Patents

Literature

80results about How to "Small flow pulsation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

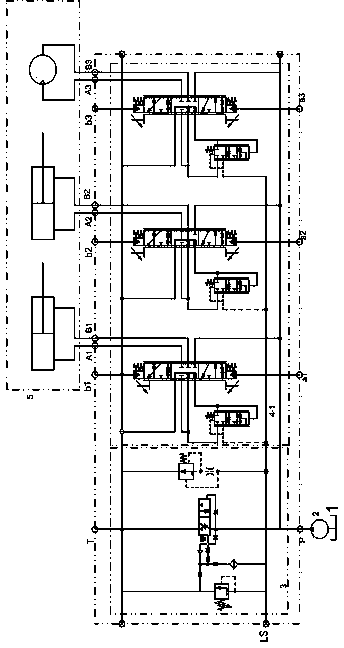

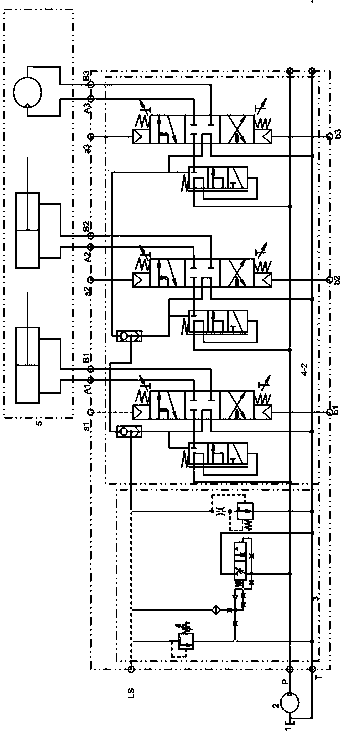

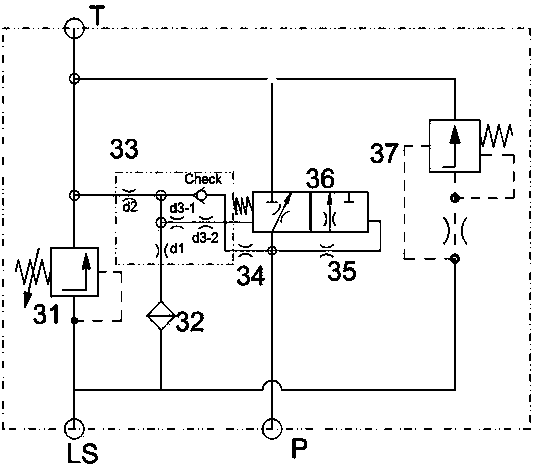

Three-way pressure compensator assembly

ActiveCN104047931AStable pressure control signalNo pressure pulsationServomotor componentsFluid-pressure actuator componentsEngineeringPeak value

The invention provides a three-way pressure compensator assembly. A three-way pressure compensator has two working positions. A spring cavity of the three-way pressure compensator is communicated with an LS port and a T port through a liquid resistance network and communicated with a P port through a dynamic damping hole. One end of the liquid resistance network is communicated with the T port, and the other end of the liquid resistance network is communicated with the LS port through a filter screen. A lower cavity of the three-way pressure compensator is communicated with the P port through a damping hole. The three-way pressure compensator assembly has the advantages that the half-bridge liquid resistance network, the dynamic damping hole and the oil inlet fixing damping hole are matched, stability of LS feedback pressure of the three-way pressure compensator is effectively achieved, it is guaranteed that a valve element of the three-way pressure compensator moves stably, and therefore stable flow division is achieved; the peak value of fluctuation of load pressure is effectively eliminated, pressure gains are reduced, and it is guaranteed that all actuators are stable; a quantitative load-sensitive system can achieve the functions that the flow is small when pressure is high and the flow is large when pressure is low.

Owner:广西中源机械有限公司 +2

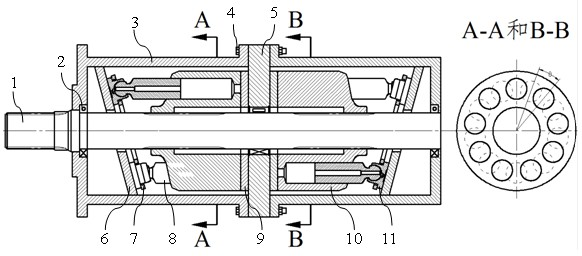

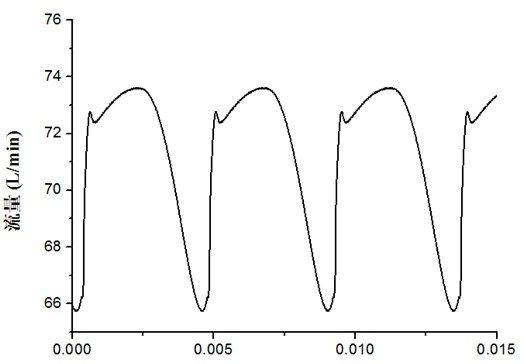

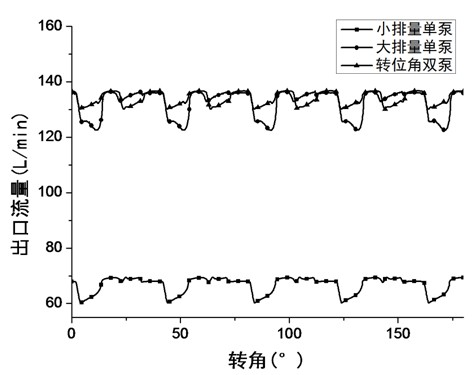

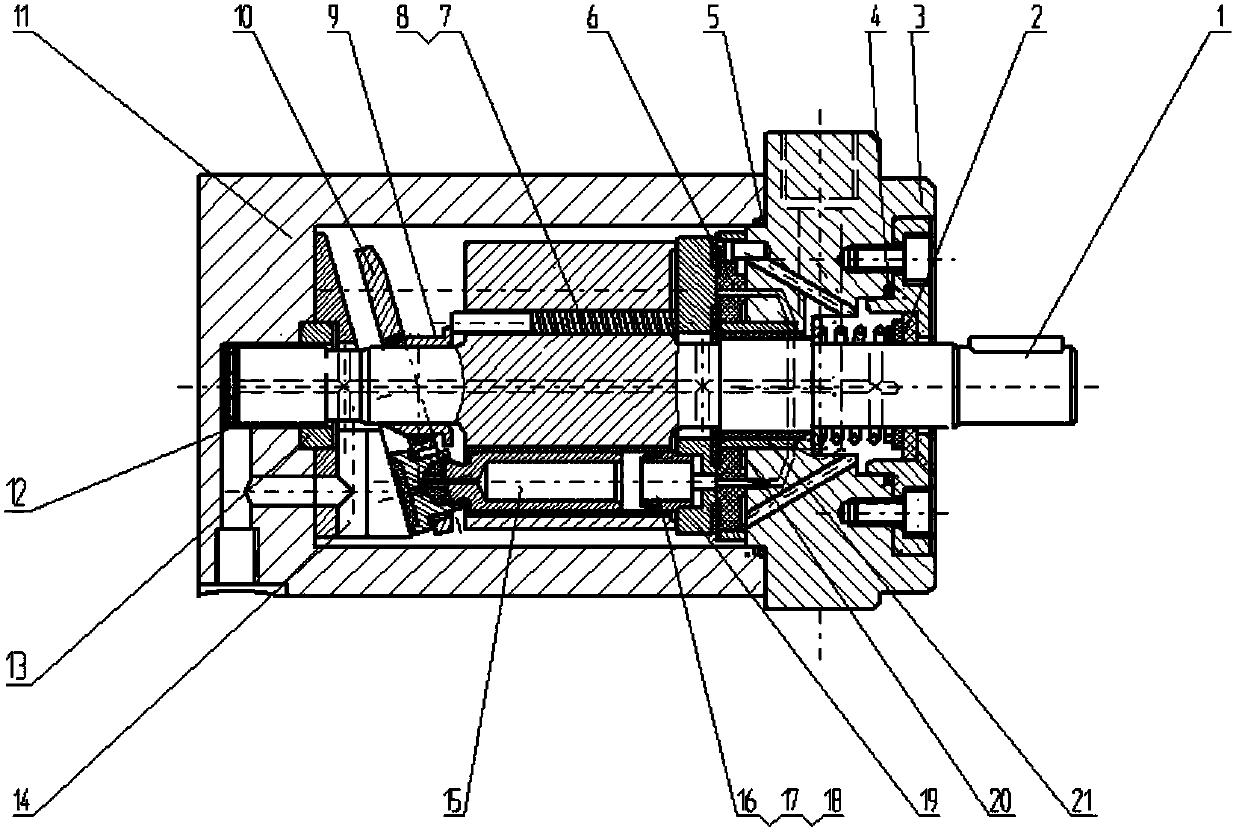

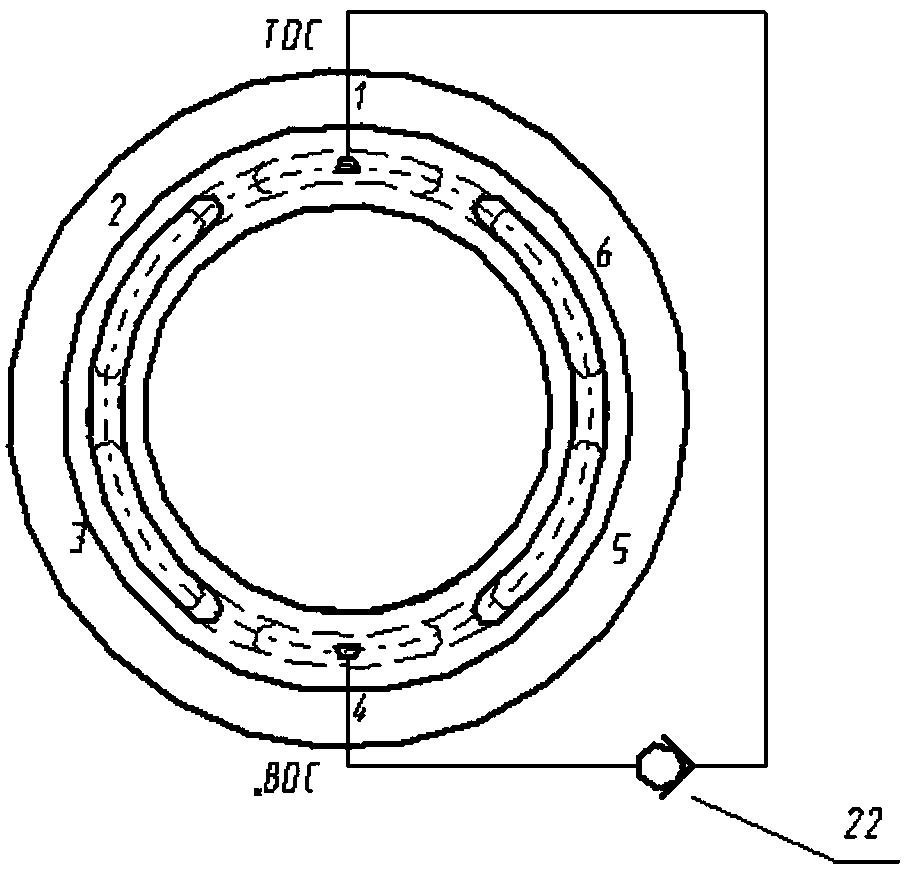

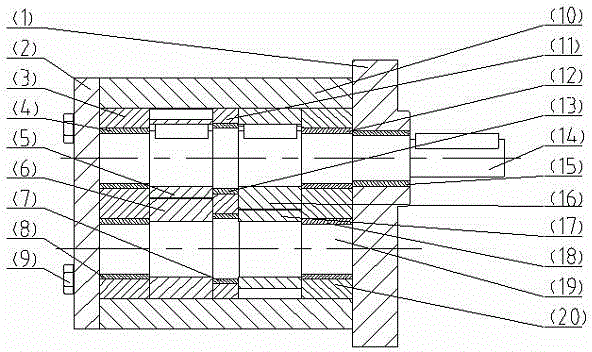

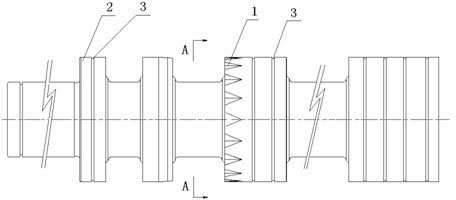

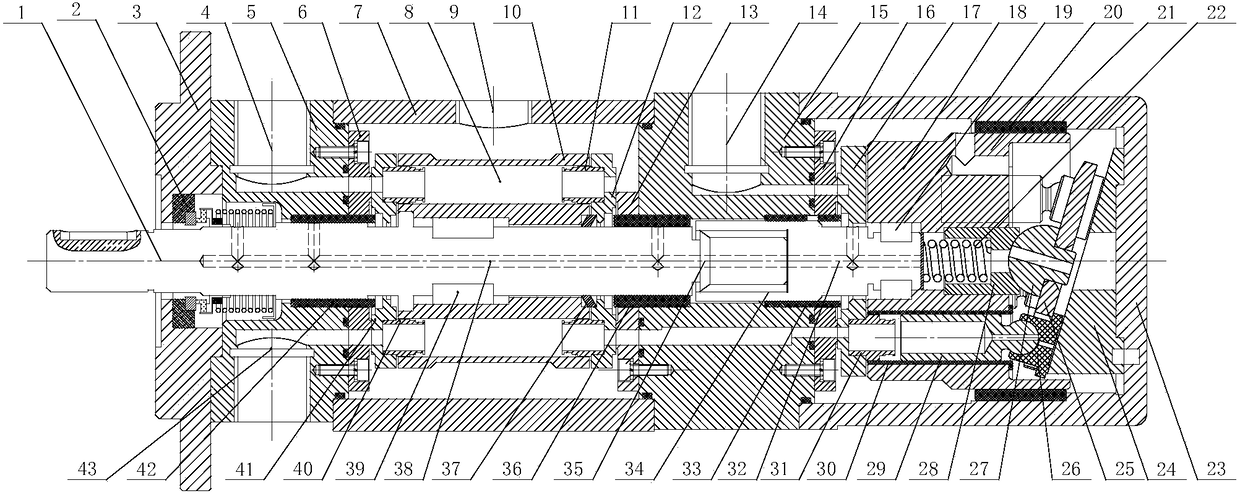

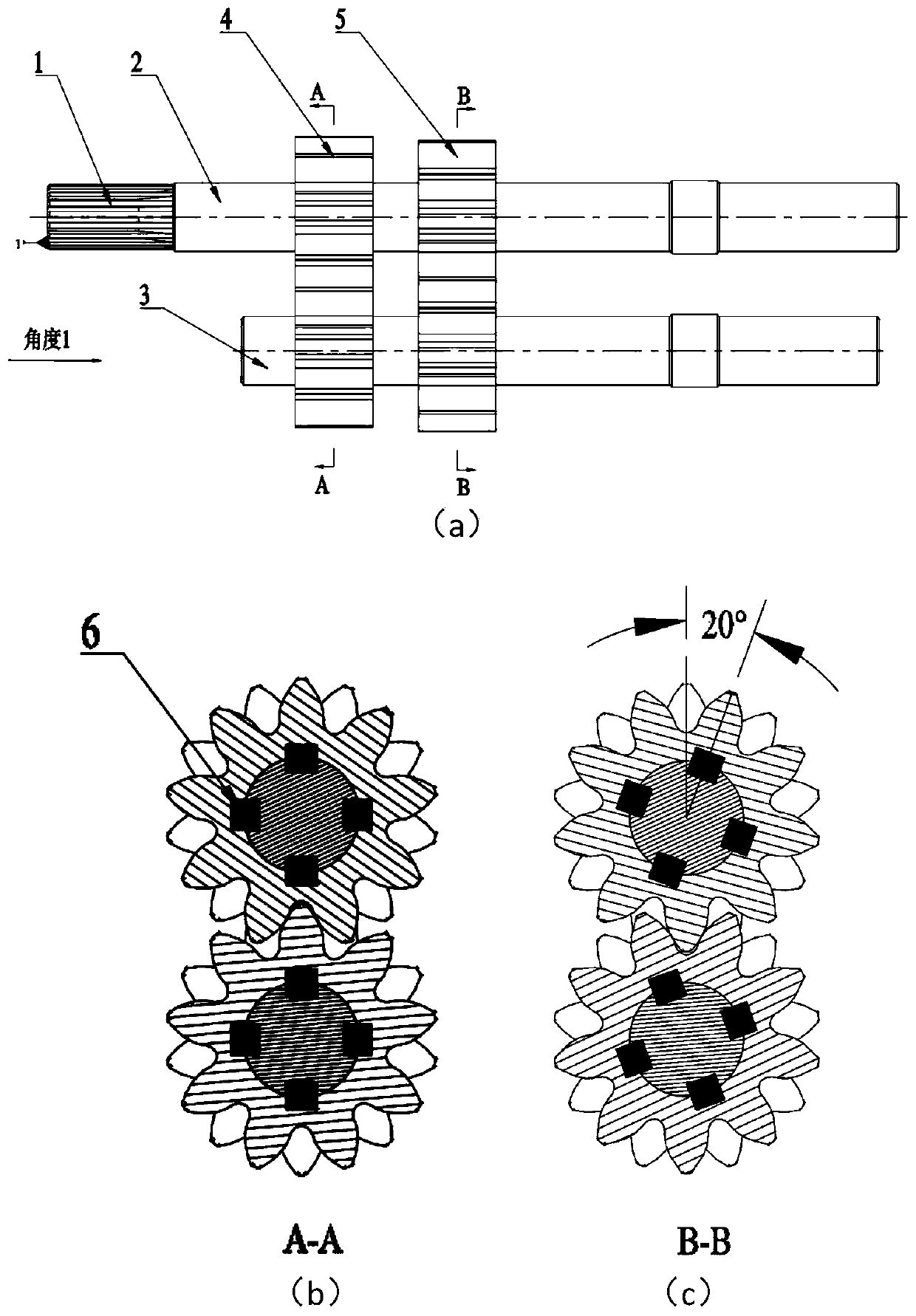

Low-noise axial plunger pump based on indexing angle of pumps in series

ActiveCN102434415AReduce outlet flow pulsationFluid noise excitation source reductionPositive-displacement liquid enginesMulti-cylinder pumpsPlunger pumpCylinder block

The invention discloses a low-noise axial plunger pump based on an indexing angle of pumps in series, mainly comprising a main shaft, a bearing, a shell body, a bolt component, a connecting body, an inclined disc, a back-stroke tray, a plunger, a flow distribution plate, a cylinder body and a slippage shoe. The axial plunger pump is provided with two sets of rotor structures which consist of the sliding shoe, the plunger, the cylinder body and the flow distribution plate, an oil sucking hole and an oil discharging hole are shared by two rotor structures, the indexing angle exists between two rotor structures, therefore, a fixed phase difference exists between the dynamic changes of oil discharging quantities of two rotor structures, when two oil flows is converged at the oil discharging hole position, an average effect is generated, the actual exit flow pulsation of the axial plunger pump is reduced by more than 50%, the fluid noise of flow pulsation as a shock excitation source is greatly reduced.

