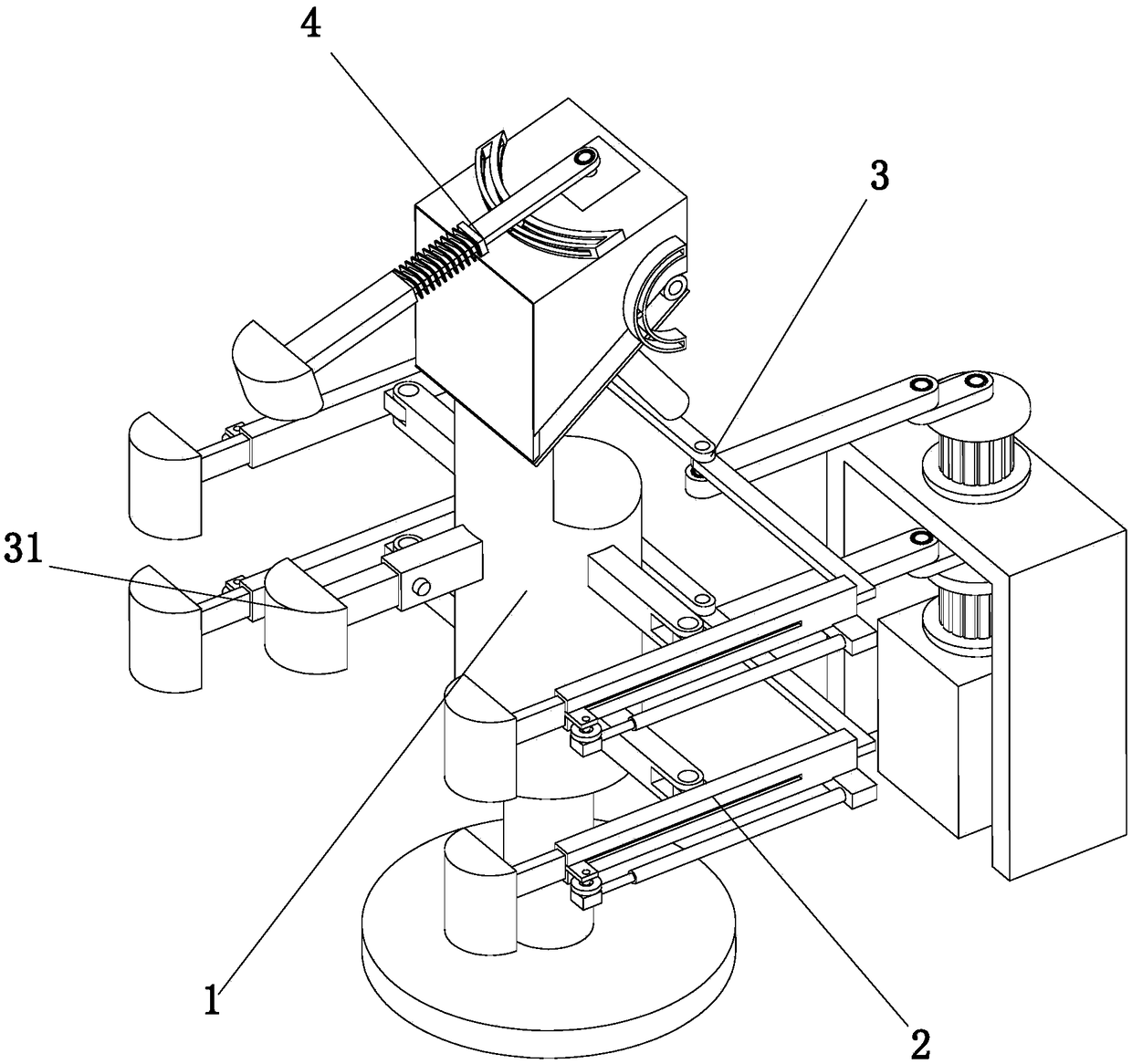

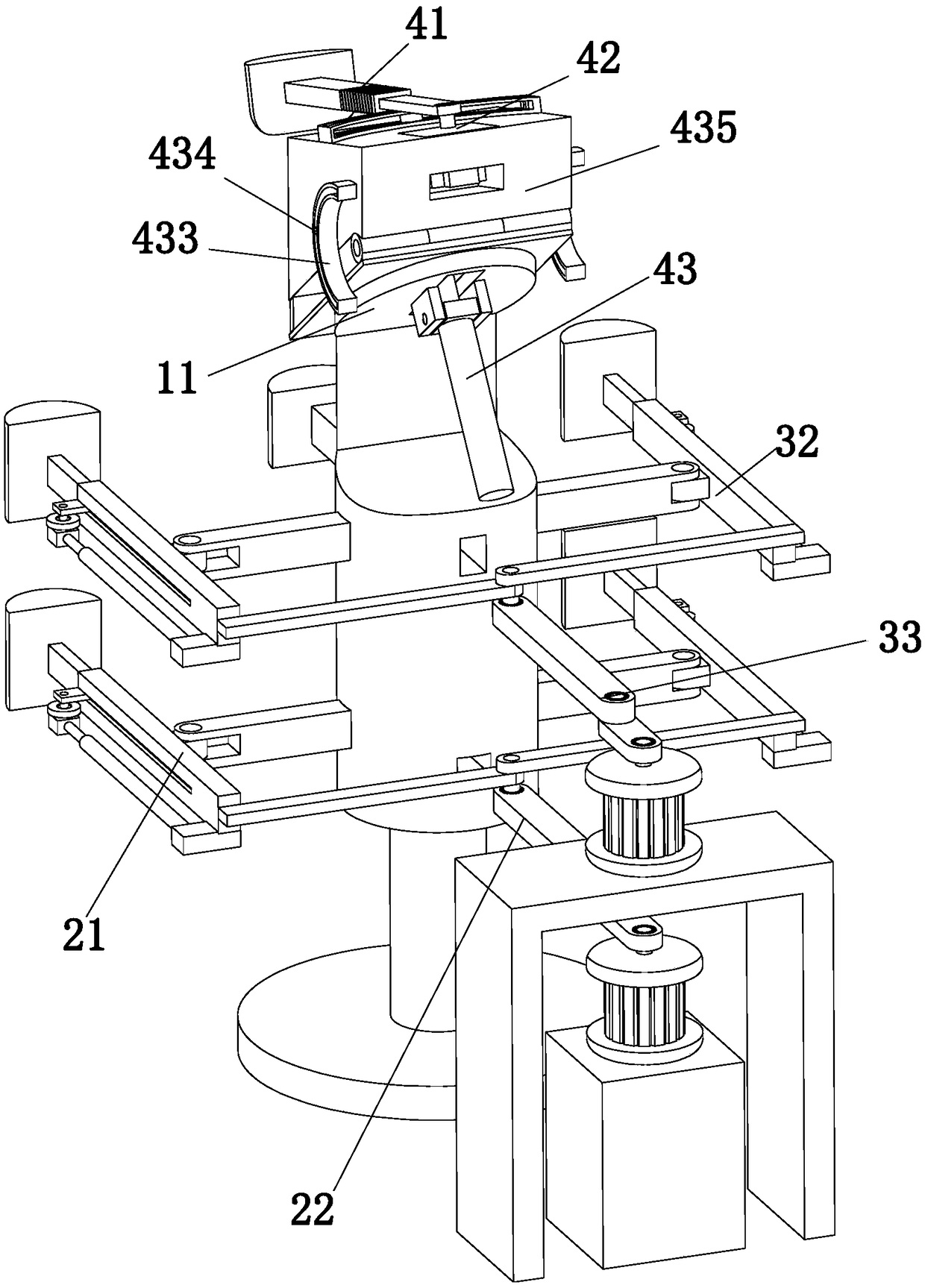

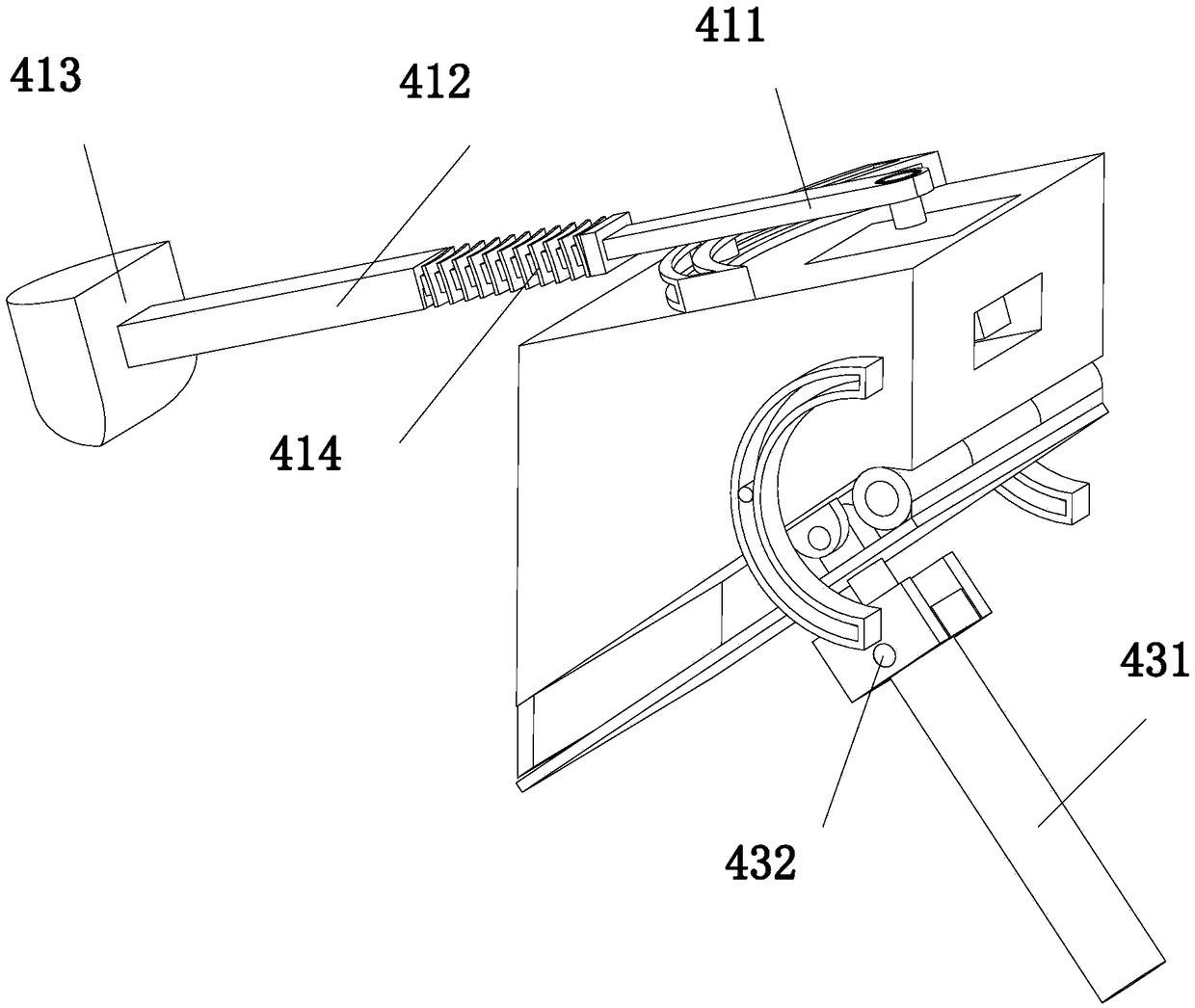

Multi-freedom-degree automatic piling device and method

InactiveCN103993600ANo tiltingImprove piling qualityBulkheads/pilesMechanical engineeringWater tanks

The invention relates to a multi-freedom-degree automatic piling device and method. The piling device comprises a piling mechanism, a water tank, a rack and a feeder which are arranged above the rack. The piling mechanism comprises a motor, a belt wheel group, a lever and an impacting rod. The motor is connected with the belt wheel group which is connected with the lever, and the lever is connected with the impacting rod. The feeder comprises a cylinder, a feeding hole, a pile transition groove and a location tube. The pile transition groove and the location tube are mounted below the rack, the pile transition groove is disposed between the location tube and the feeding hole, and the location tube is disposed below the impacting rod. The multi-freedom-degree automatic piling device is capable of arranging piles automatically, high in piling quality, convenient to use, small in size and noise, high in safety factor and high in piling efficiency.

