Patents

Literature

33results about How to "Extended overhaul period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

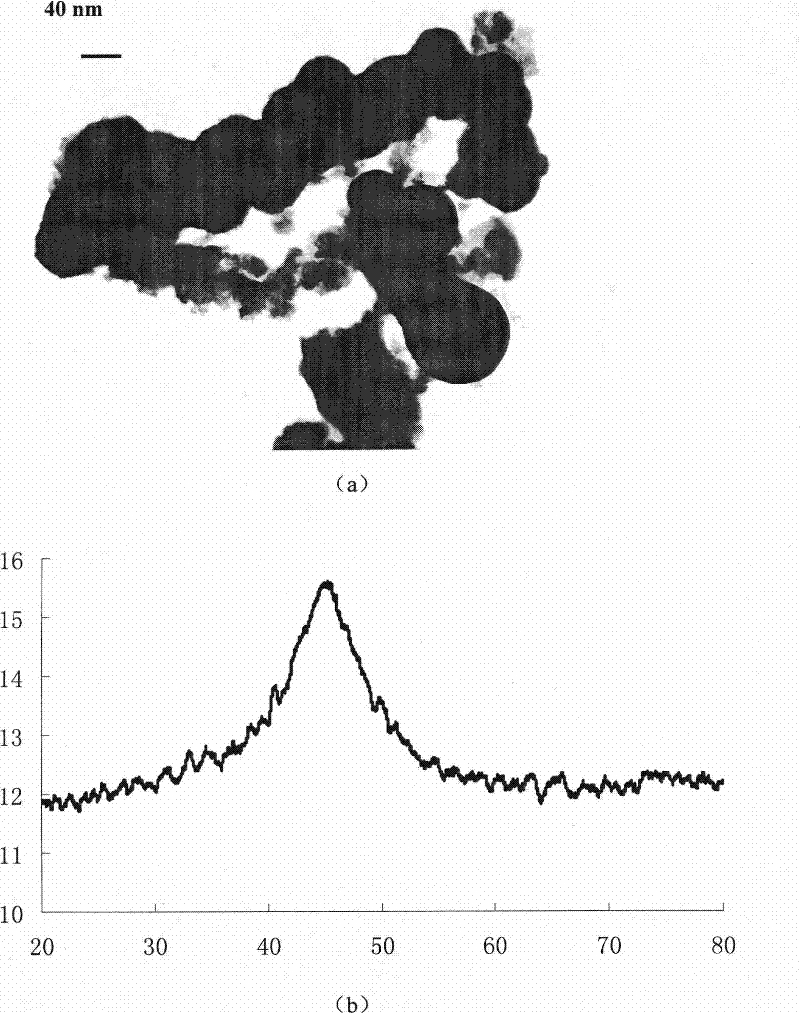

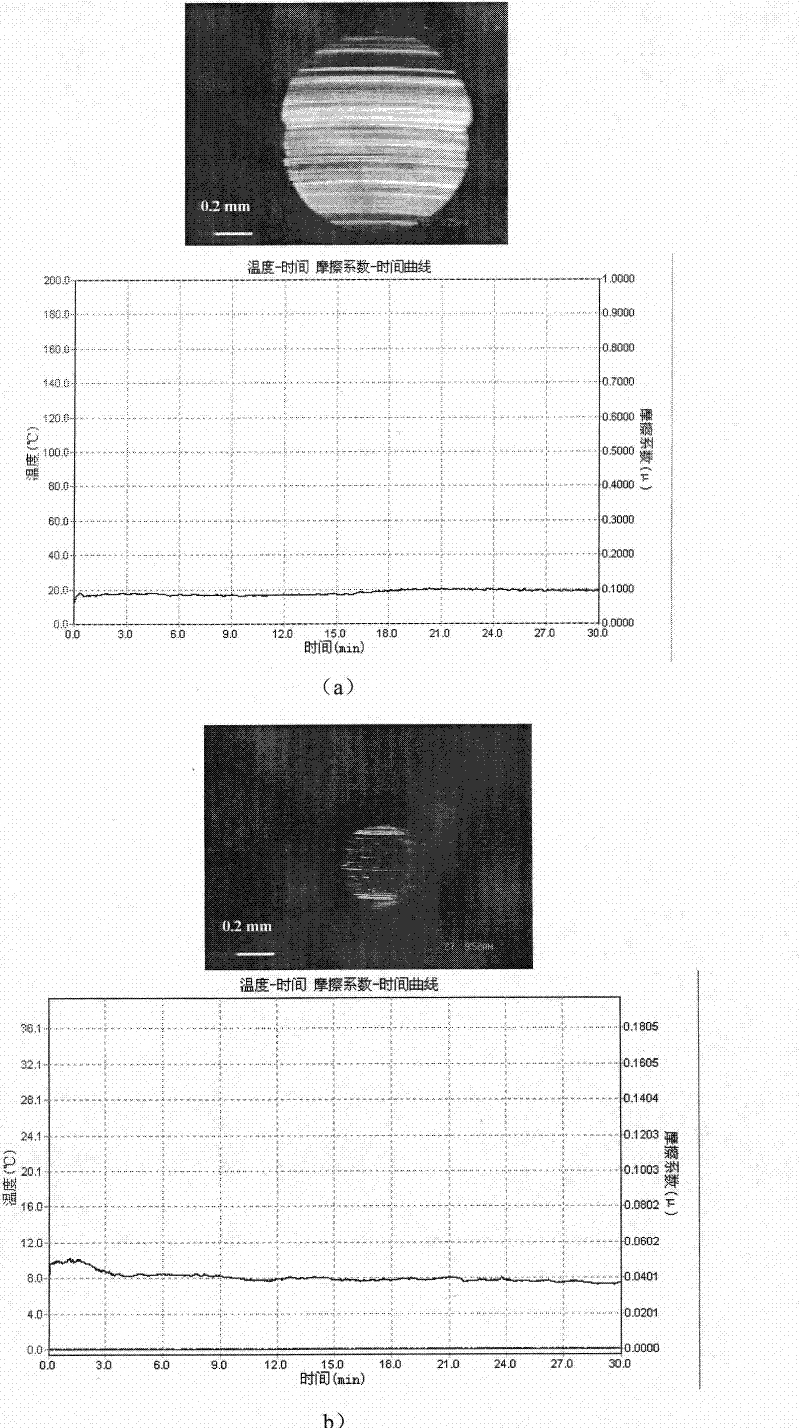

Metal/ ceramic nano composite additive of self-rehabilitation and its preparation method

The invention relates to a metal / ceramic nano complex self-repairing additive, which comprises metal nano micropowder and nano natural ore powder as main material, detergent, catalyst, antioxidant, and solvent, and can be used in lube, grease and ultrasonic medium. The advantages of this invention include: it can form rapidly high-hardness self-repairing protection layer on a plurality of metal friction surfaces with thickness adjustable to optimize gap and improve surface physical and chemical property, and has wide application in friction dual parts.

Owner:JIANGSU MOLEDN PETROCHEM

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

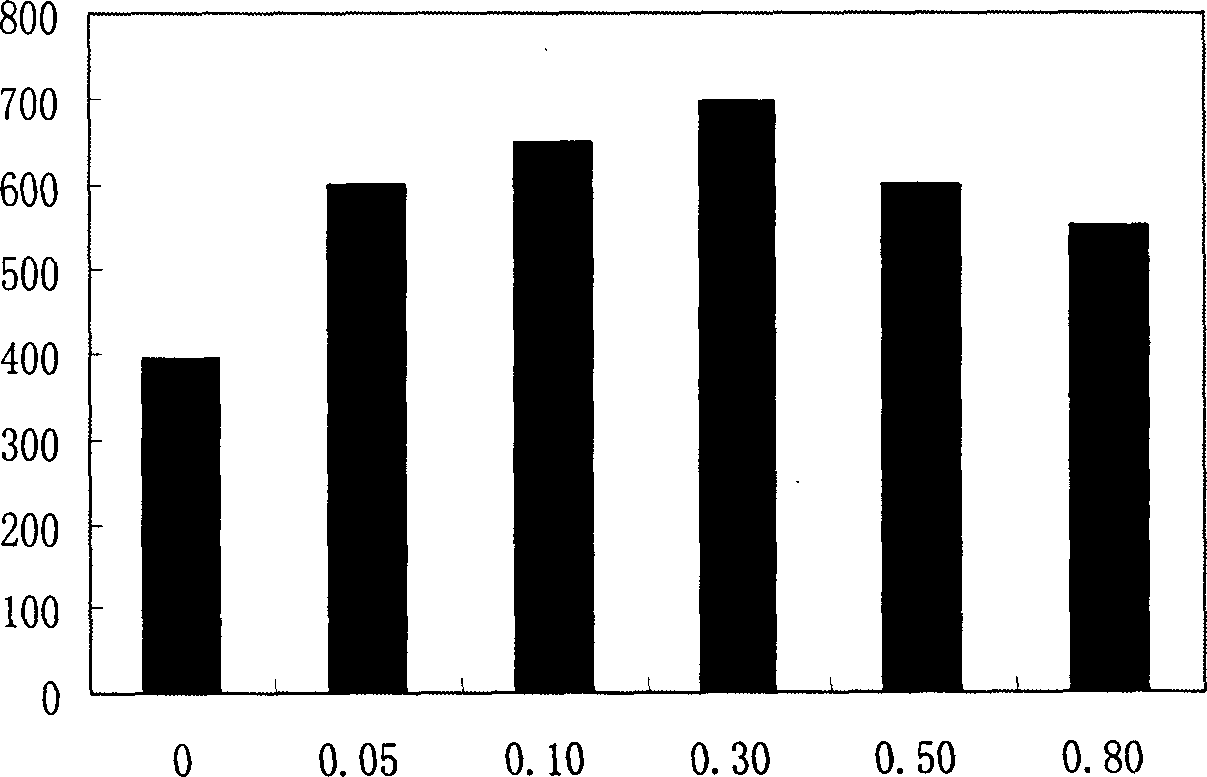

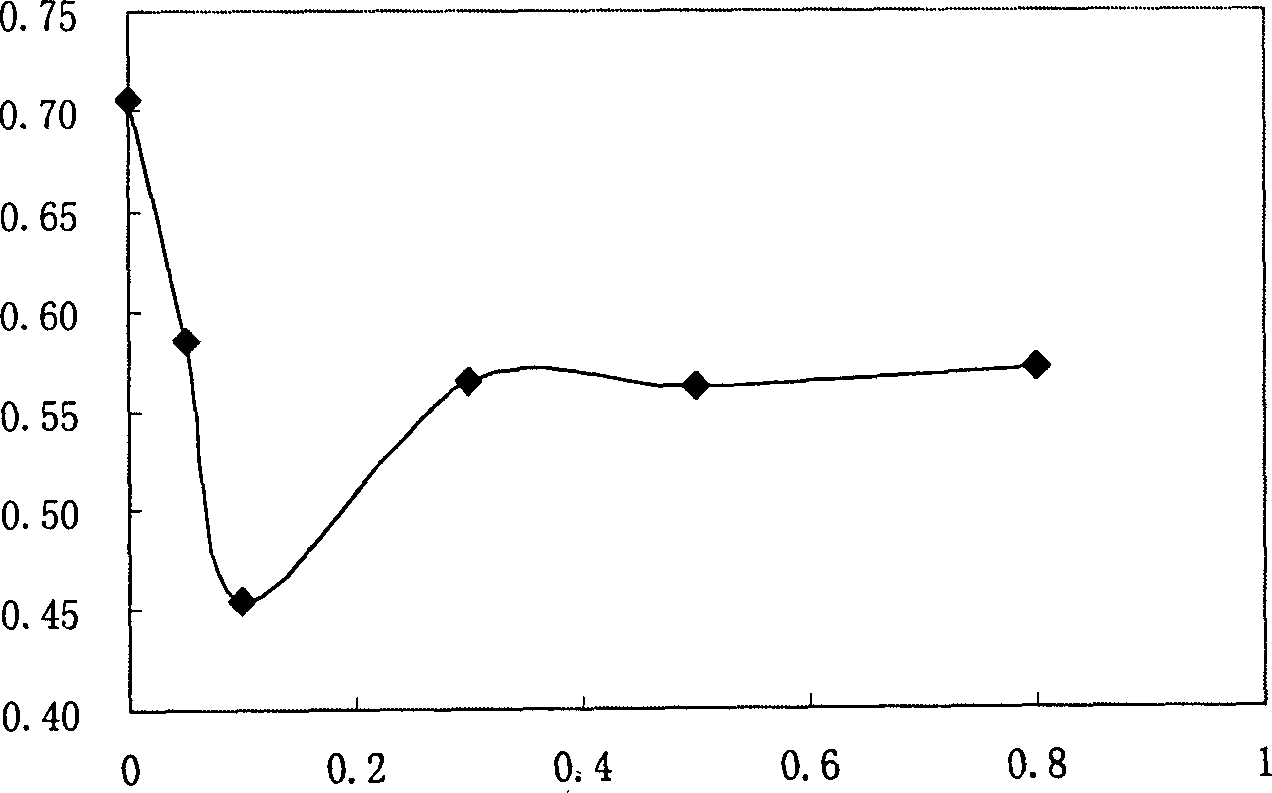

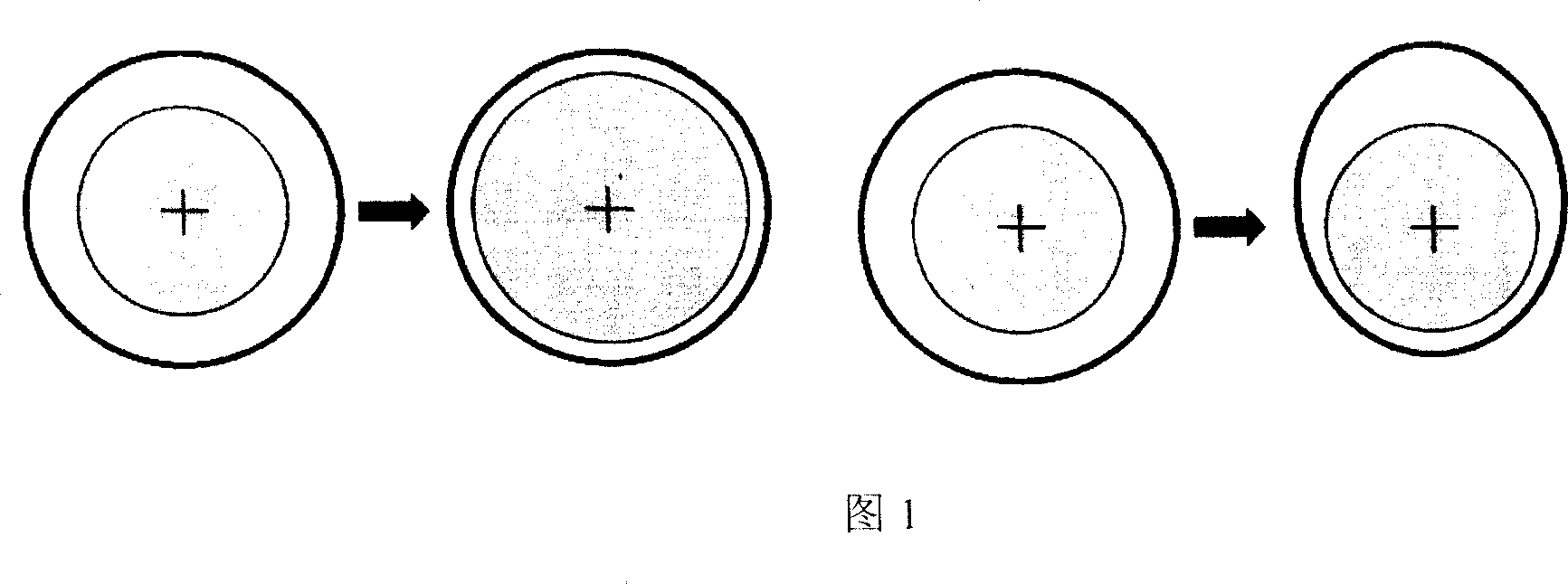

InactiveCN1740290AAutomatically adjust thicknessOptimizing friction pair clearanceBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

