Patents

Literature

116 results about "Multi resolution analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-resolution analysis in image segregation

ActiveUS20100303348A1Accurately correctly identifyImage enhancementImage analysisMulti resolution analysisScale space

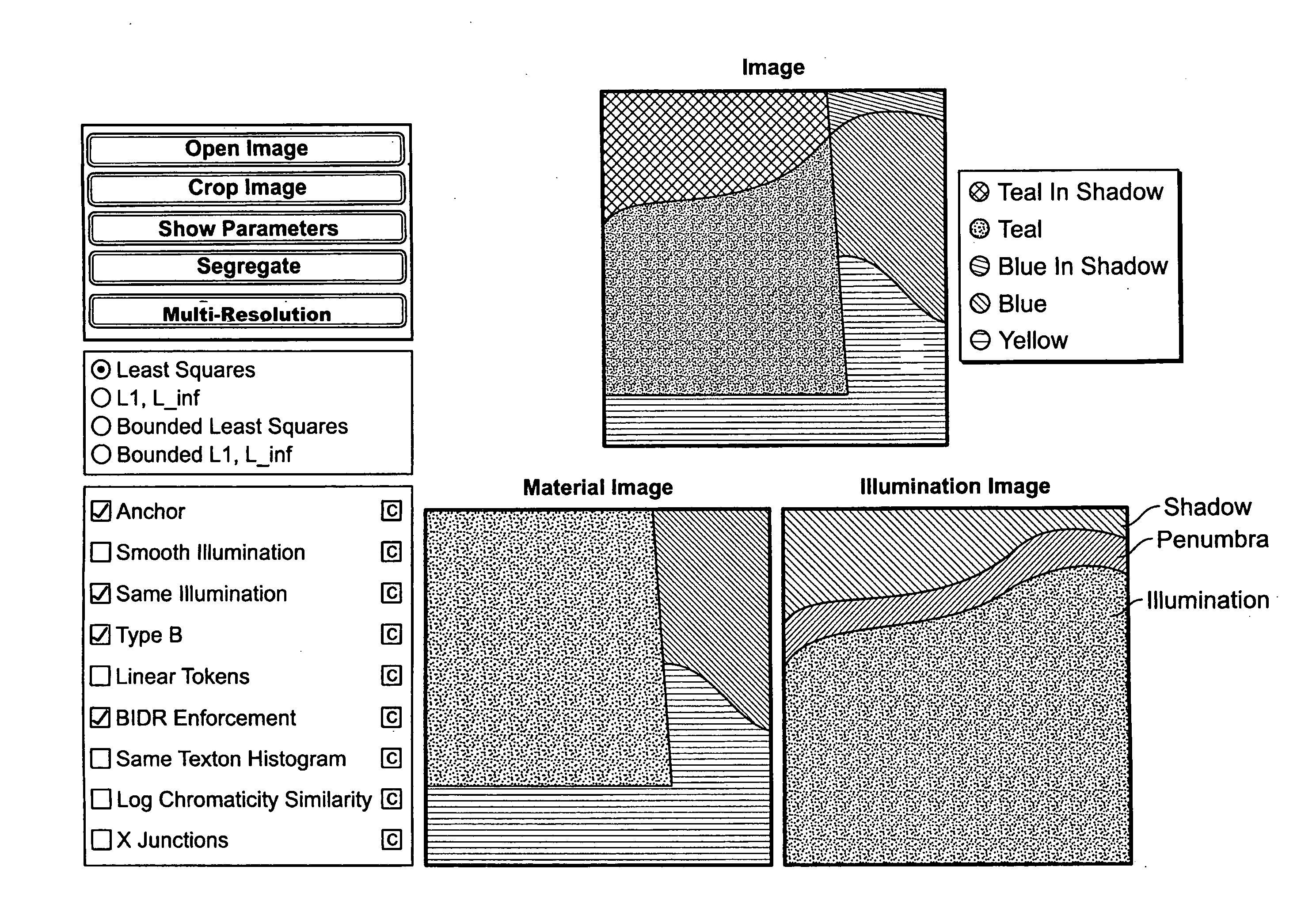

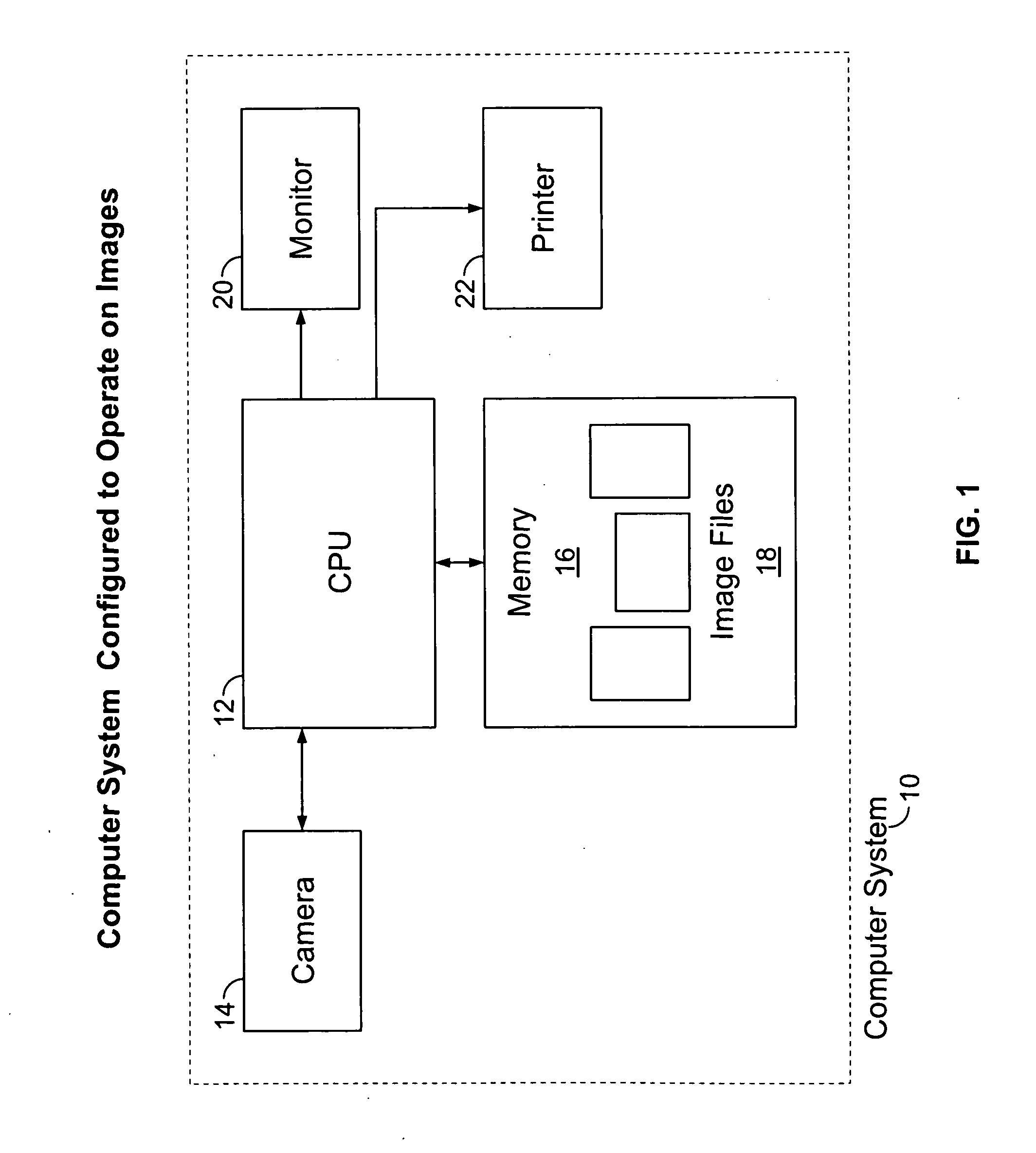

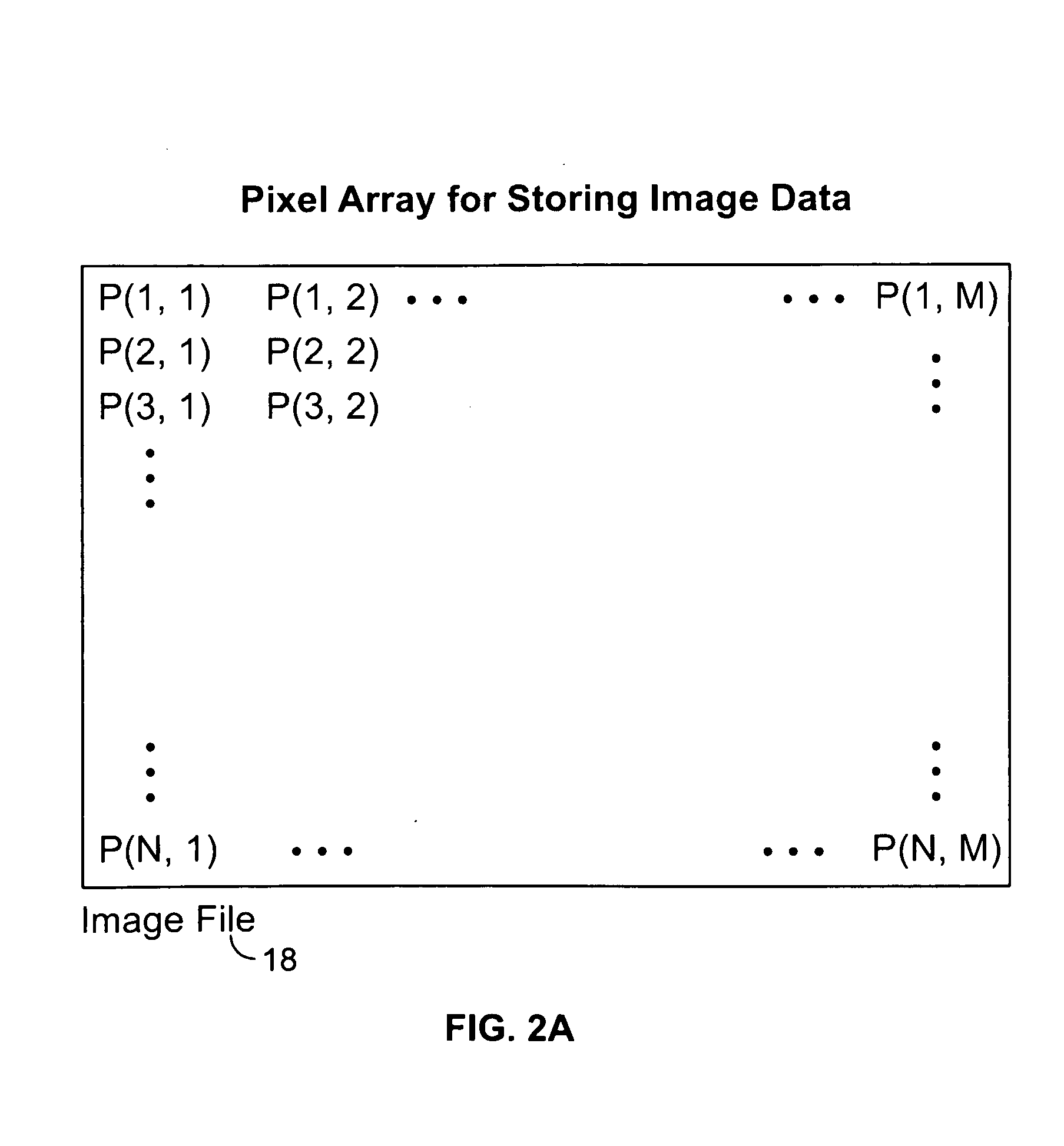

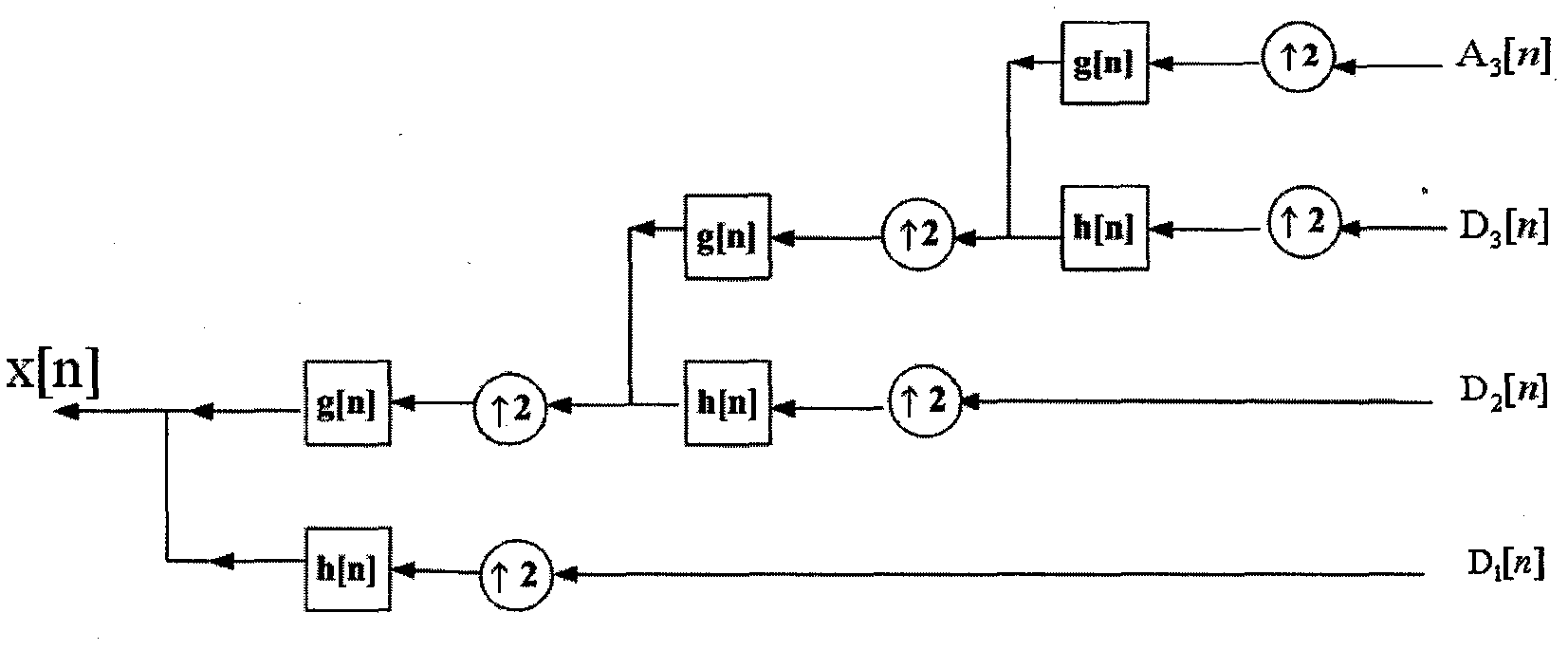

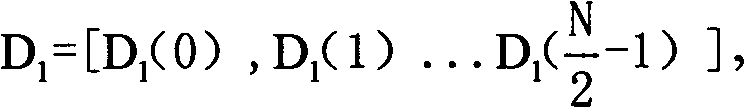

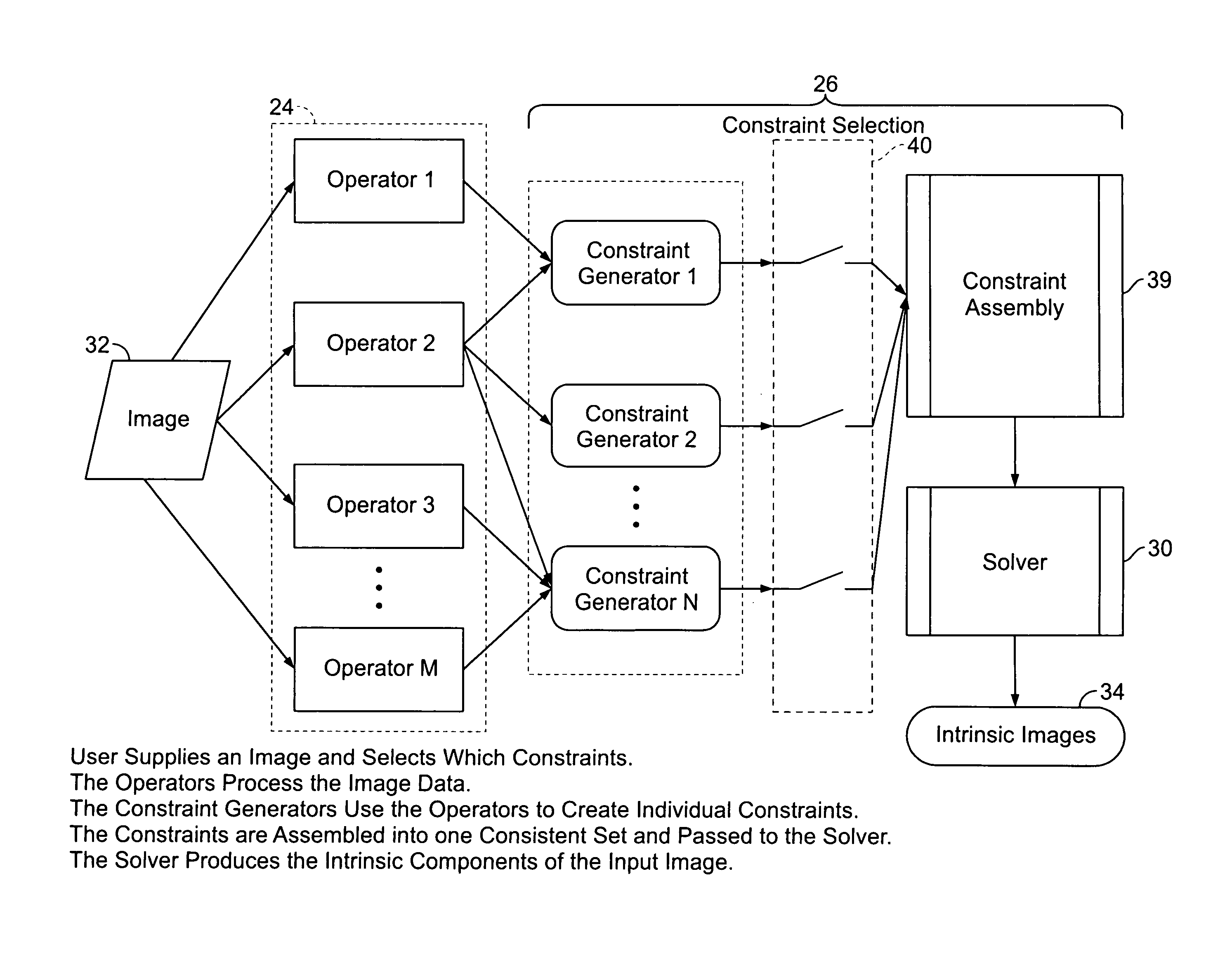

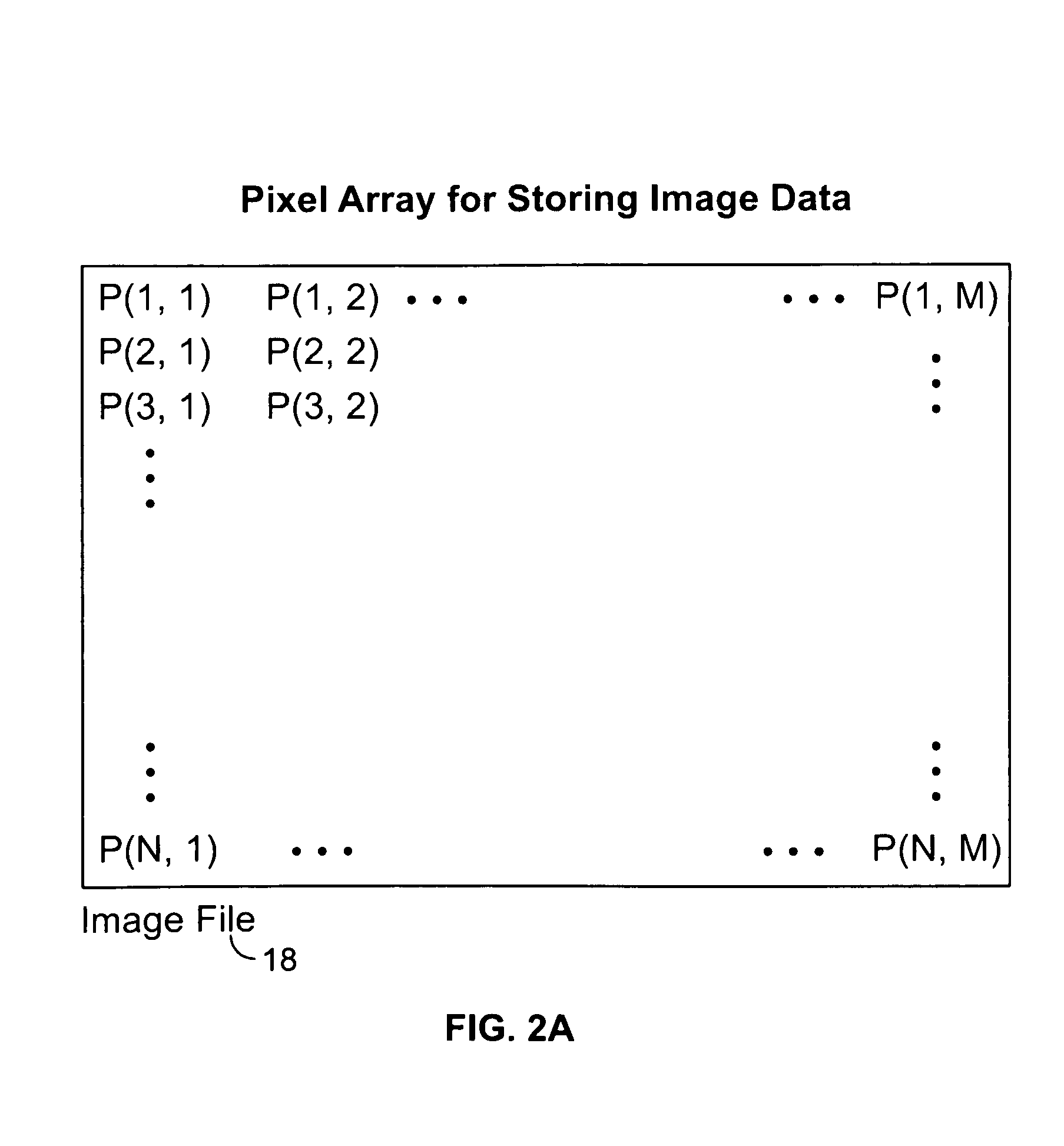

In a first exemplary embodiment of the present invention, an automated, computerized method is provided for processing an image. According to a feature of the present invention, the method comprises the steps of providing an image file depicting an image, in a computer memory, forming a set of selectively varied representations of the image file and performing an image segregation operation on at least one preselected representation of the image of the image file, to generate intrinsic images corresponding to the image. According to a feature of the exemplary embodiment of the present invention, the selectively varied representations comprise multi-resolution representations such as a scale-spaced pyramid of representations. In a further feature of the exemplary embodiment of the present invention, the intrinsic images comprise a material image and an illumination image.

Owner:INNOVATION ASSET COLLECTIVE

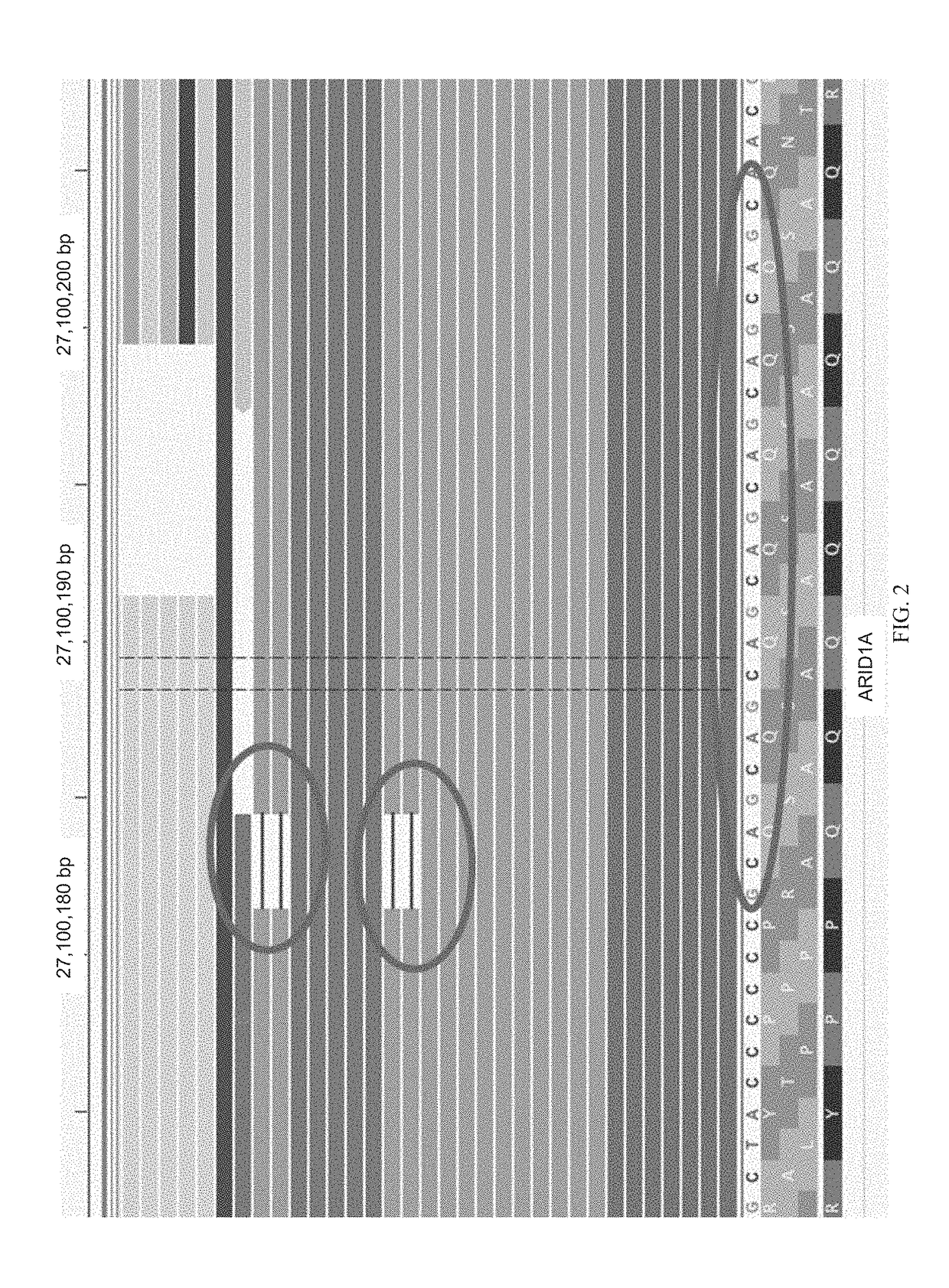

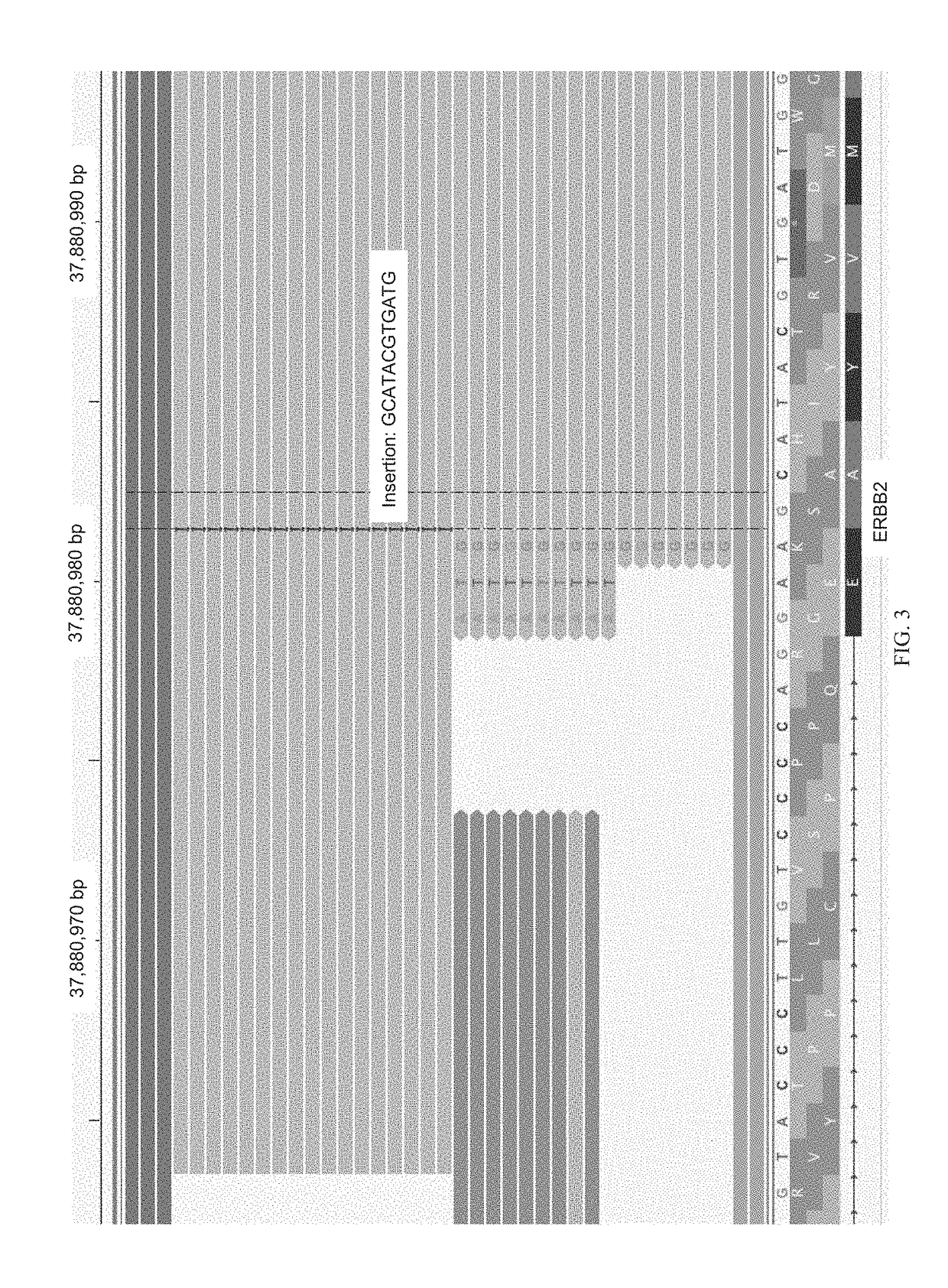

Methods for multi-resolution analysis of cell-free nucleic acids

ActiveUS9850523B1Improve capture efficiencyImprove detection accuracyMicrobiological testing/measurementHybridisationDiseaseMulti resolution analysis

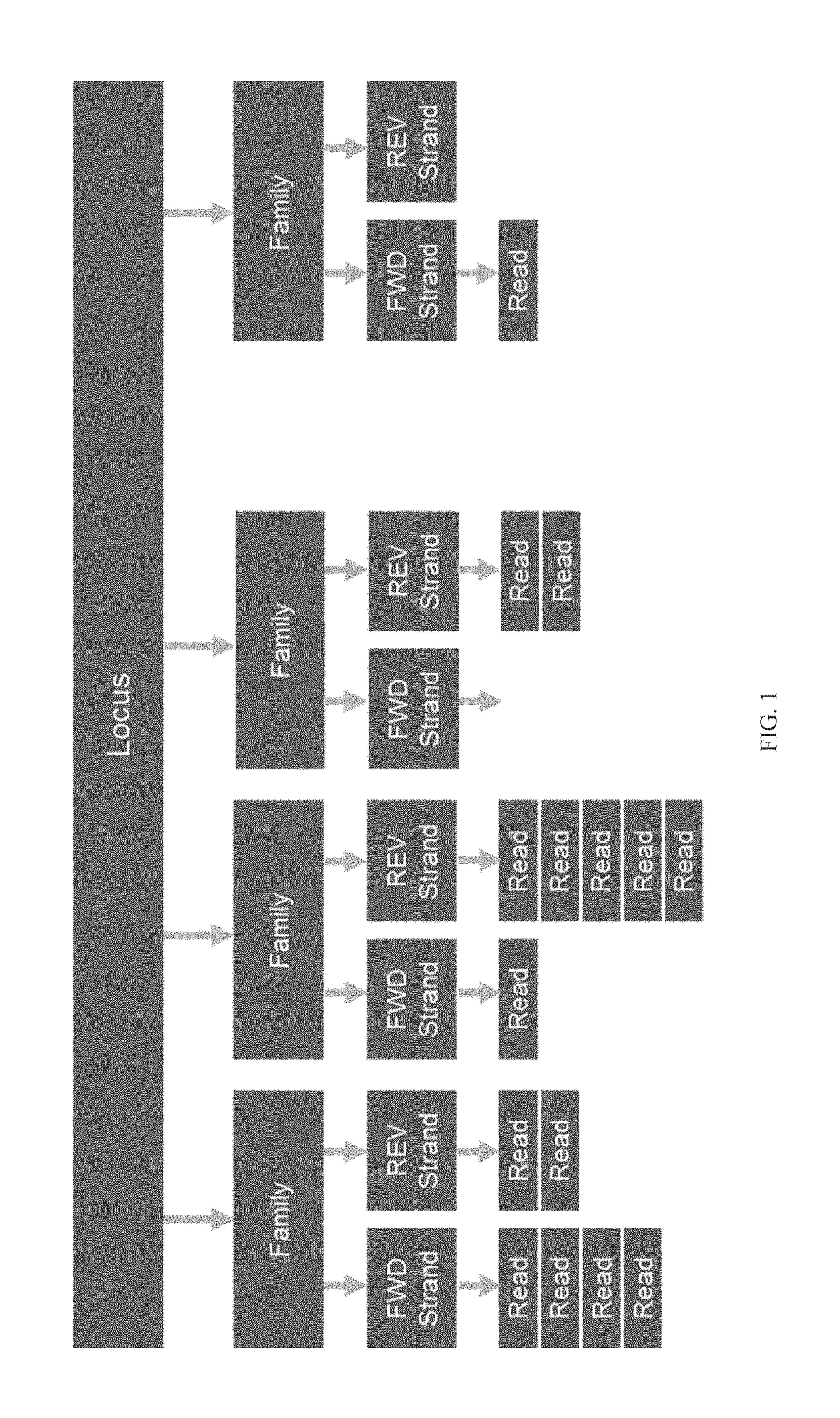

The present disclosure provides a method for enriching for multiple genomic regions using a first bait set that selectively hybridizes to a first set of genomic regions of a nucleic acid sample and a second bait set that selectively hybridizes to a second set of genomic regions of the nucleic acid sample. These bait set panels can selectively enrich for one or more nucleosome-associated regions of a genome, said nucleosome-associated regions comprising genomic regions having one or more genomic base positions with differential nucleosomal occupancy, wherein the differential nucleosomal occupancy is characteristic of a cell or tissue type of origin or disease state.

