Industrial process multiresolution softsensoring instrument and method thereof

An industrial process and multi-resolution technology, which is applied in the direction of instruments, program control, and comprehensive factory control, etc., can solve problems such as not considering the multi-resolution characteristics of data, and not being able to obtain good soft measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

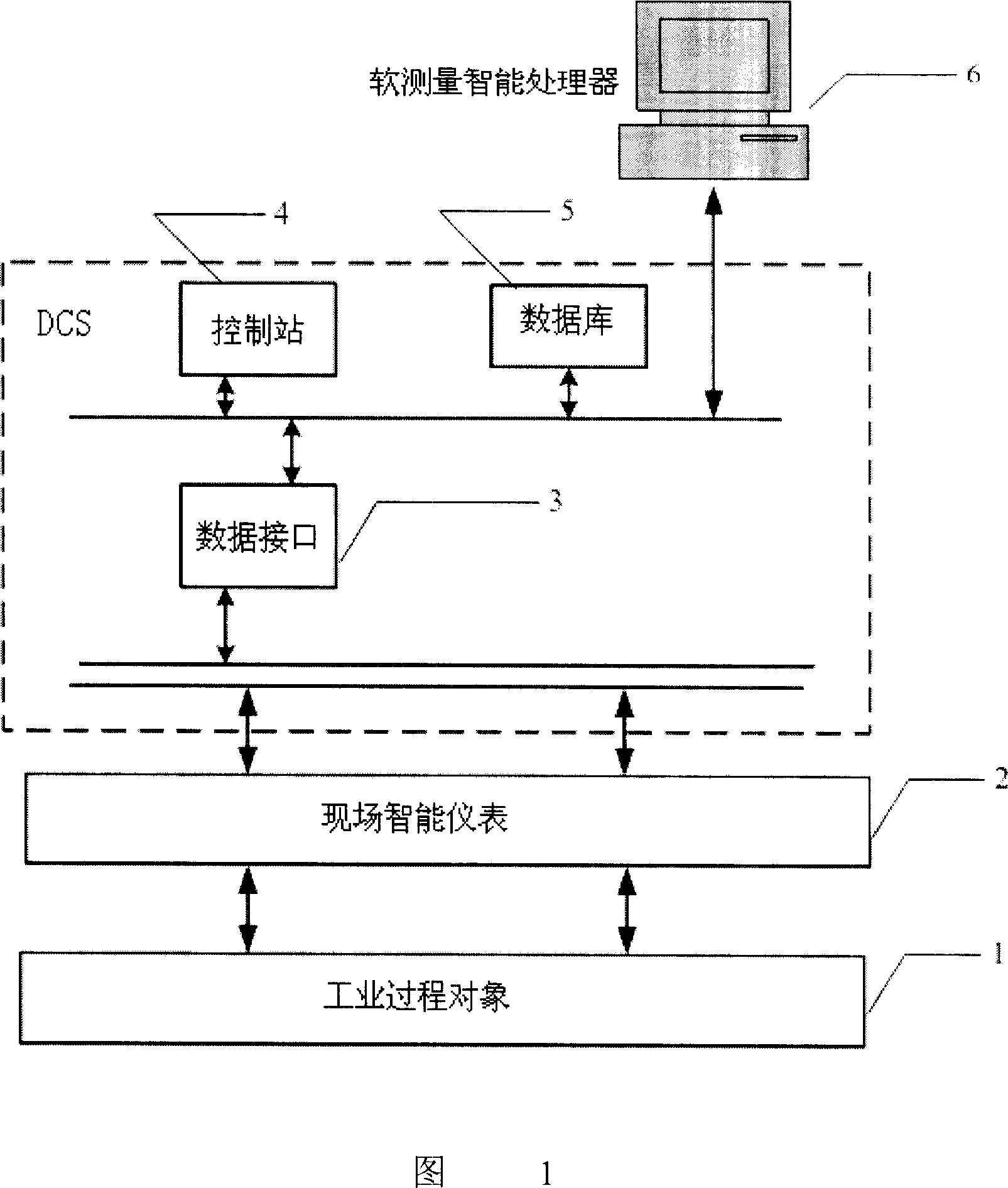

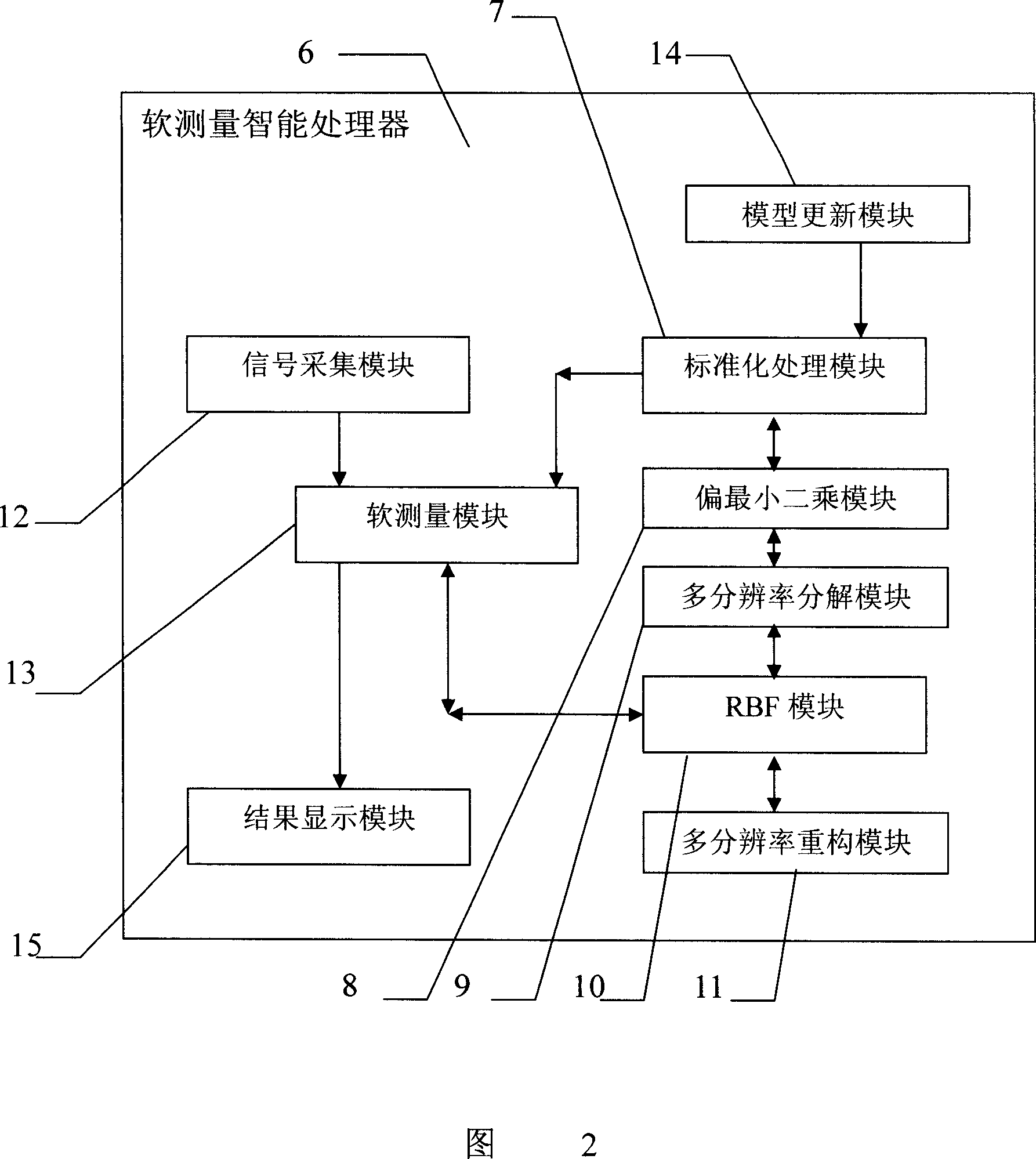

[0108] Referring to Fig. 1 and Fig. 2, an industrial process multi-resolution soft measuring instrument includes an on-site intelligent instrument 2 connected to an industrial process object 1, a data storage device 5 for storing historical data and a host computer 6, the intelligent instrument 1, Data storage device 5 and host computer 6 are connected successively, and described host computer 6 comprises:

[0109] The standardization processing module 7 is used to standardize the data collected in the database when the system is normal. The mean value of each variable is 0 and the variance is 1 to obtain the input matrix X. The following process is used to complete:

