Roller type force balancing unit pump

A force-balanced, roller-type technology, applied in the field of hydraulic plunger pumps, can solve problems such as processing, use, and maintenance requirements and high costs, affecting service life and durability, and rapid rise in cylinder temperature, so as to enhance the reliability of movement performance, improve mechanical efficiency, and reduce mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

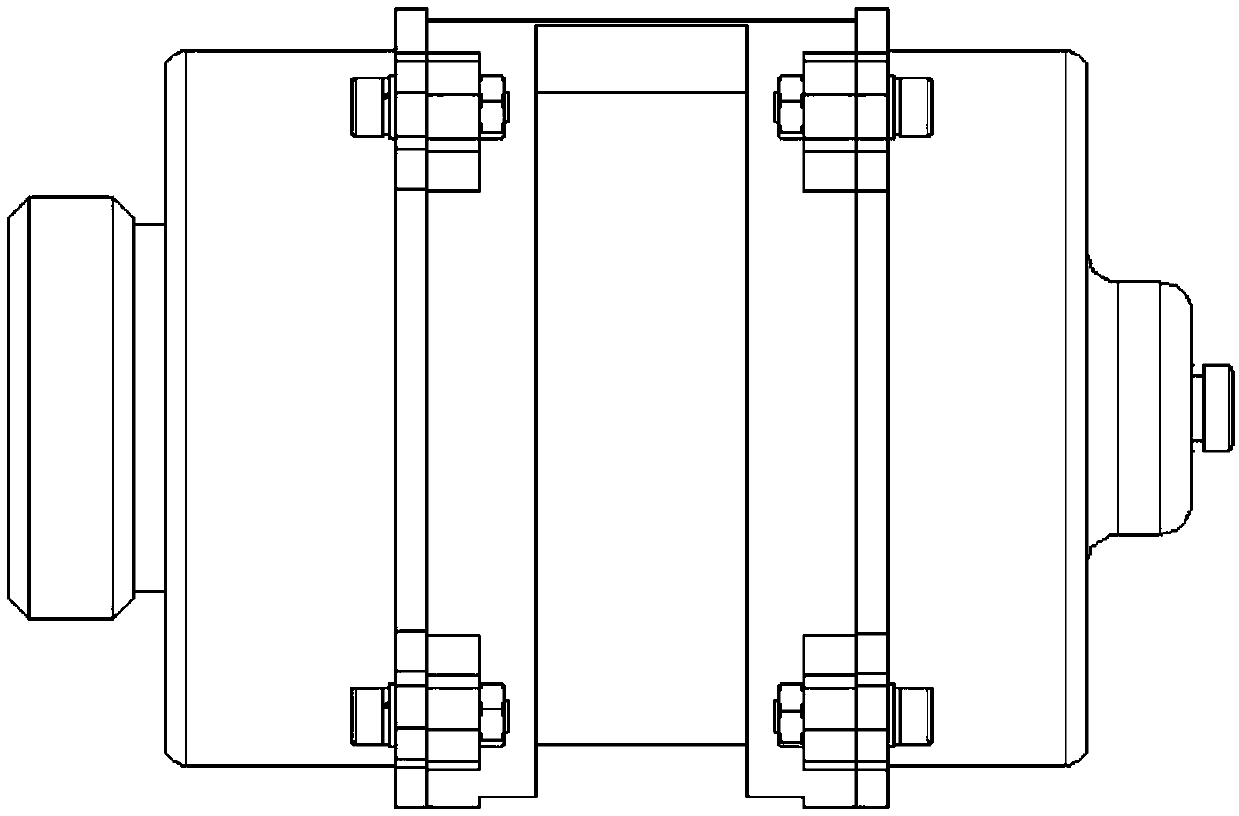

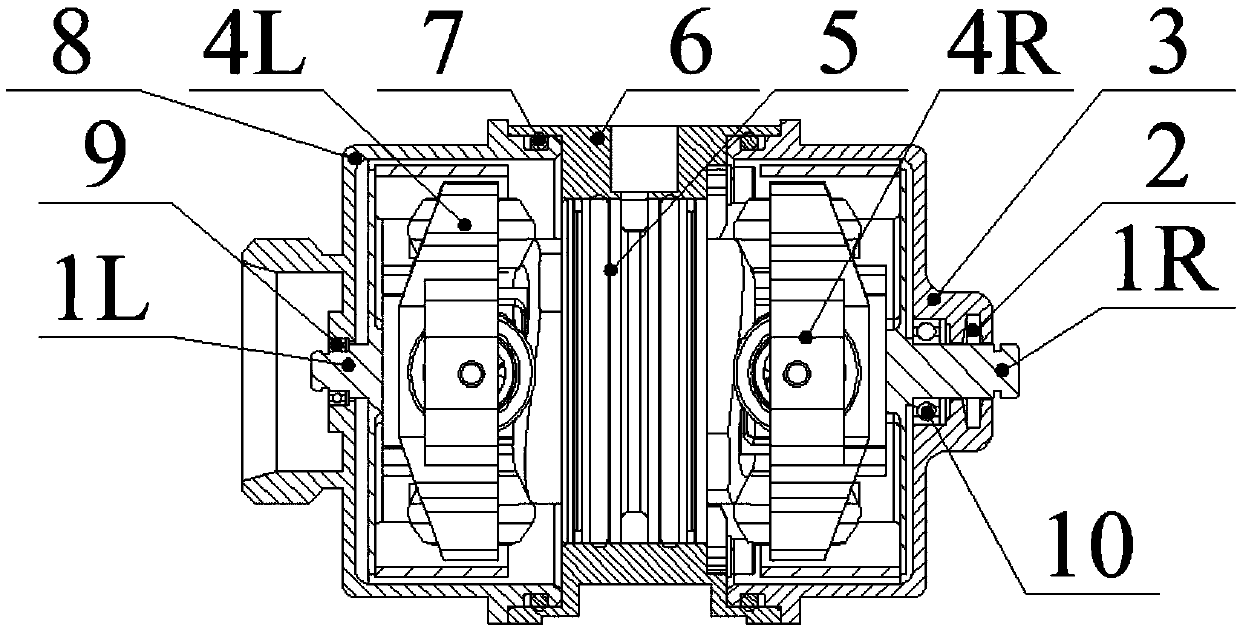

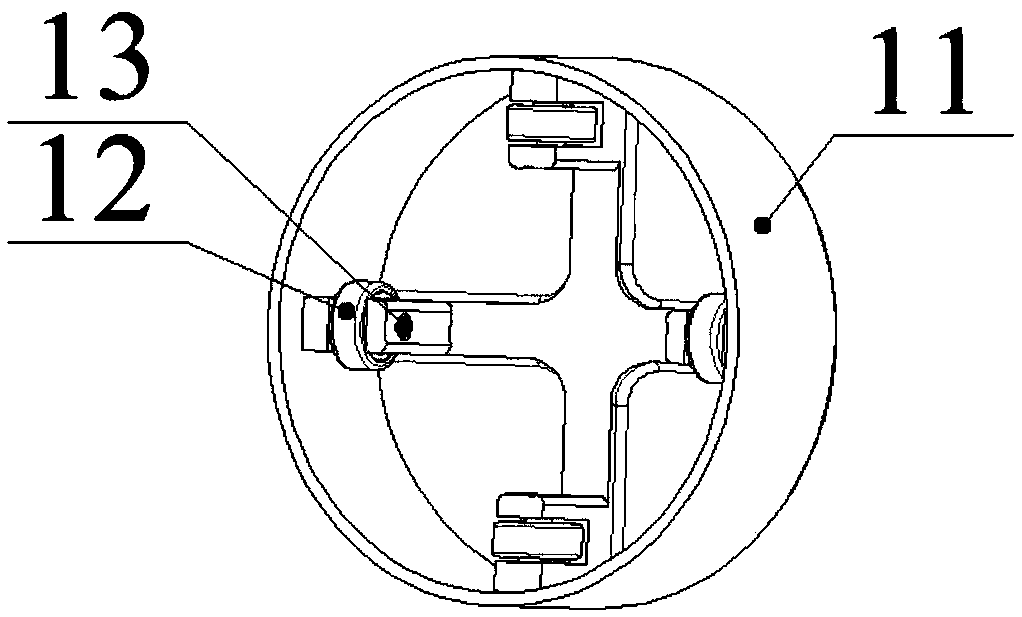

[0036] The roller-type force-balanced unit pump of the present invention includes: a right coupling assembly 1R, a right end cover 3, a left roller assembly 4L and a right roller assembly 4R, a pump core assembly 5, a pump casing 6, a left end cover 8, and a left coupling 1L . The right end cover 3 is connected to the right end surface of the pump casing 6 through bolts, and the left end cover 8 is fastened to the left end surface of the pump casing 6 through bolts. The sealing between the right end cover 3 and the pump casing 6 and the left end cover 8 and the pump casing 6 mainly depends on the sealing ring 7 . The right coupling 1R ensures the axial positioning with the right end cover 3 through the rolling ball bearing 10, and through the rolling ball bearing 10, the movement isolation between the right coupling 1R and the right end cover 3 is realized, and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com