Owner:QINGDAO UNIV OF SCI & TECH

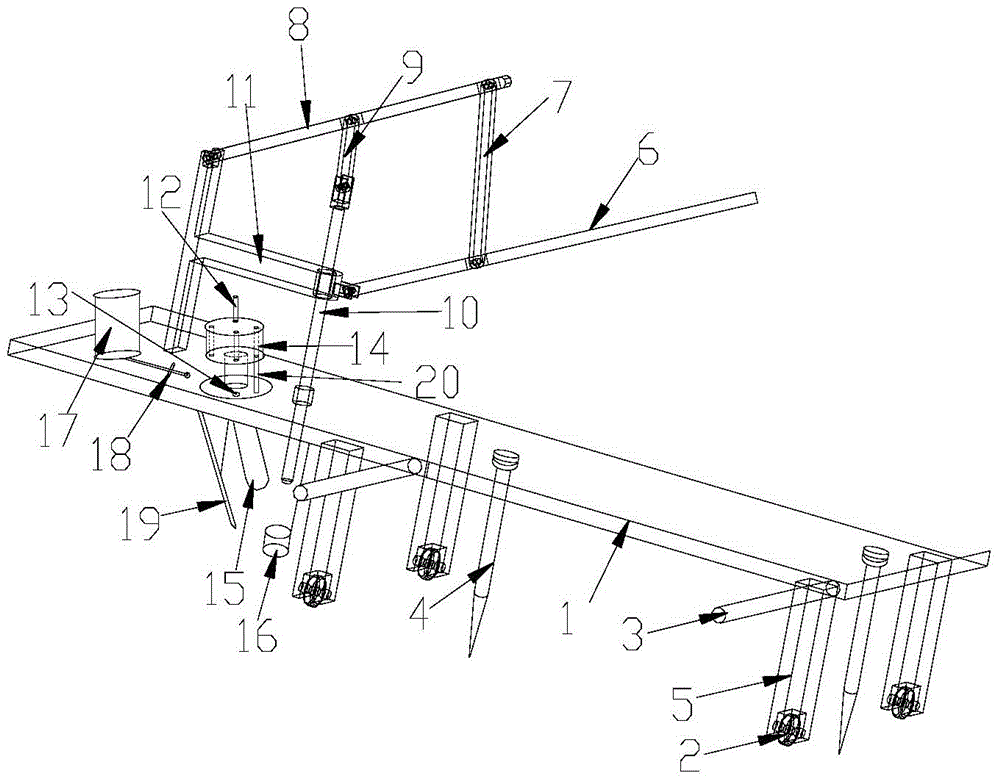

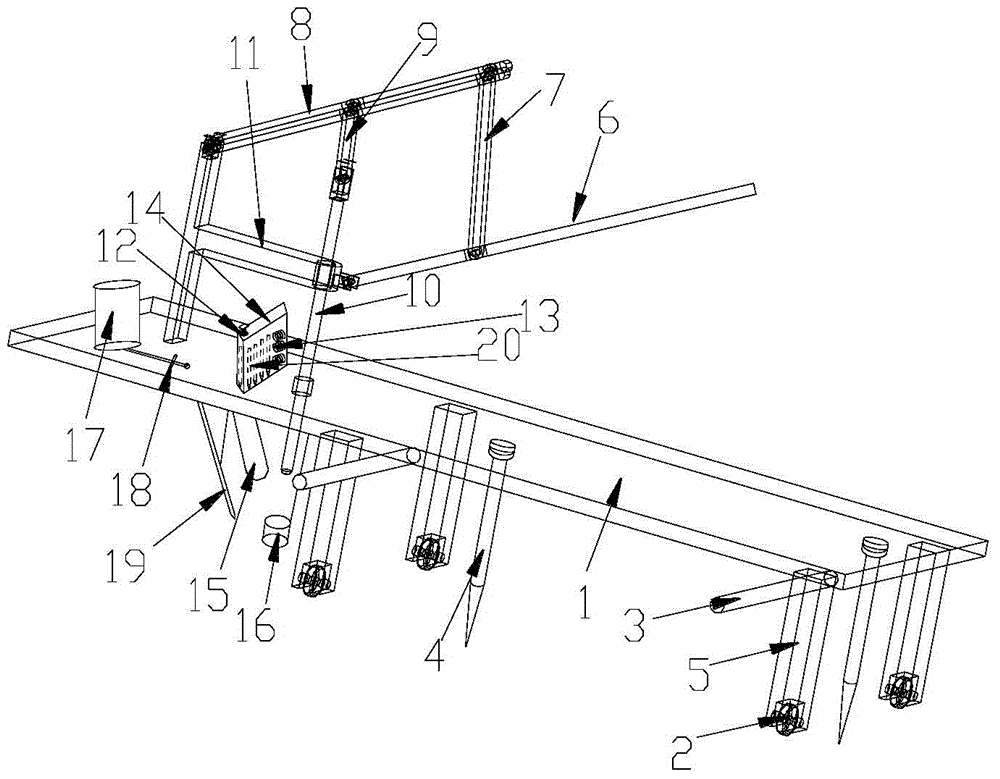

Portable automatic feeding manual pile driving equipment and pile driving method

InactiveCN103981865AImprove piling qualityIntegrity guaranteedBulkheads/pilesSafety coefficientWater tanks

The invention relates to portable automatic feeding manual pile driving equipment and a pile driving method. The pile driving equipment comprises a pile driving mechanism, a water tank, a rack and an emptying device, wherein the pile driving mechanism, the water tank and the emptying device are arranged above the rack; the pile driving mechanism comprises a compressive bar, a support supporting the compressive bar, a first connecting rod connected with the compressive bar, a rocker connected with the first connecting rod, a second connecting rod connected with the rocker, and a drop bar connected with the second connecting rod; the emptying device comprises a charging barrel, an emptying hole, a timber pile ramp pan and a locating pipe; the timber pile ramp pan and the locating pipe are arranged below the rack; the timber pile ramp pan is positioned between the locating pipe and the emptying hole; the locating pipe is positioned right below the drop bar. The portable automatic feeding manual pile driving equipment, disclosed by the invention, is pile driving equipment which has the advantages of capability of automatically placing a timber pile, high pile driving quality, convenience in use, small volume and high safety factor, and is suitable for pile driving with small pile driving workload.

Owner:QINGDAO UNIV OF SCI & TECH

Paper cutter

InactiveUS20050066787A1Easy to carryAvoid tremblingAnalogue recordingMetal working apparatusEngineeringMechanical engineering

An end surface of a stopper is formed so as to be thick which is substantially the same surface as an outer circumferential surface of a flange portion, and the stopper is engaged with an engaging groove formed at the flange portion, whereby an engaging portion formed at a locking piece of the stopper is elastically deformed and engages with an engaging portion formed at the flange portion. When the stopper is pulled out in the direction away from the surface of the base resisting with elastic force of the engaging portion, an opening portion of a slot can be opened. The paper cutter of the invention enables to take the slider out of a plate in spite of having a simple configuration, and prevent a falling of the slider from the plate even in conveying it.

Owner:CARL JIMUKI

Vehicle start power increasing device

InactiveCN102602287AAvoid chattering or stallingIncrease motivationPropulsion unit arrangementsControl devicesClutchFlameout

A vehicle start power increasing device comprises a shell, an accelerator cable and a clutch auxiliary cable. Both the accelerator cable and the clutch auxiliary cable penetrate through the shell and are connected together, the shell internally comprises an upper chamber and a lower chamber, the accelerator cable and the clutch auxiliary cable penetrate through the two chambers respectively, the accelerator cable is connected with a tripping slider in the upper chamber, a jacking body is arranged on the lower portion of the tripping slider, a slot hole is arranged on a partition plate between the upper chamber and the lower chamber, and the jacking body slides in the slot hole and extends out downwardly. The vehicle start power increasing device is capable of synchronously increasing power of an engine along with engagement of a clutch when a vehicle load start or climbing start, and is capable of avoiding shaking or flameout of the vehicle. The vehicle start power increasing device increases power by ingeniously using return action of a clutch arm.

