Seawater piston motor low in pulsation

A plunger motor and seawater technology, applied in the field of hydraulic components, can solve the problems of plunger motors such as sensitive working parameters, high machining accuracy, and high difficulty, and achieve the effects of reduced parameter sensitivity, improved motion stability, and high overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner will be further described below in conjunction with the accompanying drawings.

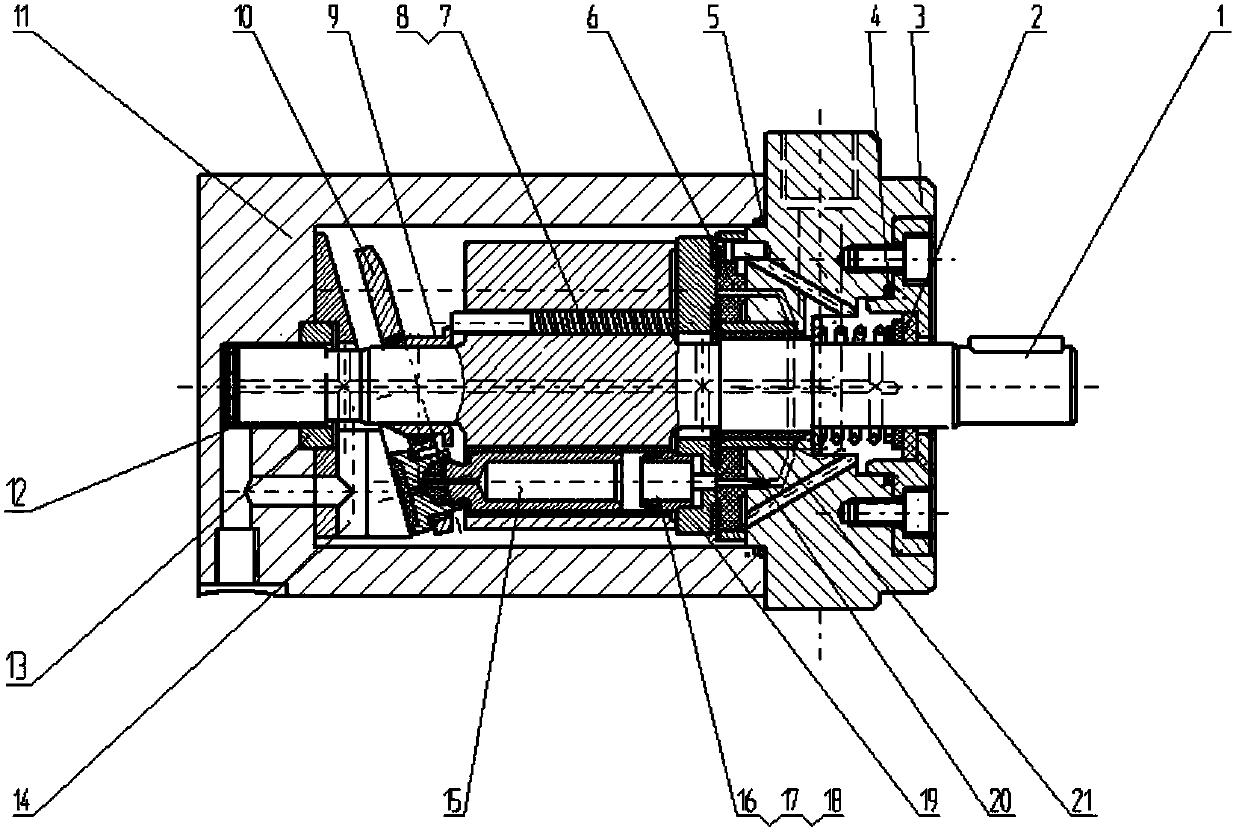

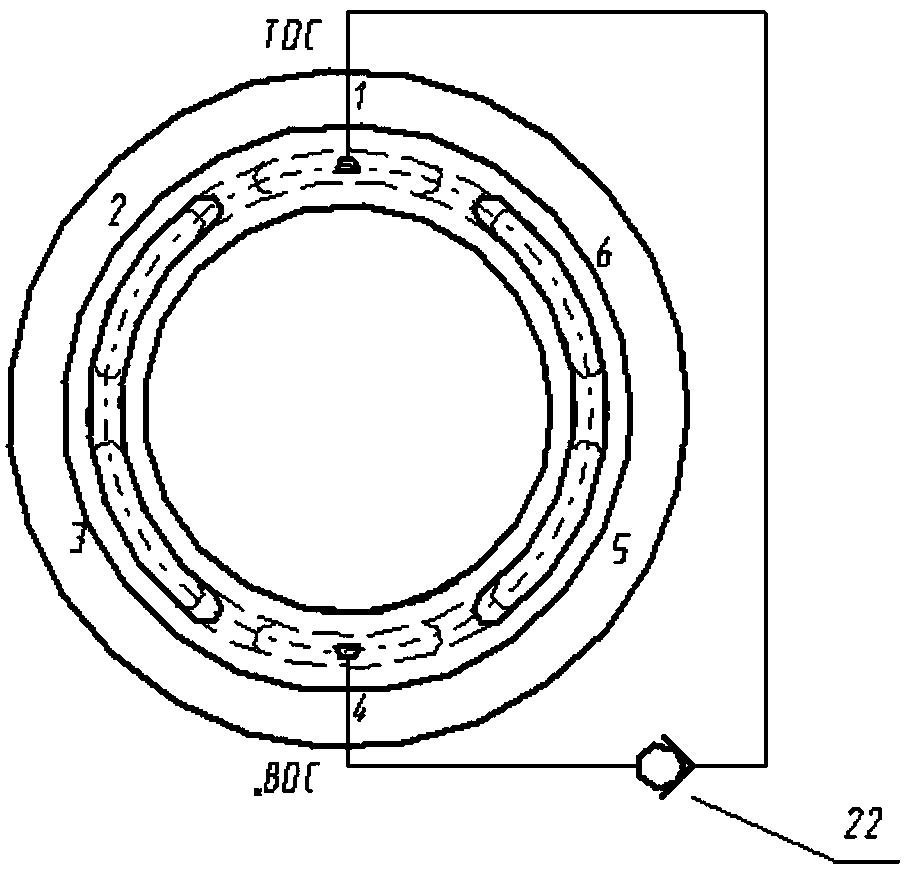

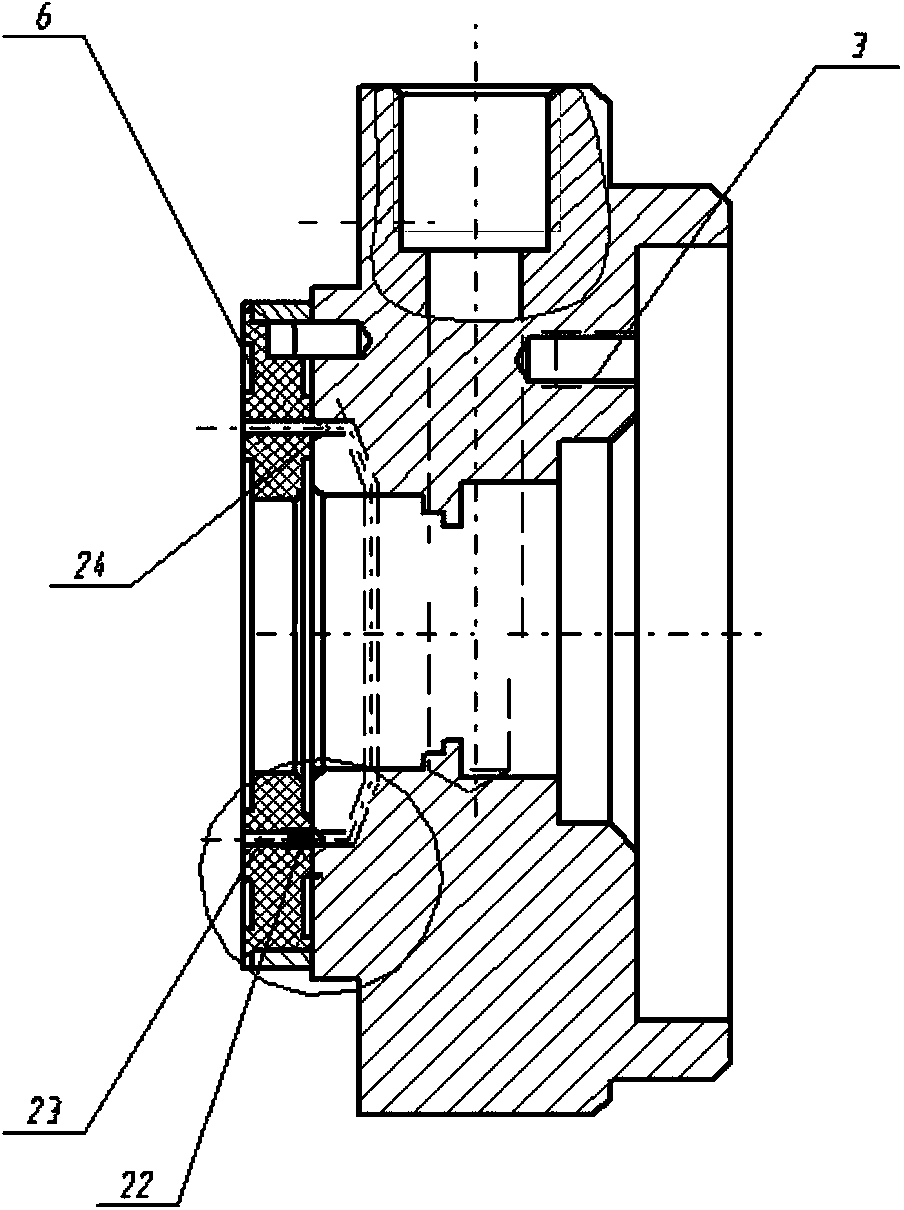

[0020] Such as figure 1 As shown, the seawater plunger motor is composed of a cylinder shaft 1, an end cover 3, a flow plate 6, a return plate 10, a housing 11, a plunger shoe assembly 15, a swash plate 14, and the like. The mechanical seal 2 is installed between the end cover and the cylinder shaft 1 to play the role of end face sealing; the cylinder shaft 1 is composed of the rear sliding bearing 12 installed in the inner hole of the housing 11 and the front sliding bearing installed inside the end cover 3 21 support, an even number of plunger assemblies 15 are inserted into an even number of cylinder holes uniformly distributed on the circumference of the cylinder shaft 1, a floating disc 19 is installed at one end of the cylinder shaft 1, and a floating sleeve 16 is installed inside and passed through the floating sleeve 16. The O-ring 17 and the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com