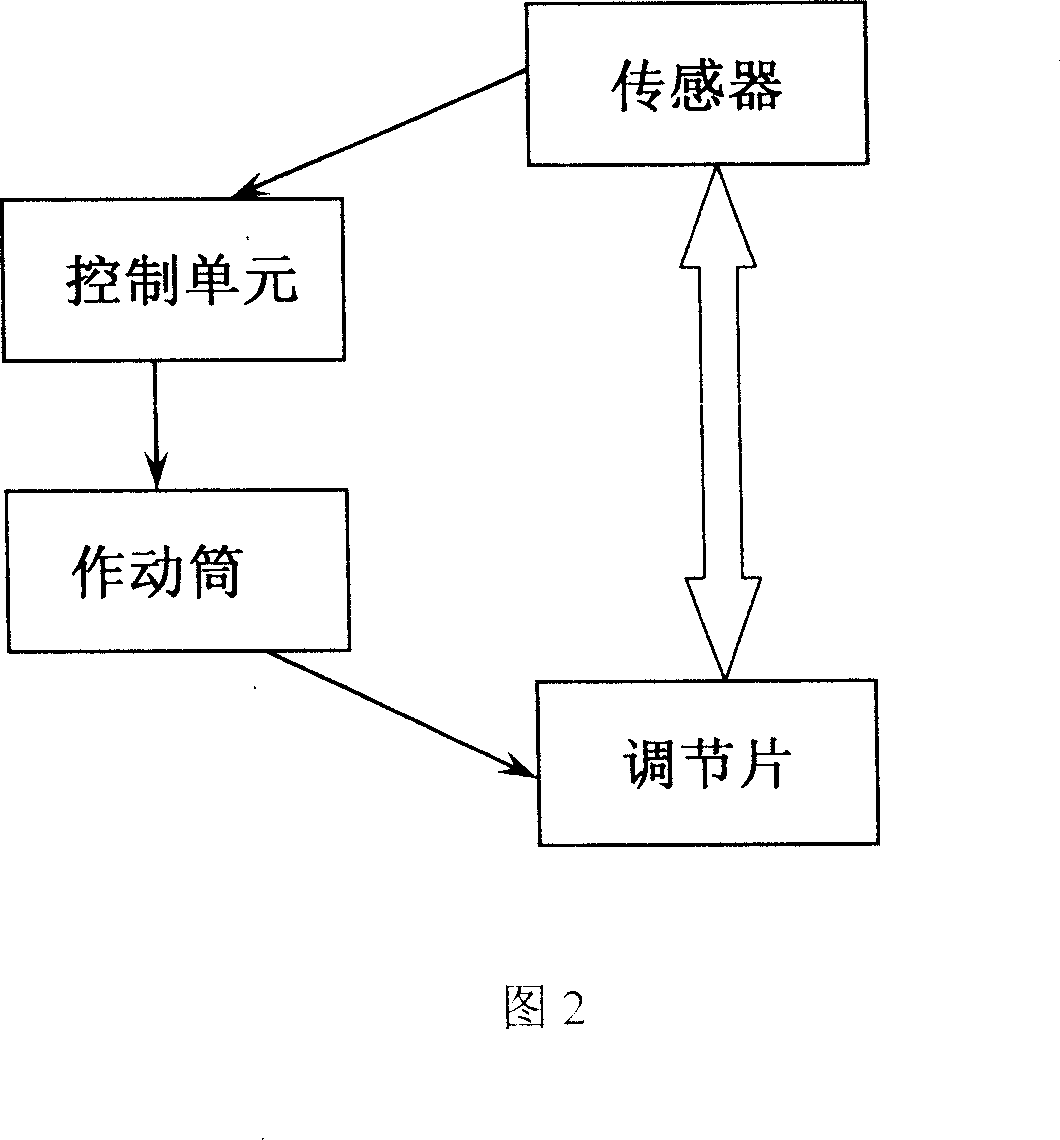

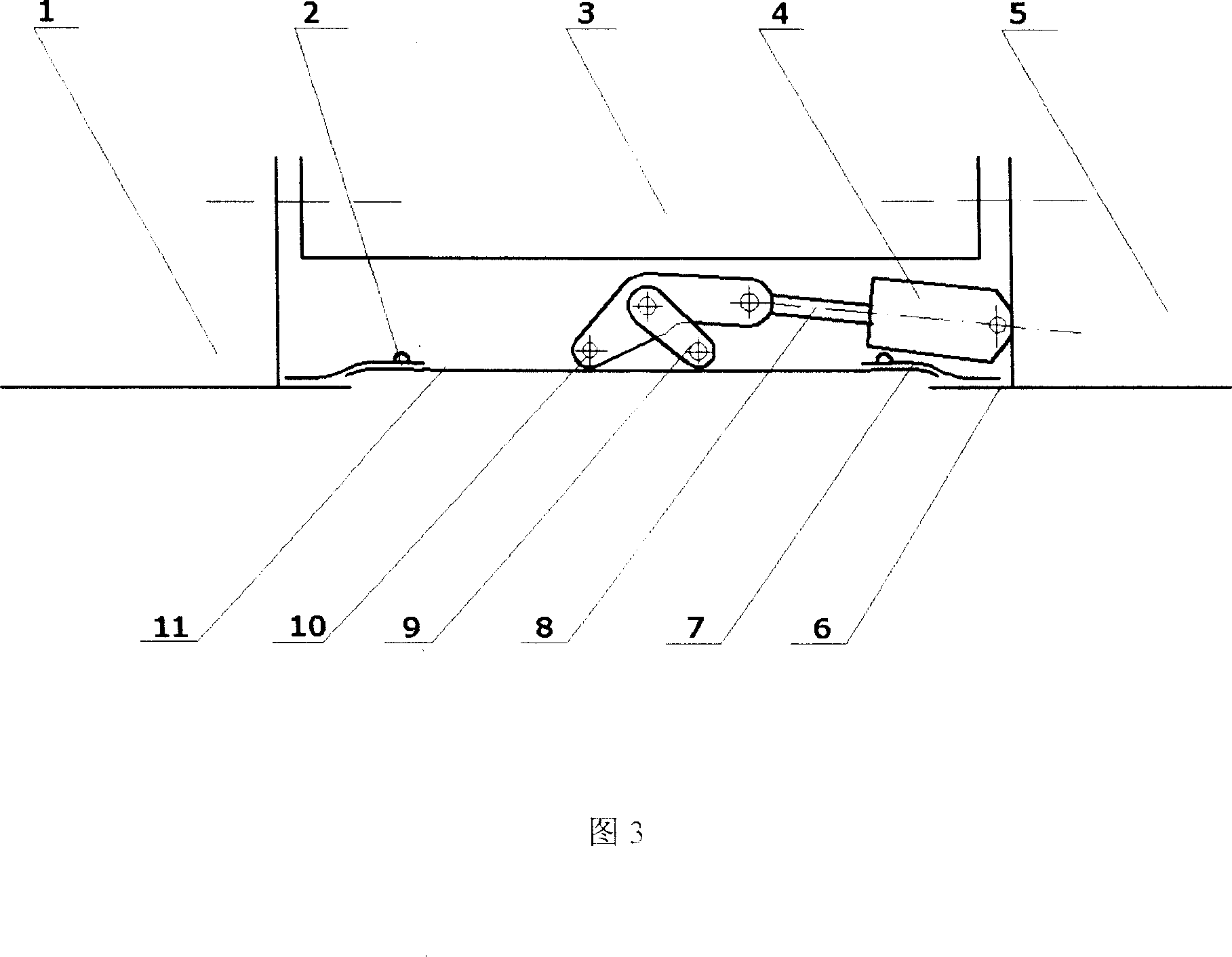

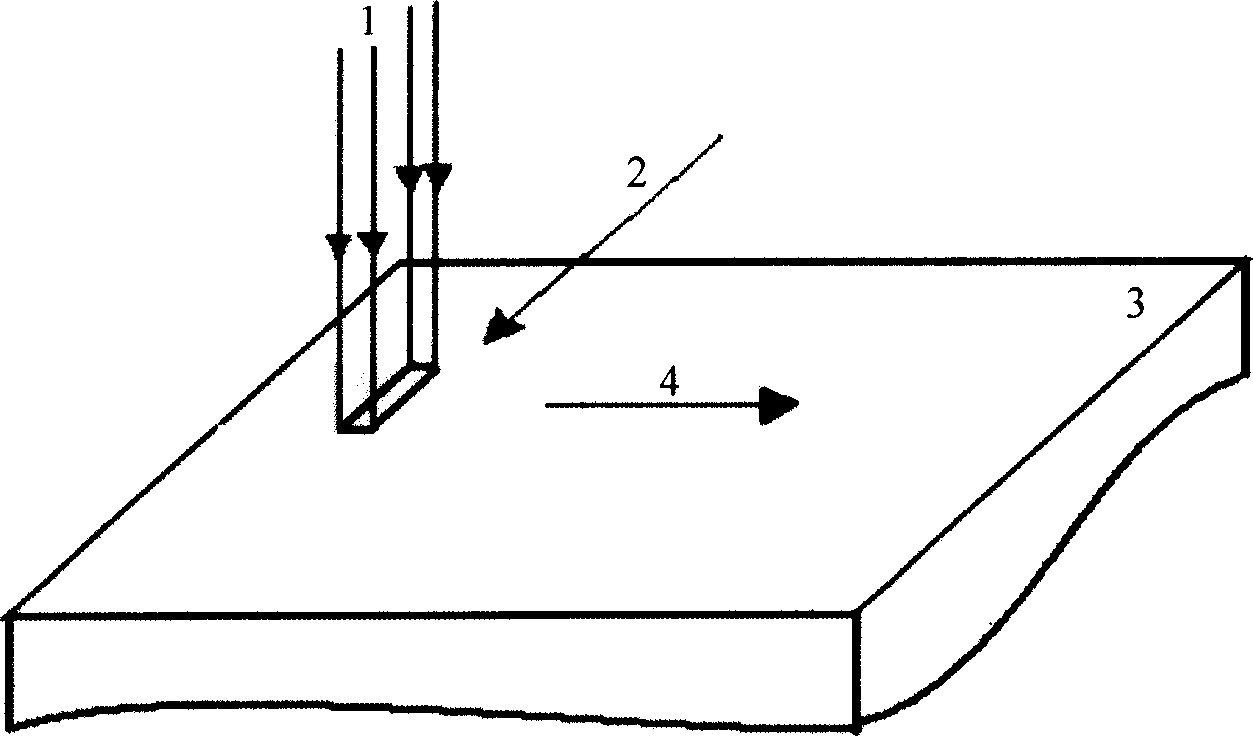

Design scheme of fast active control system for turbine vane tip interval

InactiveCN101046163AQuick responseEconomicalLeakage preventionMachines/enginesControl system designAviation

The present invention is one design scheme of fast active control system for the vane tip interval of aviation engine, and features the mechanical executing mechanism. The mechanical executing mechanism is designed by referring variable cross section tailing spout controlling technology for aviation engine and applied in the fast active control system of turbine vane tip interval. Compared with the control system designed based on traditional heat responding method, the fast active control system of turbine vane tip interval has the advantages of fast response speed, high economical efficiency, asymmetrical deformation, high reliability and long service life. The fast active control system of turbine vane tip interval consists of five parts: turbine casing, regulating sheet and sealing sheet, regulating unit, connecting section and control unit.

Owner:岂兴明 +2

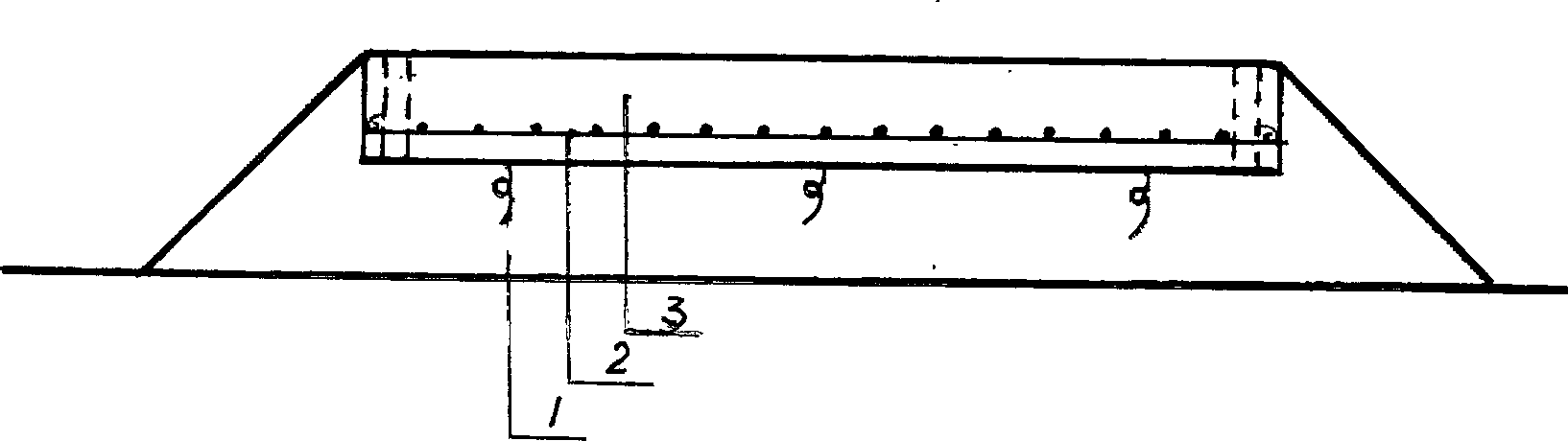

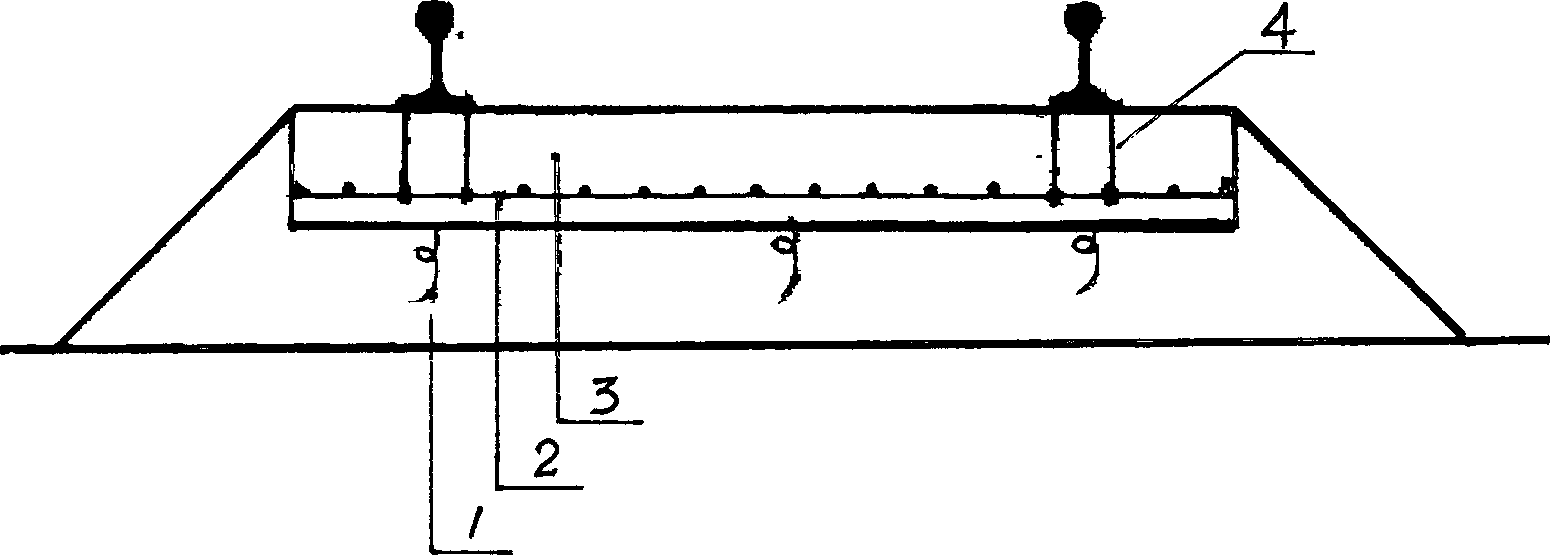

Roadbed structrue for highway and railway and its construction method

InactiveCN1460748ASimple structureImprove waterproof performanceIn situ pavingsReinforced concreteRoad engineering

The roadbed for highroad and railroad only is formed from compacted soil layer and reinforced concrete road surface layer fixedly connected on it, in which the compacted soil layer is the layer-to-layer compacted primary soil layer and the reinforced concrete road surface layer. In the concrete the grilled net reinforcing bars are set, so that said roadbed has good water-proofing property.

Owner:路福昌

Wear-resisting energy-saving agent for lubricating oil, its preparation method and application

The present invention provides an antiwear energy-saving agent containing refined mineral oil, zinc dialkyl dithiophosphate and deactivator for lubricating oil, it possesses excellent functions of reducing friction, reducing wear, resisting rust, resisting corrosion and resisting oxidation, and has strong cleaning dispersing power and good extreme pressure resistance and long-acting lubricating property and excellent compatibility with lubricant. This invention also provides its preparation method and application to lubricating oil and soaking field.