Owner:ZHEJIANG UNIV

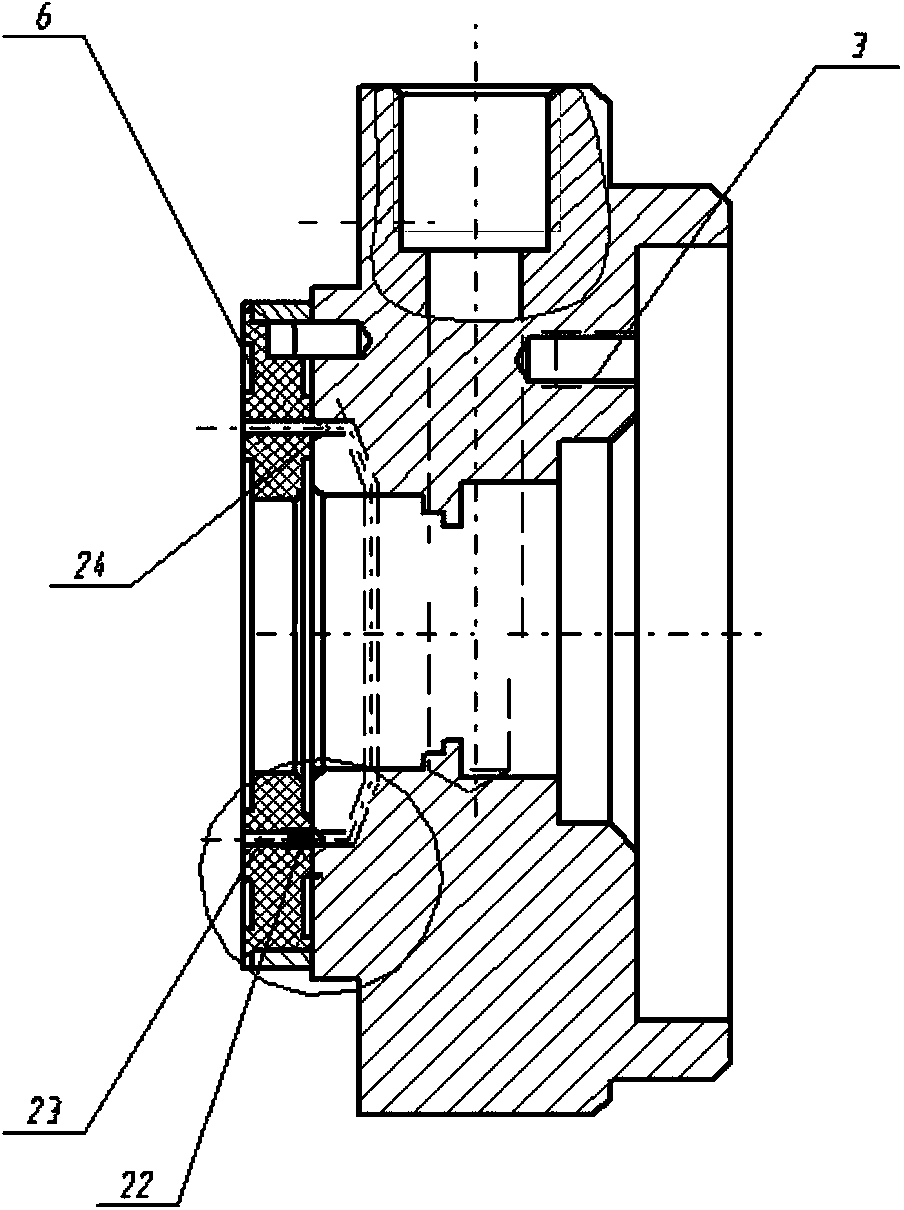

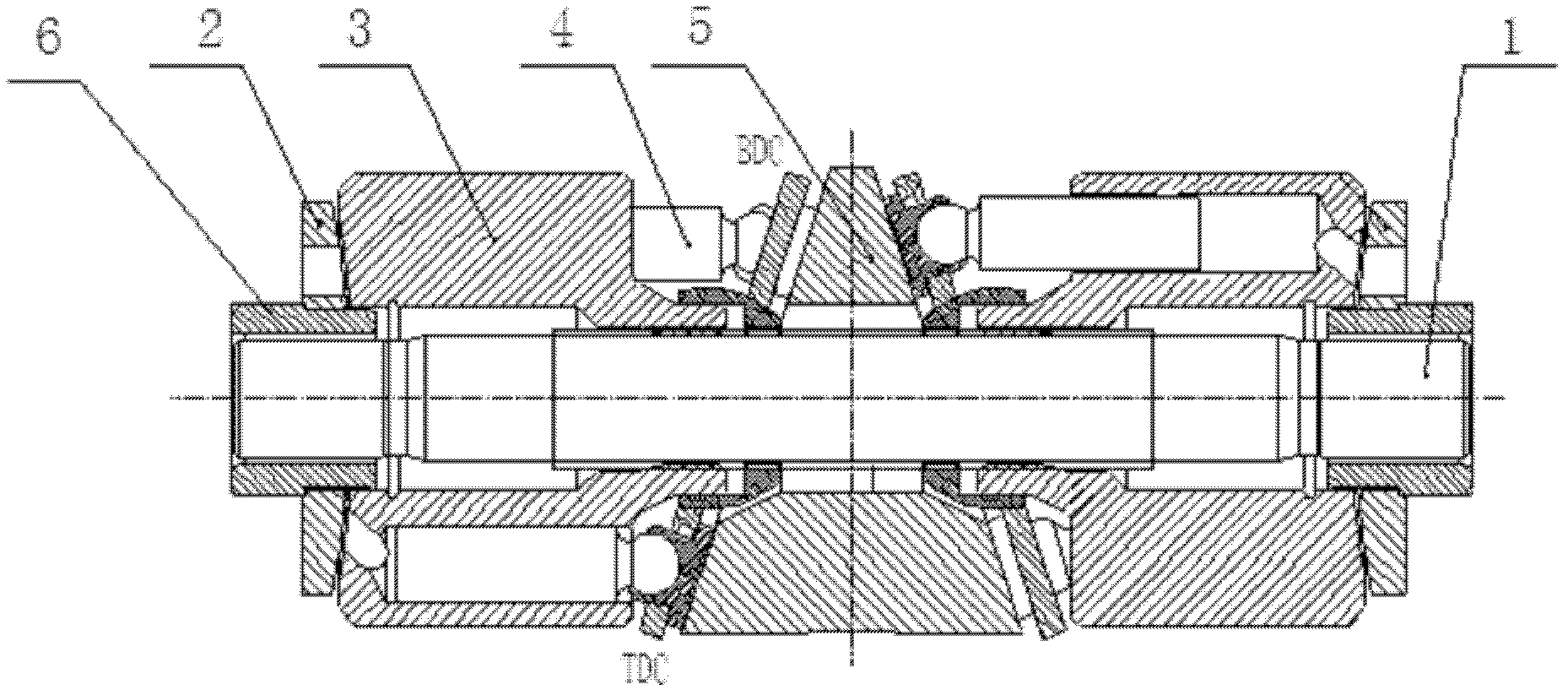

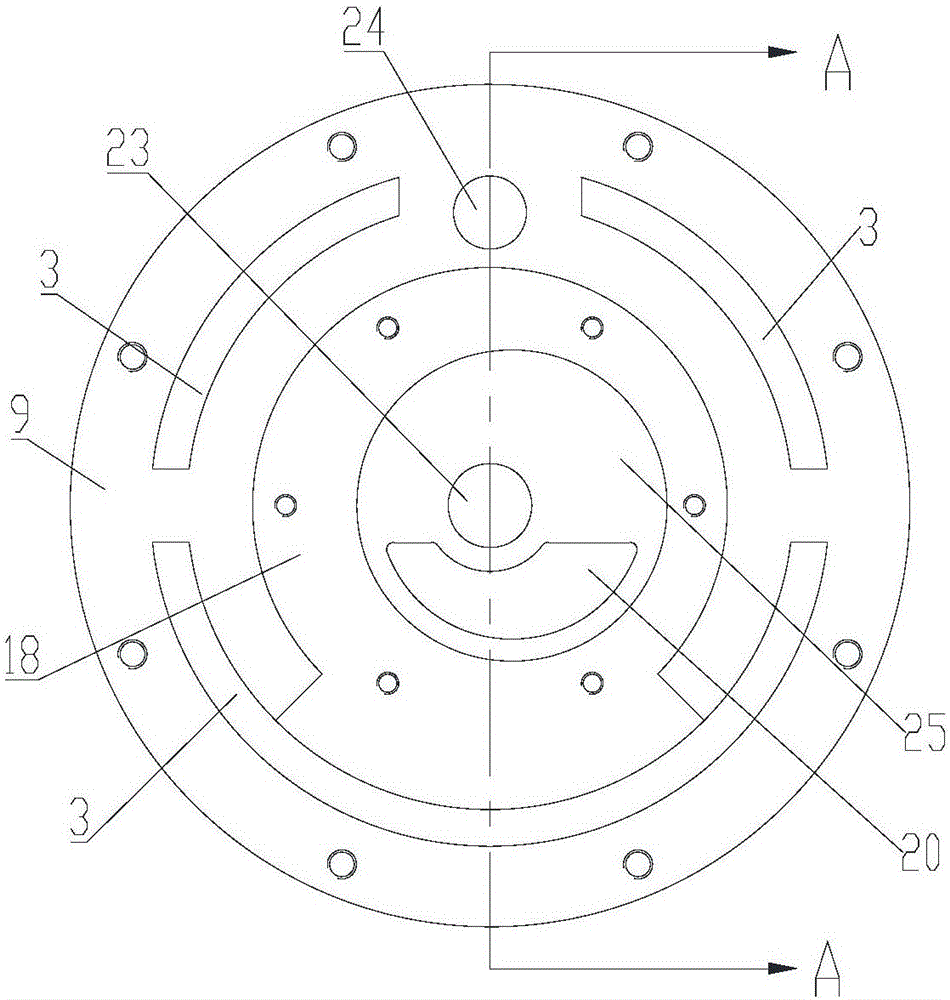

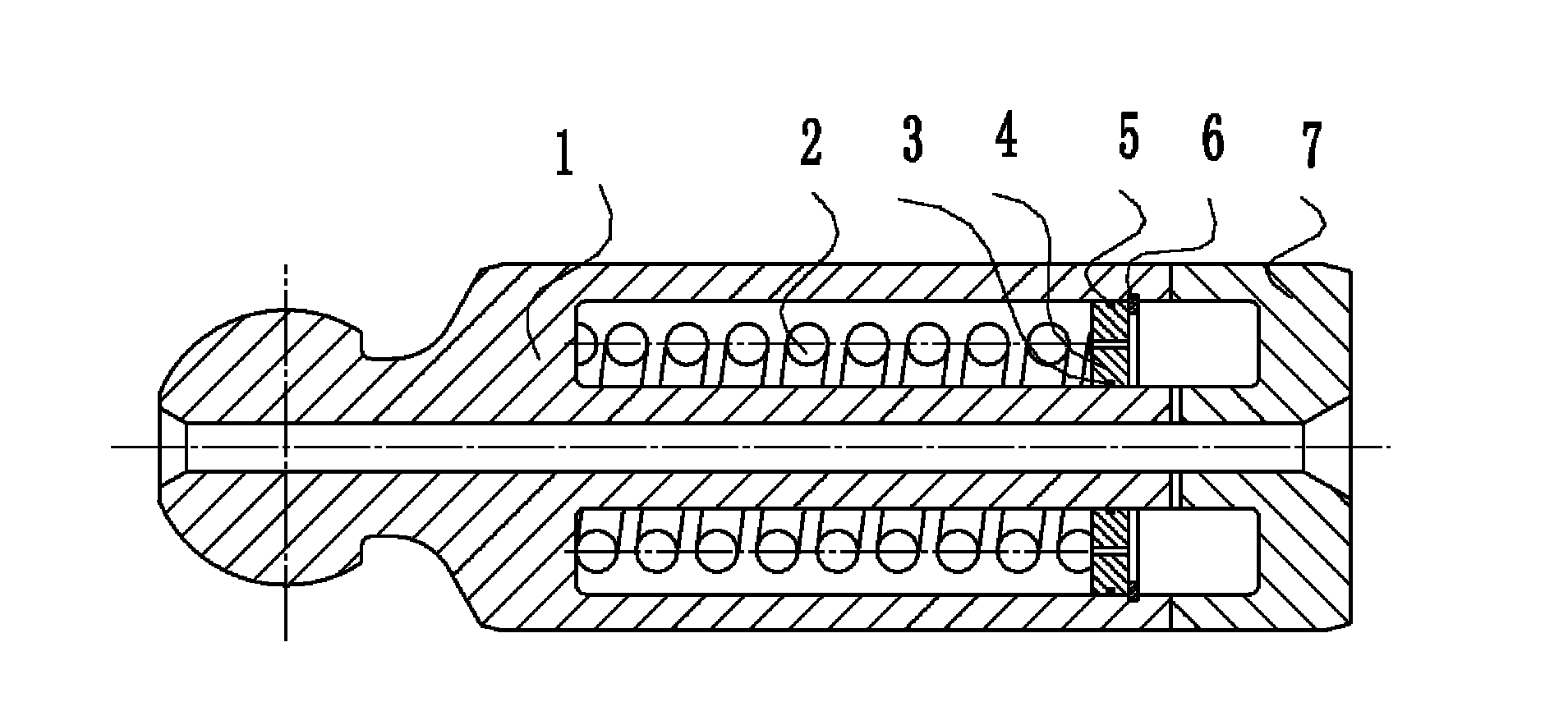

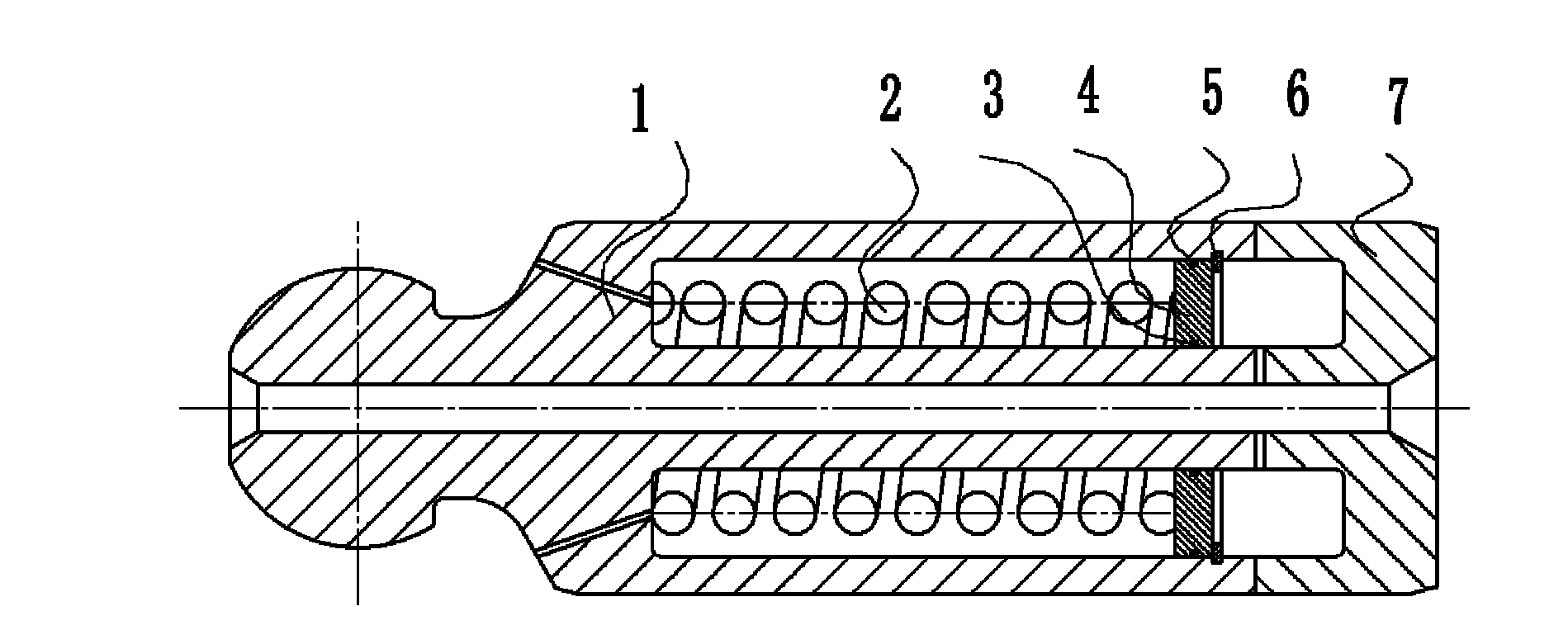

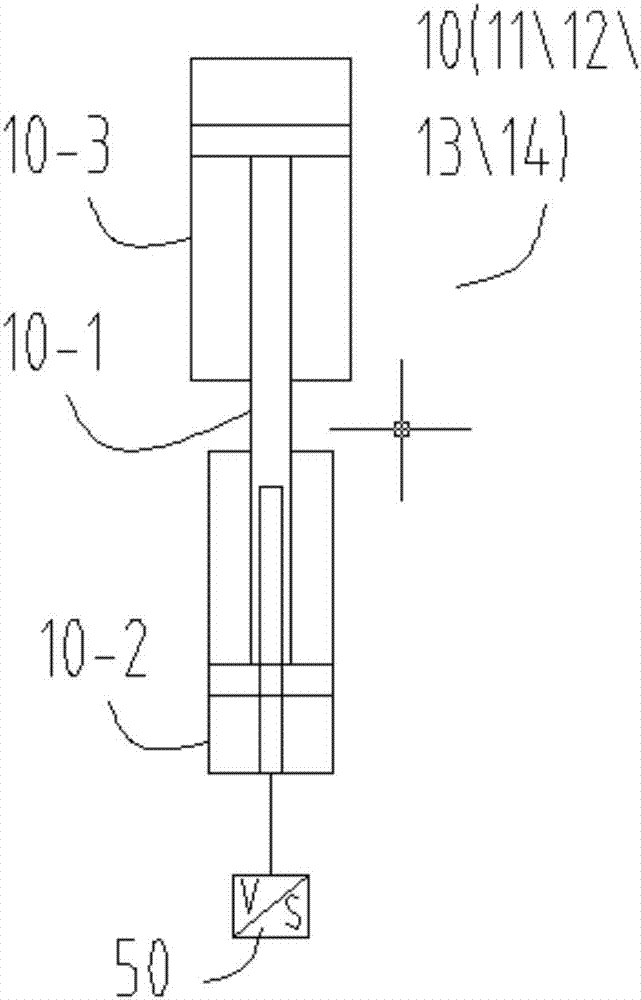

Seawater piston motor low in pulsation

ActiveCN103742380ASmall flow pulsationReduce leakagePositive displacement pump componentsPositive-displacement liquid enginesEngineeringHigh pressure water

A seawater piston motor low in pulsation belongs to the technical field of hydraulic application and comprises a swash plate, an even number of piston shoes, a piston, a cylinder shaft, a valve plate, an end cover, a casing, a miniature check valve and the like. Damping holes are formed in an upper stop point and a lower stop point of the valve plate and in the end cover. The miniature check valve is arranged between the damping hole of the lower stop point of the valve plate and the damping hole of the end cover. When a high-pressure piston cavity finishes water sucking, and the upper stop point position is reached, high-pressure water in the piston cavity enters the damping hole of the end cover through a damping hole to flow into the inlet position of the check valve. Then the check valve is opened, and the high-pressure water enters a low-pressure piston cavity through the damping hole at the lower stop point position. The high-pressure piston cavity conducts pre-depressurizing, and the low-pressure piston cavity conducts pre-pressurizing. Under the condition of combining the pressures, a pre-pressurizing and a pre-depressurizing effect of the piston cavity is approximately equal to half of the pressure difference of an axial piston motor high-pressure oil draining kidney-shaped groove and a low-pressure oil sucking kidney-shaped groove, pressure impact at the piston motor transition area is reduced, motor output rotating speed and torque pulse are reduced, and the stability is improved.

Owner:BEIJING UNIV OF TECH

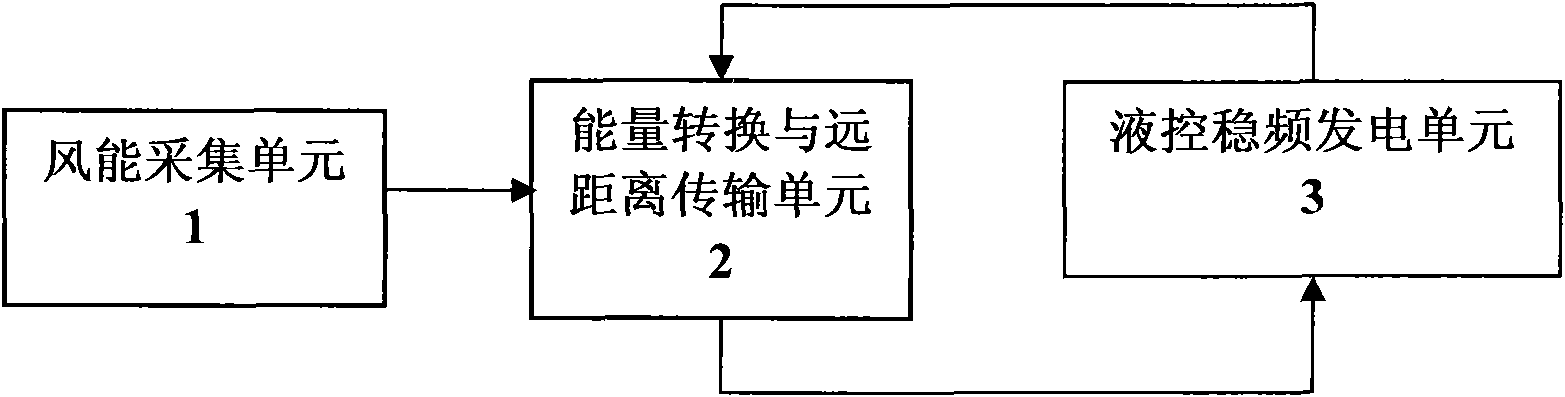

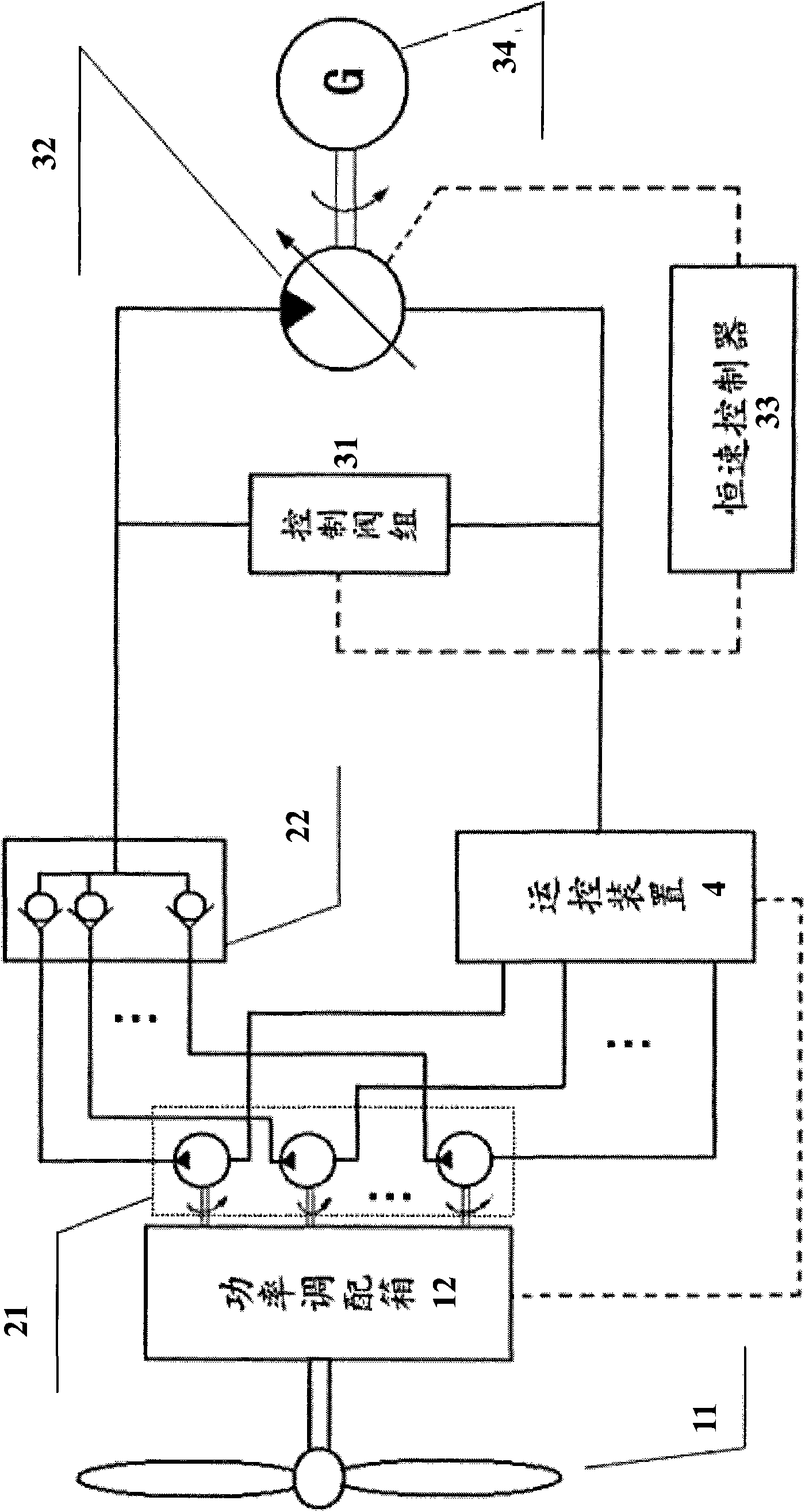

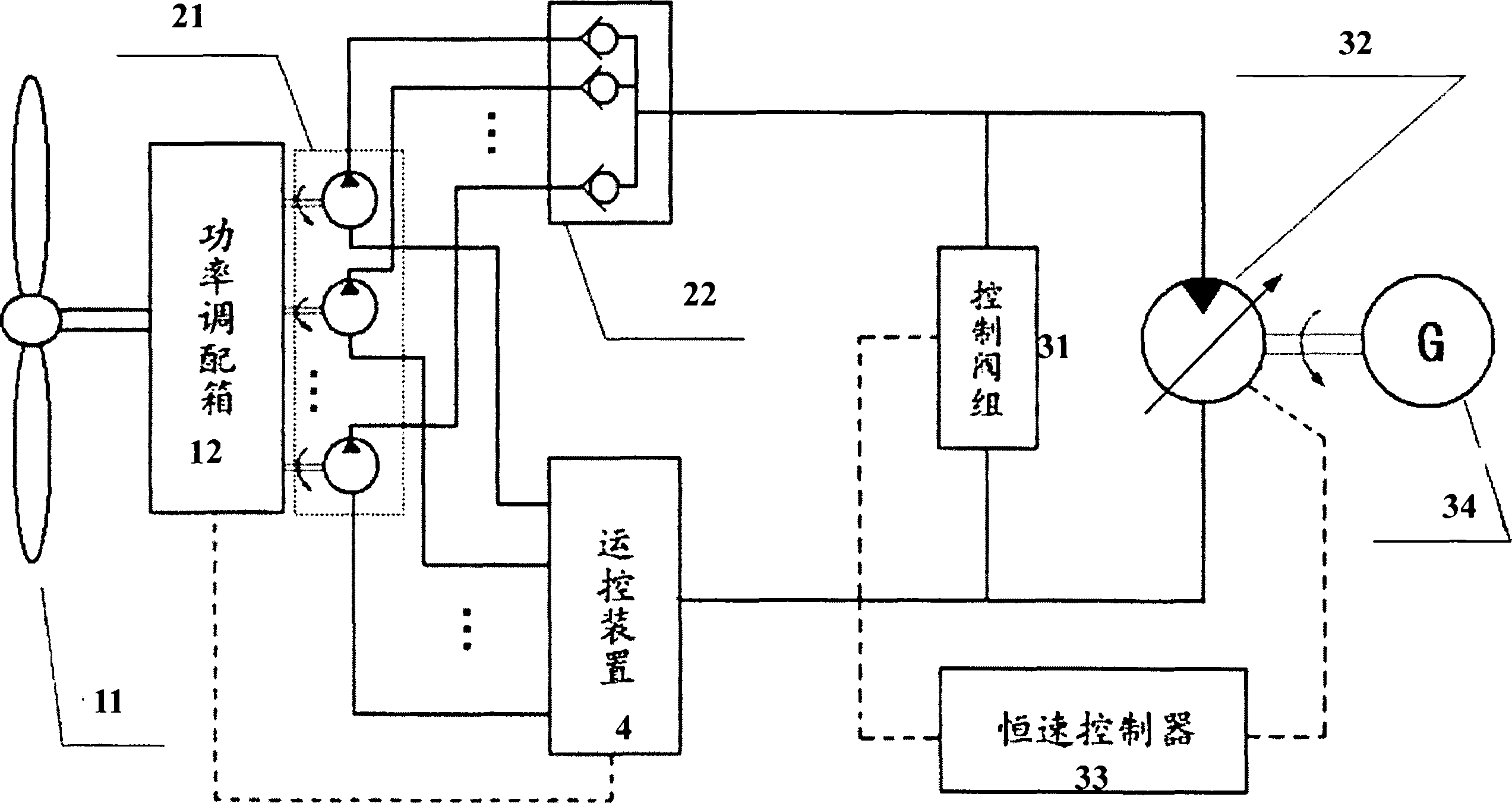

Hydraulic control frequency stabilized wind power generation apparatus

ActiveCN101782042ALow costImprove convenienceWind motor controlEnergy industryConstant frequencyHydraulic circuit

The invention relates to a hydraulic control frequency stabilized wind power generation apparatus. A system comprises a wind energy collection unit, an energy conversion and remote distance transmission unit and a hydraulic control frequency stabilized power generation unit, wherein the wind energy collection unit converts wind energy into mechanical energy, the energy conversion and remote distance transmission unit is connected with the wind energy collection unit, converts the mechanical energy to hydraulic energy, and realizes the remote distance transmission of the wind energy by adopting a hydraulic transmission principle, and the hydraulic control frequency stabilized power generation unit is connected with the energy conversion and remote distance transmission unit through a hydraulic pipeline, can convert the hydraulic energy into the mechanical energy, and can also convert the mechanical energy into electric energy, wherein the energy conversion and remote distance transmission unit and the hydraulic control frequency stabilized power generation unit are made into a closed type hydraulic loop through the hydraulic pipeline. The invention adopts the initial phase angle change arrangement of a hydraulic pump, and reduces the flow pulsation output by the hydraulic energy. The invention adopts the optimal matching of controlling the entering flow rate of a hydraulic motor and the output volume of the hydraulic motor, generates the constant rotating speed output of the hydraulic motor, drives an ordinary power generator set for generating constant frequency electric energy, and improves the quality of the electric energy.

Owner:SHANGHAI XISHUNLAI MACHINERY & ELECTRIC EQUIP MFG CO LTD

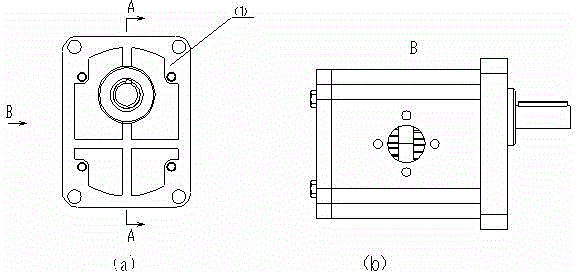

Low-pulse compound gear pump

InactiveCN104564660AStable jobHigh work pressureRotary piston pumpsRotary piston liquid enginesGear pumpWorking pressure

The invention relates to a low-pulse compound gear pump. The low-pulse compound gear pump comprises a pump body, wherein the pump body is connected with a front end mounting plate and a rear end cover plate by virtue of connection bolts; the pump body is internally provided with a driving shaft and a driven shaft; a first gear and a third gear are mounted on the driving shaft by virtue of a flat key; a second gear and a fourth gear are mounted on the driven shaft by virtue of the flat key; the first gear and the second gear are meshed with each other to form a first meshed gear pair; the third gear and the fourth gear are meshed with each other to form a second meshed gear pair; a front terminal plate, a rear terminal plate and a partition plate are respectively mounted on the front end, the rear end and the middle part of the two pairs of meshed gear pairs; sliding bearings are mounted on the front terminal plate, the partition plate and the rear terminal plate; a sliding bearing is arranged on the front end mounting plate; the driving shaft stretches out of the pump body and is connected with an external motor by virtue of the flat key. The low-pulse compound gear pump has the characteristics of simple structure, insensitivity to the oil pollution, high working pressure and low pressure pulse of an oil outlet.

Owner:SHANGHAI UNIV

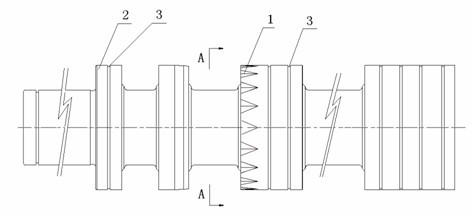

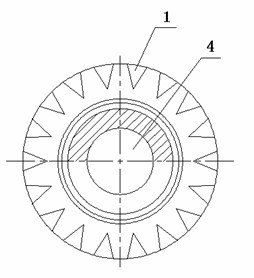

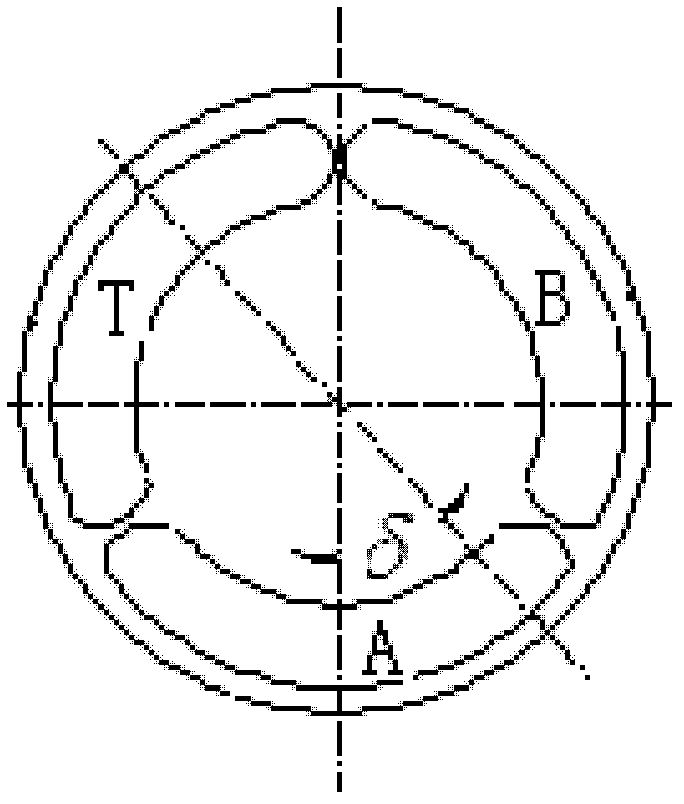

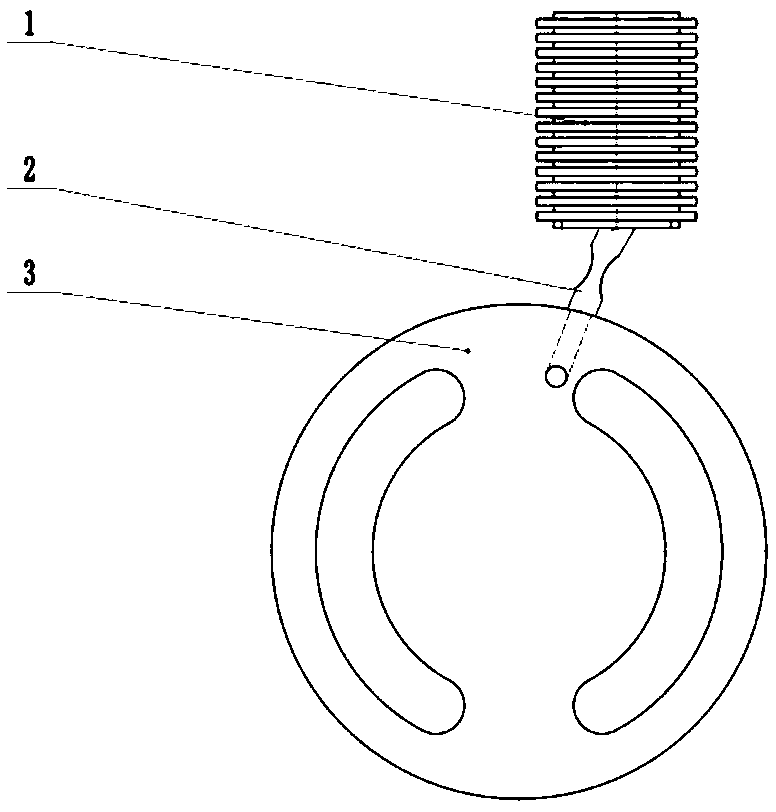

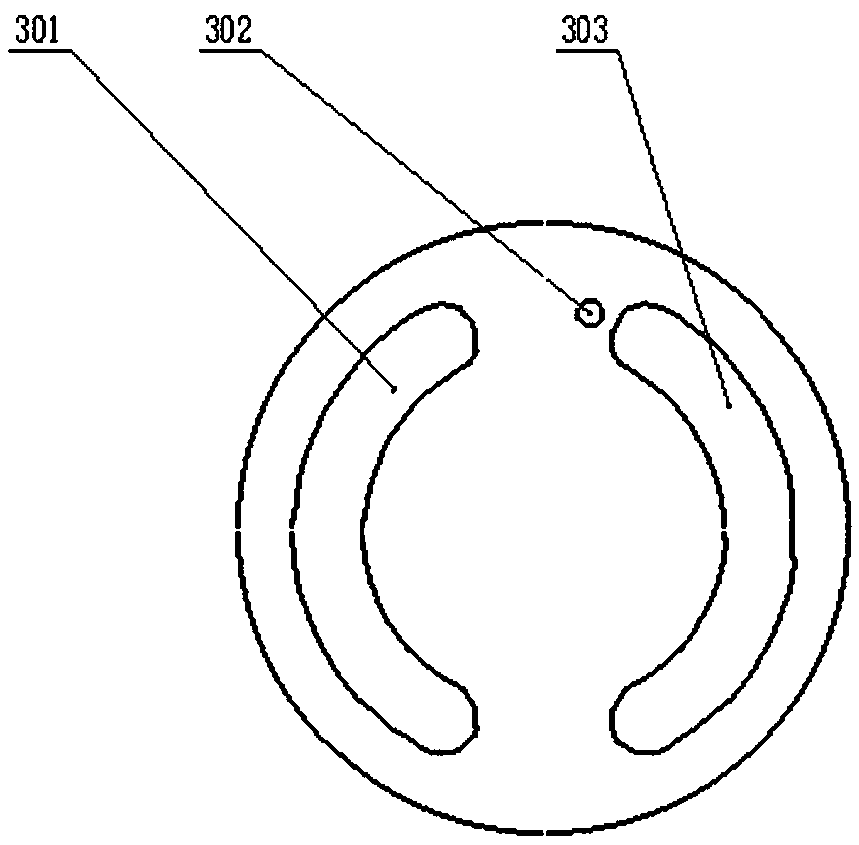

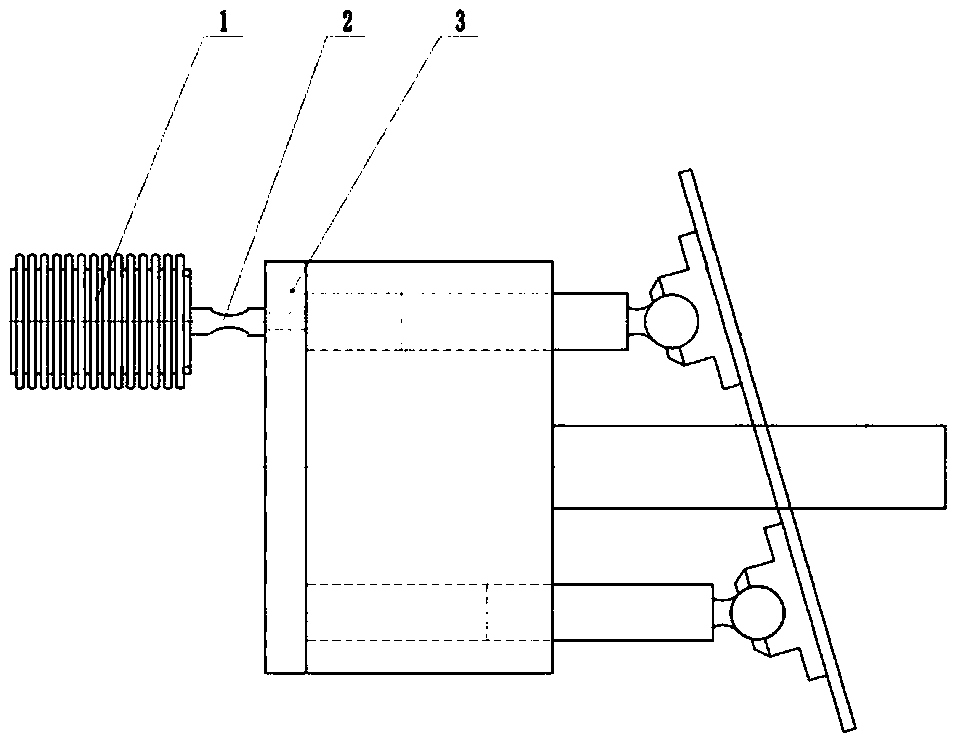

Valve core of vane hydraulic motor controller

InactiveCN102537507ANoise controlSmall flow pulsationValve members for absorbing fluid energyHydraulic motorSlope angle

The invention discloses a valve core of a vane hydraulic motor controller. Triangular grooves (1) are formed along the radial direction on the outer surface of the valve core, the slope angles of the triangular grooves (1) are 45 to 75 degrees, and 12 to 16 triangular grooves (1) are formed. According to the valve core of the vane hydraulic motor controller, by rationally designing the dimensions and the number of the triangular grooves, flow pulsation can be reduced maximally, fluid noise can be controlled maximally, and the processing difficulty and the structure cost of the valve core can be controlled.