Owner:宋丙钦

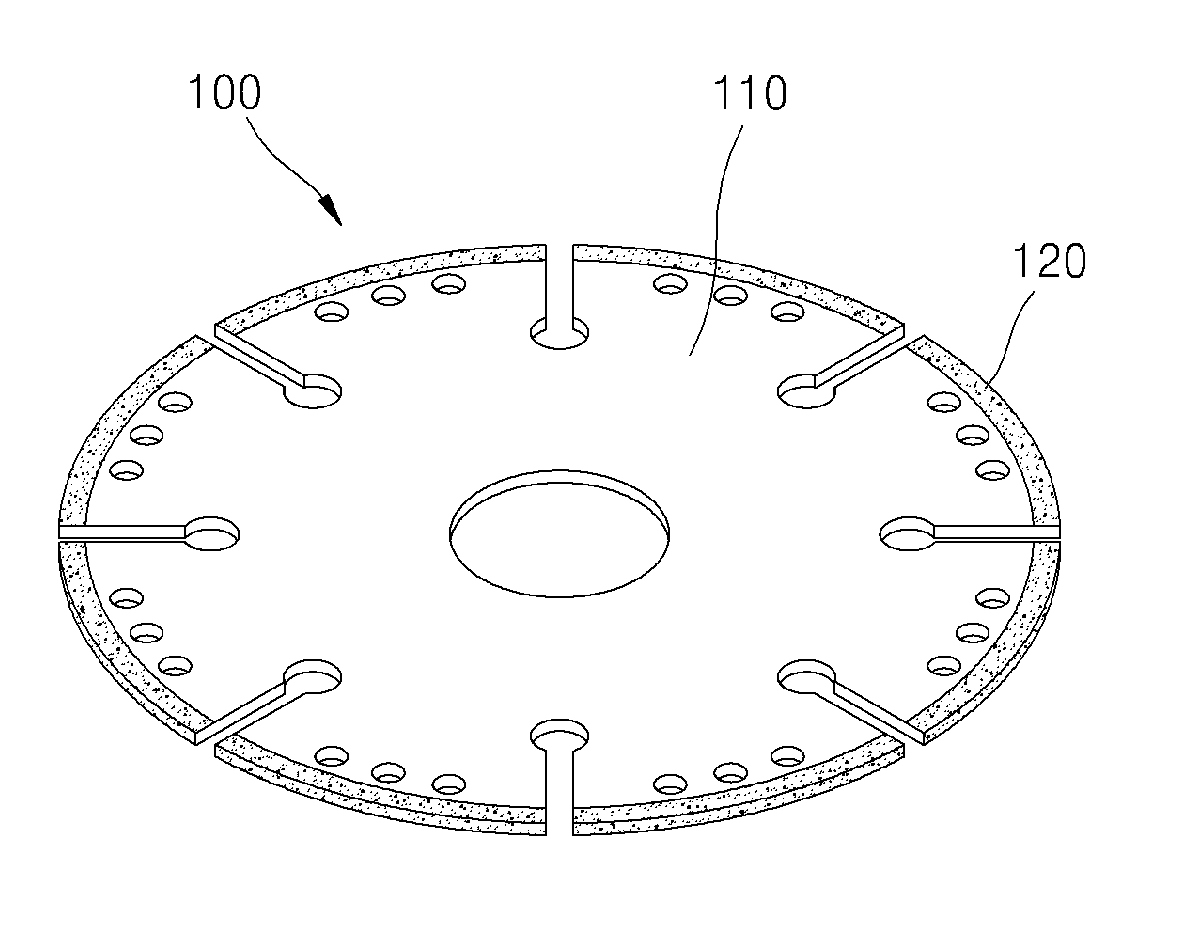

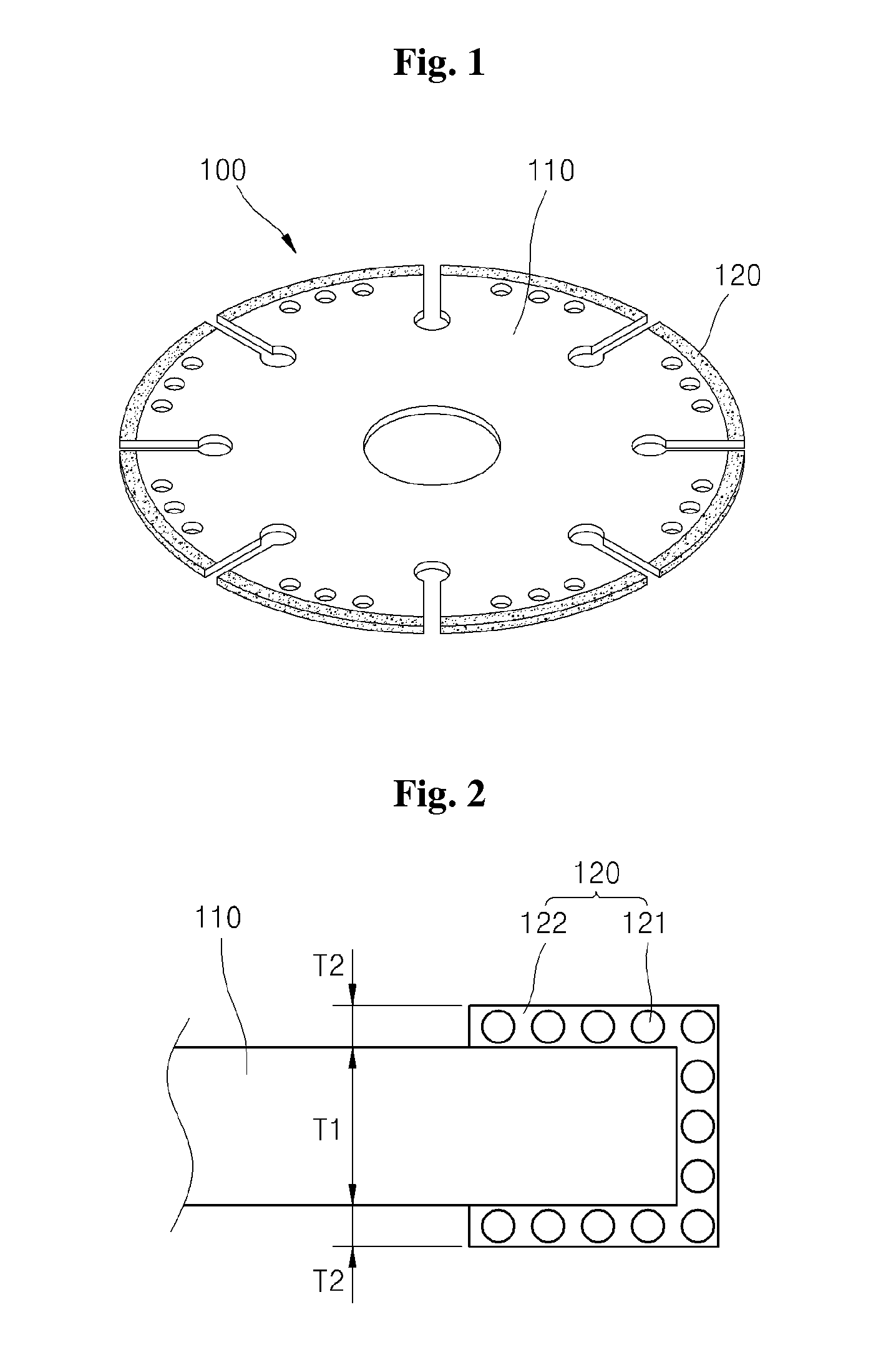

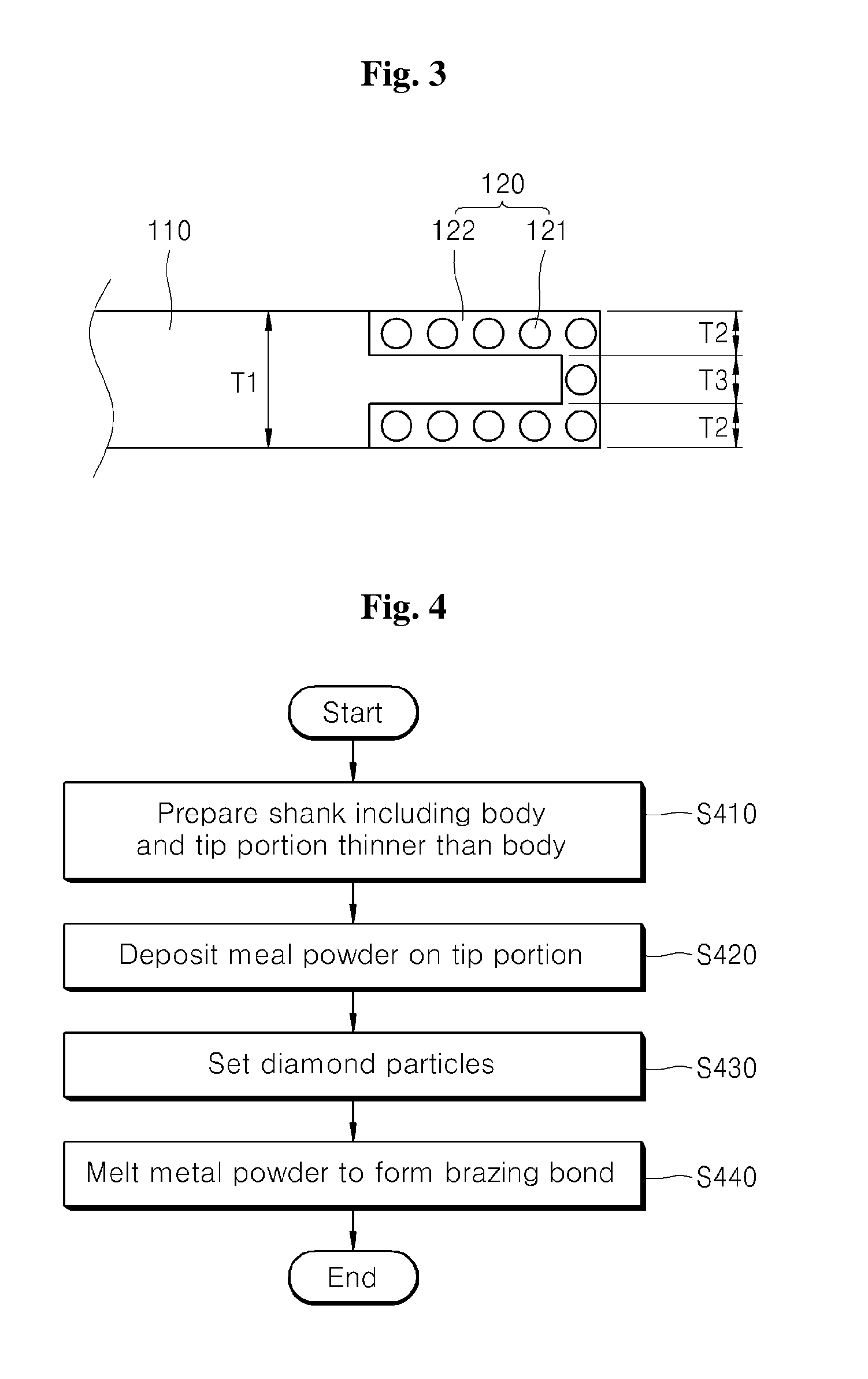

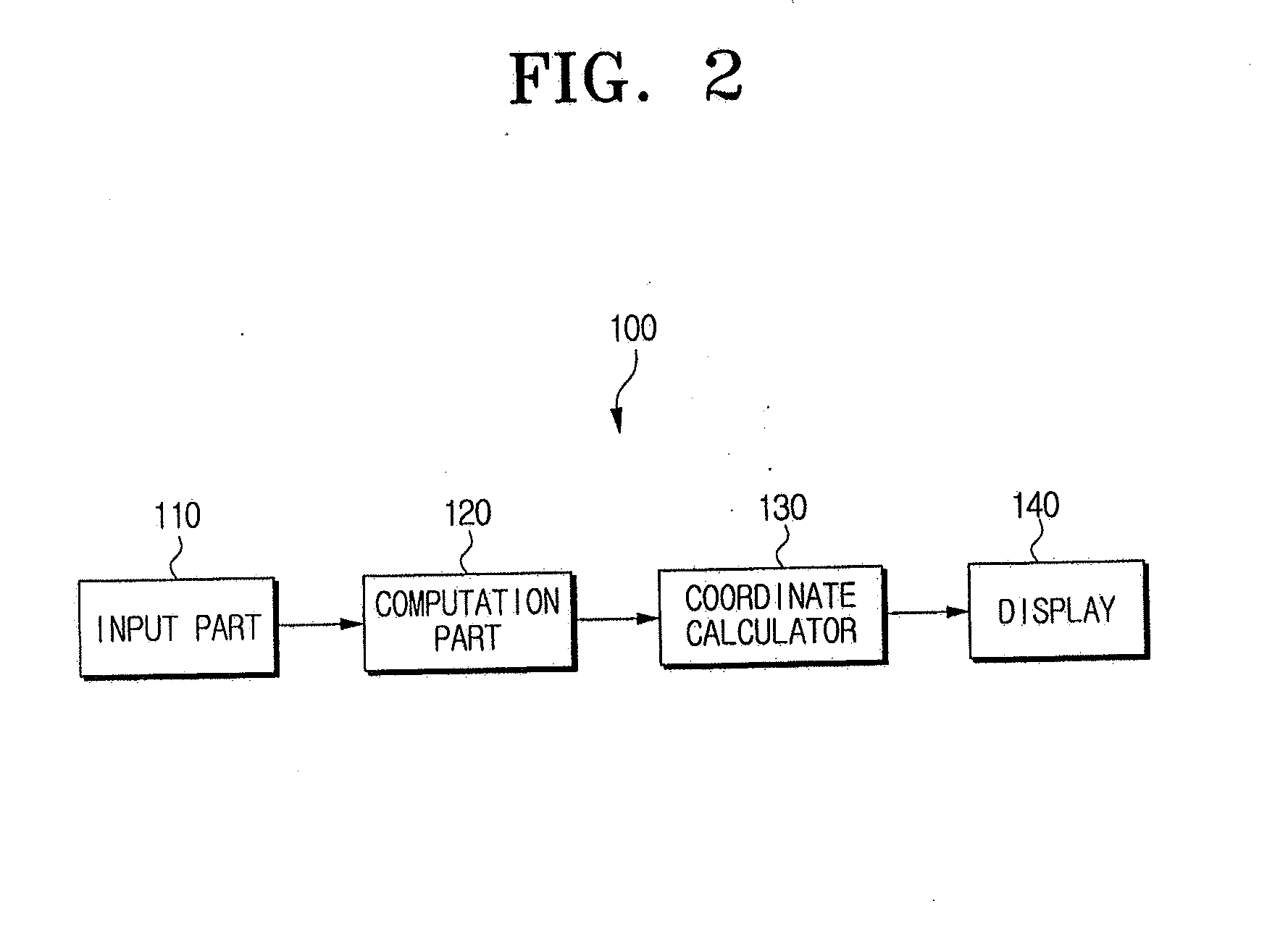

Brazing bond type diamond tool with excellent cuttability and method of manufacturing the same

InactiveUS20130059510A1Cuttability is improvedIncrease speedPigmenting treatmentRevolution surface grinding machinesDiamond toolDiamond

The present disclosure provides a brazing bond type diamond tool having excellent cuttability and a method of manufacturing the same. The diamond tool includes a shank having a body and a tip portion formed along an edge of the body, and a brazing bond layer formed on the tip portion of the shank to secure diamond particles with a brazing bond. The tip portion is thinner than the body and is integrally formed with the body.

Owner:NIWA DAIYAMONDO INDS

Input device comprising geomagnetic sensor and acceleration sensor, display device for displaying cursor corresponding to motion of input device, and cursor display method thereof

InactiveUS20140118261A1Avoid tremblingAvoid time delayDigital computer detailsCathode-ray tube indicatorsArtificial intelligenceCalculator

A display device for displaying a cursor according to motion of an input device is provided. The input device comprises an input part which receives pitch angle information and yaw angle information corresponding to motion of an external input device; a computation part which computes a first relative angle corresponding to the information of the pitch angle and a second relative angle corresponding to the information of the yaw angle; a coordinate calculator which calculates a cursor coordinate value which gradually varies according to the changes of the first and second relative angles; and a display which displays a cursor on a position corresponding to the calculated cursor coordinate value. Thus, it is possible to avoid trembling of the cursor caused by noise.

