Contraposition linear reciprocating pump driving mechanism

A driving mechanism, linear reciprocating technology, applied in the field of reciprocating pumps, can solve the problems of increased wearing parts, shortened service life, increased friction between the crosshead and the rack slide, etc., achieves small vibration and noise, and shortened service life. , Eliminate the effect of poor lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

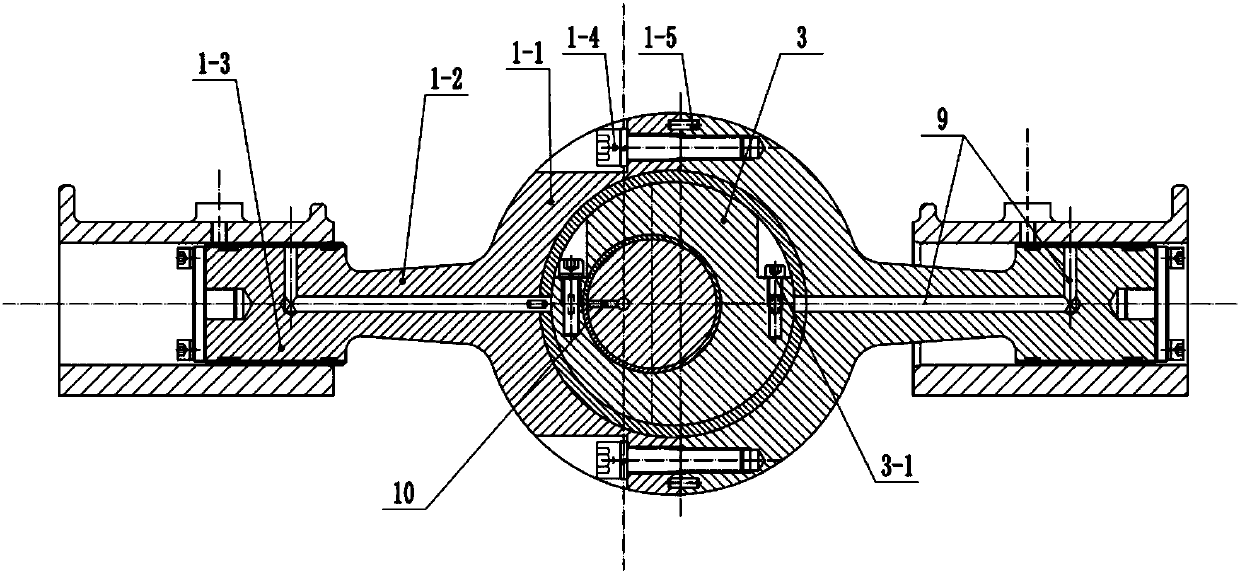

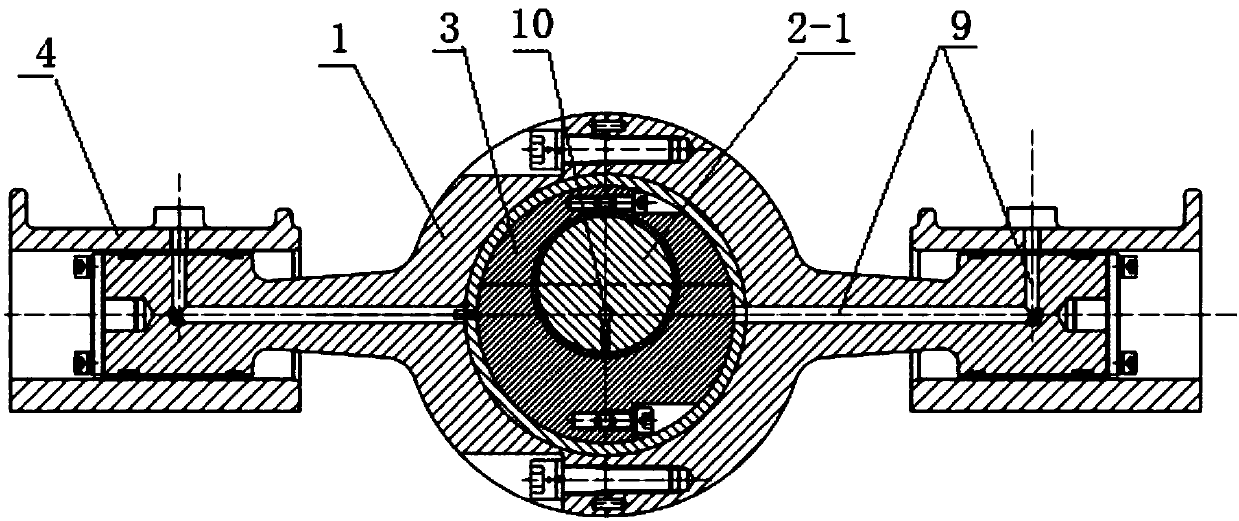

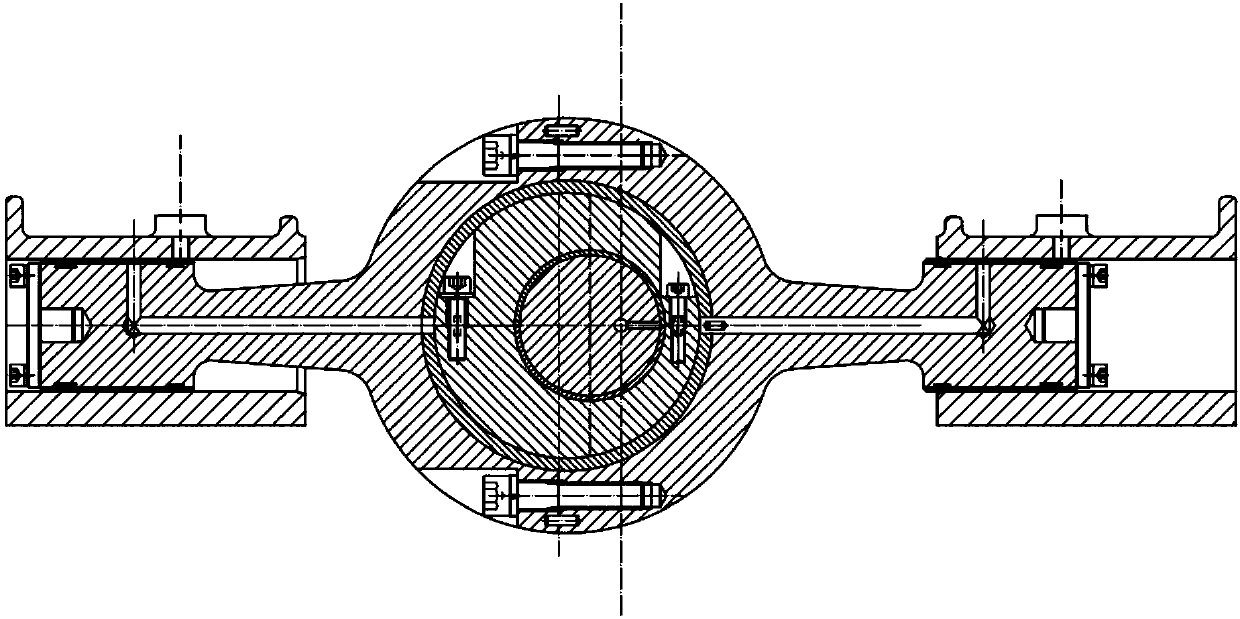

[0023] Attached below figure 1 , 2 , 3, 4, 5, 6 and specific embodiments describe the present invention in detail.

[0024] An opposed linear reciprocating pump drive mechanism, including a slider mechanism 1, a crankshaft 2, and an eccentric slider 3. The slider mechanism 1 is formed from a slider 1-1 in the middle and extends from both ends of the slider 1-1. The two connecting rods 1-2 and the pistons 1-3 at the ends of the two connecting rods 1-2 are composed, and the central axis of the two pistons 1-3 is perpendicular to the central axis of the slider 1-1; The crankshaft 2-1 of the crankshaft 2 is fitted with an eccentric slider 3, the slider 1-1 is concentrically set on the eccentric slider 3, and the piston 1-3 is coaxially inserted into the frame of the reciprocating pump. In the two symmetrical slideways 4; the eccentric slider 3 rotates around the crankshaft 2-1 while following the crankshaft 2-1 around the crankshaft 2, and the rotation direction of the eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com