Owner:臧玉蓉 +1

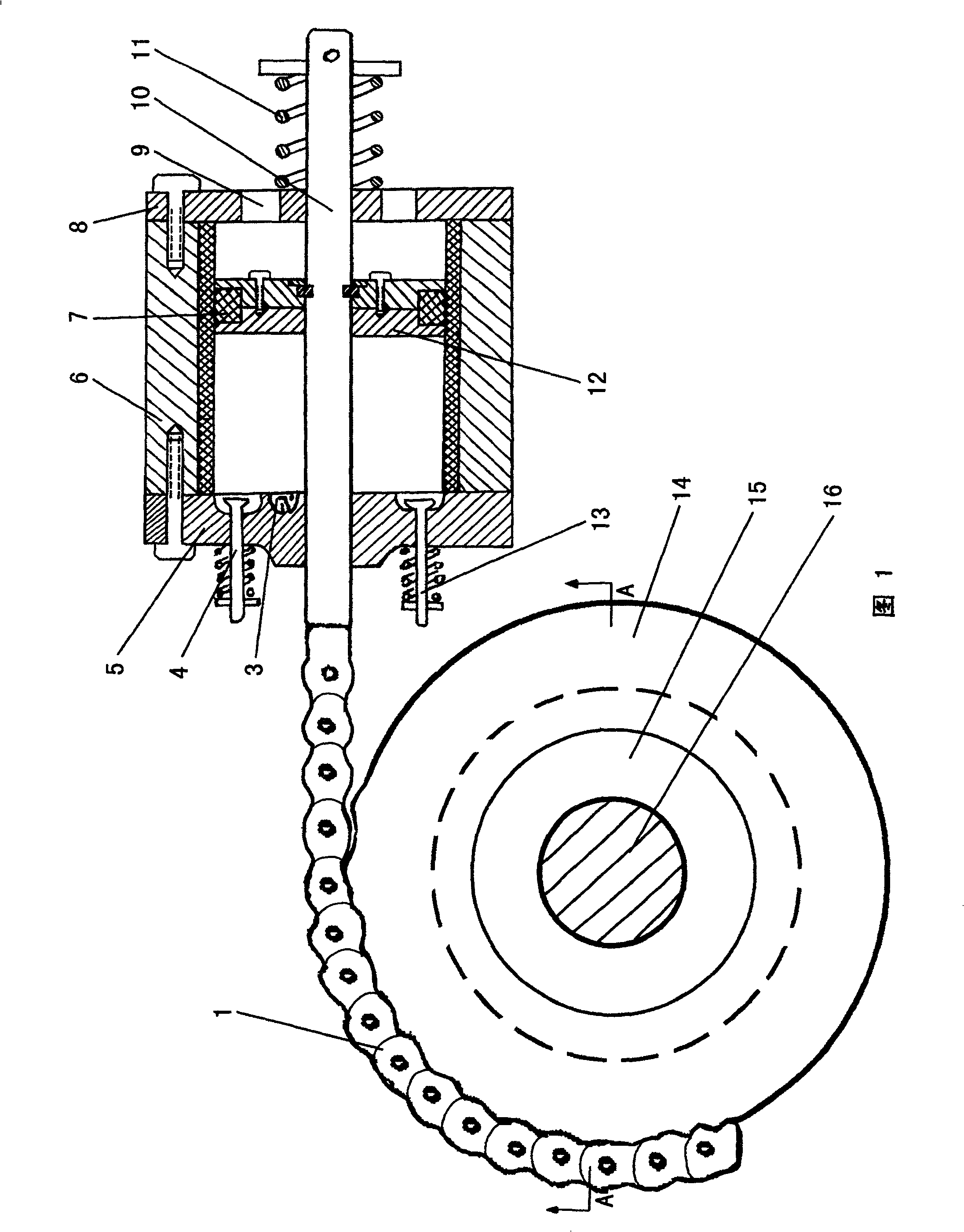

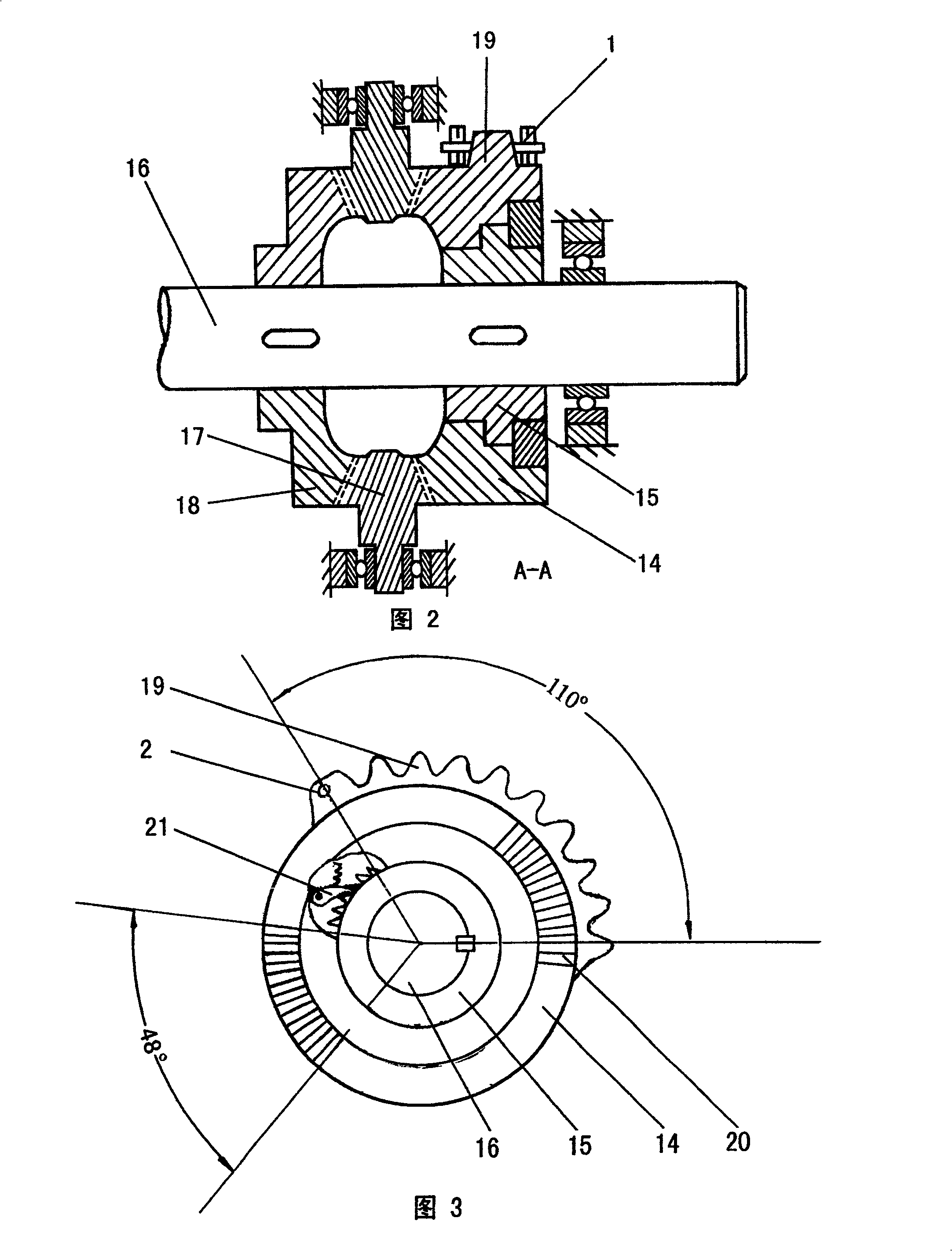

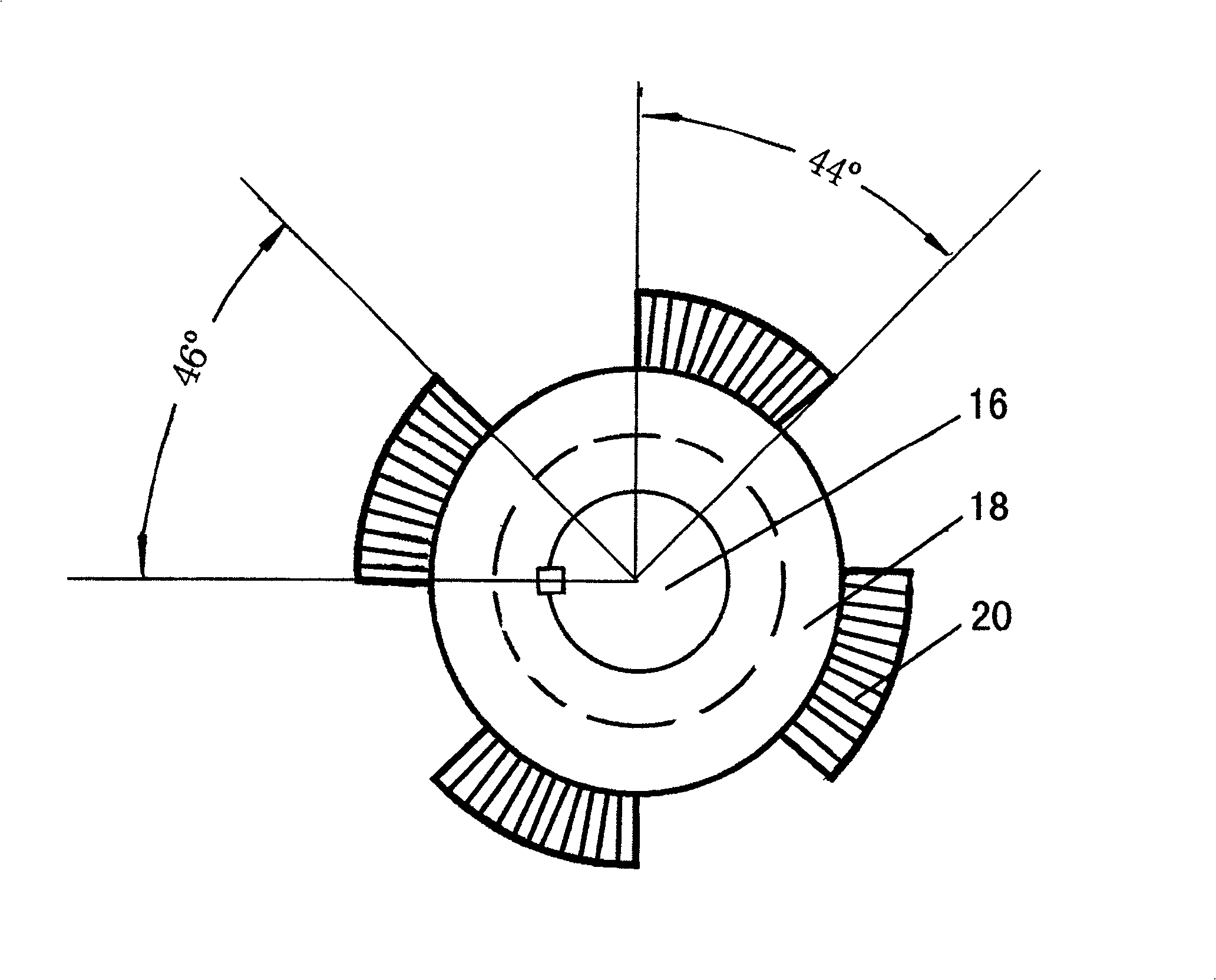

Gasoline engine

InactiveCN100419234CSimple preparation processReasonable exerciseValve arrangementsCylinder headsPower exchangeGasoline

The invention discloses a motor, especially providing a petrol motor with reasonable operation, energy-saving, high exchange efficiency and non-side force component. It is formed by a fuel fire system and a boss axle, wherein, it comprises at least one main axle of main transmission wheel element and a horizontal power cylinder relative to the main transmission wheel element; and one end of piston rod of power cylinder is hinged with the chain on the edge of main transmission wheel element. Compared with present technique, it has more reasonable operation of piston, non-side force component, less abrasion between sleeve and cylinder, and prolonged maintenance period. The tension arm for transmitting torque to the main axle is always in the longest position without dead point to improve the power exchange efficiency, save energy, simplify producing process, and reduce cost. The invention can apply variable fuels as mechanical motor.

Owner:李鱼飞

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

InactiveCN100434499CAutomatically adjust thicknessOptimizing friction pair clearanceAdditivesBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

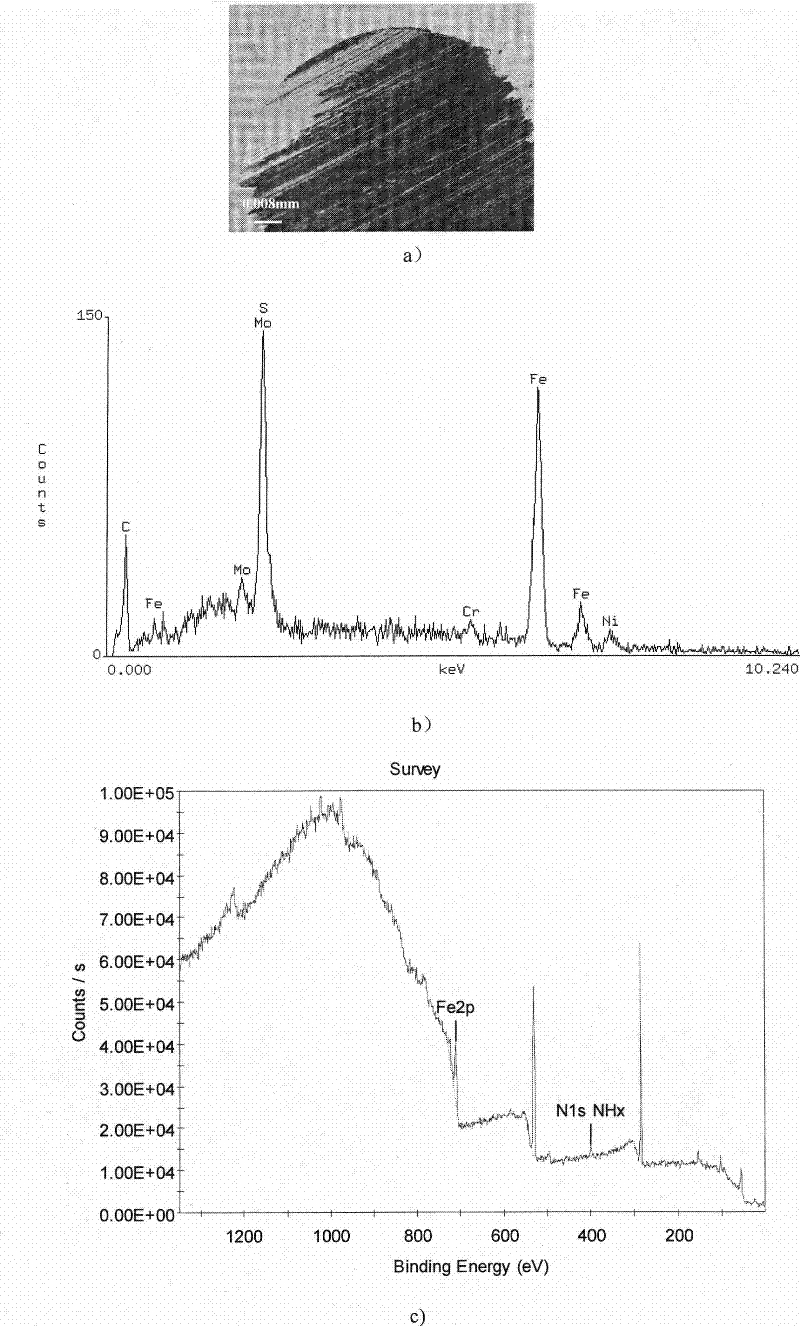

Lubricant additive containing Ni-P powder recycled from electroless plating waste liquid, preparation and application thereof

InactiveCN101747985AExtend oil change intervalsIncrease pressureAdditivesElectroless nickelLiquid waste

The invention discloses a Ni-P alloy nano-powder lubricant additive prepared from nickel and phosphorus recycled from electroless nickel plating waste liquid, and a using method thereof in different friction occasions, wherein Ni-P powder is subjected to in-situ dispersion and recovered from electroless nickel plating waste liquid, dispersed again and then prepared into the lubricant additive through certain steps, together with metal chemical friction modifiers, detergent-dispersant, oxygen corrosion-resistant agents, auxiliary performance regulator, stabilizer and base oil. The lubricant additive has the advantages of good suspension stability, capability of greatly reducing equipment friction and wear, greatly reducing the frequency of equipment maintenance and parts replacement and prolonging equipment lifespan and overhaul time limit, as well as good effect of saving energy and protecting environment. The lubricant additive can be widely used in gasoline / diesel internal combustion engines, general fluid machinery, mechanical chemical sealing pieces, transmission gearboxes and other occasions, can realize the recycling of nickel and phosphorus in the electroless nickel plating waste liquid with high added value in order to change pollutants into useful things, and realizes the coordination and unification of economic, environmental and social benefits.

