Ultrasonic method and device for testing macroscopic cleanness of continuous casting billet

A technology of detection device and detection method, which is applied to measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. It can solve problems such as detection of material conditions, so as to achieve the effect of rapid non-destructive testing, improve signal-to-noise ratio, and reduce interference on sample surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

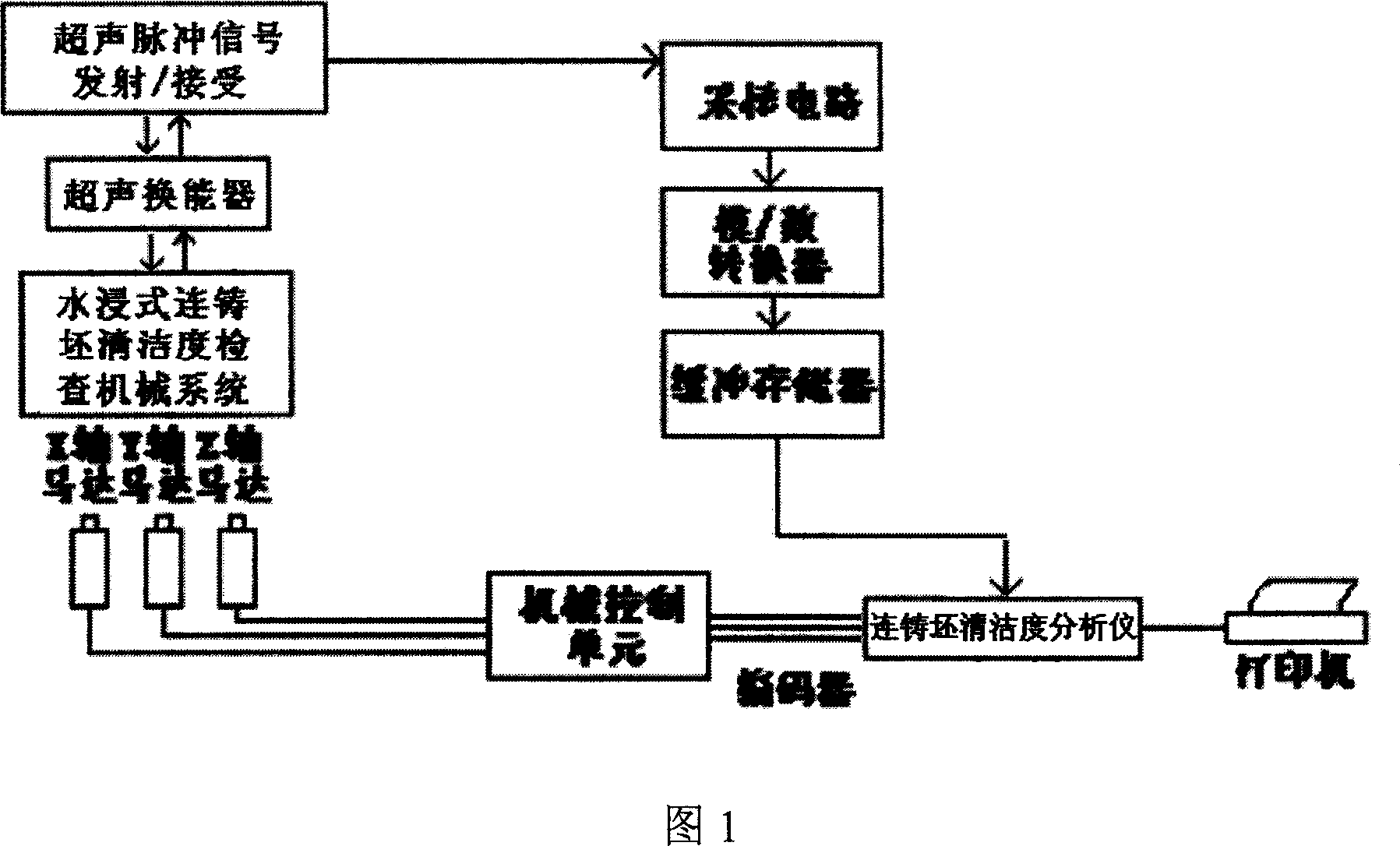

[0048] Referring to Figure 1, the composition of the ultrasonic testing system for macroscopic cleanliness of continuous casting slabs includes a water-immersed continuous casting slab cleanliness testing device with a high-frequency focused ultrasonic probe, a pulsed ultrasonic signal transmitter / receiver processor, a data acquisition card, a Slab macro cleanliness analyzer.