Owner:SAMSUNG ELECTRONICS CO LTD

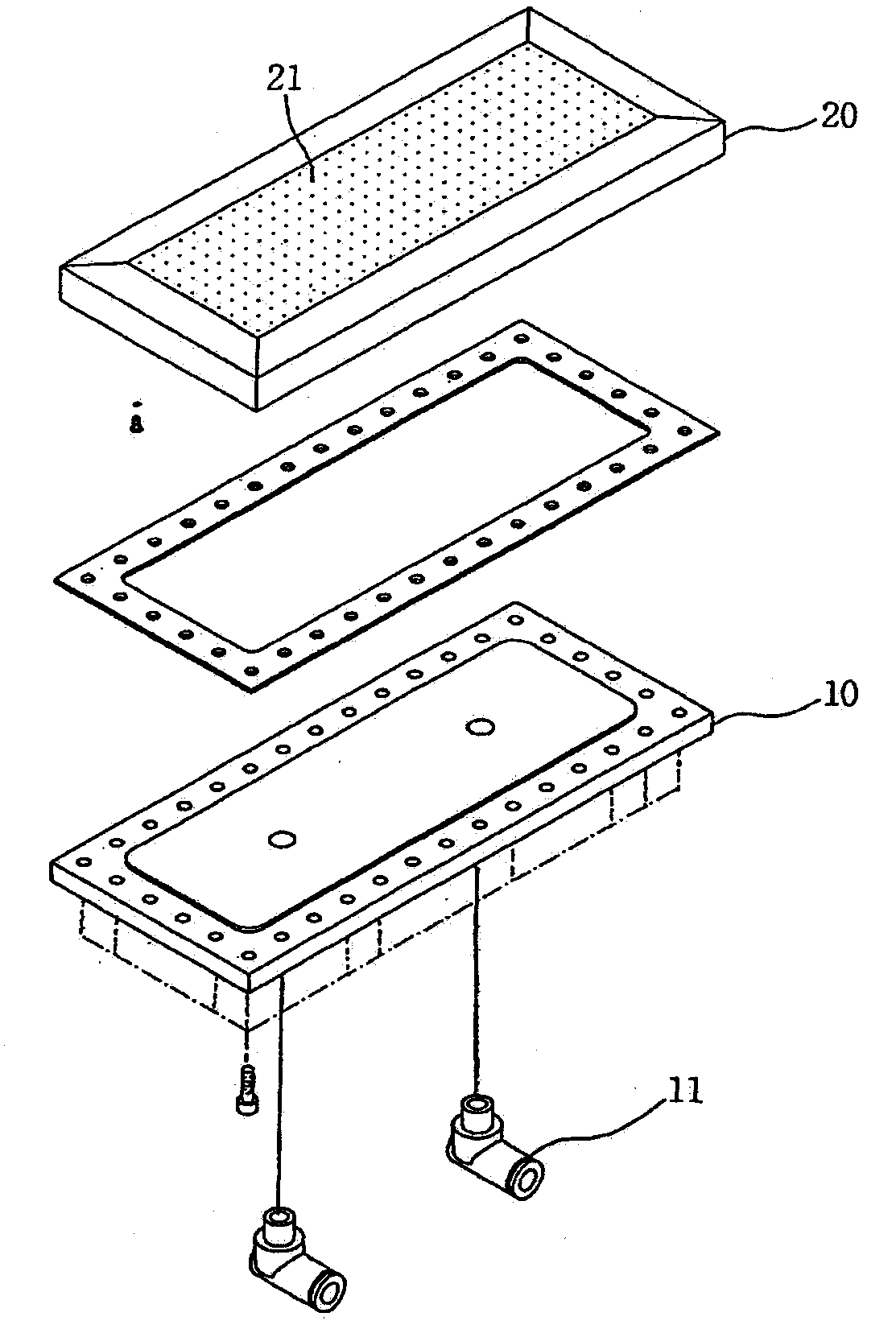

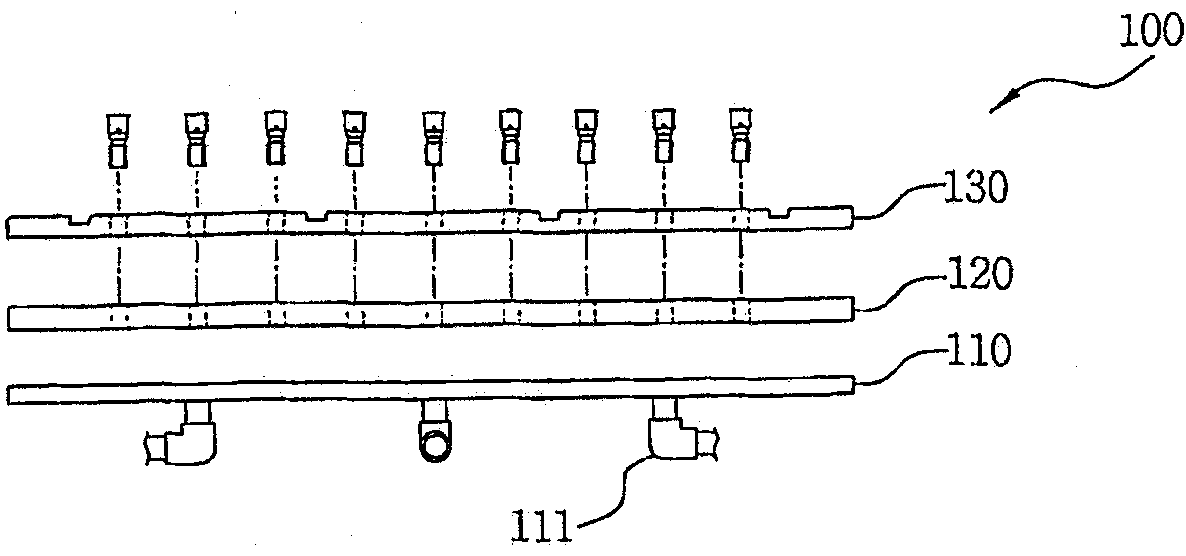

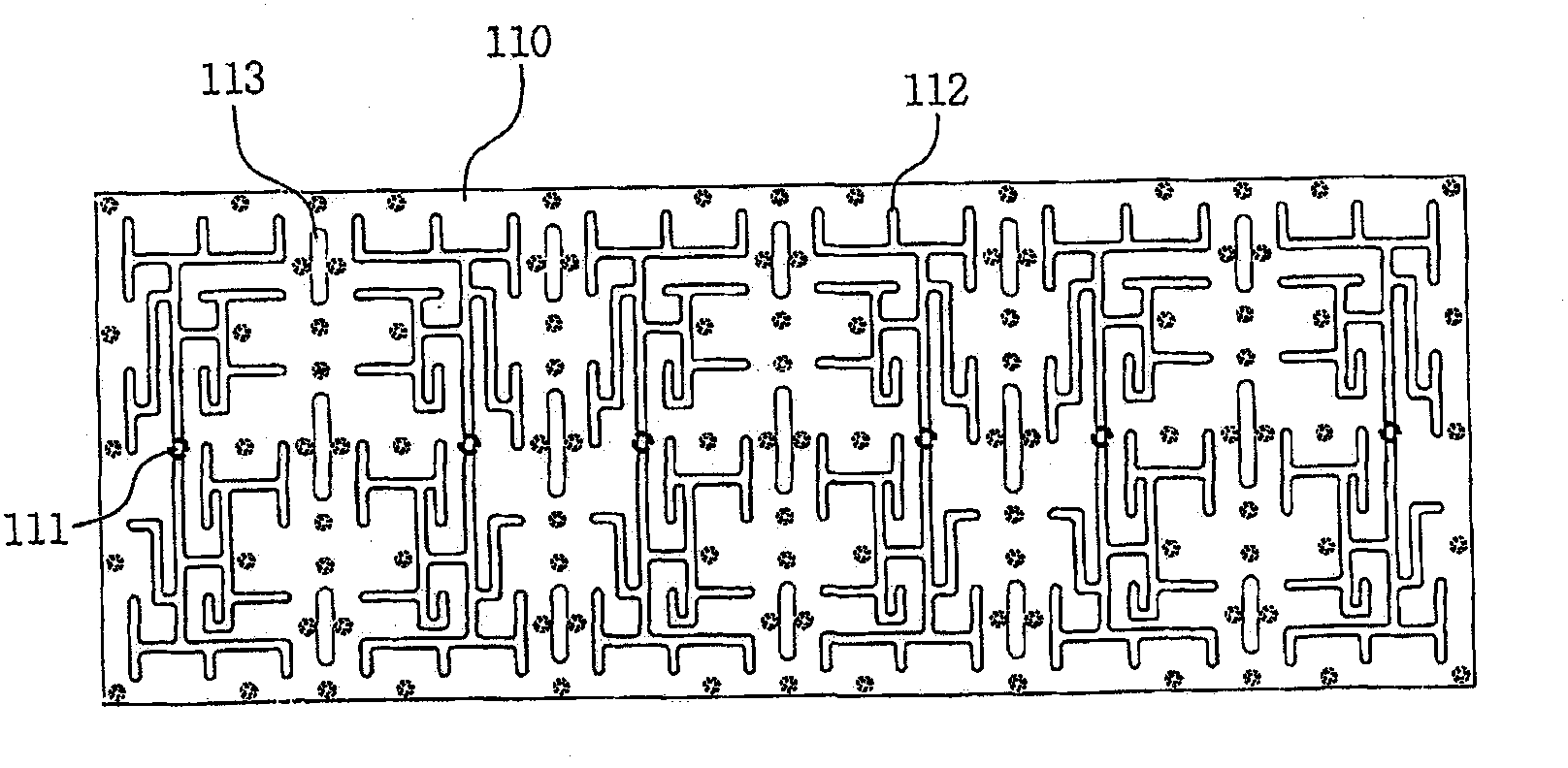

Non-contact type conveyor plate having a suction force

ActiveCN102077337AAvoid tremblingImprove wear resistanceConveyorsSemiconductor/solid-state device manufacturingSuction forceWear resistant

Disclosed is a non-contact type conveyor plate having a suction force, capable of conveying glass sheets while generating a small amount of suction force to prevent even small vibrations of the glass sheets while being conveyed and of providing an excellent wear-resistant, anti-static upper plate coming into contact with a glass sheet. A conveyor plate according to the present invention comprises: a lower plate having a chamber formed therein; a middle plate overlaid on the top surface of the lower plate and having a multiplicity of joint holes communicating with the chamber; an upper plate overlaid on the top surface of the middle plate and having air eject holes communicating with the joint holes; and air eject bolts insertedly fixed into the air eject holes to accommodate air from the chamber and guide the air into a gap between the bolts and the air eject holes. Here, on the top end of the air eject hole is formed a head to allow the air to be ejected in an oblique upward direction, and on the top surface of the air eject hole is formed a hollow cavity to produce vacuum by a difference in atmospheric pressure. Moreover, the bottom surface of the head preferably forms an inclined plane in the oblique upward direction, and the top end of the air vent hole is preferably rounded. A multiplicity of vent holes may also be provided to vent air from the top surface of the upper plate to the bottom surface of the lower plate. Further, the upper plate is made from GUR (PE-UHMW) to improve wear-resistance and prevent static buildup.

Owner:李在成

Free sparring training aid with agility improving function

InactiveCN109248427AGuaranteed stabilityWill not shiftSport apparatusSports equipmentElectric machinery

The invention relates to the technical field of sports equipment, in particular to a free sparring training aid with an agility improving function. The free sparring training aid comprises a supporting column vertically arranged, a leg main attack device, a front main attack device, a head main attach device and a control device. The head main attack device comprises a head attacking mechanism anda head driving mechanism used for driving the head attacking mechanism to rotate. The front main attack device comprises a front attacking mechanism and a first swinging assembly used for driving thefront attacking mechanism to swing. The leg main attack device comprises a leg attack mechanism and a second swinging assembly driving the leg attacking mechanism to swing. The control device comprises a controller and a sensor assembly electrically connected with the controller. Training stability of an athlete is guaranteed. Output shafts of a rotating motor and a driving motor are prevented from offset. The training effect of the athlete can be improved.