Owner:GUARDANT HEALTH

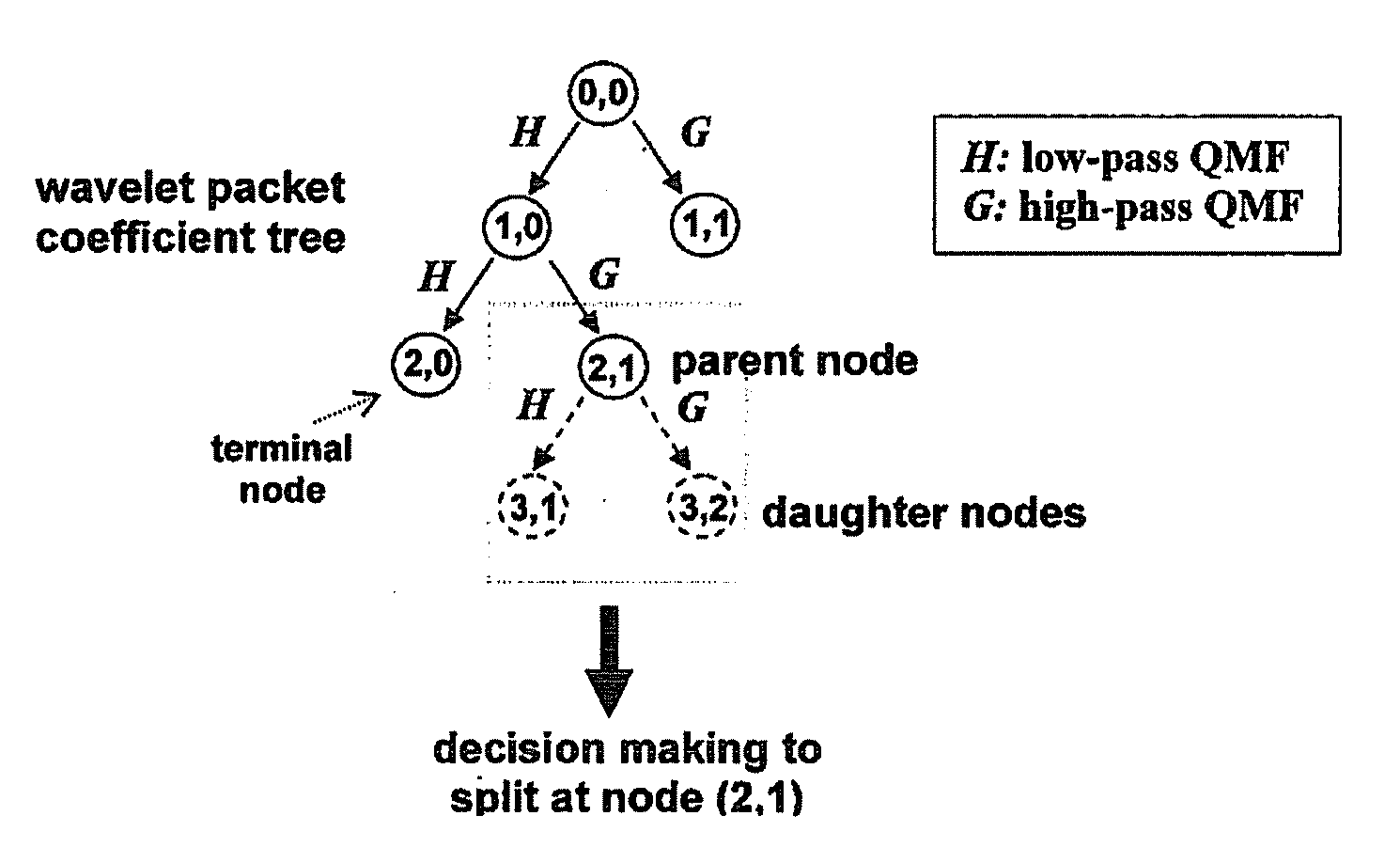

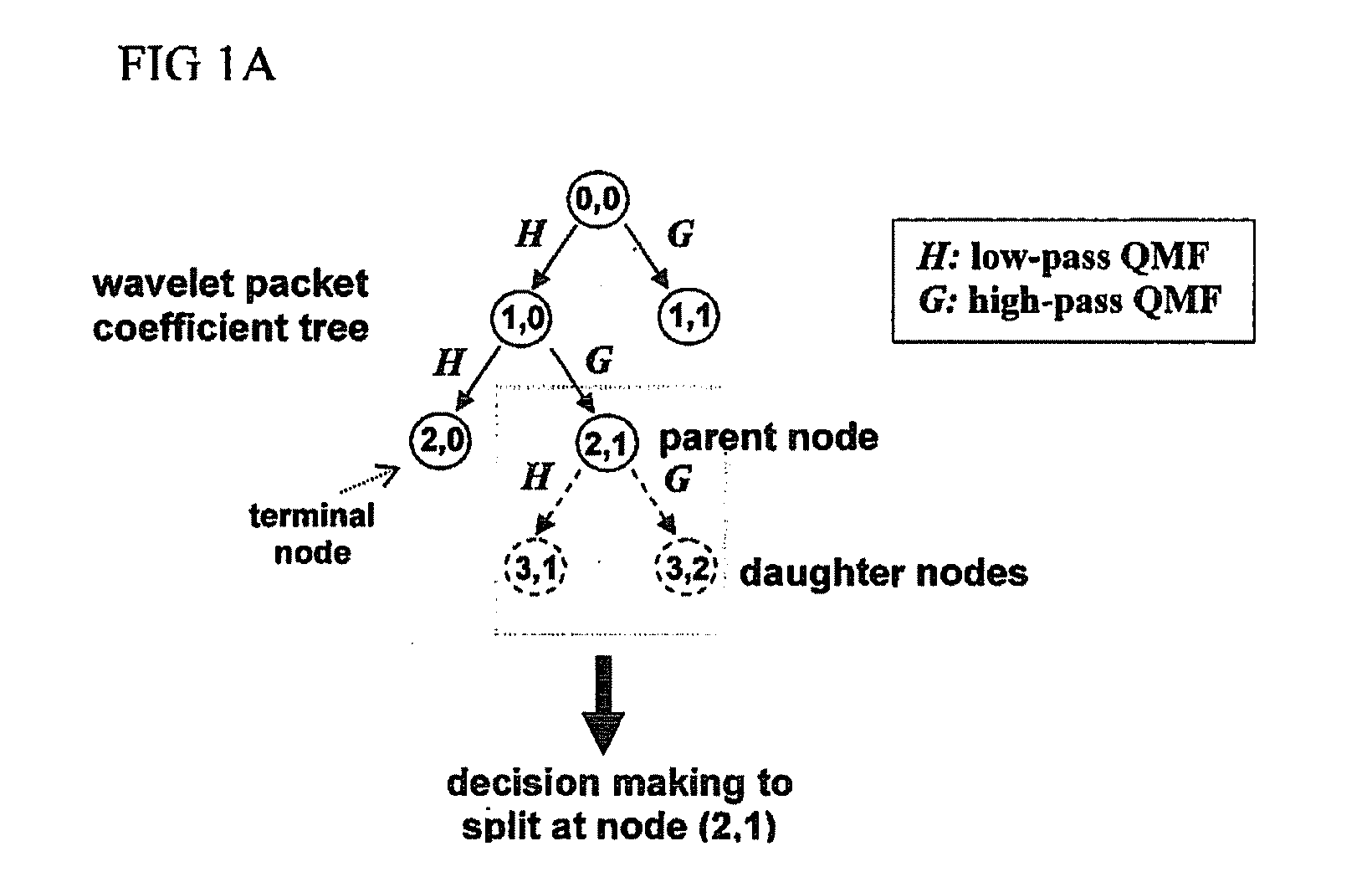

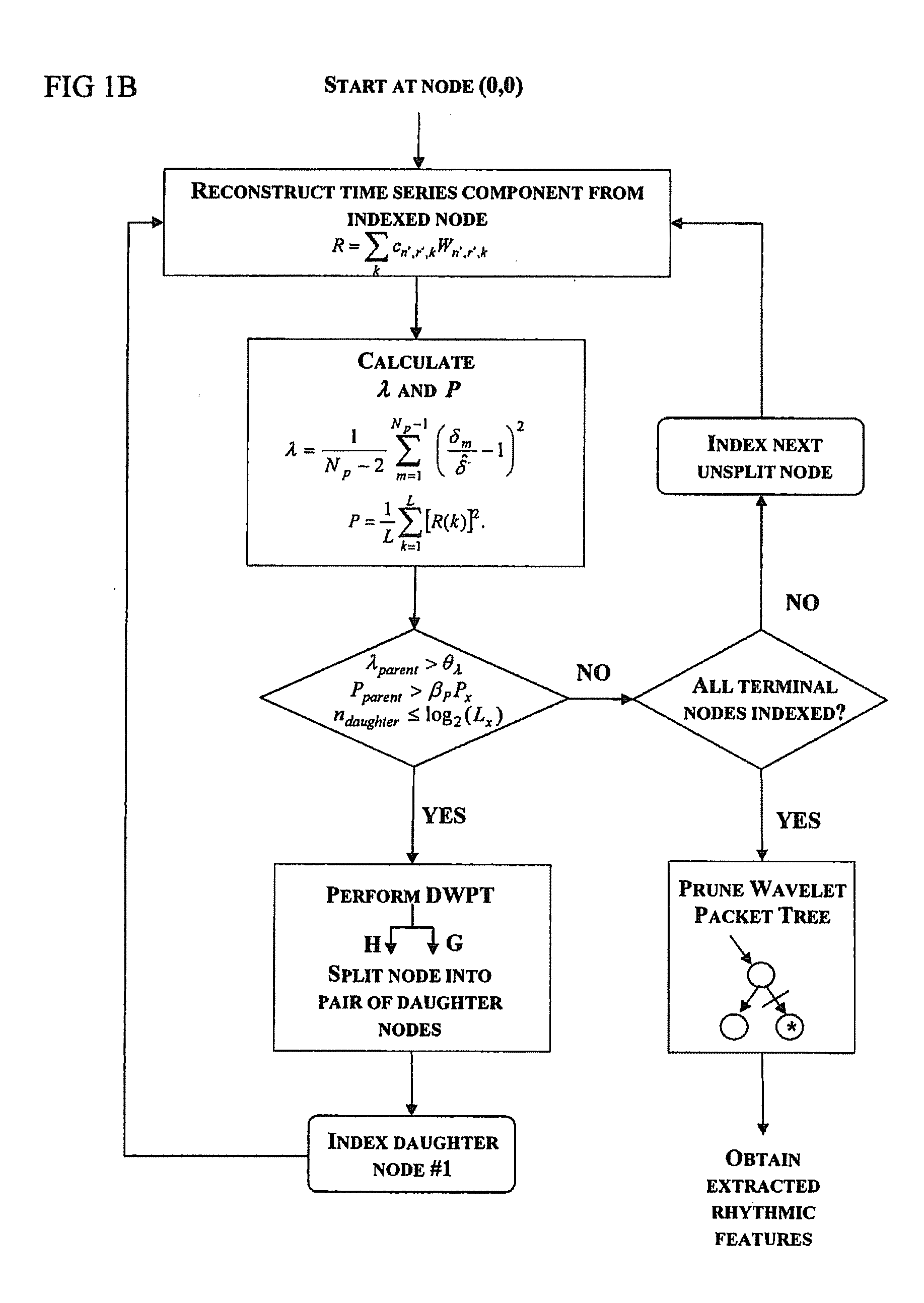

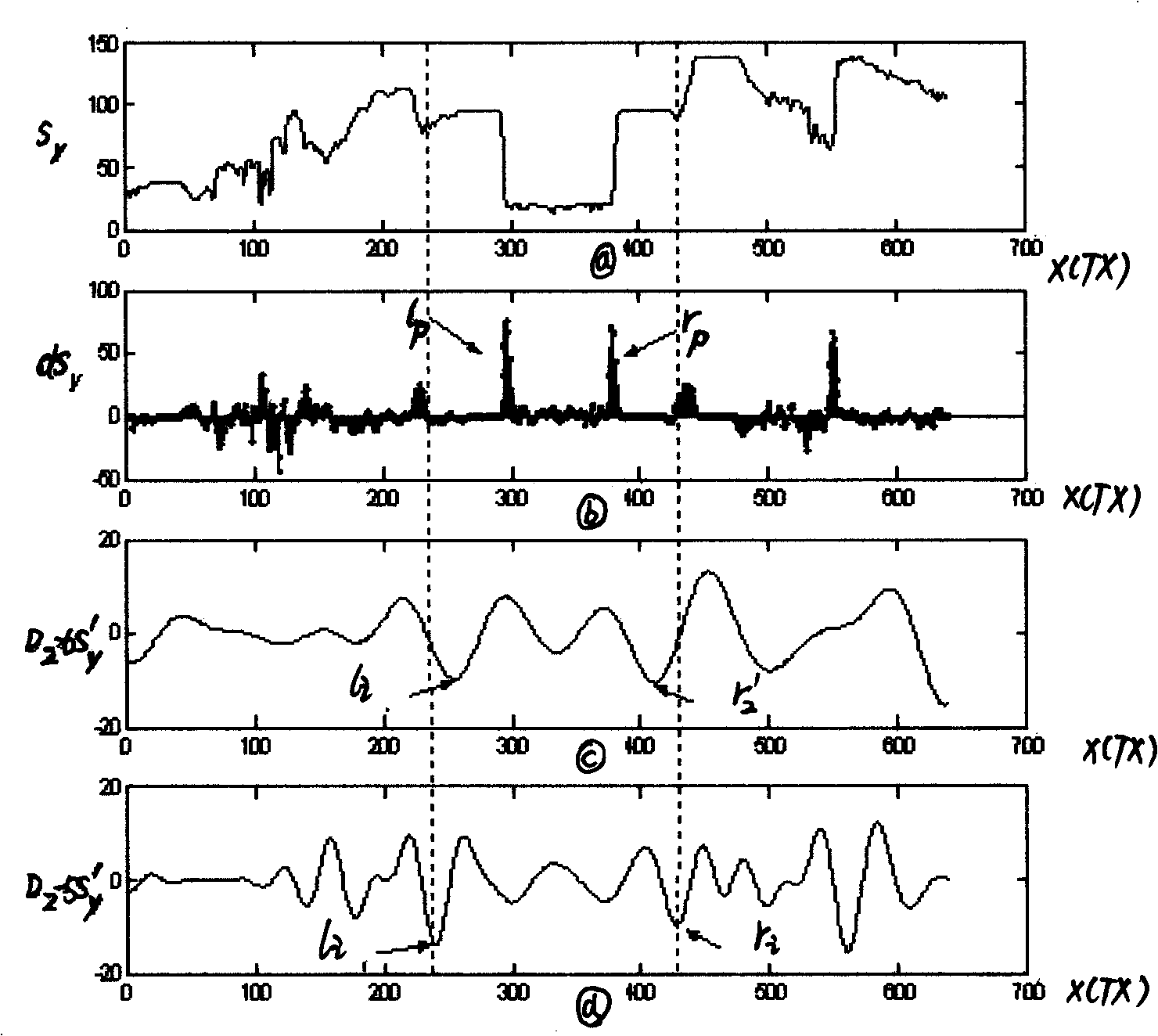

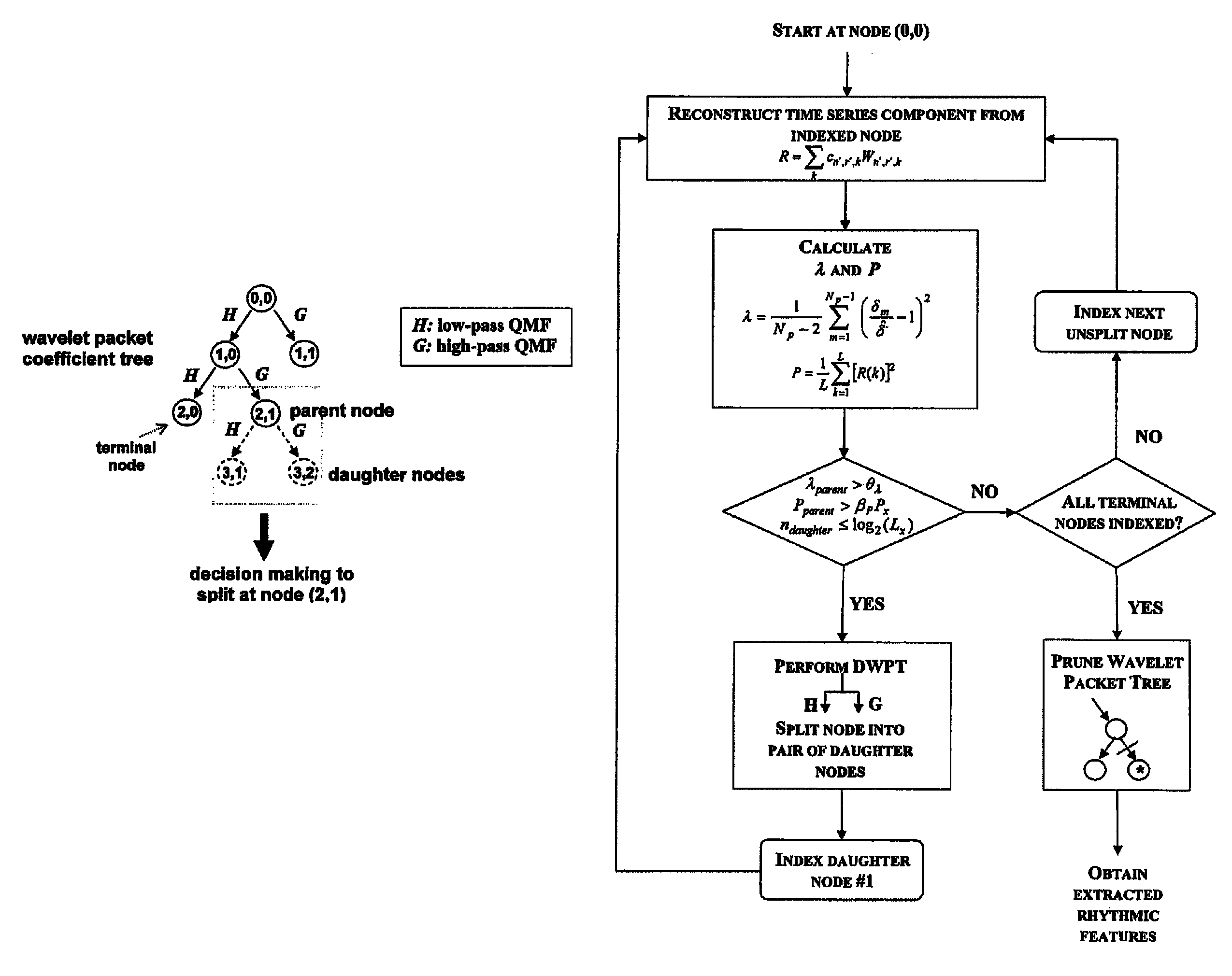

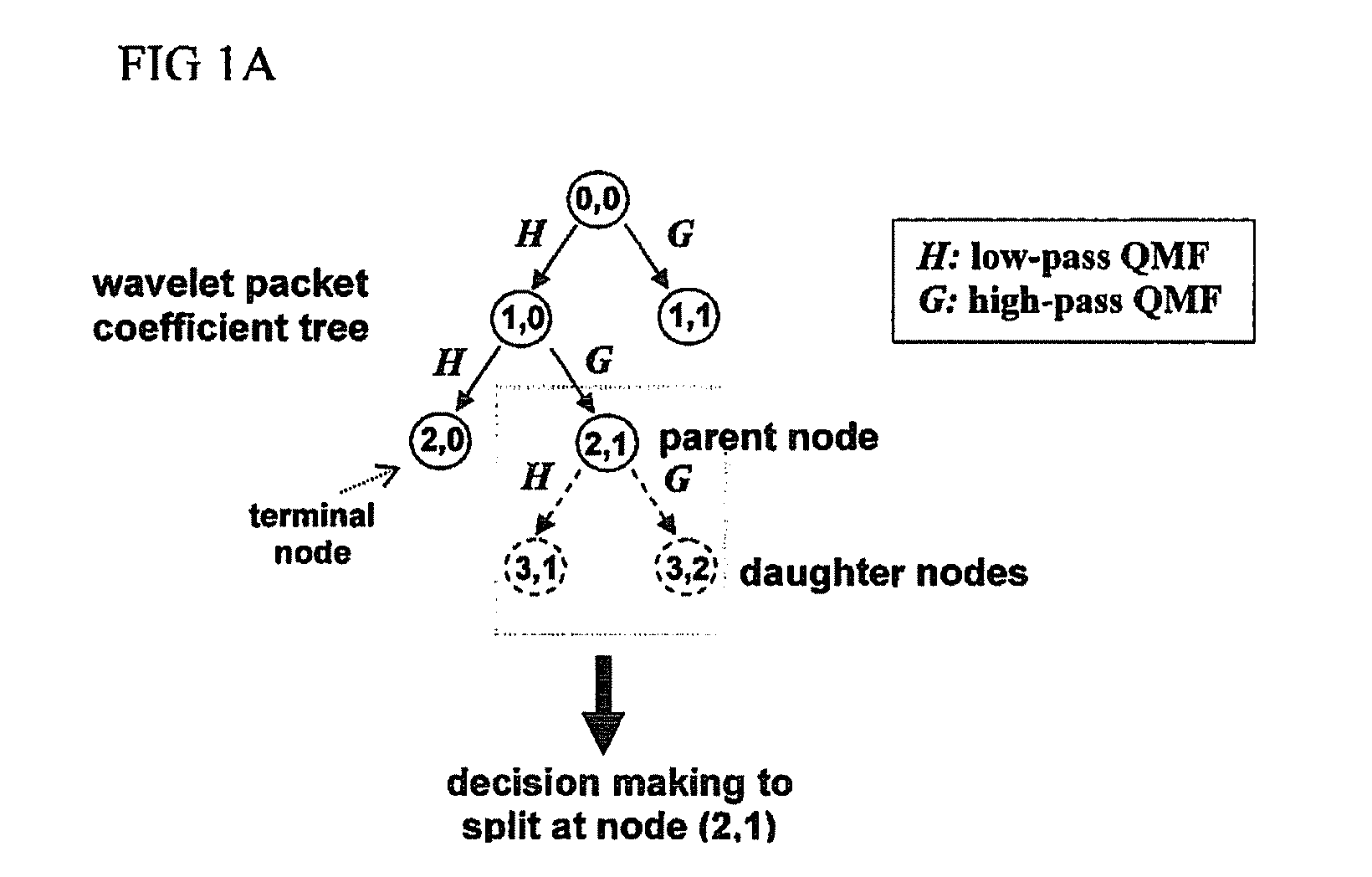

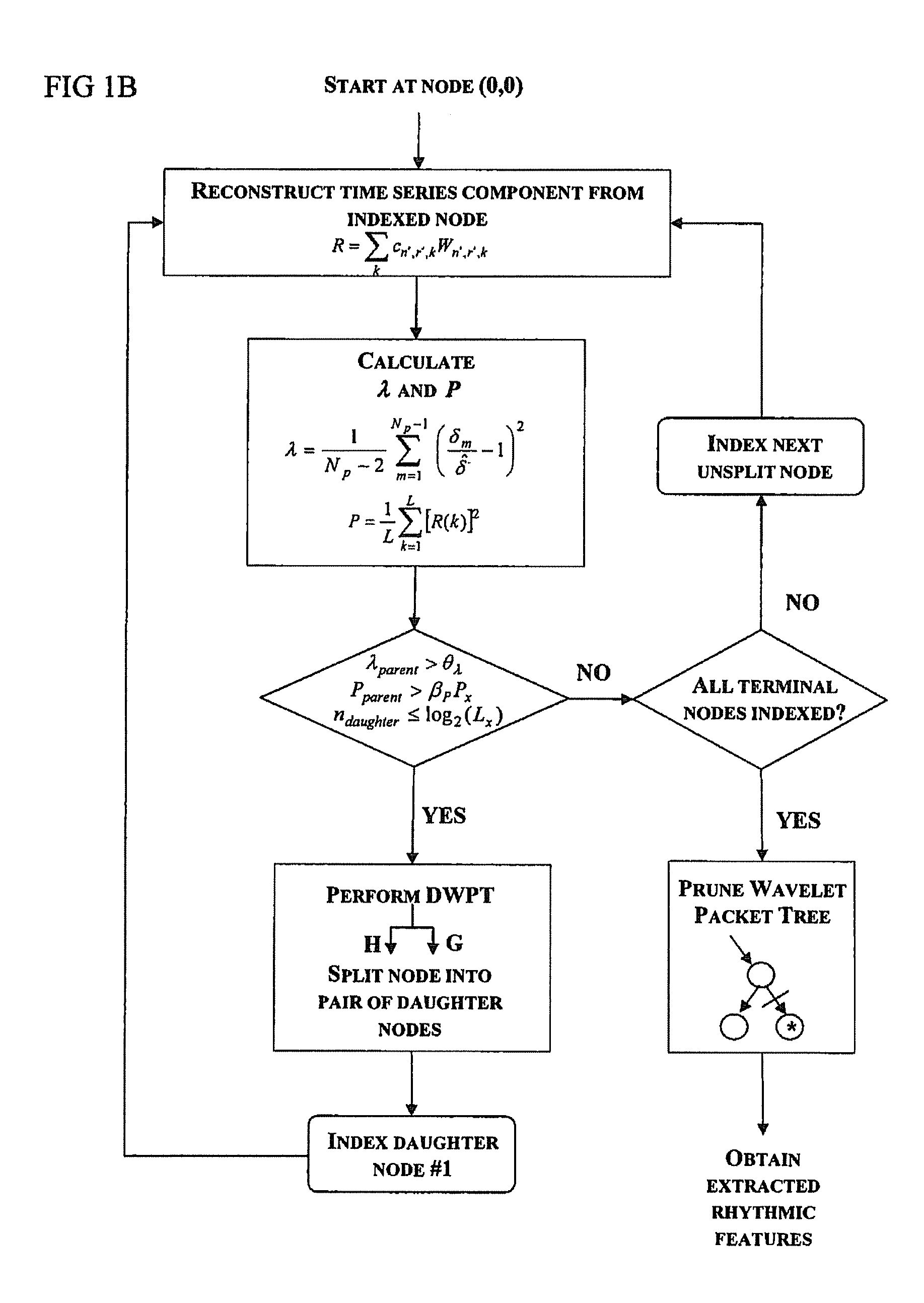

Method and rhythm extractor for detecting and isolating rhythmic signal features from an input signal using the wavelet packet transform

A method of detecting and isolating at least one rhythmic component from a discrete-time input signal, comprises subjecting the input signal to discrete wavelet packet transform multi-resolution analysis; applying wavelet packet basis selection criteria to the result of the analysis to evaluate rhythmic signal features of the input signal; and isolating at least one rhythmic signal component from the input signal based on the evaluation.