Owner:WUHAN MARINE MACHINERY PLANT

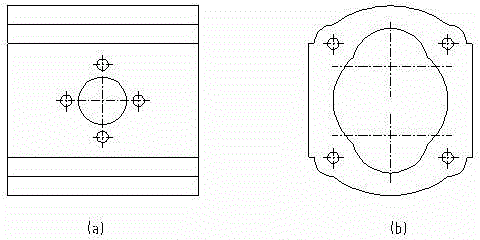

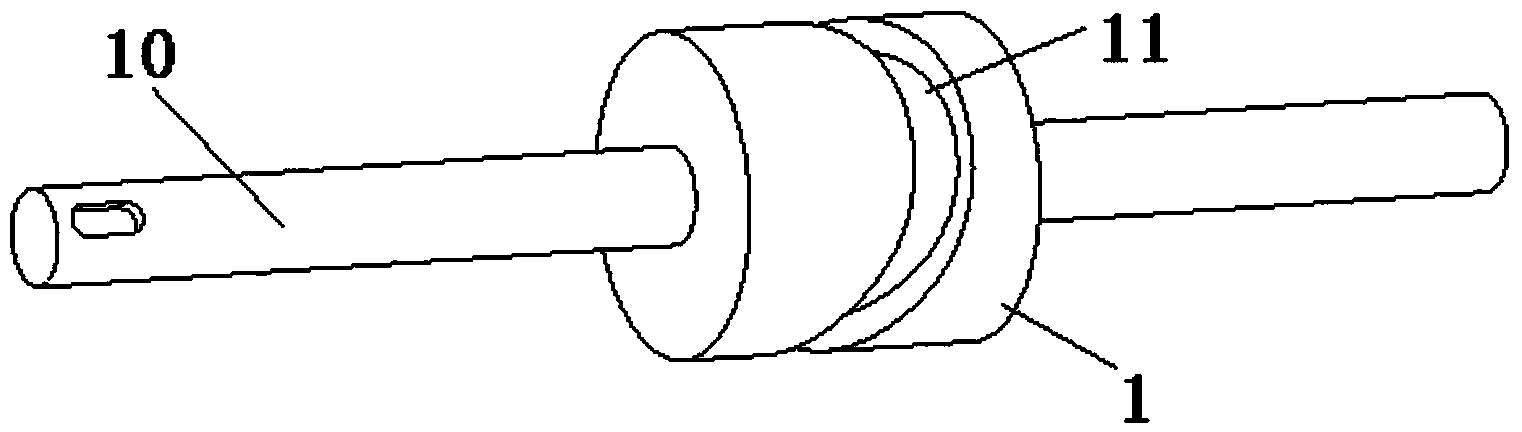

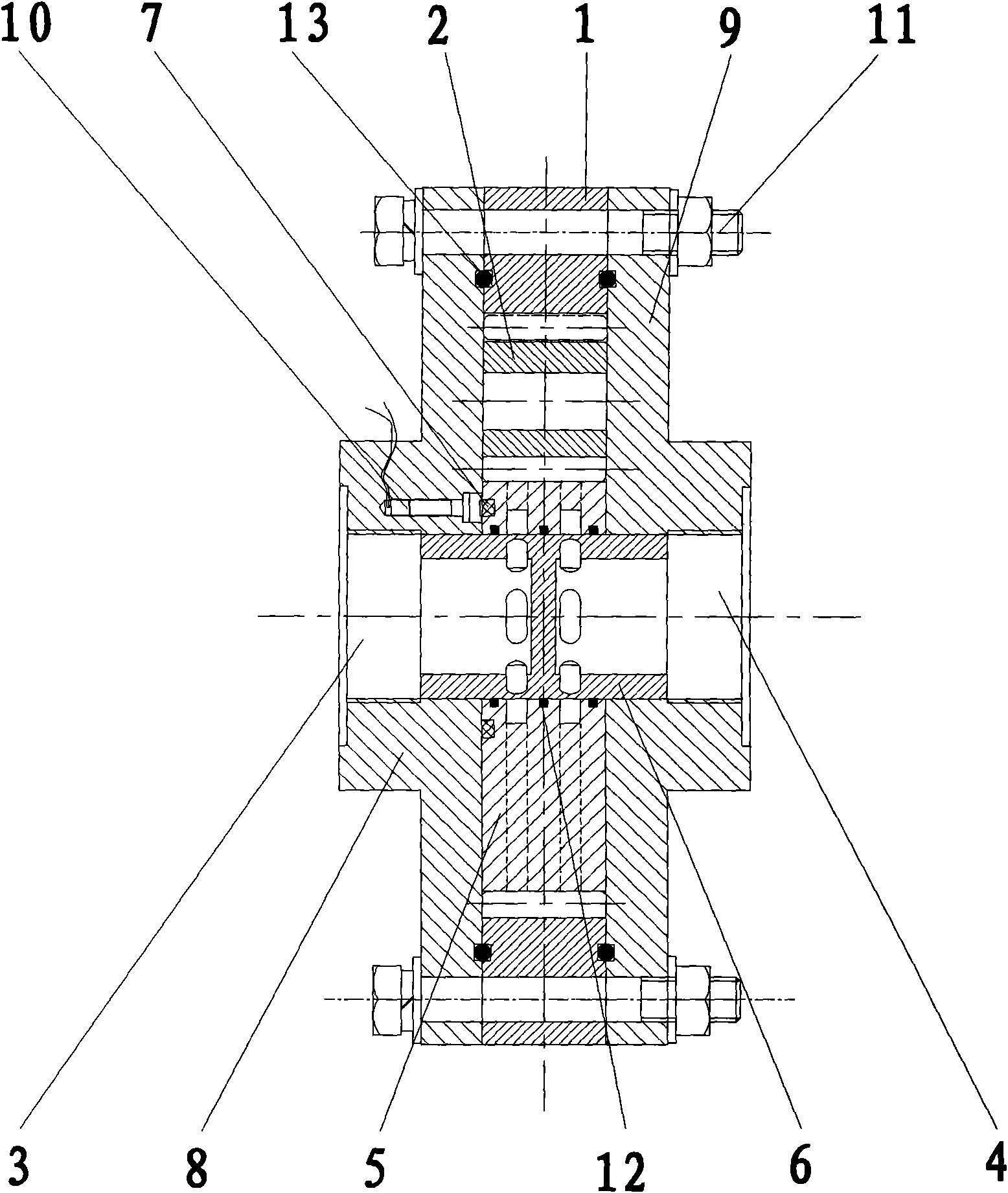

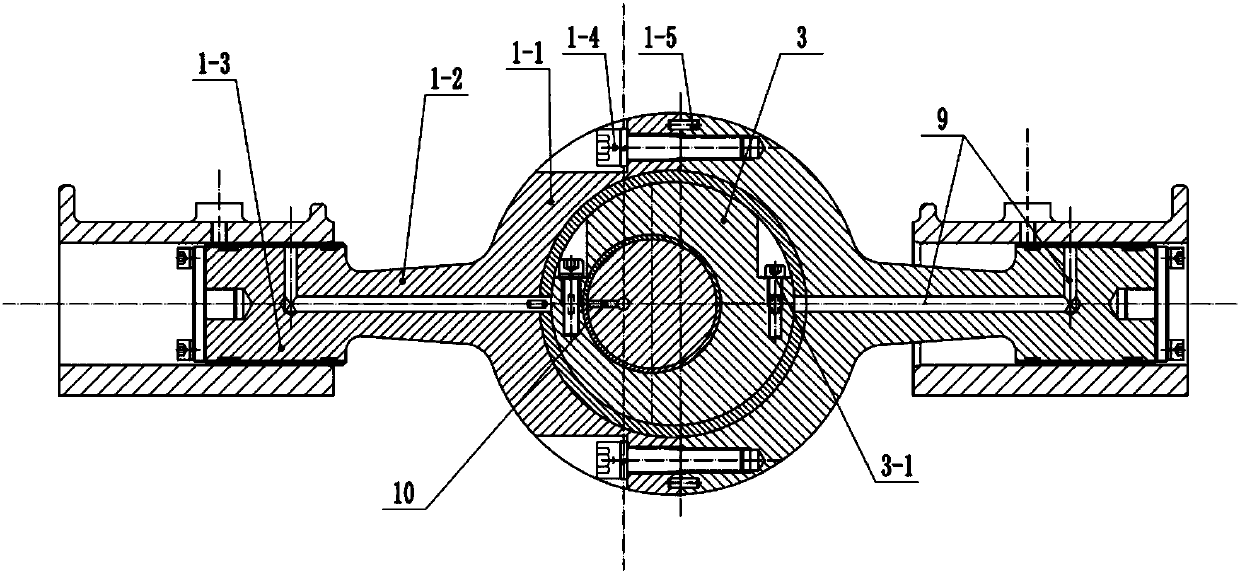

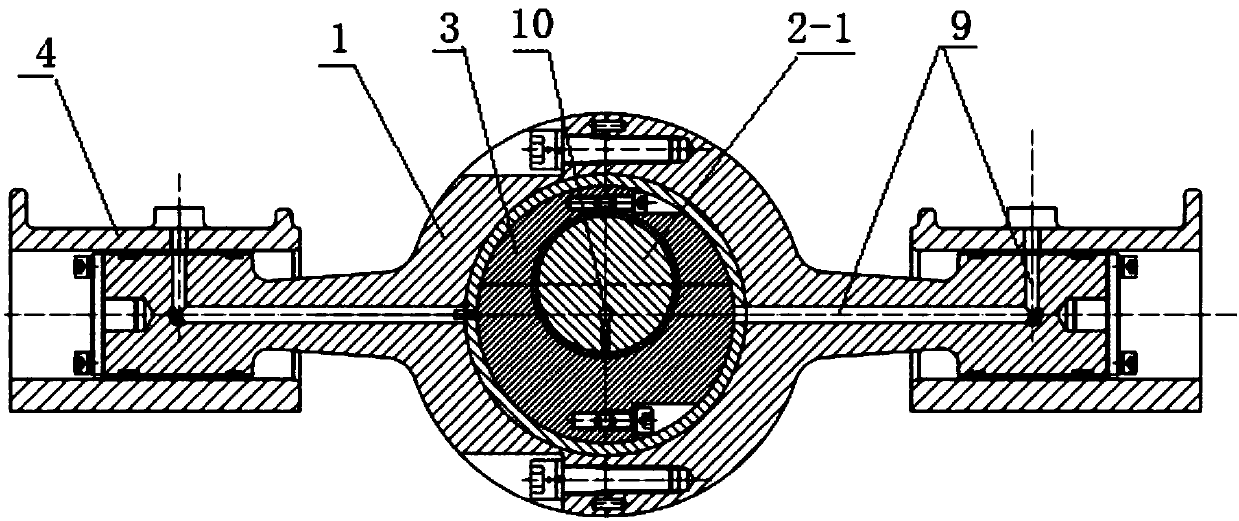

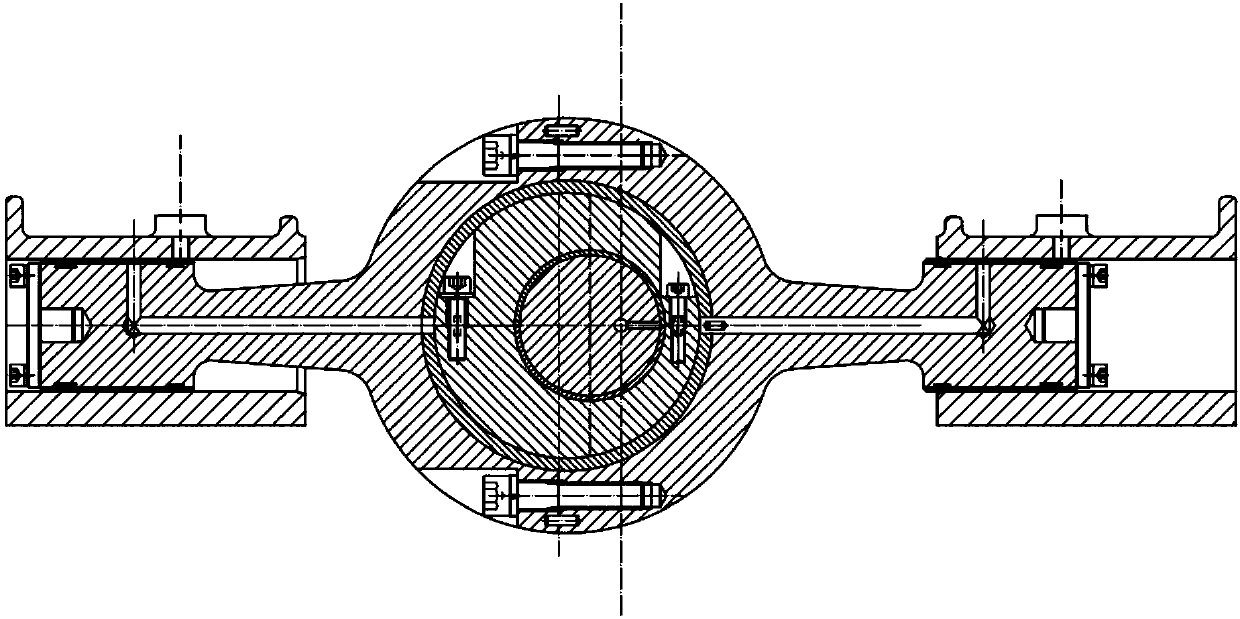

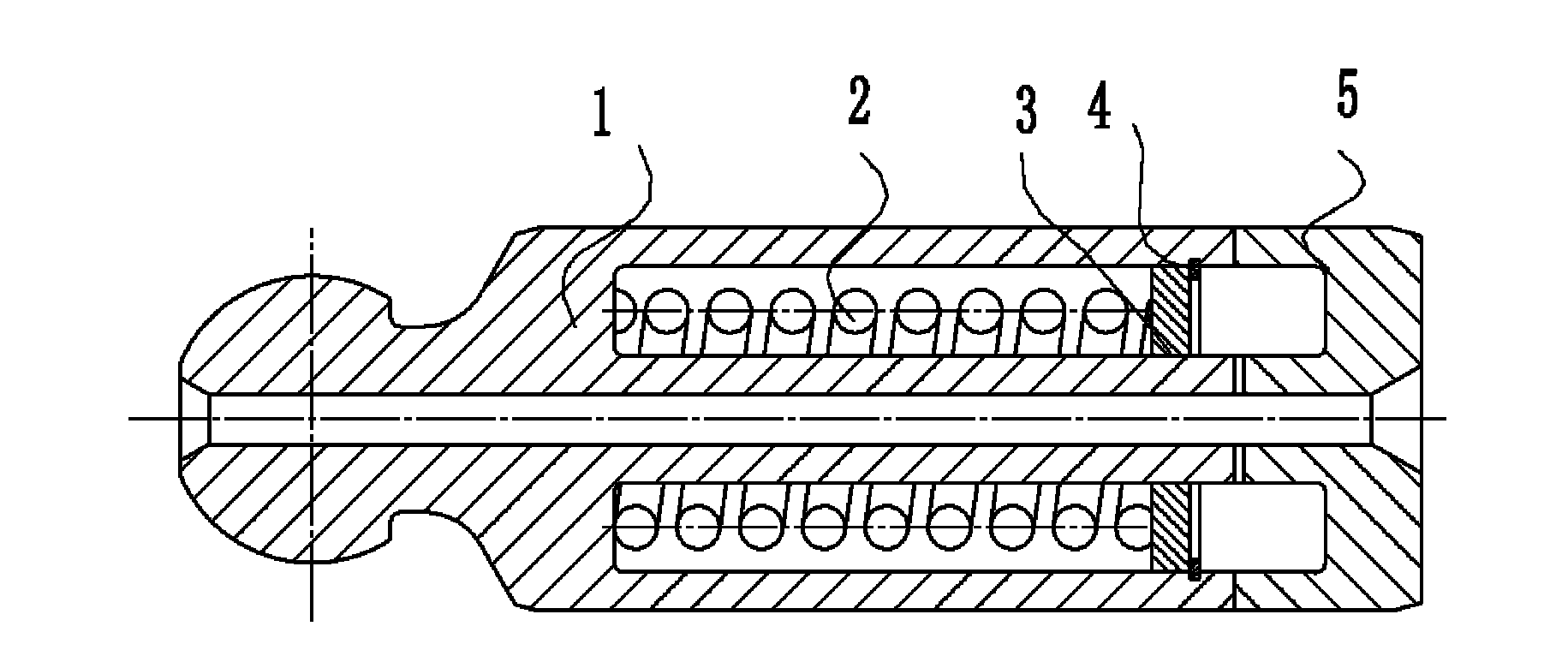

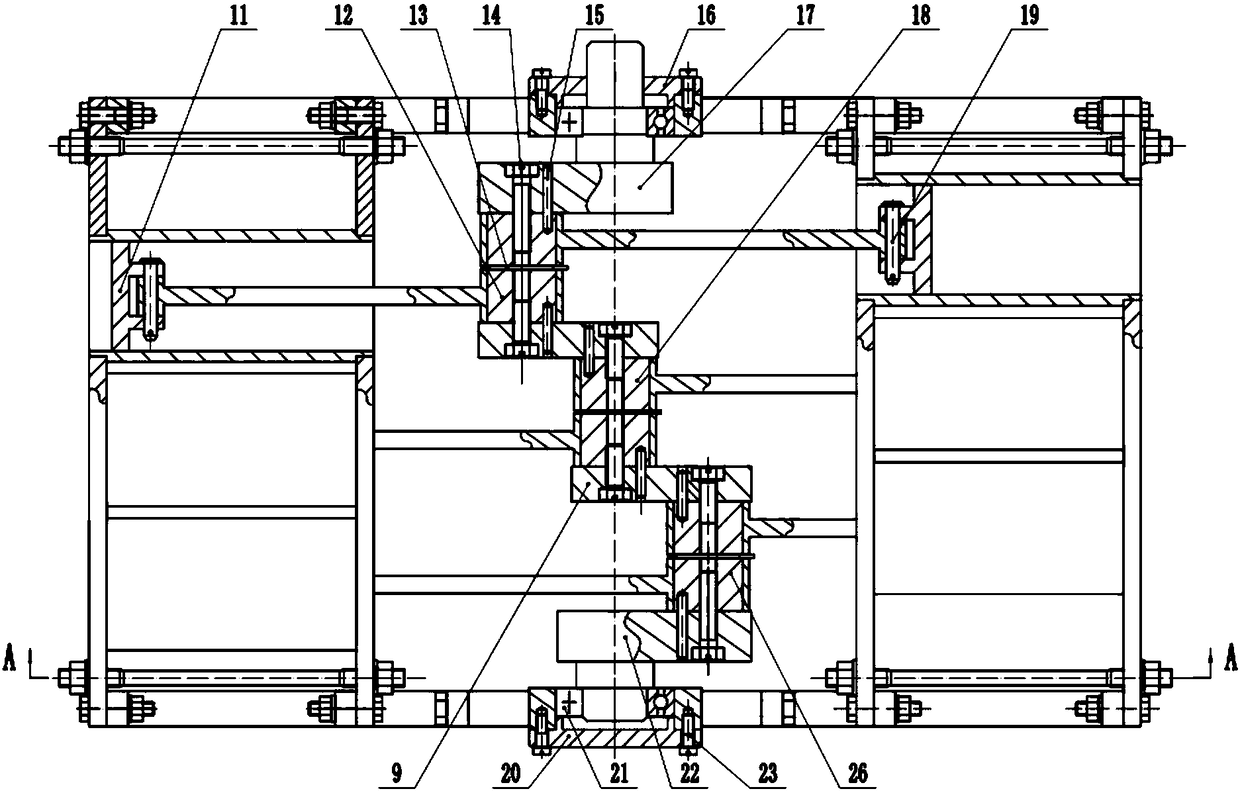

Low flow pulsation hydraulic pressure transformer

ActiveCN102562690AIncrease the number ofSmall flow pulsationFluid-pressure convertersEngineeringEnergy loss

The invention provides a low flow pulsation hydraulic pressure transformer, which comprises a spindle, a tilting tray, a left pressure transformation component and a right pressure transformation component, the tilting tray is a conical column table, a transverse through hole is machined in the center of the tilting tray, the spindle is transversely mounted in the through hole, and the left pressure transformation component and the right pressure transformation component are mounted at the left end and the right end of the spindle respectively and symmetrically arranged along a central axis of the tilting tray. By means of coaxial rotation of double rotators, the number of plungers working at each distributing port is doubled in each moment of the rotation process of the rotators, so that the flow pulsation of the hydraulic pressure transformer can be reduced, and system operation stability is improved. By the aid of the tilting tray capable of bidirectionally and freely rotating around the spindle, the pressure of an oil source can be adjusted to an arbitrary value without energy loss.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

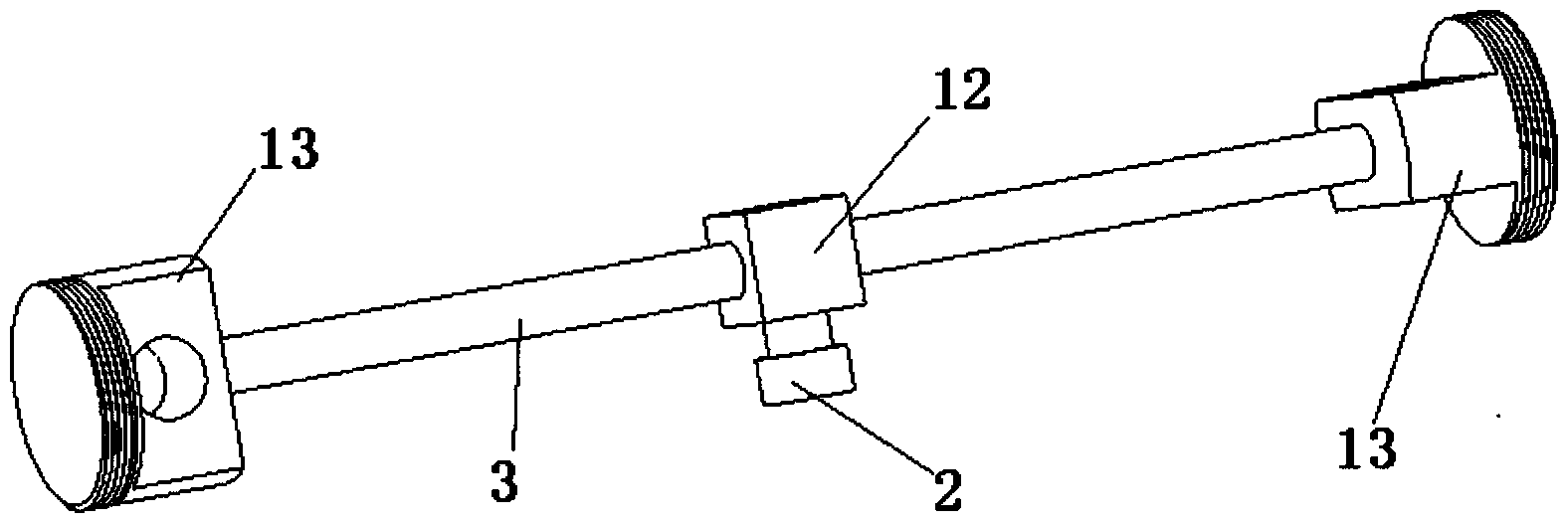

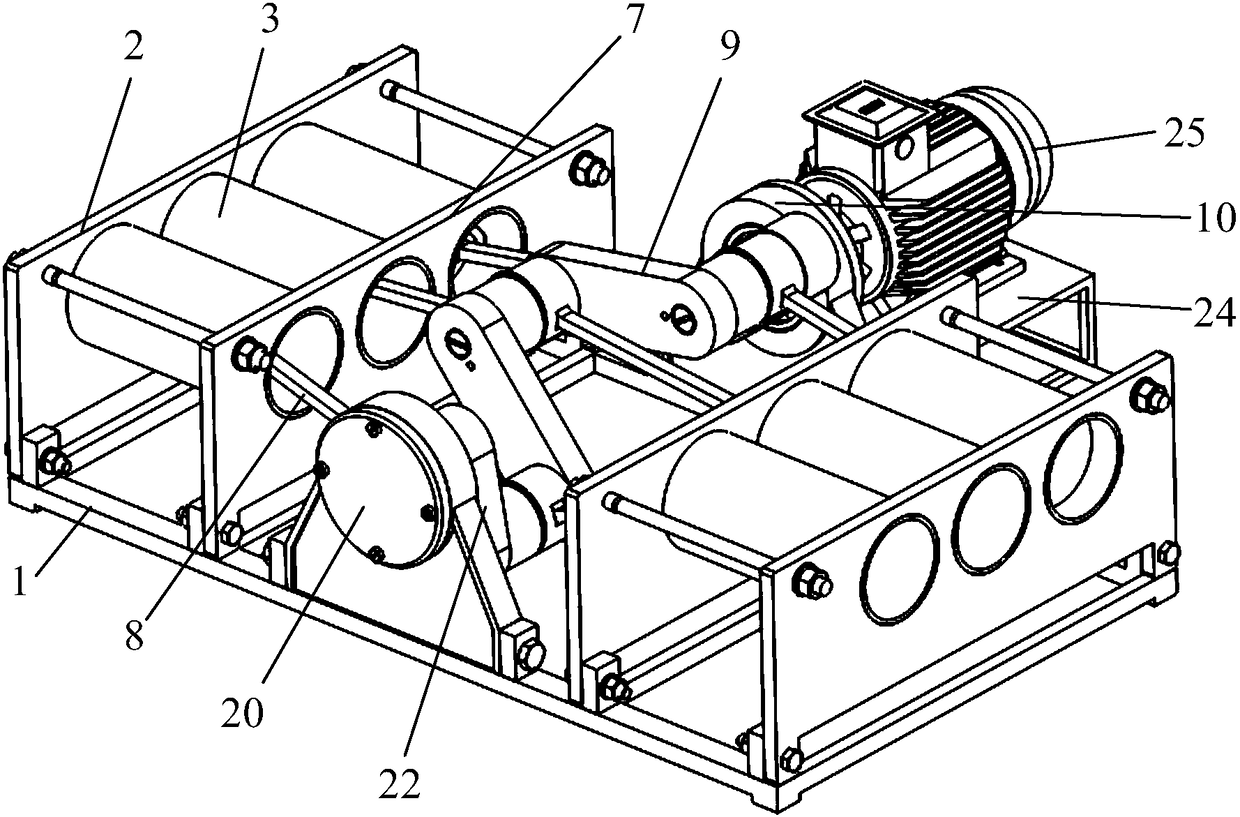

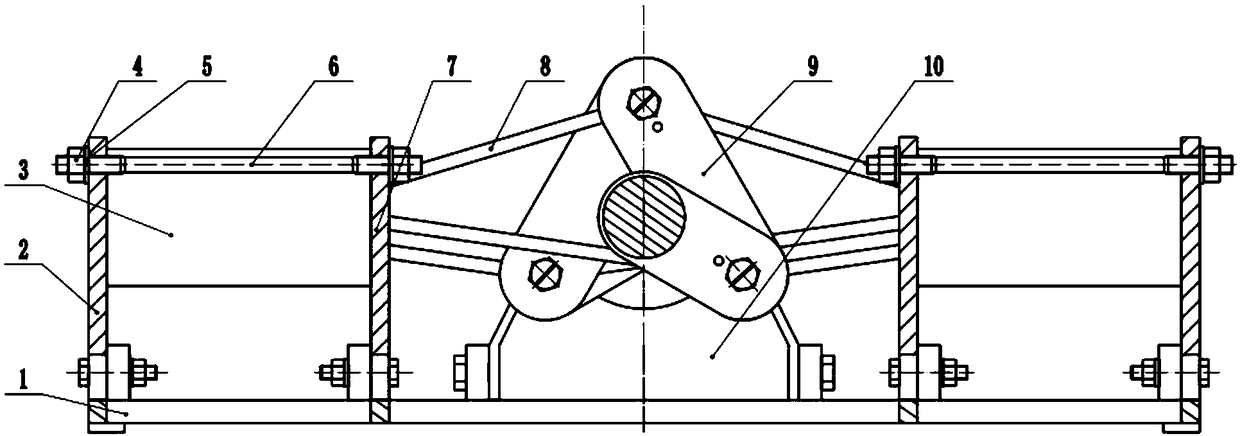

Cylindrical cam-driven multi-cylinder bi-directional plunger pump

ActiveCN104047823ASmall flow pulsationImprove stressPump installationsPositive-displacement liquid enginesEngineeringCam

A cylindrical cam-driven multi-cylinder bi-directional plunger pump comprises a cylindrical cam, a roller, plunger push rods, cylinder bodies and small cylinder bodies, wherein the cylindrical cam is in a cylindrical shape, the top surface and the bottom surface of the cylindrical cam are respectively provided with a cylindrical shaft, the side face of the cylindrical cam is provided with a groove, the roller is arranged in the groove, can slide in the groove and is fixedly connected with the plunger push rods through connecting devices, the two ends of each plunger push rod are provided with plungers which are arranged in the corresponding small cylinder bodies, the small cylinder bodies are positioned in the cylinder bodies and are provided with oil inlets and oil outlets, the cylinder bodies are provided with a main oil inlet and a main oil outlet, and the main oil inlet is communicated with the oil inlets. The cylindrical cam-driven multi-cylinder bi-directional plunger pump provided by the invention can meet the requirements of the plunger pump and reduce the flow pulsation of a reciprocating pump and improve the working efficiency, and has the characteristics of simple and reliable structure, low requirement on the bending resistance of the push rod, larger output and small flow pulsation.

Owner:SHAANXI UNIV OF SCI & TECH

Uniform motion pipeline pump

ActiveCN104061141ASolve the unsatisfactory flow pulsationSolve the requestPositive displacement pump componentsFlexible member pumpsEngineeringHigh pressure

The invention discloses a uniform motion pipeline pump. The uniform motion pipeline pump comprises a pump casing; a cylindrical inner cavity is formed in the pump casing; a plurality of convex curved surfaces are arranged on the inner wall of the cylindrical inner cavity; a central shaft is arranged in the inner cavity of the pump casing; two eccentric wheels are arranged on the central shaft; a bearing is fixed outside each eccentric wheel; a pressing wheel is fixed on each bearing; two gaps are formed between the two pressing wheels and the inner cavity wall of the pump casing; liquid passing pipes which can be deformed elastically are arranged in the two gaps; a filtering joint is arranged on the pump casing, and is provided with a liquid inlet hole and a liquid outlet hole. The liquid passing pipes are compressed completely by pressing wheels at the minimum gaps, and the liquid cannot pass; when the central shaft is driven by the motor to rotate, the pressing wheels press the liquid in the pipes through the liquid passing pipes; pressure difference is formed on the two sides of the minimum gaps; the liquid is inhaled on the low pressure side; the liquid is exhausted on the high pressure side; pulsating flow rates output by the two liquid passing pipes is combined into a flow rate with a relatively uniform pulsating range at the liquid inlet hole and the liquid outlet hole of the filtering joint.

