Rolling process method for nuclear power station nuclear main pump long shaft sleeve

A process method and technology of nuclear main pump, applied in nuclear engineering, nuclear power generation, presses, etc., can solve the problems of cost loss, deformation of the long shaft sleeve of the mandrel, scrapped workpiece, etc., and achieve increased service life, hardness and strength. , the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

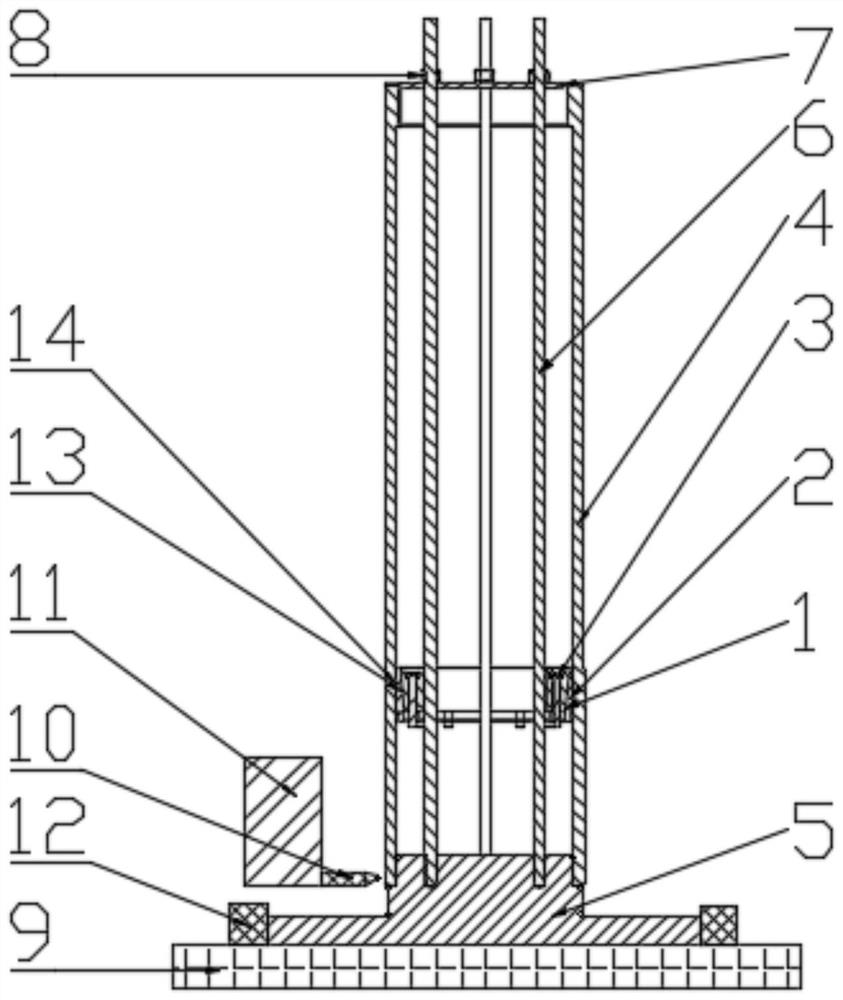

[0023] A rolling process method for a long shaft sleeve of a nuclear main pump of a nuclear power plant, comprising the following steps:

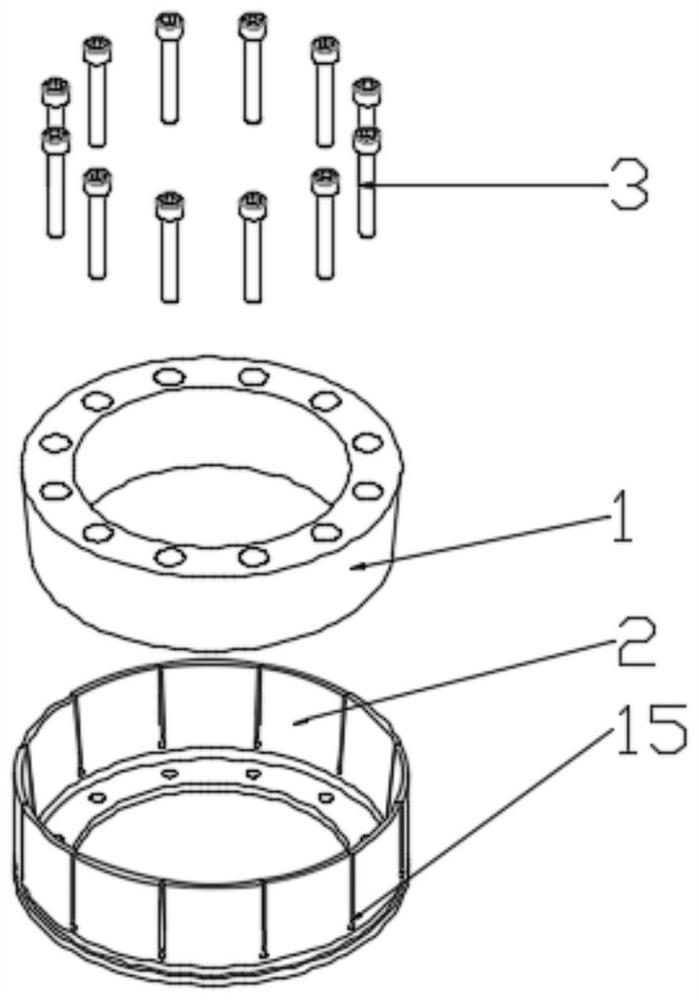

[0024] 1) The inner support 1 and the outer support 2 are assembled together by bolts 3 and installed on the inner hole step 14 of the long shaft sleeve 4, such as figure 1 As shown, through the clockwise rotation of the bolt 3, the inner support 1 slides on the contacting slope 13 to the bottom surface of the outer support 2, and the outer support 2 is evenly distributed with 12 openings 15, as figure 2 As shown, the outer support 2 is tightened outward, and the outer support 2 supports the inner hole step 4 of the long shaft sleeve 4;

[0025] 2) Install the rolling lower supporting plate 5 on the workbench 9 of the vertical lathe;

[0026] 3) The lower step of the long shaft sleeve 4 is installed on the upper step of the rolling lower supporting plate 5, and the fit gap J1 of the two positions satisfies

[0027] J1≤0.01mm;

[0028] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com