Owner:NEUROCHIP CORP

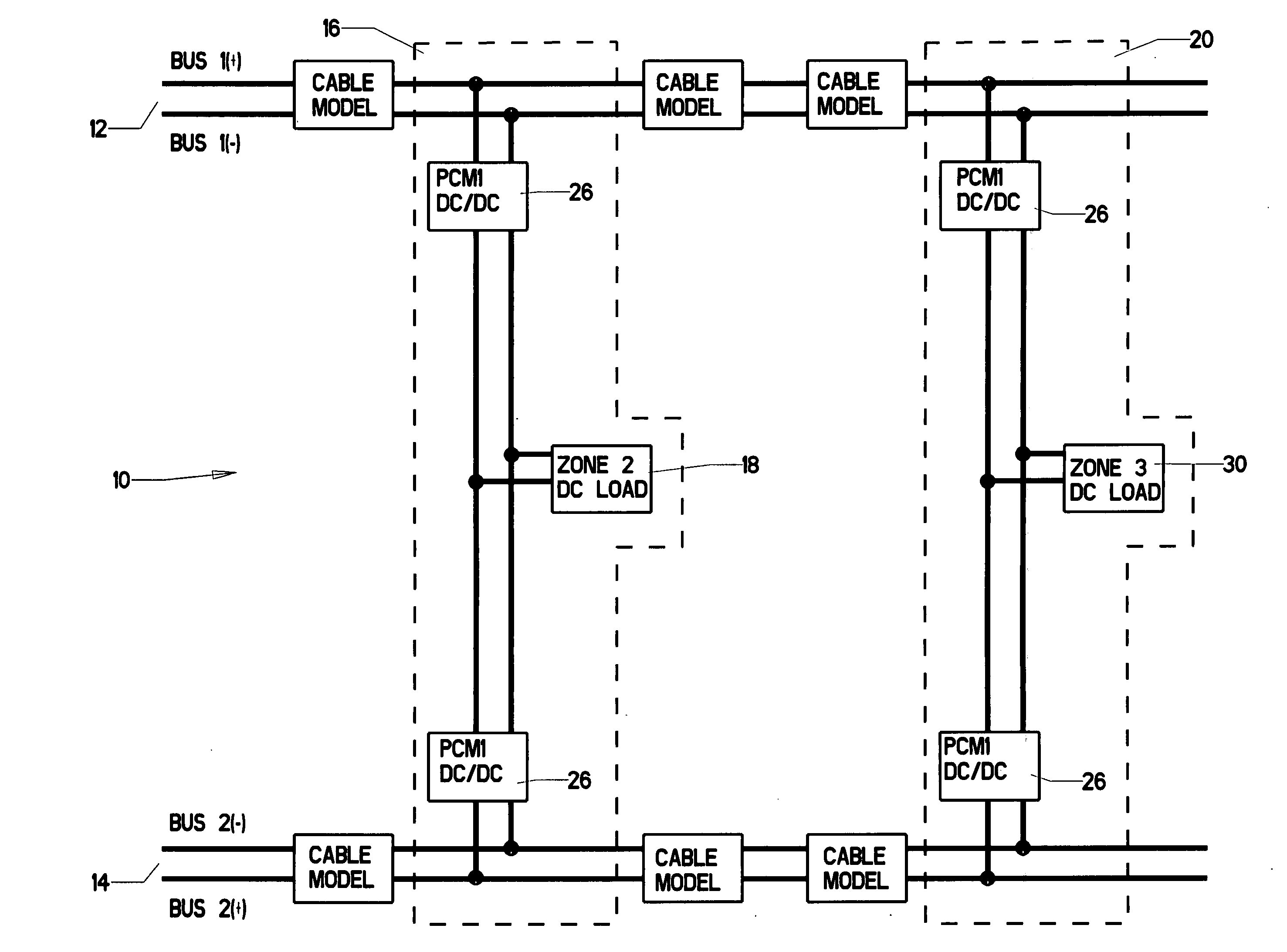

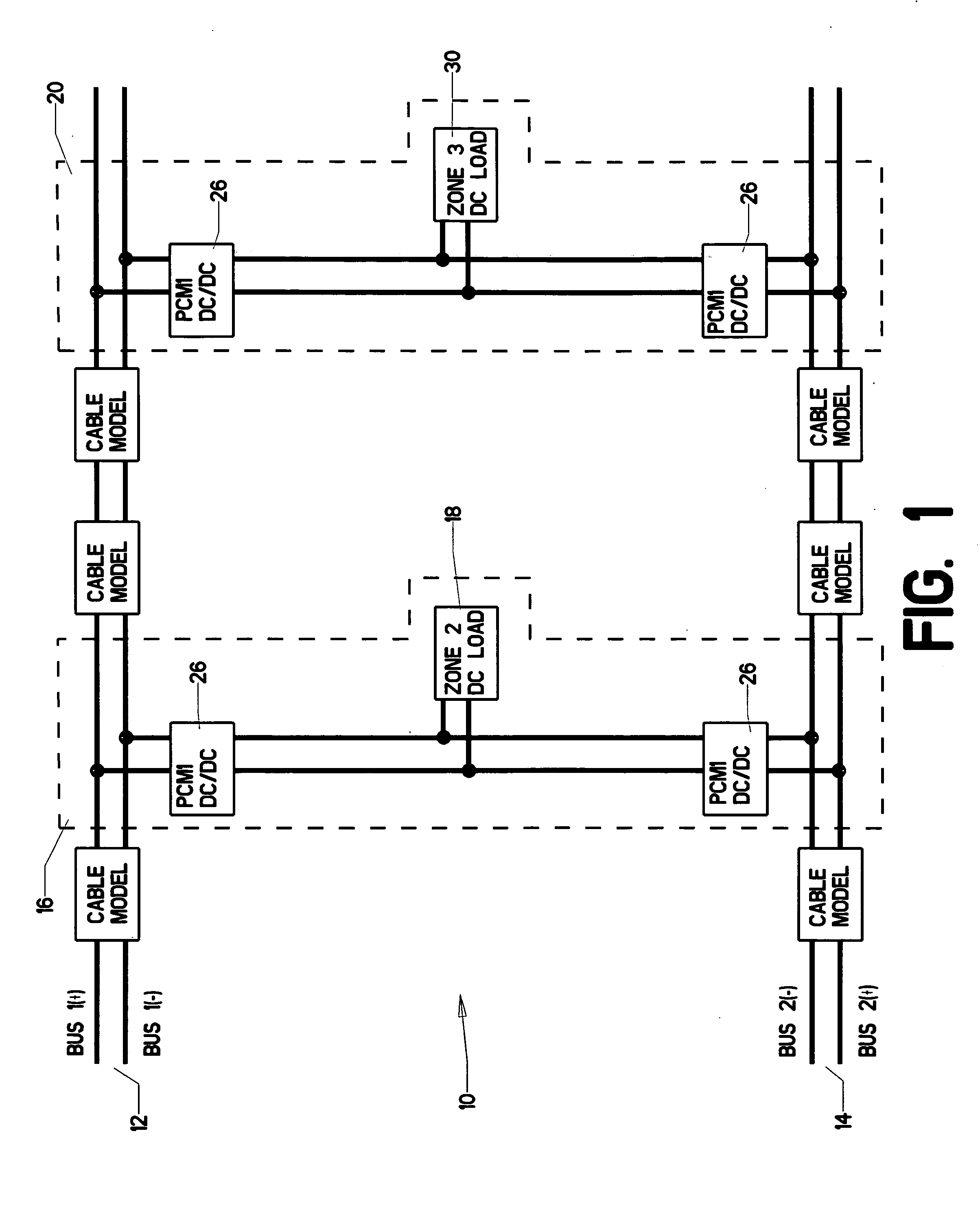

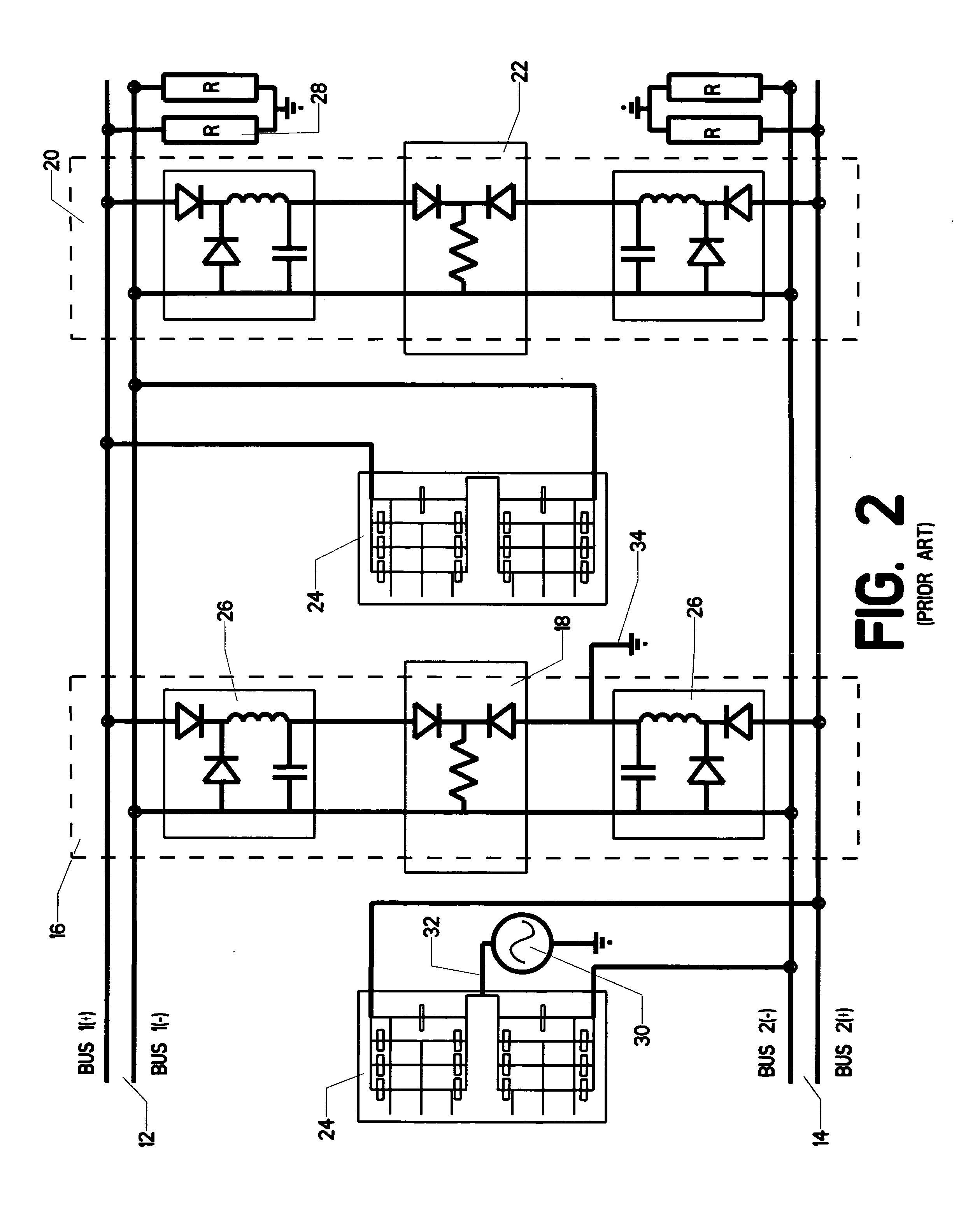

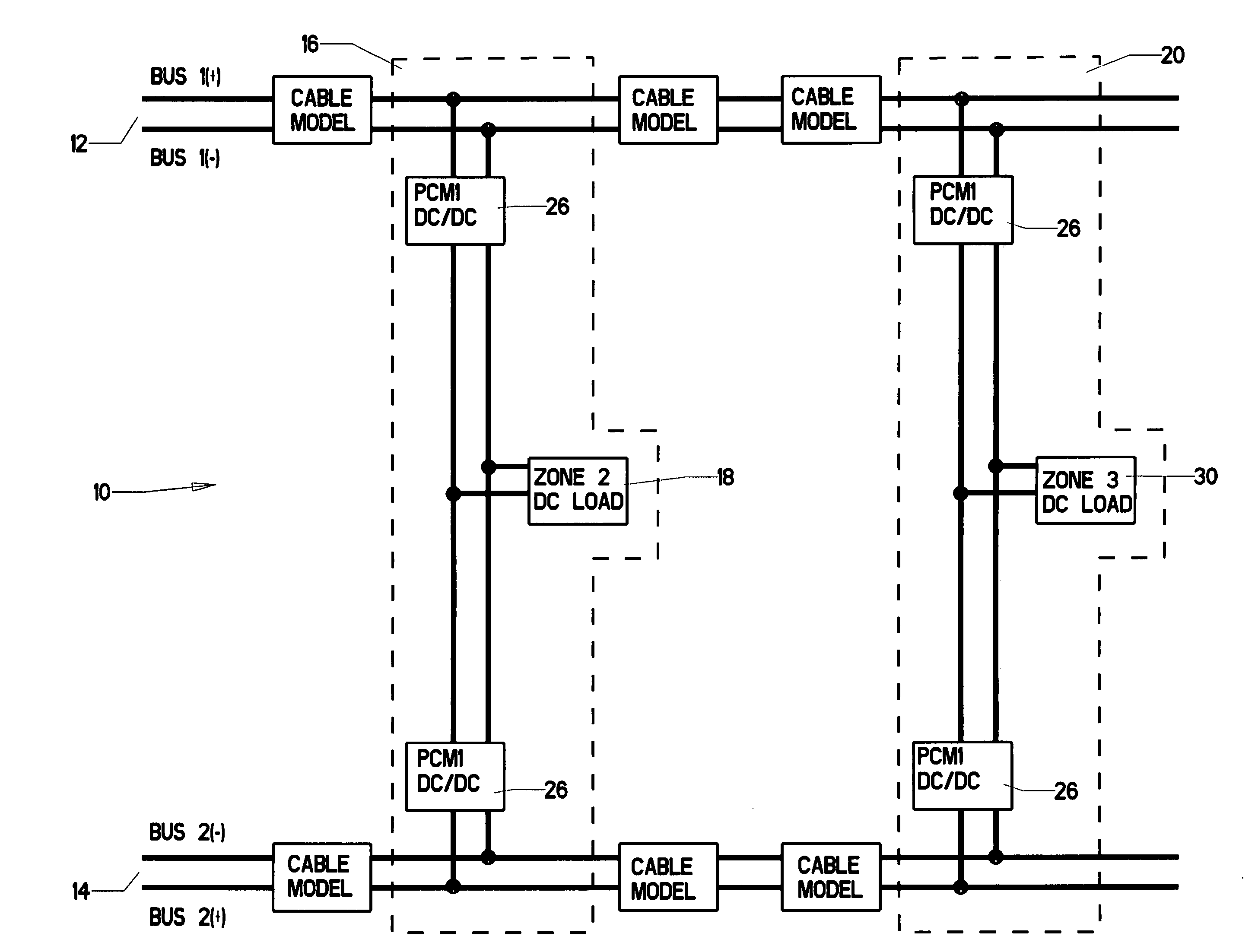

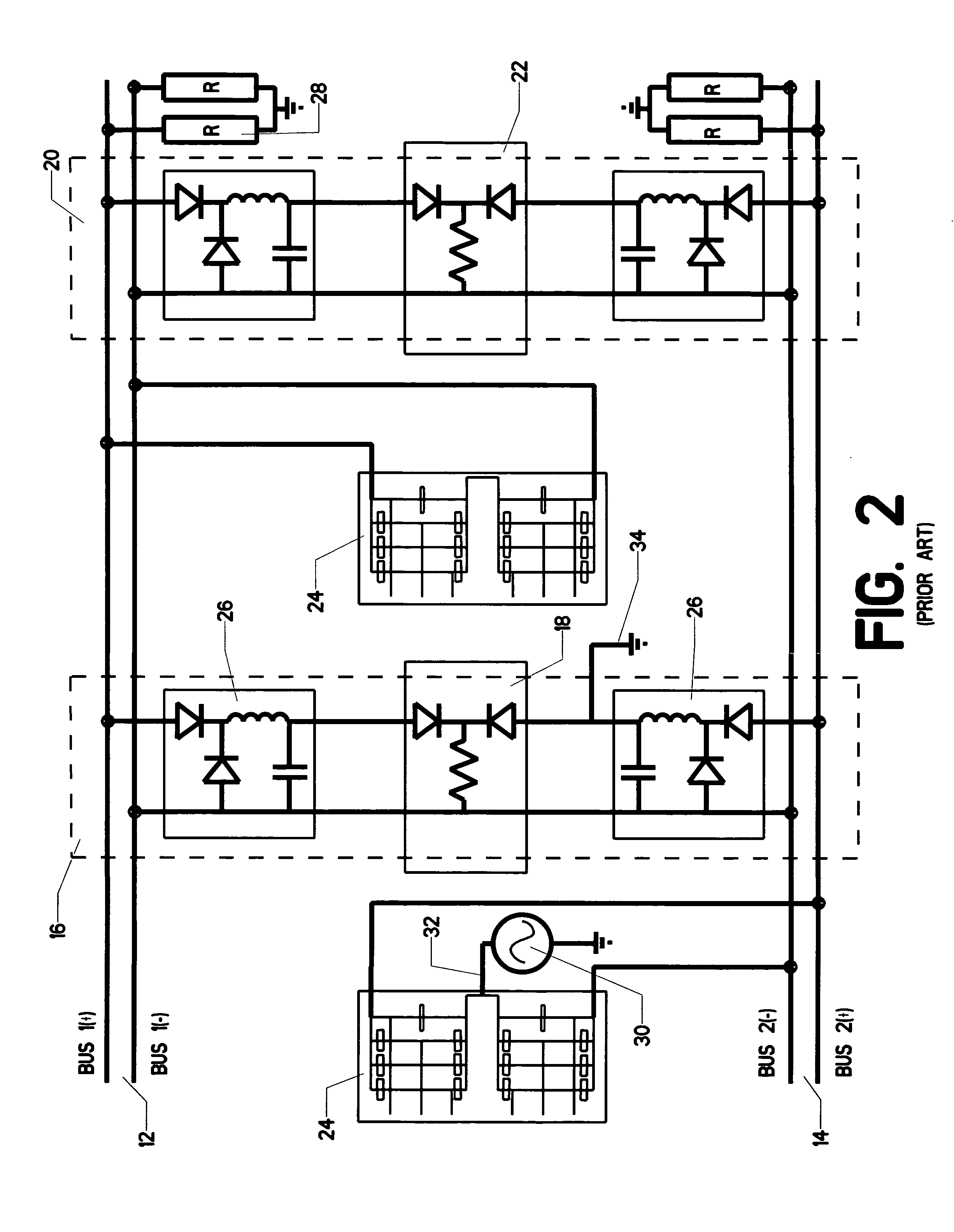

Method for locating phase to ground faults in DC distribution systems

ActiveUS20090085574A1Quick checkFast locationFault location by conductor typesShort-circuit testingMulti resolution analysisSwitching frequency

A method for locating phase to ground faults in DC distribution systems. The method includes utilizing wavelet analysis using Multi-Resolution Analysis (MRA) as a signal processing tool for recognition of characteristic features in the voltage signal. The voltage signal contains characteristic information in the high frequency range above the switching frequencies of the PE converters which allows for localization of the fault.

Owner:FLORIDA STATE UNIV RES FOUND INC

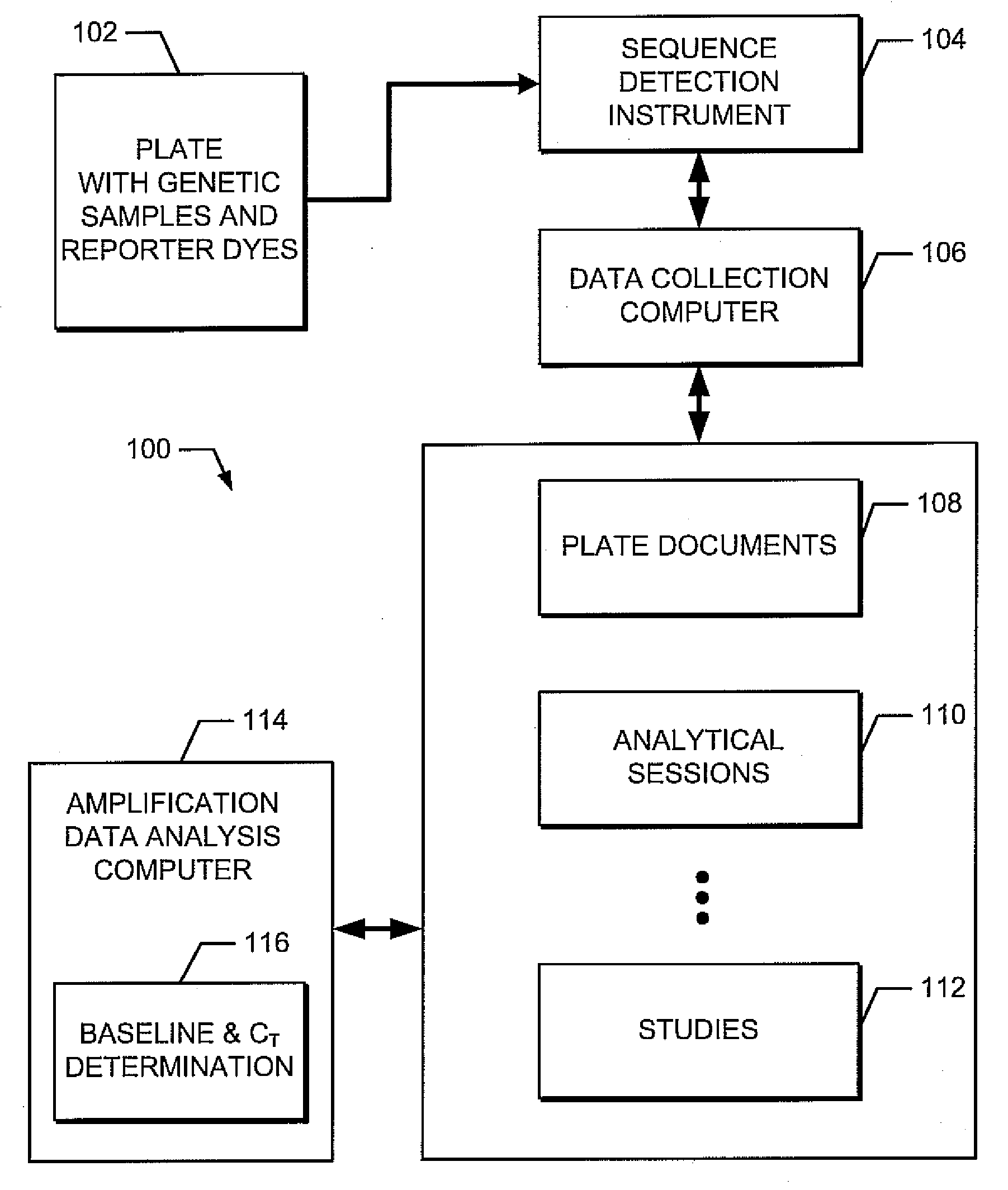

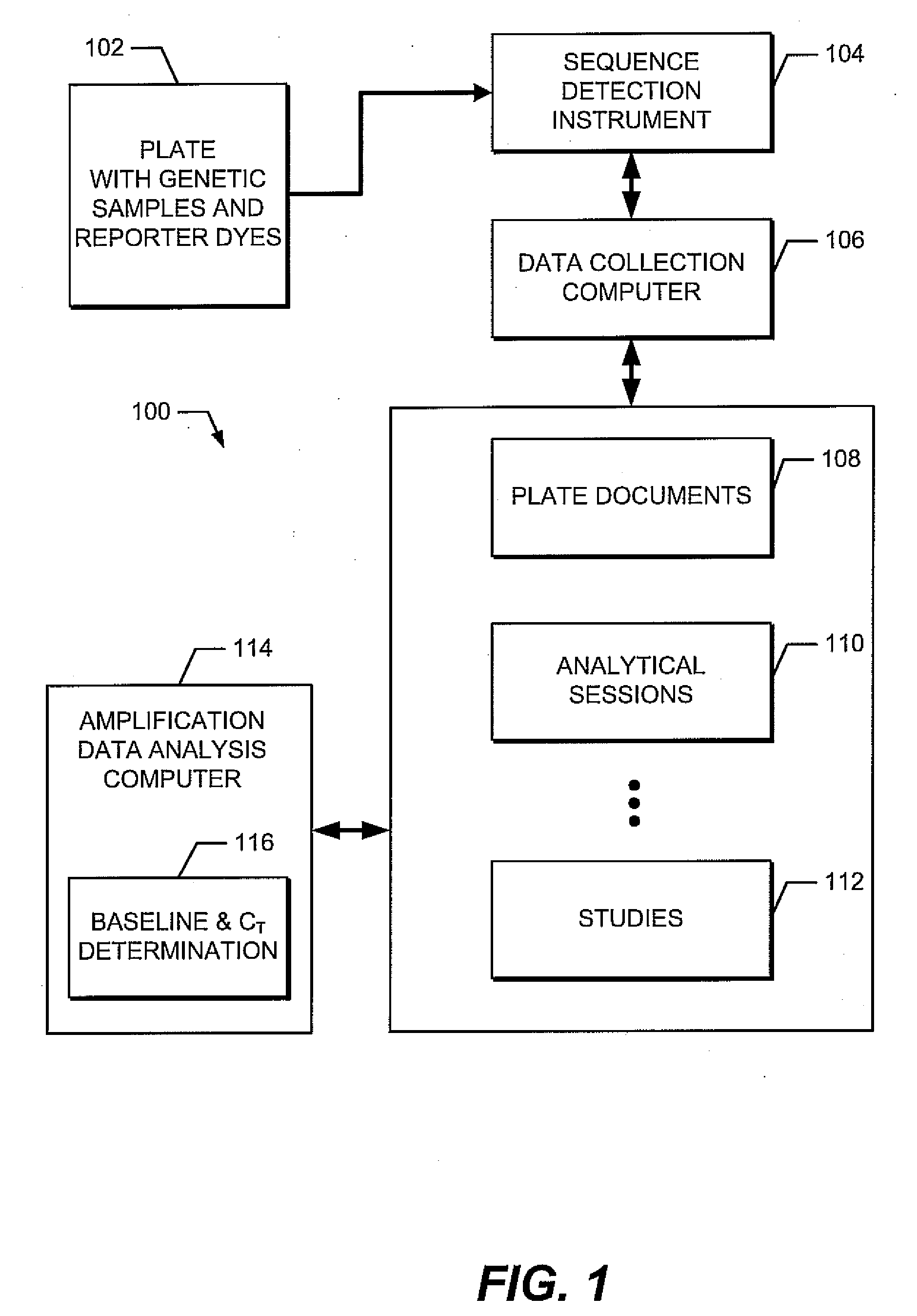

Systems and methods for baselining and real-time PCR data analysis

InactiveUS20080154512A1Amplifier modifications to reduce noise influenceMicrobiological testing/measurementMulti resolution analysisFluorescence

Systems and methods according to embodiments of the present teachings incorporate a set of possible signal transforms that can be used to examine the baseline region of an amplification profile for noise. In embodiments, a difference time series analysis can be performed to determine deviations of detected fluorescent or other signal intensity in the early cycles of a PCR or other reaction over a median difference time series magnitude. In embodiments, difference time series analysis or other detection techniques can be performed over different hop sizes producing a multi-resolution analysis. In embodiments, the amplification profile can be transmitted to a set of noise detectors whose individual results or decisions are polled or weighted to determine the presence of noise in the baseline or other region. In embodiments, a second derivative analysis on the baseline region can be performed.

Owner:APPL BIOSYSTEMS INC

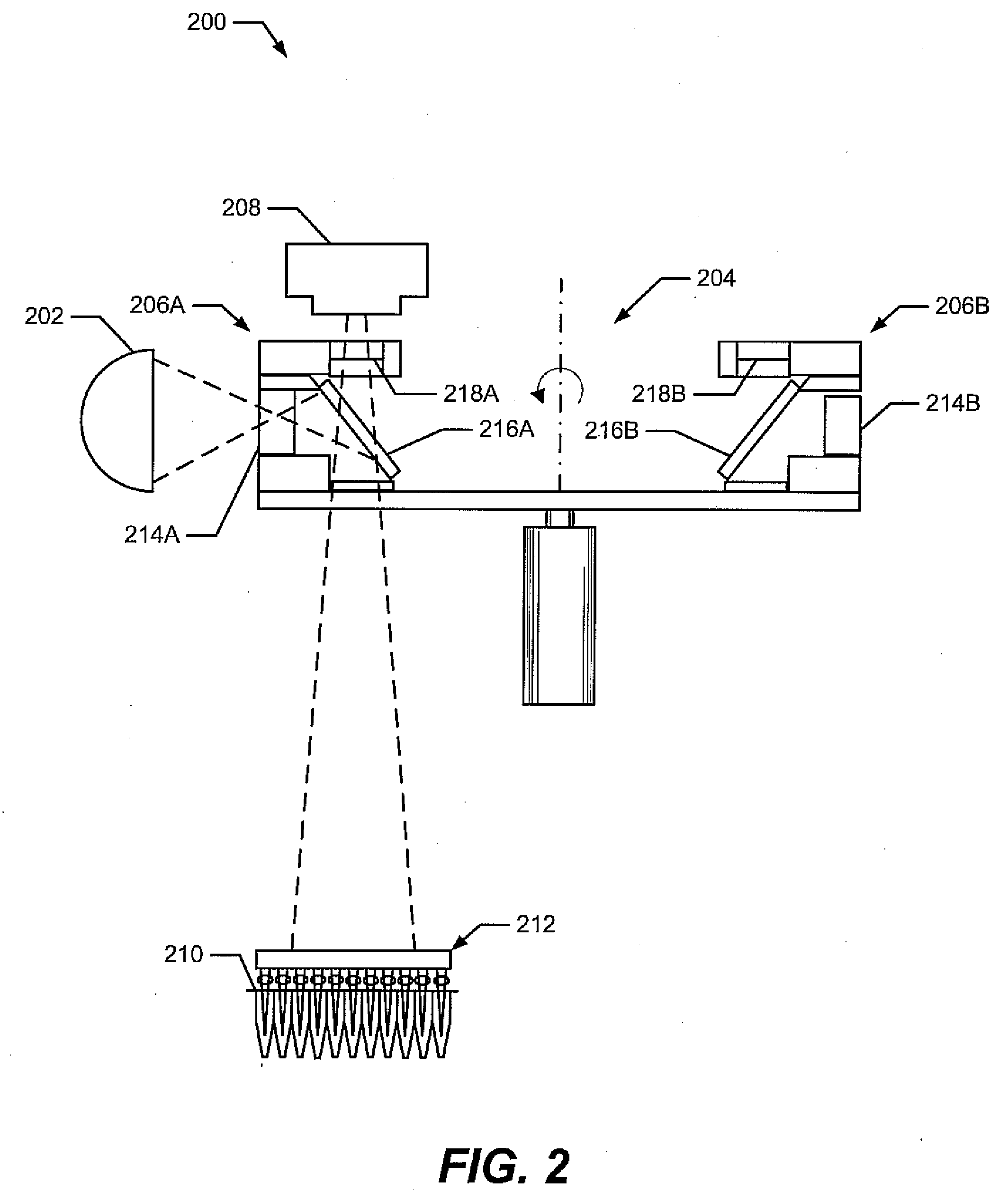

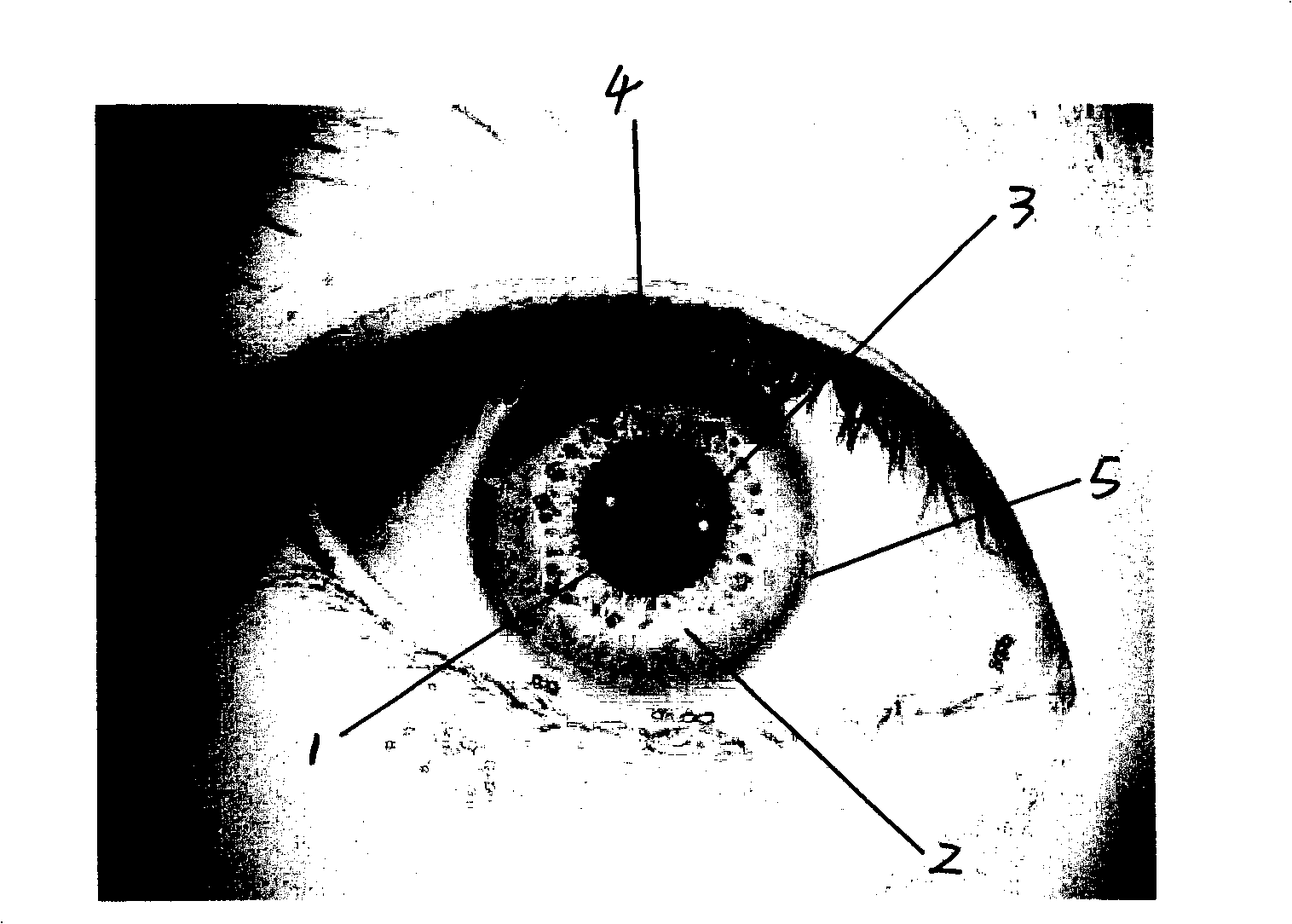

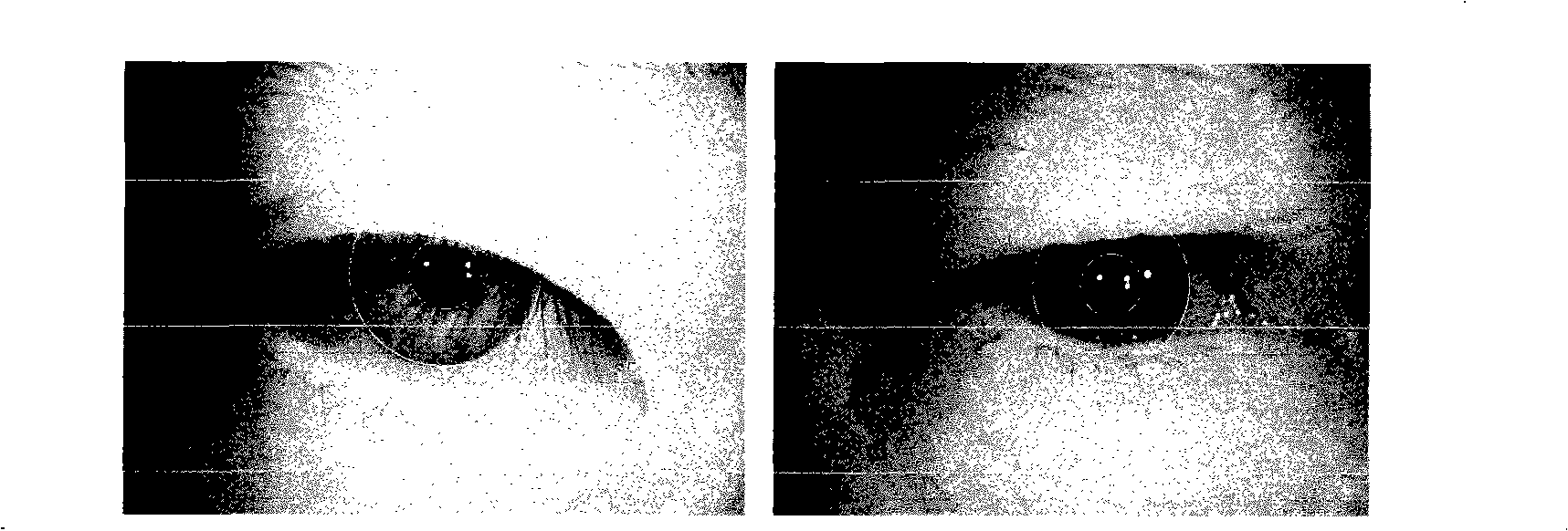

Iris positioning method based on multi-resolutions analysis

InactiveCN101266645AAvoid occlusion of more sensitive issuesAvoid interferenceCharacter and pattern recognitionEyelidMulti resolution analysis

The invention provides a method of iris location based on multi-resolution analysis, comprising: locating out rough circle center (x, y) of a pupil via operations, such as binary, mathematical morphology, gray scale, searching for smallest pieces and so on; then searching for a coordinate of a maximum value of the gray scale and gradient in certain rage on a plurality of lines near (x<0>, y) as the coordinate of pupil boundary point, and locating out exact circle center and radius of the pupil via curve fitting; according to precise components of each line of gray serial near the rough circle center (x, y) in the resolution of 2<-5> and 2<-6>, searching for the coordinate of local minimum value point as an external border boundary point of the iris and processing curve fitting to gain exact circle center and radius of the external border of the iris. Adopting the method based on multi-resolution analysis which is provided by the invention can effectively process a positioning operation of iris image, and avoid a problem that traditional arithmetic is sensitive for occlusion of eyelid and eyelash.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

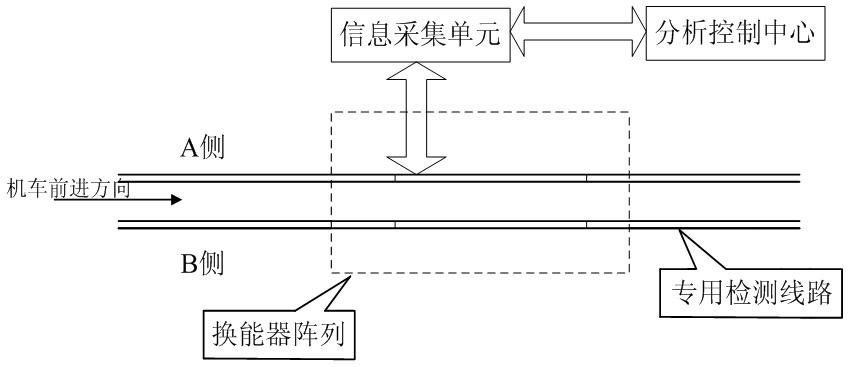

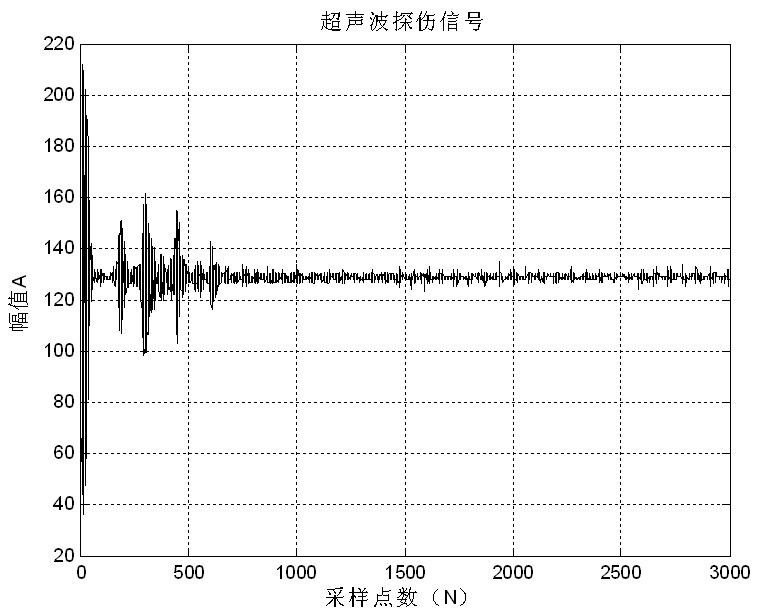

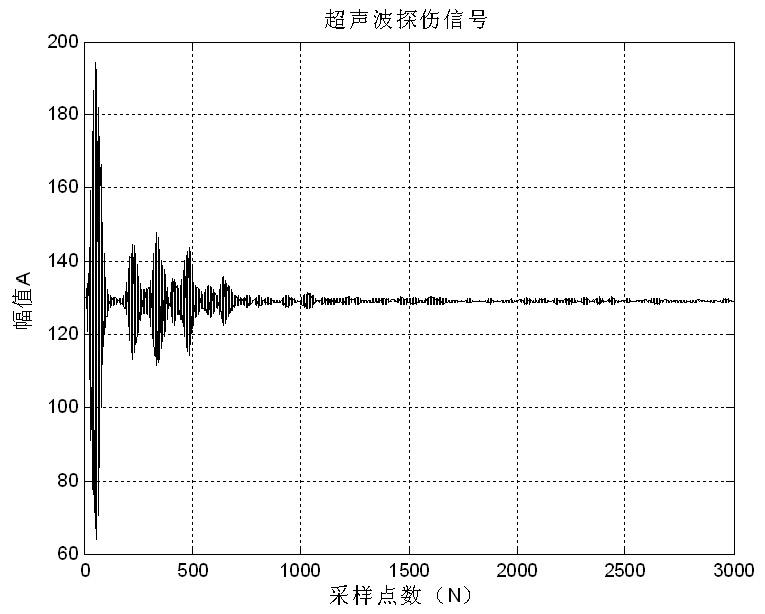

Method for extracting rim ultrasonic flaw detection signal on the basis of wavelet transformation

ActiveCN102636577ASmall echo peak lossImprove defect detection rateProcessing detected response signalMulti resolution analysisPeak value

The invention discloses a method for extracting rim ultrasonic flaw detection signals on the basis of wavelet transformation, and particularly relates to an effective signal identifying method provided aiming at complex discrete signals collected by an online automatic flaw detection device for a locomotive wheel on an industrial site. The method mainly comprises the following steps of loading collected initial data, carrying out wavelet multi-resolution analysis to original signals, carrying out threshold value processing to each layer coefficient obtained after the wavelet transformation, and then inversely transforming wavelet coefficient to reconstruct signals. After the denoising is accomplished, the effective signals can extract positive detection enveloping curves so as to read flaw detection reports to be displayed in a user interface. Compared with the traditional digital filter in the aspect of extracting effective signals, the method has the advantages that the loss of an echo peak value is small, thus the defect detection rate is greatly enhanced, and the false dismissal possibility is avoided; and the denoising effect is obvious, and the effective signals are smooth, thus pulse signals can be effectively extracted from high-frequency noise, so as to avoid the possibility of false detection.