Owner:楚天源创生物技术(长沙)有限公司

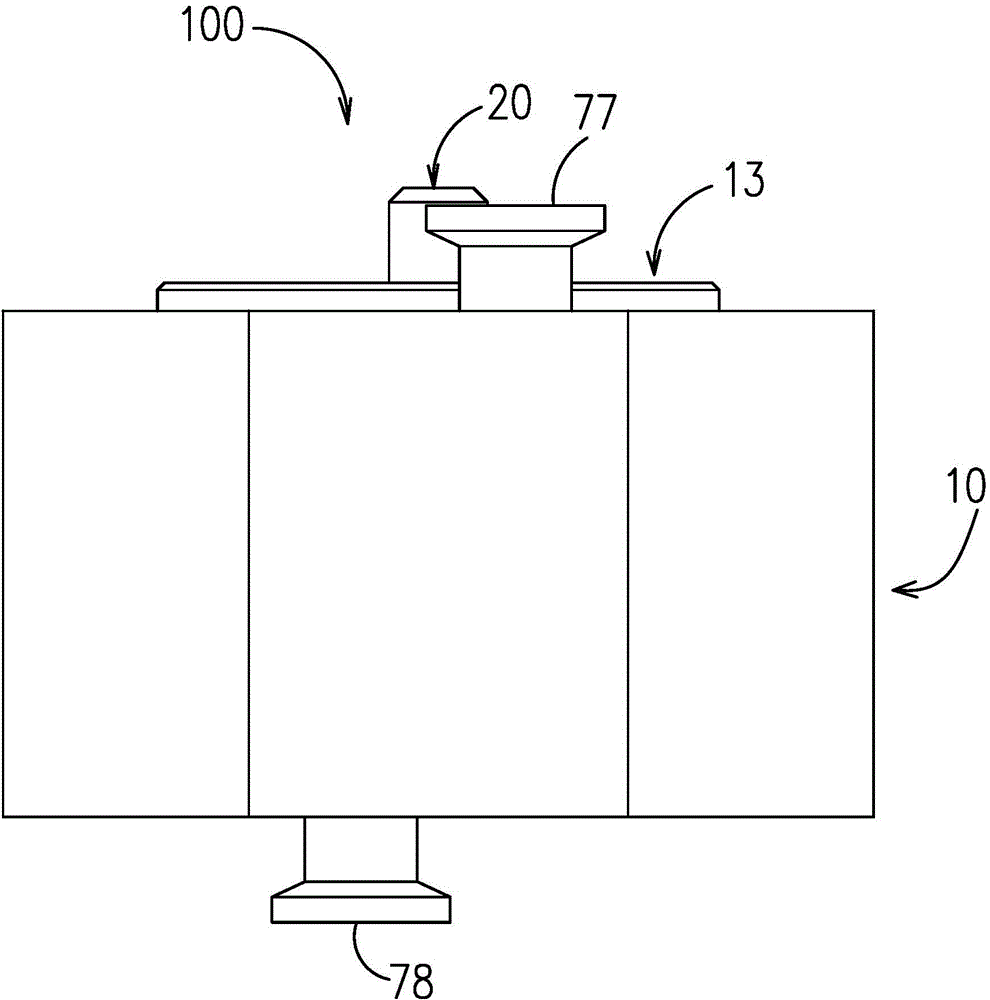

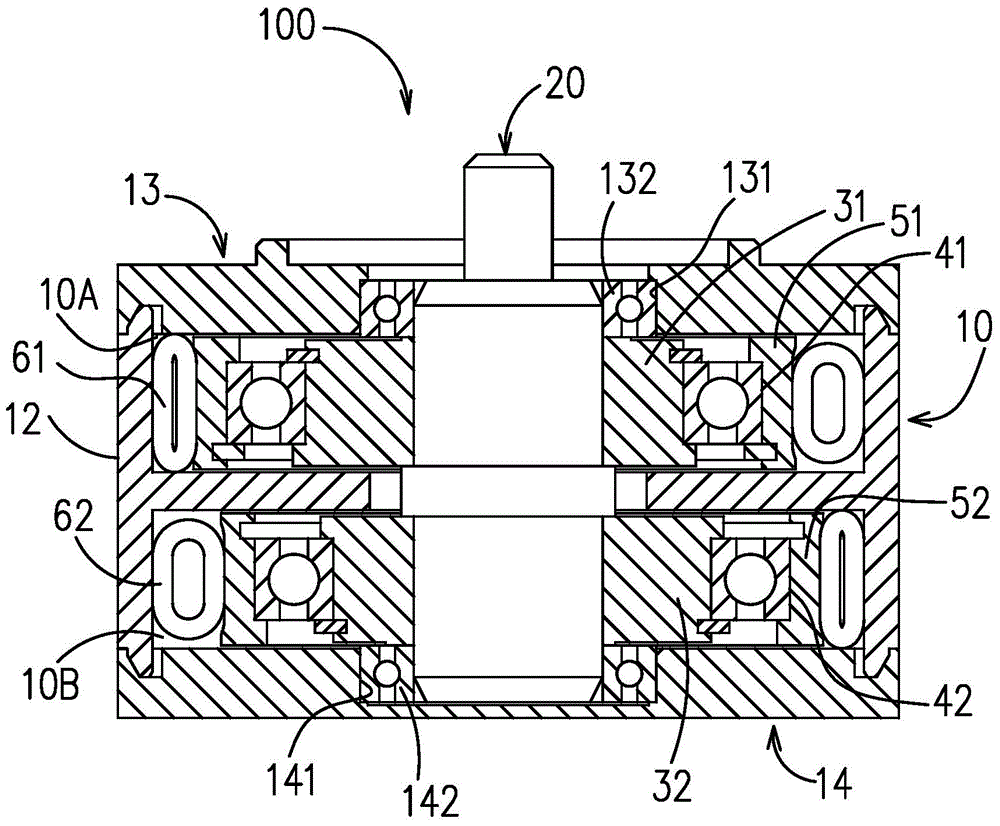

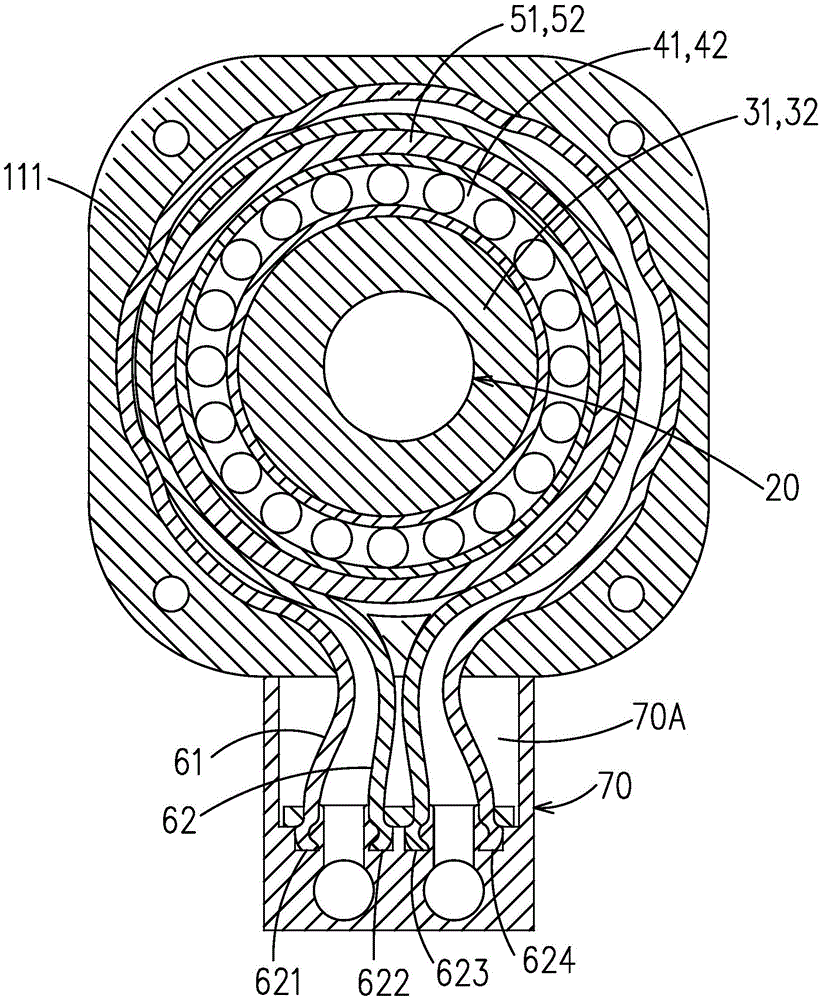

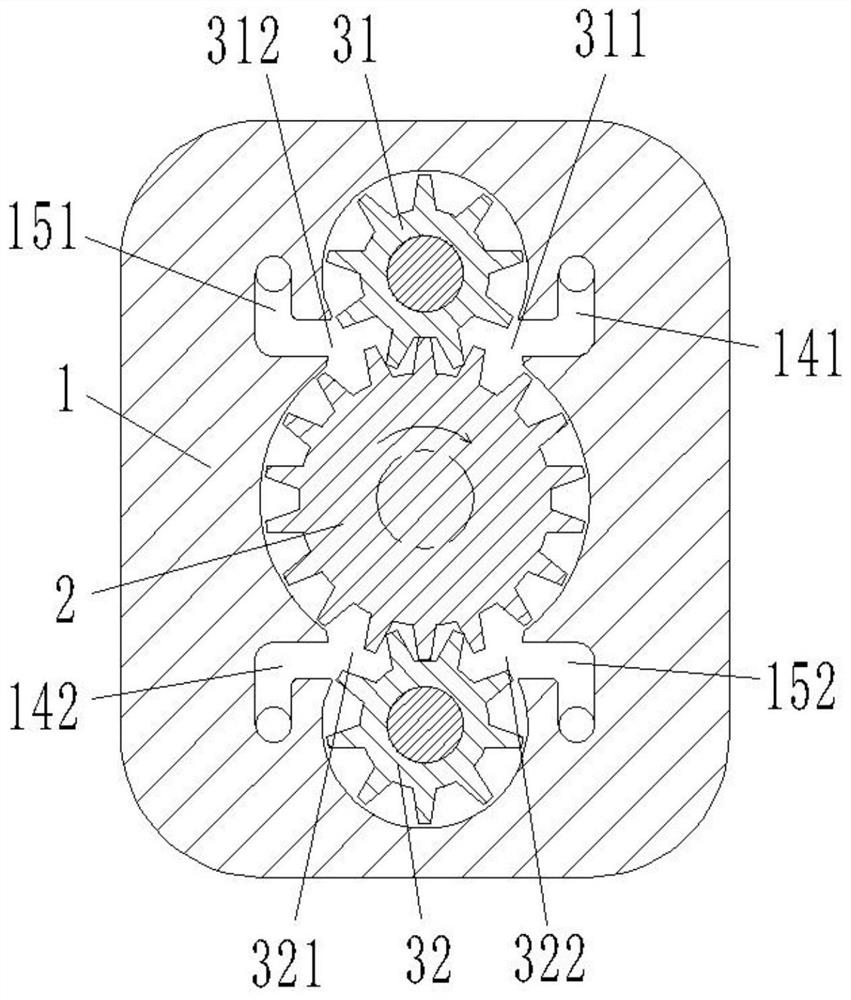

Pump

ActiveCN106438341AImprove cooling effectImprove efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringMotor efficiency

The invention provides a pump. The pump comprises a shell, a driving part and a fluid pumping part. A supporting separation part is arranged in the shell and divides the interior of the shell into a first cavity and a second cavity. An annular groove communicating with the second cavity is formed between the supporting separation part and the inner wall of the shell. The fluid pumping part is mounted in a mounting cavity of the supporting separation part. One end of the driving part penetrates through a through hole in the supporting separation part and then is connected with the fluid pumping part. The fluid pumping part presses fluid in the first cavity into the second cavity and pumps the fluid out of the second cavity. According to the pump, noise generated by the fluid pumping part in the rotating process is effectively absorbed and lowered through fluid filled up in the annular groove, and heat of the shell and the supporting separation part can be taken away. Overall heat dissipation of the shell is facilitated. Flow pulsation is small. The motor efficiency is high. The pump has the characteristics of being compact in structure, low in cost and noise and good in heat dissipation.

Owner:GREE ELECTRIC APPLIANCES INC

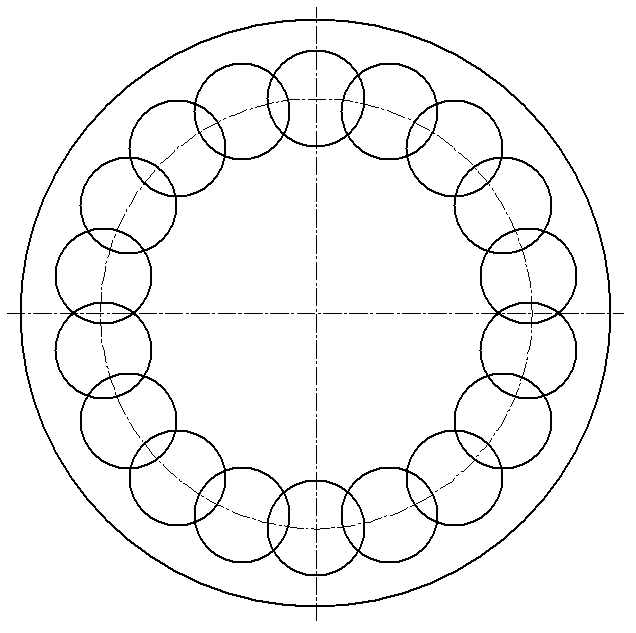

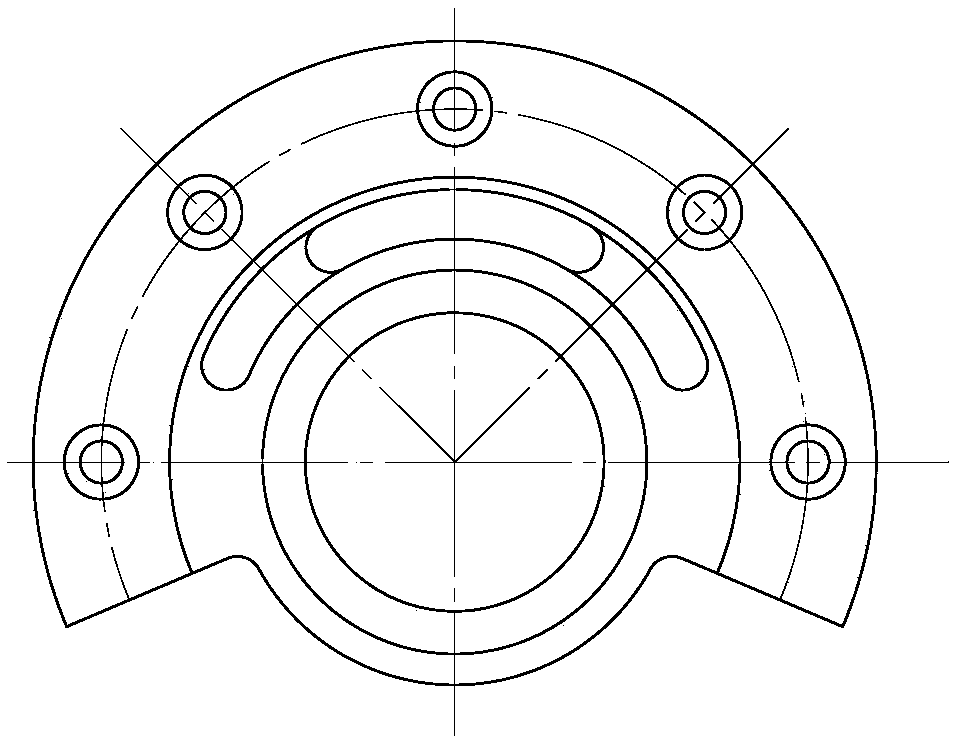

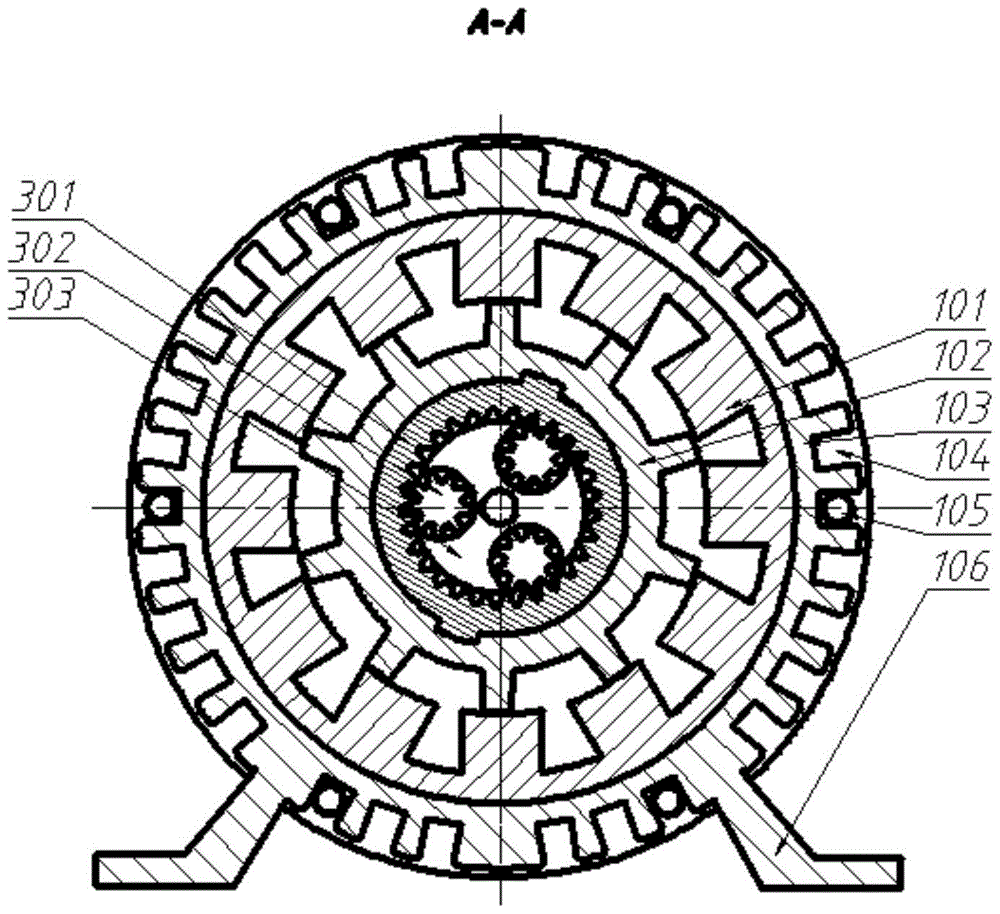

High-pressure dynamic internal gear flowmeter

InactiveCN101526379ASmall flow pulsationImproved traffic qualityVolume/mass flow by mechanical effectsWear resistantEngineering

The invention discloses a high-temperature dynamic internal gear flowmeter. An internal gear and a shell are fixed together, and the number of small pinions can be 2 to 4. Three pinions are taken as instance for description as follows: a liquid to be measured passes through a pintle valve and a retainer through an oil inlet to enter three oil inlet cavities of the internal gear; the three pinions and the retainer are pushed to move so as to bring the oil into three oil outlet cavities of the internal gear; the oil passes through the retainer and the pintle valve to reach an oil outlet; a flow rate signal of the liquid to be measured is converted to a rotating speed signal of the retainer, and the rotating speed signal is converted to an electric signal by a rotary transducer; and the dynamic flow rate of a system to be measured is determined by the measured electric signal finally. The pinions and the retainer are made of light wear resistant materials and have small moment of inertia; the tooth number of the internal gear is a non-three interger multiple, and the flow rate realizes dislocation and superposition; the flow pulsation of the flowmeter is very small, and the flow quality is obviously improved; and because the flowmeter belongs to a volumetric flowmeter, the flowmeter is not influenced by testing environmental conditions, can accurately measure the high-pressure flow rate of a hydraulic system, has the advantages of wide measuring range, high precision, good reliability and the like, and can be widely used for measuring the flow rate of high-pressure hydraulic systems in the industries such as chemical engineering, coal mine, metallurgy and the like.

Owner:ANHUI UNIV OF SCI & TECH

Contraposition linear reciprocating pump driving mechanism

PendingCN107642469AEliminate poor lubricationImprove reliabilityPositive displacement pump componentsPositive-displacement liquid enginesEngineeringMechanical engineering

The invention discloses a contraposition linear reciprocating pump driving mechanism. The contraposition linear reciprocating pump driving mechanism comprises a slide block mechanism, a crankshaft andan eccentric slide block, wherein the slide block mechanism is composed of a slide block, two connection rods and two pistons, and the central axis of the two pistons is orthogonal to that of the slide block; a crank throw of the crankshaft is sleeved with the eccentric slide block, the slide block concentrically sleeves the eccentric slide block, and the pistons are coaxially inserted into two symmetric slide ways on a reciprocating pump rack; the eccentric slide block rotates on the axis of the slide block around the crank throw while following the crank throw to rotate around the crankshaft, in the entire rotation process, the center axis of the eccentric slide block is maintained parallel to the center axis of the crank throw all the time, so that the movement trail of the eccentric slide block in the horizontal direction is approximately linear, through the eccentric slide block, the slide block is driven to conduct linear movement, and then the two pistons conduct reciprocatinglinear movement in the two symmetric slide ways of the reciprocating pump respectively.

Owner:宝鸡航天动力泵业有限公司

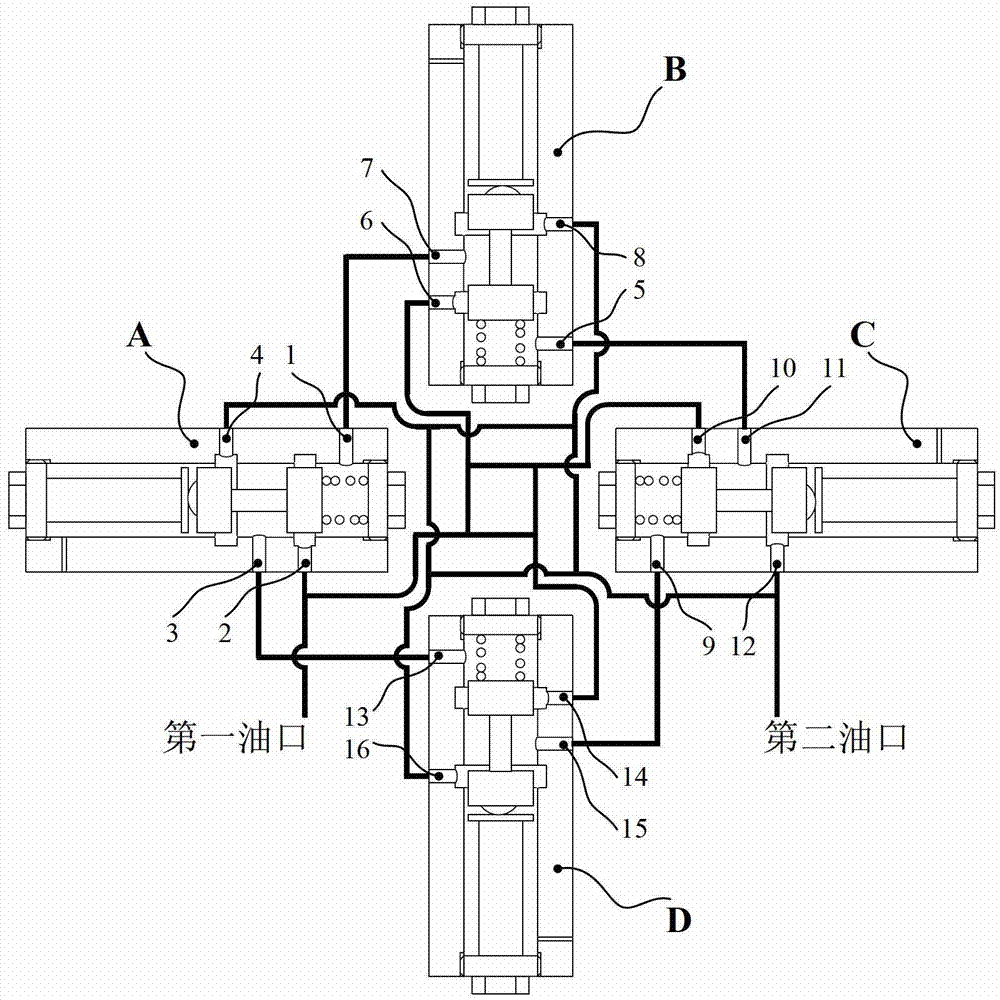

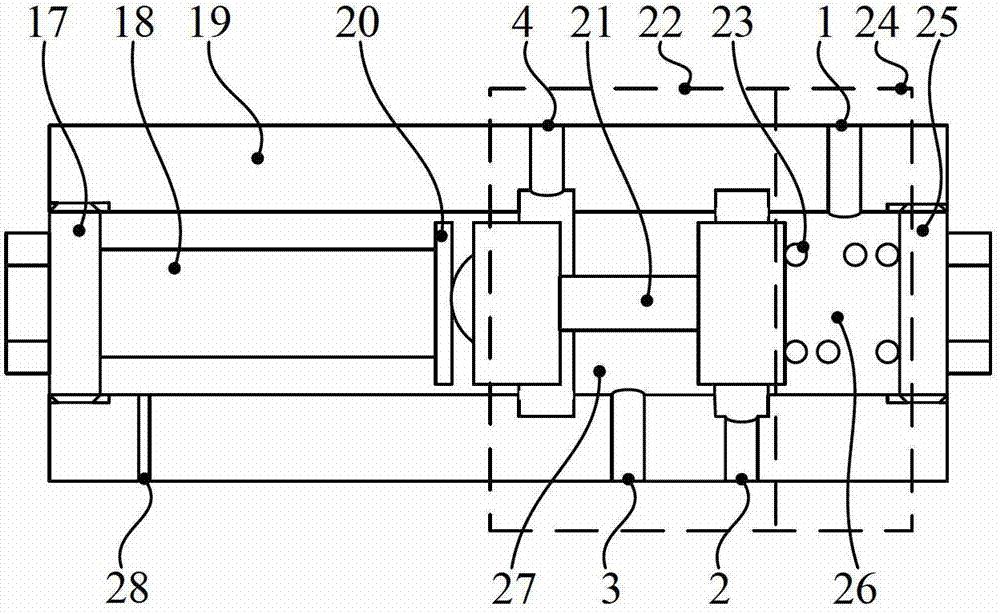

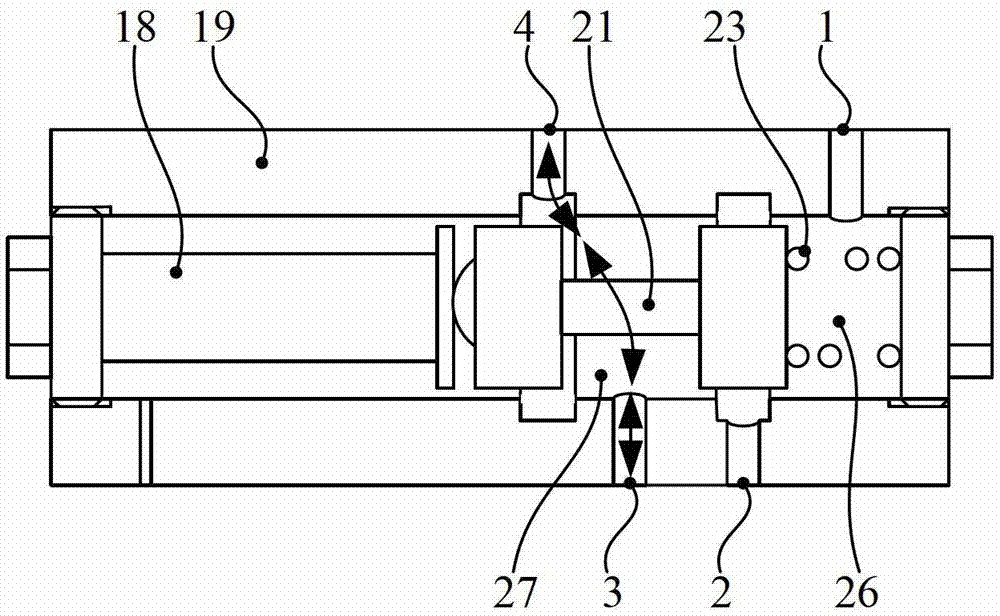

Multi-piezoelectric-drive circulation active distribution pump

ActiveCN103133322BAchieve continuous flow outputIncrease output powerPump controlPositive-displacement liquid enginesElectricityComputer module

The invention discloses a multi-piezoelectric-drive circulation active distribution pump and belongs to the technical field of piezo-hydraulics. The multi-piezoelectric-drive circulation active distribution pump mainly comprises four piston-valve modules and an oil circuit for connecting the four modules. The four piston-valve modules include a piston-valve module A, a piston-valve module B, a piston-valve module C and a piston-valve module D. The four piston-valve modules are the same and are mutually connected through the oil circuit. Each piston-valve module comprises a piston operation area and a reversing valve operation area, which are driven by a stacked piezoceramic driver simultaneously. The stacked piezoceramic drivers are driven by sinusoidal signals to sinusoidally reciprocate so as to drive the piston-valve modules to operate. The multi-piezoelectric-drive circulation active distribution pump driven by multiple stacked piezoceramic drivers allows for continuous oil suction and drainage and reduced flow pulsation. In addition, system output efficiency is increased, and output flow and output direction are controlled conveniently.

Owner:BEIHANG UNIV

Low-inertia plunger resisting pressure impact

ActiveCN102588269AReduce volumeLight in massPositive displacement pump componentsLiquid fuel engine componentsEngineeringPlunger

A low-inertia plunger resisting pressure impact comprises a left plunger body and a right plunger body. The right end face of the left plunger body is fixedly connected with the left end face of the right plunger body, and a center cavity is formed in the middle of the left plunger body and the right plunger body. A left annular groove arranged circumferentially is formed on the left plunger body, the opening of the left annular groove is located on the right end face of the left plunger body, a spring, an annular retainer ring and a snap ring are mounted in the left annular groove, the back end of the spring is butted to the bottom of the left annular groove, the front end of the spring is butted against the annular retainer ring, the annular retainer ring is slidably hermetically mounted in the left annular groove and is limited by the snap ring, and the snap ring is mounted in the left annular groove. A right annular groove is circumferentially formed on the right plunger body, the opening of the right annular groove is located on the left end face of the right plunger body, and is communicated with that of the left annular groove, and the right annular groove is communicated with the center cavity through a through hole. Both the inertia of the plunger and flow pulsation can be reduced.