Owner:NANJING UNIV OF TECH

Precipitation hardening stainless steel of surface laser alloy and its preparation process and application

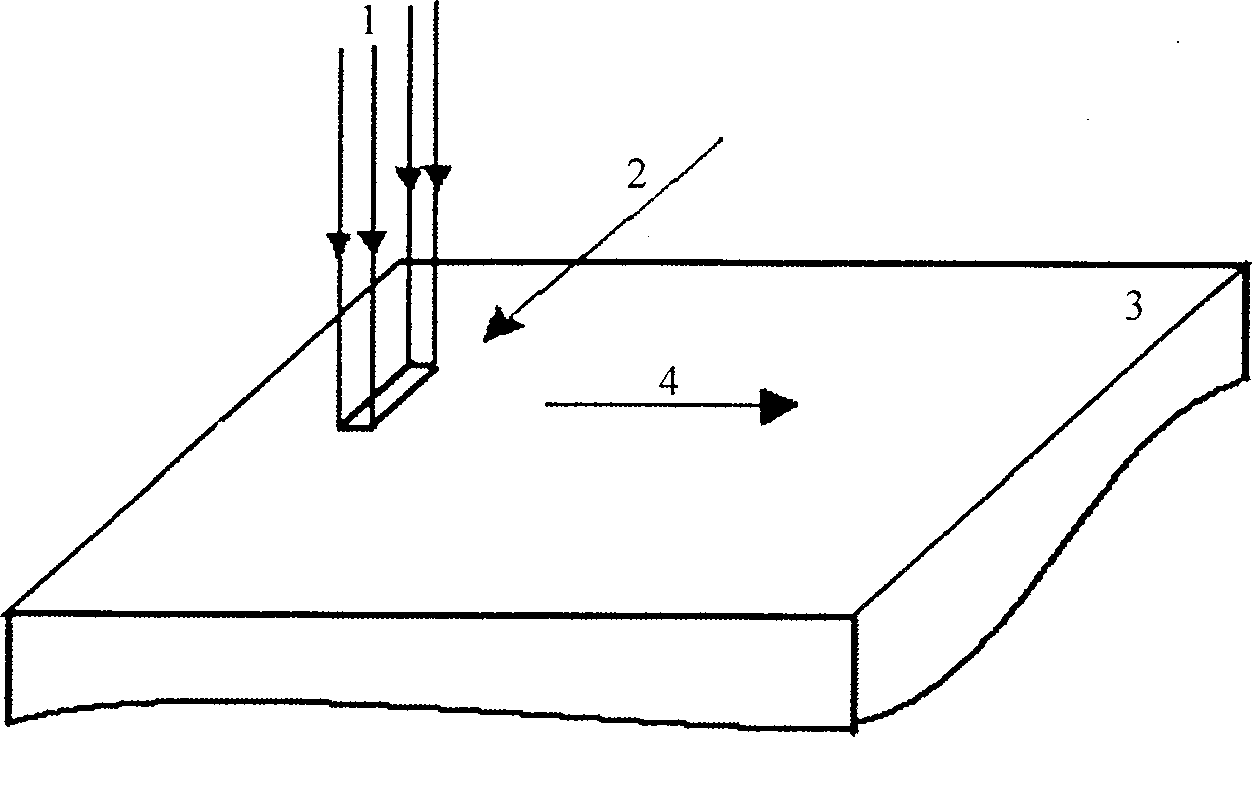

ActiveCN1912182AHigh hardnessImprove surface qualityMetallic material coating processesManufacturing technologySteam turbine blade

The invention relates to a precipitation hardening stainless steel material with laser alloying surface manufacturing technology and its application. It is made up precipitation hardening stainless steel basal body and alloying coating which is processed by alloying technology for paint contains W, Co, Cr, Ni alloy powder. The processed precipitation hardening stainless steel remains original better comprehension mechanical property, and has high surface hardness. Thus it has wide application range. The 17-4PH stainless steel is fit for making turbine blade.