Owner:NANJING TYCHO INFORMATION TECH

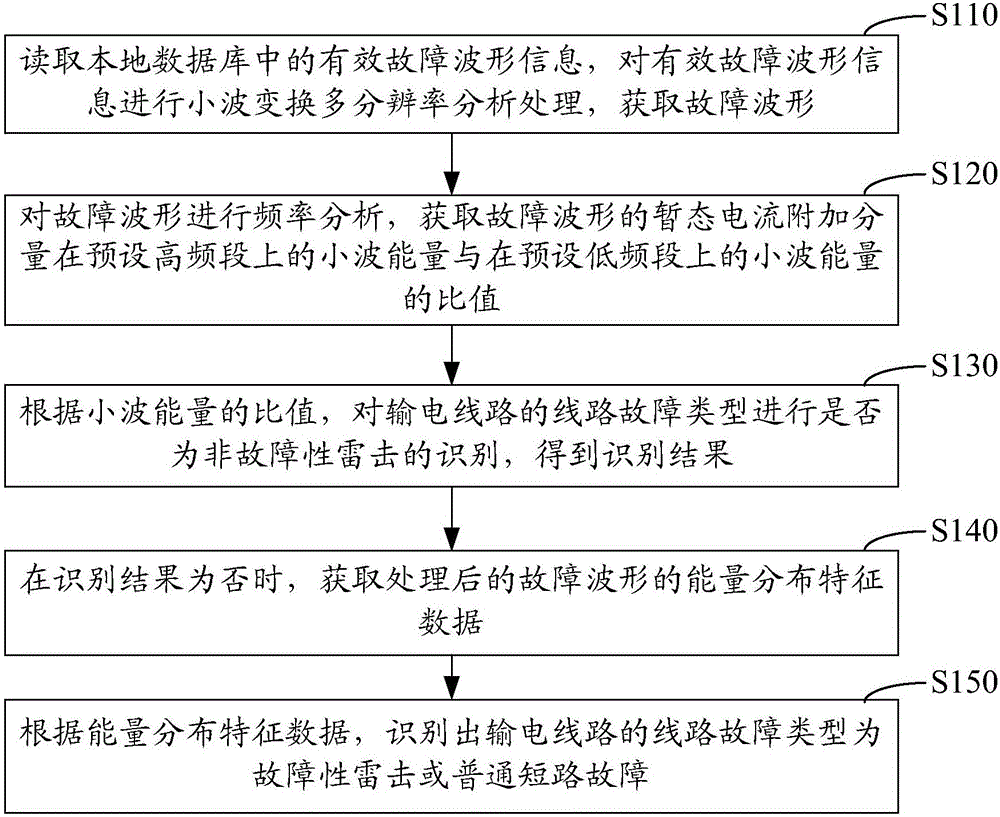

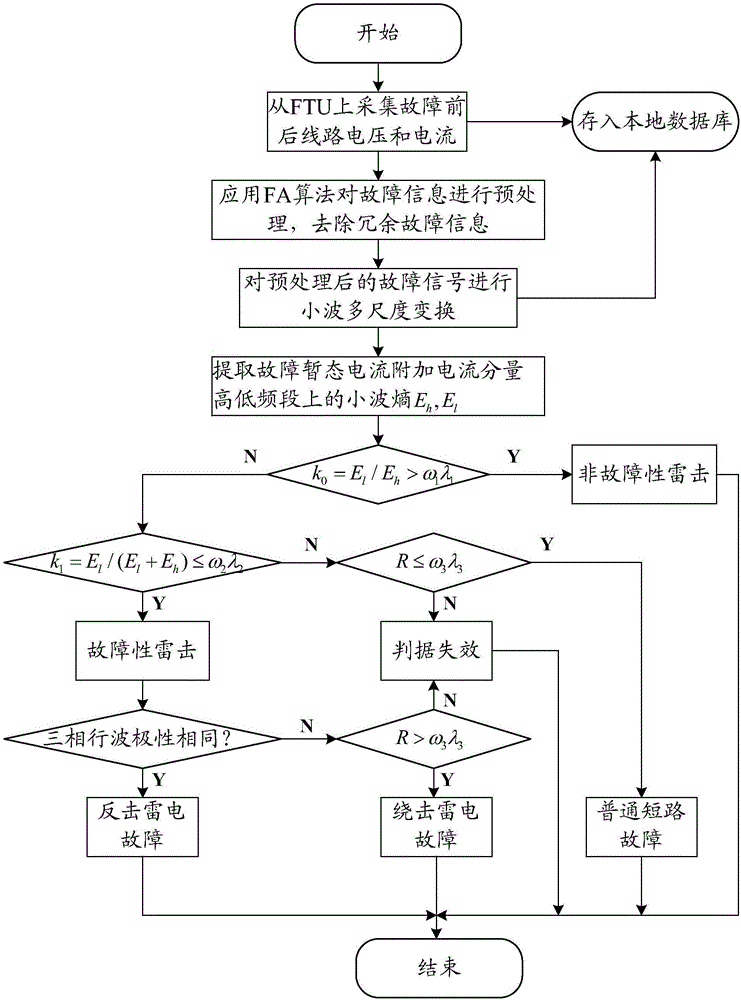

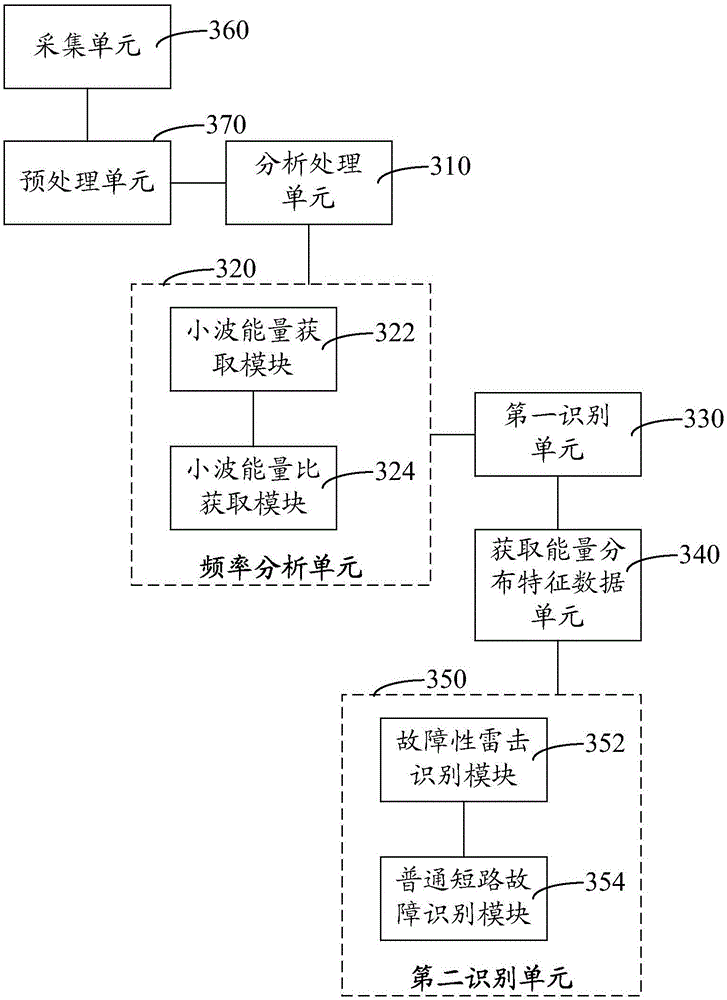

Lightning stroke fault identification method and system

InactiveCN106443335AHigh expressionImprove accuracyFault location by conductor typesMulti resolution analysisLow frequency band

The invention relates to a lightning stroke fault identification method and system. The lightning stroke fault identification method comprises the following steps of reading valid fault waveform information in a local database, performing wavelet transform multi-resolution analysis on the valid fault waveform information, and obtaining a fault waveform; analyzing the frequency of the fault waveform to obtain a ratio of the wavelet energy of the transient current additional component of the fault waveform at a preset high-frequency band to the wavelet energy of the transient current additional component of the fault waveform on a preset low-frequency band; according to the ratio of the wavelet energy, identifying whether the line fault type of a transmission line is non-fault lightning stroke to obtain an identification result; if the identification result is indicative of no, obtaining the energy distribution characteristic data of the fault waveform; according to the energy distribution characteristic data, identifying the line fault type of the transmission line is fault lightning stroke or ordinary short-circuit fault. The method and system can improve the utilization rate of fault information and the accuracy rate of identification, and increase the identification rate of lightning fault type.

Owner:QINZHOU POWER SUPPLY BUREAU OF GUANGXI POWER GRID CO LTD

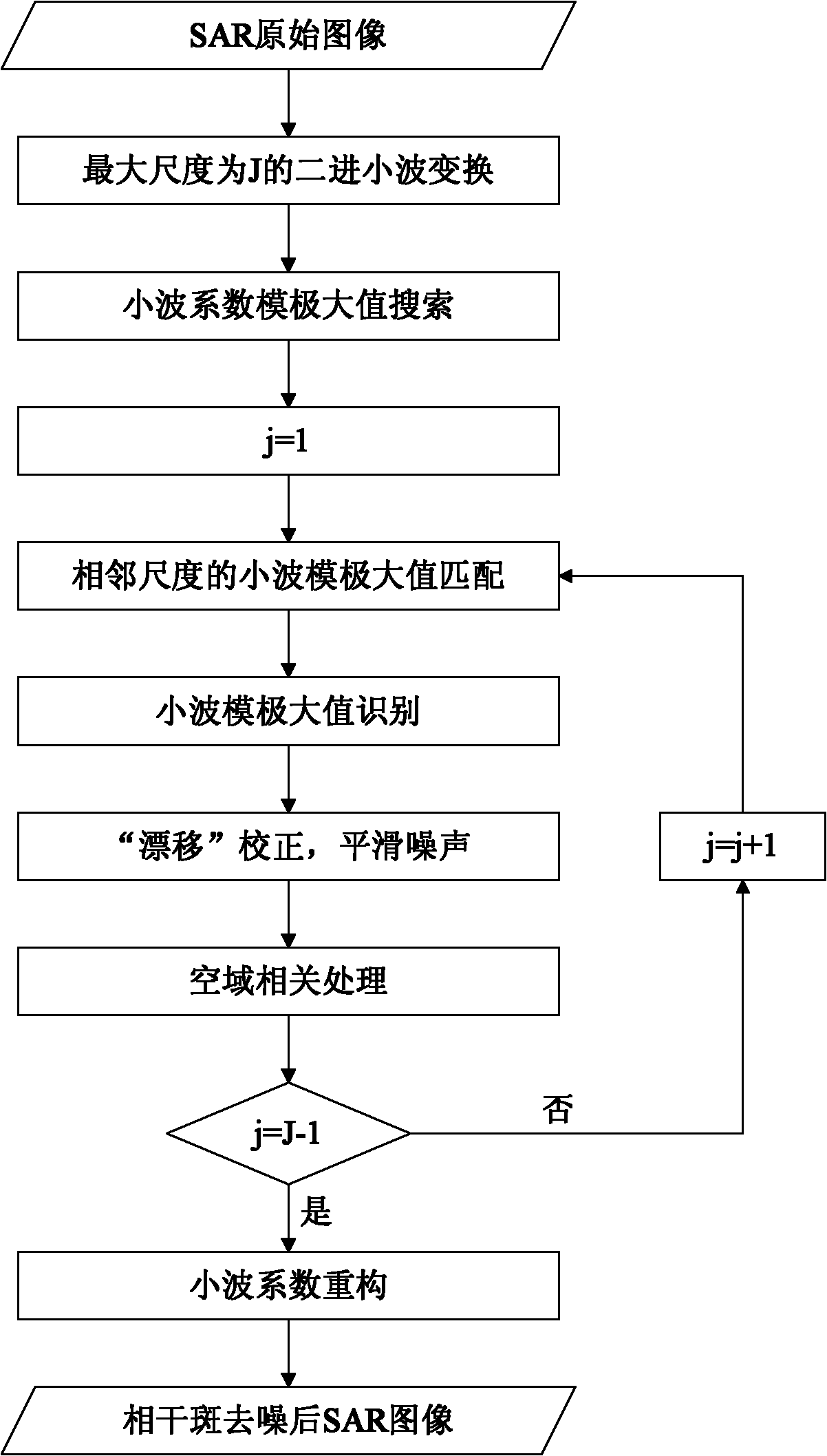

High-resolution SAR satellite image speckle de-noising method

ActiveCN102073992AImprove robustnessAccurately reflectImage enhancementSpatial correlationMulti resolution analysis

The invention discloses a high-resolution synthetic aperture radar (SAR) satellite image speckle de-noising method. Speckle noise statistic characteristics are analyzed, and based on wavelet modulus maximum and Lyapunov exponent theories, useful signals and speckle noise in SAR images are identified by using spatial related processing technology, so when the marginal information is not lost, the speckle noise is greatly attenuated; meanwhile, the 'drift' phenomenon caused by wavelet multi-resolution analysis is corrected, so the de-noising capacity is enhanced and the processing speed is improved; and the method can identify the useful signals and the speckle noise in the SAR images, greatly attenuate the speckle noise when the marginal information is not lost, meanwhile correct the 'drift' phenomenon caused by the wavelet multi-resolution analysis, enhance the de-noising capacity and improve the processing speed.

Owner:STATE GRID ELECTRIC POWER RES INST

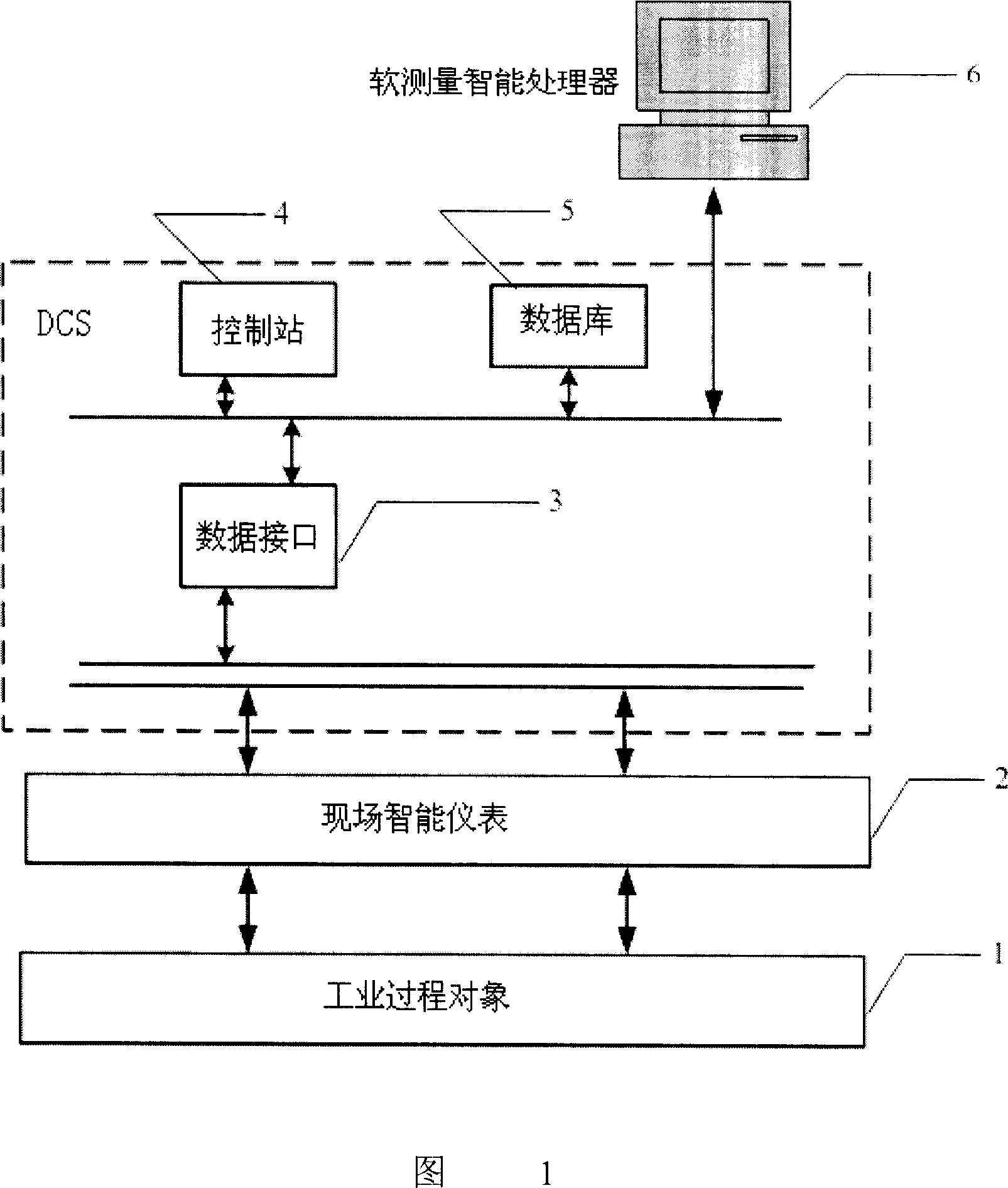

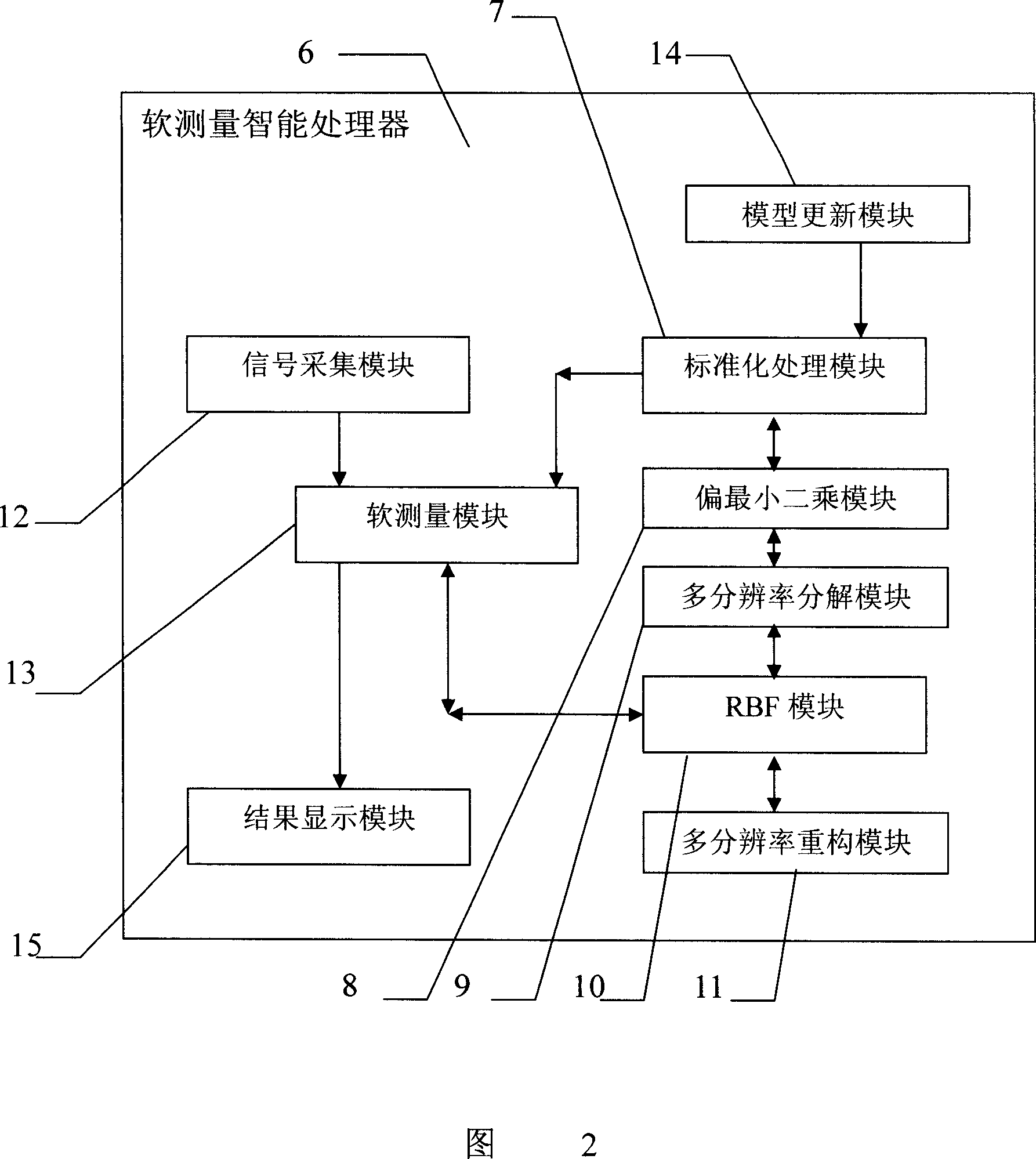

Industrial process multiresolution softsensoring instrument and method thereof

InactiveCN101017373AEasy to predictImprove generalization abilityComputer controlSimulator controlMulti resolution analysisImage resolution

This invention relates to one industry process multi-resolution flexible measurement meter, which comprises spot intelligent meter connected with industry subjects, data memory device and upper machine to store historical data, wherein, the intelligent meter, memory device and upper machine are orderly connected; the upper machine is of flexible intelligent controller; the said flexible measurement controller comprises standard process module, bias OLS module, multi-resolution analysis module, radium function neutral network establish module, multi-resolution recreation module, signal collection module and flexible test module. This invention provides one flexible measure method.

Owner:ZHEJIANG UNIV

Method for locating phase to ground faults in DC distribution systems

ActiveUS8067942B2Fault location by conductor typesShort-circuit testingMulti resolution analysisSwitching frequency

A method for locating phase to ground faults in DC distribution systems. The method includes utilizing wavelet analysis using Multi-Resolution Analysis (MRA) as a signal processing tool for recognition of characteristic features in the voltage signal. The voltage signal contains characteristic information in the high frequency range above the switching frequencies of the PE converters which allows for localization of the fault.

Owner:FLORIDA STATE UNIV RES FOUND INC

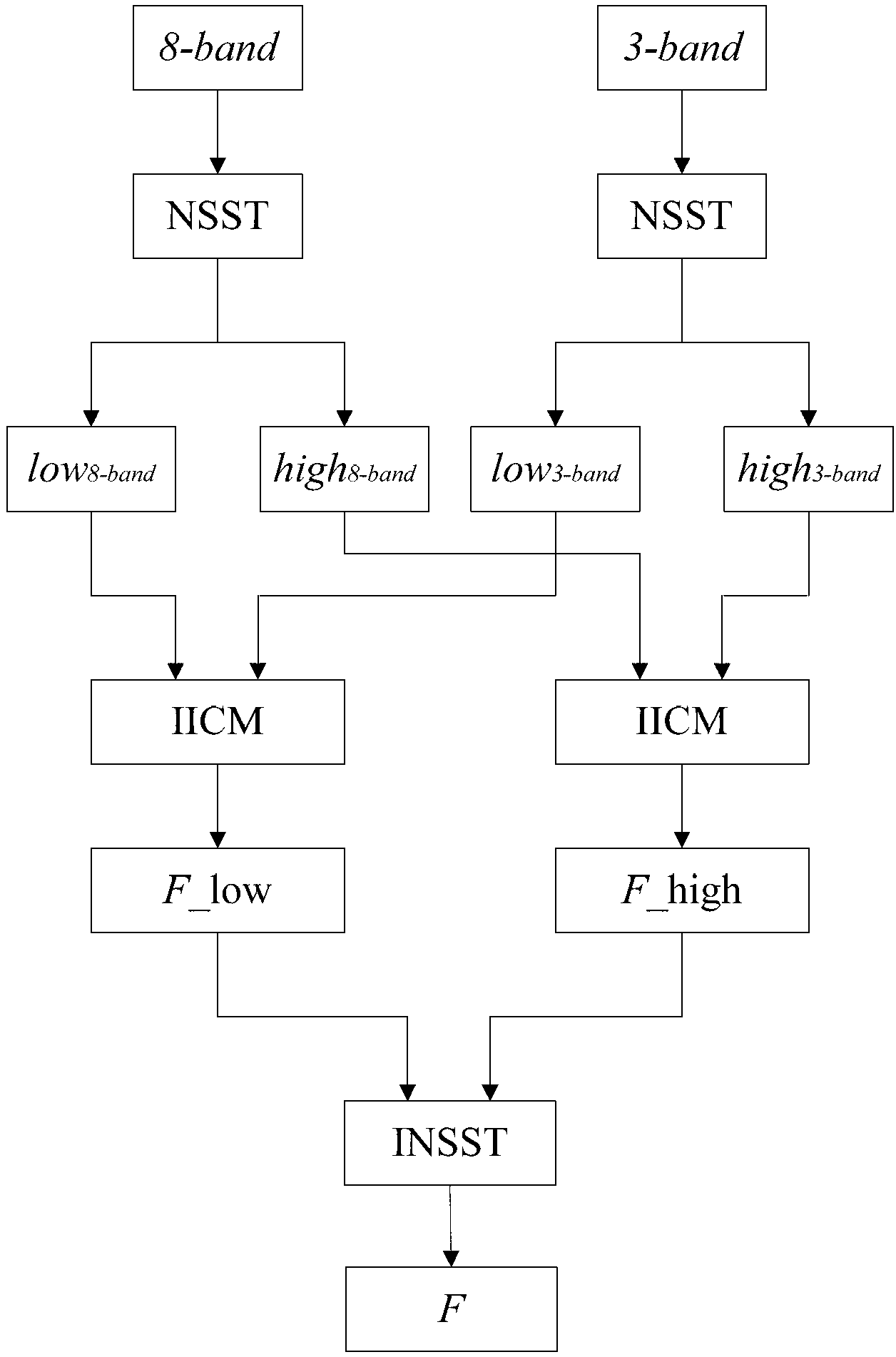

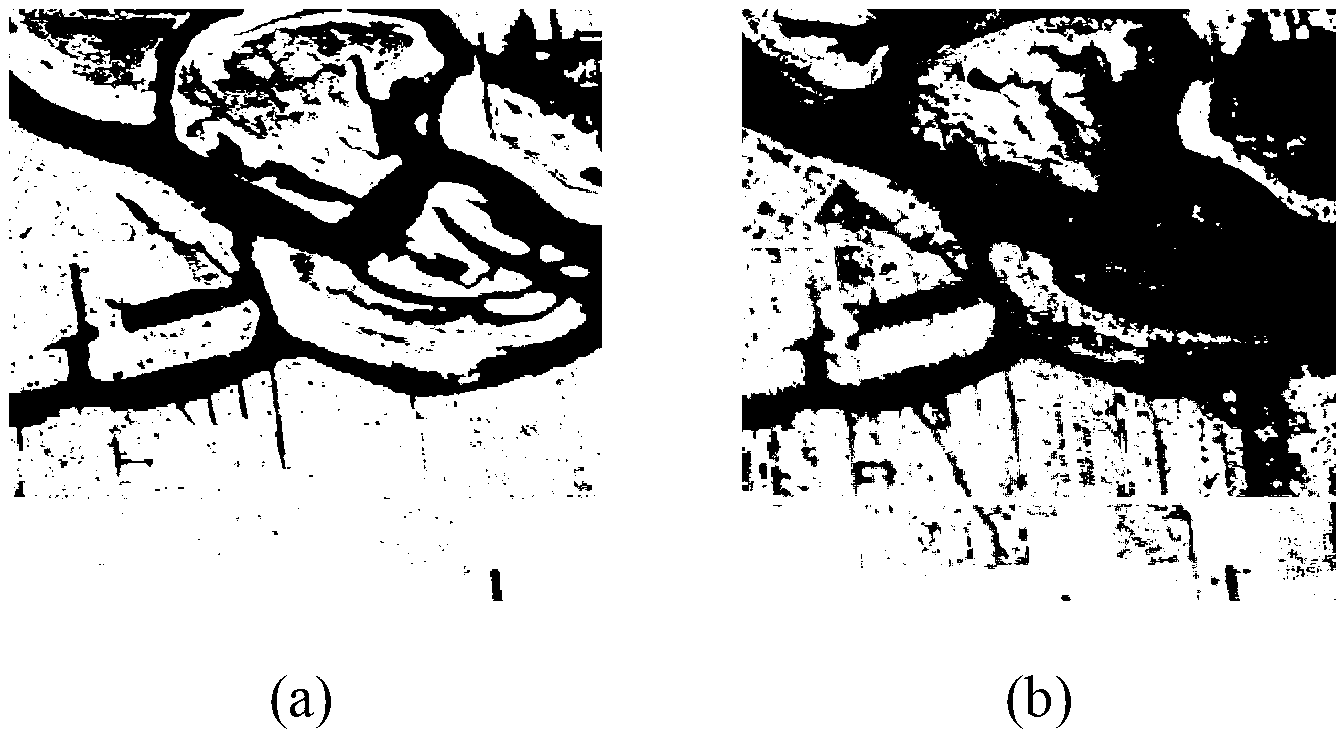

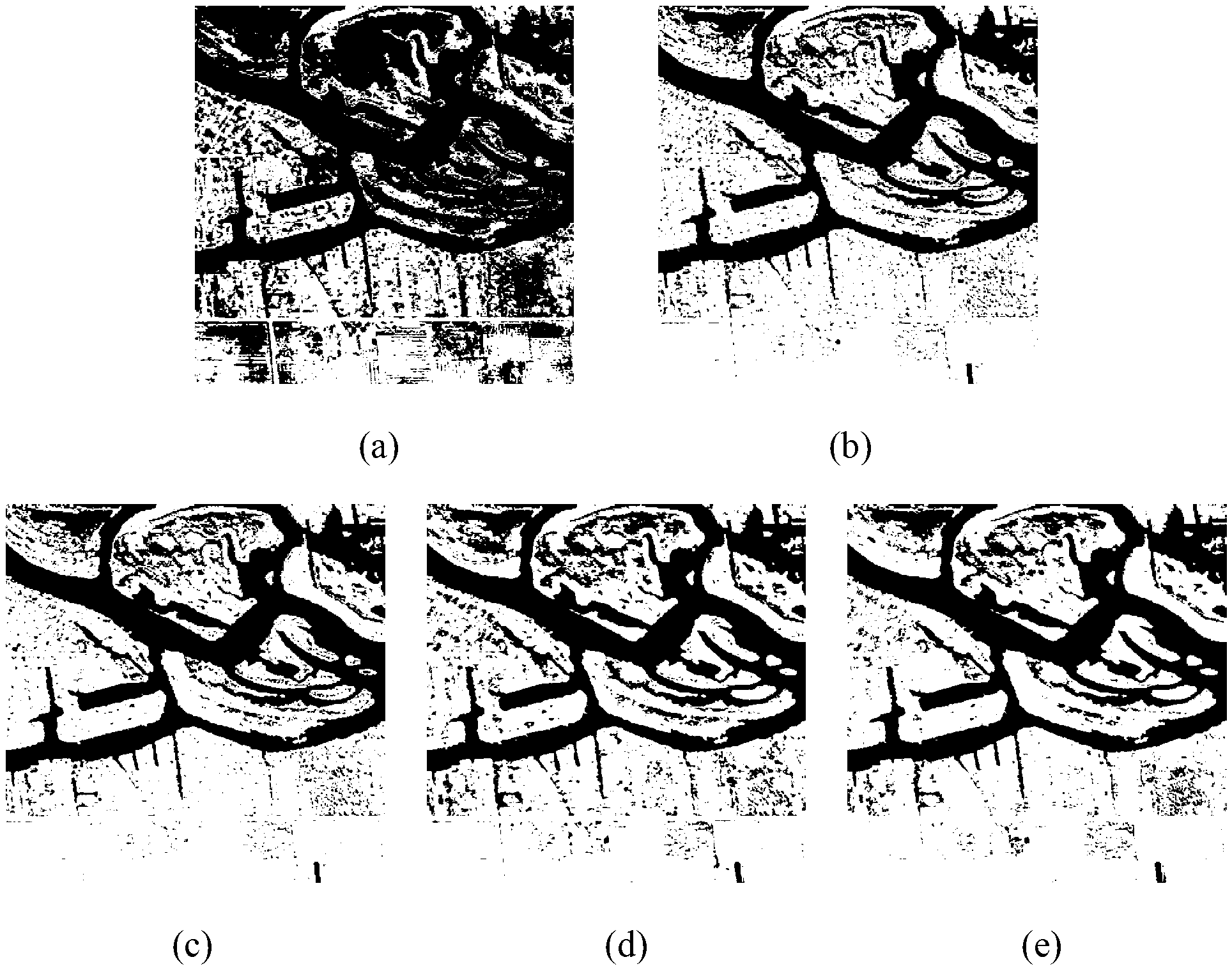

Multi-sensor image fusion method on basis of IICM (improved intersecting cortical model) in NSST (nonsubsampled shearlet transform) domain

The invention discloses a multi-sensor image fusion method on the basis of an IICM (improved intersecting cortical model) in an NSST (nonsubsampled shearlet transform) domain. The multi-sensor image fusion method includes: step 1, building the IICM; step 2, inputting all the multi-sensor source images to be fused to perform NSST and acquiring one low-frequency sub-band image and multiple high-frequency sub-band images from each multi-sensor source image to be fused; step 3, importing all the high-frequency sub-band images and the low-frequency sub-band images into the IICM to complete fusion of the low-frequency sub-band images and fusion of the high-frequency sub-band images; step 4, performing NSST inverse transformation on the high-frequency sub-band images and the low-frequency sub-band images which are fused finally to acquire the final fusion image. The improved model, namely the IICM is provided on the basis of the classical ICM, multi-resolution analysis of the multi-sensor source images and reconstruction of the finally fused image are completed by means of NSST, and problems about fusion of the multi-sensor images are solved reasonably since the IICM is utilized for realizing fusions of the high-frequency sub-band images and the low-frequency sub-band images.