Owner:高婷婷

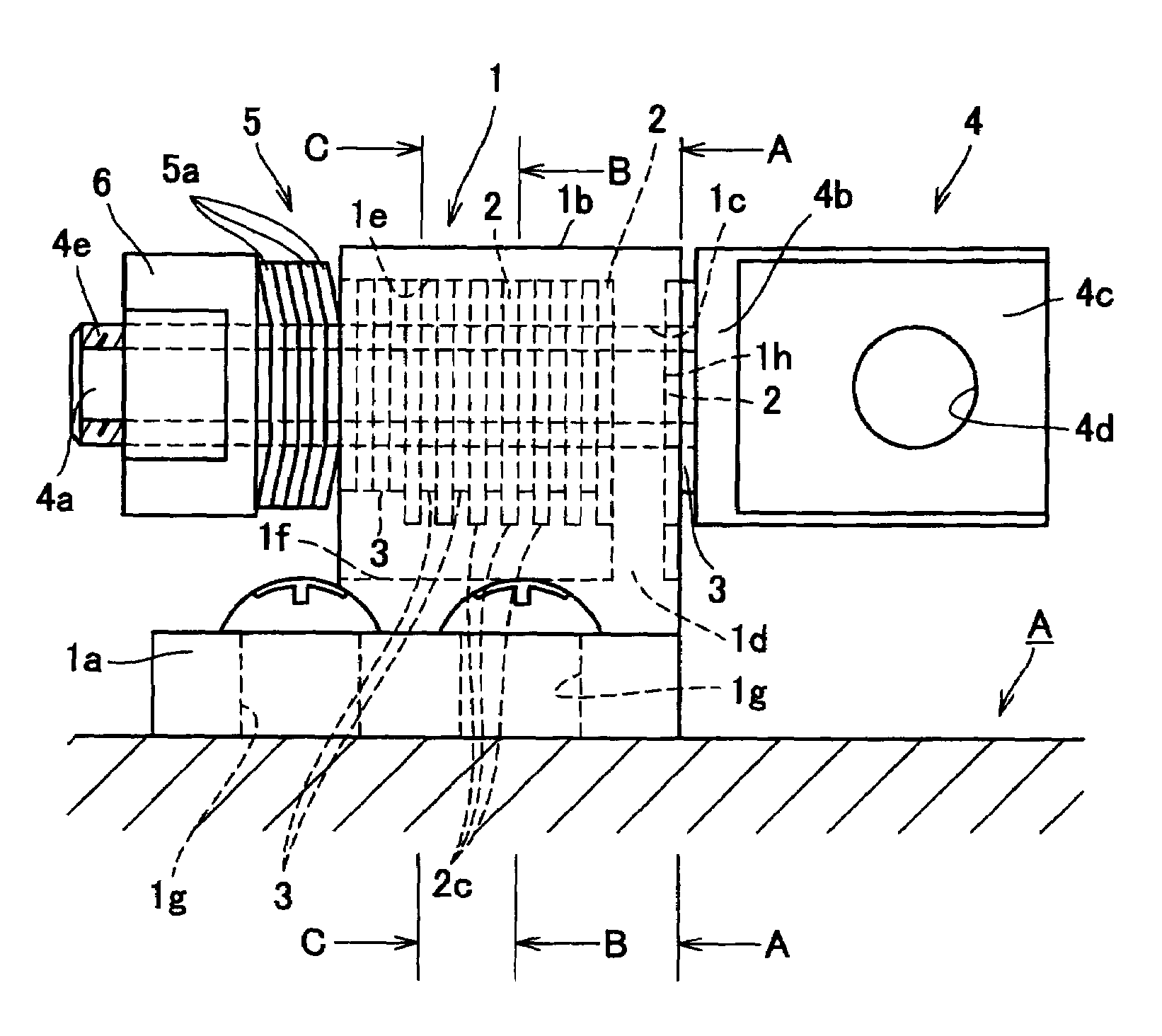

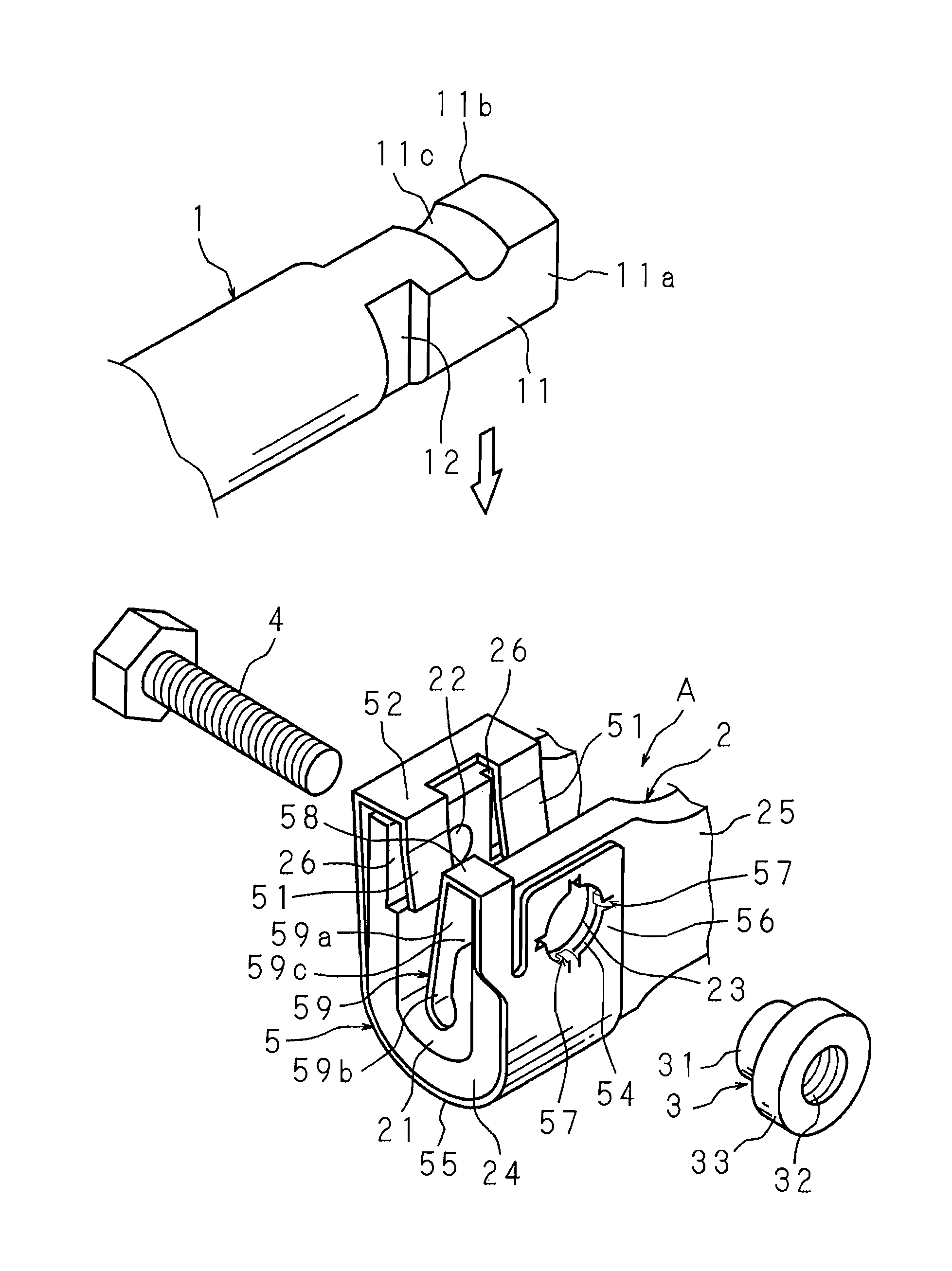

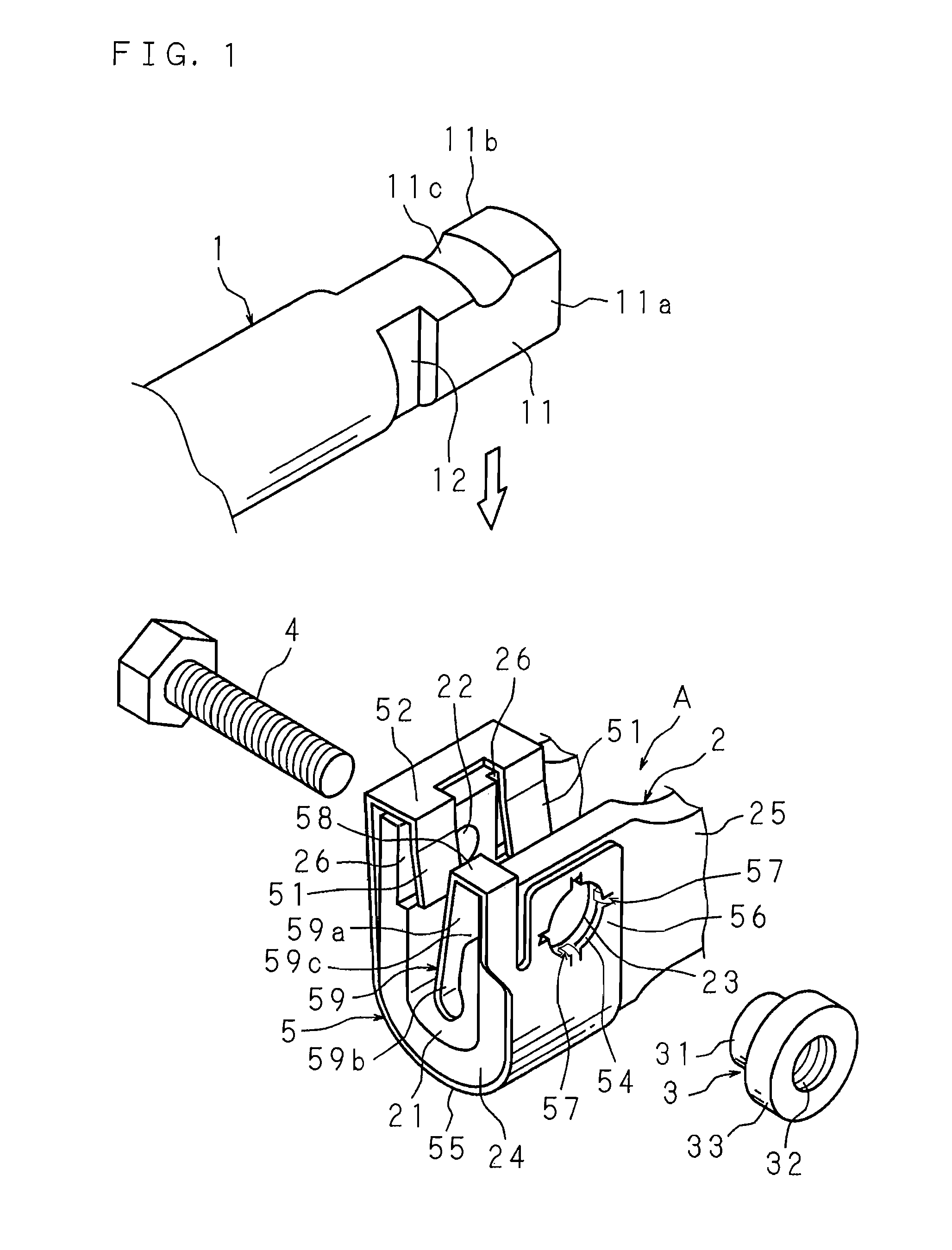

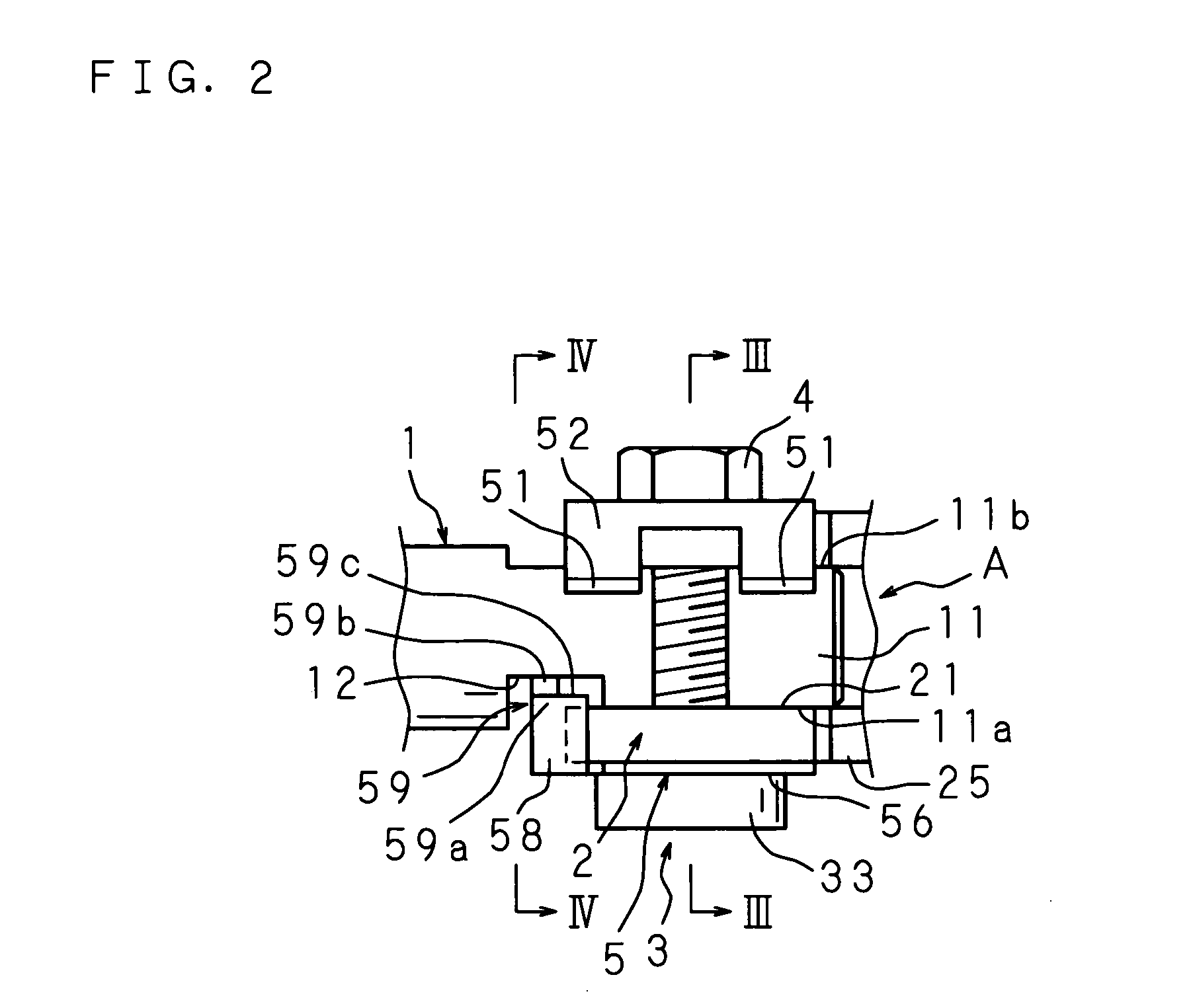

Coupling structure of shaft body and shaft joint

The coupling structure includes: a shaft body 1 having an engagement portion 11 with a slip-off preventing groove; a shaft joint body 2 having an engagement groove 21 with which the engagement portion 11 is engaged and bores 22 and 23 facing the engagement groove 21; a locking body 3 press-fitted into the bore 23; and a plate body 5 having regulating tongues 51 for regulating movement of the shaft body 1, a supported portion 56 extending from the regulating tongues 51 and supported between the locking body 3 and the shaft joint body 2, and a projection 57 projecting from the supported portion 56. The shaft joint body 2 and / or the locking body 3 have a recessed portion 27 into which the projection 57 is fitted.