Owner:HANGZHOU BOHUA LASER TECH

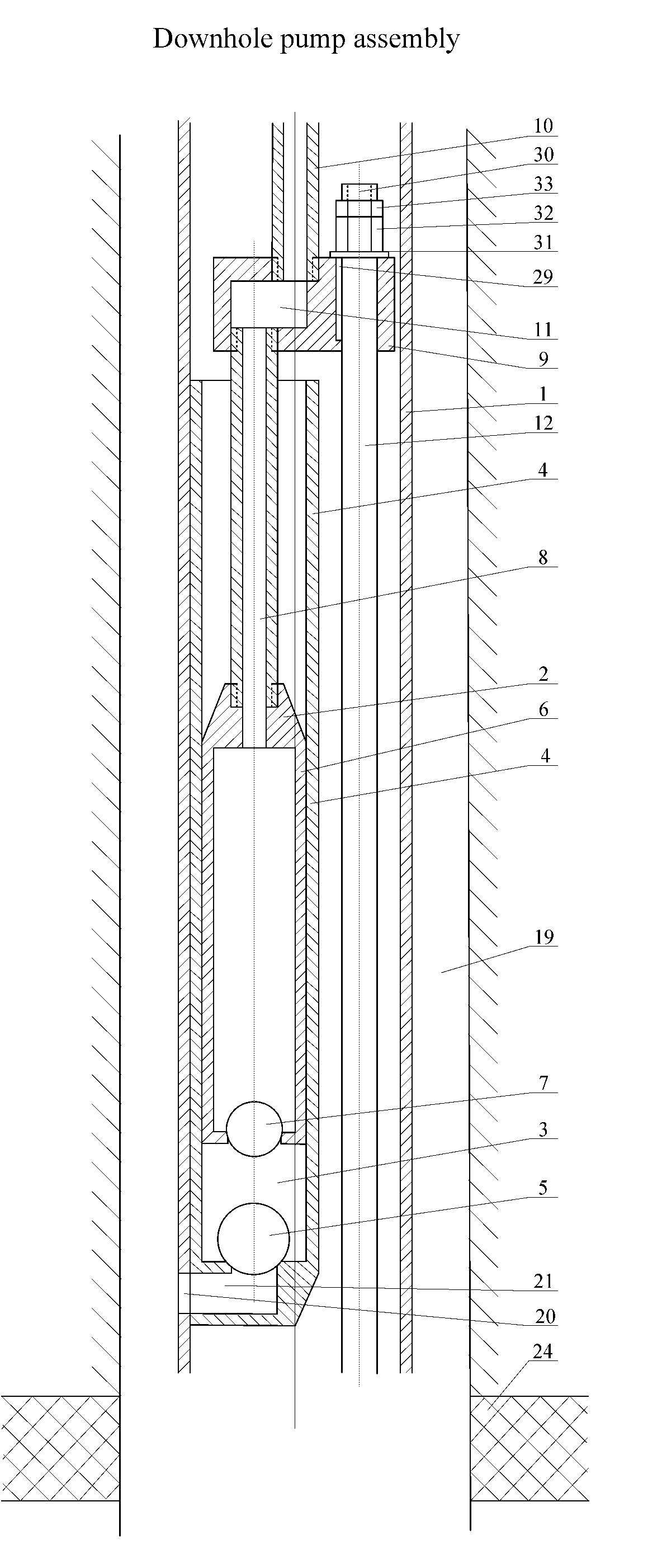

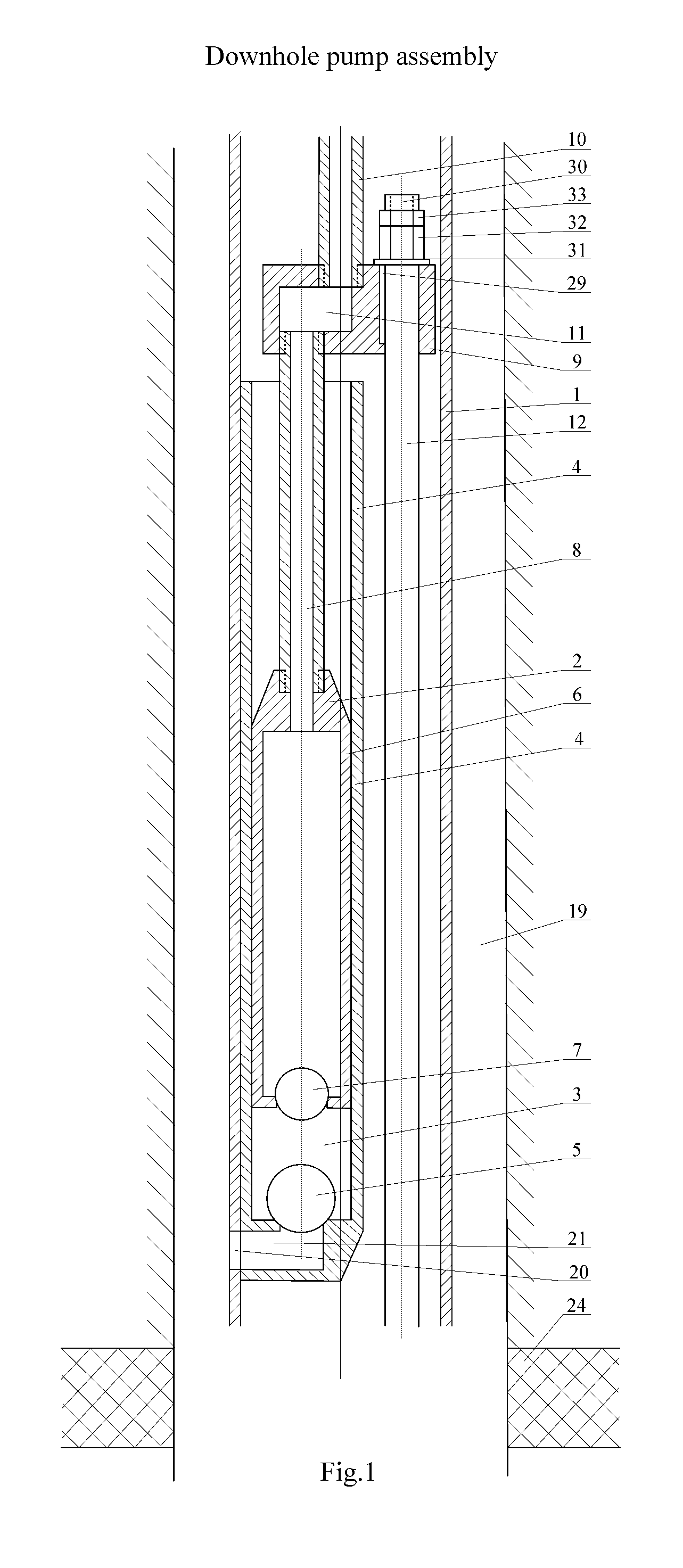

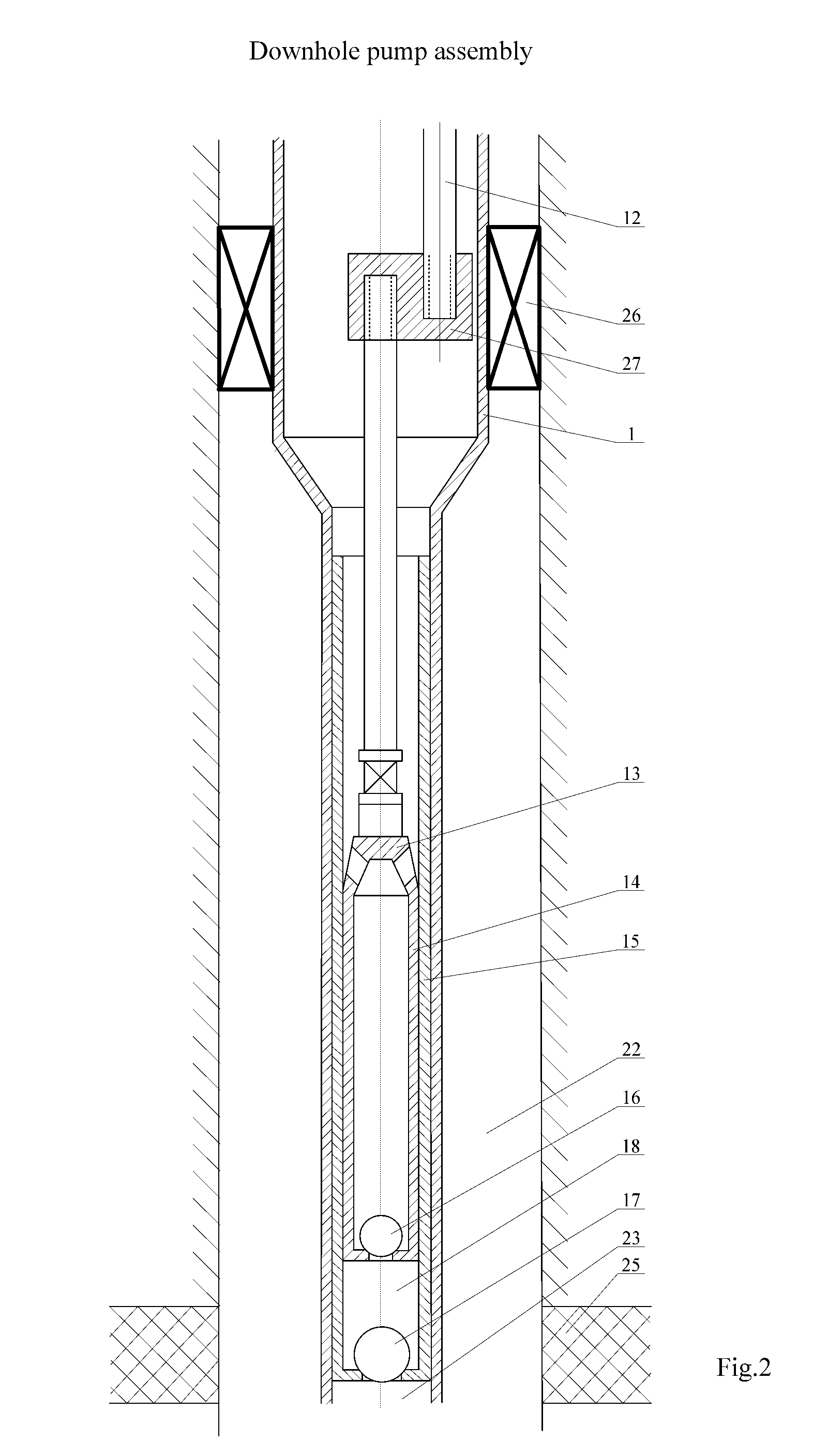

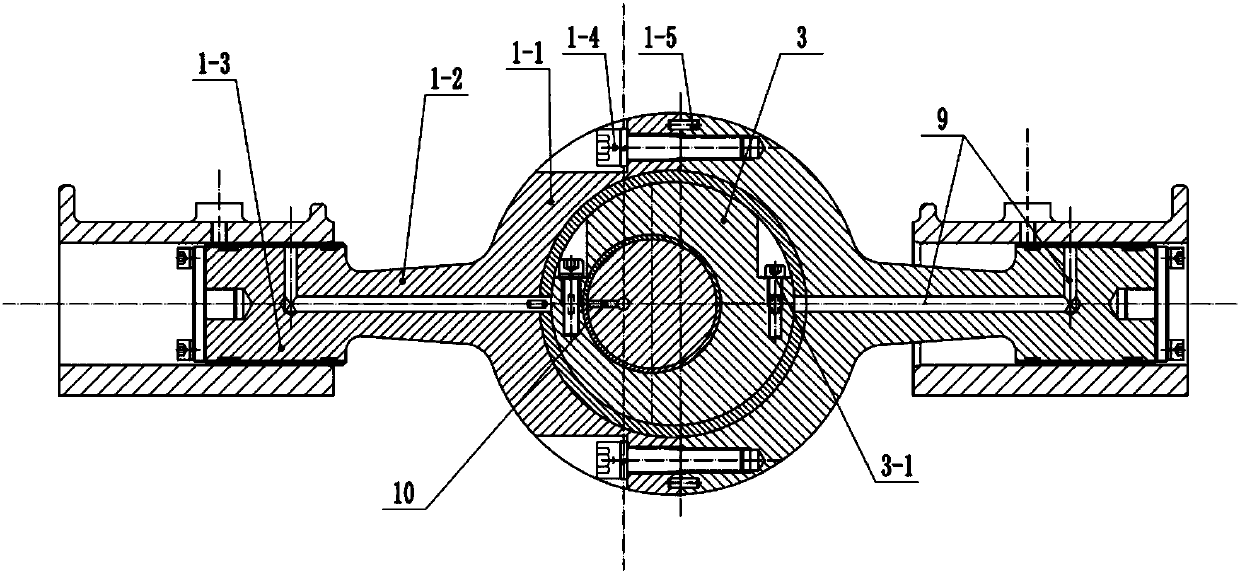

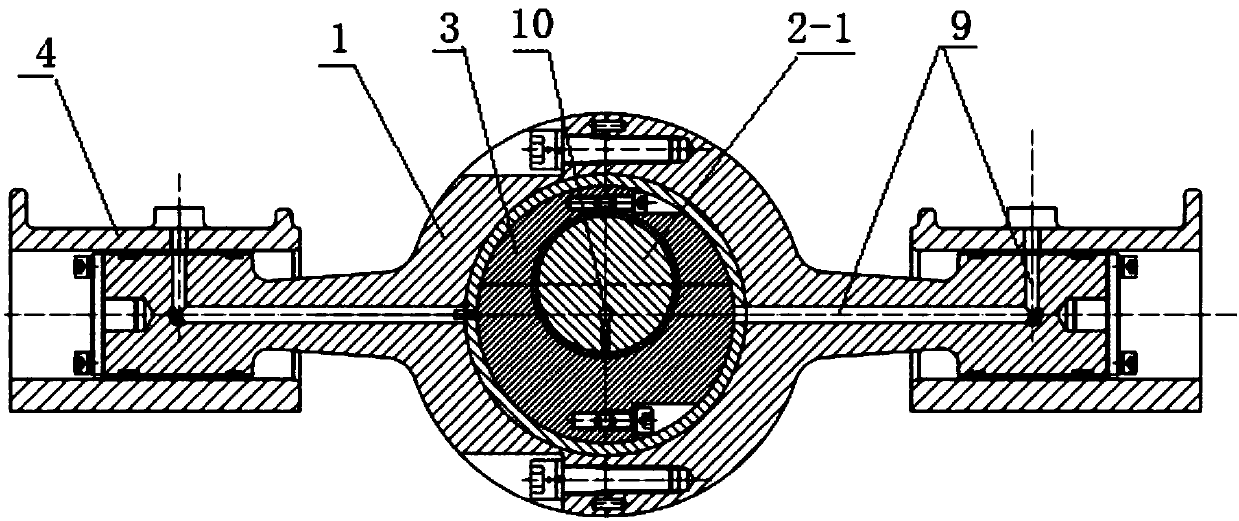

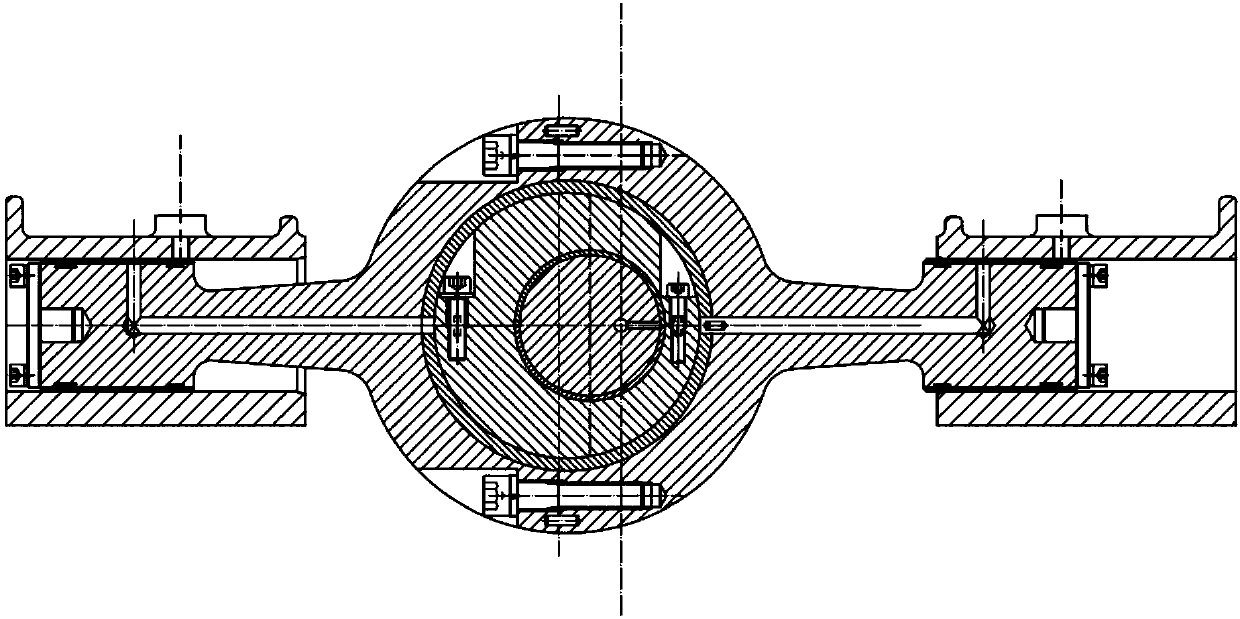

Downhole pump assembly

InactiveUS20140119965A1Operational reliability is increasedExtended overhaul periodFlexible member pumpsFluid removalBody axisReservoir fluid

The invention pertains to oil production pumping equipment in particular to submersible downhole pumps with rod drives to simultaneously and separately lift reservoir fluids to the surface from two reservoirs of a single well. The downhole pump assembly comprises a drive, upper and lower oil-well sucker-rod pumps each connected with its own rod string. In addition to this the unit is equipped with the body, crossbar and joint hollow rod string the latter being attached to the upper part of the crossbar to the bottom of which the rod strings of the upper and lower oil-well sucker-rod pumps are fixed, moreover, the rod string of the upper oil-well sucker-rod pump being made hollow and interconnected with the hollow plunger of the upper oil-well sucker-rod pump and the channel in the crossbar with the joint hollow rod string, and the rod string of the lower oil-well sucker-rod pump is installed between the cylinder of the upper oil-well sucker-rod pump and the downhole pump assembly body, moreover, the upper oil-well sucker-rod pump being offset from the longitudinal downhole pump assembly body axis. Coaxiality of the lower oil-well sucker-rod pump is achieved through the use of the rod crossover shoe, S-shaped rod and non-central pipe sub. The lower plunger pump rod has a shaped cross-section. As a result a standard pumping unit and two oil-well sucker-rod pumps are used and both enhanced reliability of the downhole pump assembly and increased overhaul life of its operation are achieved.