Owner:ENG UNIV OF THE CHINESE PEOPLES ARMED POLICE FORCE

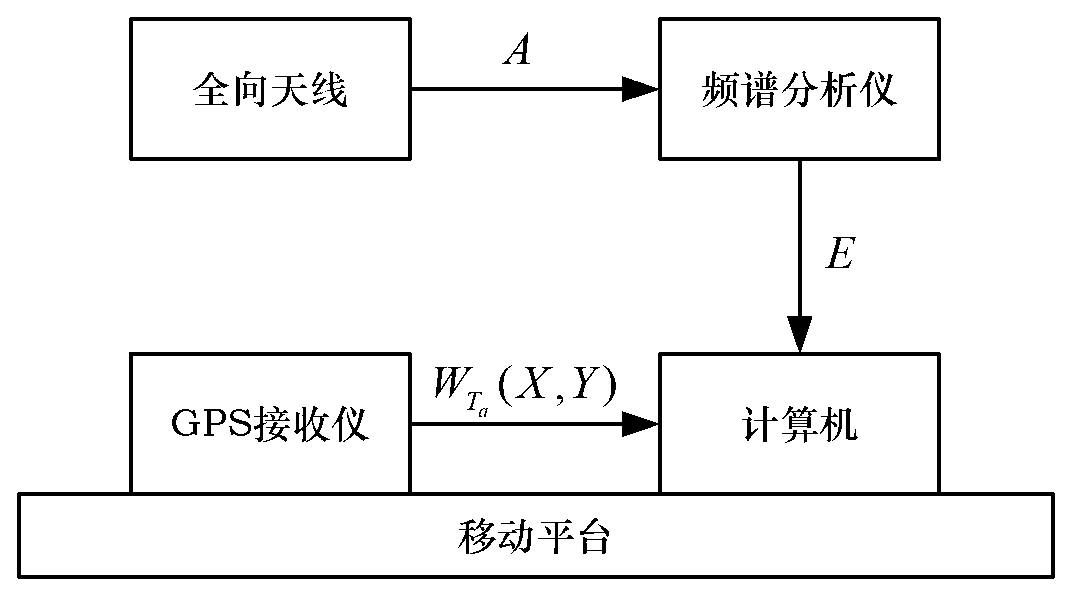

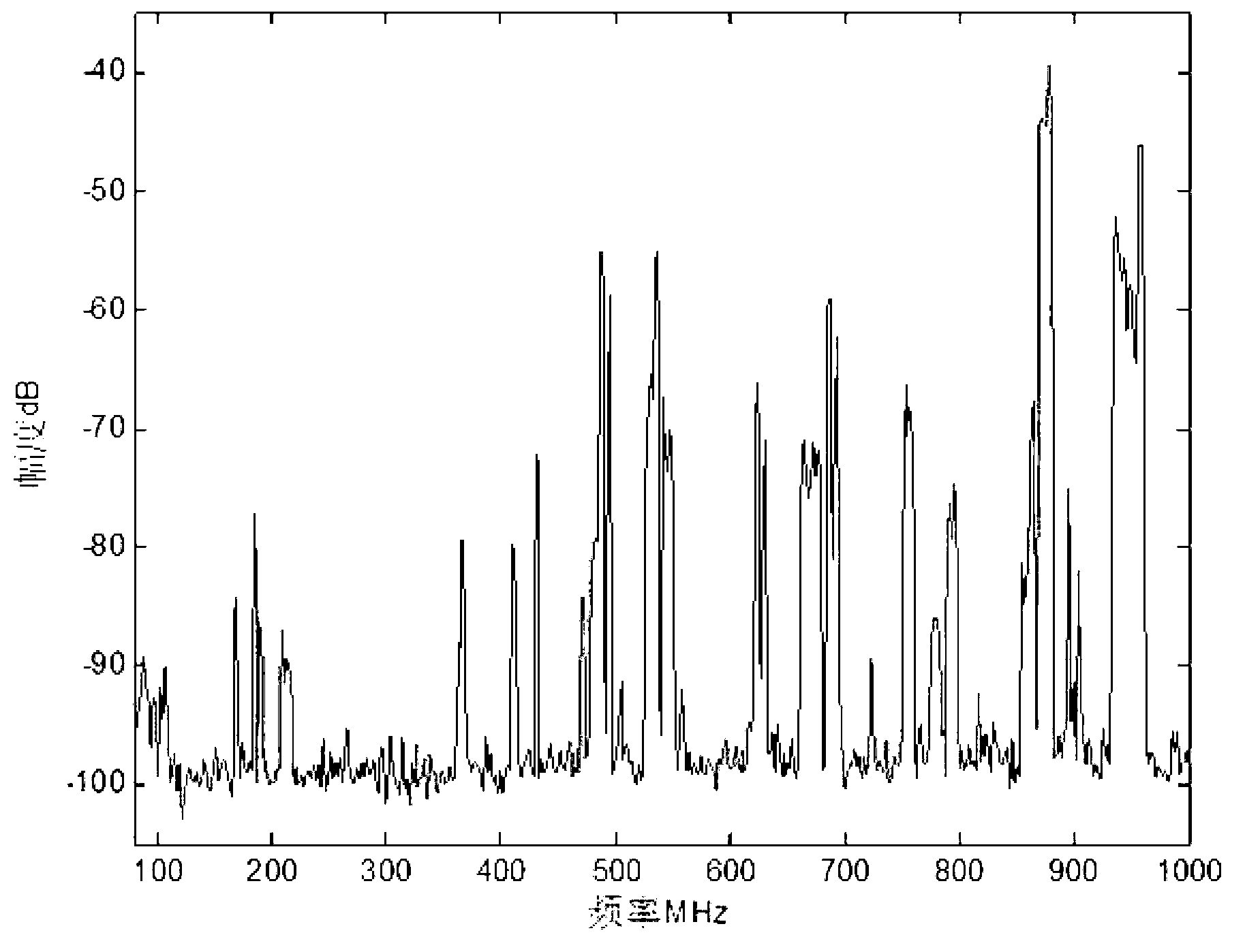

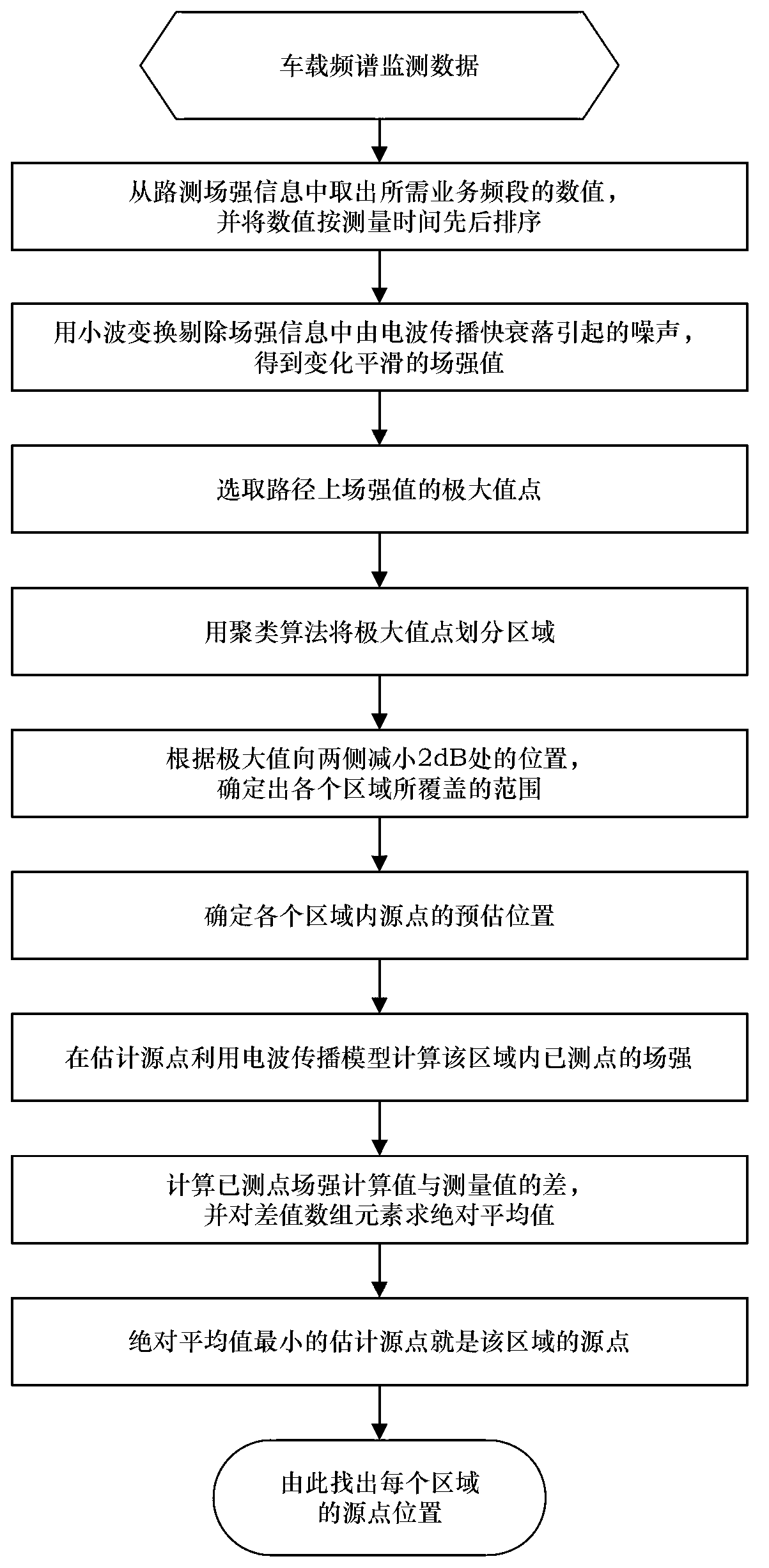

Positioning method of plurality of same-frequency radiation sources based on field intensity

ActiveCN103018759ARealize automatic operationAvoid high feesSatellite radio beaconingArray data structureFrequency spectrum

The invention discloses a positioning method of a plurality of same-frequency radiation sources based on field intensity, which belongs to the field of spectrum management. The method is based on the field intensity of a certain frequency channel measured by a vehicle-mounted omnidirectional antenna and longitude and latitude data measured by a GPS (Global Position System). The field intensity data are arrayed according to the measurement sequence, wavelet multi-resolution analysis is used to remove the noise caused by fast fading in the field intensity; and then latitude / longitude coordinates corresponding to the maximum value point are found out; the maximum value point is divided into different areas by a clustering algorithm; and at last, each estimated source point in the area and useable detected points in the area are calculated by an Egli model formula to obtain an absolute mean of difference array elements, so that the position of the source point in the area is determined. The positioning method disclosed by the invention is the positioning under a passive direction finding condition, the reliability is rather high, and the positioning method has a wide practical value and application prospect in the field of the spectrum management.

Owner:BEIHANG UNIV

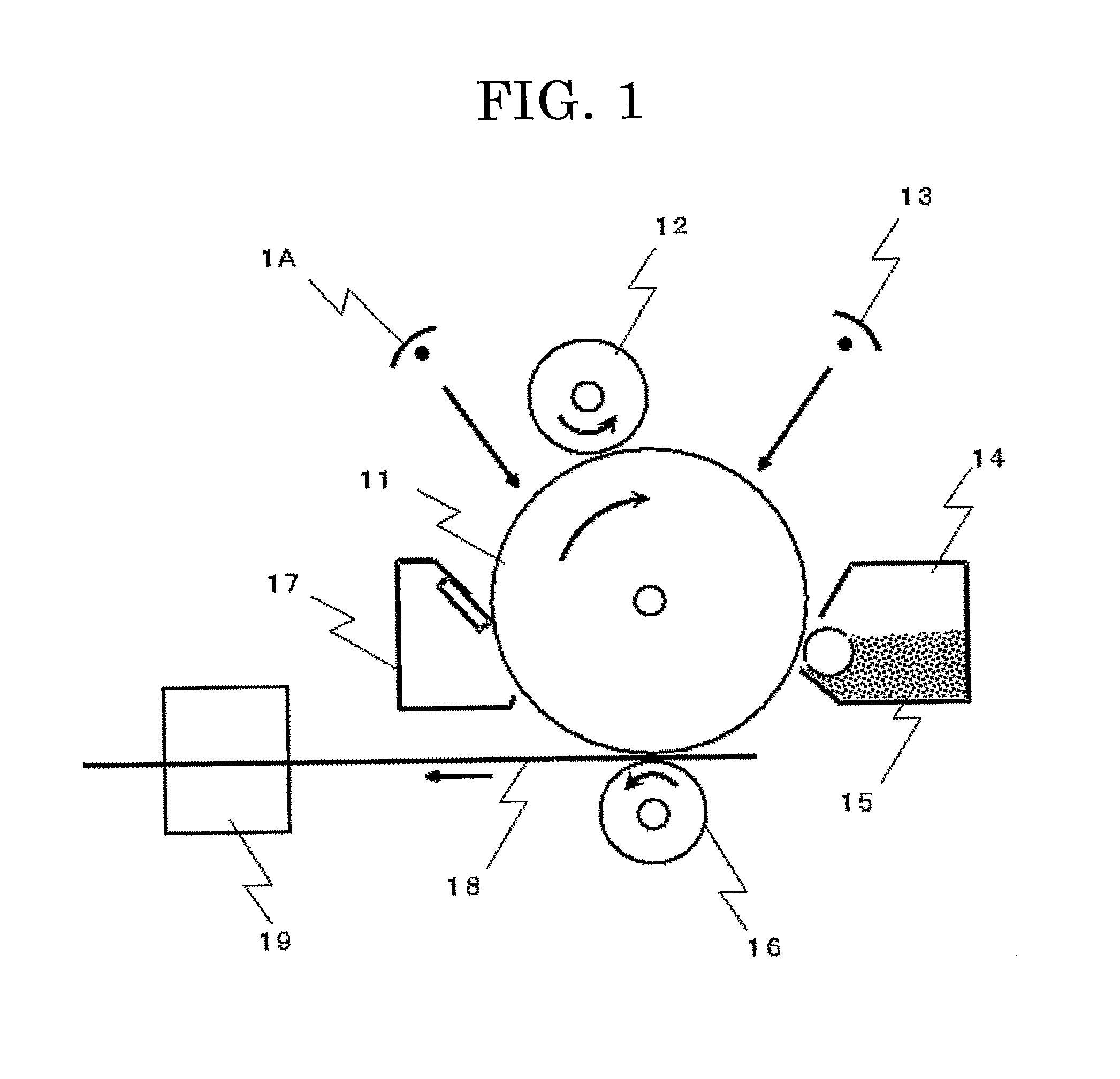

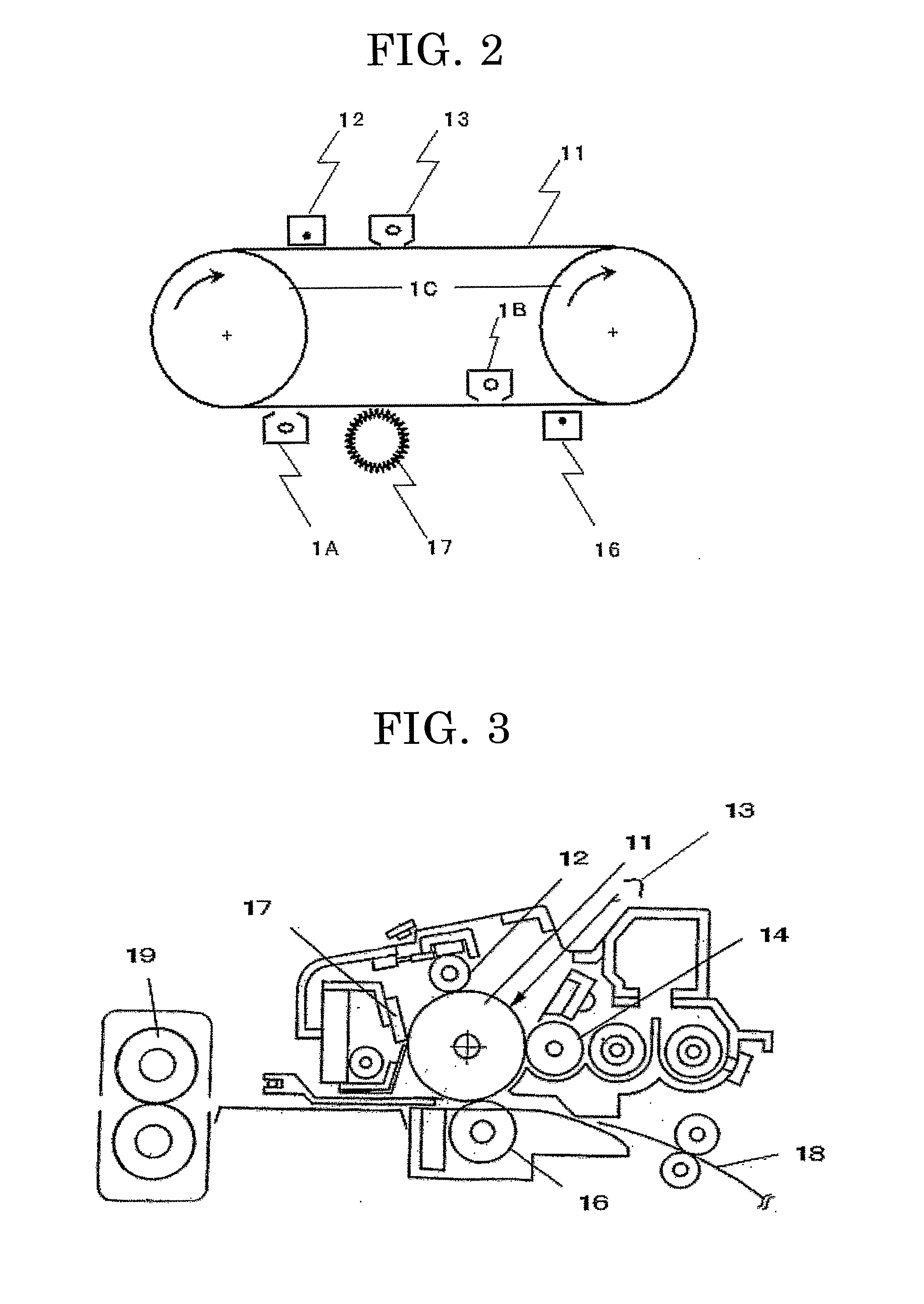

Electrophotographic photoconductor, production method of the same, image forming apparatus, and process cartridge

ActiveUS20120008984A1High acceptabilityHigh sensitivityElectrographic process apparatusCoatingsMultiresolution analysisElectrical conductor

An electrophotographic photoconductor having a photosensitive layer and a crosslinked resin surface layer over a support, wherein shapes of concaves and convexes in a surface of the electrophotographic photoconductor are measured by a surface roughness / profile measuring device to obtain one-dimensional data arrays, the arrays are subjected to multiresolution analysis (MRA-1) through wavelet transformation to be separated into six frequency components including HHH, HHL, HMH, HML, HLH and HLL to obtain one-dimensional data arrays, the arrays of the HHL are thinned out to be reduced 1 / 10 to 1 / 100, thereby producing one-dimensional data arrays, which are then subjected to multiresolution analysis (MRA-2) through wavelet transformation to be separated into six frequency components including LHH, LHL, LMH, LML, LLH and LLL to thereby obtain 12 frequency components in total; and a center-line average roughness (WRa) of the 12 frequency components satisfies relationship (i) below.1−597×WRa(HML)+238×WRa(HLH)−95×WRa(LHL)+84×WRa(LMH)−79×WRa(LML)+55×WRa(LLH)−17×WRa(LLL)>0 (i)

Owner:RICOH KK

Method and rhythm extractor for detecting and isolating rhythmic signal features from an input signal using the wavelet packet transform

A method of detecting and isolating at least one rhythmic component from a discrete-time input signal, comprises subjecting the input signal to discrete wavelet packet transform multi-resolution analysis; applying wavelet packet basis selection criteria to the result of the analysis to evaluate rhythmic signal features of the input signal; and isolating at least one rhythmic signal component from the input signal based on the evaluation.

Owner:NEUROCHIP CORP

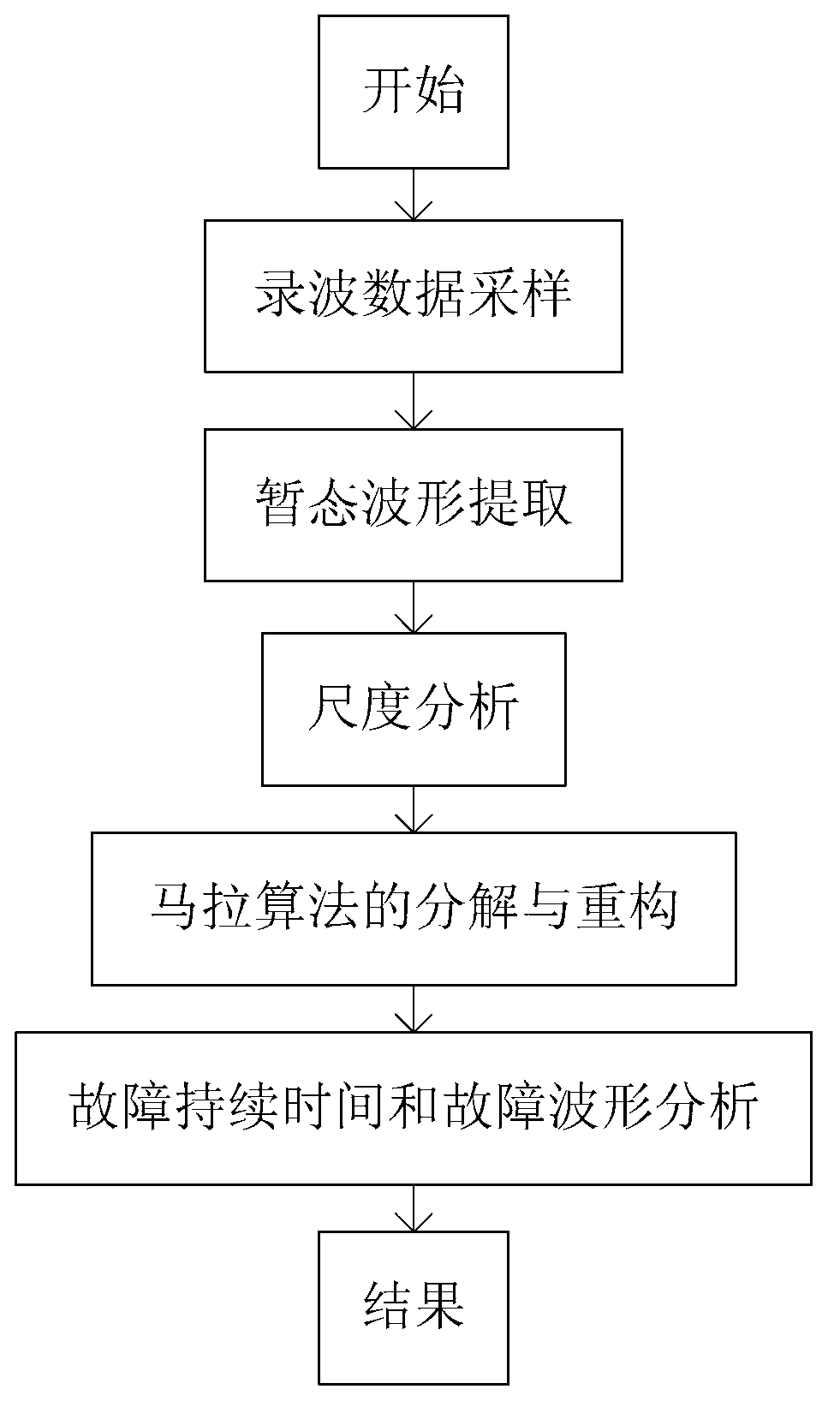

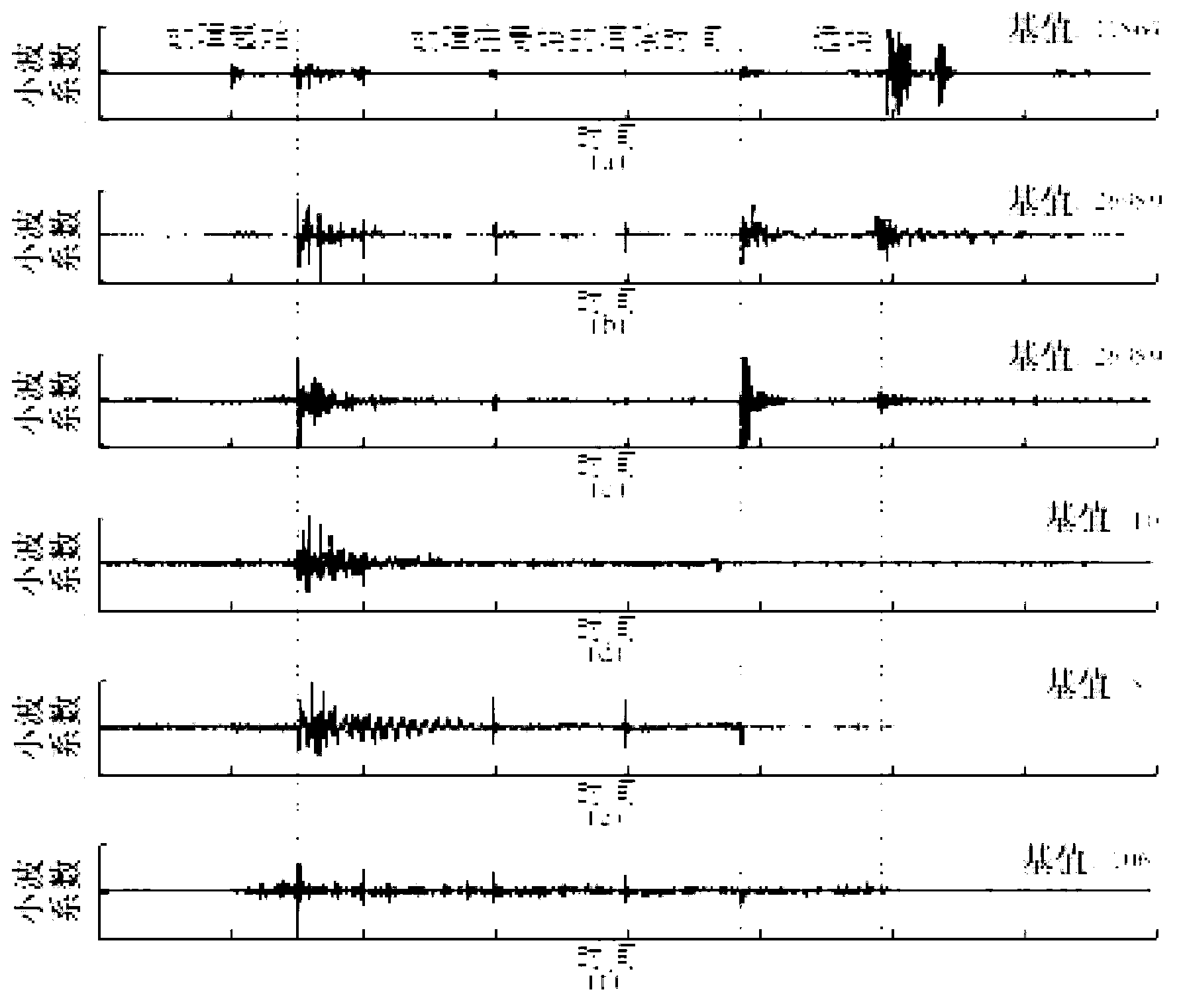

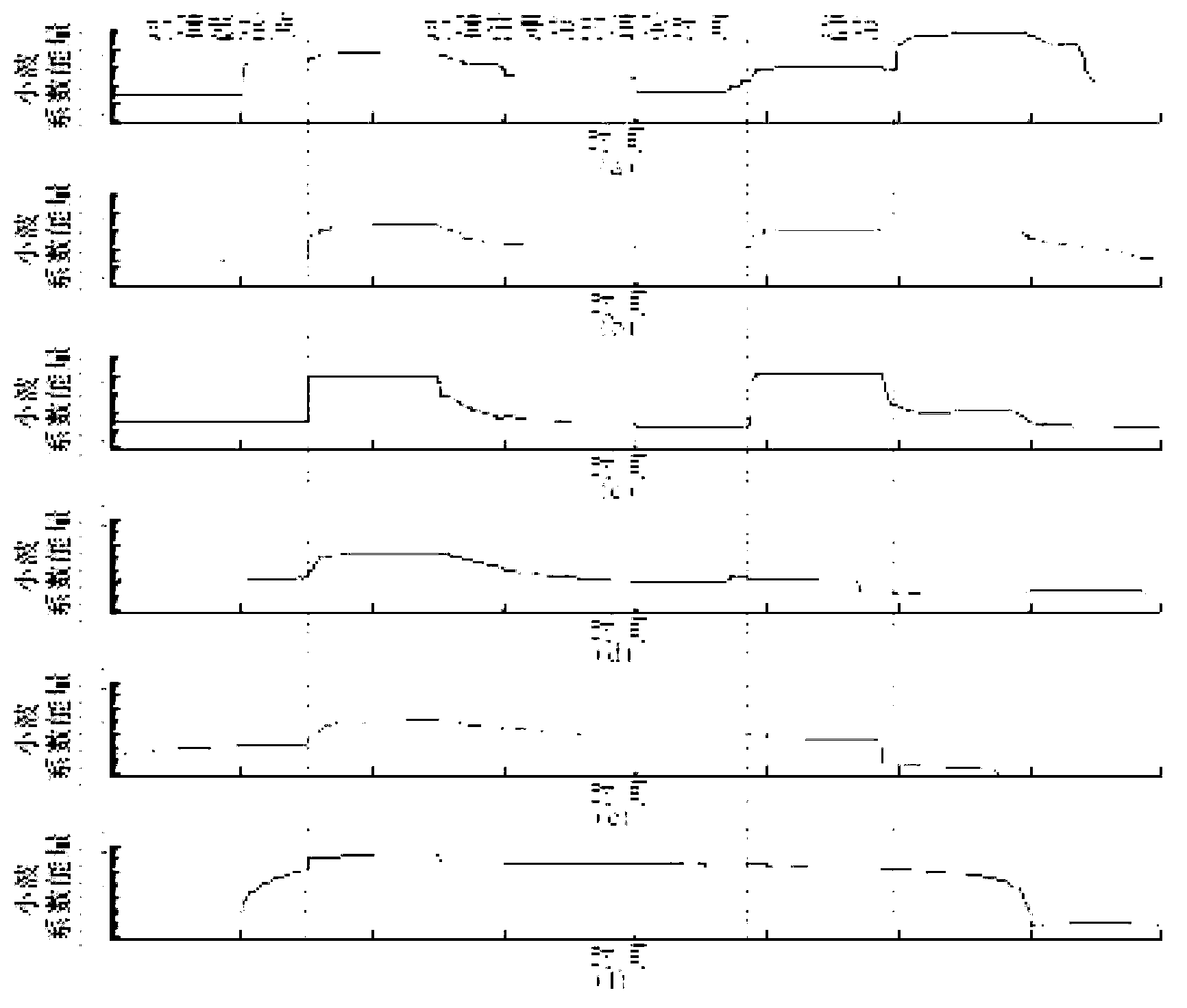

Method for analyzing power system fault recording data based on Marla algorithm

InactiveCN103018629ASmall amount of calculationEasy to analyzeFault locationTransient stateMulti resolution analysis

The invention relates to a method for analyzing power system fault recording data based on the Marla algorithm, which comprises the following steps of: 1, sampling recording data, wherein the sampling point number N in each period is 128, and the corresponding sampling frequency is fs=Nff=128*50=6400Hz; 2, extracting transient waveform; 3, analyzing the scale; 4, decomposing and reconstructing the Marla algorithm: carrying out five-layer multi-resolution analysis of a signal, detecting the mutational site of the signal by utilizing wavelet transform, and detecting a modulus maximum; and 5, analyzing fault duration and fault waveform. The method disclosed by the invention is capable of greatly reducing the calculation amount of the wavelet transform and well analyzing a power system fault process and extracting fault feature genes, and is beneficial to processing the power system fault signal containing large amounts of information in real time, therefore, diagnosis and location of a fault are carried out.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +2