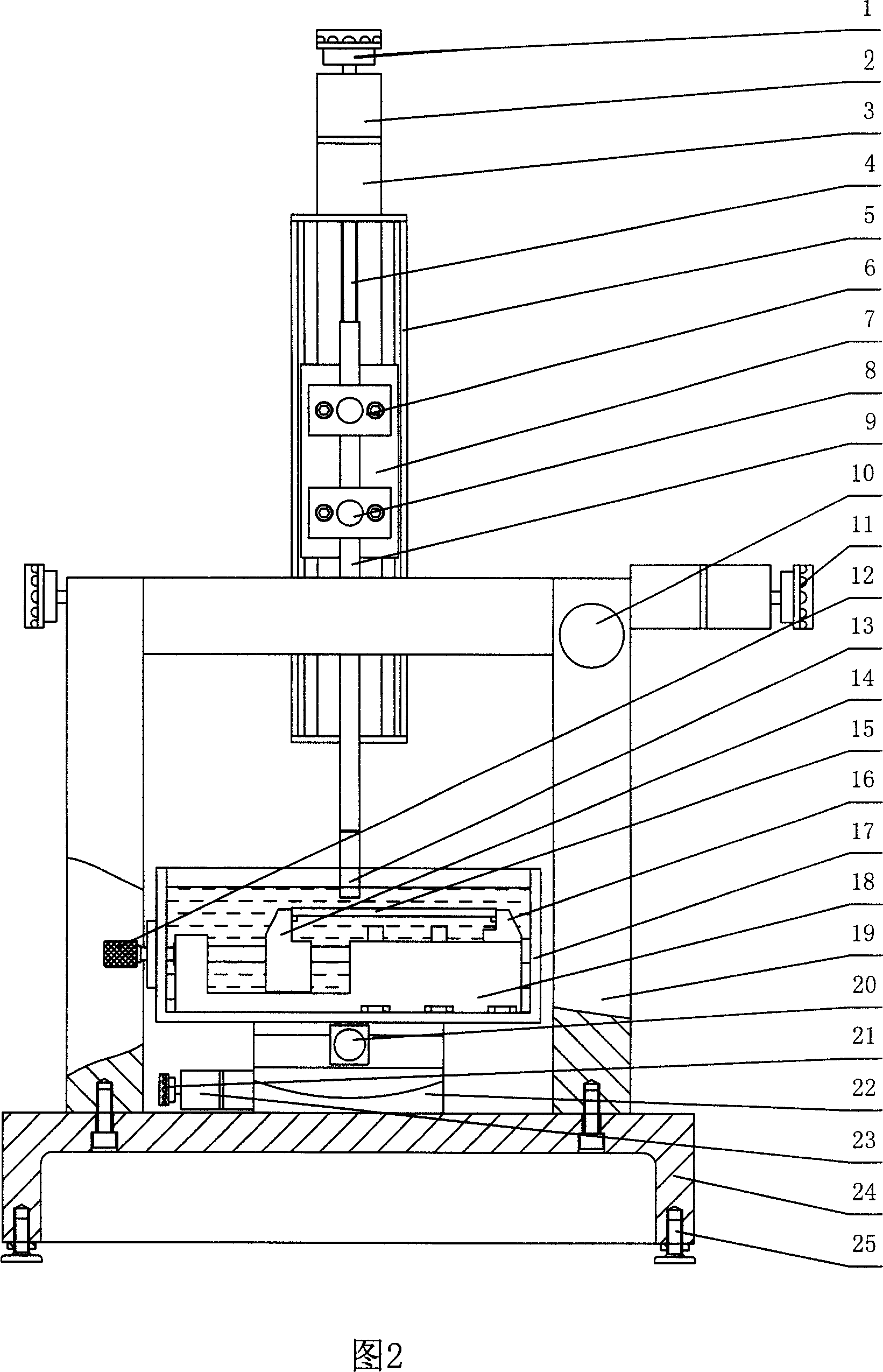

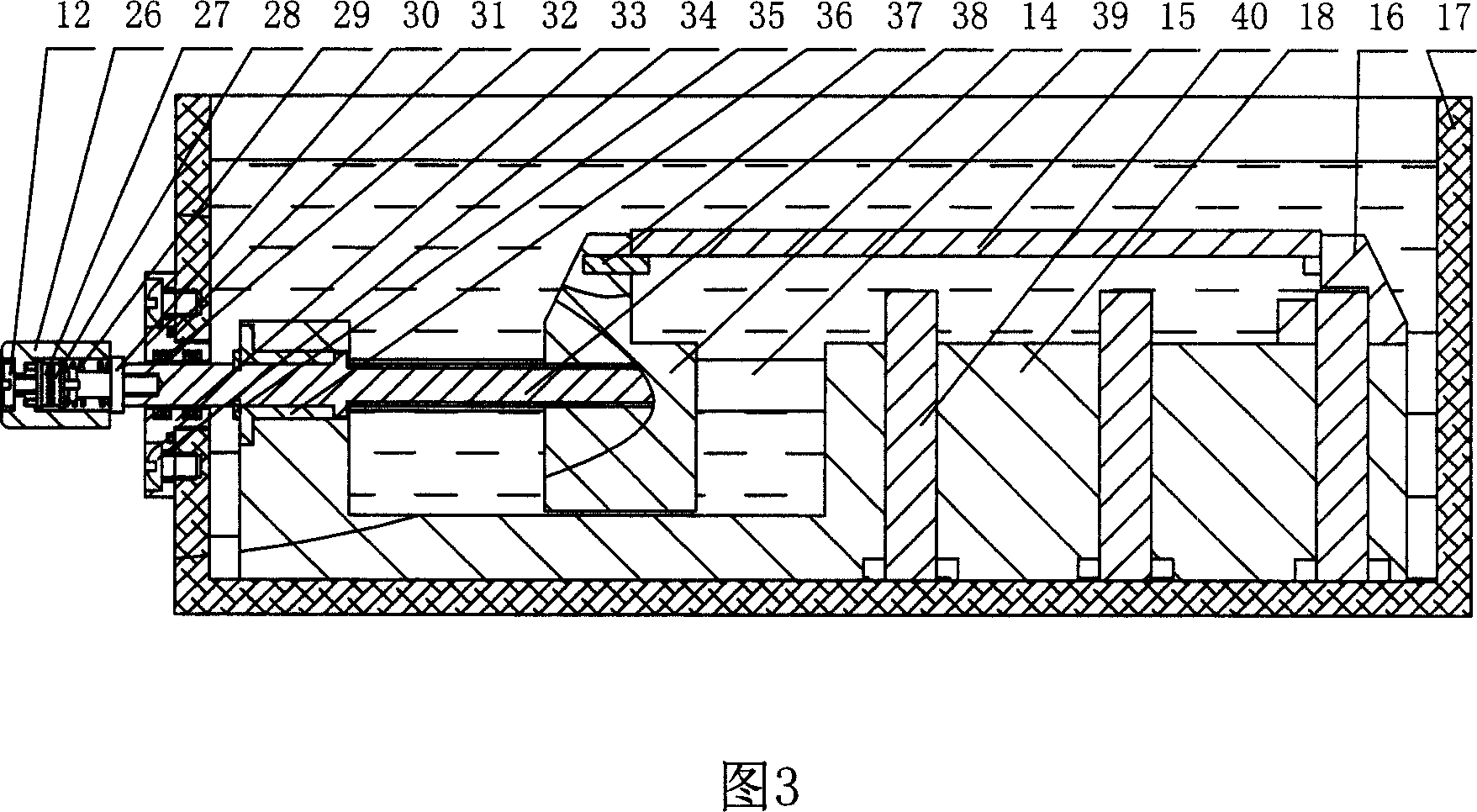

[0049] Referring to Fig. 2 and Fig. 3 again, the ultrasonic testing device for the macroscopic cleanliness of continuous casting slabs of the present invention includes a base 24, the bottom of which is provided with a horizontal adjustment screw 25; a fixed frame 19, located on the base 24, includes an upper beam 191 , the fixed bracket 192; the two-dimensional arc pendulum table 22, which is arranged on the base 24, in the fixed frame 19, the θ of the two-dimensional arc pendulum table 22 X and one end in the θY direction are installed with stepper motors 20 and 21 with adjustment knobs; a water tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com