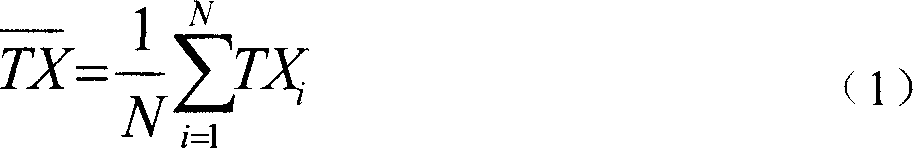

[0110] 1) Calculate the mean: TX ‾ = 1 N Σ i = 1 N TX i , - - - ...

Embodiment 2

[0208] Referring to Fig. 1 and Fig. 2, a soft sensing method realized by a multi-resolution soft sensing instrument in an industrial process, the soft sensing method includes the following steps:

[0209] (1), determine the used key variable of soft sensor, collect the data of described variable when system is normal from history database as training sample TX;

[0210] (2), the number of latent variables extracted by the partial least squares module, the number of decomposition layers of the multi-resolution decomposition module, the kernel parameter parameters of the radial basis function neural network modeling module are set, and the sampling period is set;

[0211] (3) In the soft sensor intelligent processor, the training sample TX standardizes the data so that the mean value of each variable is 0 and the variance is 1, and the input matrix X is obtained. The following process is used to complete, and the formula is (1) , (2), (3):

[0212] 3.1) Calculate the mean: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com