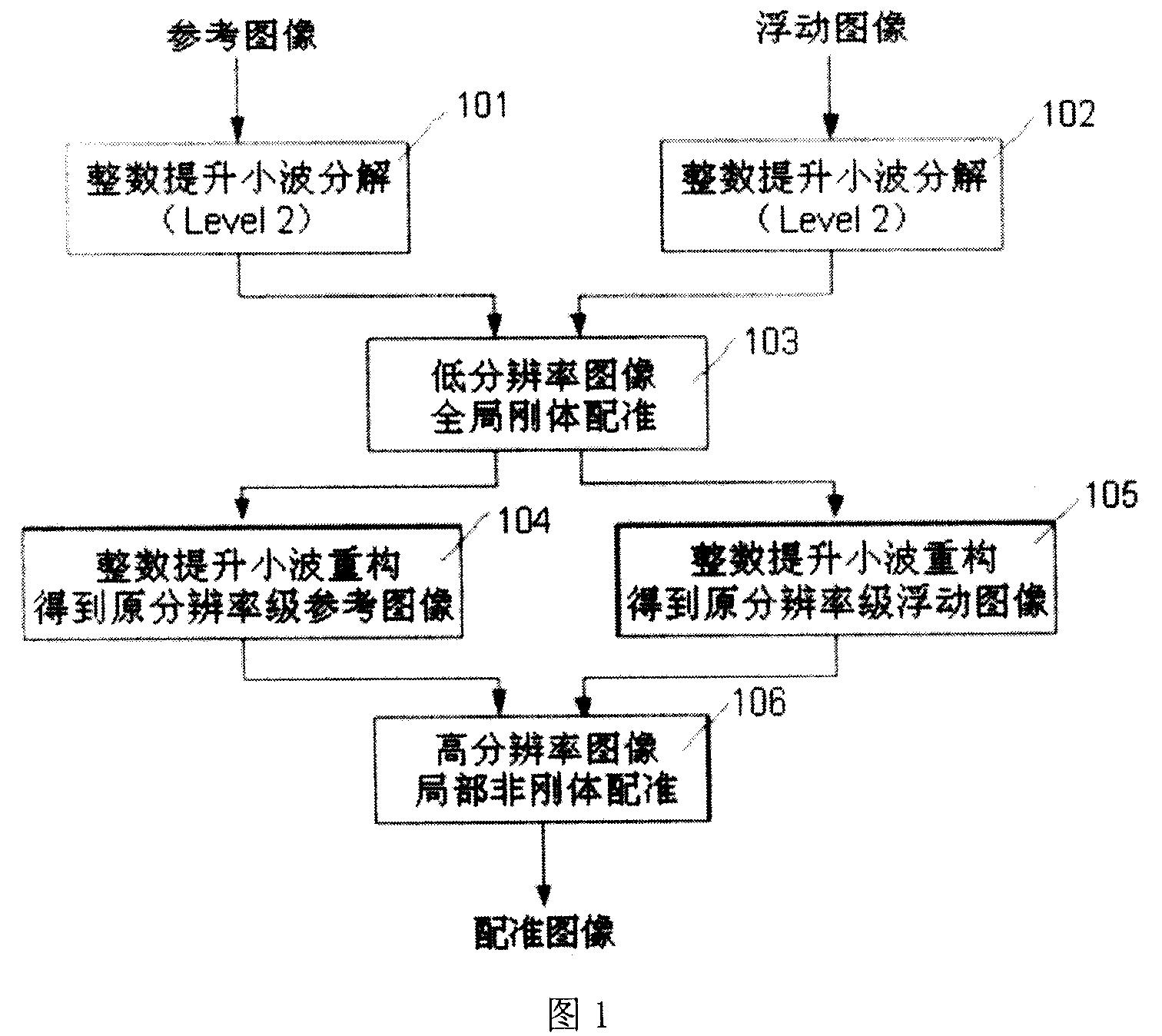

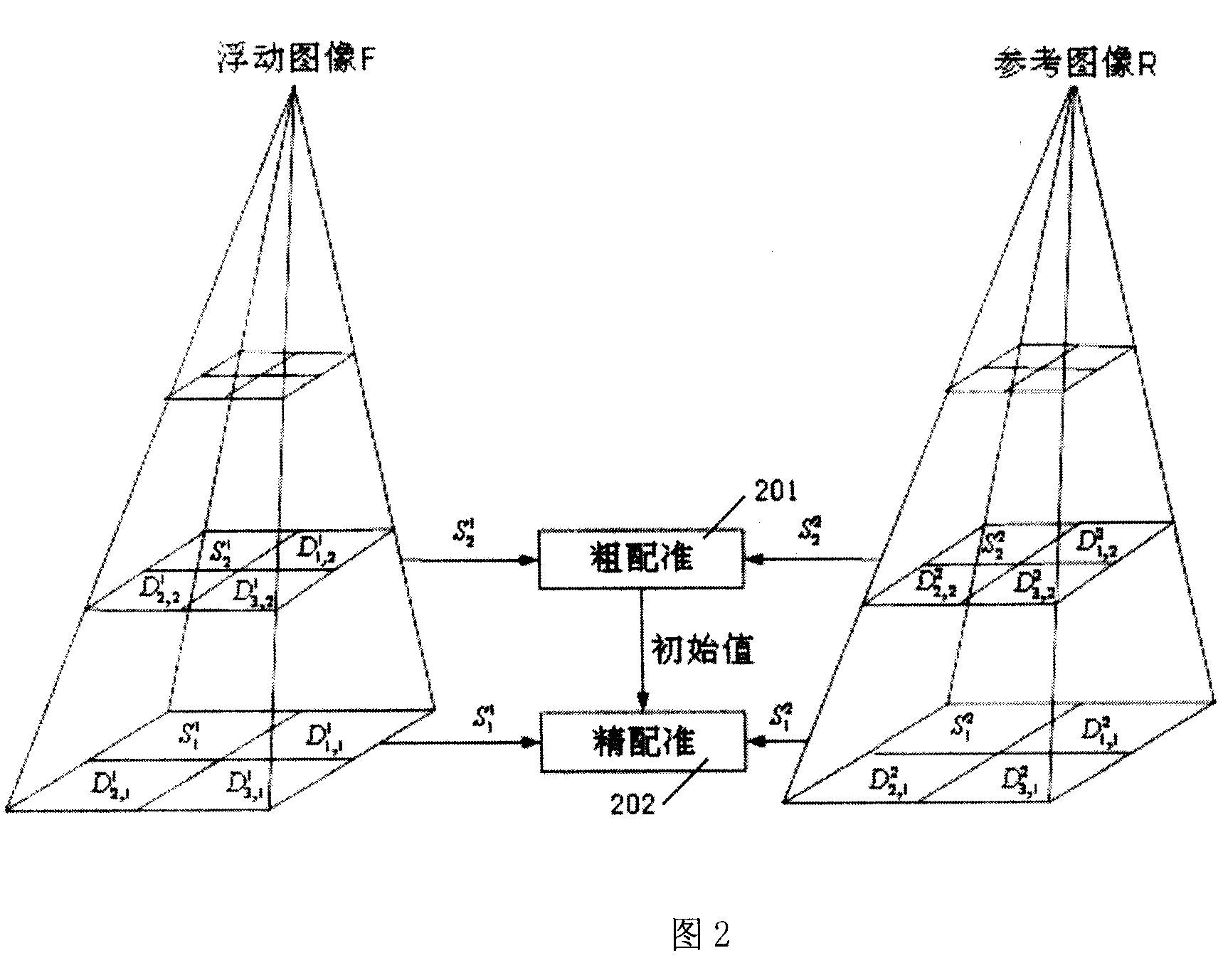

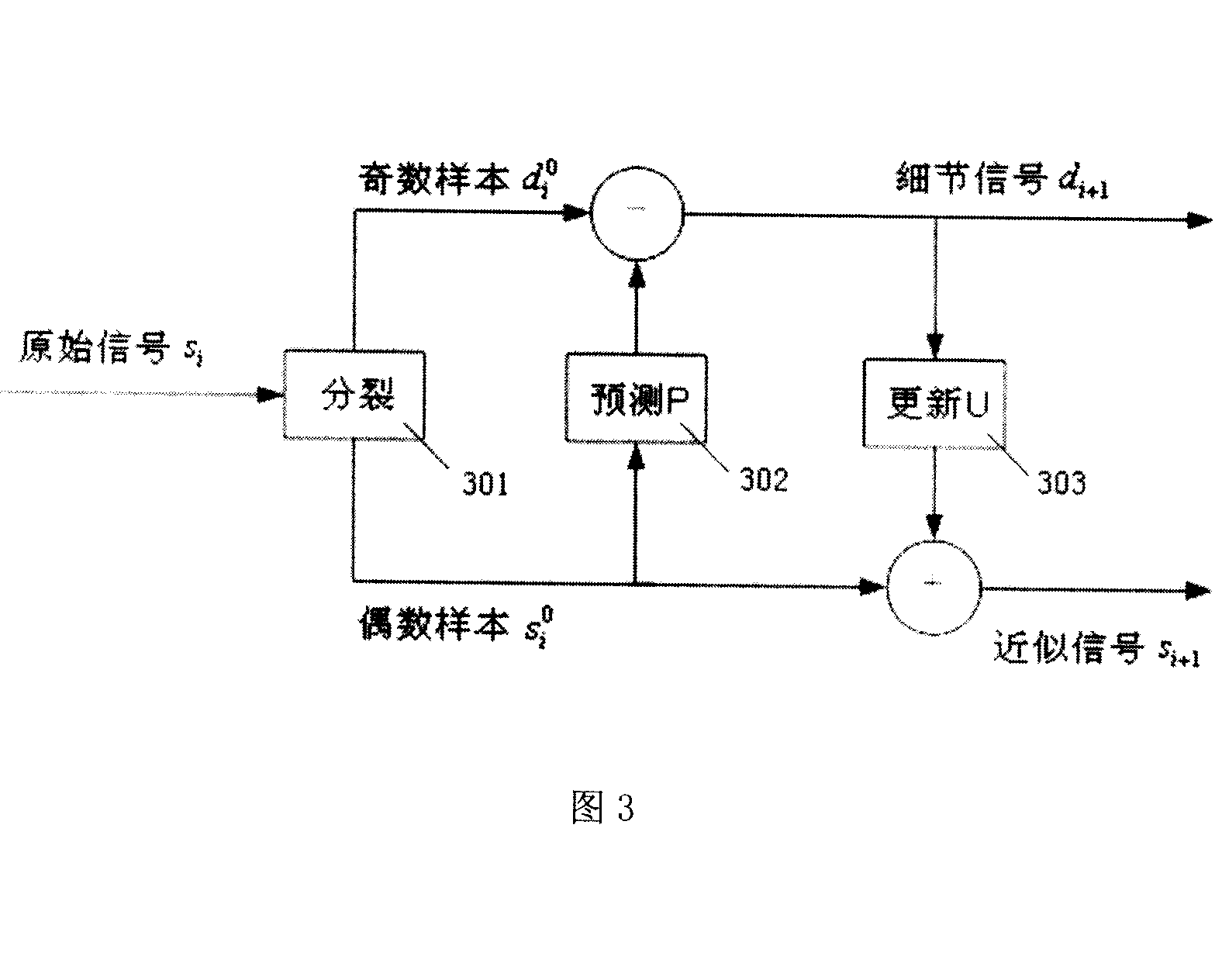

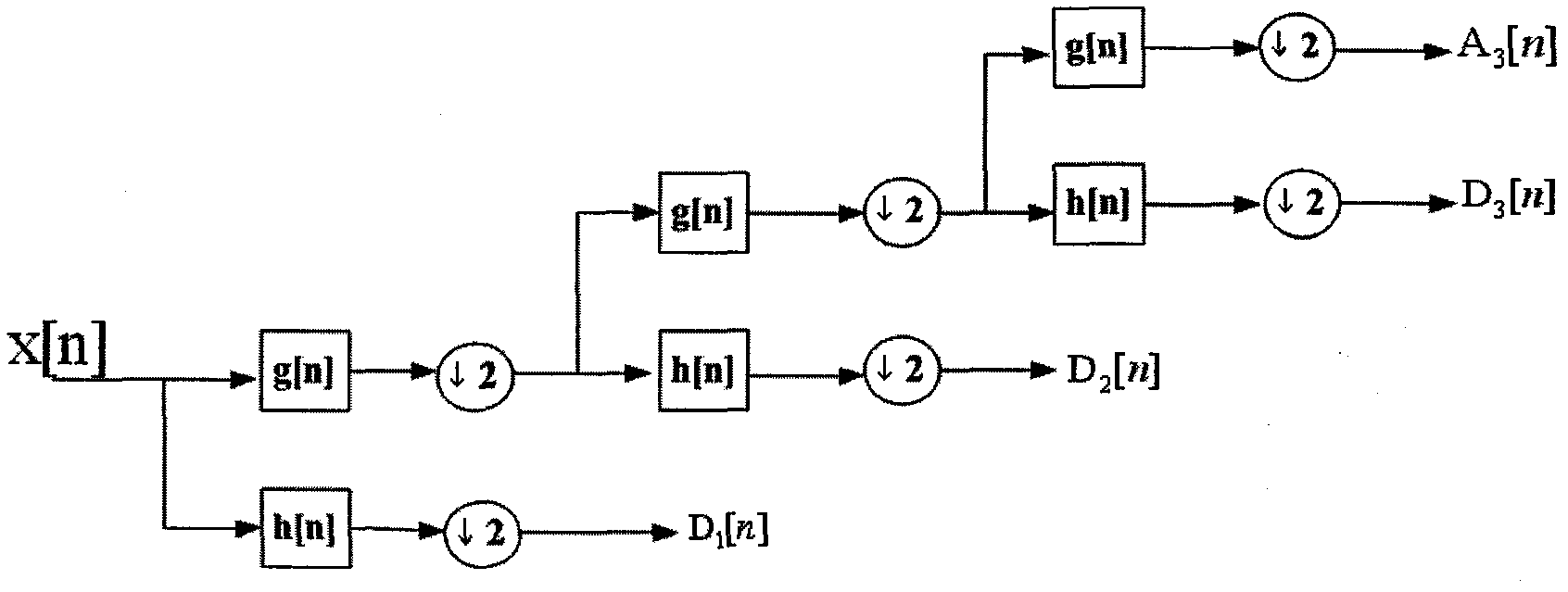

Medical ultrasound image registration method based on integer lifting wavelet multiresolution analysis

InactiveCN101238993AUltrasonic/sonic/infrasonic diagnosticsImage analysisUltrasonographySonification

A non-rigid body image registering method, belongs to medicine ultrasonic image processing field. The invention provides a ultrasonic image registering method implemented by multi-resolution analysis and lamination based on integer lifting wavelet, directing towards the difficulty that the previous registering computation of non rigid body image is complicated and the requirement for memory is large. The registration image is subjected to two-layer decomposition using integer lifting wavelet and then the decomposed approximate image is subjected to overall rigid body registration of low resolution, furthermore the registered image is subjected to image reconstruction of original resolution using integer lifting wavelet, finally the local non-rigid body registration is performed at the original image resolution, therefore the final registered image is obtained. The method of multi-resolution analysis based on integer lifting wavelet can reduce the amount of calculation and the computation complexity and registration accuracy are unified using the method of multi-layer decomposition and fine and rough combination, therefore the amount of calculation is reduced without reducing the registration accuracy. The non-rigid body image registering method has wide application prospect in ultrasound imaging field.

Owner:HARBIN INST OF TECH

Signal processing method for distributed optical fiber vibration measurement system based on wavelet analysis

InactiveCN103134580AEfficient removalEffective recoverySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansTime domainVibration measurement

The invention discloses a signal processing method for a distributed optical fiber vibration measurement system based on wavelet analysis. The time domain and the frequency domain of signals are simultaneously analyzed by means of wavelet analysis, the signals are multi-resolution, and each moment of the signals can be analyzed, so that original signals are effectively extracted from the signals mixed with strong noise. The signal processing method has the advantages that on one hand, the noise and background signals can be effectively removed, real vibration signals are effectively restored, on the other hand, multi-resolution analysis is performed for the vibration signals, misinformation vibration signals and the real intrusion vibration signals are distinguished by the aid of experience wavelet coefficient threshold values, and accordingly, the misinformation rate and the missing report rate of the system are reduced.

Owner:SHANGHAI BOOM FIBER SENSING TECH

Multi-resolution analysis in image segregation

ActiveUS8478029B2Accurately correctly identifyImage enhancementImage analysisMulti resolution analysisScale space

In a first exemplary embodiment of the present invention, an automated, computerized method is provided for processing an image. According to a feature of the present invention, the method comprises the steps of providing an image file depicting an image, in a computer memory, forming a set of selectively varied representations of the image file and performing an image segregation operation on at least one preselected representation of the image of the image file, to generate intrinsic images corresponding to the image. According to a feature of the exemplary embodiment of the present invention, the selectively varied representations comprise multi-resolution representations such as a scale-spaced pyramid of representations. In a further feature of the exemplary embodiment of the present invention, the intrinsic images comprise a material image and an illumination image.

Owner:INNOVATION ASSET COLLECTIVE

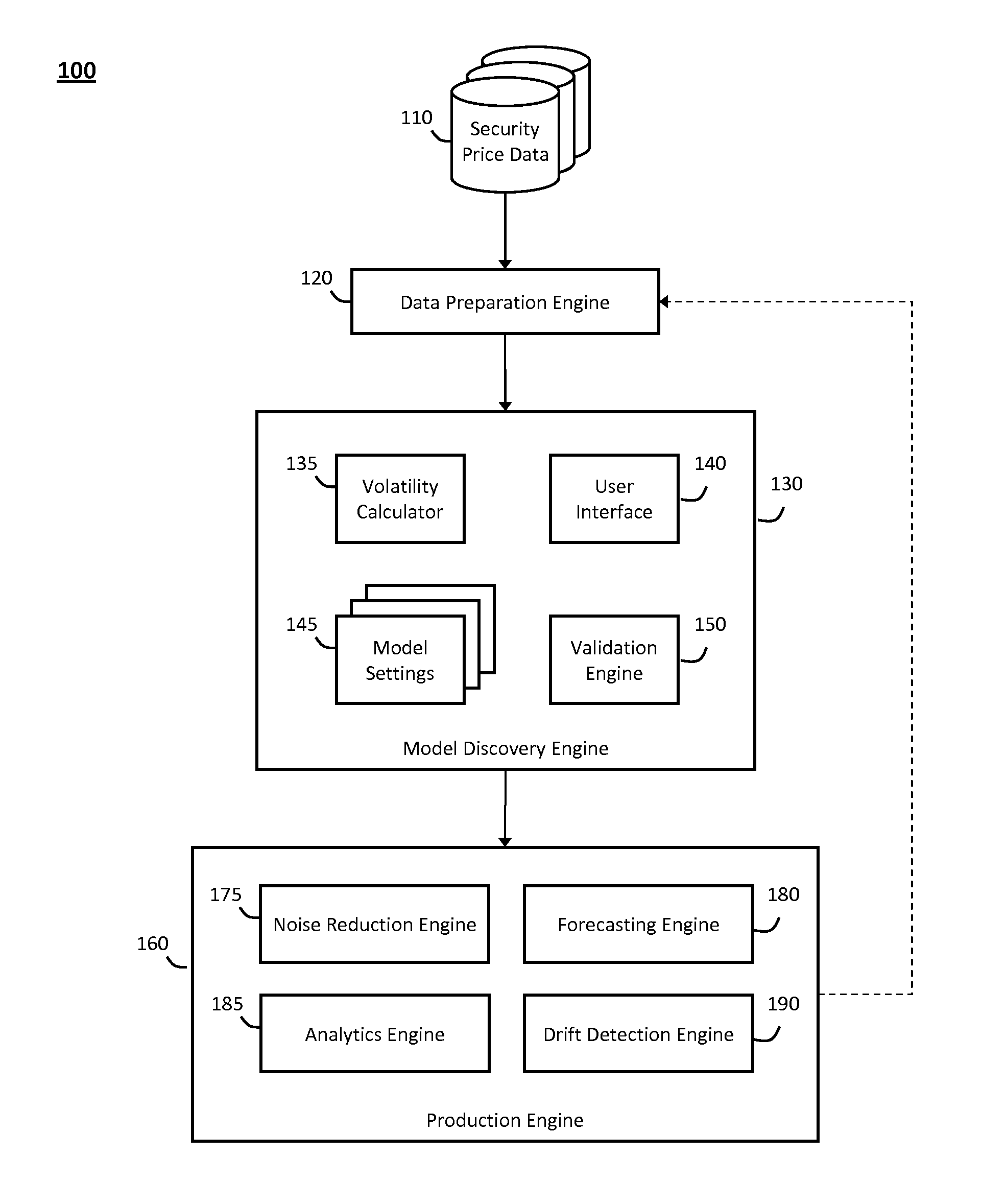

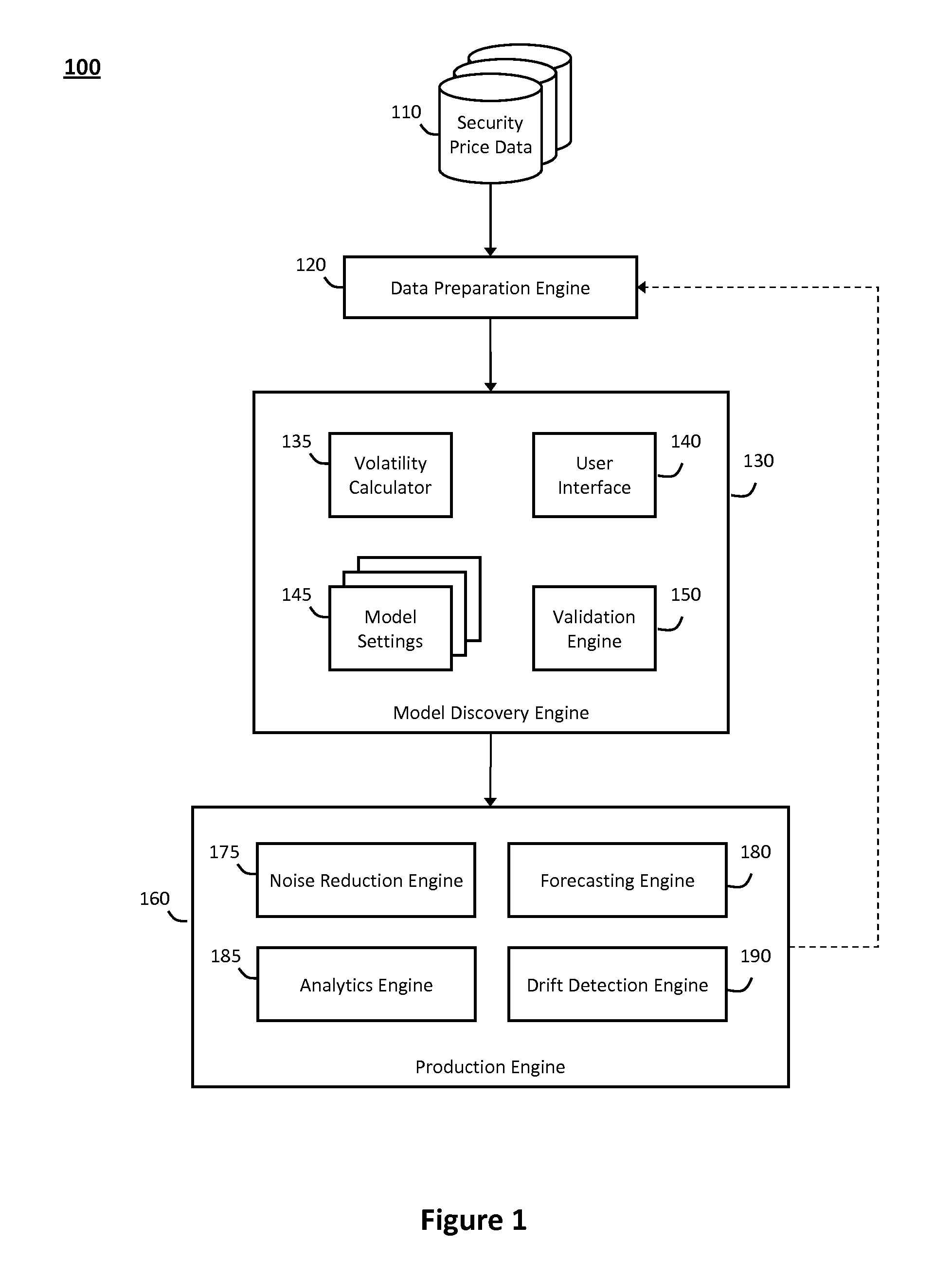

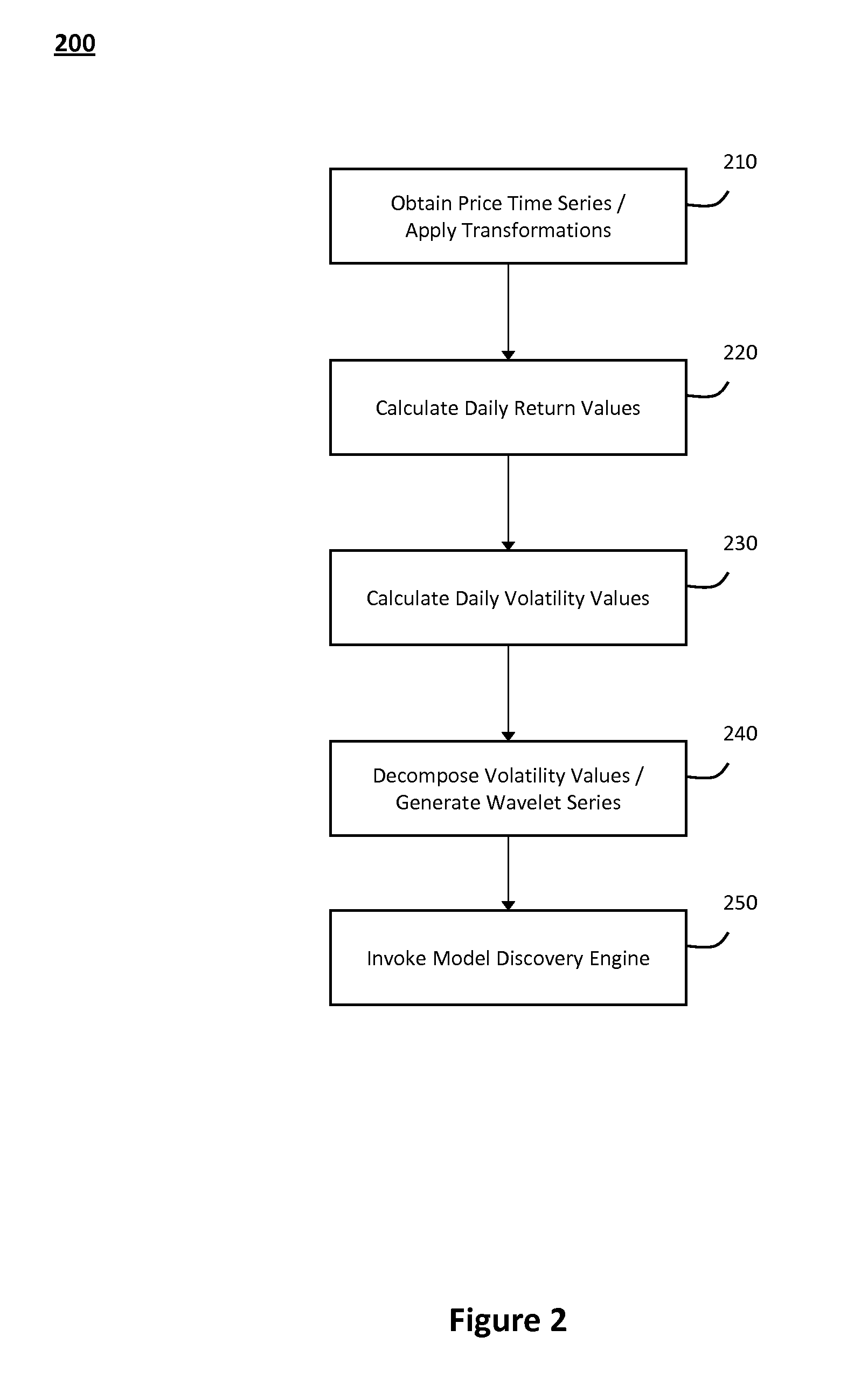

System and method for forecasting realized volatility via wavelets and non-linear dynamics

ActiveUS20120078814A1Improvement in maximum absolute errorBig errorFinanceMulti resolution analysisNon linear dynamic

The system and method described herein may be used to forecast realized volatility via wavelets and non-linear dynamics. In particular, a volatility time series that includes daily volatility values associated with a security may be decomposed into wavelets via multi-resolution analysis and dynamical properties associated with the individual wavelets may be analyzed to identify deterministic and non-deterministic wavelets and produce a volatility forecast derived from a fit computed on the deterministic wavelets. For example, the wavelets may be analyzed to discover time delay, Theiler, and embedding dimension values associated therewith, which may be used to project volatility values associated with each wavelet. The projected volatility values associated with each wavelet may then be summed to produce a volatility forecast associated with the security.

Owner:THOMSON REUTERS GLOBAL RESOURCES UNLIMITED CO

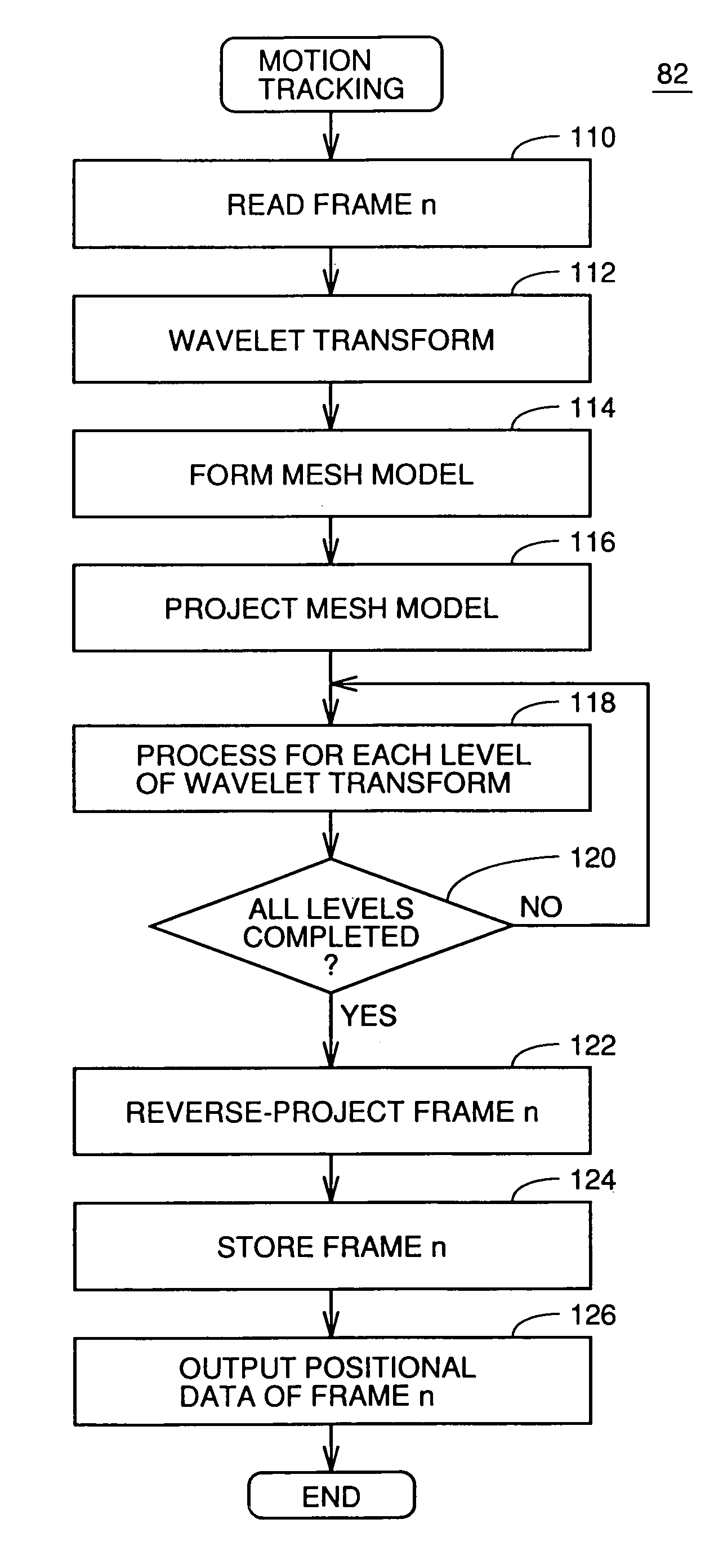

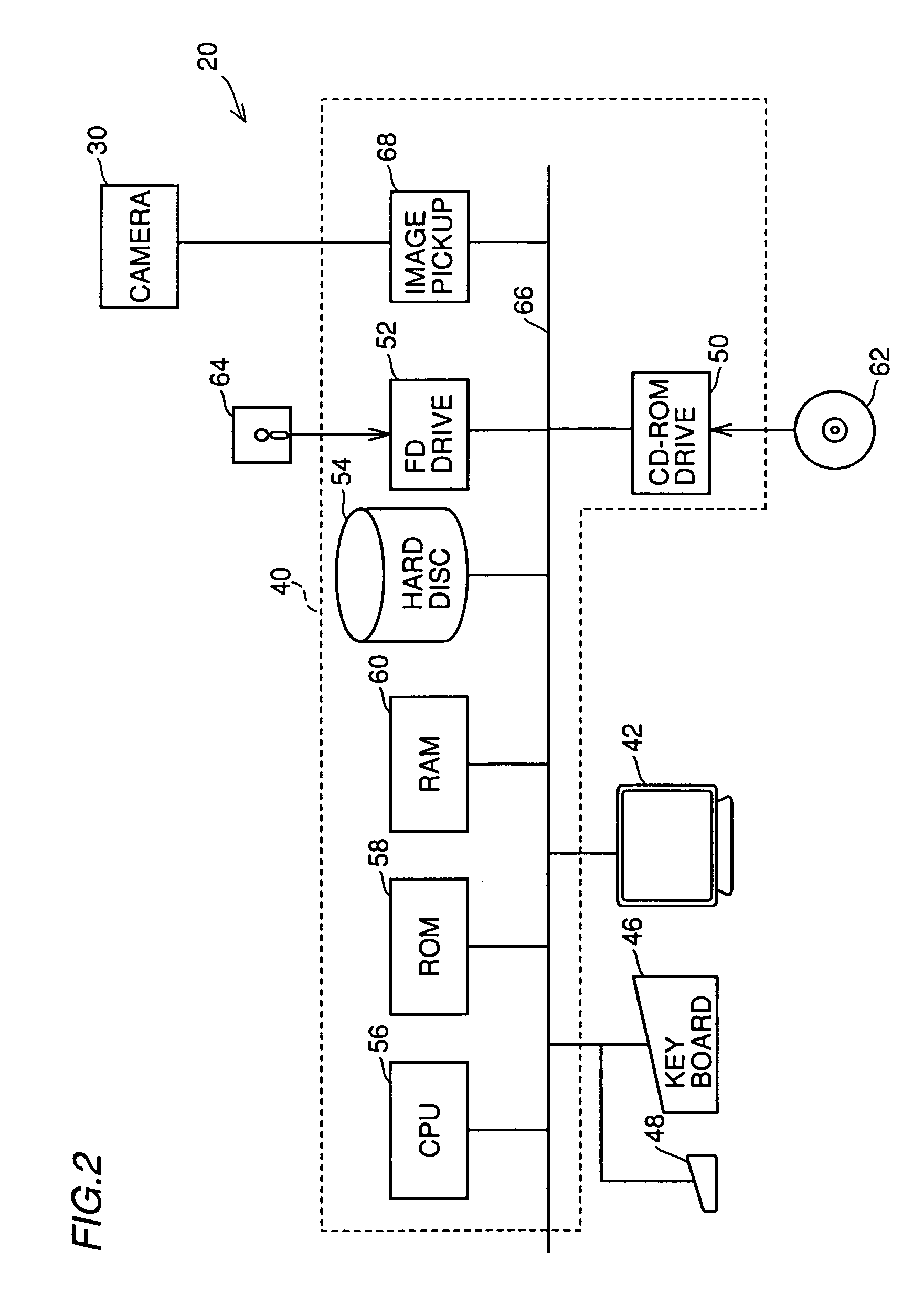

Method and apparatus for measuring motion of an object surface by multi-resolution analysis using a mesh model

InactiveUS6931145B1Efficient analysisSpeed efficientImage analysisCharacter and pattern recognitionMulti resolution analysisMaximum level

Owner:ATR ADVANCED TELECOMM RES INST INT

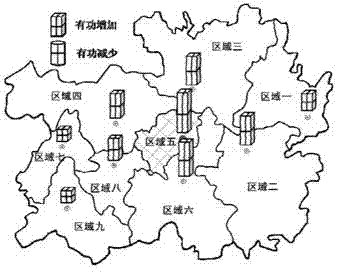

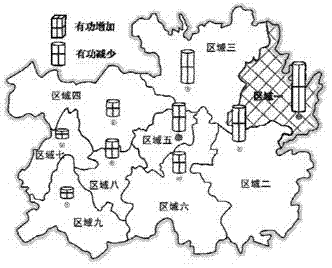

Online identification and visualization method for power grid disturbances based on multi-resolution wavelet analysis

ActiveCN102931728AReality matchThe analysis result is accurateCircuit arrangementsInformation technology support systemWide areaMulti resolution analysis

The invention relates to an online identification and visualization method for power grid disturbances based on multi-resolution wavelet analysis, which belongs to the technical field of wide-area dynamic monitoring and visualization of power systems. The method comprises the following steps: carrying out offline simulation analysis on the features of typical dynamic disturbance accidents in power grid, and selecting a wavelet function Psi and the decomposition layer-number I corresponding to the obtained maximum wavelet coefficient energy as online wavelet multi-resolution analysis tools; carrying out regionalization according to the PMU (power management unit) configuration situation of a target power grid, so that each region has one and only one PMU substation for measurement, and transmitting frequency signals measured by each PMU substation to a WAMS (wide area measurement system) master station; acquiring frequency signals of each PMU substation from the WAMS master station, and carrying out I-layer online wavelet multi-resolution analysis on the frequency signals by using the determined wavelet function so as to obtain wavelet coefficients of an I(th) layer; and discriminating disturbance occurrence time, disturbance occurrence potion and disturbance type according to the wavelet coefficients; and carrying out visualized display through taking a map as the background. The method disclosed by the invention can improve the running reliability of an electrical power grid.

Owner:TSINGHUA UNIV +1

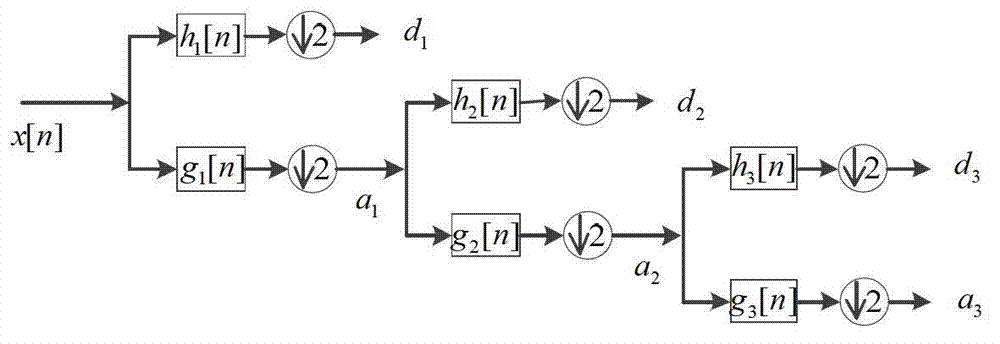

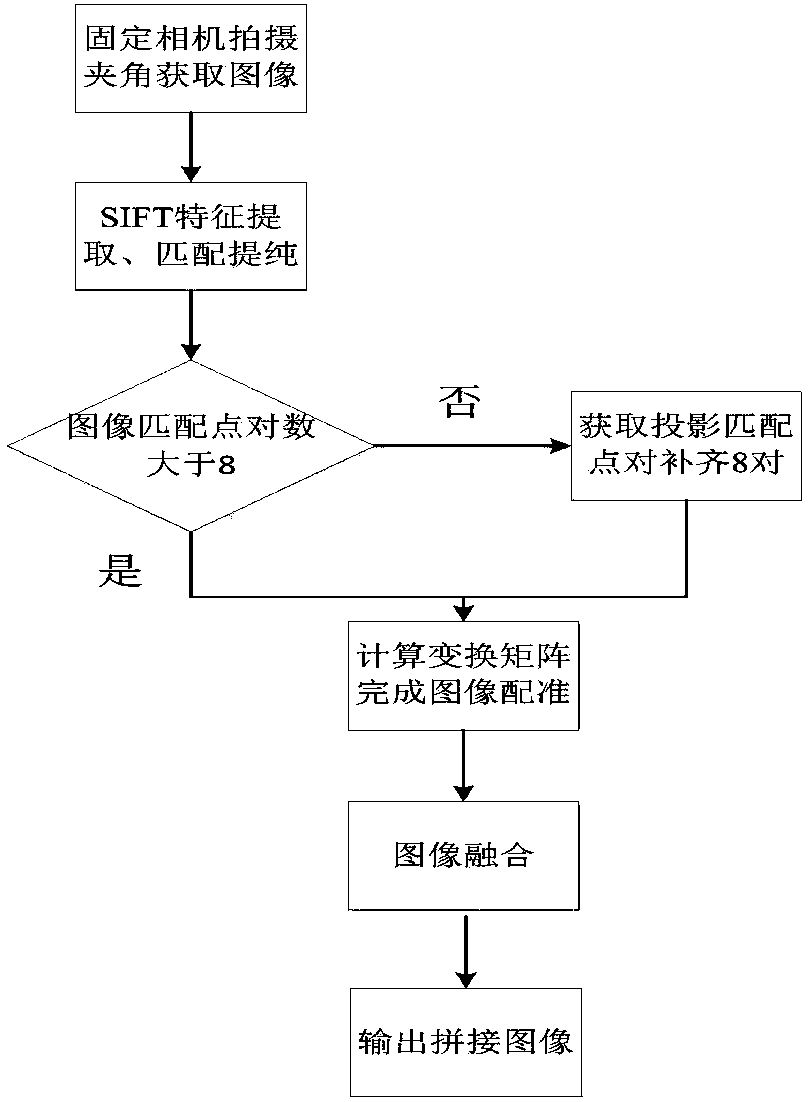

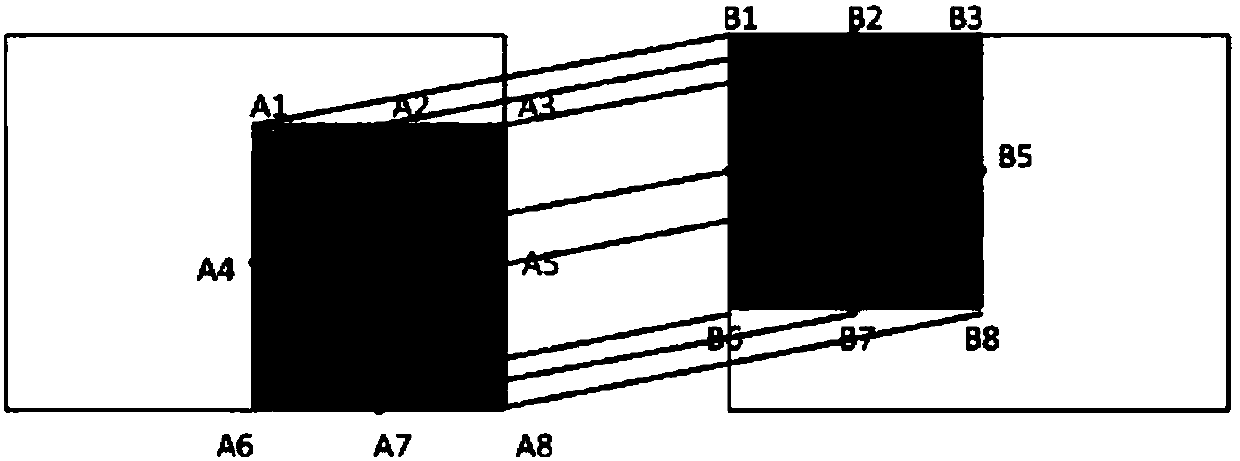

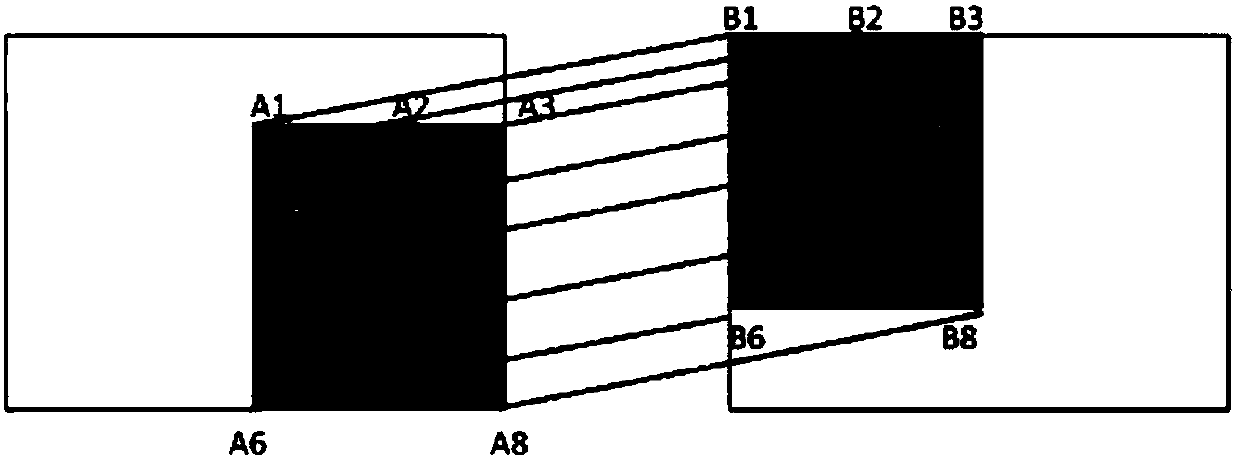

Image splicing method based on projection geometry and SIFT characteristics

InactiveCN108460727AIncrease success rateGood stitchingImage analysisGeometric image transformationMulti resolution analysisMatrix completion

The invention discloses an image splicing method based on projection geometry and SIFT characteristic matching point pairs. According to the method, firstly, two images with overlapping areas are captured, SIFT characteristic points are extracted from to-be-spliced images, characteristic point matching is carried out through the K-D tree search algorithm, the RANSAC algorithm is further utilized to carry out characteristic point purification to eliminate wrong matching point pairs, a transformation matrix is calculated if the number of characteristic matching point pairs after purification isgreater than 8, if the number of characteristic matching point pairs after the purification is less than 8, the corresponding number of projection matching point pairs are extracted according to the known overlapping areas of the two images to complete the 8 pairs of matching points, a transformation matrix is calculated, image registering is completed, image fusion is carried out through employing the multi-resolution analysis method for the images after registering, and lastly, the spliced image is outputted. The method is advantaged in that a problem of image registration failure due to thefewer pairs of characteristic matching points can be solved through image splicing, and the image splicing effect is excellent.