Owner:GABDULLIN RIVENER MUSAVIROVICH

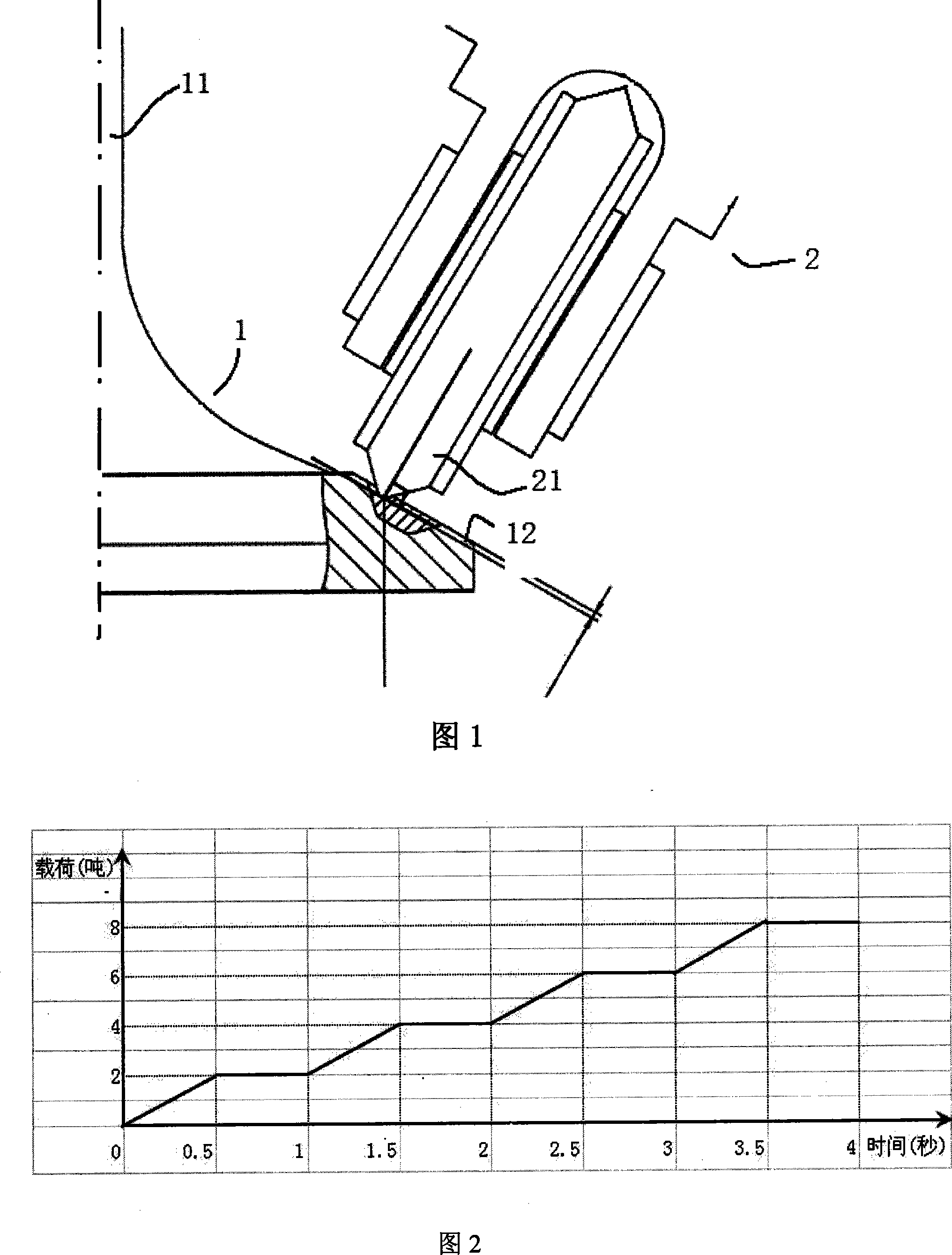

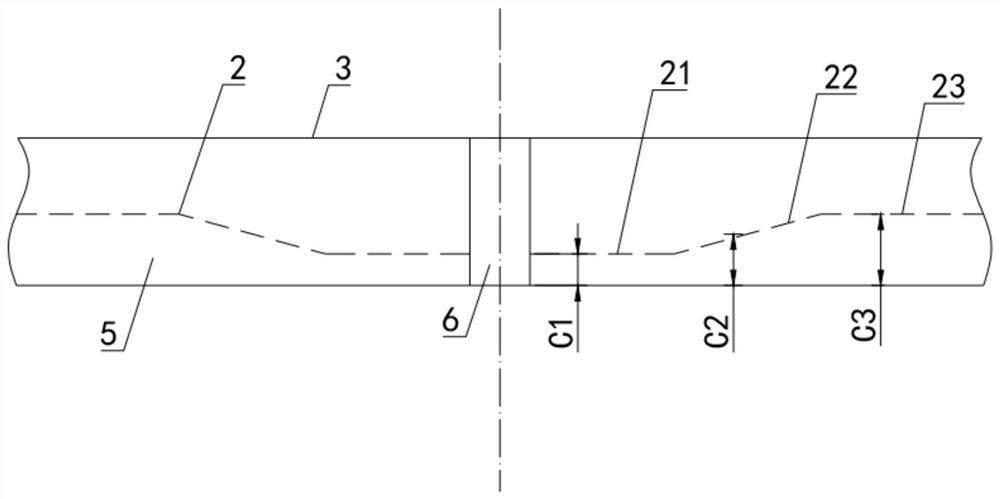

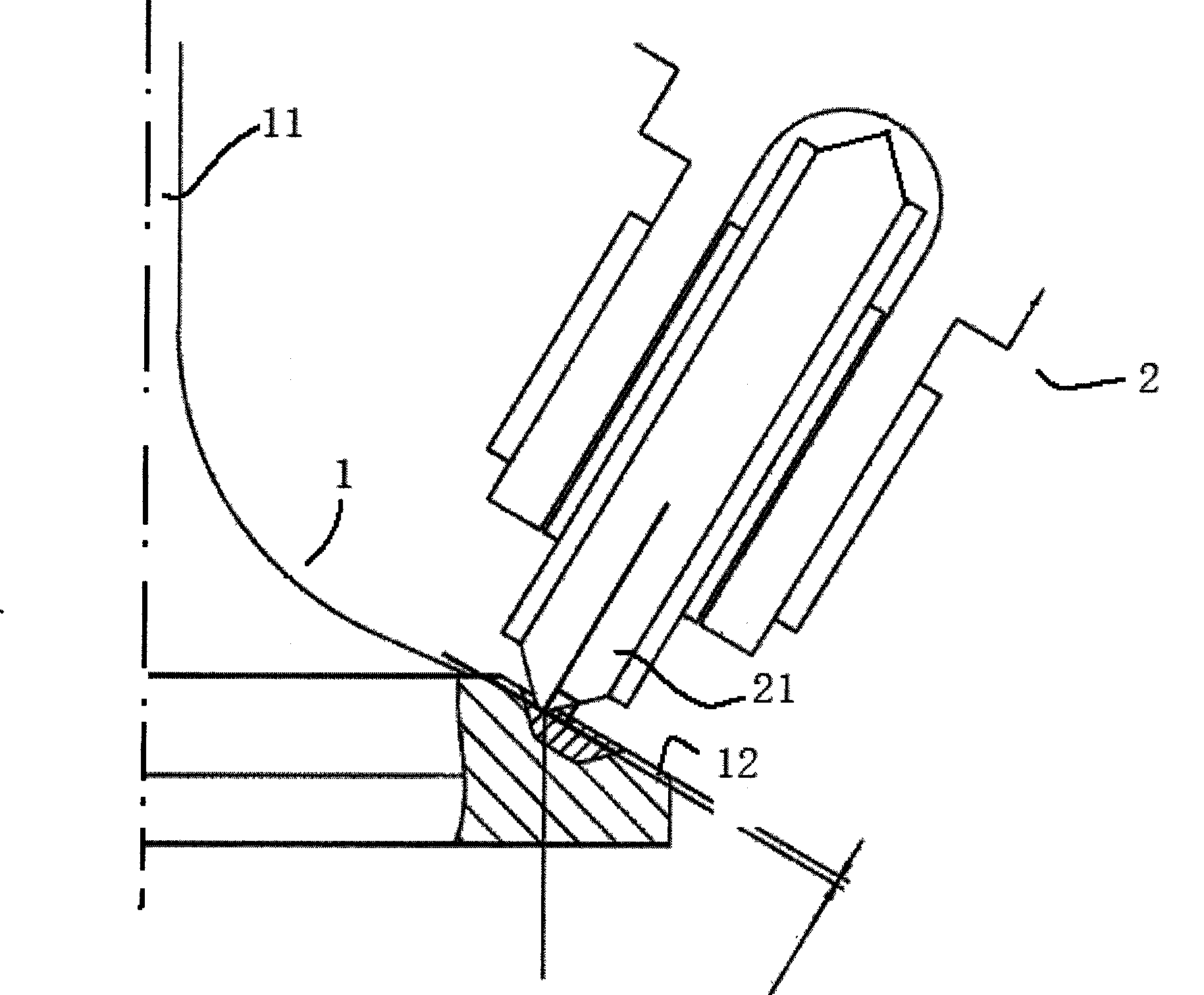

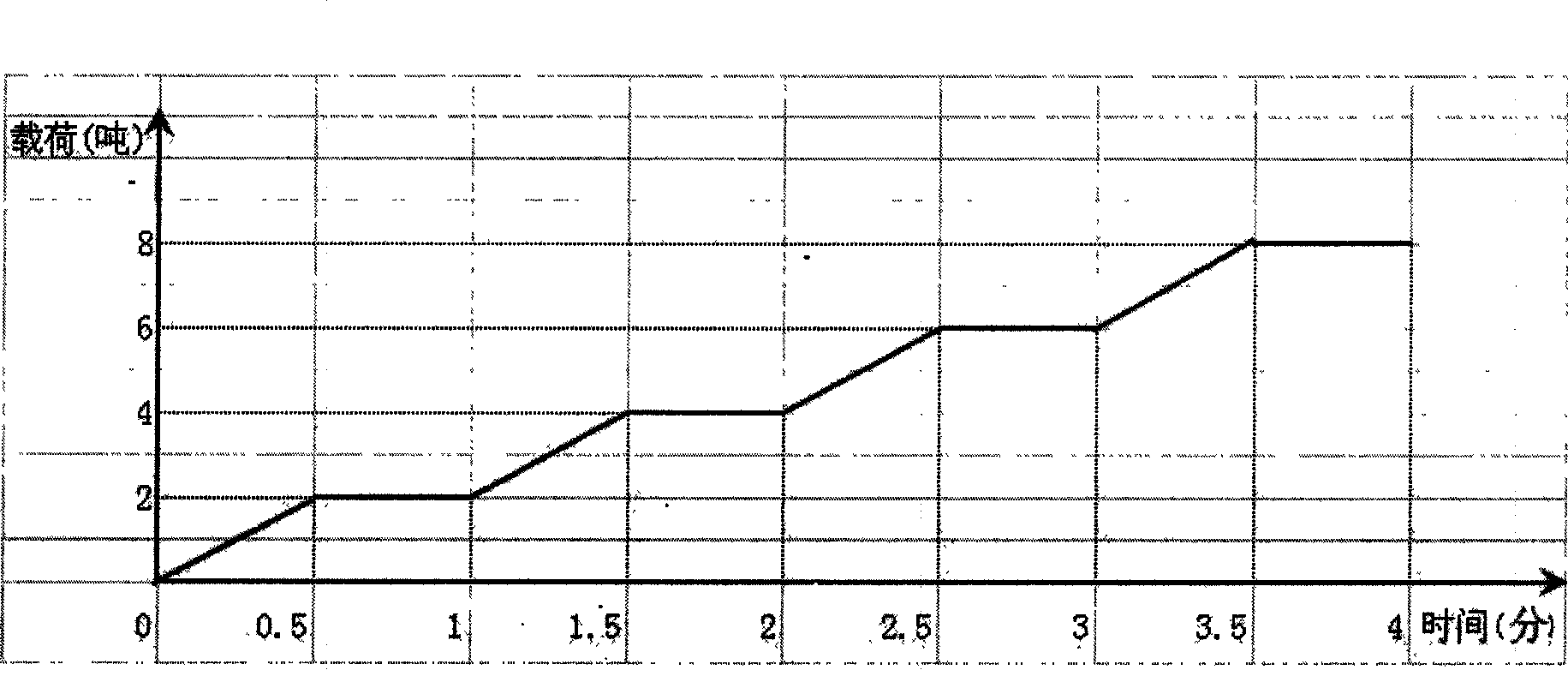

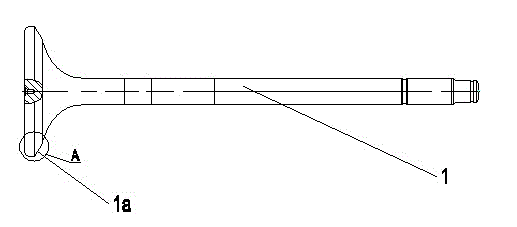

Rolling method for exhaust valve surface

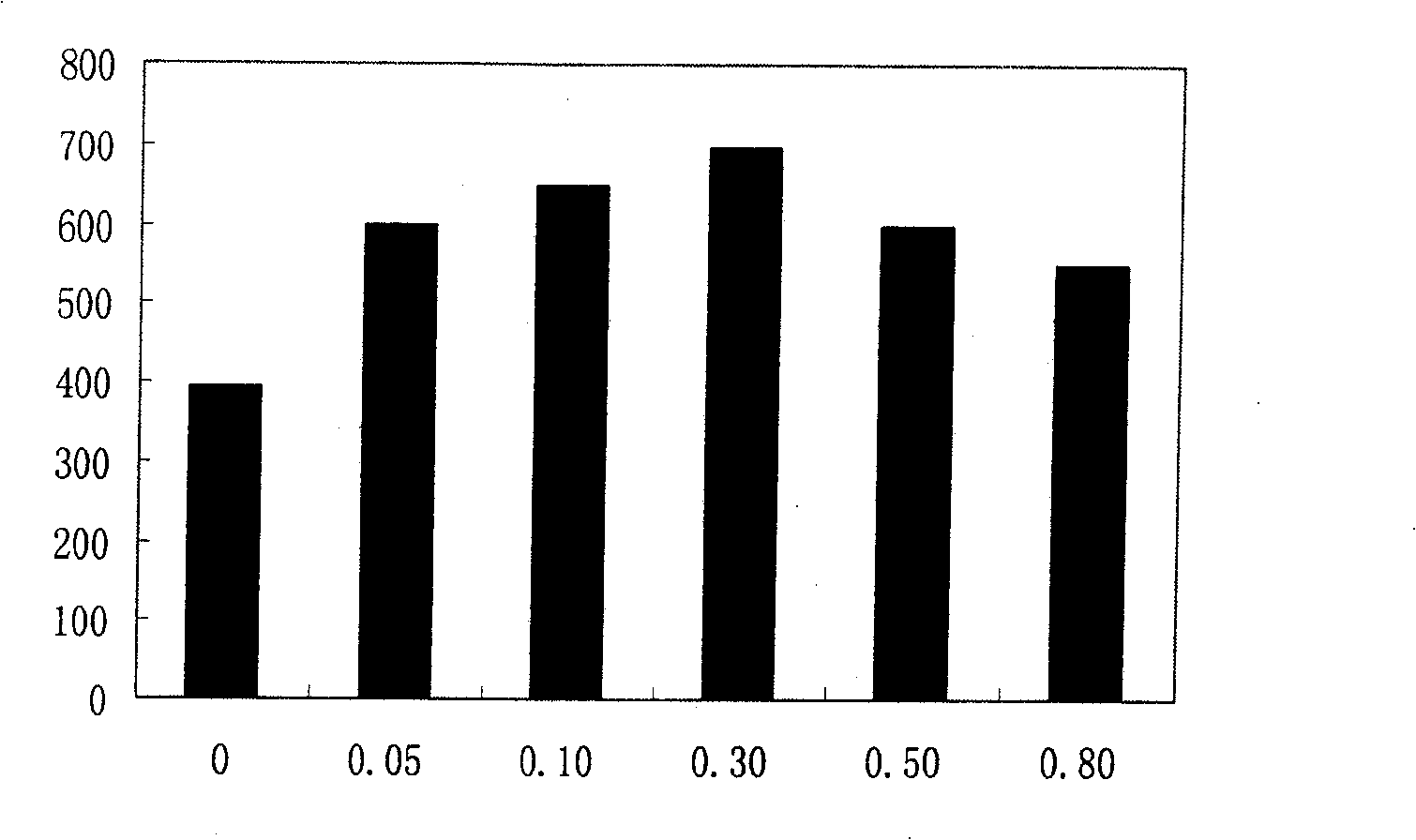

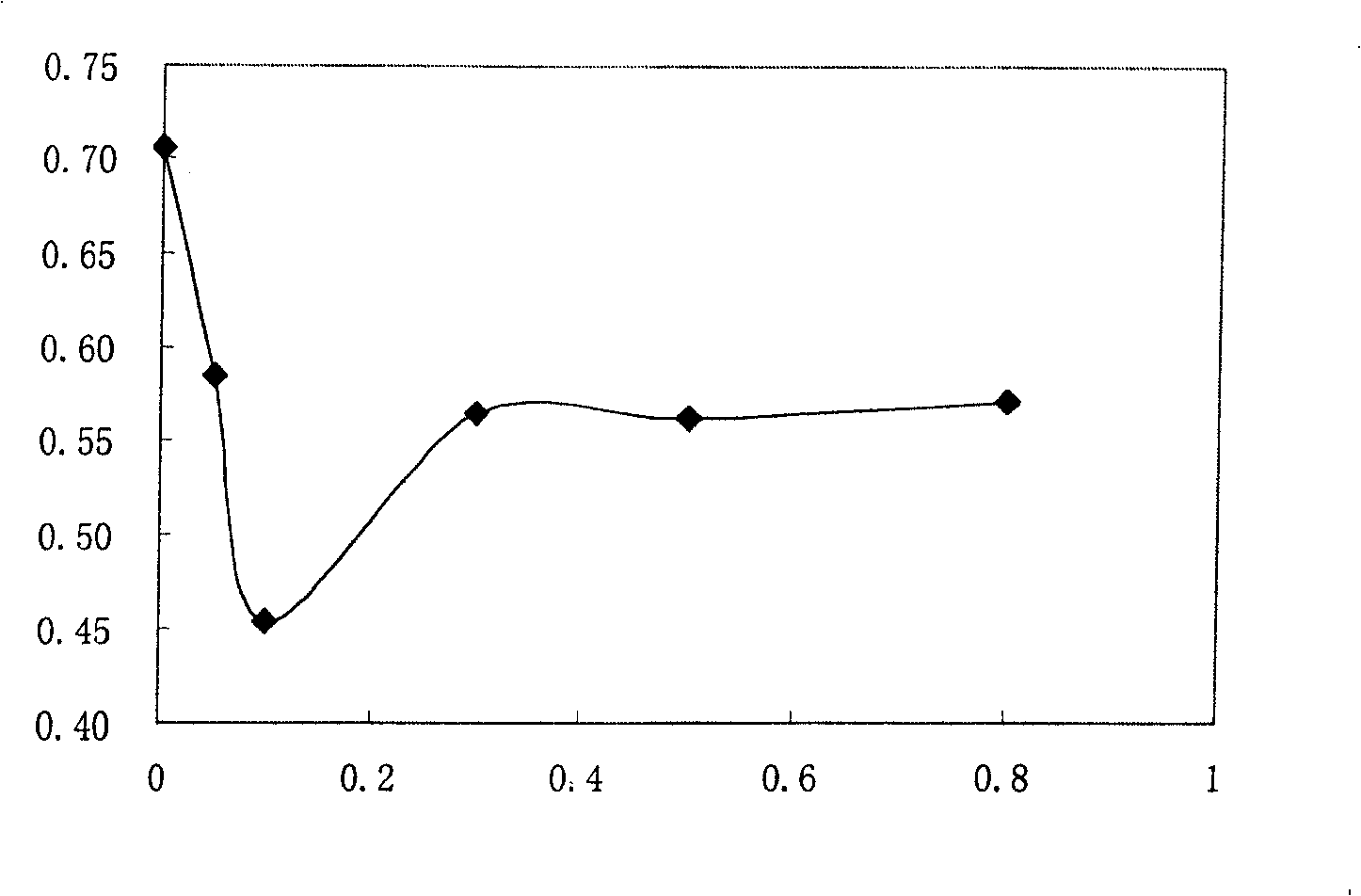

The invention relates to a surface rolling method for vent valves, which comprises the following steps of: fixing a vent valve on the rotary disk of a rolling device, pressing rollers on the surface of the vent valve, and applying pressure on the valve surface by the rollers during rotation process of the vent valve, wherein the pressure application step includes the steps of: aligning the rollers of the rolling device to the inner side of the valve surface, and applying pressure on the valve surface by the rollers in such a process of increasing pressure, holding pressure, increasing pressure, holding pressure,ellipsis, until reaching a maximal pressure; the pressure is generally increased in stepwise; a first groove with a certain depth is formed on the valve surface, and then the rollers are loosened, move to the outer side of the first groove and further roll the valve surface to form a plurality of other grooves; finally, the valve surface with the plurality of grooves provided thereon are processed to remove the margin. According to the invention, the surface hardness of the vent valve can be improved by 80 to 110 HV in comparison with the common rolling method, thus improving the service life of the vent valve by 1 to 3 times.

Owner:HUDONG HEAVY MACHINERY

Lubricating oil contg. additive

A lubricating oil containing additive is characterized by that its additive includes powdered magnesium hydroxysilicate, microtubular magnesium hydroxysilicate, flaky magnesium hydroxy silicate, superfine staple of magnesium hydroxy silicate, microtubular aluminium hydroxysilicate, superfine staple of aluminium oxide and silicon oxide, and flaky aluminium silicate.

Owner:北京劳森兄弟科贸有限公司

Contraposition linear reciprocating pump driving mechanism

PendingCN107642469AEliminate poor lubricationImprove reliabilityPositive displacement pump componentsPositive-displacement liquid enginesEngineeringMechanical engineering

The invention discloses a contraposition linear reciprocating pump driving mechanism. The contraposition linear reciprocating pump driving mechanism comprises a slide block mechanism, a crankshaft andan eccentric slide block, wherein the slide block mechanism is composed of a slide block, two connection rods and two pistons, and the central axis of the two pistons is orthogonal to that of the slide block; a crank throw of the crankshaft is sleeved with the eccentric slide block, the slide block concentrically sleeves the eccentric slide block, and the pistons are coaxially inserted into two symmetric slide ways on a reciprocating pump rack; the eccentric slide block rotates on the axis of the slide block around the crank throw while following the crank throw to rotate around the crankshaft, in the entire rotation process, the center axis of the eccentric slide block is maintained parallel to the center axis of the crank throw all the time, so that the movement trail of the eccentric slide block in the horizontal direction is approximately linear, through the eccentric slide block, the slide block is driven to conduct linear movement, and then the two pistons conduct reciprocatinglinear movement in the two symmetric slide ways of the reciprocating pump respectively.

Owner:宝鸡航天动力泵业有限公司

Precipitation hardening stainless steel of surface laser alloy and its preparation process and application

ActiveCN100500940CHigh hardnessImprove surface qualityMetallic material coating processesManufacturing technologySteam turbine blade

The invention relates to a precipitation hardening stainless steel material with laser alloying surface manufacturing technology and its application. It is made up precipitation hardening stainless steel basal body and alloying coating which is processed by alloying technology for paint contains W, Co, Cr, Ni alloy powder. The processed precipitation hardening stainless steel remains original better comprehension mechanical property, and has high surface hardness. Thus it has wide application range. The 17-4PH stainless steel is fit for making turbine blade.

Owner:HANGZHOU BOHUA LASER TECH

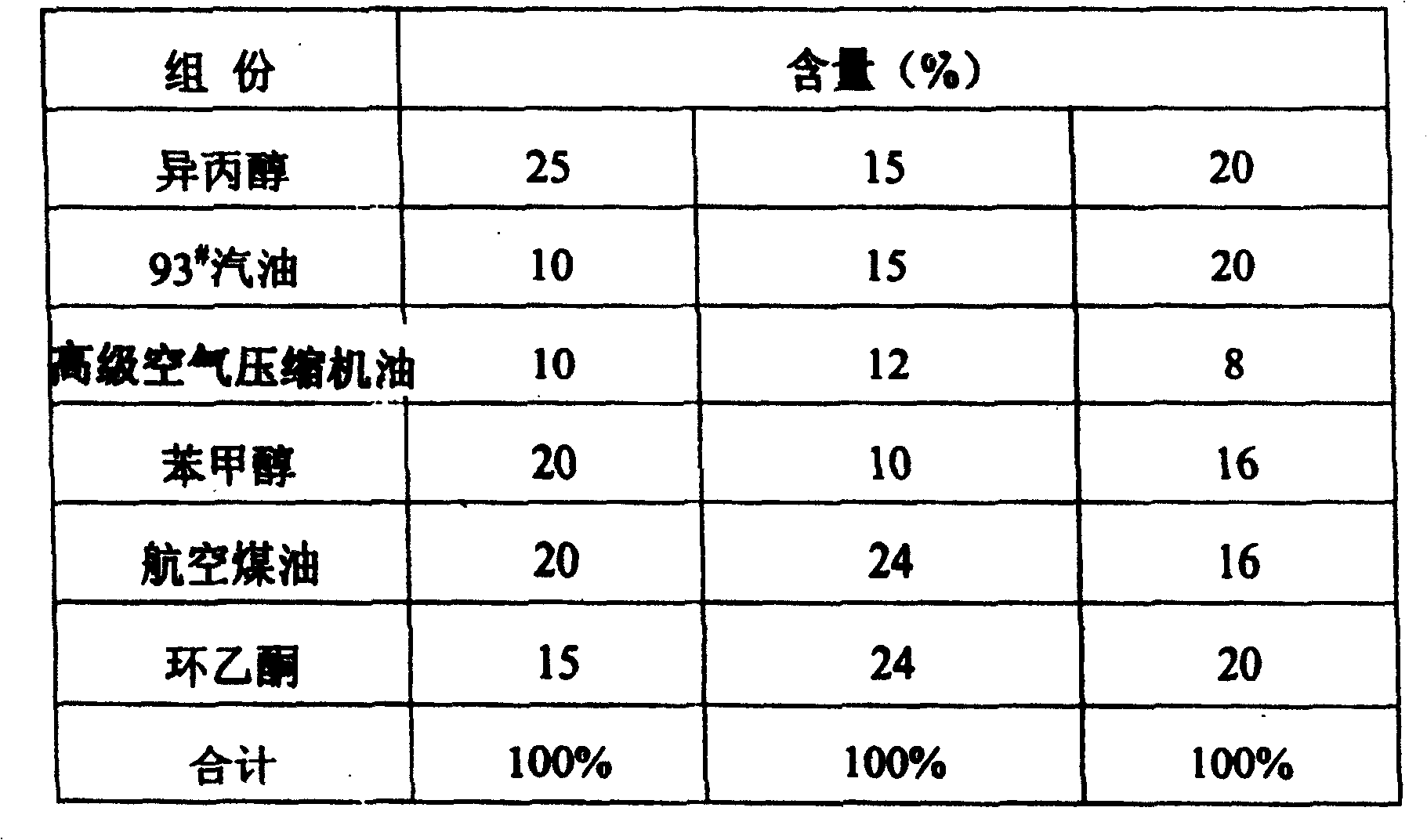

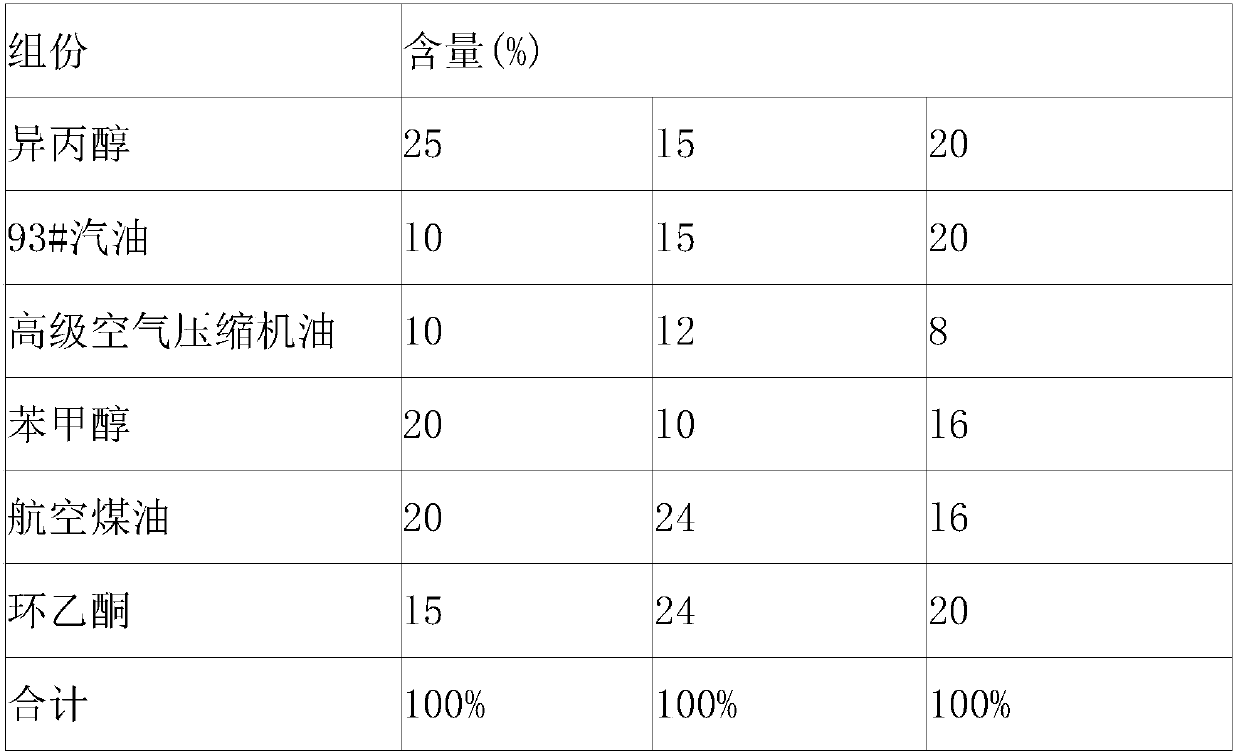

Process for environment protectional energy-saving diesel additive

The invention relates to a process for preparing environmental friendly diesel fuel additive comprising, placing alcohol isopropylicum into reaction kettle, mixing with 93# gasoline, after 1.5-2.5 hrs, continuing charging in phenylmethanol and mixing, obtaining solution A, placing plane kerosene (D40) into another reaction kettle, mixing with cyclohexanone to obtain solution B, after 8-14 hours, mixing solution an and B, filtering 2-5 times.