Owner:ZHEJIANG UNIV

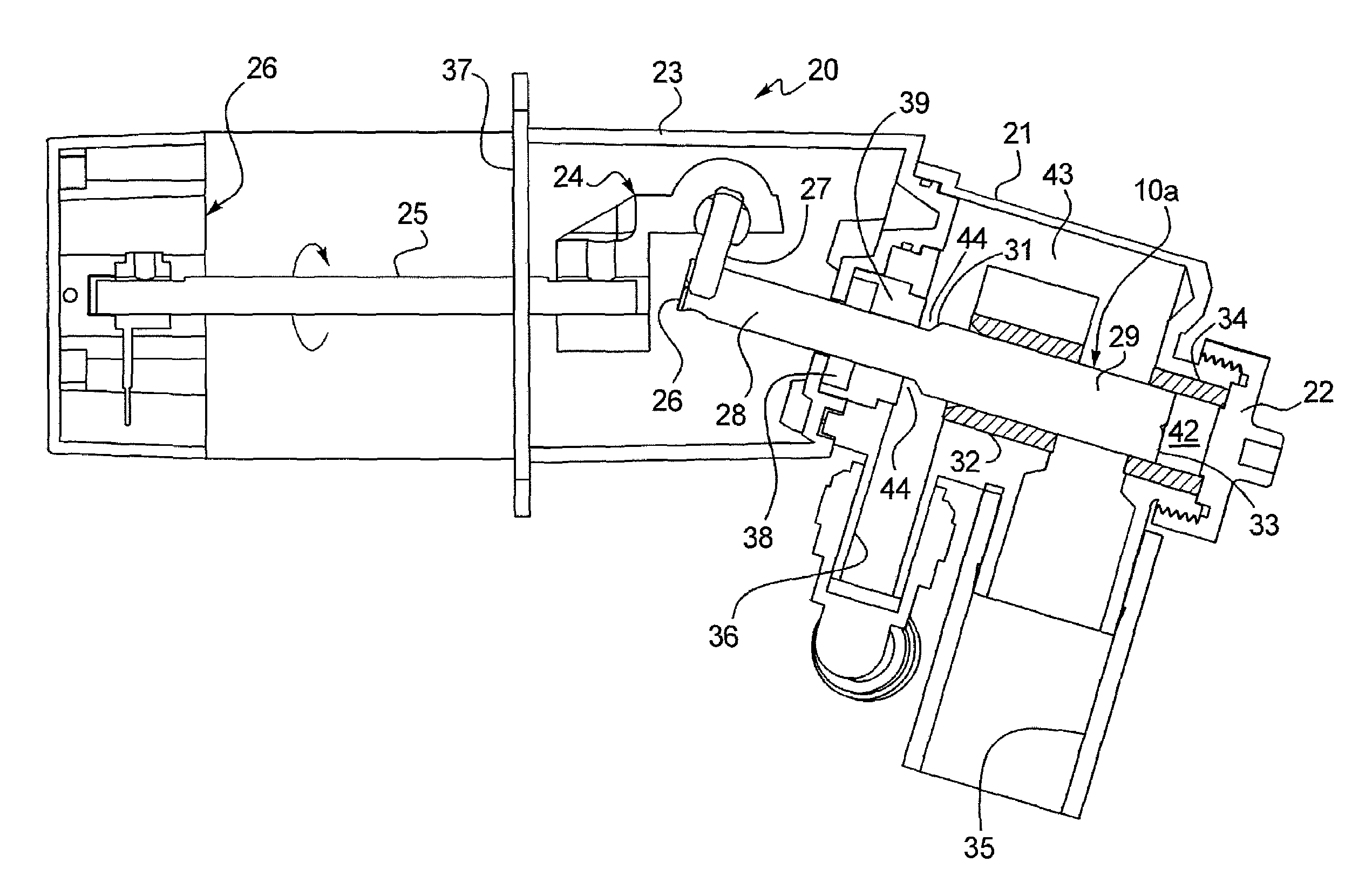

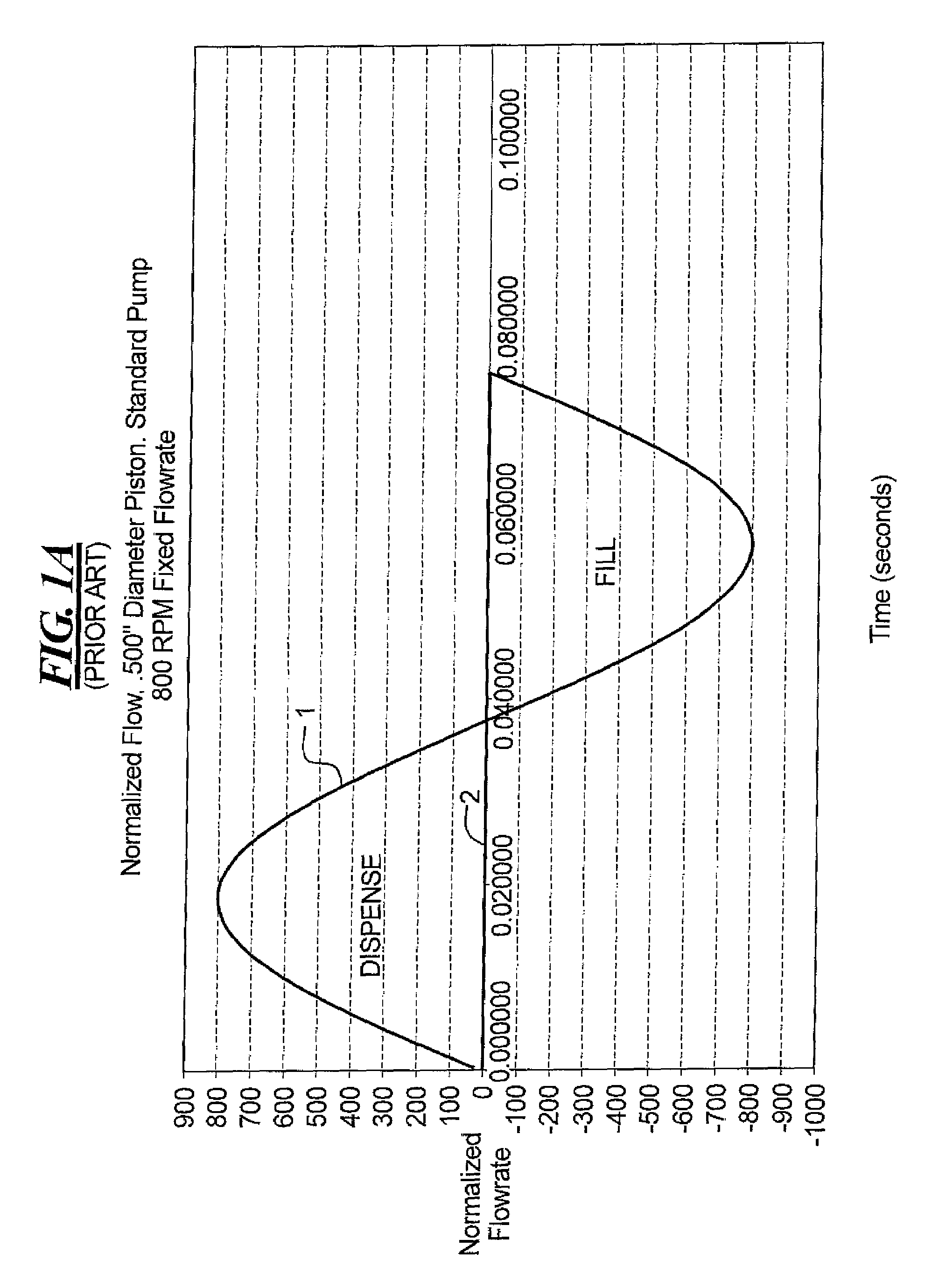

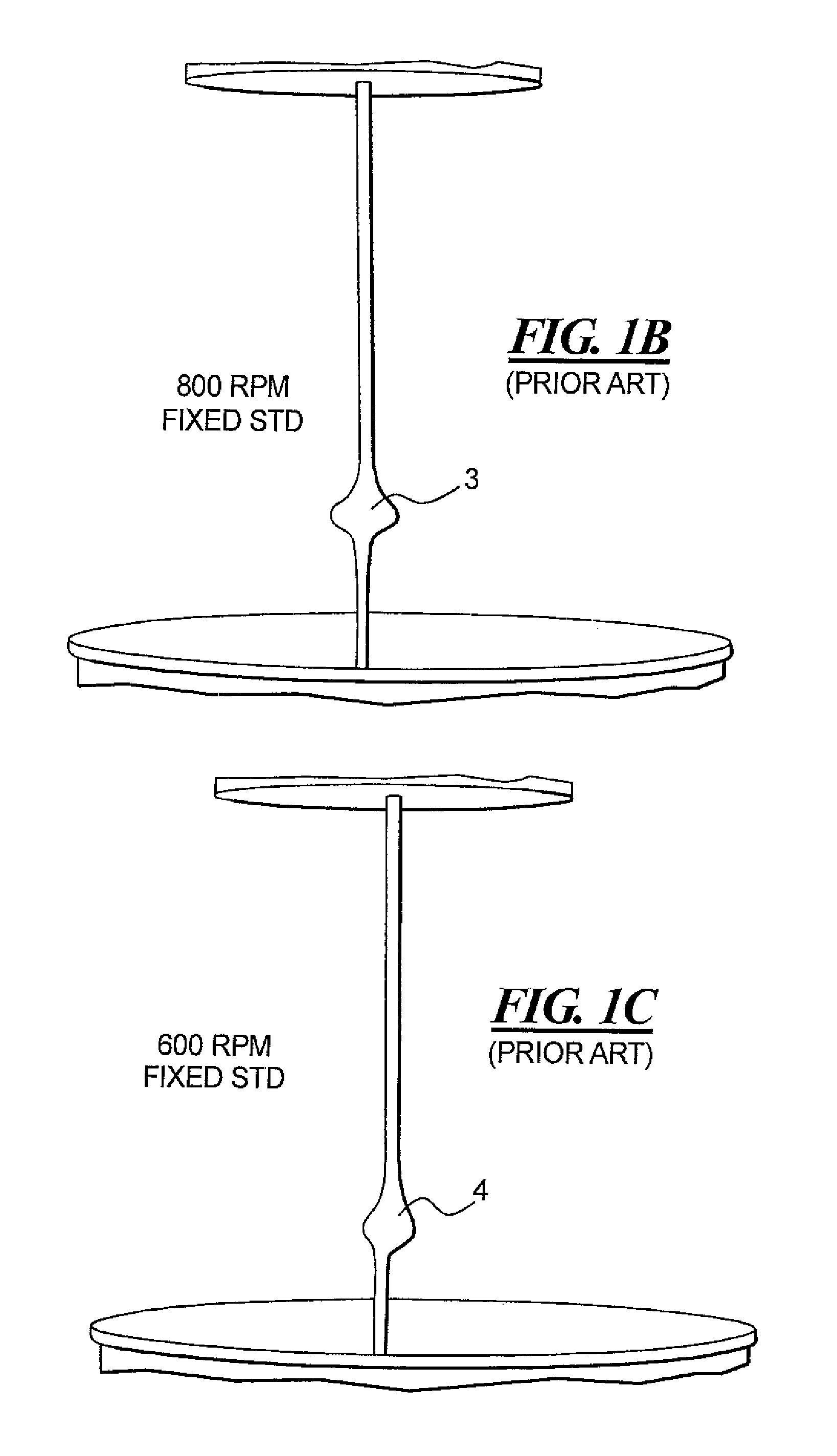

Nutating pump with reduced pulsations in output flow

ActiveUS7648349B2Improve flow patternReducing eliminating occurrencePositive displacement pump componentsPiston pumpsPump chamberEngineering

A nutating pump is disclosed which has a modified piston and housing or casing that provides two distinct pump chambers or areas. Output from the first pump chamber is delivered during a first half of the dispense cycle or the piston movement cycle. A substantial portion of this output is held for delivery by the second chamber during a second part or half of the dispense cycle. Thus, the output generated by the pump is not altered or reduced, it is delivered over the entire piston movement cycle as opposed to prior art pumps which deliver all of the fluid during a first half or first portion of the piston movement cycle. In this way, superior pulse modification is achieved as fluid is delivered across the entire piston movement cycle as opposed to a first half or first portion of the piston movement cycle. In additional embodiments disclosed, two distinct chambers are also provided but each chamber generates its own output as the piston includes two machined or flat sections for active pumping. Thus, each chamber generates its own positive output flow but the flow from each chamber is delivered during a different half of the piston movement cycle. Thus, the flow is still distributed throughout the entire piston movement cycle. In the first embodiment with a first and second chamber, the second chamber essentially acts as a holding station for fluid to be delivered during a second half of the piston movement cycle.