Owner:CENT SOUTH UNIV

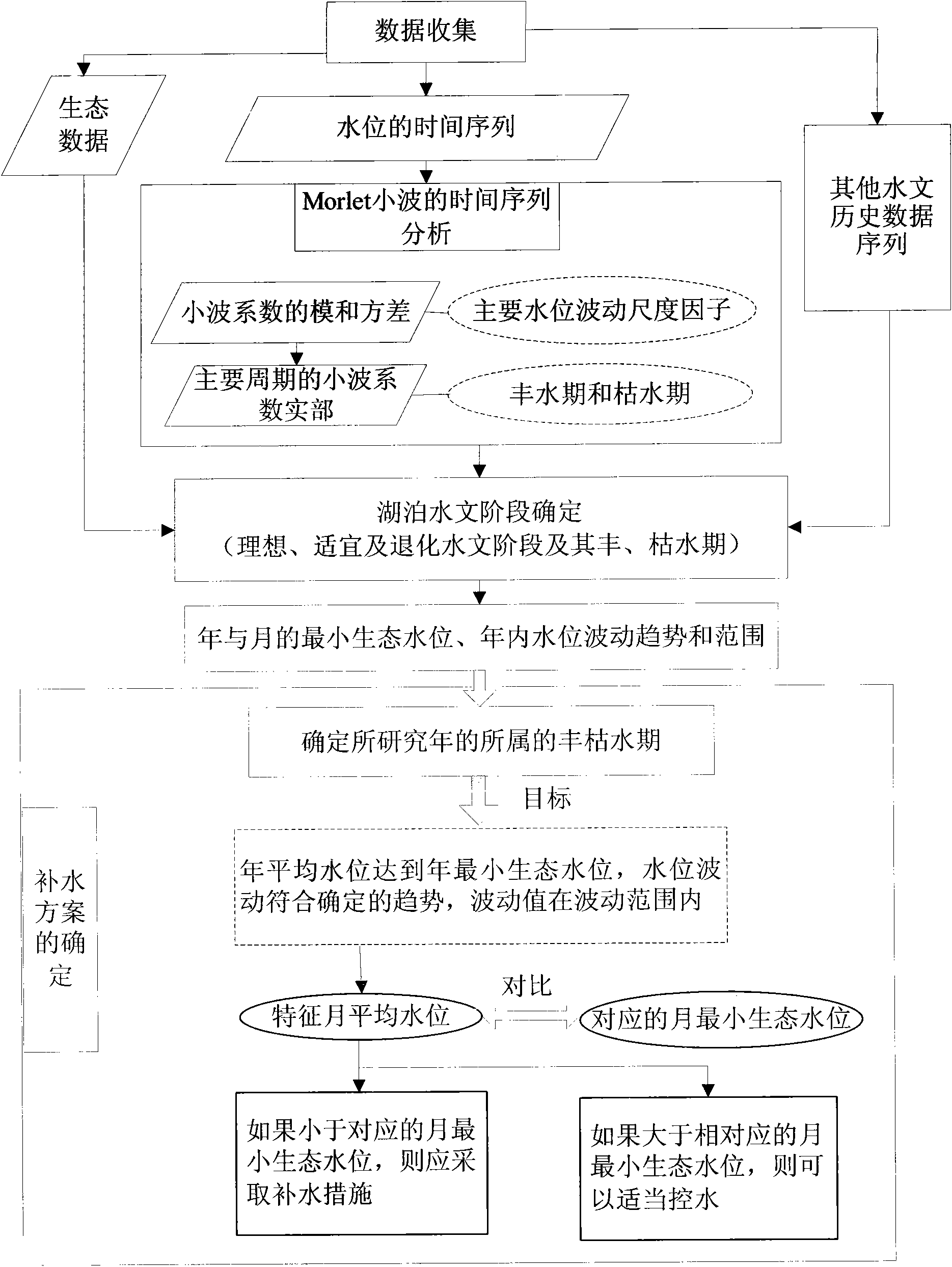

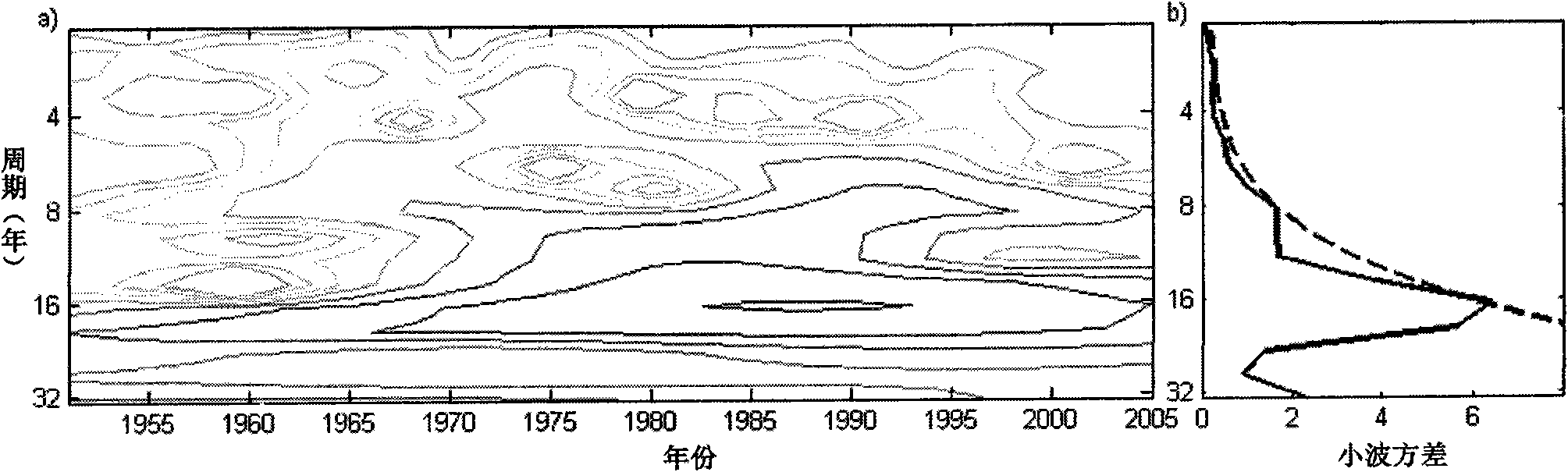

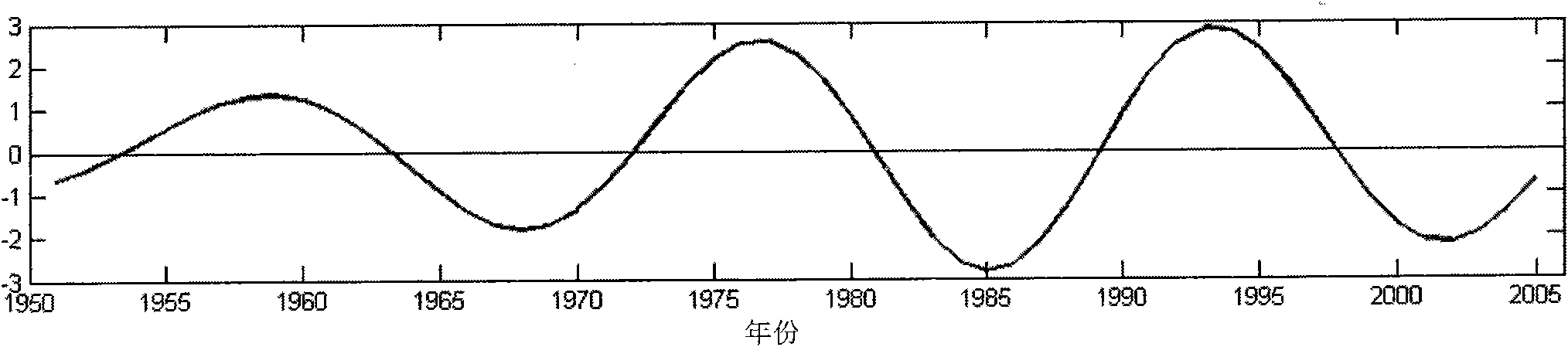

Ecological water supplement technology for lakes based on multi-scale wavelet transform

InactiveCN101824808AImprove hydration efficiencyHydraulic engineering apparatusStream regulationHydrometryDry season

The invention relates to ecological water supplement technology for lakes based on multi-scale wavelet transform, which is characterized by not only well extracting the information of the water level on different scales by applying the excellent performance of multi-resolution analysis of wavelet transform but also reconstructing the wavelet coefficients of main scales and combining other hydrological and ecological data to obtain the division standards of hydrological stages, determining the suitable hydrological stage containing the wet and dry seasons and putting forward a scheme of ecological water supplement for lakes, which simultaneously takes both the minimum ecological water level and the in-year water level fluctuation characteristic into account. Compared with the prior art, the invention is characterized by more deeply discussing the multi-scale characteristic of hydrology, being closer to the natural hydrological conditions of lakes than the single minimum ecological water level of traditional water supplement and providing bases for analyzing the state of the hydrological environment of degraded wetlands, formulating water supplement schemes suitable for specific regions and improving efficiency of water supplement for lakes.

Owner:BEIJING NORMAL UNIVERSITY

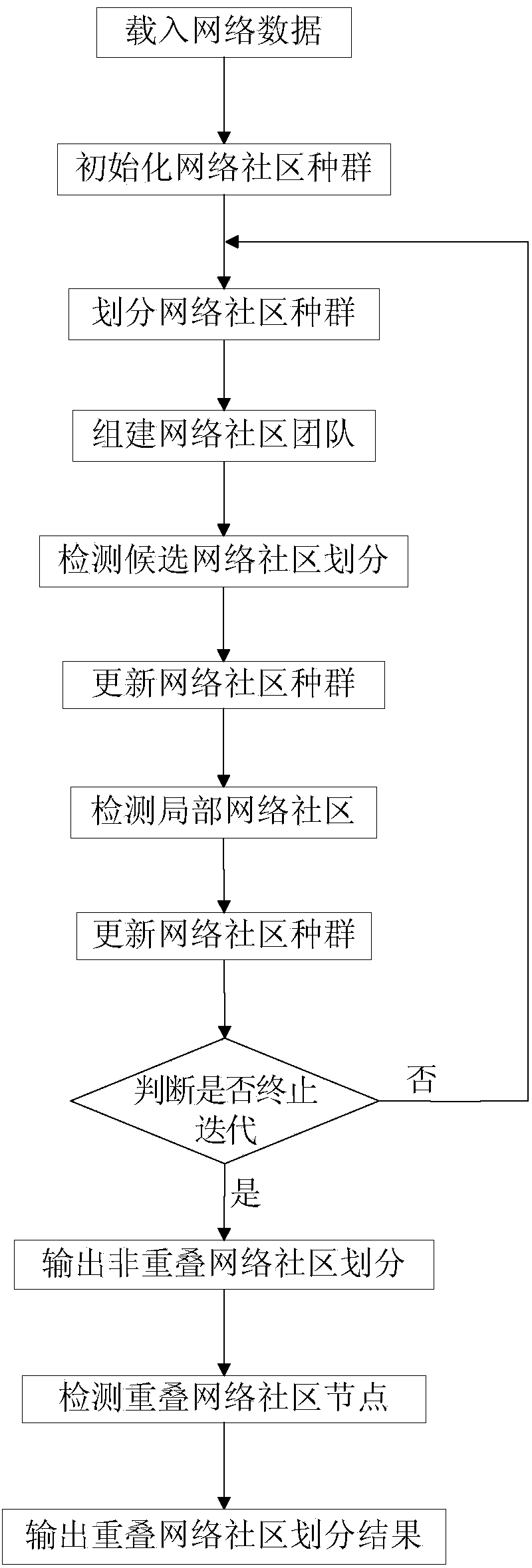

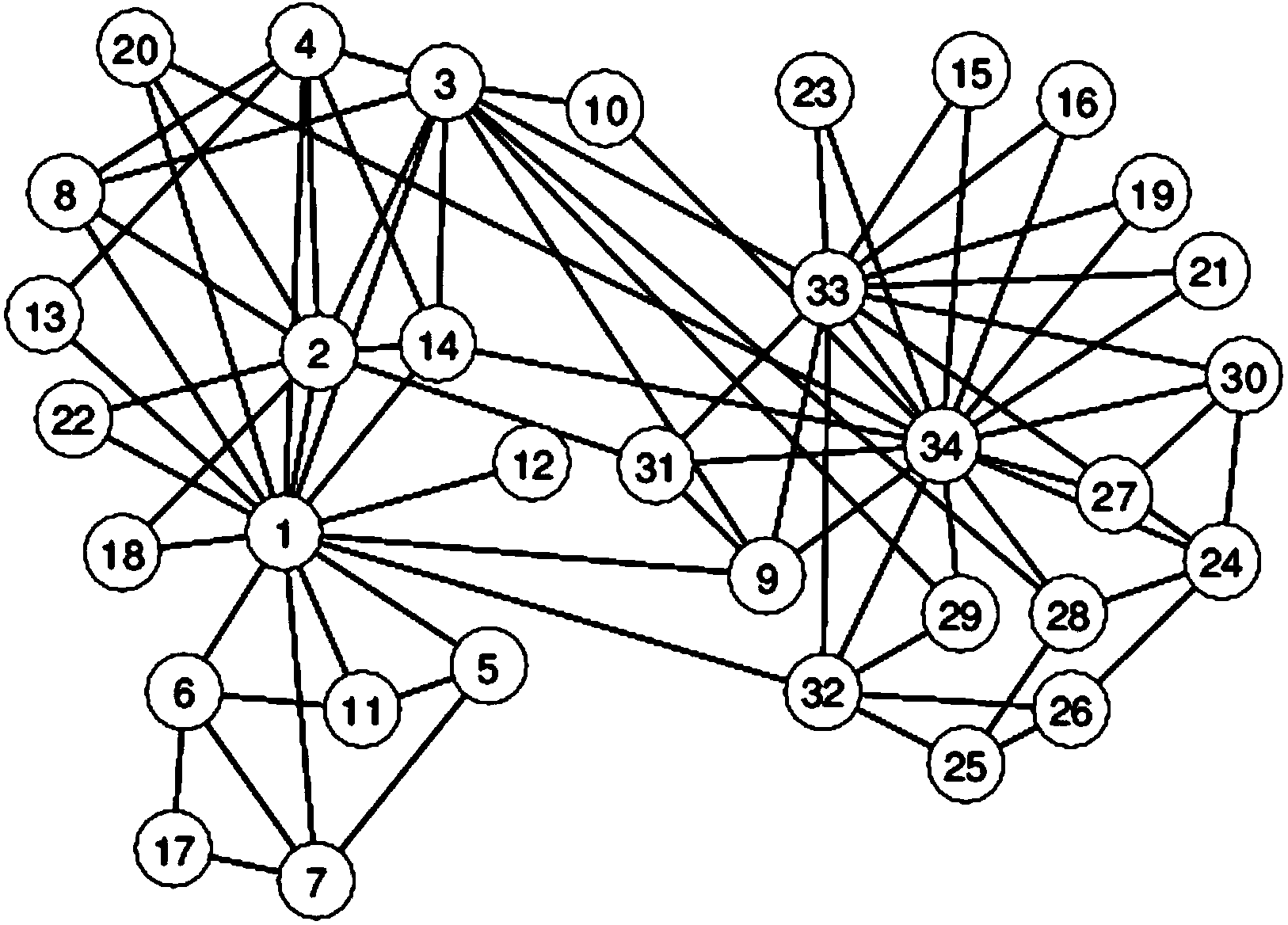

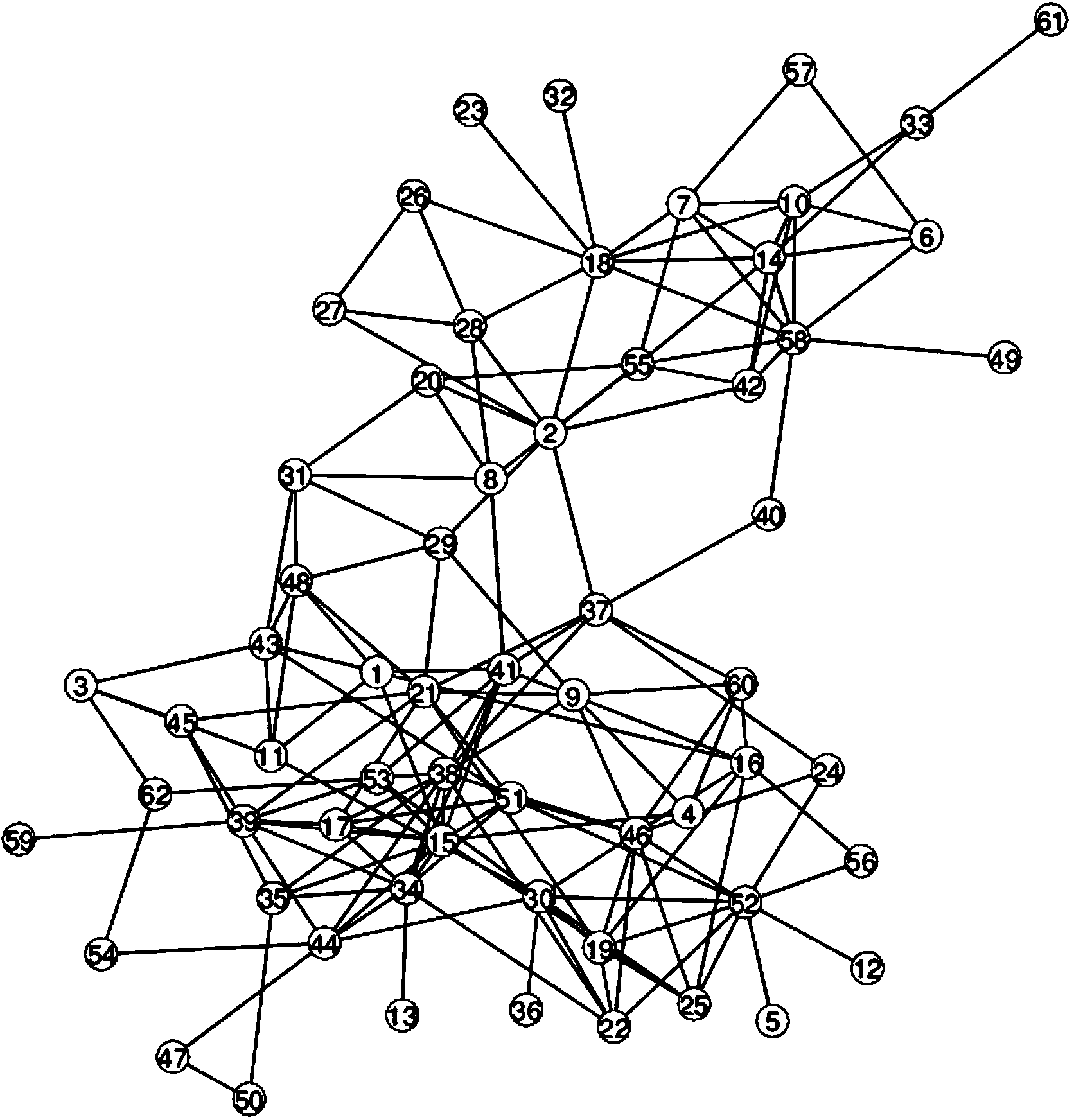

Method for detecting non-overlapping network communities and overlapping network communities based on two-stage strategy

InactiveCN103455612AOvercoming detectionOvercoming the disadvantages of overlapping network communitiesSpecial data processing applicationsCommunity basedNODAL

The invention discloses a method for detecting non-overlapping network communities and overlapping network communities based on a two-stage strategy, which solves the problem of incapability of multi-resolution analysis of an overlapping network community structure in the prior art. The method has the implementation steps of (1) loading network data; (2) initiating the population of network communities; (3) dividing the population of the network communities; (4) building a network community team; (5) detecting candidate network community division; (6) updating the population of network communities; (7) detecting local network communities; (8) updating the population of network communities; (9) judging whether iteration is terminated or not; (10) outputting non-overlapping network community division; (11) detecting nodes of overlapping network communities; (12) outputting an overlapping network community division result. A module density function and a membership function are introduced, so that multi-resolution analysis of the overlapping network community structure is realized, and the overlapping network communities with different overlapping degrees can be detected.

Owner:XIDIAN UNIV

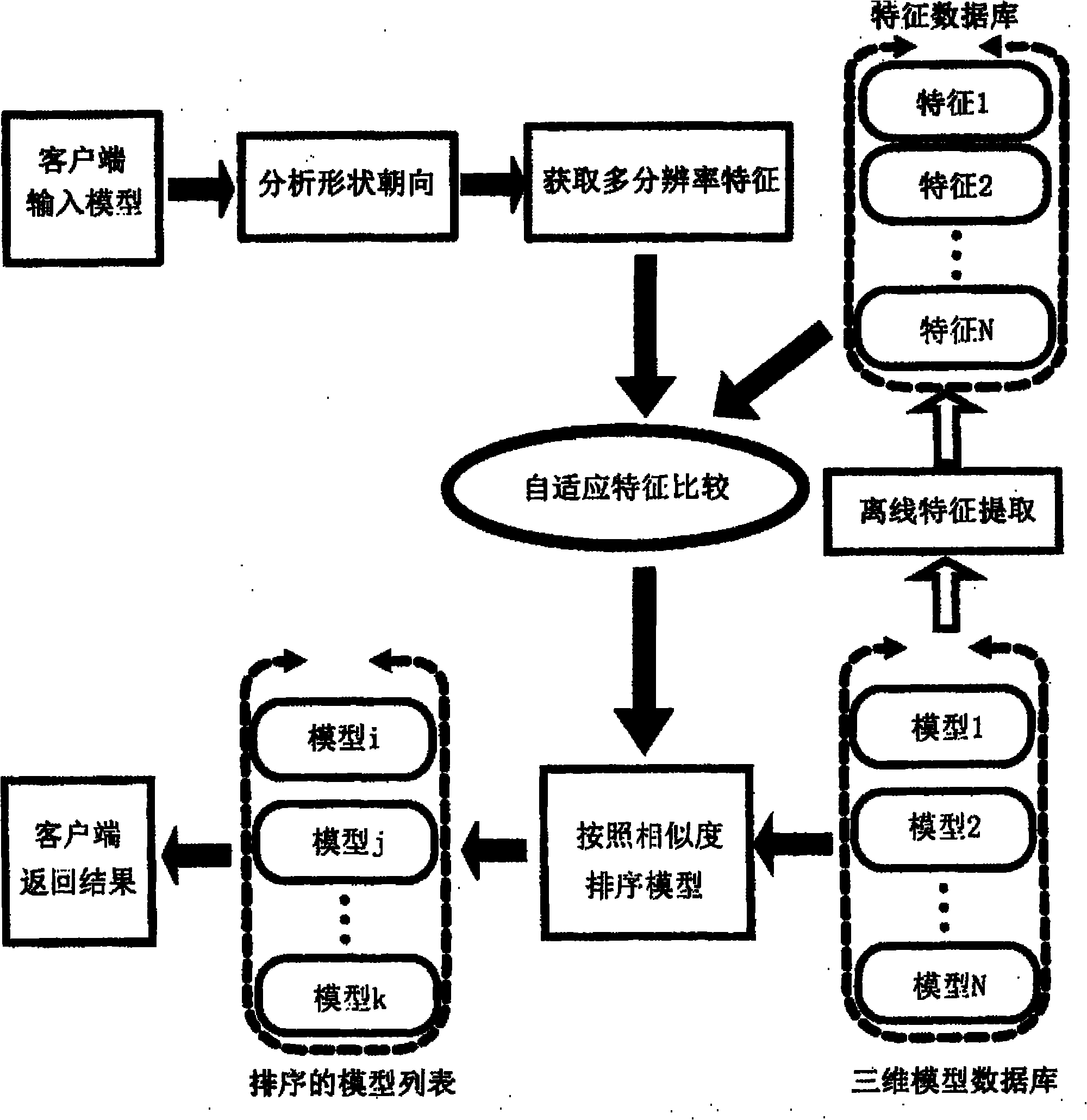

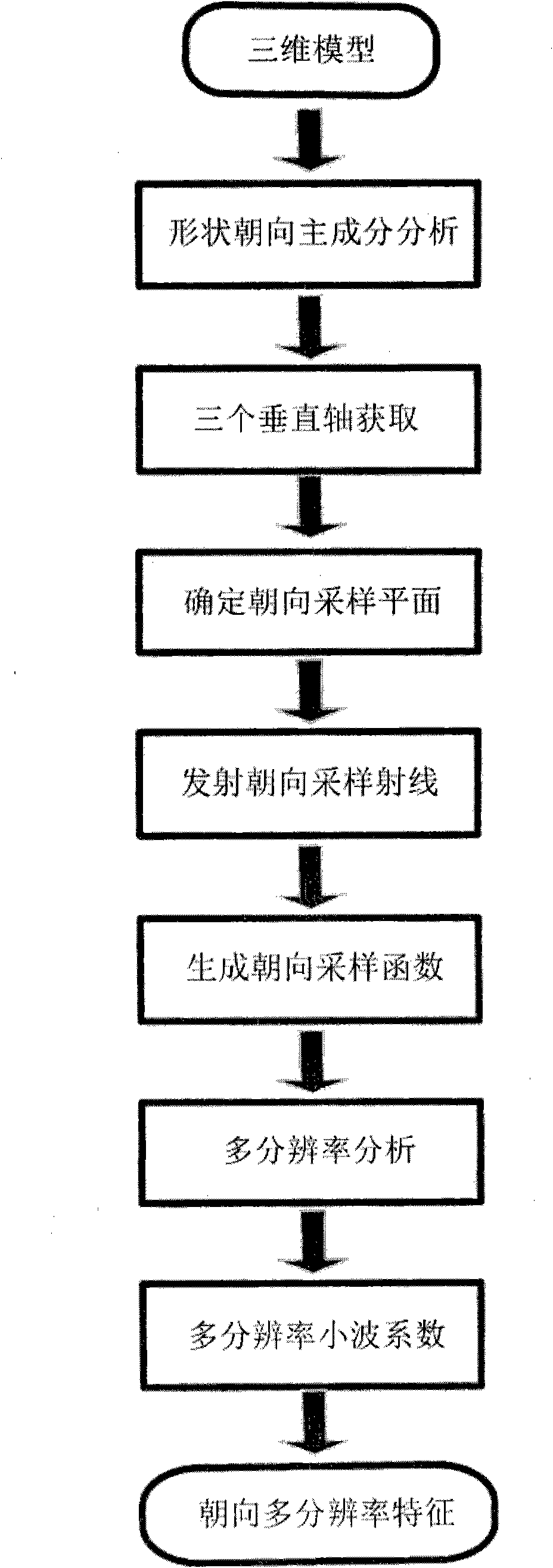

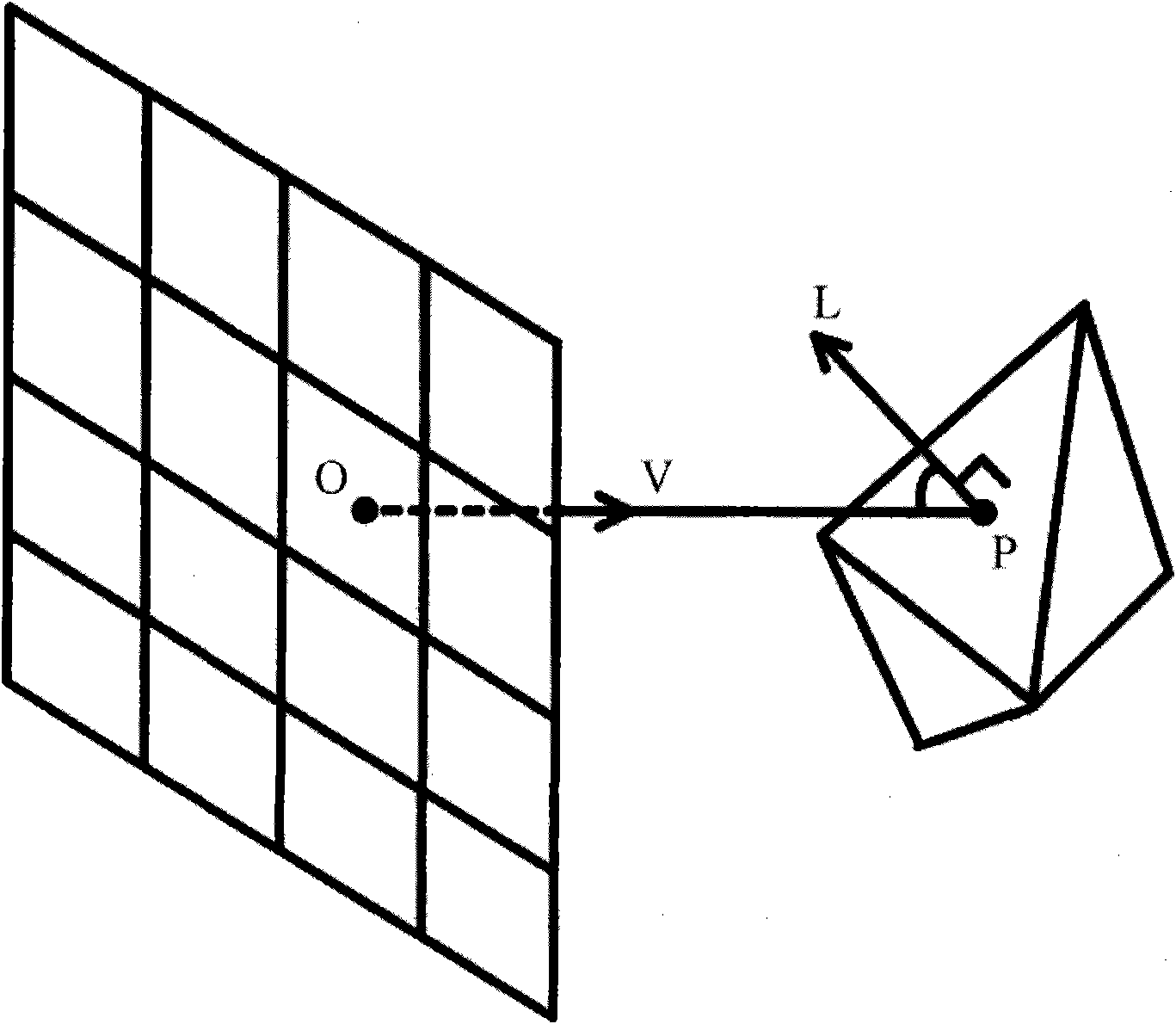

Three-dimensional model searching method based on shape orientation multi-resolution analysis

InactiveCN101916284AFeature distance maximizationOptimal Multi-Resolution Feature Weighting CoefficientsSpecial data processing applicationsMulti resolution analysisPrincipal component analysis

The invention discloses a three-dimensional model searching method based on shape orientation multi-resolution analysis, and the method comprises the following steps: obtaining an orientation sampling plane by adopting a three-dimensional plane patch orientation principle component analysis method; sampling orientation distribution of the three-dimensional shape and generating a sampling function of the orientation distribution; analyzing the sampling function and extracting a multi-resolution low-frequency wavelet coefficient of the sampling function; and calculating feature distance in a self-adaption multi-resolution feature distance calculating method. The method can enhance the precision and speed of searching the three-dimensional model and can be applied to the fields of three-dimensional model multiplex, model identification, robot vision, virtual reality and the like.