Owner:刘恩祥

Additive-containing lubricating oil

The invention discloses an additive-containing lubricating oil. The weight-to-volume ratio of additives to lubricating oil is 7.5-12.5 mg / L. The additives comprise 20% of potassium oxide, 25% of magnesium hydroxysilicate powder, 10% of fine silicon oxide short fiber, 20% of shredded aluminum silicate and 25% of sodium hydroxide. The chemical composition of the magnesium hydroxysilicate powder is Mg,Si,O,o(OH), and the powder particle diameter is less than 5 mu m; the chemical composition of the fine silicon oxide short fiber is SiO, the diameter is less than 1 mu m, and the length is less than 20 L; and the thickness of the shredded aluminum silicate is less than 2 mu m, and the plane size is less than 6 mu m. The additives in the lubricating oil can be directly added into the lubricating oil, or added into the lubricating oil after adding the additives into various greases to prepare a liquid or viscous cream, or directly added to the frictional part surface in other modes.

Owner:钟长涛

Automobile nutrient

InactiveCN106753617AIncrease kinetic energyLess smokeLiquid carbonaceous fuelsFuel additivesEngine powerN-Butyl Alcohol

The invention discloses an automobile nutrient which contains the following components in percentage by mass: 8-12% of ferrocene, 8-15% of triethanolamine, 6-12% of Tween 80, 20-30% of cosolvent and 30-40% of higher alcohol, wherein the cosolvent contains gasoline and oleic acid, and the higher alcohol contains methanol, n-butyl alcohol and ethylene glycol. According to the invention, the fuel system can be automatically cleaned, the engine ignition failure and unstable idle speed caused by carbon deposition are reduced, the fuel can be saved by 5-15%, the kinetic energy is increased by 10-20%, the smoke emission is reduced by 80-95%, 80-90% of carbon deposition is eliminated, an engine protection film is effectively formed, the engine power and fuel economy are improved, the engine oil is saved by 20-40%, the time and maintenance cost are saved, the overhaul period of engine is prolonged, the low-temperature start efficiency is enhanced, fuel label is raised, the fuel combustion efficiency is increased, the PM2.5 emission is reduced, and environmental pollution is relieved.

Owner:甘肃华一新能源科技有限公司

Engine cleaning oil

ActiveCN100449037CPerfect protection functionImprove anti-rust and anti-wear functionRegulation temperaturePreservative

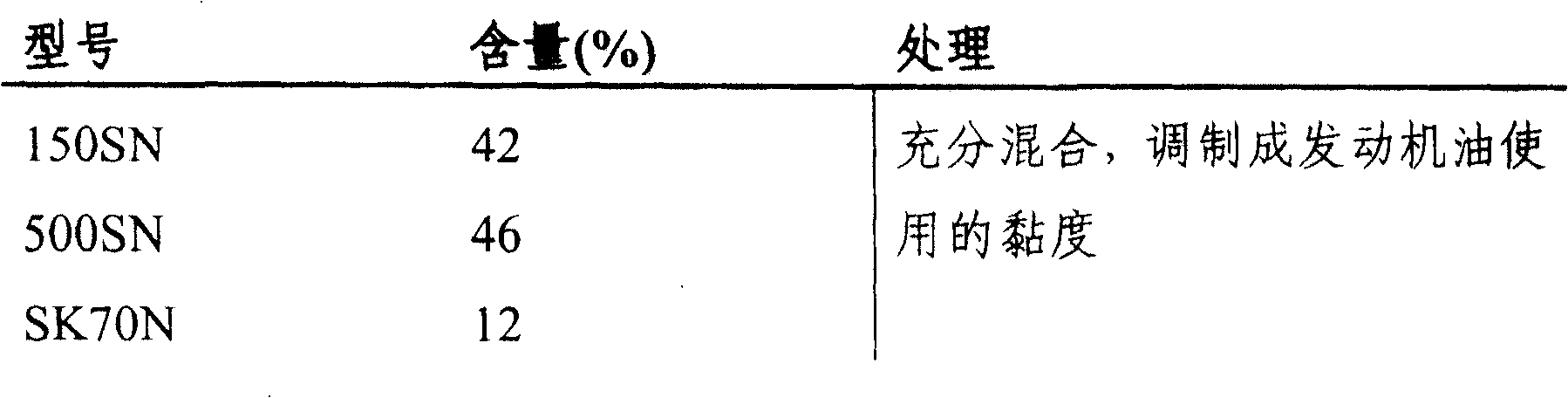

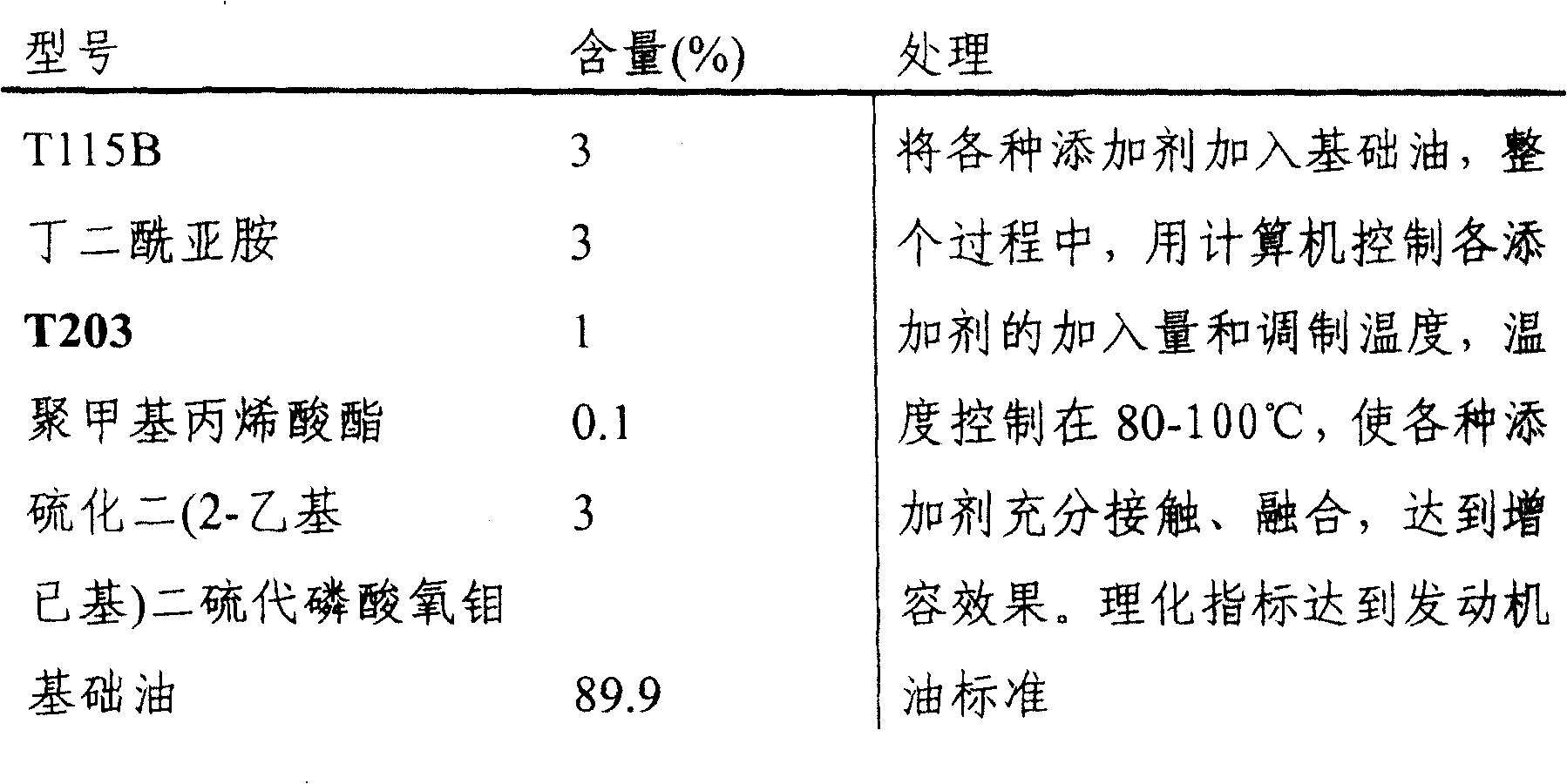

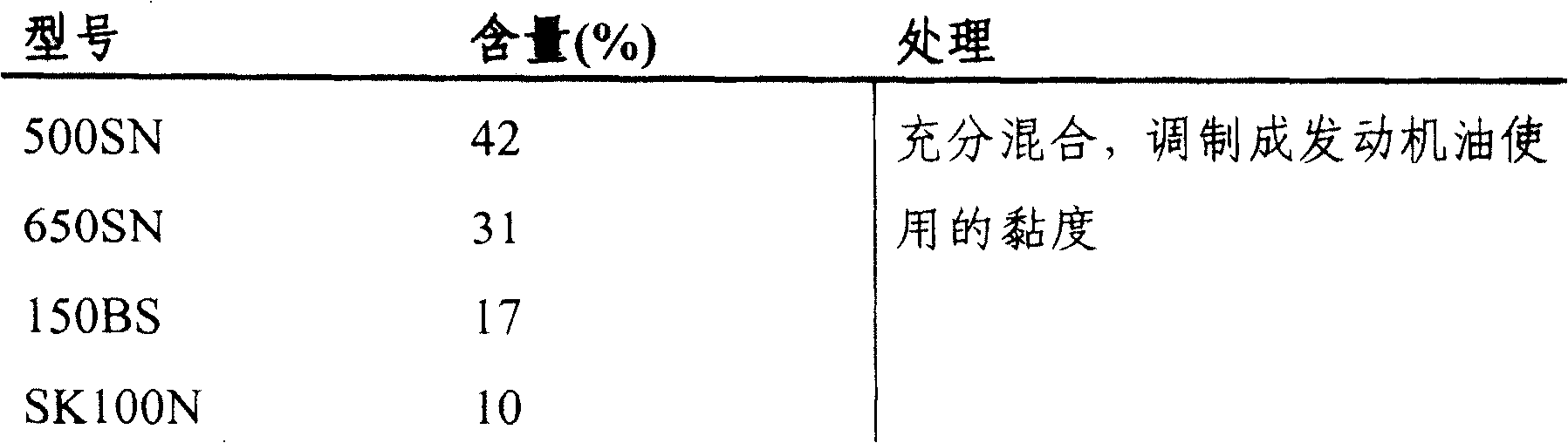

This invention relates to new cleaning oil for engines, which is composed of one or many of ordinary motor-oils as the basic oil: 150SN, 500SN, 650SN, 150BS and advanced motor-oil from south Korea: SK70n, SK150N, and SK100N, anticorrosive, oxidation inhibitor, antiwear agent, detersive pour-point depressant and freely selected defoamer agent. In preparation, a computer is used to control the volume of the additives and the regulation temperature so that, they can fully contact with each other and interfuse with each other to get the target of the engine oil standard.

Owner:孙国中

Metal/ ceramic nano composite additive of self-rehabilitation and its preparation method

InactiveCN100445353CCompensation for wearReduce self-healing timeAdditivesBase-materialsMachine partsAntioxidant

The invention relates to a metal / ceramic nanocomposite self-healing additive, which is made of metal nanopowder and nanoscale natural ore powder as the main raw materials, supplemented with cleaning and dispersing agents, catalysts, antioxidants, solvents and other materials after certain process conditions and High-performance nanocomposite self-healing additives for lubricating oils, greases or ultrasonic media made in the production step. Its advantage is that it can quickly form a high-hardness metallurgical bonded self-repairing protective layer on the surface of various metal friction pairs, and automatically adjust the thickness of the self-repairing protective layer according to the friction force and the friction pair gap, so as to optimize the friction pair gap and significantly improve The physical and chemical properties of the surface of the friction pair, energy saving and environmental protection, greatly prolong the service life of machine parts and the period of machine overhaul. The invention is widely used in improving the lubricating performance of the friction pair.

Owner:JIANGSU MOLEDN PETROCHEM

Heat-absorption anticorrosive energy-saving coating, preparation method thereof and use method of coating

ActiveCN107641342AGood heat absorptionStrong anti-corrosion functionChemical industryAnti-corrosive paintsSolventBrown iron oxide

The invention relates to a coating, in particular to a heat-absorption anticorrosive energy-saving coating, a preparation method thereof and a use method of the coating. The coating comprises, by weight, 10-30 parts of boron nitride, 20-40 parts of corundum, 20-40 parts of brown aluminum oxide, 10-20 parts of talcum powder, 5-10 parts of graphene, 10-30 parts of iron oxide red, 10-30 parts of ironoxide black and water glass solvents. The preparation method of the coating includes the steps: placing the materials into a container according to proportion; uniformly mixing the materials; gradually and slowly adding triple water glass solvents; stirring mixture for 4-6 minutes when the water glass solvents are added. The use method of the coating includes the steps: cleaning up coated surfaces; coating or spraying the surface with 0.1-0.3 millimeters of the coating. The coating is good in heat-absorption effect and high in anticorrosive function, the service life of a boiler can be prolonged, and heat conduction is facilitated.

Owner:王珩

Preparation method of high-and-low-temperature-resistant micro-nano lubricating material

InactiveCN106190502AIncrease frictionReduce coefficient of frictionLubricant compositionMicro nanoOxyacetylene torch

The invention discloses a preparation method of a high-and-low-temperature-resistant micro-nano lubricating material, and belongs to the technical field of lubricating materials. According to the method, firstly, cobalt nitrate and iron nitrate are dissolved and mixed; evaporative crystallization is performed to obtain uniform crystals; then, the uniform crystals are mixed with urea; through ball milling, mixed crystal powder is obtained; cooled marsh gas liquid is used as a cooling medium; oxygen is used as conveying gas; the mixed crystal powder is subjected to meltallizing in a high-energy flame spray gun through an oxyacetylene torch and enters the cooling medium to obtain micro-nano scale hollow microsphere powder; the hollow microsphere powder is uniformly mixed with surfactants such as Tween-20, and polyoxyethylene lauryl ether through heating; then, the mixture is uniformly dispersed with basic oil through ultrasound when the mixture is still hot; cooling is performed, so that the hollow microsphere powder absorbs lubricating oil; then, the temperature is raised again, and the cooling is performed again; the absorption is further performed; after the curing, the high-and-low-temperature-resistant micro-nano lubricating material is obtained. The obtained lubricating material has the advantages that the uniform dispersion is performed in high-temperature environment; the oxidation cannot easily occur; the adhesion does not occur under a low-temperature condition; the lubricating performance is excellent; wide application values are realized.