Owner:FLUID MANAGEMENT LLC

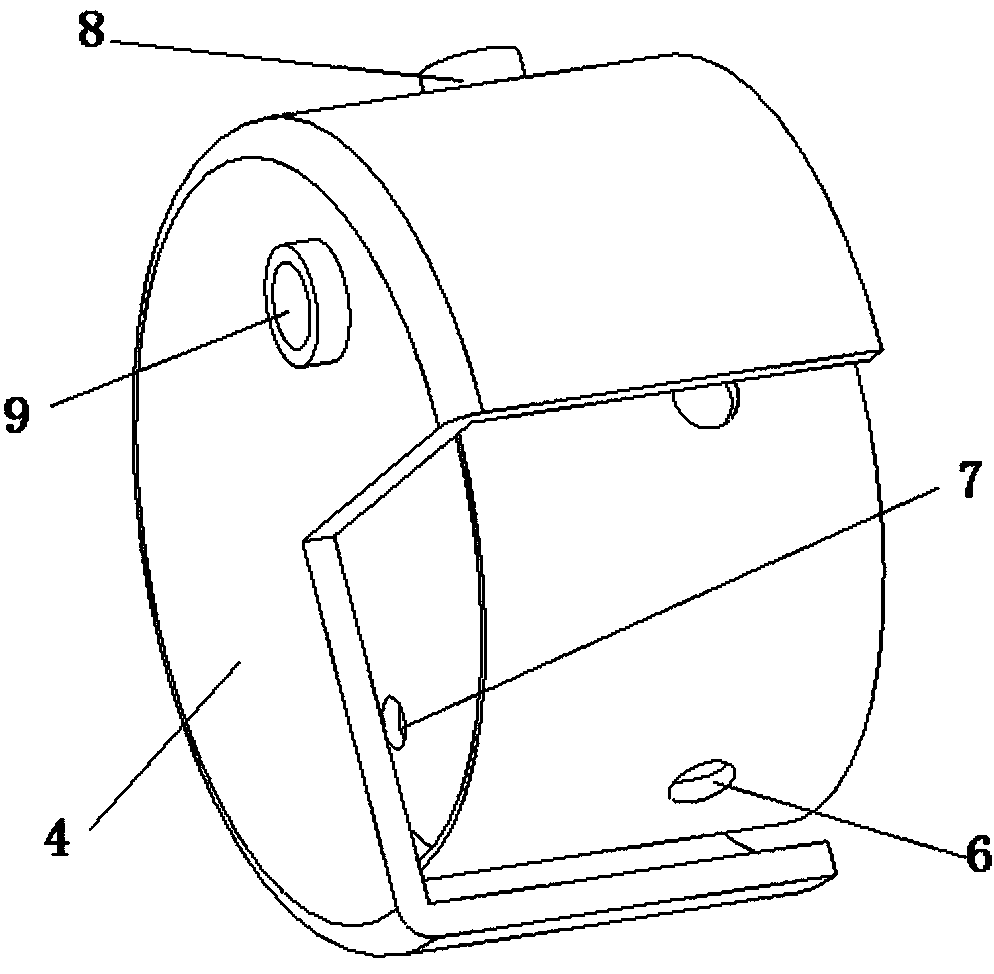

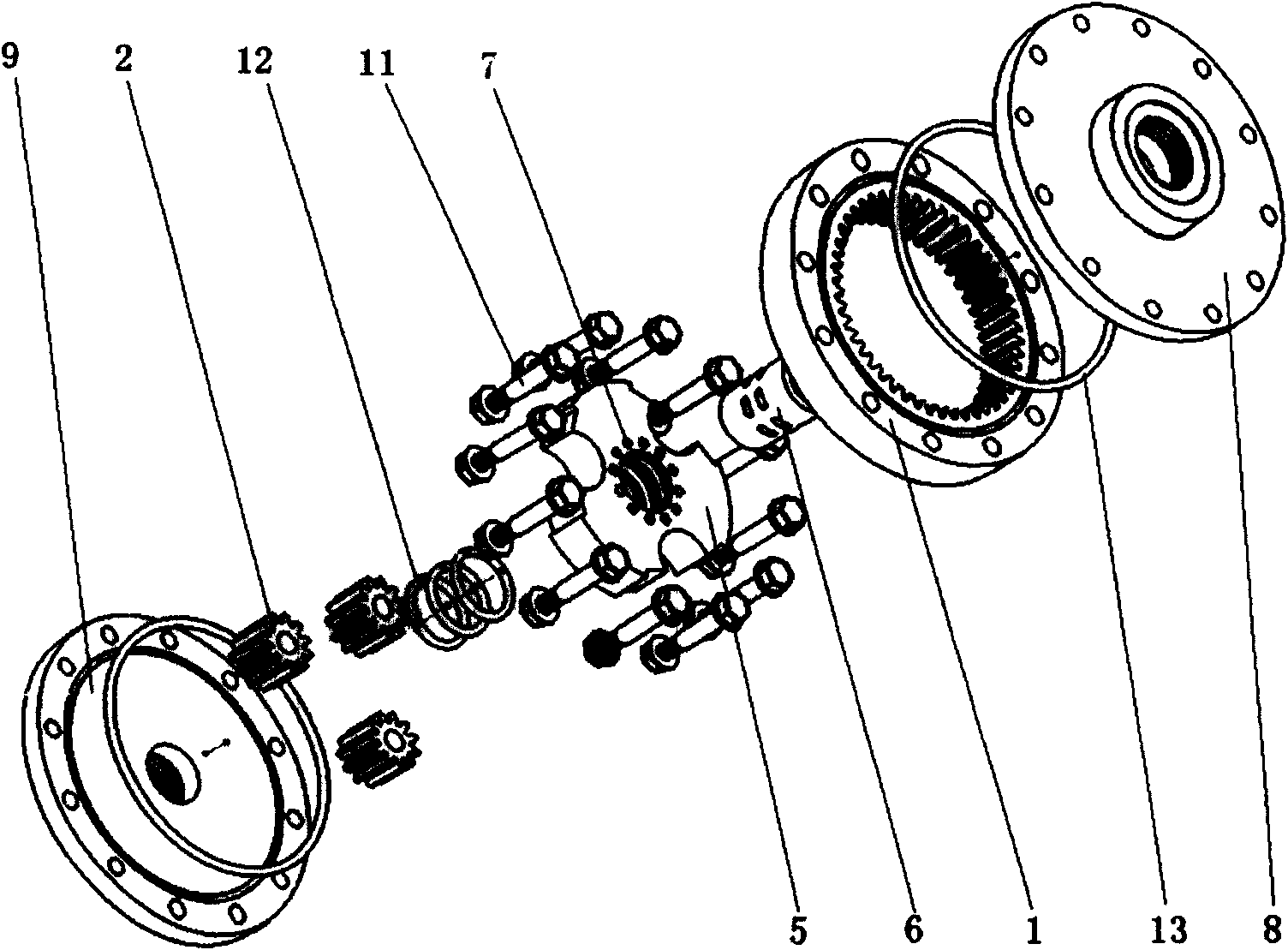

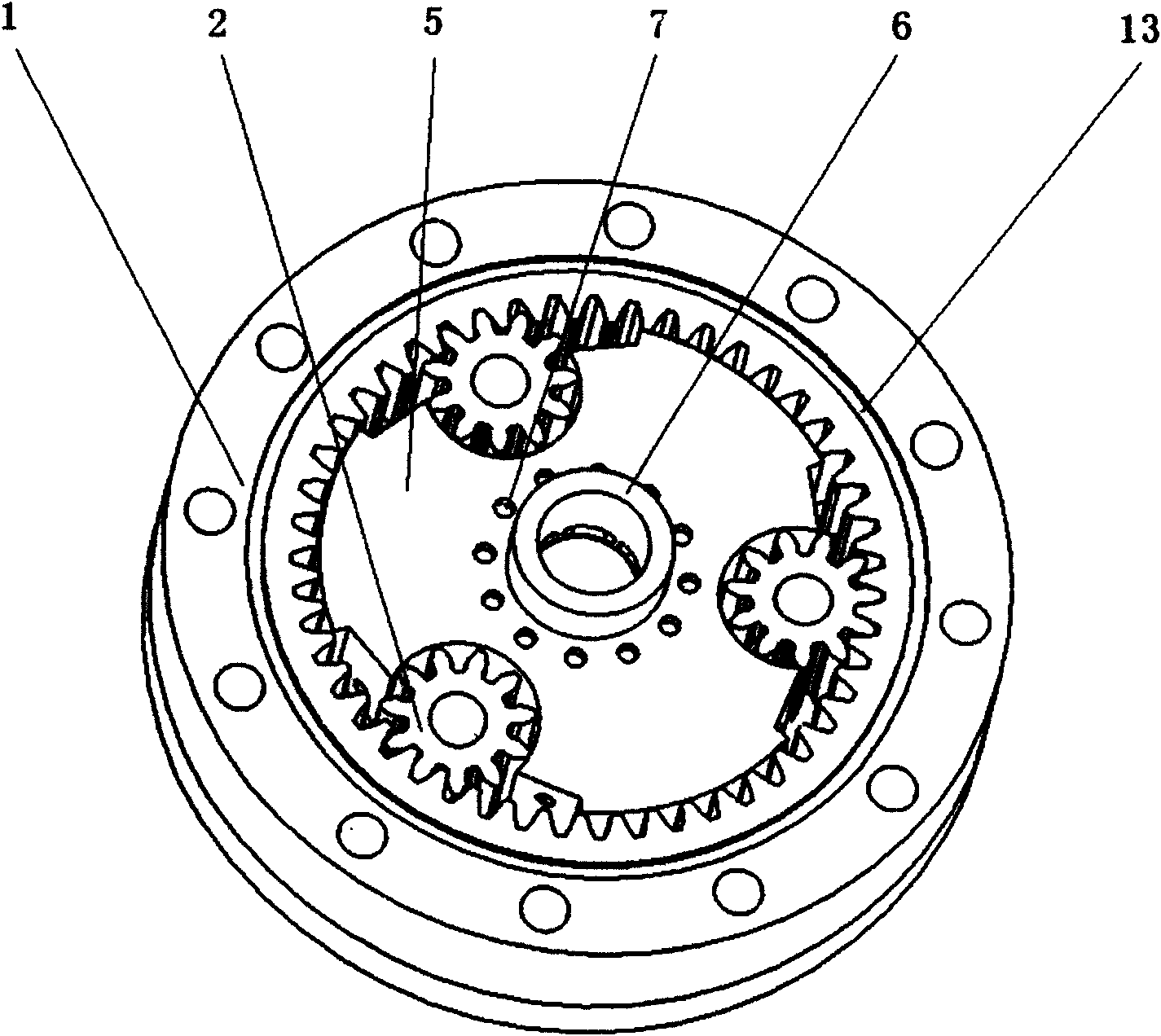

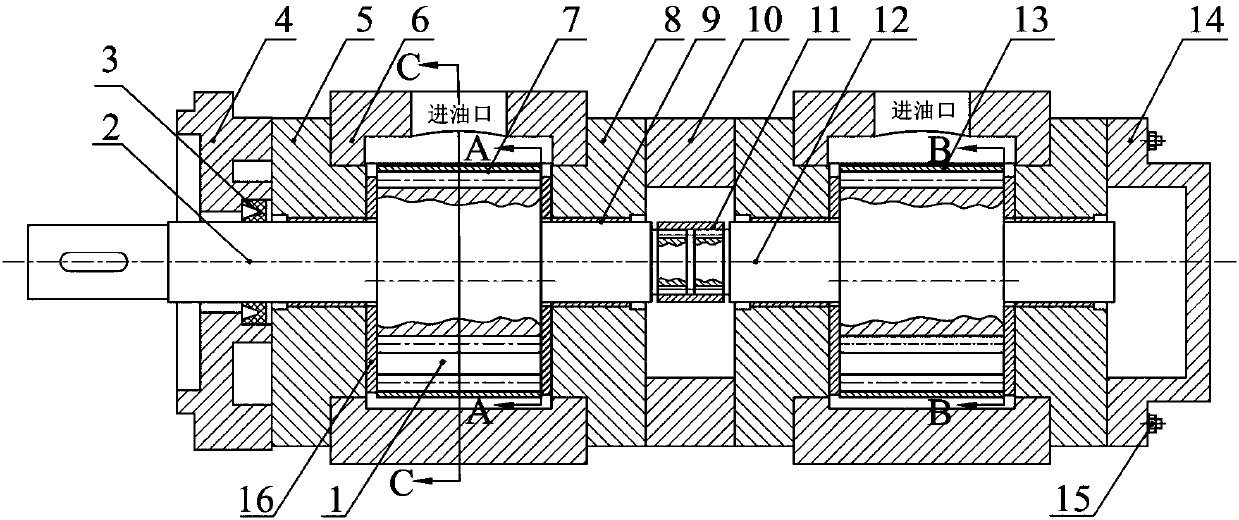

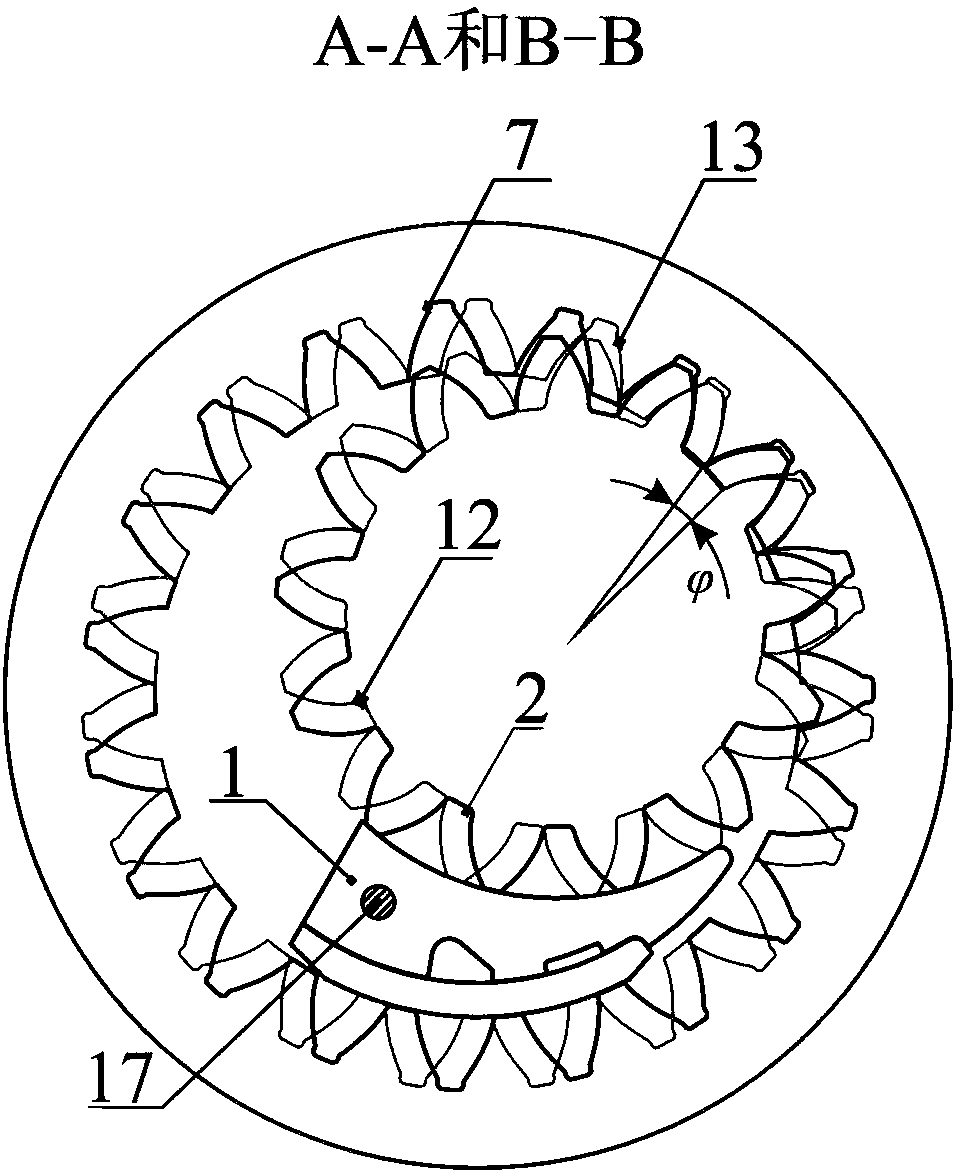

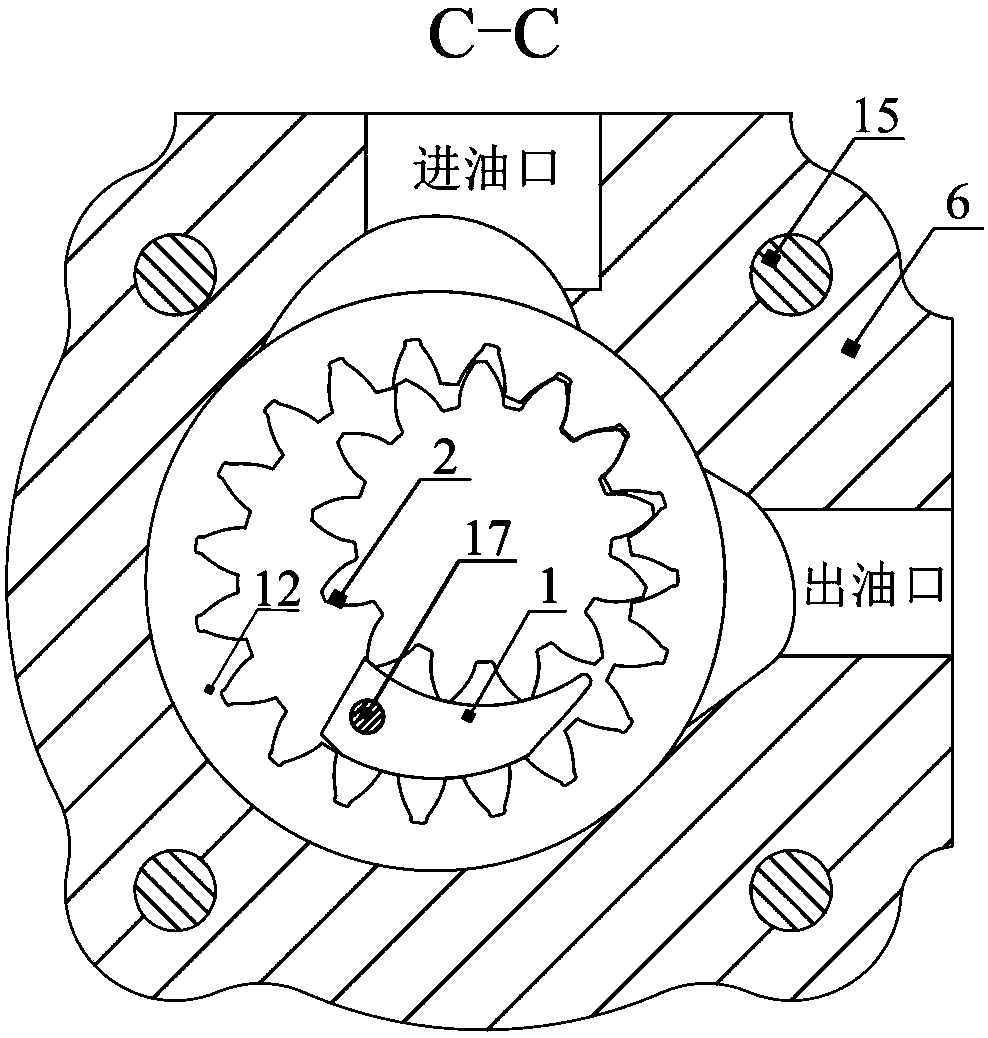

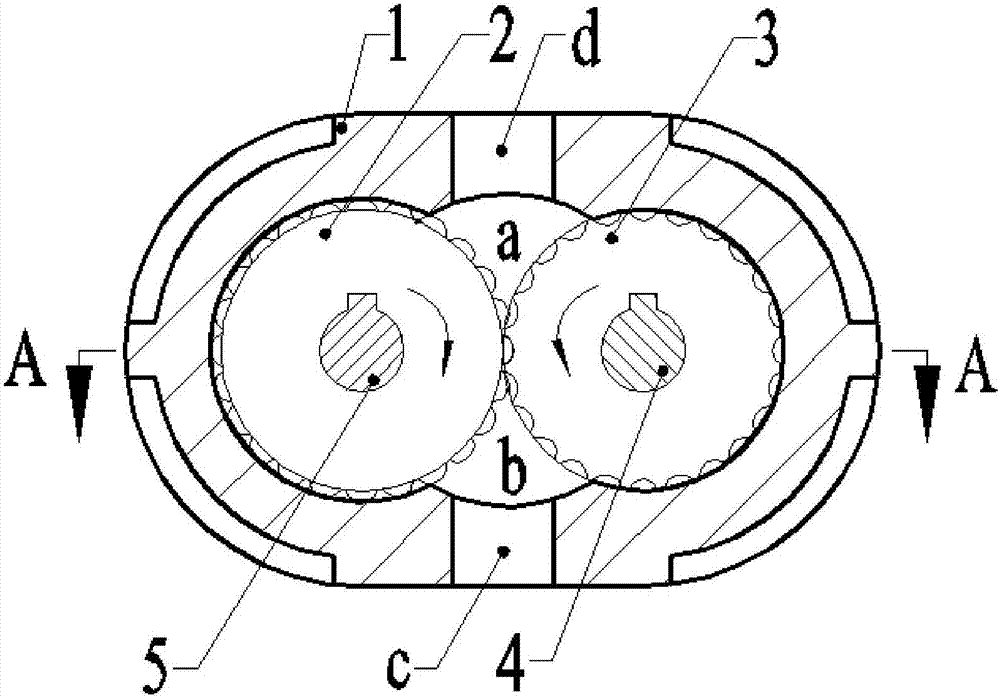

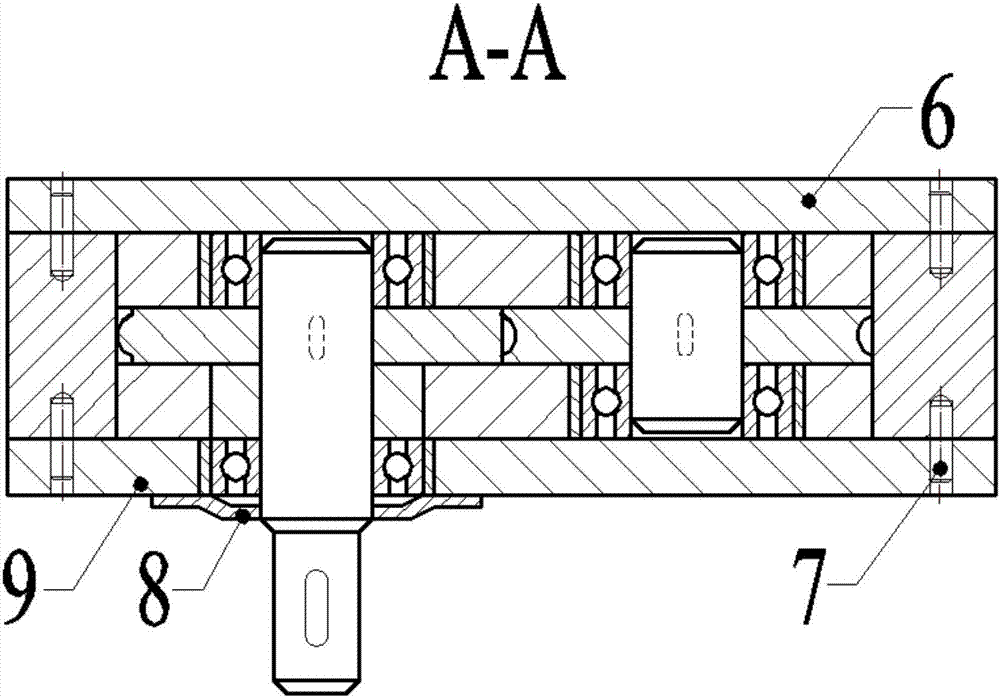

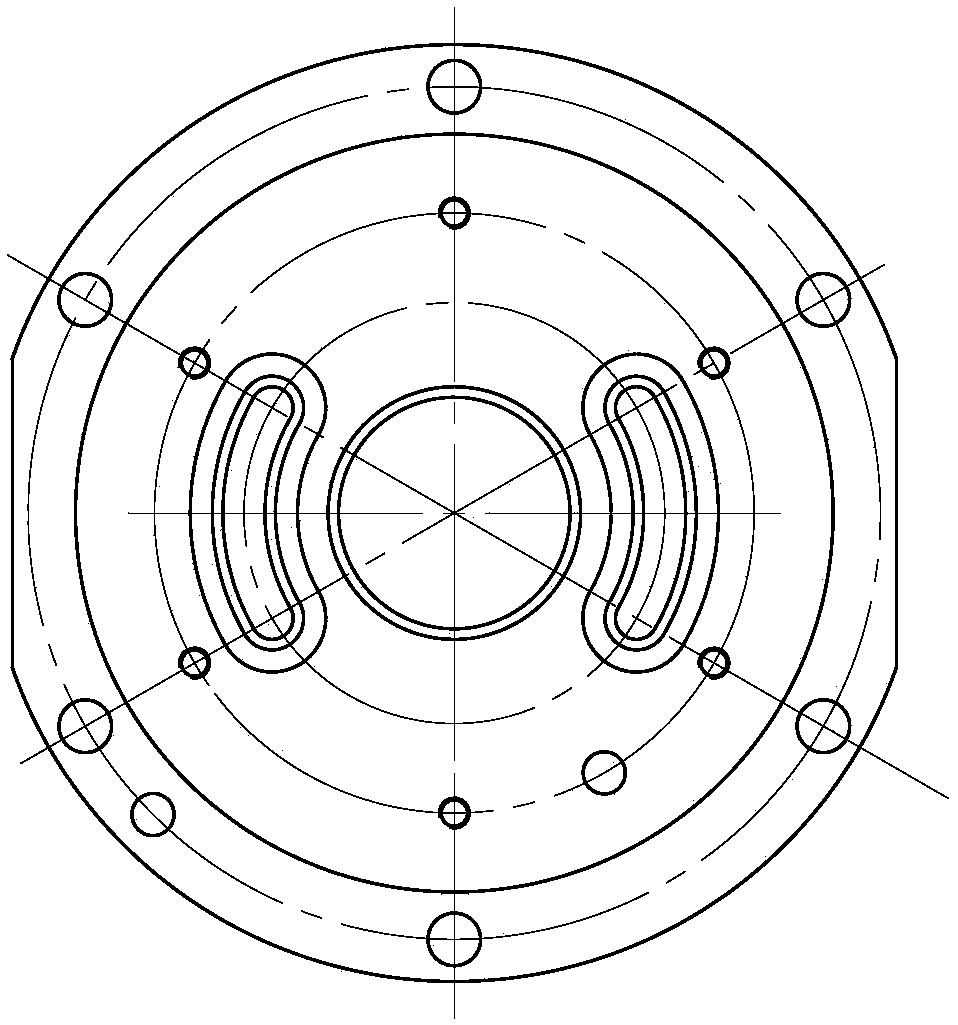

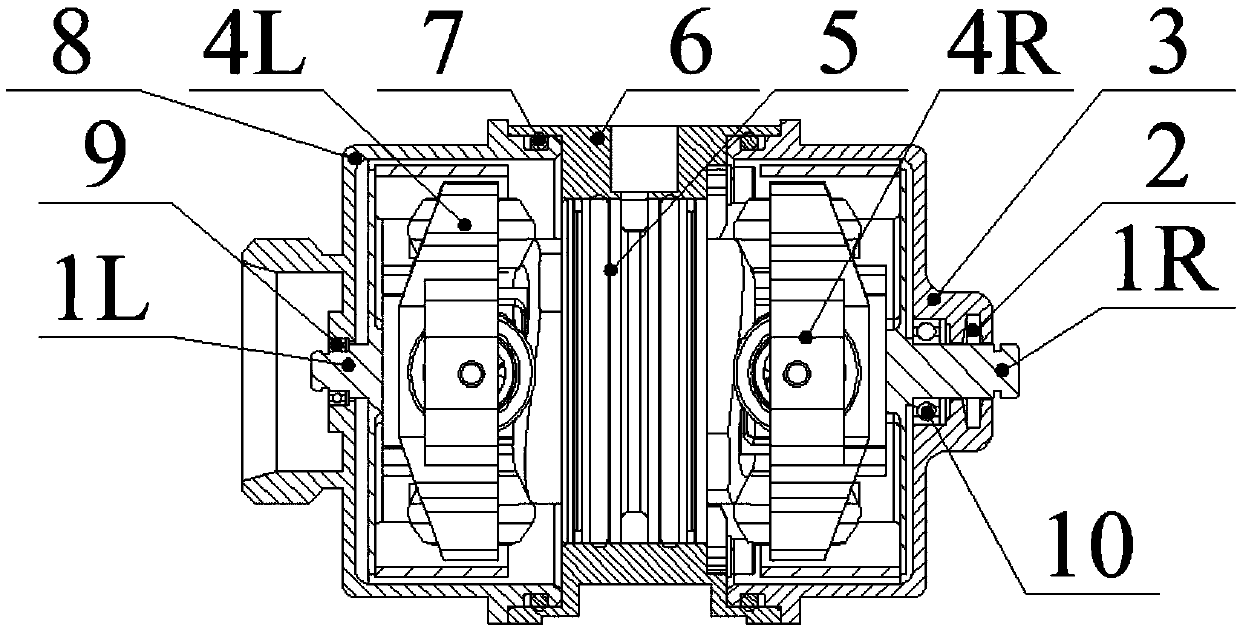

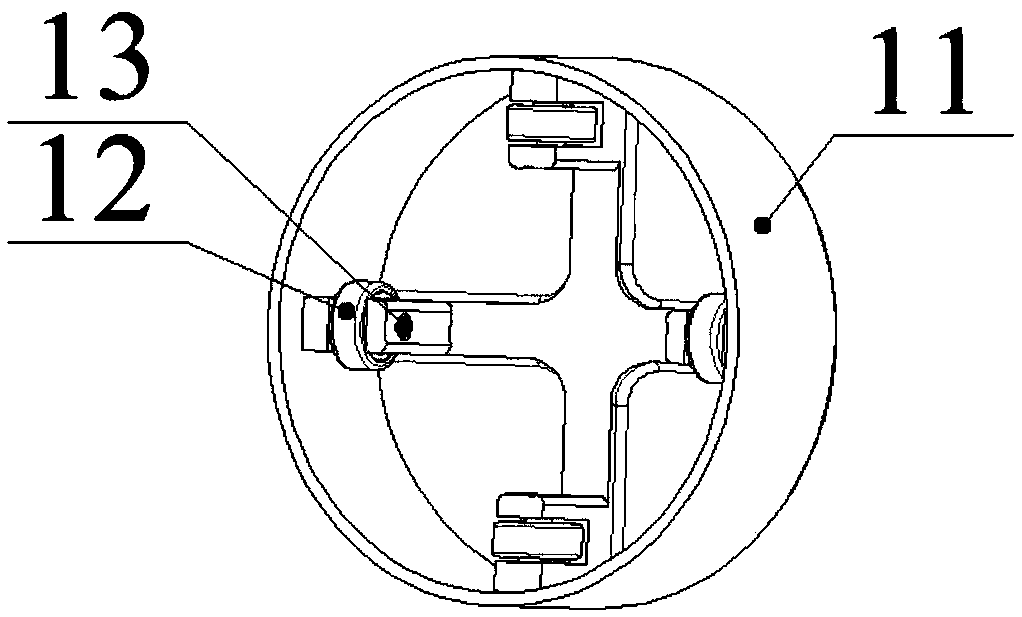

Tandem type low impulse internally engaged gear pump with malposition angle

InactiveCN107939671ASmall flow pulsationRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention discloses a tandem type low impulse internally engaged gear pump with a malposition angle. A front gear box is connected and mounted between a front cover and a connection body, a rear gear box is connected and mounted between a rear cover and the connection body, and the front gear box and the rear gear box are of a same structure, and each comprises a front bearing disc, a shell and a rear bearing disc. A driving gear shaft is coaxially connected with a linkage gear shaft, power is input into the driving gear shaft, and the driving gear shaft drives the linkage gear shaft to conduct torque transmission. The driving gear shaft and the linkage gear shaft are both of a stepped shaft structure which is mainly composed of a front shaft section, a rear shaft section and a gear section. The gear sections of the driving gear shaft and the linkage gear shaft are mounted in the front gear box and the rear gear box correspondingly in a sleeving mode, and the gear sections of the driving gear shaft and the linkage gear shaft are mounted in the gear boxes through crescent gear ring assemblies. The tandem type low impulse internally engaged gear pump can make the flow impulse atan outlet decrease by more than 65%, and the purpose that the flow impulse at the outlet of the gear pump is reduced is achieved.

Owner:ZHEJIANG UNIV

Externally-engaged spherical gear pump

InactiveCN106989011AExtended service lifeImprove contact strengthRotary piston pumpsRotary piston liquid enginesLow noiseGear pump

The invention relates to an externally-engaged spherical gear pump which comprises a pump body (1), a male-tooth gear (2), a female-tooth gear (3), a driven shaft (4), a driving shaft (5), a rear pump cover (6), positioning pins (7), a bearing cover (8) and a front pump cover (9). The tooth shape of the male-tooth gear (2) is a convex spherical gear, and the tooth shape of the female-tooth gear (3) is a concave spherical gear engaged with the convex spherical gear of the male-tooth gear (2). The work tooth face of the male-tooth gear and the work tooth face of the female-tooth gear are a spherical convex-tooth gear profile and a spherical concave-tooth gear profile correspondingly, the volume change quantity of an oil absorption cavity is large, the circular arc radius of the convex-tooth gear profile is equal to that of the concave-tooth gear profile, therefore the gear tooth contact strength is high, the inter-tooth load is small, the output flow is large, flowing the pulse is small, noise is low, and steadiness of pump operation and the service life are both superior to those of a traditional gear pump adopting an involute gear profile.

Owner:CHANGZHOU UNIV

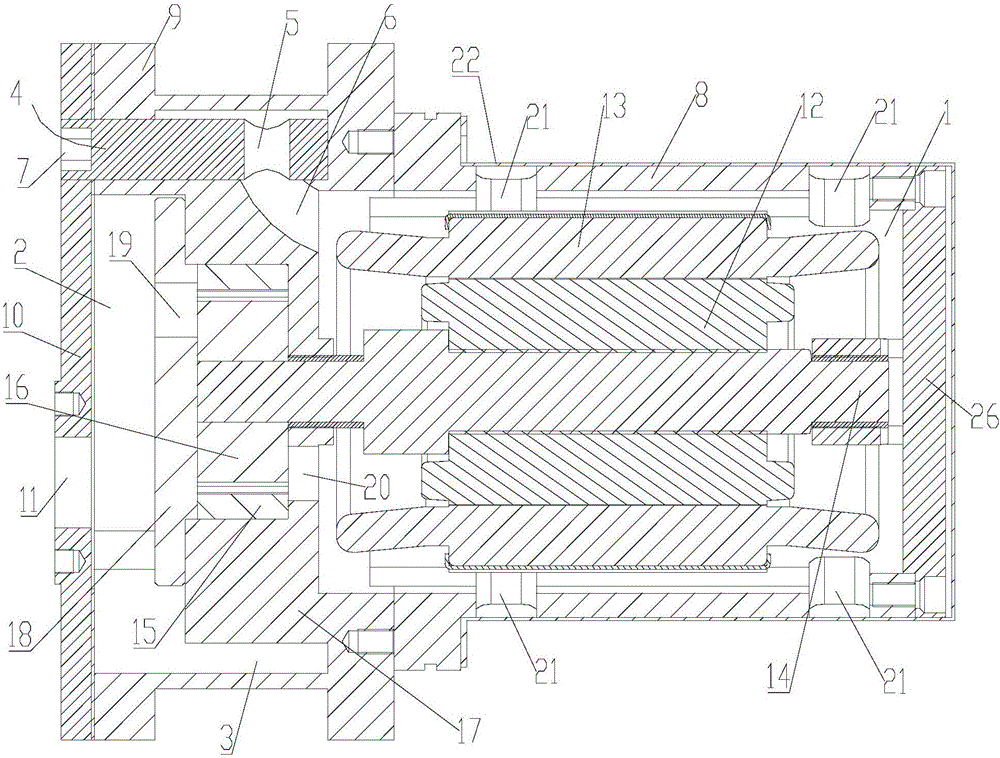

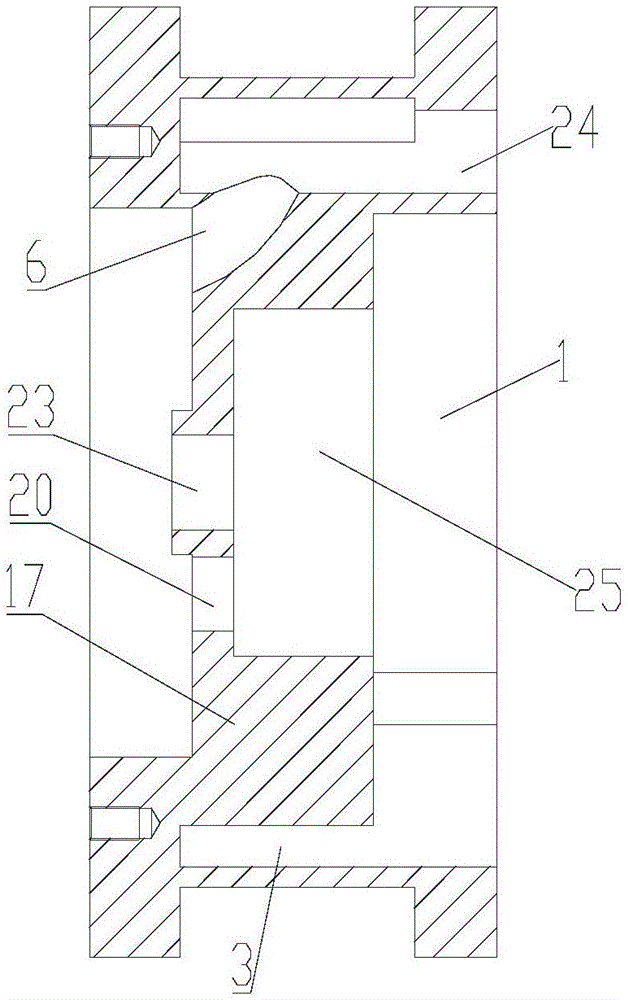

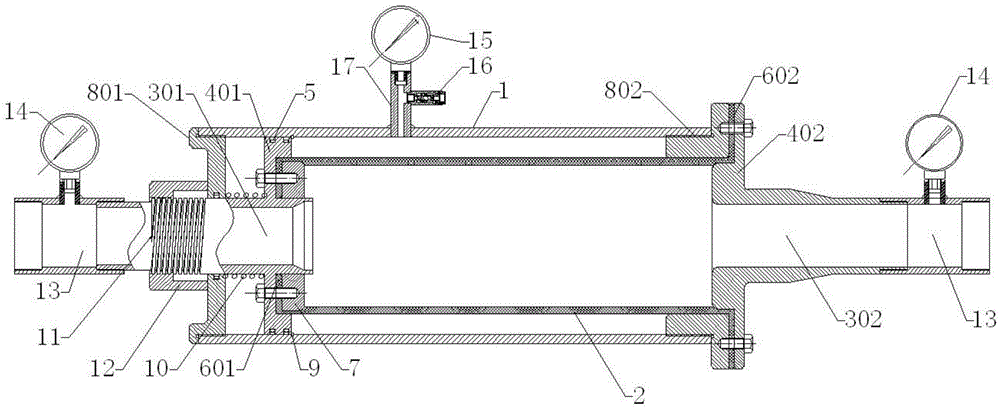

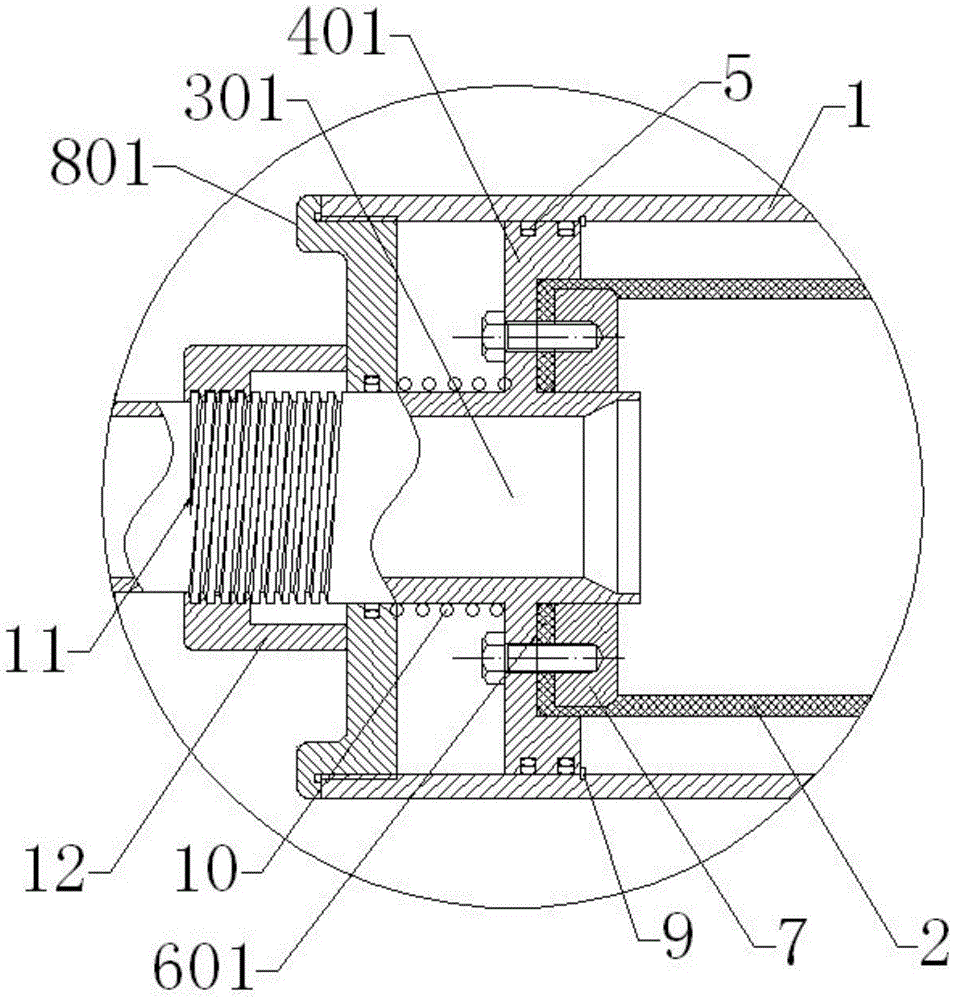

Integrated low-pulsation seawater-desalination energy-recovery and pressurization device

ActiveCN108238664AImprove traffic qualityExtend working lifeGeneral water supply conservationSeawater treatmentHigh energyEngineering

The invention relates to an integrated low-pulsation seawater desalination energy recovery and pressurization device. A structure type of a rotary pressure exchanger and a swash plate plunger type booster pump is adopted; the low-pressure area of a fresh seawater valve plate has an open design; a pressure exchanger cylinder hole directly sucks water from a cavity of a device shell during operation, so that the suction performance is improved; the inlet of the booster pump is equipped with high-pressure water, so that the self-suction performance is improved; the flow pulsation of a high-pressure seawater outlet is reduced through water suction and drainage of a plurality of plungers, the flow quality of an energy recovery supercharging device is improved, the impact of the outlet flow pulsation of the device outlet on a reverse osmosis membrane is reduced, and the service life of the reverse osmosis membrane is improved. The device provided by the invention overcomes the defects of lowintegration degree, large flow pulsation, large volume weight and the like of a rotary energy recovery device in the prior reverse osmosis seawater desalination system, and has the obvious technicaladvantages of high energy recovery rate, high flow quality, high integration degree, small structure size and the like.

Owner:BEIJING UNIV OF TECH

Axial flow type mud pulse slow release machine

InactiveCN105485465AChange the stiffnessReduce mud pulsePipe elementsFlushingEngineeringPulse slowing

The invention discloses an axial flow type mud pulse slow release machine. The axial flow type mud pulse slow release machine comprises a cavity filled with inert gas; the cavity includes a cover and a rubber inner cylinder; two ends of the rubber inner cylinder are respectively connected with a first outlet pipe and a second outlet pipe; and the inner diameters of the first outlet pipe and the second outlet pipe are the same, and are smaller than the inner diameter of the rubber inner cylinder. The axial flow type mud pulse slow release machine reduces pressure fluctuation and flow pulsation in an absorption pipeline through the large-diameter cavity and the inert gas filled between the rubber inner cylinder and an outer cylinder. In addition, an adjustable mechanism is designed by using a mud inlet pipe with a rectangular thread, an added pre-pressure spring and self elasticity of the rubber inner cylinder; and an adjustable rotating drum out of an end cover rotates to stretch the rubber inner cylinder to change the rigidity of the rubber cylinder to adapt to mud currents with different parameters so as to achieve an effect of reducing the mud pulse to the maximum extent. Finally, the mud pulse slow release machine adopts a split design; and although the part number is relatively increased, the part manufacturing difficulty is reduced.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