Owner:NANTONG JINNIU MACHINERY MFR +1

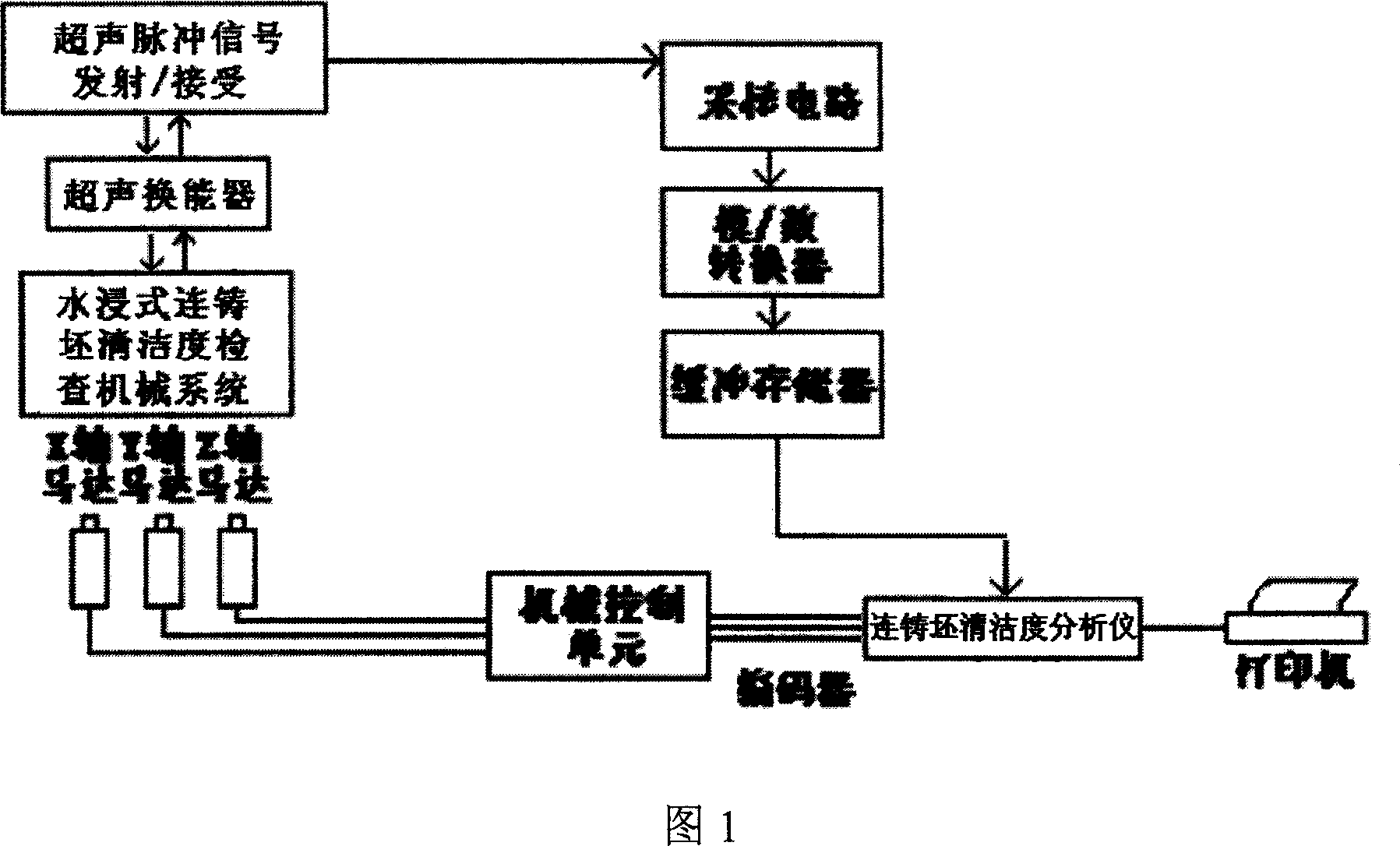

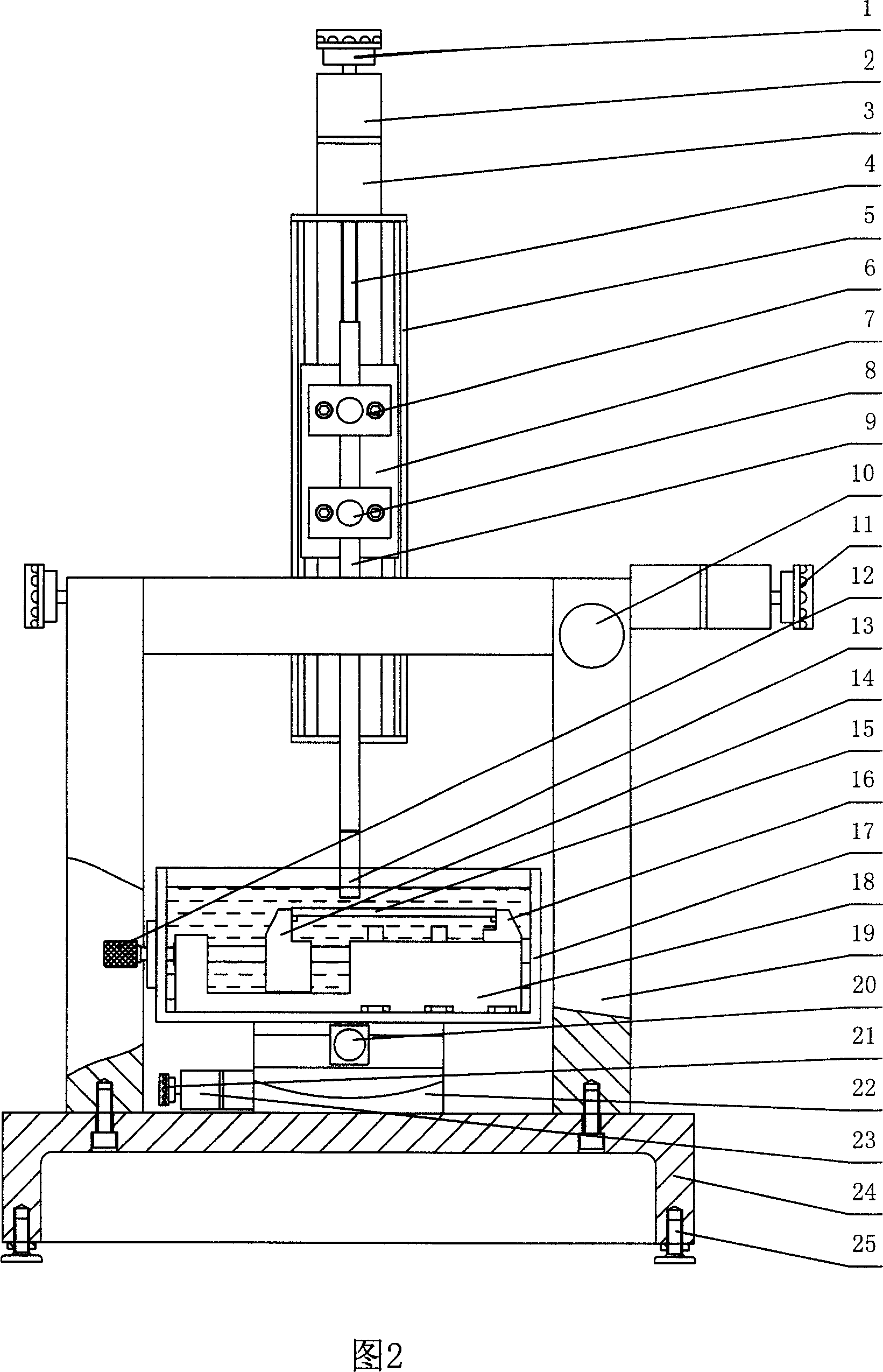

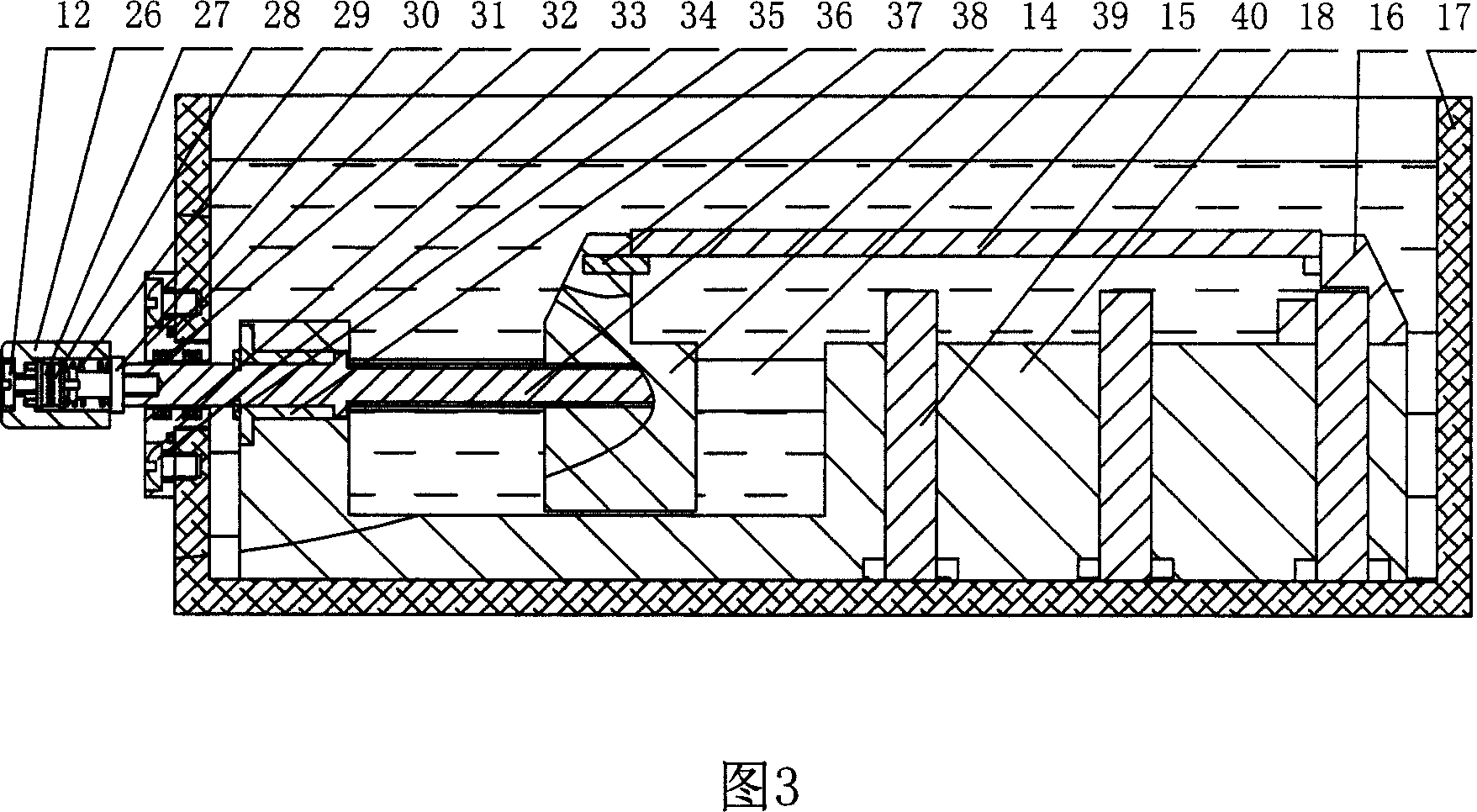

Ultrasonic method and device for testing macroscopic cleanness of continuous casting billet

ActiveCN1959404ANo low-speed crawling phenomenonHigh movement precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationSlag

A ultrasonic detection method of macrocleanness on continuous casting billet includes using multiple resolution analysis means to carry out analysis on original ultrasonic echo signal series at different frequency scope and carrying out treatment on analysis said echo signal with reasonable time frequency analysis, reconfigurating treated signal to generate signal with the same length as said echo signal series, comparing treated signal with defect judgment standard used at production unit to form planar distribution drawing of slag as per sample surface distribution.

Owner:BAOSHAN IRON & STEEL CO LTD +1

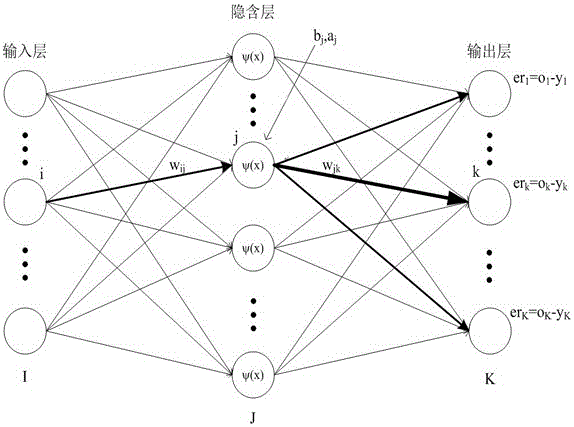

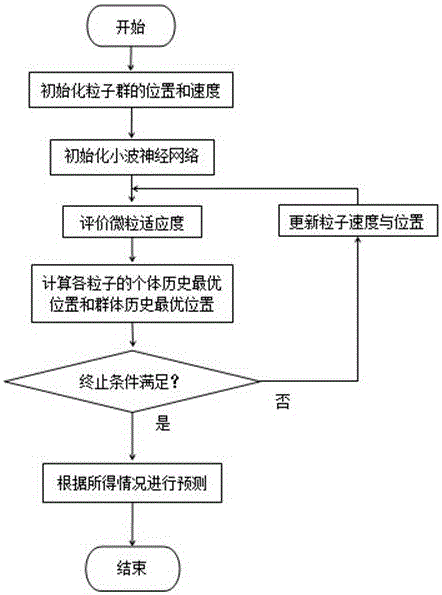

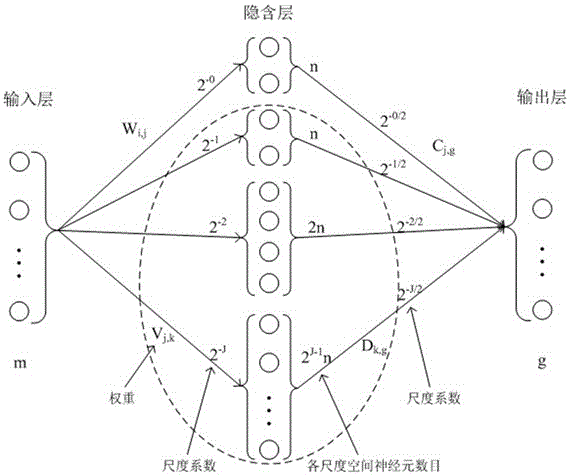

Particle swarm optimization-based multi-resolution wavelet neural network power consumption prediction method

InactiveCN106779177AFast convergenceImprove forecast accuracyForecastingArtificial lifePattern recognitionHidden layer

The invention relates to a particle swarm optimization-based multi-resolution wavelet neural network power consumption prediction method, and belongs to the field of neural network prediction research. According to the technical scheme, the method involves contents such as a wavelet neural network, a particle swarm optimization-based wavelet neural network and a particle swarm optimization-based multi-resolution wavelet neural network; the wavelet neural network, a particle swarm algorithm and multi-resolution analysis are combined; and high efficiency of the prediction method is verified by predicting power consumption. The feasibility and high efficiency of the prediction method are verified specifically through a simulation experiment: a wavelet neural network prediction method, a particle swarm optimization-based wavelet neural network prediction method and a particle swarm optimization-based multi-resolution wavelet neural network prediction method are compared. A target function and a regression analysis graph obtained by analysis can clearly show that by adopting the last prediction method, a target function value is converged more quickly, the prediction precision is higher, the influence caused by crossed overlapping of neurons in a hidden layer is effectively avoided, falling into local minimum is avoided, and the prediction effect is better.

Owner:STATE GRID JIBEI ELECTRIC POWER CO LTD TANGSHAN POWER SUPPLY CO +1

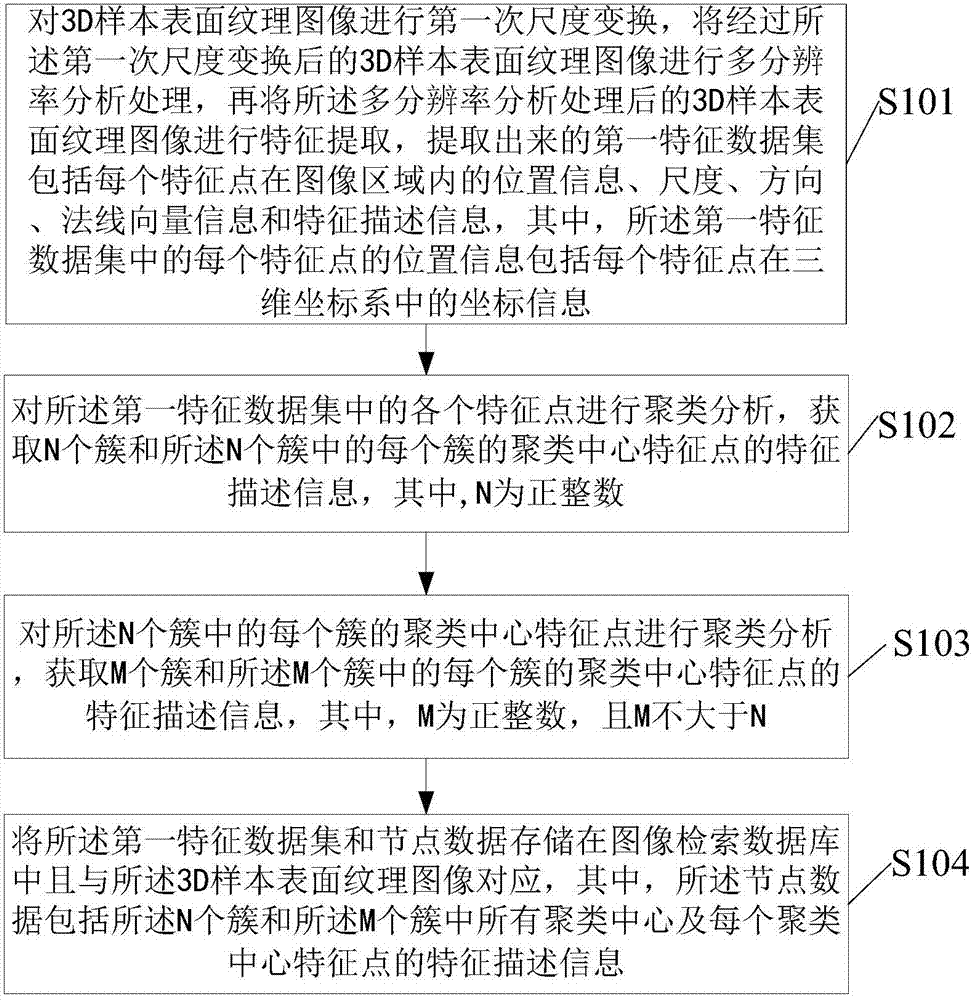

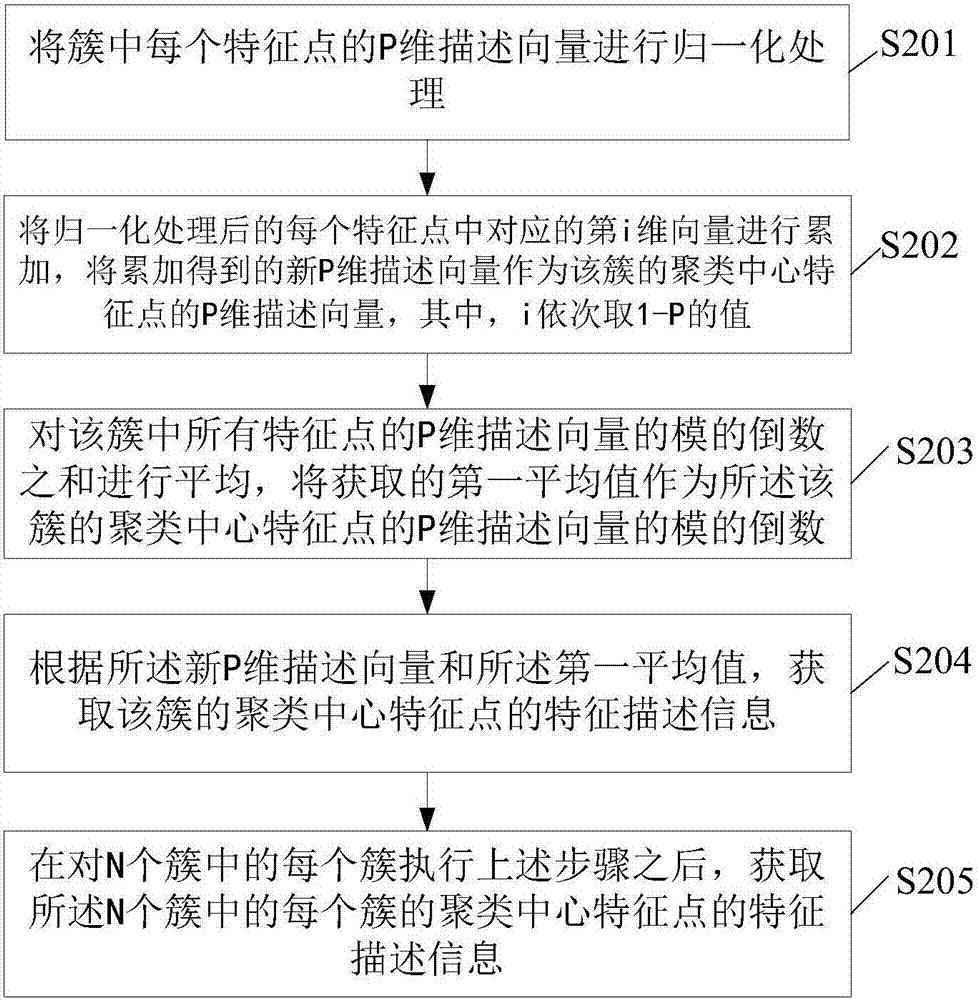

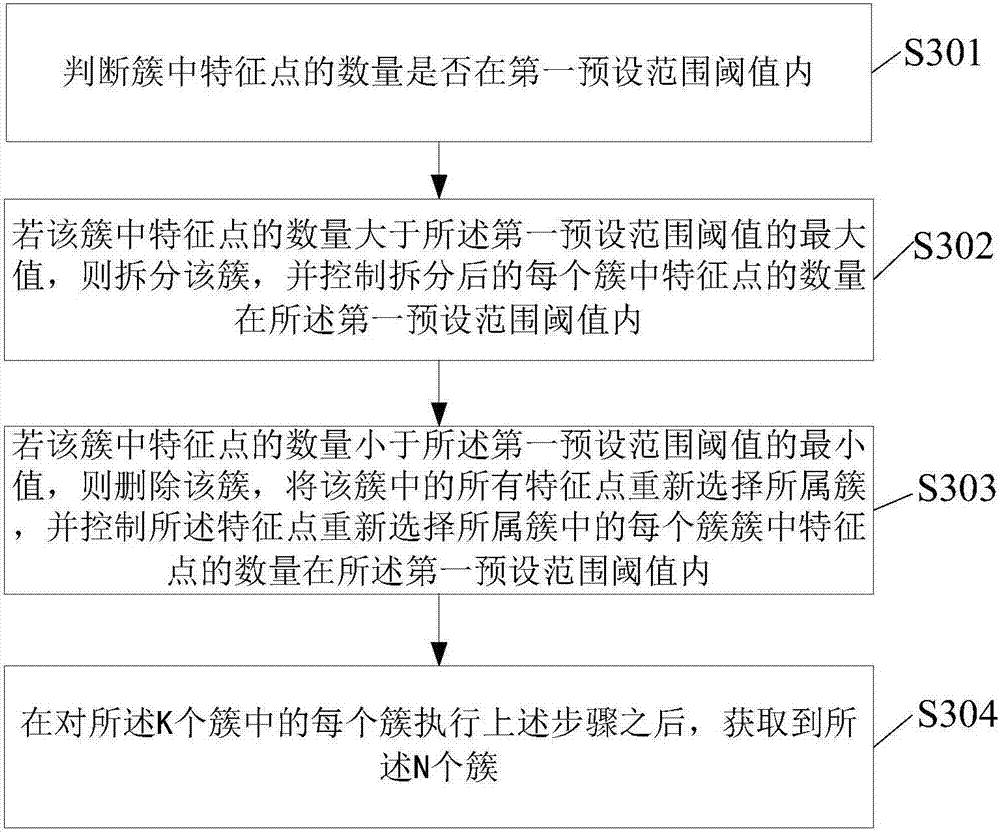

Method for generating image retrieval database, method and device for augmenting reality

ActiveCN107329962AImprove matchPrecise positioningCharacter and pattern recognitionSpecial data processing applicationsData setMulti resolution analysis

The invention discloses a method for generating image retrieval database, a method and device for augmenting reality. After a first scale transformation is performed on the 3D sample surface texture image, multi-resolution analysis is performed; then, the multi-resolution analysis processed 3D sample surface texture image is subjected to feature extraction; a first feature data set is extracted; cluster analysis is performed on the feature points in the first feature data set to obtain N clusters and feature description information of cluster center feature points of the clusters; cluster analysis is performed on the cluster center feature points of each cluster of the N clusters to obtain M clusters and description information of the cluster center feature point of each cluster of the M clusters; the first feature dataset and node data are stored in an image retrieval database and correspond to a 3D sample surface texture image, wherein the node data includes all the cluster centers of the N clusters and the M clusters and the feature description information of each cluster center feature point.

Owner:CHENGDU IDEALSEE TECH

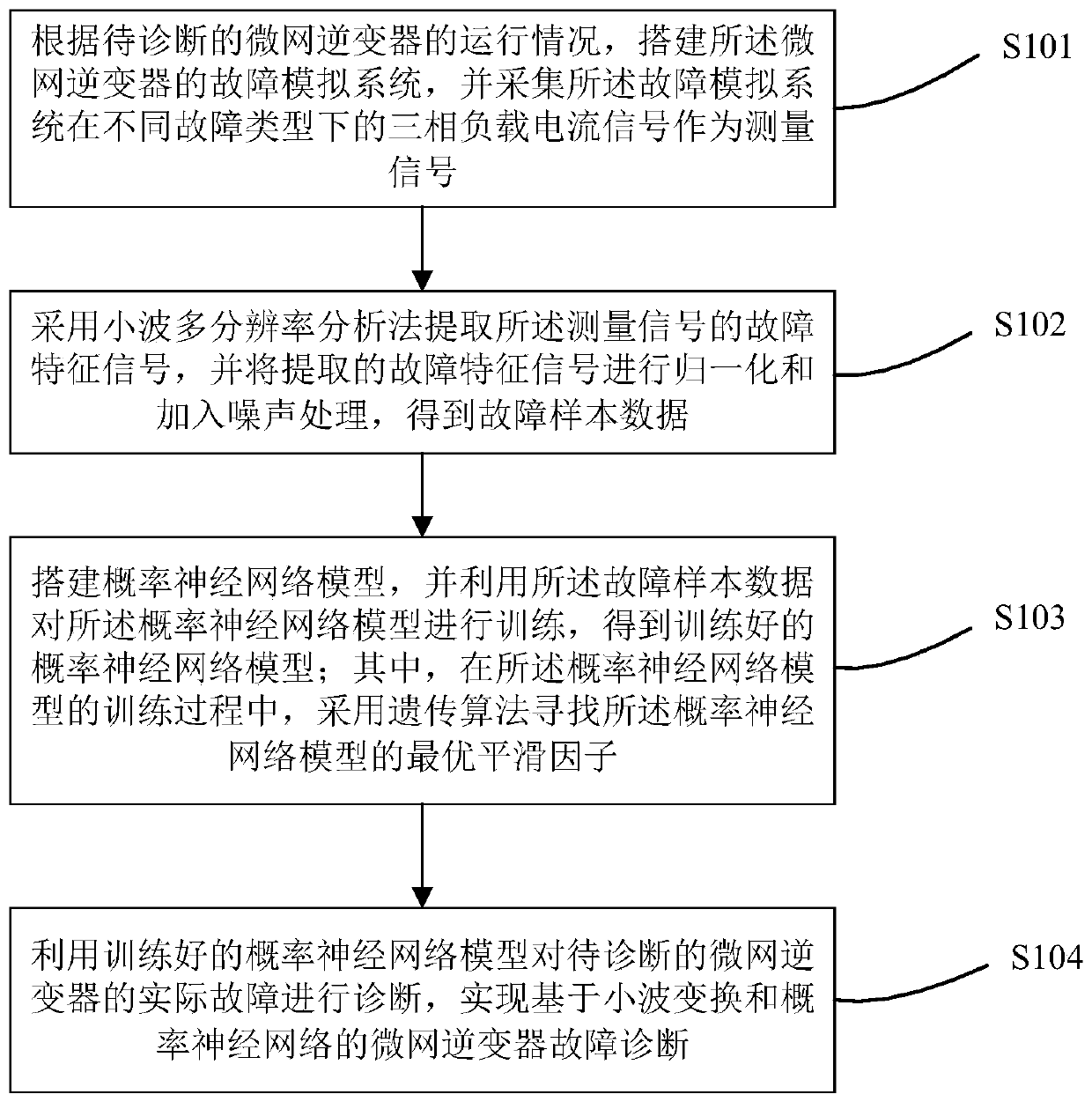

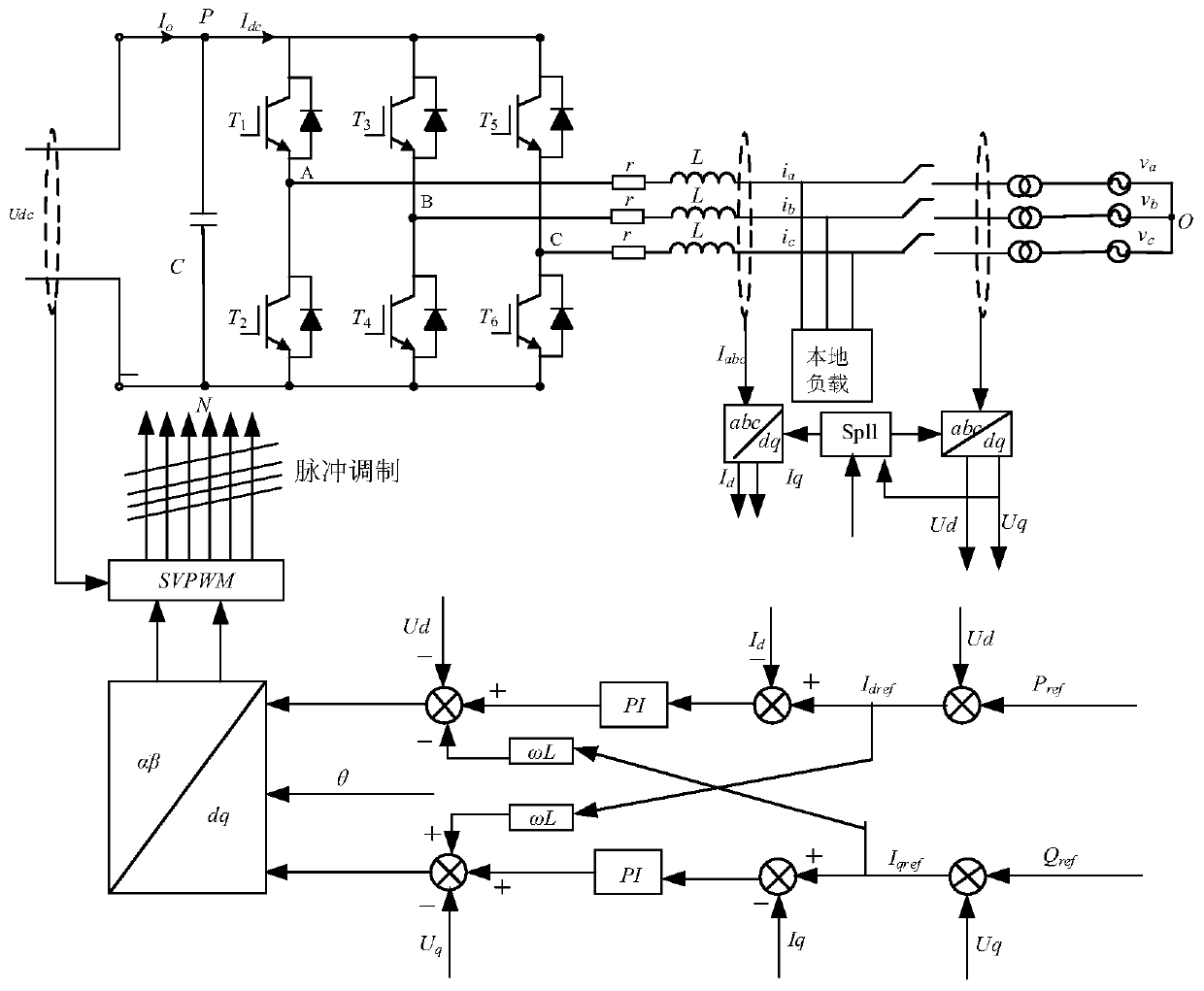

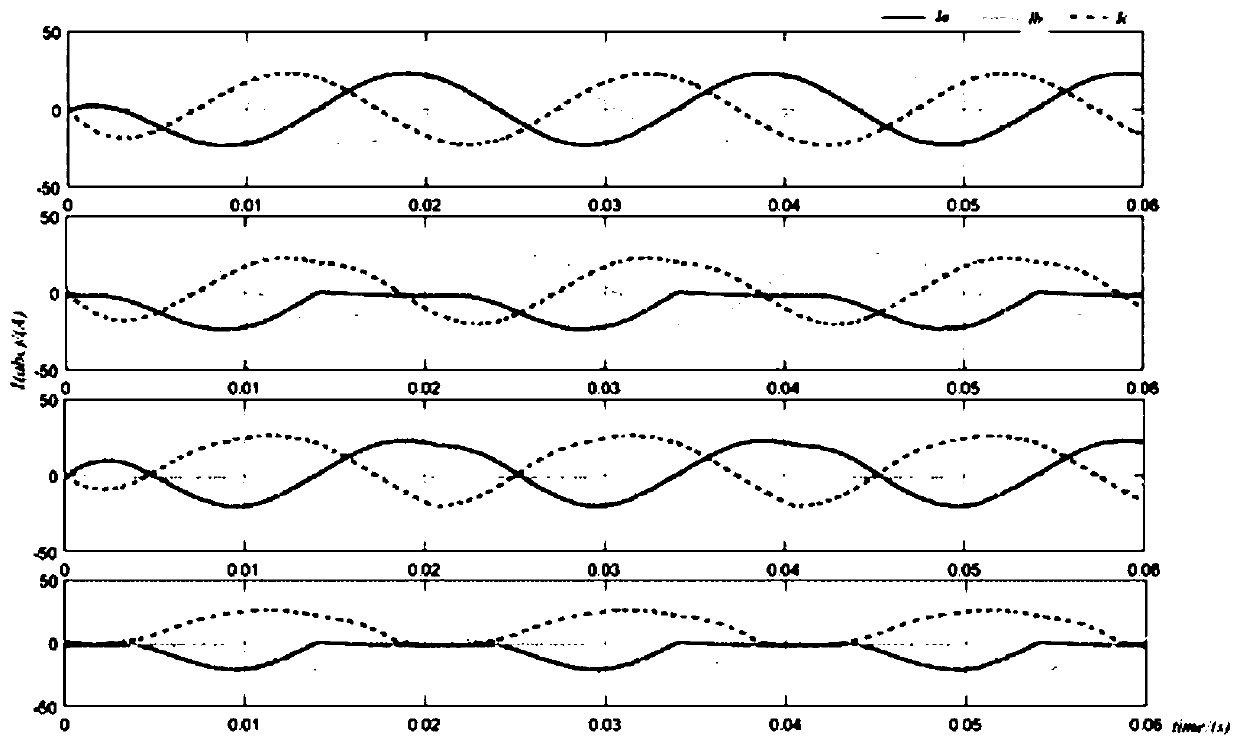

Microgrid inverter fault diagnosis method based on wavelet transformation and probabilistic neural network

PendingCN110084106AStrong ability to addEase of engineering integrationElectrical testingCharacter and pattern recognitionMulti resolution analysisMicrogrid

The invention provides a microgrid inverter fault diagnosis method based on wavelet transformation and a probabilistic neural network. The method comprises the steps that firstly, building a fault simulation system of the microgrid inverter on simulation software, then collecting three-phase load currents under different fault types to serve as measurement signals, and extracting fault characteristic signals of the three-phase load currents through a wavelet multi-resolution analysis method; carrying out normalization processing on the extracted fault feature signal to construct a feature vector; and finally, selecting a part of the extracted fault feature vectors as training data to train the PNN model, and when a genetic algorithm is adopted to find an optimal smoothing factor of the probabilistic neural network, and when the inverter has a fault, carrying out fault positioning on a current signal according to the method, thereby realizing fault diagnosis of the microgrid inverter. The method has the advantages that the structure model is simple, determination is easy, the convergence speed is high, a Bayes optimization solution is converged, the sample adding capacity is high, retraining is not needed, the precision is high, the practicability is high, and engineering combination is easy.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com