A Micro-Reformer for Hydrogen Production with Catalyst Support of Fractal Structure

A catalyst carrier, fractal structure technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the catalyst carrier loading capacity, reforming reaction time, carrier surface parameters, flow and heat transfer characteristics to be studied, hydrogen unit inlet The problems of large gas flow pulsation and weak catalyst loading capacity can improve the efficiency of the reforming reaction, increase the conversion rate of alcohols, and improve the performance of hydrogen production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

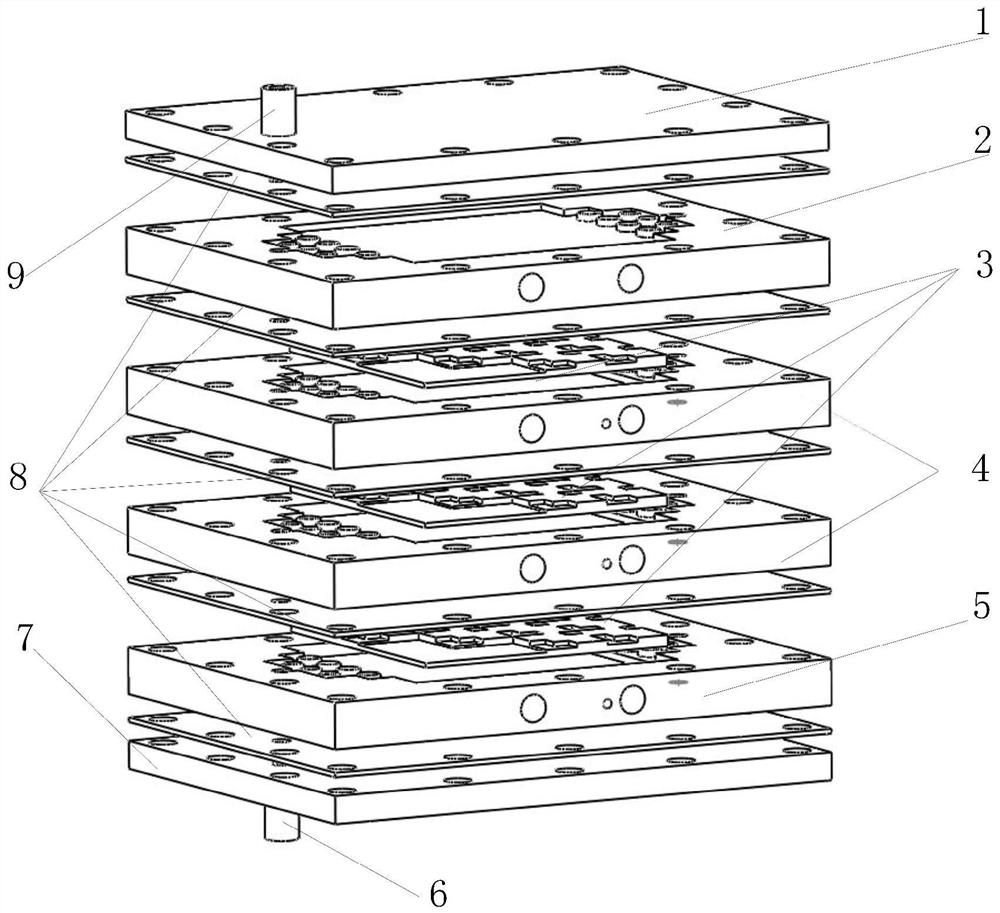

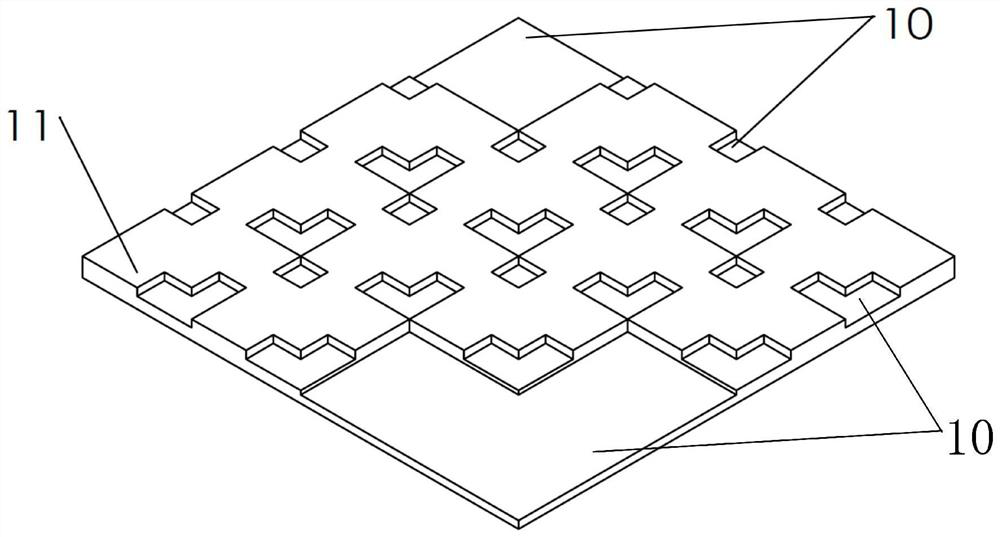

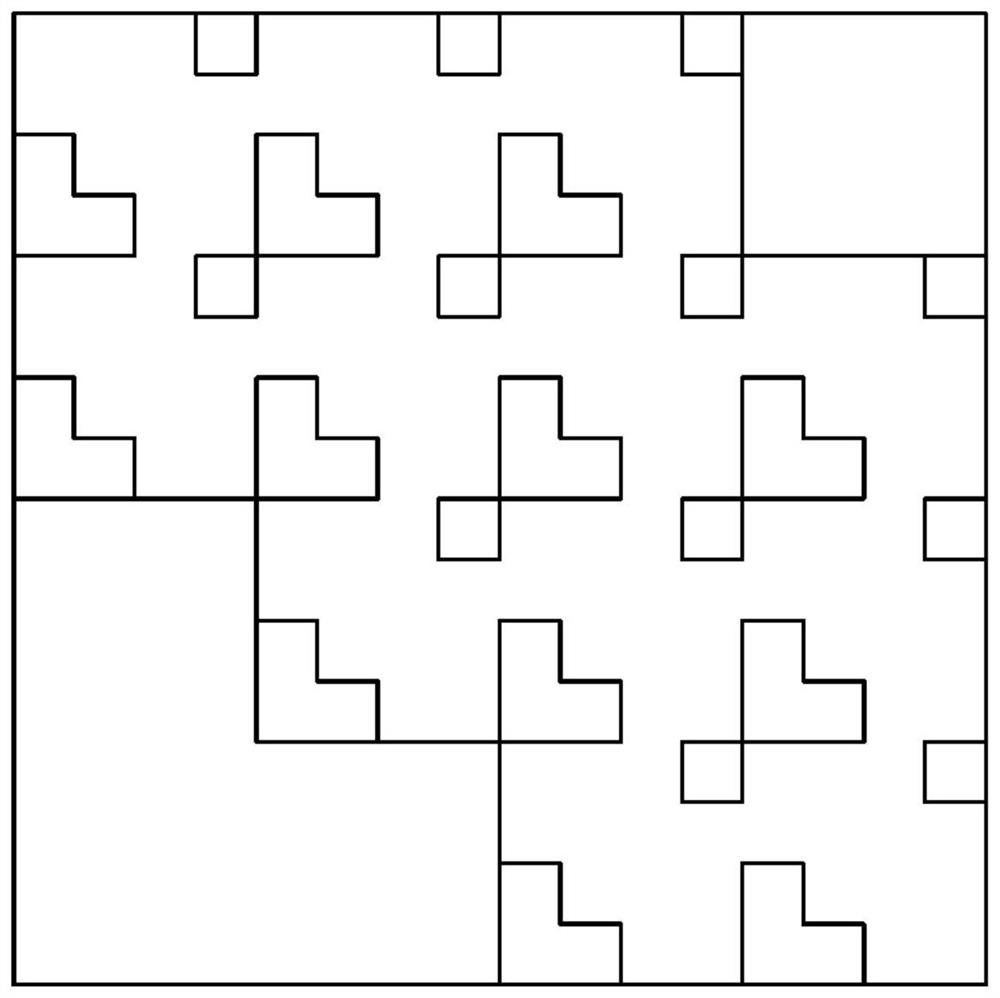

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the present invention comprises the upper cover plate 1 that top surface is provided with inlet pipe 9, the lower cover plate 7 that bottom surface is provided with outlet pipe 6, and sealing is installed between upper cover plate 1 and lower cover plate 7 from top to bottom The evaporating plate 2, multiple upper reforming plates 4 and lower reforming plates 5 installed in sequence; inlet and drainage chambers with drainage function are symmetrically distributed on both sides of the evaporating plate 2, upper reforming plate 4 and lower reforming plate 5 cavities 12 and outlet drainage chamber 14. A rectangular reaction carrier plate 3 with a fractal structure is installed in the reforming reaction chamber 20 in the middle of the upper reforming plate 4 and the lower refor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com