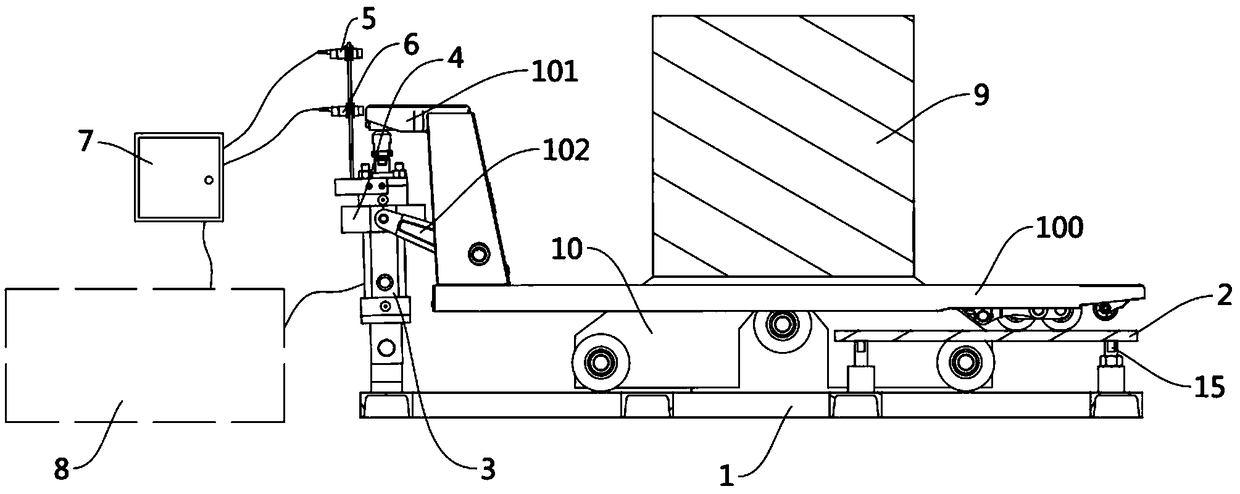

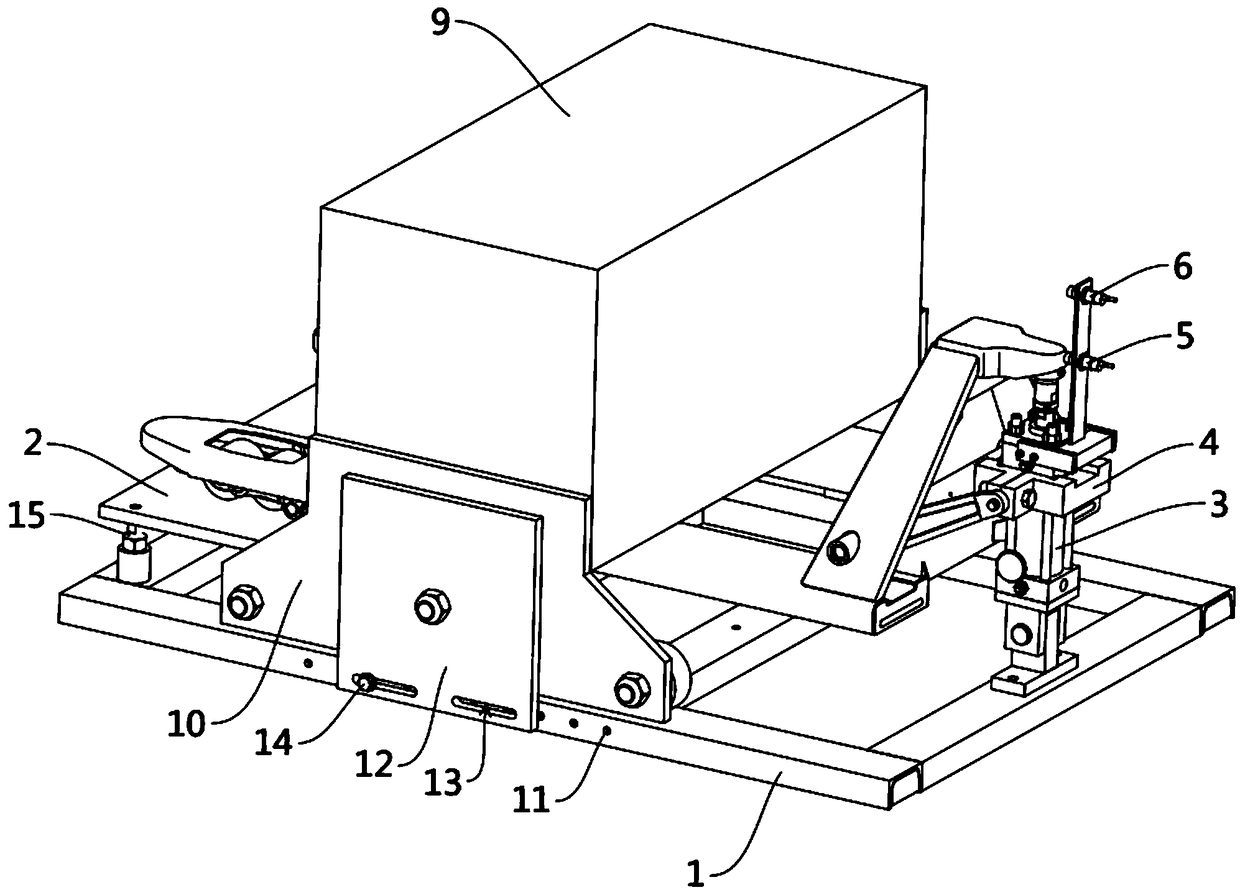

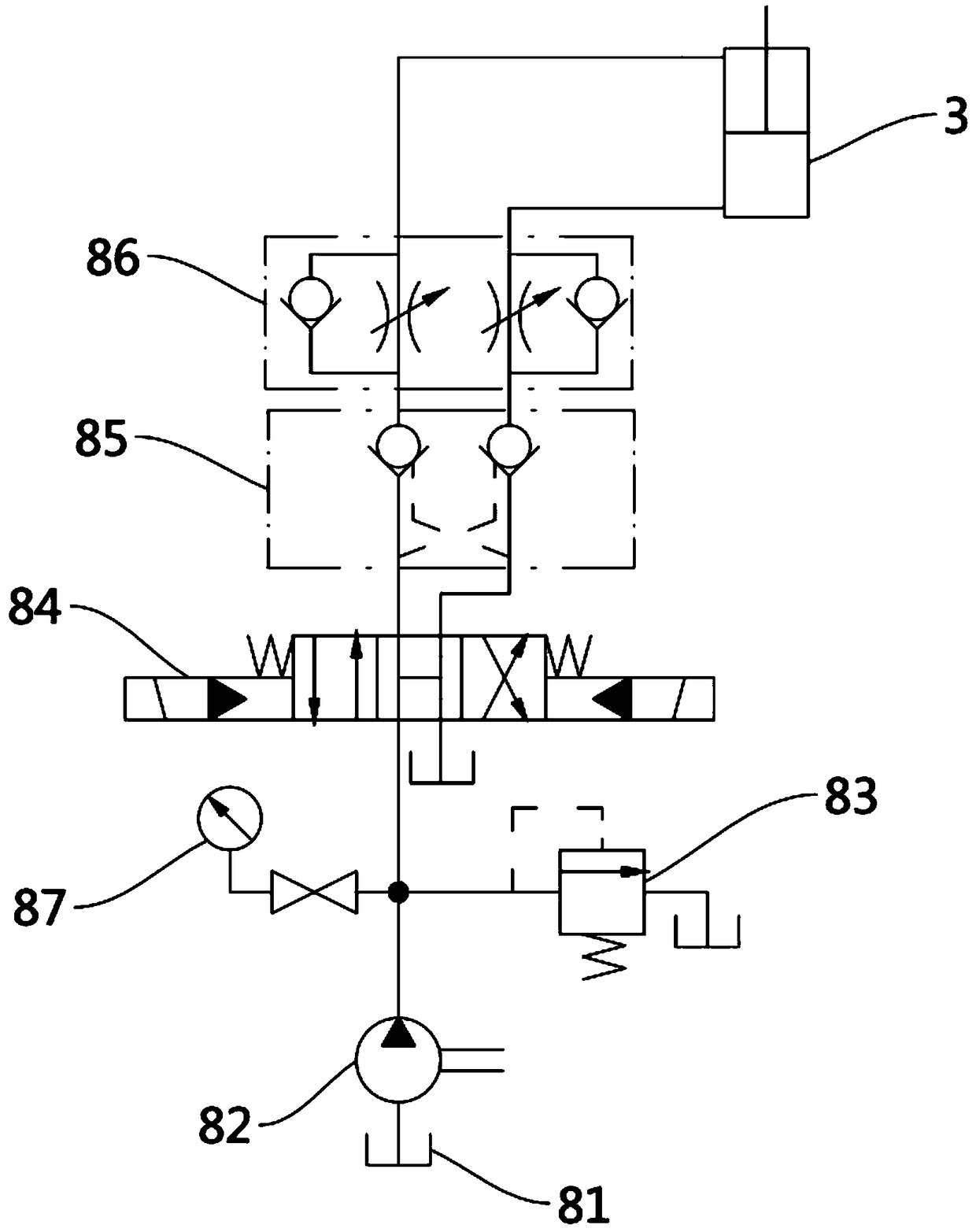

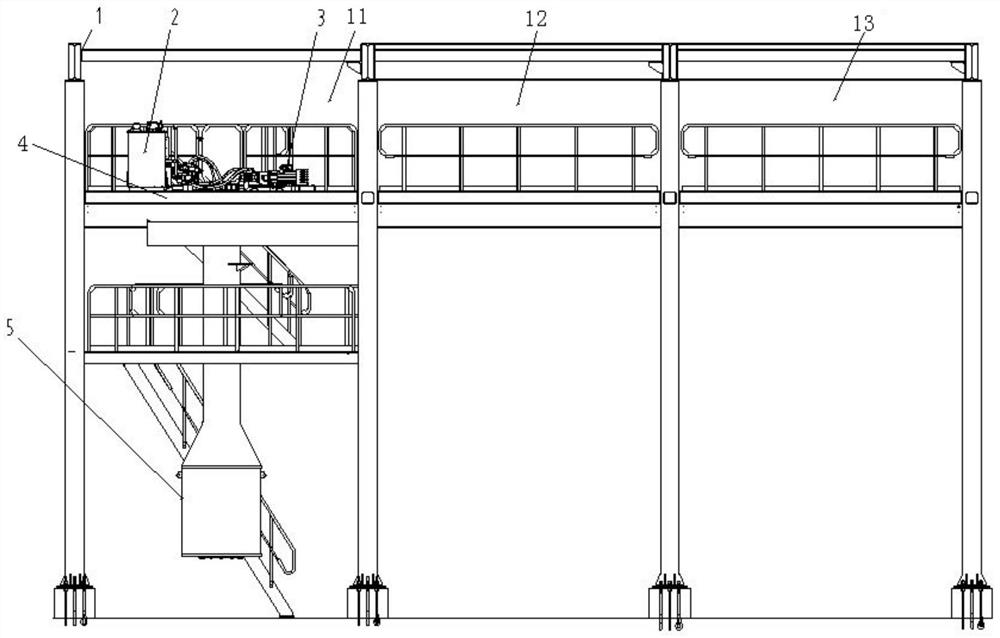

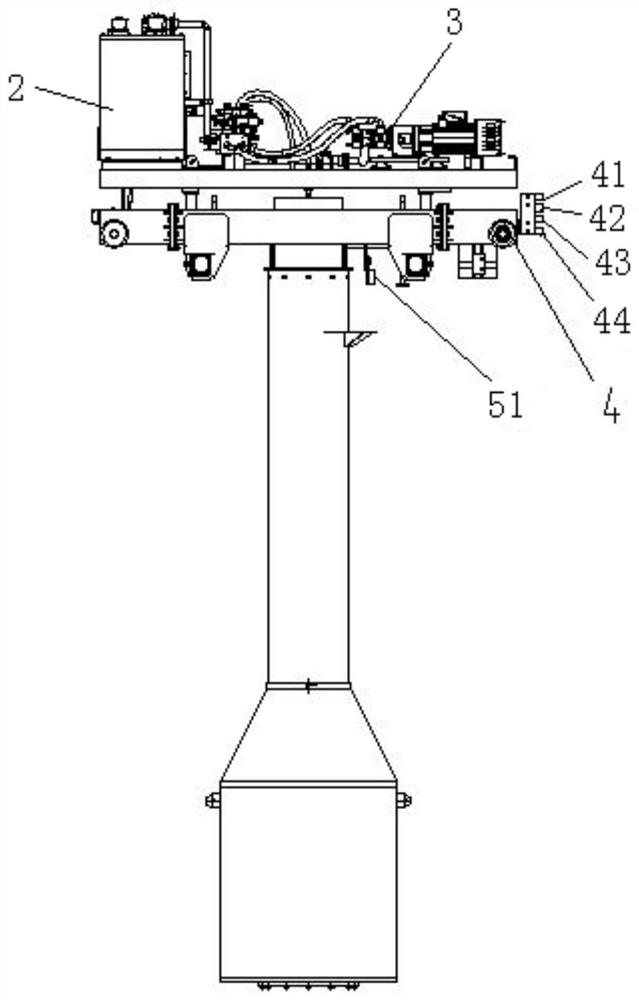

Vehicle frame fatigue test machine for hand moving vehicle

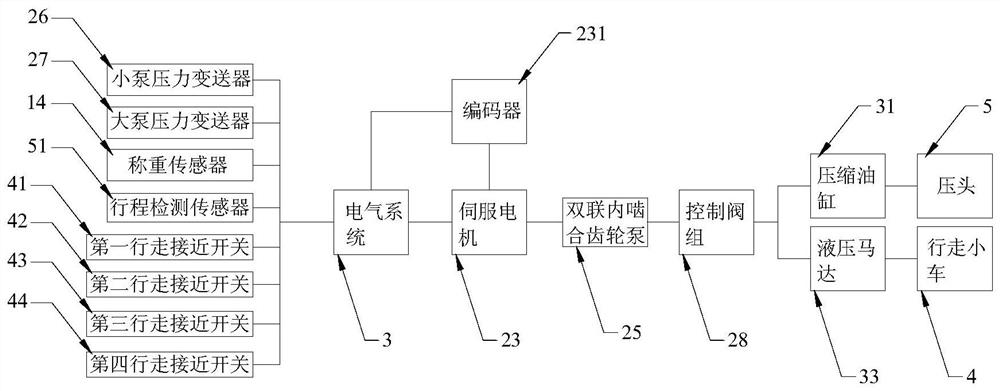

PendingCN108760282AImprove test efficiencySafe and convenient operationMachine part testingVehicle suspension/damping testingMobile vehicleTest efficiency

The invention discloses a vehicle frame fatigue test machine for a hand moving vehicle. The vehicle frame fatigue test machine for the hand moving vehicle comprises a pedestal, a supporting platform plate and a hydraulic oil cylinder, wherein the supporting platform plate is arranged on the pedestal and is adjustable in height; the hydraulic oil cylinder is rotatably connected with the pedestal; arocker arm fixing base is arranged on the hydraulic oil cylinder; an upper position sensor and a lower position sensor which are fixedly connected with the hydraulic oil cylinder are arranged above the rocker arm fixing base; the upper position sensor and the lower position sensor are in signal connection with a control assembly; the hydraulic oil cylinder is connected with an oil supply system;the oil supply system is controlled by the control assembly; the vehicle frame fatigue test machine for the hand moving vehicle also comprises a balancing weight positioned above the pedestal; and side frames which are in rolling connection with the pedestal are arranged on the two sides of the balancing weight. The fatigue test machine adopts automatic control, has high test efficiency, has a memory function after power failure, is safe and convenient to operate, and has perfect integrated function and high practicability.

Owner:ZHEJIANG ZHONGBEI MACHINERY CO LTD

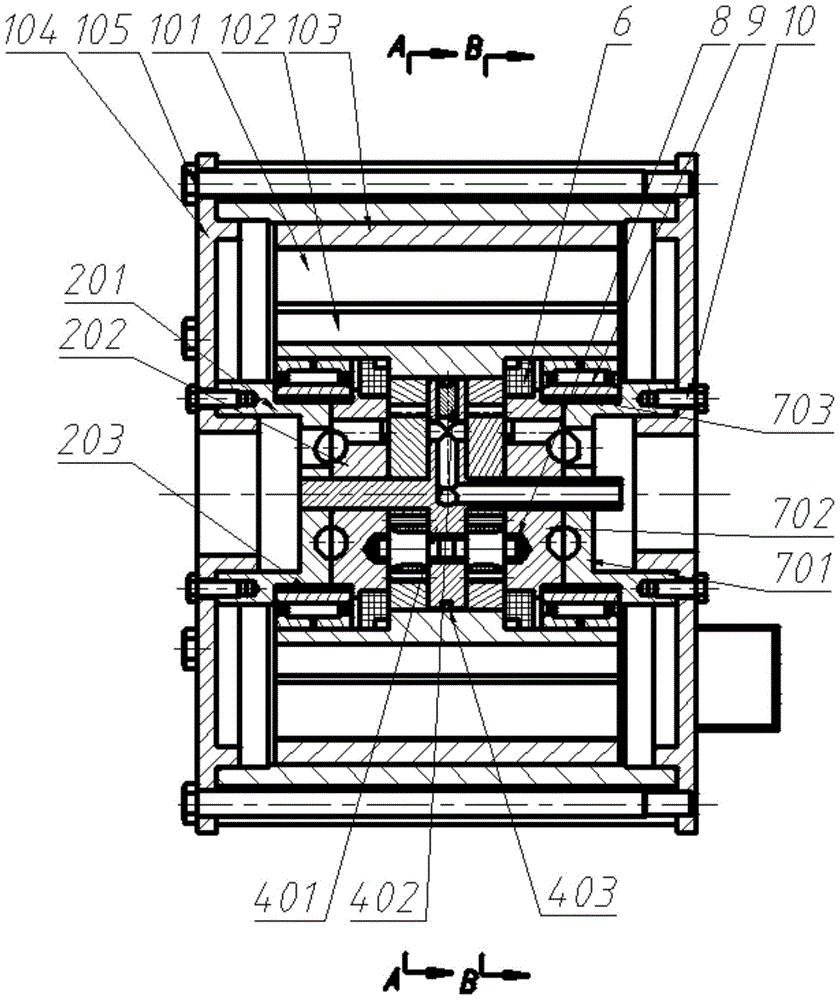

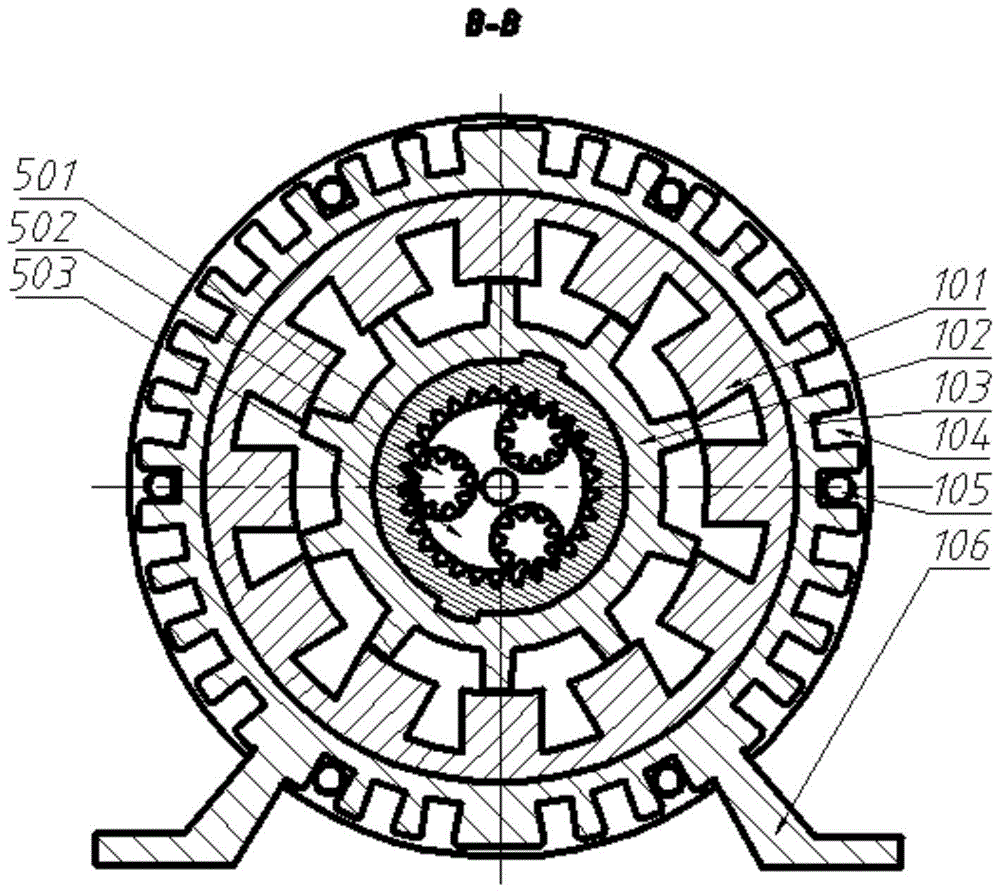

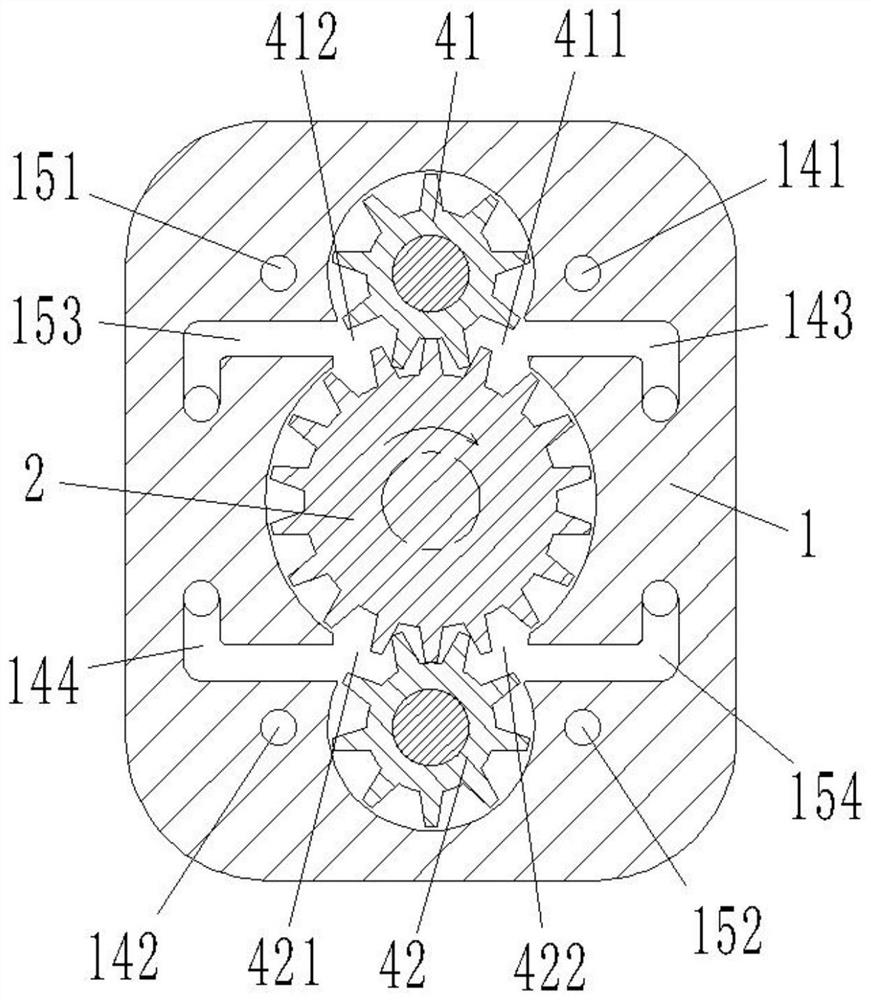

A double-connected three-gear internal meshing compound motor pump driven by a switched flux motor

InactiveCN103967780BImprove cooling effectEasy to useRotary piston pumpsRotary piston liquid enginesWork performanceGear pump

The invention discloses a duplex three-gear inner gearing compound motor pump driven by a switch flux motor. A motor rotor adopts a hollow structure; a first pump body composed of a first outer gear ring, a first pinion and a first partition board and a second pump body composed of a second outer gear ring, a second pinion and a second partition board are embedded in the motor rotor; the first pump body and the second pump body adopt inner gearing compound gear pumps and are connected in parallel to form a double-pump structure; the double-pump structure adopts the manner of oil feeding at two ends and oil discharging at one end; one side of each pump body is provided with an oil feeding oil distribution disc and an oil feeding end cover; an oil discharging oil distribution disc is arranged between two pump bodies. According to the invention, the pump bodies are embedded in the switch flux motor, so that the pumping capacity is increased, the pump flow pulsation is reduced, and the characteristic of high-pressure mass flow is easy to realize to enable the working performance to be safe and stable.

Owner:XI AN JIAOTONG UNIV

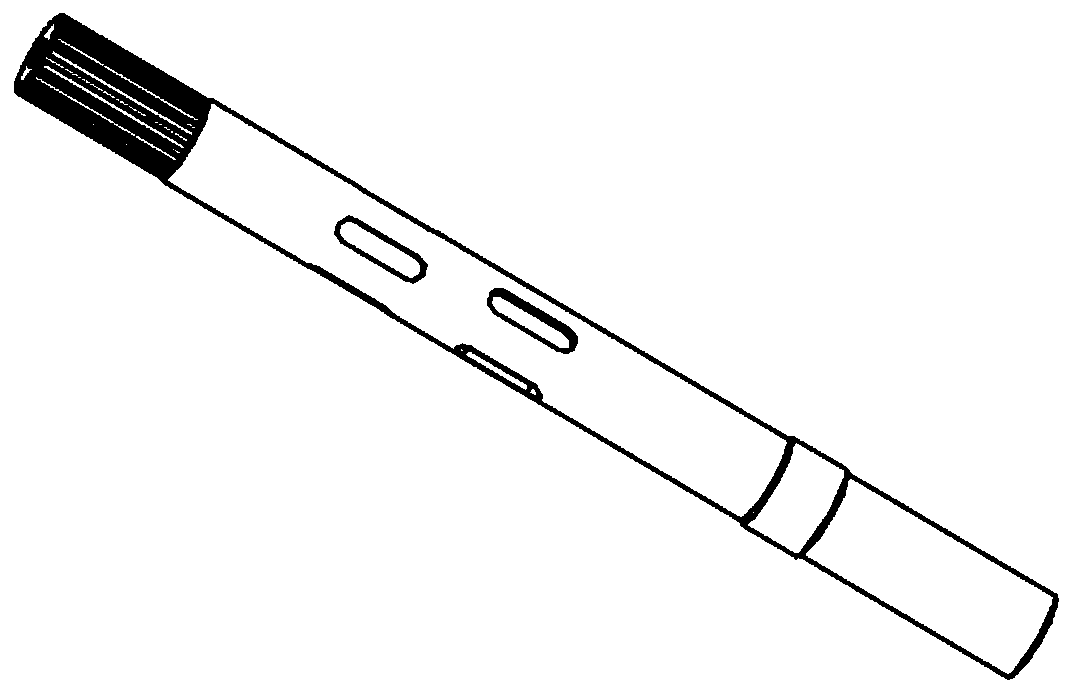

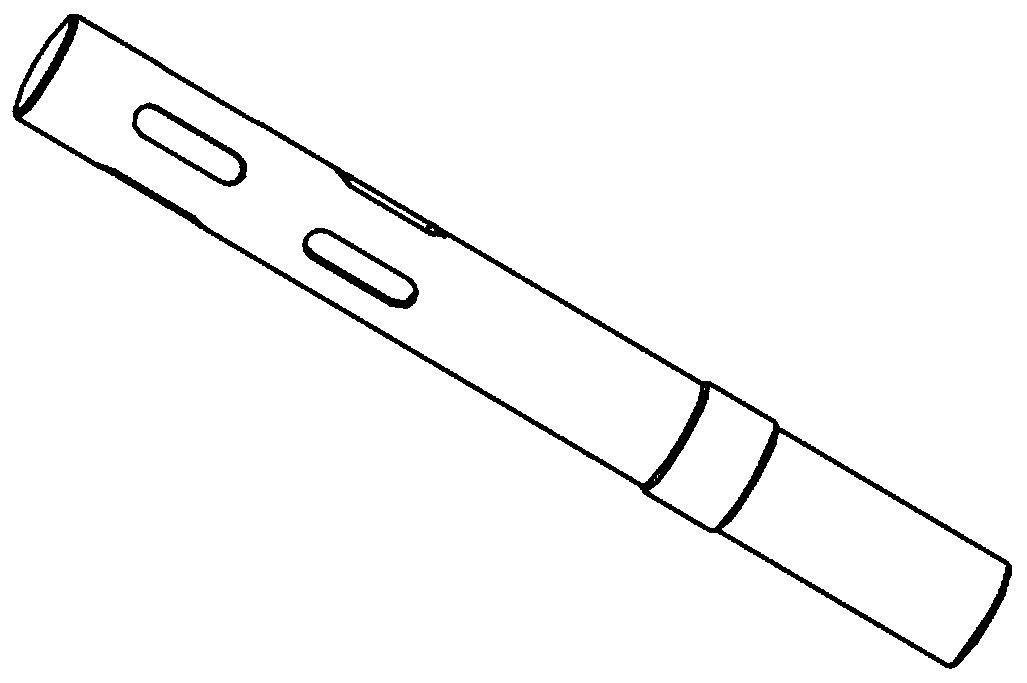

Coaxial pump set double-pump converging working condition flow pulsation phase complementary structure

InactiveCN111350659AImprove reliabilityExtended service lifeRotary piston pumpsRotary piston liquid enginesGear pumpDrive shaft

The invention provides a coaxial pump set double-pump converging working condition flow pulsation phase complementary structure. The structure comprises a driving shaft, a driven shaft, a first gear pump set and a second gear pump set, and a pair of spur gears in each gear pump set are connected with key groove sets in the driving shaft and the driven shaft through multiple keys respectively; a spline is arranged at one end of the driving shaft, the end face of the driving shaft on one side of the spline is taken as a datum plane, the driving shaft and the driven shaft are provided with a first key groove set close to the datum plane and used for installing the first gear pump set and a second key groove set away from the datum plane and used for installing second gear pump set, and a staggered phase angle exists between the first key groove set and the second key groove set. Through staggered tooth phase adjustment of the spur gears, so that the phase deviation exists in the meshing process of the two gear pumps, the peak-valley superimposition of the meshing stiffness of the spur gears is achieved, the meshing stiffness fluctuation coefficient is reduced, two flow pulsations arecaused to be counteracted from each other, and the outlet flow pulsation of the gear pumps is reduced.

Owner:CHINA NORTH VEHICLE RES INST

Noise reduction method for plunger pump and noise reduction device thereof

InactiveCN108180137ALow precompression rateCompression stabilityPositive displacement pump componentsLiquid fuel engine componentsDifferential pressureHydraulic pump

The invention belongs to the field of fluid drive and control, and particularly relates to a noise reduction method for a plunger pump and a noise reduction device thereof. A filtering cavity is connected with a valve plate, the filtering cavity has a filtering function utilized to filter hydraulic oil in a plunger cavity, and after the plunger cavity is contacted with the filtering cavity, the pressure fluctuation in the plunger cavity can be reduced; oil fluid in the plunger cavity is pressurized through a pressure boost cavity, a differential pressure between the plunger cavity and a plunger pump eduction oil cavity can be reduced so as to reduce the outlet flow fluctuation of a fluid pump. A metal corrugated pipe is connected with the valve plate through damping pinholes to form an RCfilter, the metal corrugated pipe can be dismantled and has different specifications, the damping pinholes can be adjusted, and the filter range can be adjusted by changing parameters of the metal corrugated pipe and damping pinholes. According to the plunger pump working in different conditions, the parameters can be adjusted to achieve a best noise reduction effect.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Horizontal type spatial multiphase crank pump

InactiveCN108105058AMeet long stroke requirementsImprove performancePositive displacement pump componentsPositive-displacement liquid enginesHydraulic cylinderPhase difference

The invention discloses a horizontal type spatial multiphase crank pump which comprises a bottom plate, an outer baffle plate, hydraulic cylinders, an inner baffle plate, two connecting rods, a secondcrank, a bearing pedestal, pistons, a first crank pin, a bearing transparent cover, a first crank, a second crank pin, a bearing end cover, a bearing, a third crank, a third crank pin, a motor rack and a motor. The horizontal type spatial multiphase crank pump has the following advantages: a sectional type crankshaft is adopted to drive the two connecting rods to move; and multiple groups of cylinder blocks work simultaneously to meet the long stroke requirement of the piston, realize large flow operation and greatly improve the overall performance of the pump. The three crank pins are distributed on the circumference in 120-degree phase difference; each of the crank pins drives the two connecting rods to move simultaneously; the pistons driven by the two connecting rods are in 180-degreephase difference; through flow superposition of the multiple cylinders, the pump is ensured to have smaller flow pulsation and liquid supply pressure; the six hydraulic cylinders adopt opposite horizontal type layout; and compared with the traditional reciprocating pump structure, the horizontal type spatial multiphase crank pump is more compact and stable in structure, so that the size and weight of the pump are reduced.