Owner:JTEKT CORP

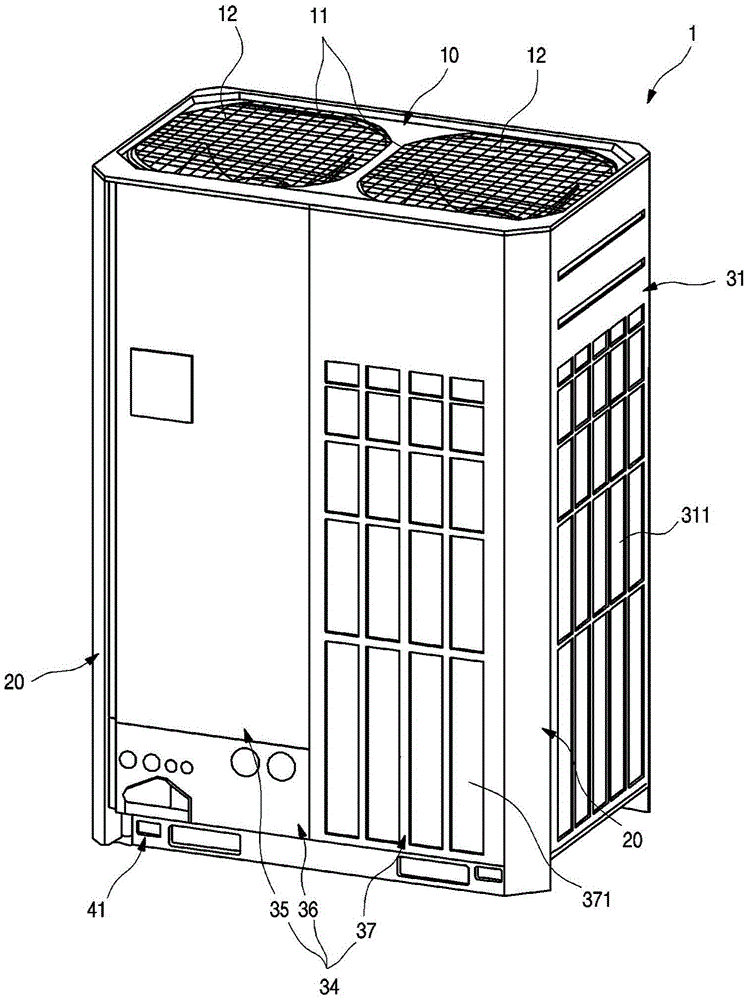

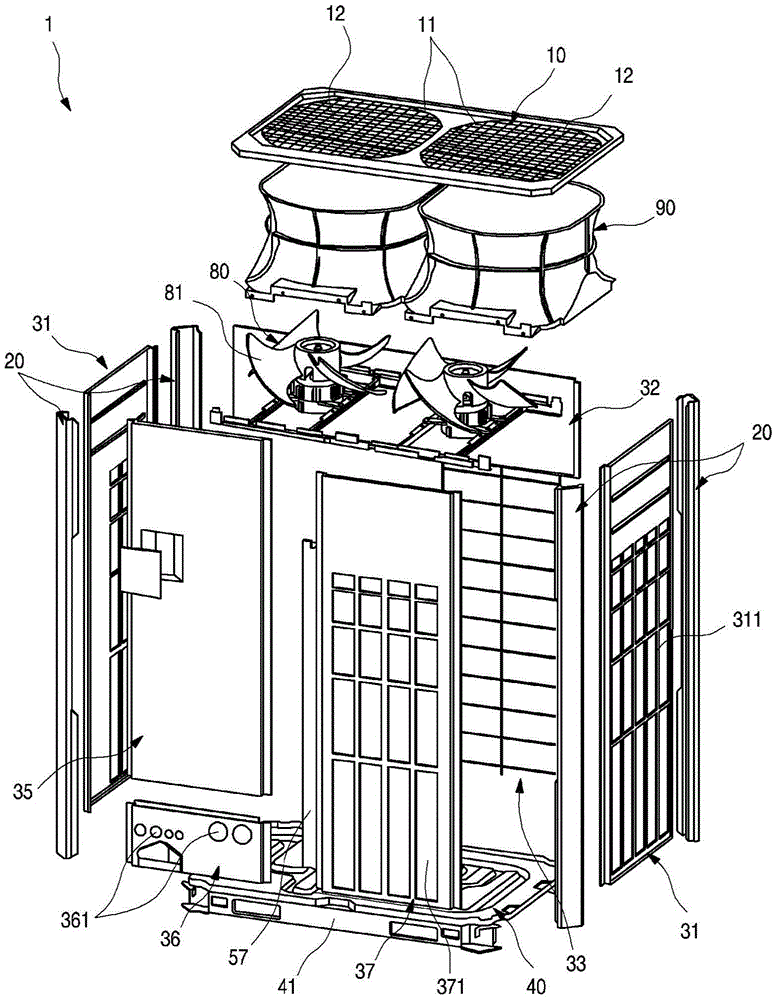

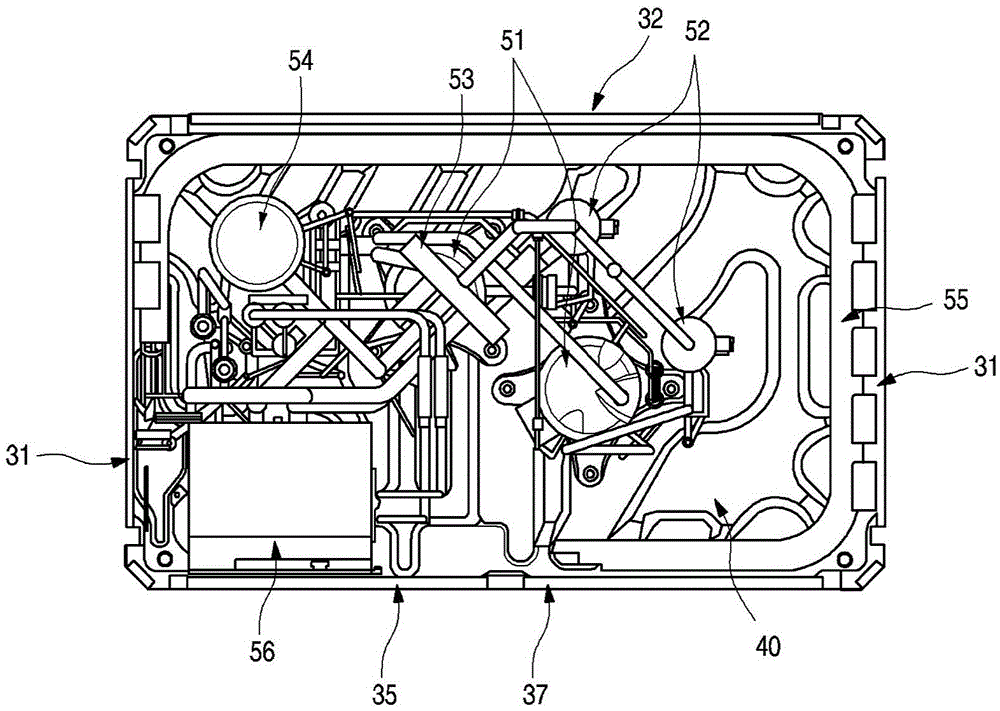

Outdoor device of air conditioner

ActiveCN105737274AEasy to moveIncrease discharge flowLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

An outdoor device of an air conditioner is provided and may include a top cover that forms an upper surface of the outdoor device and provided with a discharge port through which air may be discharged, a fan provided under the top cover, and a shroud that accommodates the fan and that connects with the discharge port to guide air flow. A transverse width of the shroud that passes through central lines of the side surfaces of the shroud and the fan may be constant from height direction of the shroud. A cross sectional area of the outlet port may gradually increase toward the discharge port.

Owner:LG ELECTRONICS INC

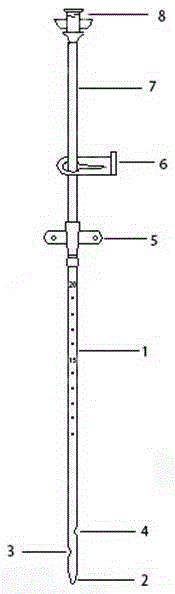

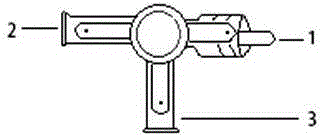

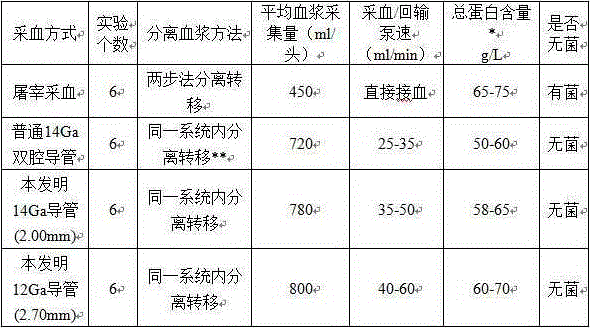

Vein blood sampling catheter

The invention provides a vein blood sampling catheter which comprises a catheter body, a connecting base, an extension tube, a sliding buckle and an extension tube connector. The rear end of the catheter body is connected with one end of the extension tube through the connecting base, and the other end of the extension tube is connected with the extension tube connector. Two side holes communicated with the catheter body are formed in the side face of a front end catheter opening of the catheter body and located in the two opposite side walls of the catheter body respectively. The diameter of each side hole is 1 / 3-2 / 3 of the opening diameter of the catheter body. The distance between the two side holes is 3-8 mm. The side hole close to the catheter opening is distanced from the rear portion of the catheter opening by 5-10 mm. A straight single-cavity catheter is adopted as the catheter body, and the range of the opening diameter of the catheter is 1.40-2.70 mm. The side holes are formed in the front end of the catheter body, the opening diameter for blood sampling is relatively increased through the side holes, the blood sampling speed is increased, fibrous protein sheaths do not form easily, and the problem that the blood sampling speed is difficult to increase or the catheter is difficult to place is solved.

Owner:GUANGZHOU MUNICIPAL ZHONGWEI BIOTECH CO LTD +1

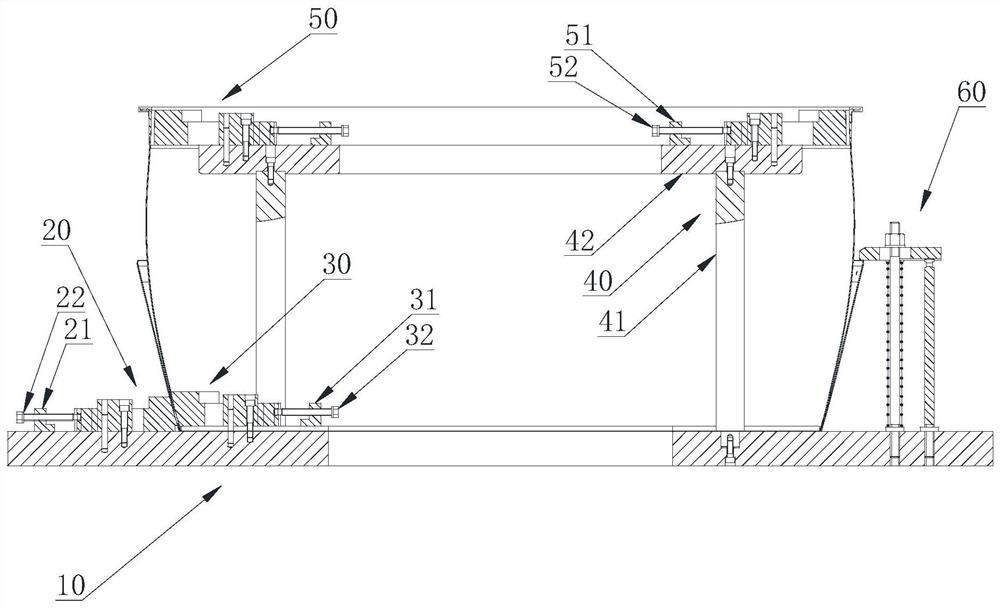

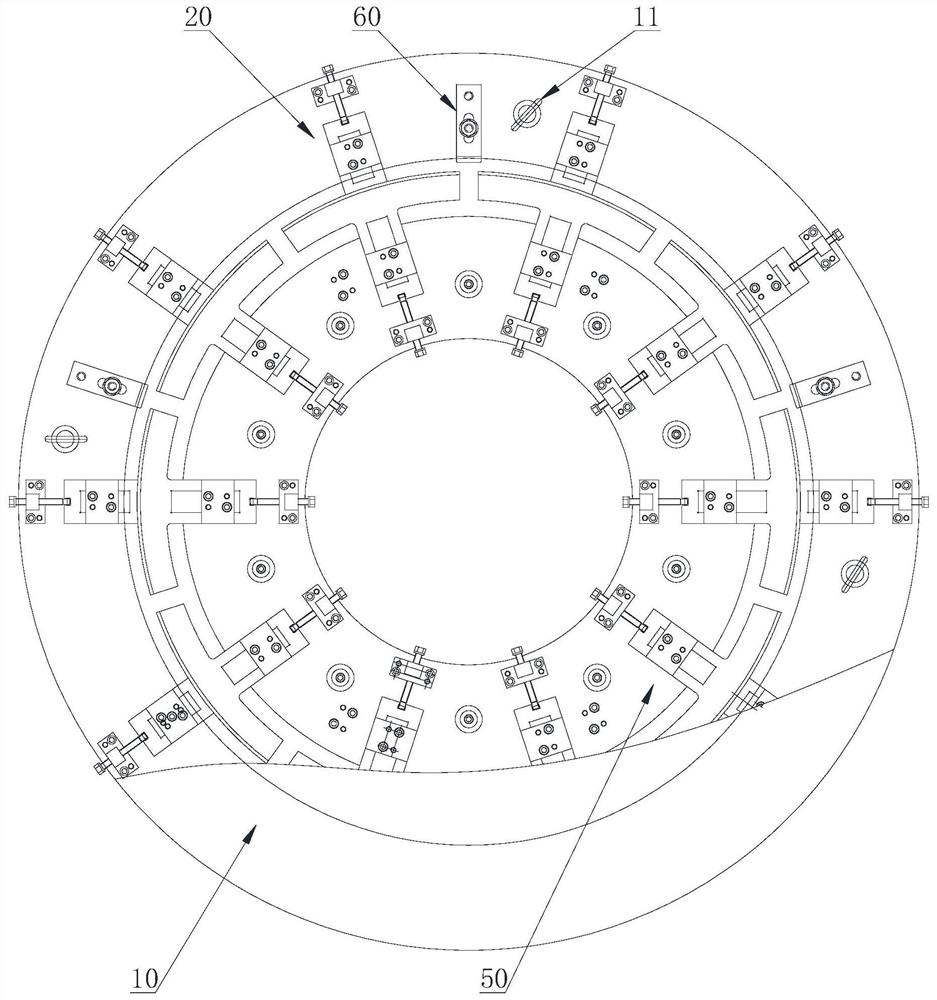

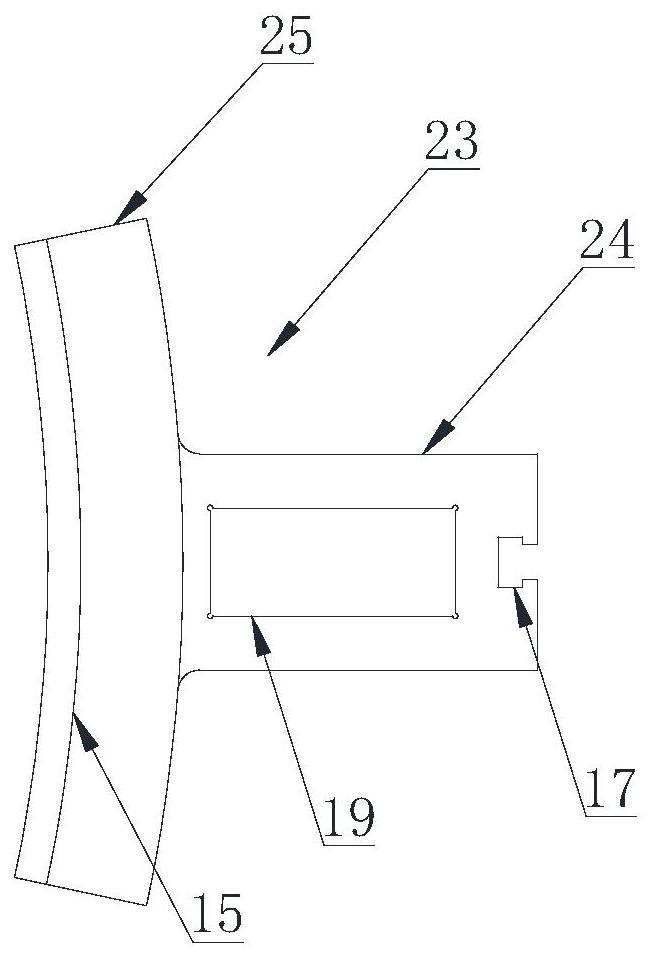

Turning and milling machining clamp for aero-engine exhaust nozzle assembly

InactiveCN113478261AAvoid tremblingAvoid deformationPositioning apparatusMetal-working holdersMachining processAero engine

The invention discloses a turning and milling machining clamp for an aero-engine exhaust nozzle assembly, and belongs to the technical field of aero-engine part manufacturing. The turning and milling machining clamp for the aero-engine exhaust nozzle assembly comprises a base, an outer limiting assembly, a bottom inner limiting assembly, a supporting assembly and a top limiting assembly. The base of the clamp is used for bearing all assemblies and the aero-engine exhaust nozzle assembly, the bottom outer limiting assembly and the bottom inner limiting assembly are in cooperation, and therefore a metal plate barrel is clamped and positioned from the inner side and the outer side; and supporting columns are used for lifting a supporting plate, the supporting plate is used for bearing the top limiting assembly, and the top limiting assembly makes contact with the inner wall of a flange above the metal plate barrel so as to tightly jack the inner wall of the flange. An outer pressing assembly makes contact with a boss on the side wall of the metal plate barrel, and therefore the metal plate barrel is pressed, the metal plate barrel and the flange welded to the upper portion of the metal plate barrel are in a stable state, and the problems of loosening, displacement and vibration in the machining process are avoided.