Owner:陕西天工云科智能科技有限公司

Preparation raw materials and method of antiwear protective agent of engine

InactiveCN103897776AReduce coefficient of frictionImprove extreme pressure performanceAdditivesSuccinic acidHigh pressure

The invention discloses preparation raw materials and a method of an antiwear protective agent of an engine. The preparation raw materials comprise the following materials in parts by mass: 50-100 parts of lubricating oil, 10-20 parts of chlorinated paraffin, 5-10 parts of dibutyl phosphate, 5-10 parts of vulcanized oil, 2-5 parts of alkenyl succinic acid, and 2-5 parts of petroleum calcium sulfonate. The prepared protective agent has the advantages that (1) a firm lubrication protective film capable of bearing high temperature and high pressure can be formed on the frictional surface, the friction coefficient is small and the extreme pressure property is high; (2) due to the added anti-corrosion material, the corrosion of an extreme-press antiwear powder dispersion product can be prevented; (3) after being practically applied to the surface on site, the protective agent can reduce the afterburnt and engine oil consumption, the wear of an air cylinder can be reduced, the airtightness of the air cylinder can be enhanced, the overhaul period of vehicles can be prolonged, the starting and acceleration can be improved, noise can be reduced, the emission of black smoke can be eliminated, and the environmental pollution can be reduced; (4) after the protective agent is added in engine oil of the engine, a layer of film can be formed on the frictional surface, so that the friction can be reduced, the direct contact with metal can be prevented, and further the friction damage can be decreased.

Owner:SOUTHEAST UNIV

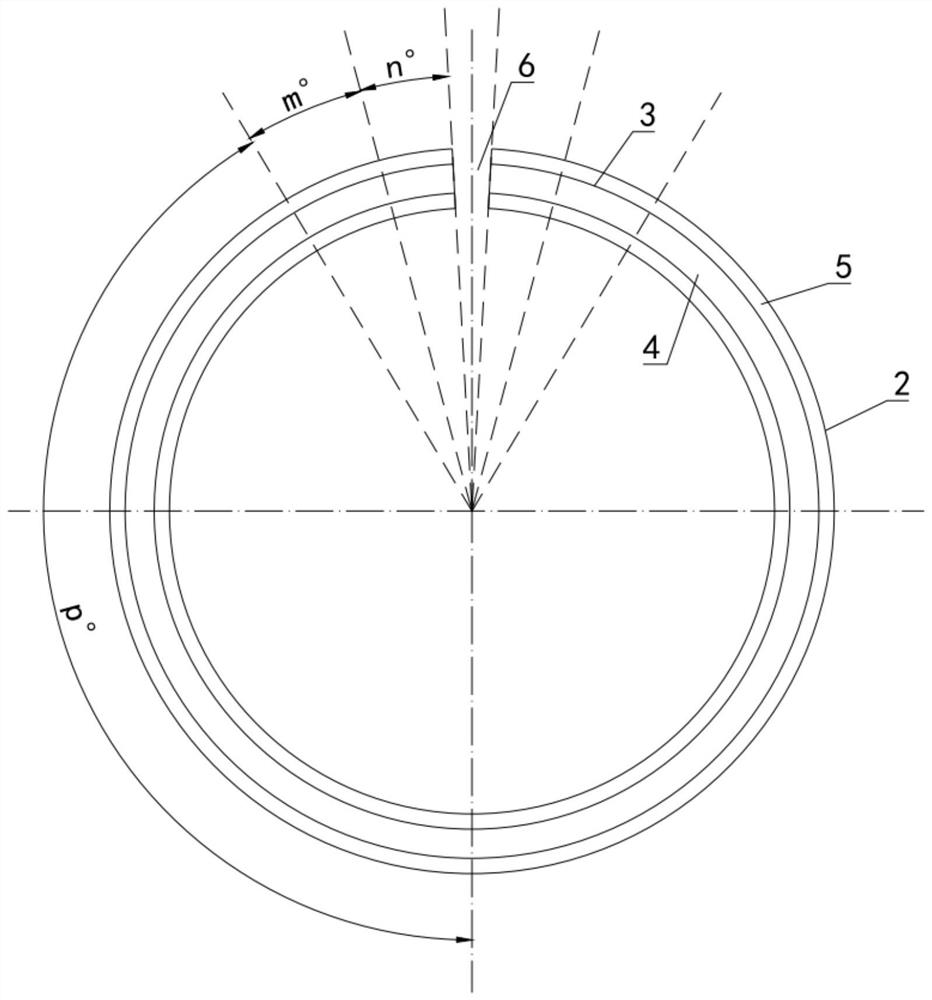

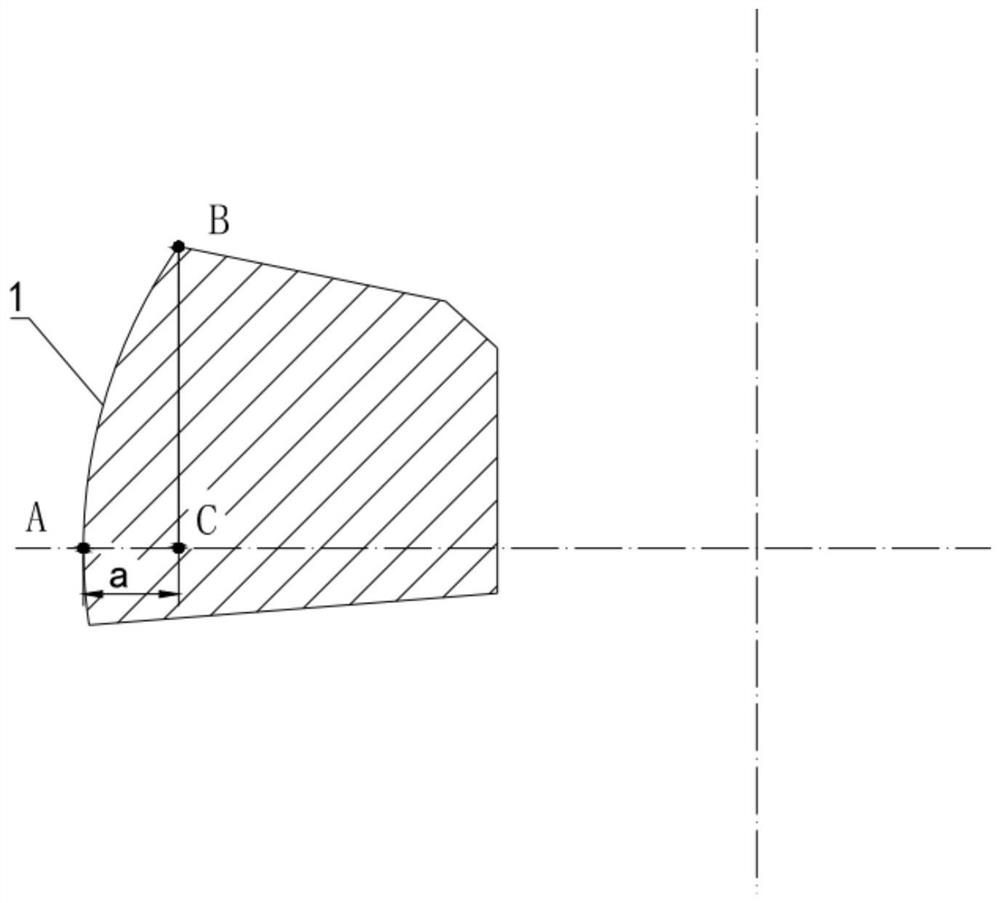

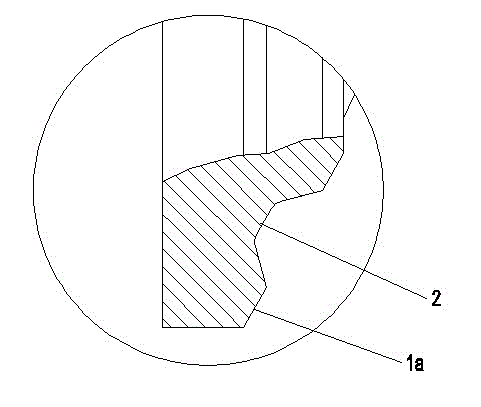

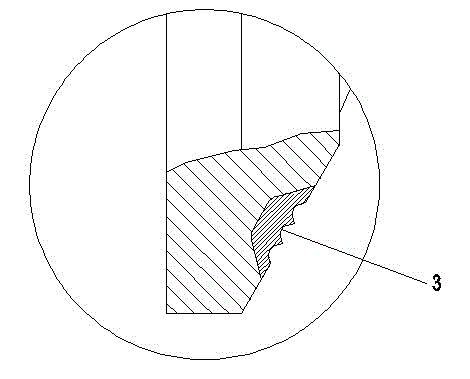

A kind of piston ring, piston assembly and engine

ActiveCN111075598BExtended service lifeImprove wear resistancePiston ringsMachines/enginesOil canCombustion chamber

The invention relates to the field of engines, and discloses a piston ring, a piston assembly and an engine. The piston ring is a broken ring structure with an opening, each shaft section of the piston ring and the outer peripheral wall of the piston ring intersect to form a first curve, and points furthest from the central axis of the piston ring on the first curve are sequentially connected in the circumferential direction of the piston ring to form a second curve; and the end face, facing the bottom of the piston, of the piston ring is a first plane, and the distance from the points on thesecond curve to the first plane has an increased trend in the direction far away from the opening. On the premise of not greatly adjusting the structure of the piston ring, the type line of the outerperipheral wall of the piston ring is optimized, the contact pressure between the outer peripheral surface of the piston ring and the inner wall of a cylinder sleeve is almost consistent, the wear resistance of the outer peripheral surface of the piston ring, especially the wear resistance of the opening position of the piston ring, is improved, and after the piston ring is worn, the piston ring cannot be subjected to abnormal wear with the cylinder sleeve, so that the engine oil cannot be scraped into a combustion chamber when the piston ring moves upwards.

Owner:WEICHAI POWER CO LTD

Rolling method for exhaust valve surface

Owner:HUDONG HEAVY MACHINERY

Process for environment protectional energy-saving diesel additive

InactiveCN100419051CImprove combustion efficiencyHelp pyrolysisLiquid carbonaceous fuelsCyclohexanoneParaffin wax

The invention relates to a process for preparing environmental friendly diesel fuel additive comprising, placing alcohol isopropylicum into reaction kettle, mixing with 93# gasoline, after 1.5-2.5 hrs, continuing charging in phenylmethanol and mixing, obtaining solution A, placing plane kerosene (D40) into another reaction kettle, mixing with cyclohexanone to obtain solution B, after 8-14 hours, mixing solution an and B, filtering 2-5 times.

Owner:刘恩祥

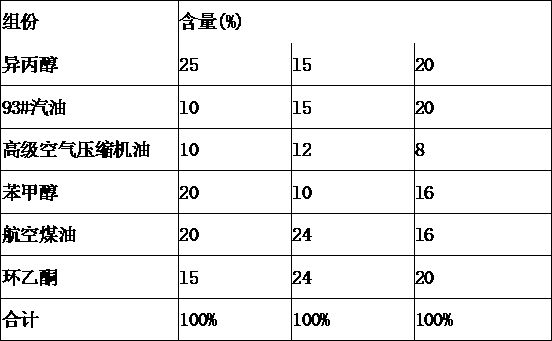

Production technology of environment-friendly energy-saving lubricant additive

InactiveCN109777532AIncrease powerStart fastLiquid carbonaceous fuelsFuel additivesParaffin waxCyclohexanone

The invention relates to a production technology of an environment-friendly energy-saving lubricant additive. The production technology comprises the following processes: firstly, putting isopropanolin a reaction kettle, mixing with 93# gasoline, putting advanced air compressor oil in the reaction kettle in 1.5- 2.5 hours, then continuing to put benzyl alcohol in the reaction kettle, and mixing to obtain an A solution; a B solution arranging another reaction kettle, putting aviation kerosene (D40) into the reaction kettle, finally mixing with cyclohexanone, mixing the A solution and the B solution and filtering for 2-5 times in 8-14 hours to obtain the environment-friendly energy-saving lubricant additive. After the environment-friendly energy-saving lubricant additive involved in the invention is added, paraffin pyrolysis is promoted, and the distillation range, condensation point and viscosity of lubricating oil are all in downtrend; therefore, the flow and atomization of fuel oil are promoted; engine power obviously increases; a locomotive starts quickly; noise is low; an oil injection head is not prone to blockage; and the service lives of an engine and machine parts can be effectively prolonged.

Owner:都江堰惠农生物技术有限责任公司

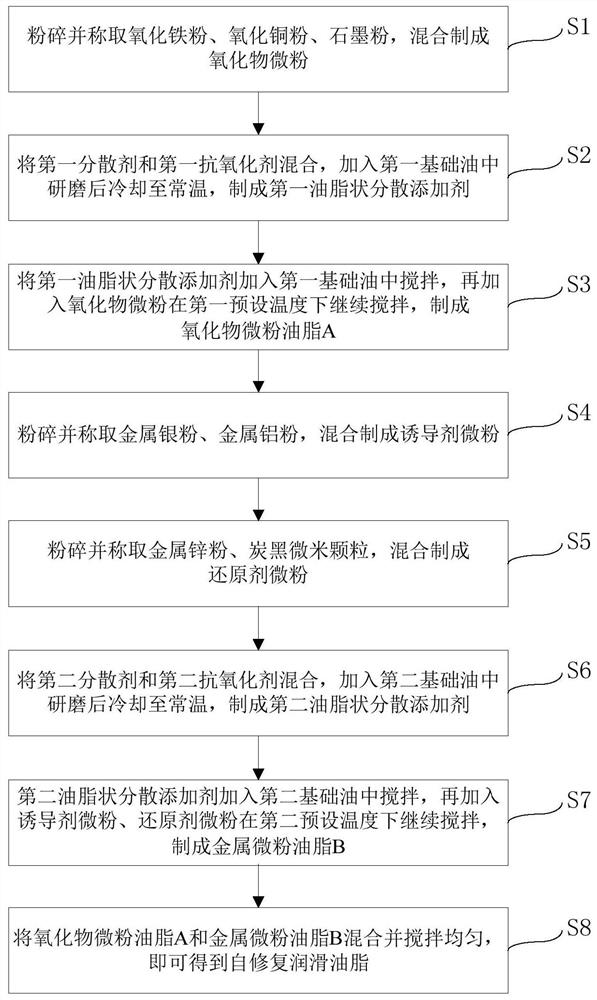

A kind of self-healing lubricating grease and preparation method thereof

ActiveCN111303960BPromote redox reactionsAchieve the effect of adaptive repairAdditivesAl powderMetallic aluminum

The invention provides a self-repairing lubricating grease and a preparation method thereof. The grease comprises the following components: iron oxide powder, copper oxide powder and graphite powder are mixed as oxide micropowder; metal zinc powder and carbon black micron particles are mixed as reducing Agent powder; metal aluminum powder, metal silver powder mixed as inducer powder; succinimide as dispersant; polyacrylamide as antioxidant; HVIWH150 as base oil. Compared with the prior art, in addition to the conventional lubricating effect of the grease of the present invention, the oxide fine powder and reducing agent fine powder will be oxidized by the inducer fine powder only when the gap between metal friction pairs increases to cause extreme pressure conditions. The reduction reaction produces zinc oxide and iron to fill the grooves and defects on the surface of the friction pair, thereby achieving the effect of self-healing.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

Production process of environment-friendly energy-saving lubricating oil additive

InactiveCN108018096AIncrease powerStart fastLiquid carbonaceous fuelsFuel additivesParaffin waxCyclohexanone

The invention relates to a production process of an environment-friendly energy-saving lubricating oil additive. The production process comprises the following steps: isopropanol is put into a reaction kettle, then 93# gasoline is mixed with the isopropanol, and after 1.5-2.5 h, an advanced air compressor oil is put into the reaction kettle, and then benzyl alcohol is put into the reaction kettlefor mixing, so as to obtain a solution A; an aviation kerosene (D40) is put into another reaction kettle, and then cyclohexanone is mixed with the aviation kerosene, and after 8-14 h, a solution B isobtained; and the solution A and the solution B are mixed, and the mixture is filtered for 2-5 times, so that the environment-friendly energy-saving lubricating oil additive is prepared. After the environment-friendly energy-saving lubricating oil additive is added into lubricating oil, pyrolysis of the paraffin is facilitated, thereby making the distillation range, condensation point and viscosity of the lubricating oil all show a downward trend, so that flowing and atomization of the fuel are facilitated, and power of an engine is obviously increased, therefore, the motor vehicle starts fast, noise is small, an injector head is not easily blocked, and the service life of the engine and machine parts can be effectively prolonged.

Owner:绵阳双甘科技有限公司

Processing method of sealing surface of exhaust valve of low-speed diesel engine

The invention discloses a processing method of a sealing surface of an exhaust valve of a low-speed diesel engine, which is characterized in that a deformed and high-temperature Ni-Cr precipitation-hardening alloy containing Nb is utilized to be overlaid in a ring groove of the exhaust valve, and a reticular precipitation tissue with hardness of HV10540-580 is formed through rolling and aging precipitation-hardening processing. By the method, the hardness of the sealing surface is improved; and when in use, the sealing surface has small possibility of cracking, the production cost is controlled effectively, major repair time of the diesel engine is prolonged, and the method has a wide promotion value and market prospect.

Owner:CHONGQING YUEJIN MACHINERY

A preparation method of high and low temperature resistant micro-nano lubricating material

InactiveCN106190502BIncrease frictionReduce coefficient of frictionLubricant compositionMicro nanoOxyacetylene torch

Owner:陕西天工云科智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com