Owner:CIVIL AVIATION UNIV OF CHINA

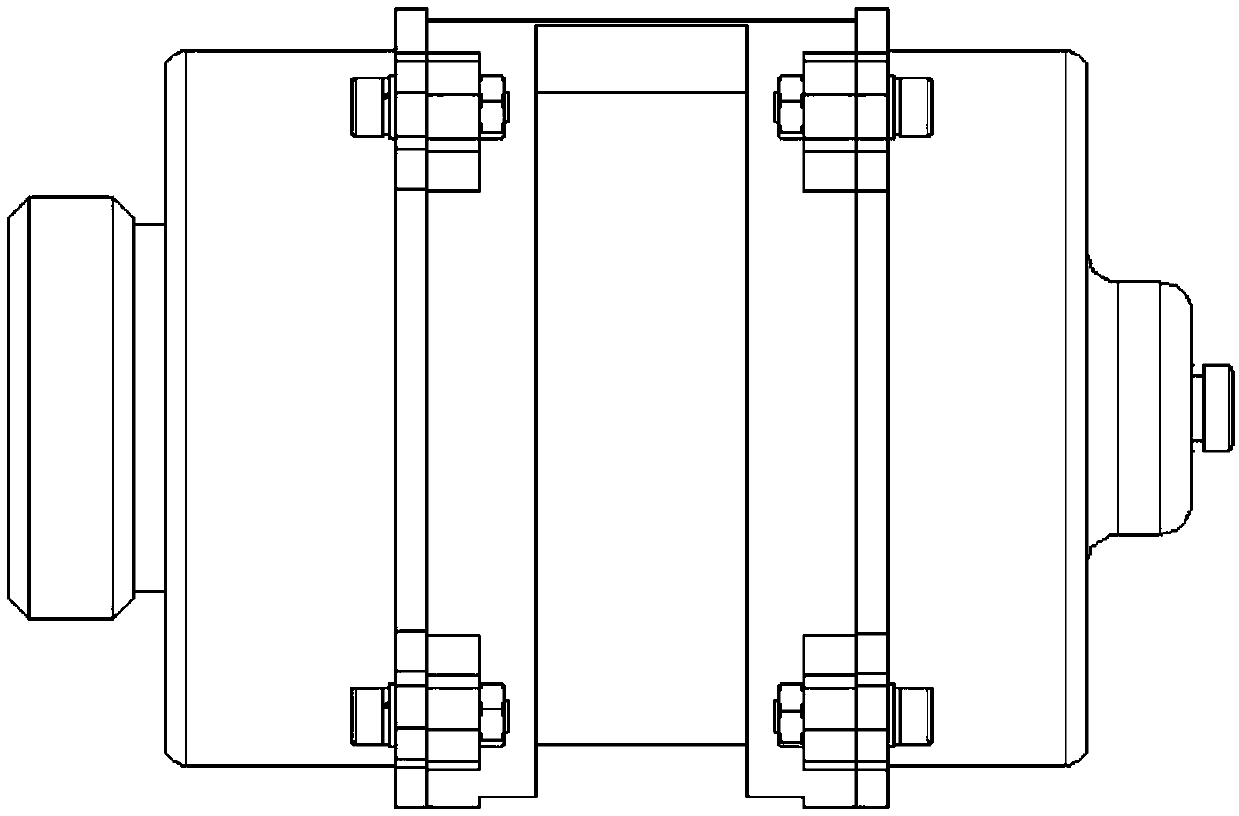

trash compactor

ActiveCN110482084BReduce output torqueReduce operating costsRefuse transferringLoading/unloadingGear pumpLow speed

The invention discloses a garbage compactor. The garbage compactor of the present invention adopts a combination of double pumps combined with servo volume speed regulation to drive the pressure head to perform garbage compression operations and drive the walking trolley to travel. When the pressure head performs compression operations and the walking trolley moves, the hydraulic system does not have variable throttling Energy consumption; the motor responds quickly, and it can sleep without turning during standby loading, and the system has no energy consumption; it adopts double-connected internal gear pumps, which have lower noise and smaller flow pulsation; when the load is heavy or light, the double pumps flow together at low pressure and high speed Operation, the small pump runs at high pressure and low speed when pressing garbage into the tank, which can reduce the output torque of the motor compared with the single pump system, reduce the operating cost of the motor, and generate less heat, no need to install a radiator, and reduce the compactor Low manufacturing cost; when the trolley is moving, the small pump of the double-internal gear pump is loaded separately, and the motor outputs a low speed, so as to obtain a stable small flow rate, and the walking speed of the trolley has good repeat stability.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Roller type force balancing unit pump

PendingCN111502951AReduce stressSave spacePositive displacement pump componentsPiston pumpsRolling-element bearingDrive shaft

Disclosed is a roller type force balancing unit pump. A rolling bearing is mounted between a right coupling and a right roller assembly. Left and right cams are symmetrically distributed on both sidesof a pump core assembly with the phase difference of 90 DEG. A roller assembly rolls on the cam surfaces. Four conical rollers are distributed on the single side. Every two conical rollers are fixedto a C-shaped roller support as a group through a pin shaft. A copper sleeve of a pump core assembly and a cylinder body are respectively provided with two pairs of rectangular high pressure and low pressure oil holes uniformly distributed in the circumferential direction. The rectangular high pressure and low pressure oil holes correspondingly make contact with first and second flow distributiongrooves in the upper portions of a piston to suck and discharge oil. The cylinder body is provided with an annular oil groove communicating with the high-pressure oil holes, and oil liquid flowing outof the two high-pressure oil holes is collected together. The mass of a rotor which is composed of a first roller support assembly, a third roller support assembly, a transmission shaft and left andright concentric rings should be equal to the sum of the mass of a rotor which is composed of a second roller set, a fourth roller support assembly and the piston. First high pressure and low pressurecavities in a pump core communicate with the first flow distribution groove of the piston all the time. Second high pressure and low pressure cavities communicate with the second flow distribution groove of the piston all the time.

Owner:ZHEJIANG UNIV OF TECH

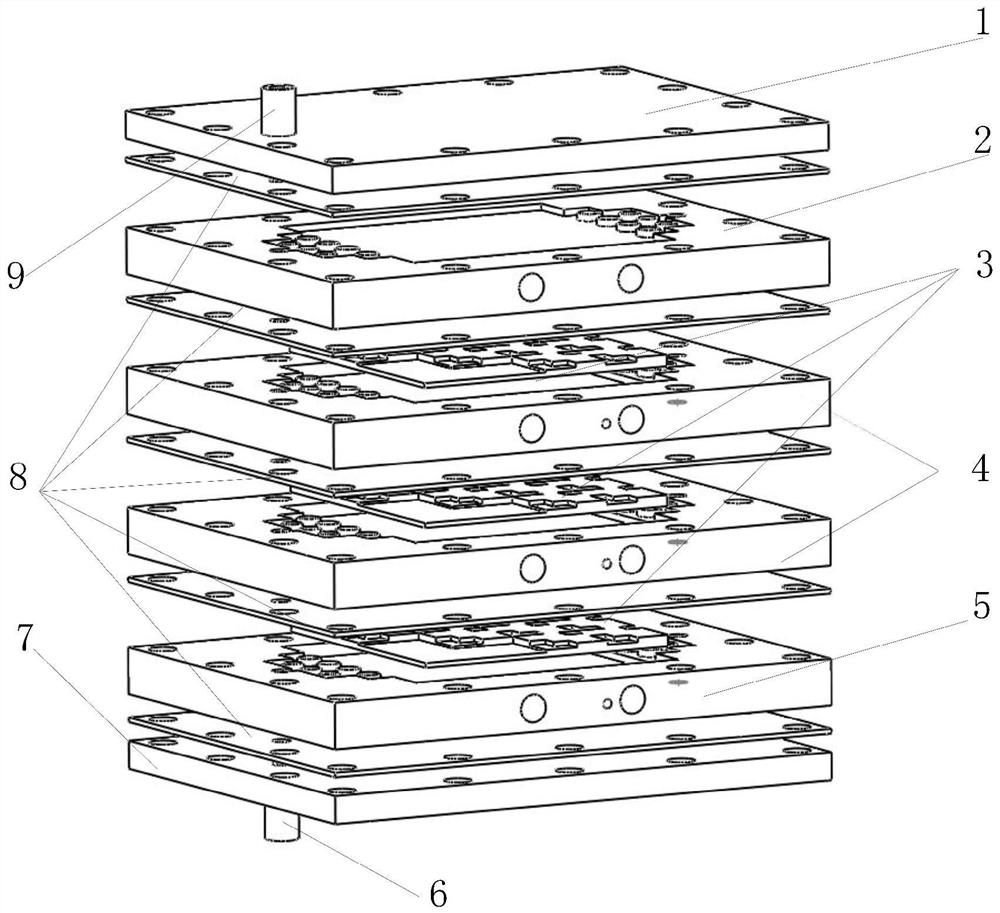

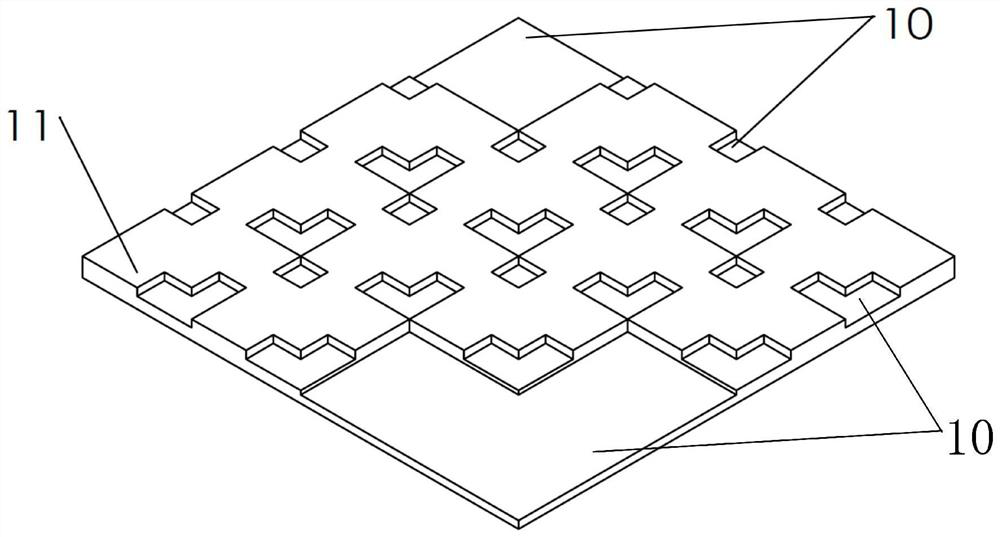

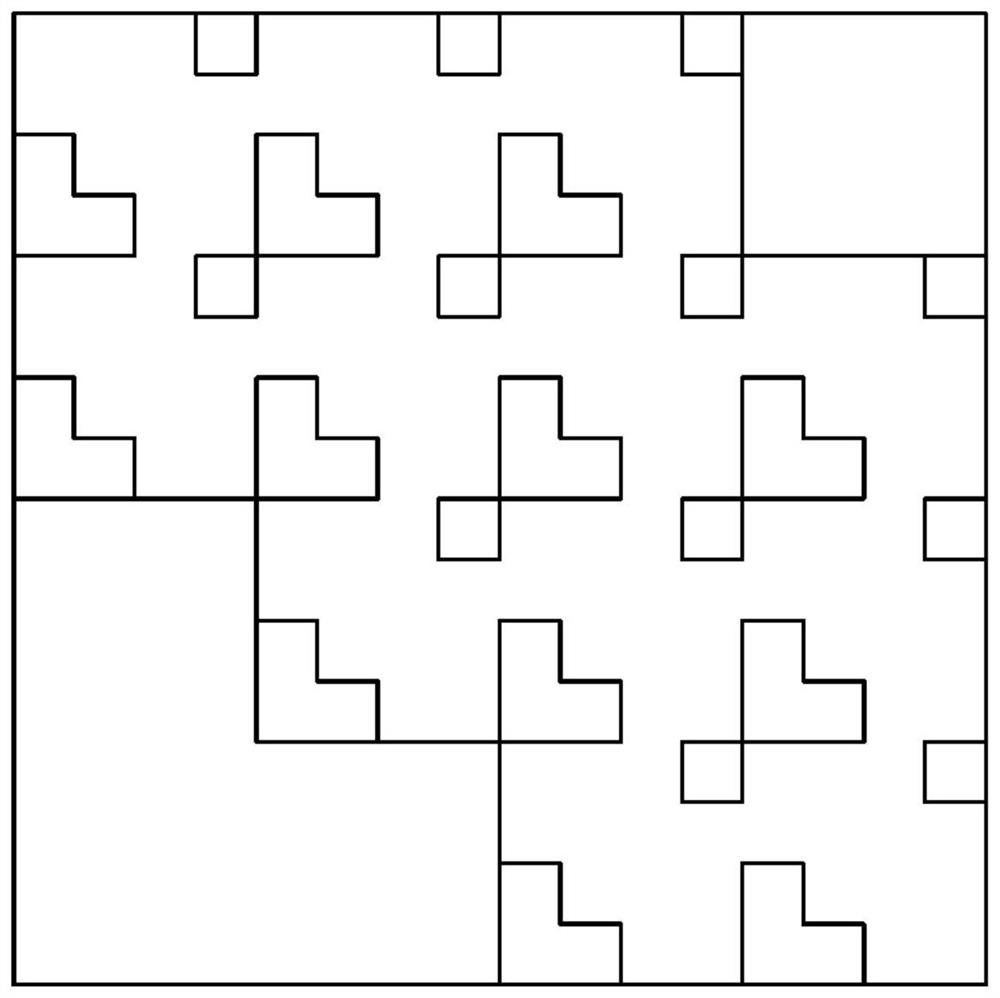

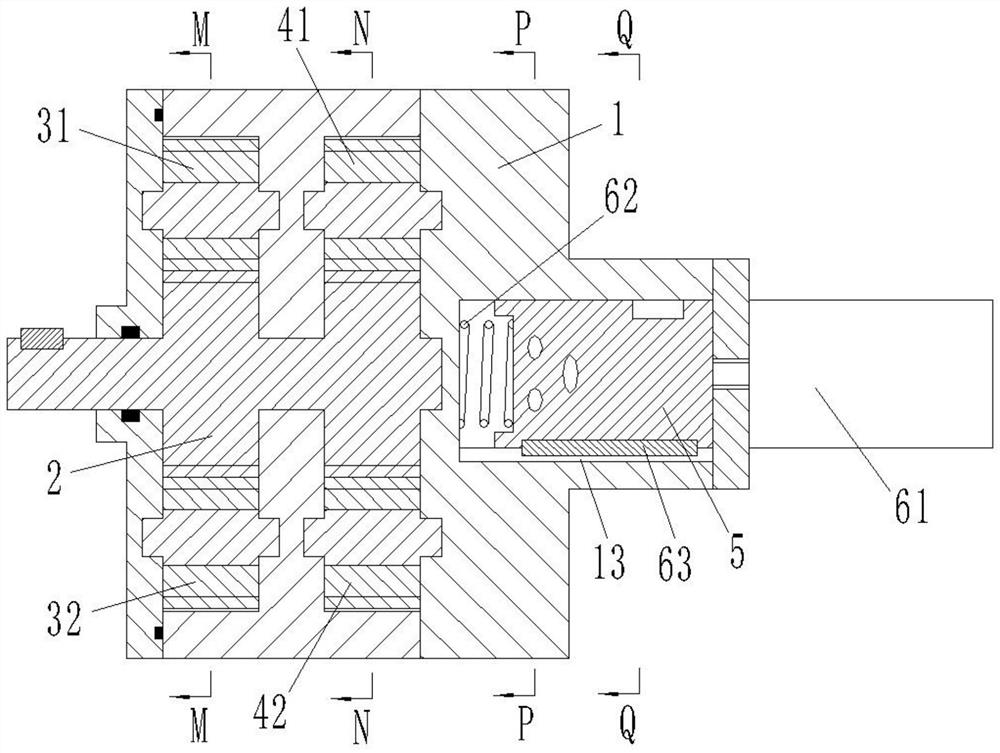

A Micro-Reformer for Hydrogen Production with Catalyst Support of Fractal Structure

ActiveCN110155946BImprove adhesionNot easy to fall offHydrogenHydrogen/synthetic gas productionThermodynamicsPtru catalyst

The invention discloses a hydrogen production micro-reformer with a fractal-structure catalyst carrier. The micro-reformer comprises an upper cover plate, a lower cover plate, an evaporation plate, aplurality of upper reforming plates and a plurality of lower reforming plates, wherein an inlet pipe is arranged on the top surface of the upper cover plate, an outlet pipe is arranged on the bottom surface of the lower cover plate, and the evaporation plate, the upper reforming plates and the lower reforming plates are sealed between the upper cover plate and the lower cover plate sequentially from top to bottom; inlet drainage chambers and outlet drainage chambers are symmetrically formed on both sides of the evaporation plate and the chambers of the reforming plates, drainage columns are distributed in the drainage chambers, and rectangular reaction carrier plates are mounted in reaction chambers of the upper reforming plates and the lower reforming plates; and a fluid passage of a fractal structure is arranged on the upper surface of each reaction carrier plate, the initial shape of the fractal structure is rectangular, and conforms to the Selpinsky fractal law, and a flexible graphite pad is mounted on the mounting surface between every two adjacent plates. Through the micro-reformer, the specific surface area of the reaction carrier plates can be increased, the catalyst loading capacity can be improved, the efficiency of heat transfer and mass transfer of the reformer can be enhanced, and therefore the hydrogen production performance of the hydrogen production micro-reformer is improved.

Owner:ZHEJIANG UNIV

Duplex external gear pump

InactiveCN112879281ARealize free switchingEasy to useRotary piston pumpsRotary/oscillating piston combinationsGear pumpGear wheel

The invention provides a duplex external gear pump which comprises a pump body, a driving gear, a first-stage driven gear set, a second-stage driven gear set and a variable plunger. The driving gear, the first-stage driven gear set and the second-stage driven gear set are located in the pump body, the first-stage driven gear set and the second-stage driven gear set are in meshing connection with different radial sections of the driving gear respectively, a first-stage oil suction cavity and a first-stage oil discharge cavity are formed in the meshing position of the driving gear and the first-stage driven gear set, and a second-stage oil suction cavity and a second-stage oil discharge cavity are formed in the meshing position of the driving gear and the second-stage driven gear set. The variable plunger is movably connected with the pump body so as to control the communication relation between an oil inlet and the first-stage oil suction cavity and the second-stage oil suction cavity, the communication relation between an oil outlet and the first-stage oil discharge cavity and the second-stage oil discharge cavity and the communication relation between the first-stage oil discharge cavity and the second-stage oil suction cavity. The duplex external gear pump disclosed by the invention can be switched between high-pressure small flow and low-pressure large flow, can be used under more working conditions, and has higher use efficiency.

Owner:宁波真格液压科技有限公司

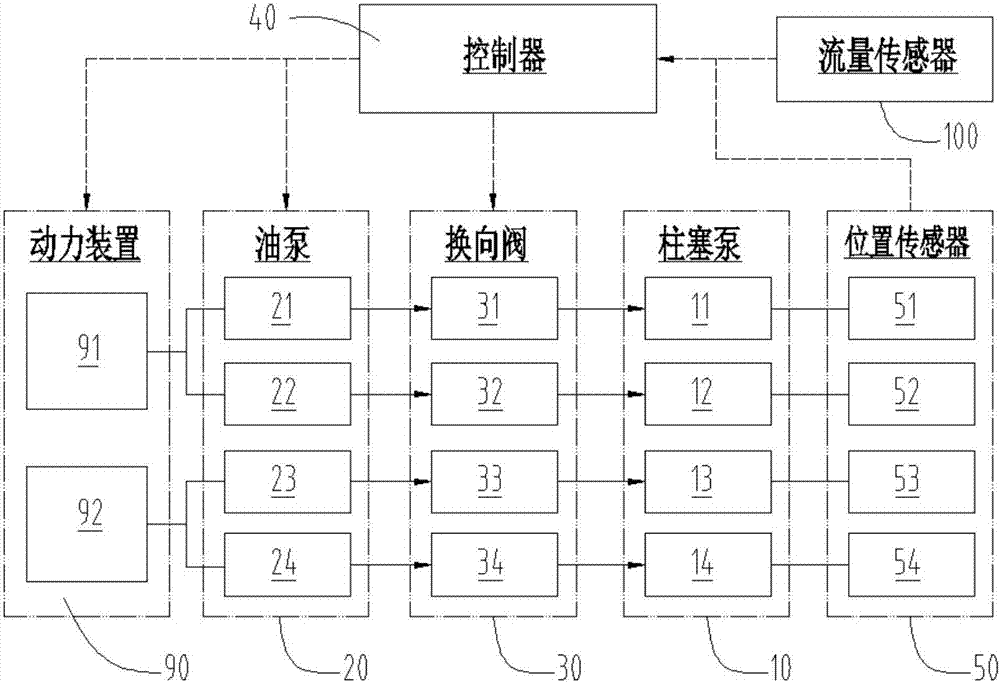

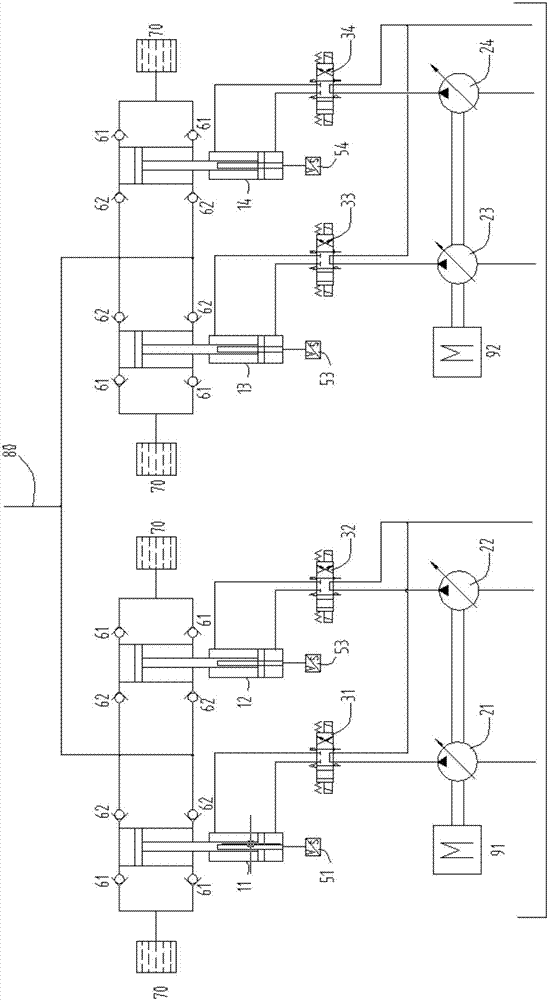

Plunger pump water-supply system, fire-fighting machine and building

InactiveCN107246367AImprove continuityGood pumping continuityFire rescuePump controlClosed loopEngineering

The invention provides a plunger pump water-supply system, a fire-fighting machine and a building. The plunger pump water-supply system comprises a plurality of plunger pumps, oil pumps and reversing valves. Each plunger pump comprises an oil cylinder and a water cylinder connected with the oil cylinder through a piston rod and further comprises a controller and a position sensor, wherein the position sensor is used for acquiring the moving position of the piston rod of the plunger pump, the signal output end of the position sensor is connected with the controller, and the signal output end of the controller is connected with the reversing valve. The controllers are used for controlling the action sequence of the multiple plunger pumps according to signals of the position sensors and / or controlling the moving speeds of the piston rods of the plunger pumps according to the signals of the position sensors. According to the plunger pump water-supply system, closed-loop control is adopted so that it can be ensured that the multiple plunger pumps act in the designed sequence for a long time, the pumping continuity is good, and flow pulsation is small. Meanwhile, through the position sensors, the speeds of the plunger pumps can be monitored and adjusted in time, and the water supply continuity of the system can be improved.

Owner:SANY AUTOMOBILE MFG CO LTD

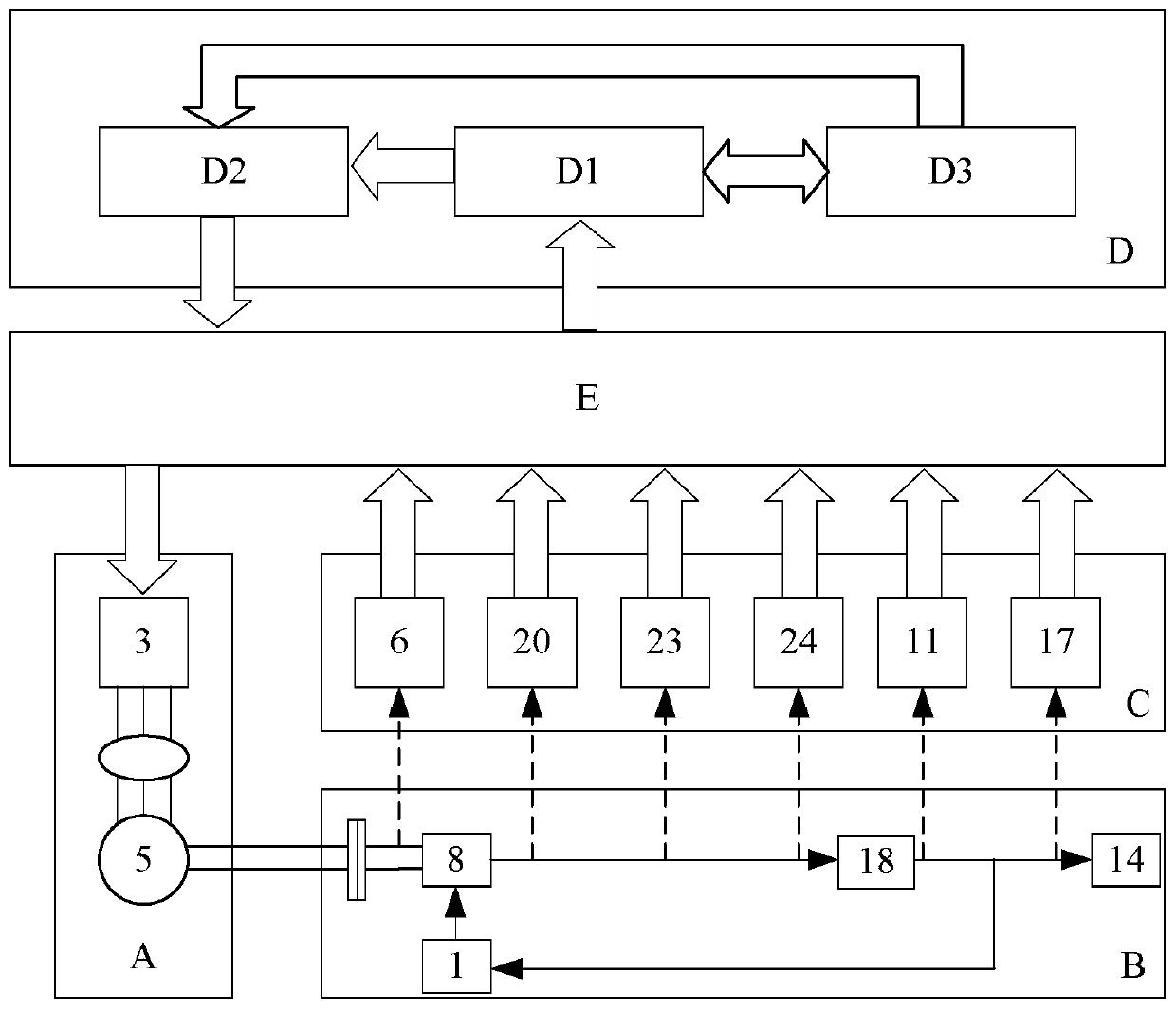

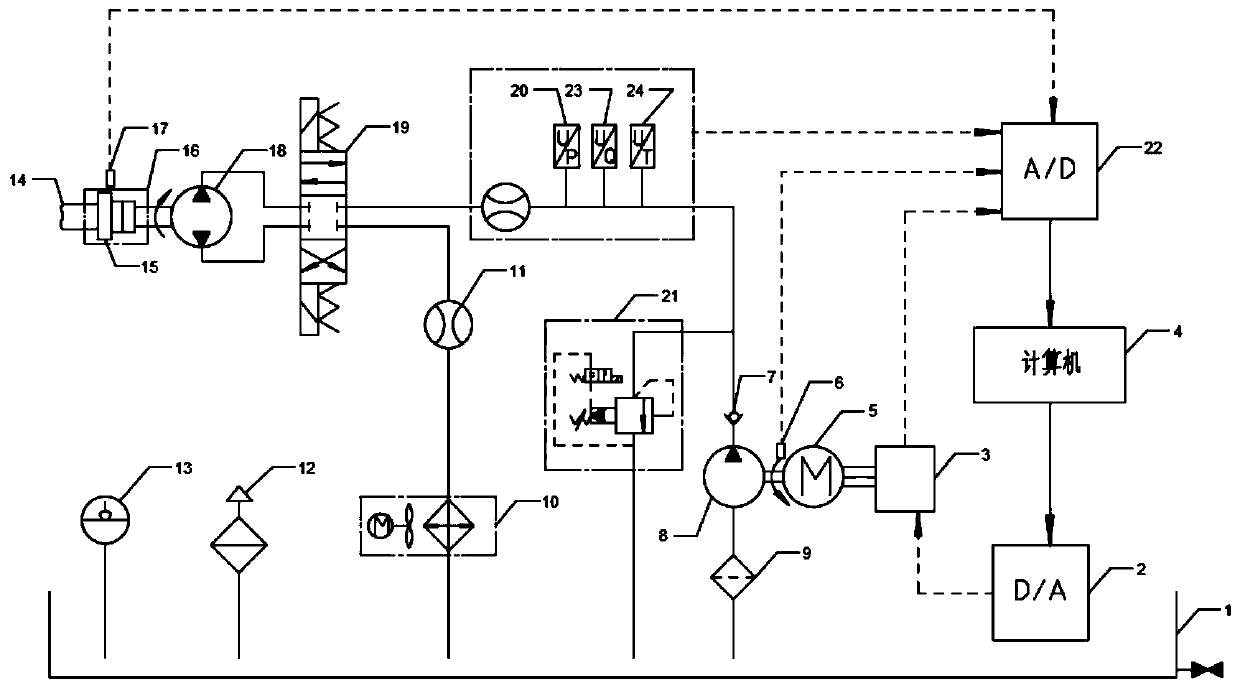

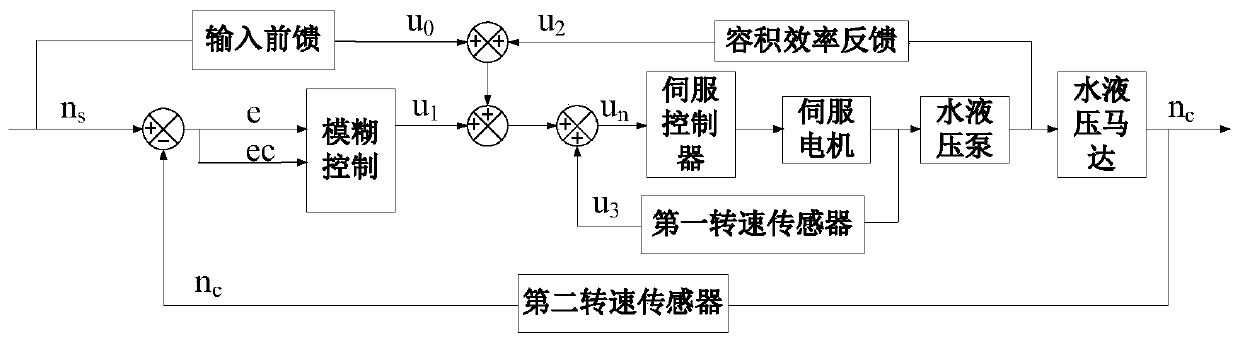

Rotating speed control system and method of water hydraulic motor

The invention discloses a rotating speed control system and method of water hydraulic motor. The method comprises the following steps that 1, fuzzy control is used for overcoming the defect that because a traditional control mode is not high in control precision, the traditional control mode cannot adapt to the variable quantity and non linearity of a water hydraulic system; 2, feedforward is carried out by utilizing target rotating speed, and the rotating speed fluctuation of the water hydraulic motor is compensated in advance according to the total volume efficiency feedback mode of the system; 3, the difference between the theoretical rotating speed of a servo motor and the actual rotating speed is fed back, a local small closed loop is formed on the control of the rotating speed of theservo motor, and the precision of the rotating speed control of the servo motor is improved; 4, the interference components in the flow signals are stripped based on a multi-resolution analysis theory, and then the signals are reconstructed; and 5, wavelet transformation is carried out on the rotating speed signals to reduce or eliminate quantization errors in the rotating speed information. Thecontrol precision of the rotating speed of the hydraulic motor is high, and the response speed is high, the anti-disturbance capability is strong, and the rotating speed of the water hydraulic motor is smooth.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com