Owner:AECC AERO SCI & TECH CO LTD

Working method of free-kick trainer capable of improving agility

The invention relates to the technical field of sports equipment, in particular to a working method of a free-kick trainer capable of improving agility, comprises vertically arranged support columns,leg main attack device, frontal main attack device, headgear and controls, the head attacking device comprises a head attacking mechanism and a head driving mechanism for driving the head attacking mechanism to rotate, the frontal main attack device comprises a frontal attack mechanism and a first swing assembly for driving the frontal attack mechanism to swing, the leg main attack device comprises a leg attack mechanism and a second swing assembly for driving the swing of the leg attack mechanism, the control device comprises a controller and a sensor assembly electrically connected with thecontroller. The invention can ensure the stability of the athlete during training, can ensure the the output shafts of the rotating motor and the driving motor are not offset, and can improve the training effect of the athlete.

Owner:浙江森创服装股份有限公司

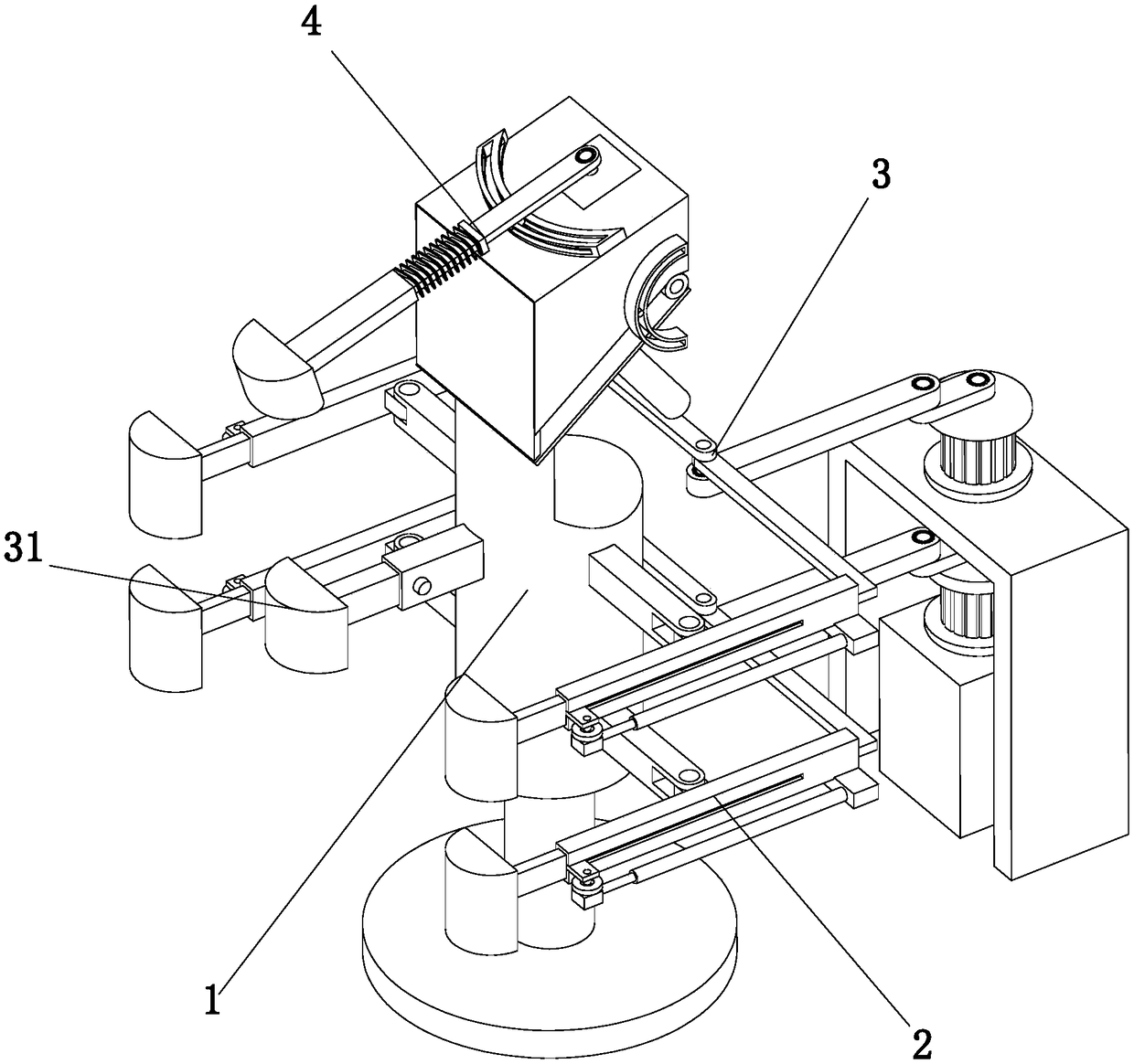

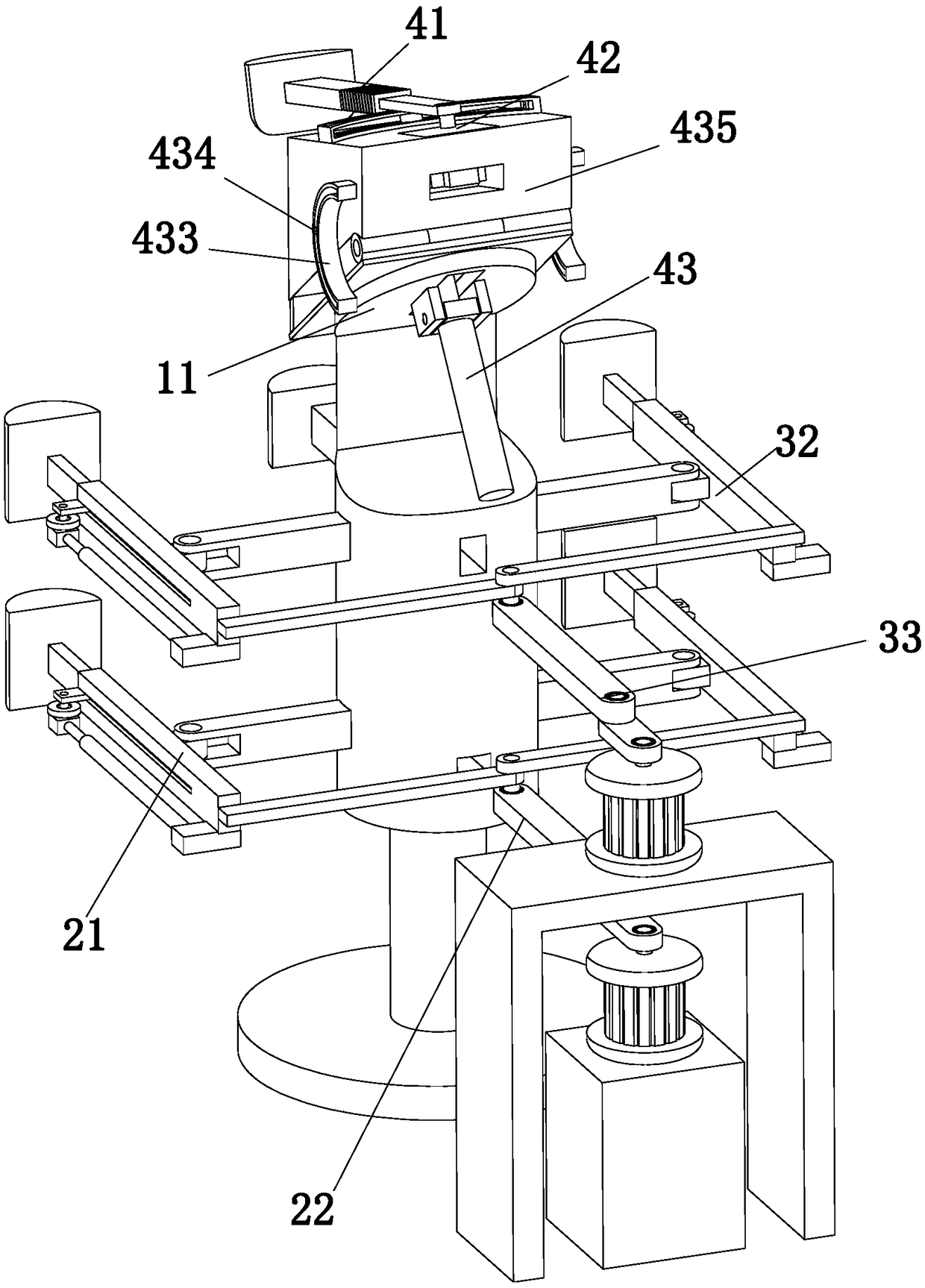

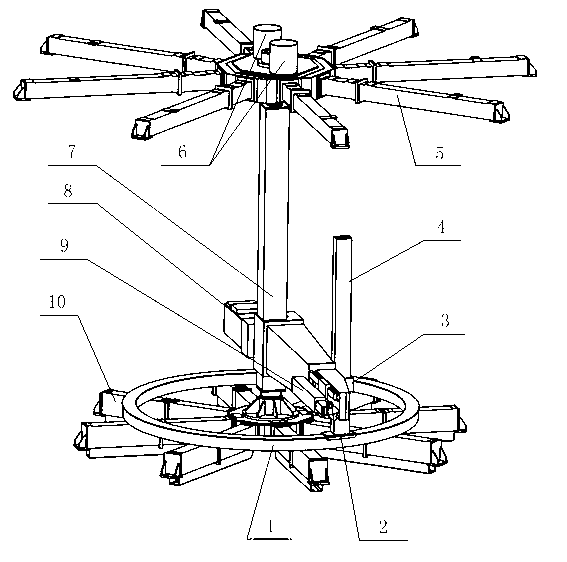

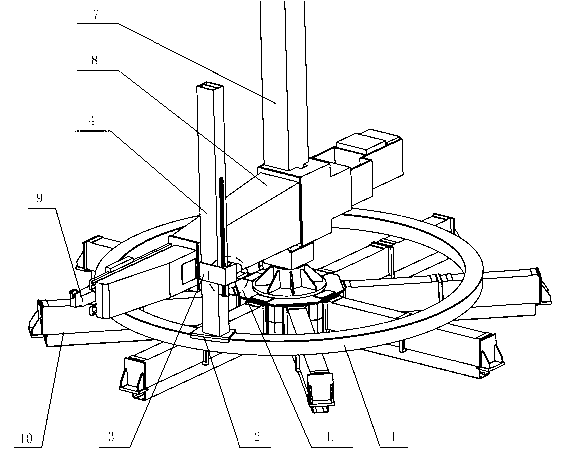

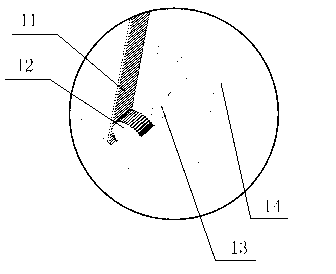

Stiffness compensation device for remanufactured cantilever beam of heavy-duty machine

ActiveCN103056728AIncrease stiffnessReduce weightOther manufacturing equipments/toolsEngineeringCantilever

The invention aims to provide a device which can increase stiffness of a remanufactured cantilever beam of a heavy-duty machine without modifying primary structure of the heavy-duty machine and slightly increasing primary weight of the heavy-duty machine, particularly relates to a stiffness compensation device for the remanufactured cantilever beam of the heavy-duty machine. The stiffness compensation device comprises an arc guide rail and an auxiliary column which are arranged on the heavy-duty machine. The heavy-duty machine mainly comprises a main column, the cantilever beam, lower supports and upper supports. The main column is installed perpendicularly to the ground. A plurality of the lower supports are radially arranged around a shaft sleeve of a rotating shaft at the lower end of the main column, and the cantilever beam is arranged on the main column which drives a knife rest to move circularly when rotating; the arc guide rail is arranged on a supporting platform composed of a plurality of lower supports, the auxiliary column is parallel to the main column while being perpendicular to the cantilever beam; and a sliding block mounted on the arc guide rail is arranged at the lower end of the auxiliary column.

Owner:CHONGQING UNIV

Cloud platform handheld frame with high stability

The invention discloses a cloud platform handheld frame with high stability. The cloud platform handheld frame comprises a handle body; a rotating shaft is arranged at the upper end of the handle body, a supporting table is horizontally arranged on the rotating shaft, and the midpoint position of the left edge of the lower end face of the supporting table is movably connected to the upper end of the rotating shaft through a hinge; a telescopic rod is horizontally arranged at the left portion of the lower end of the handle body, and the right end of the telescopic rod is movably connected withthe lower end of the handle body through the hinge; the left end of the telescopic rod is horizontally connected with a connecting rod in a hinged mode, and the connecting rod is perpendicular to thetelescopic rod; and the front and back ends of the connecting rod are horizontally and fixedly connected with shoulder plates. According to the cloud platform handheld frame, the shoulder plates at the two ends of the connecting rod hinged to the telescopic end head of the telescopic rod are erected on the shoulders, a movable clamping plate and a fixed clamping plate are opened along second sliding ways on the lower end faces of the shoulder plates, during the process, a second pulley slides and compresses a second spring, then the movable clamping plate and the fixed clamping plate clamp theshoulders, the second spring produces resilience force, so that the movable clamping plate is propped against the shoulders, and shaking is avoided by holding the handle body through the hands alonefor launching.

Owner:程梦轩

Fried bread stick cutting machine

The invention discloses a fried bread stick cutting machine. The machine comprises a pedestal (1), a connecting rod (2), a straight rod (3), a rocking rod (4), a push rod (5) and a blade (6); the pedestal (1) is connected with a workbench (8) through a support (7), the workbench (8) is provided with a conveyer belt (9), and the pedestal (1) is provided with a first motor (14); the connecting rod (2) is hinged to the pedestal (1), the straight rod (3) is in sliding fit with the pedestal (1), the rocking rod (4) is hinged to the pedestal (1), the left end portion of the rocking rod (4) is positioned above the straight rod (3), and the right end portion of the rocking rod (4) is provided with a first cam (12); the push rod (5) is in sliding fit with the pedestal (1), the upper end of the push rod (5) is provided with a flat plate (19), and the lower end of the push rod (5) is connected with the blade (6) through a reset device; the pedestal (1) is provided with a driving device; and the push rod (5) is provided with a projection (24). The fried bread stick cutting machine allows the workload of food and drink personnel to be small and the size of fried bread sticks to be consistent.

Owner:冯霞霞

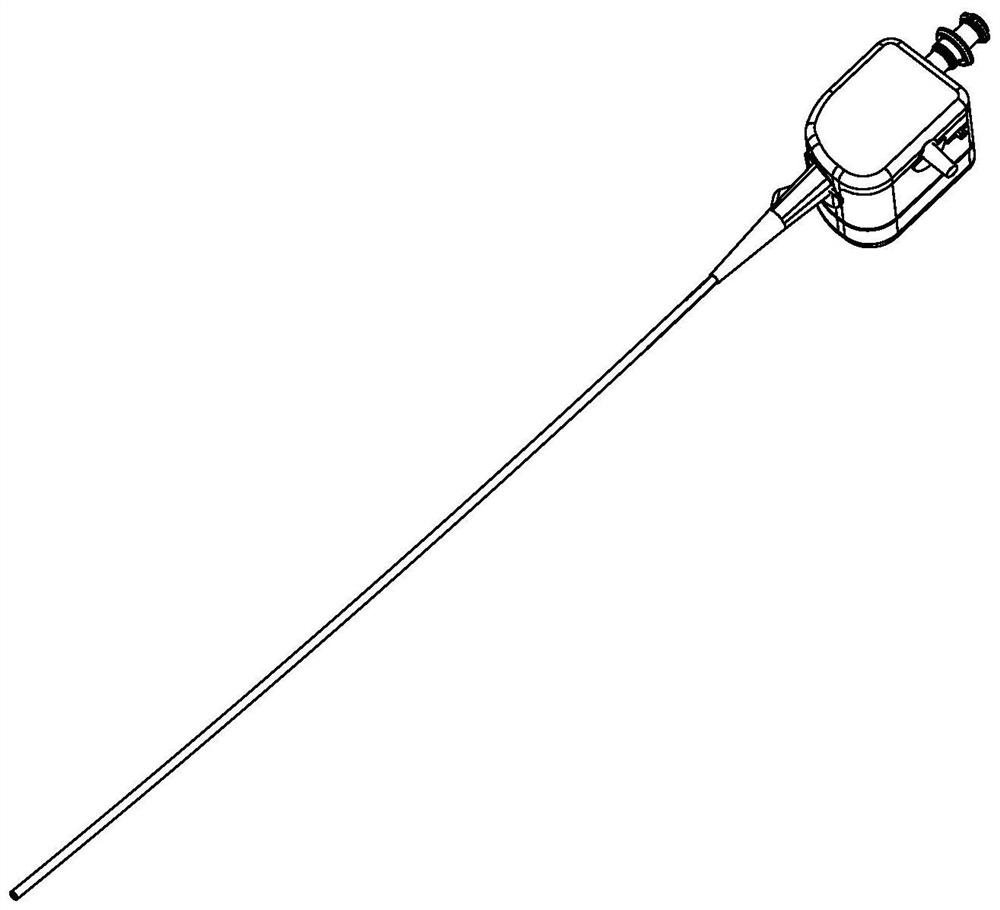

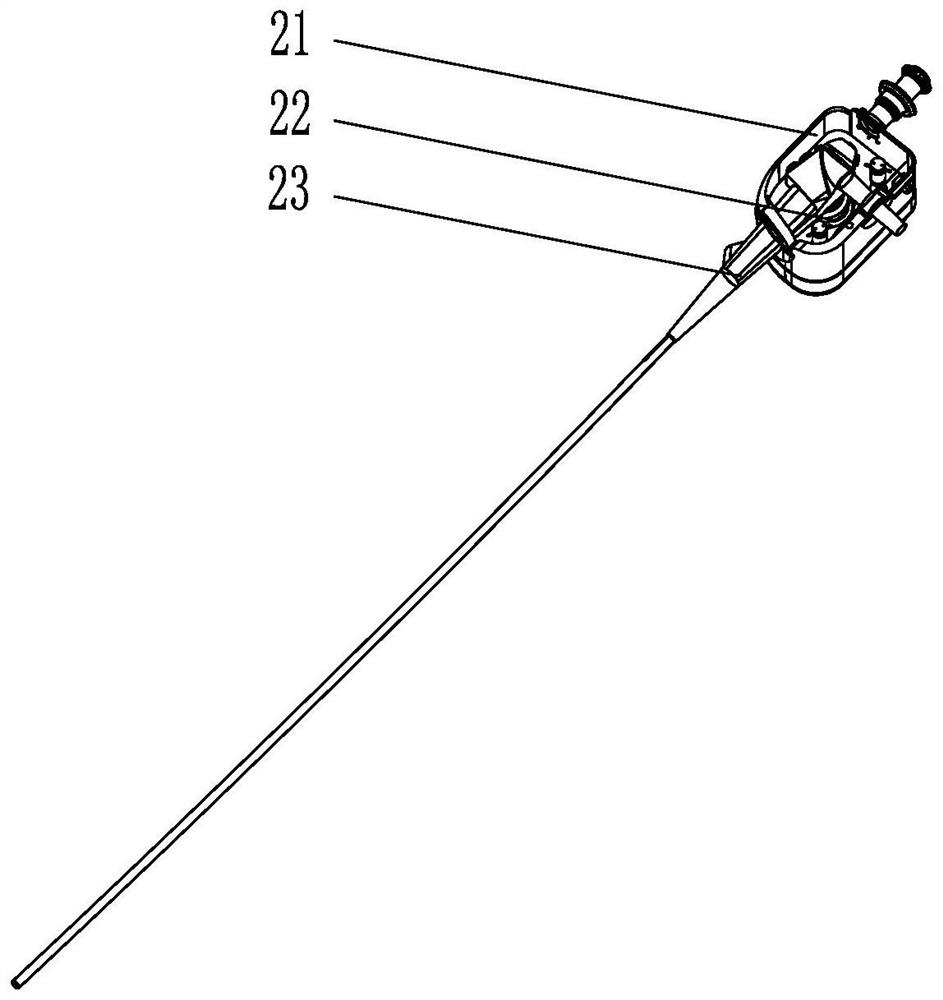

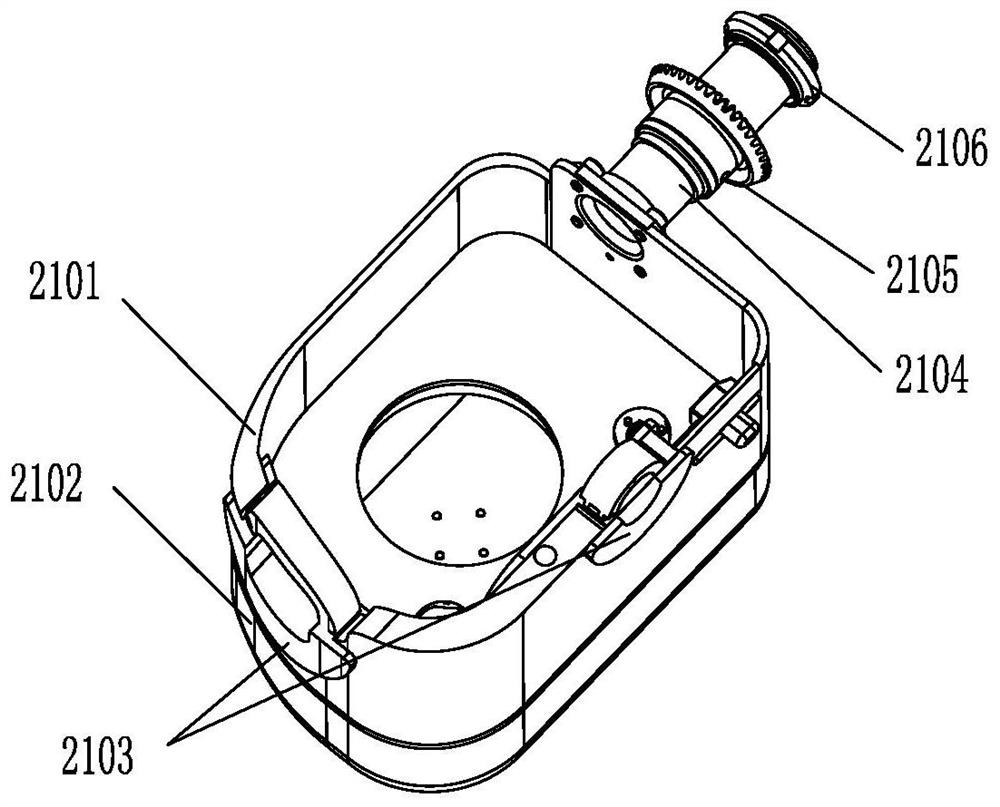

Endoscope body and digestive endoscope robot

PendingCN113662491AAvoid tremblingQuality assuranceSurgeryEndoscopesHuman bodyPhysical medicine and rehabilitation

The invention relates to an endoscope body and a digestive endoscope robot, in particular to an endoscope body and a digestive endoscope robot. The objective of the invention is to solve the problem that the examination or treatment quality is affected because a doctor is prone to fatigue when standing and holding an endoscope for a long time. An endoscope handle (23) is installed in a driving mechanism shell (21), and a driving mechanism (22) is installed in the driving mechanism shell (21) and located at the lower end of the endoscope handle (23). The driving mechanism (22) comprises a first driving unit and a second driving unit, the first driving unit and the second driving unit are arranged in an up-down double-layer mode, and the first driving unit and the second driving unit directly drive one steel wire in the endoscope handle (23) through gear pairs respectively and drive the corresponding steel wire to be shrunk and released so as to achieve control over the bending angle of the tail end of the endoscope handle (23). The digestive endoscope robot comprises the endoscope body. The digestive endoscope robot is used in the operation process of the human digestive system.

Owner:HARBIN INST OF TECH

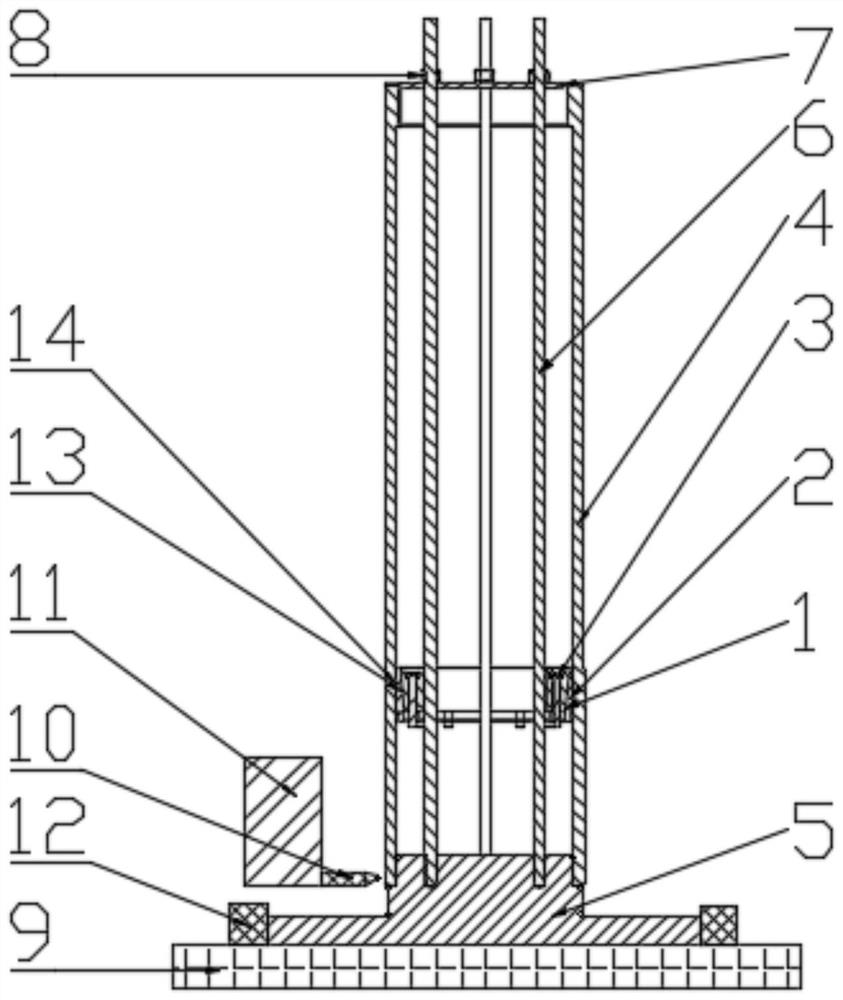

Rolling process method for nuclear power station nuclear main pump long shaft sleeve

ActiveCN111922628AExtended service lifeImprove wear resistanceNuclear energy generationReactors manufactureNuclear power plantNuclear power

The invention relates to a rolling process method for a nuclear power station nuclear main pump long shaft sleeve. According to the rolling process method for the nuclear power station nuclear main pump long shaft sleeve, an inner support (1) and an outer support (2) are installed to an inner hole step (14) of the long shaft sleeve (4) after being assembled together through bolts (3), the inner support (1) is made to slide to the bottom face of the outer support (2) on a contacted inclined plane (13) through clockwise rotation of the bolts (3), the outer support (2) is evenly distributed with12 openings (15) to make the outer support (2) be tightly supported outwards, and the outer support (2) is supported at the inner hole step (14) of the long shaft sleeve (4). By means of the rolling process method for the nuclear power station nuclear main pump long shaft sleeve, the situation that a jacking tip is subjected to force to cause tool core shaft deformation and cause long shaft sleeve(4) deformation can be avoided, three-segment supporting forms powerful supporting on an inner hole of the long shaft sleeve (4), the long shaft sleeve (4) deformation will not be generated in rolling, and generated long shaft sleeve (4) shaking can be effectively avoided.

Owner:HARBIN ELECTRIC POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com