Patents

Literature

54results about How to "Consistent clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

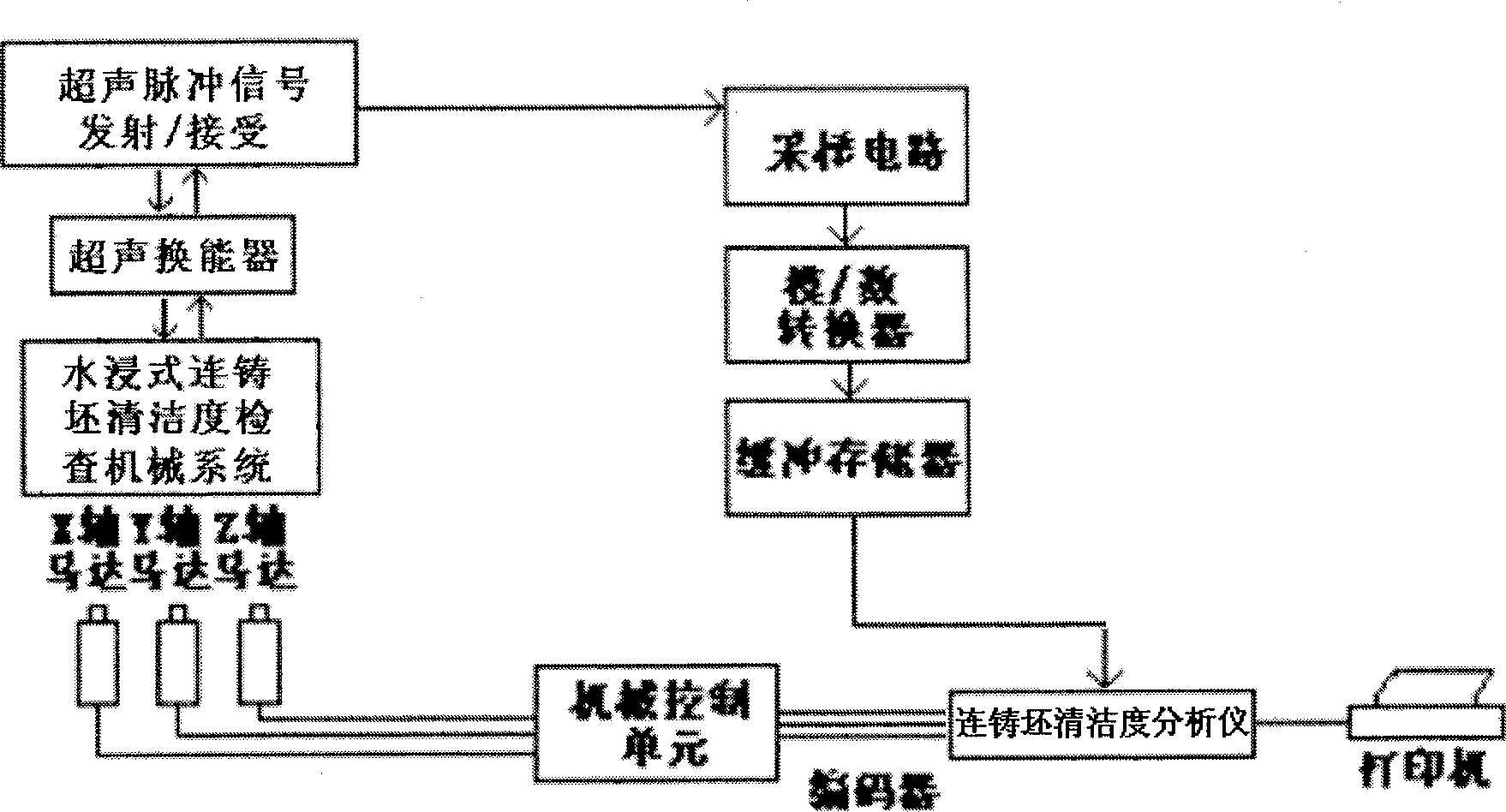

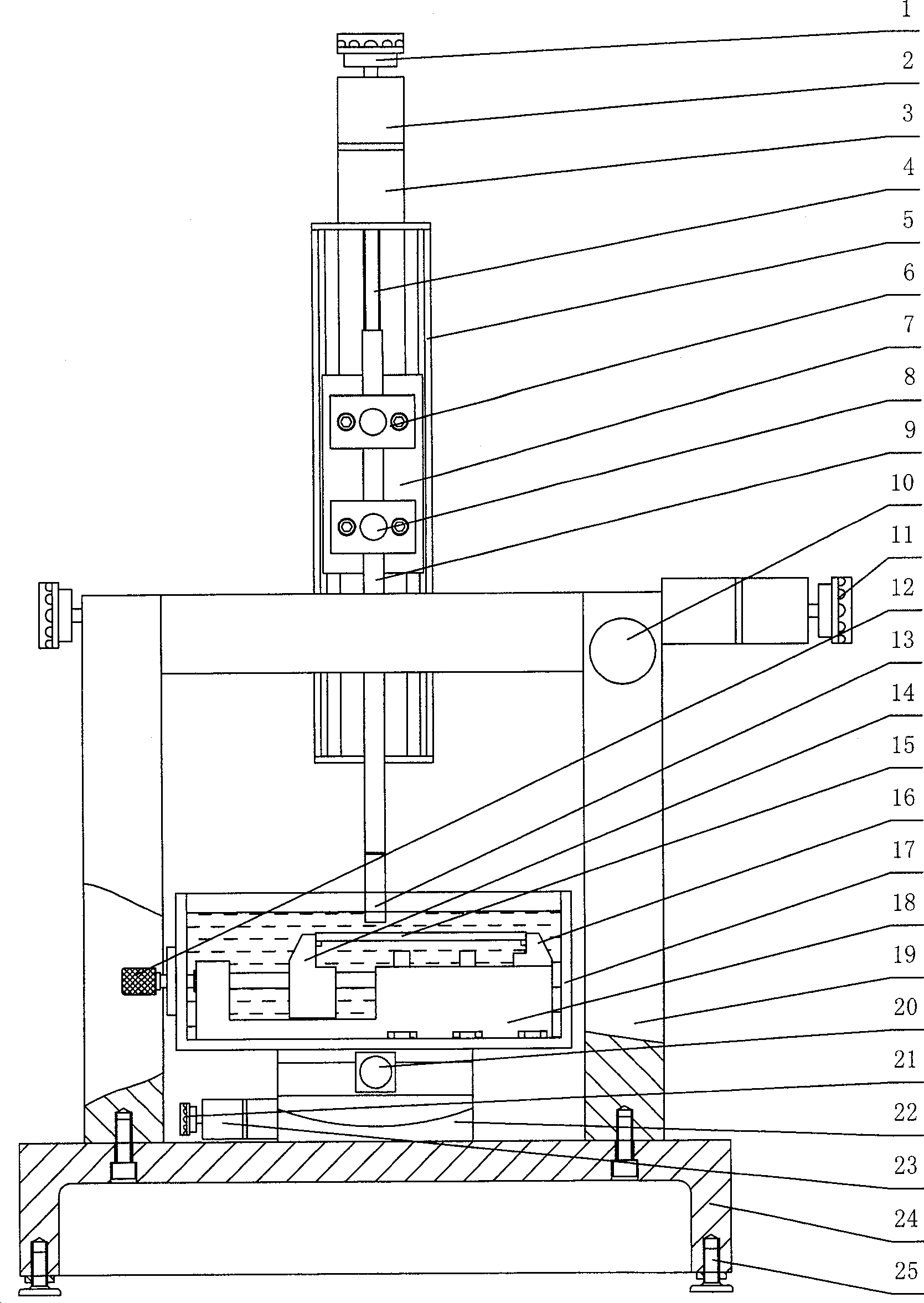

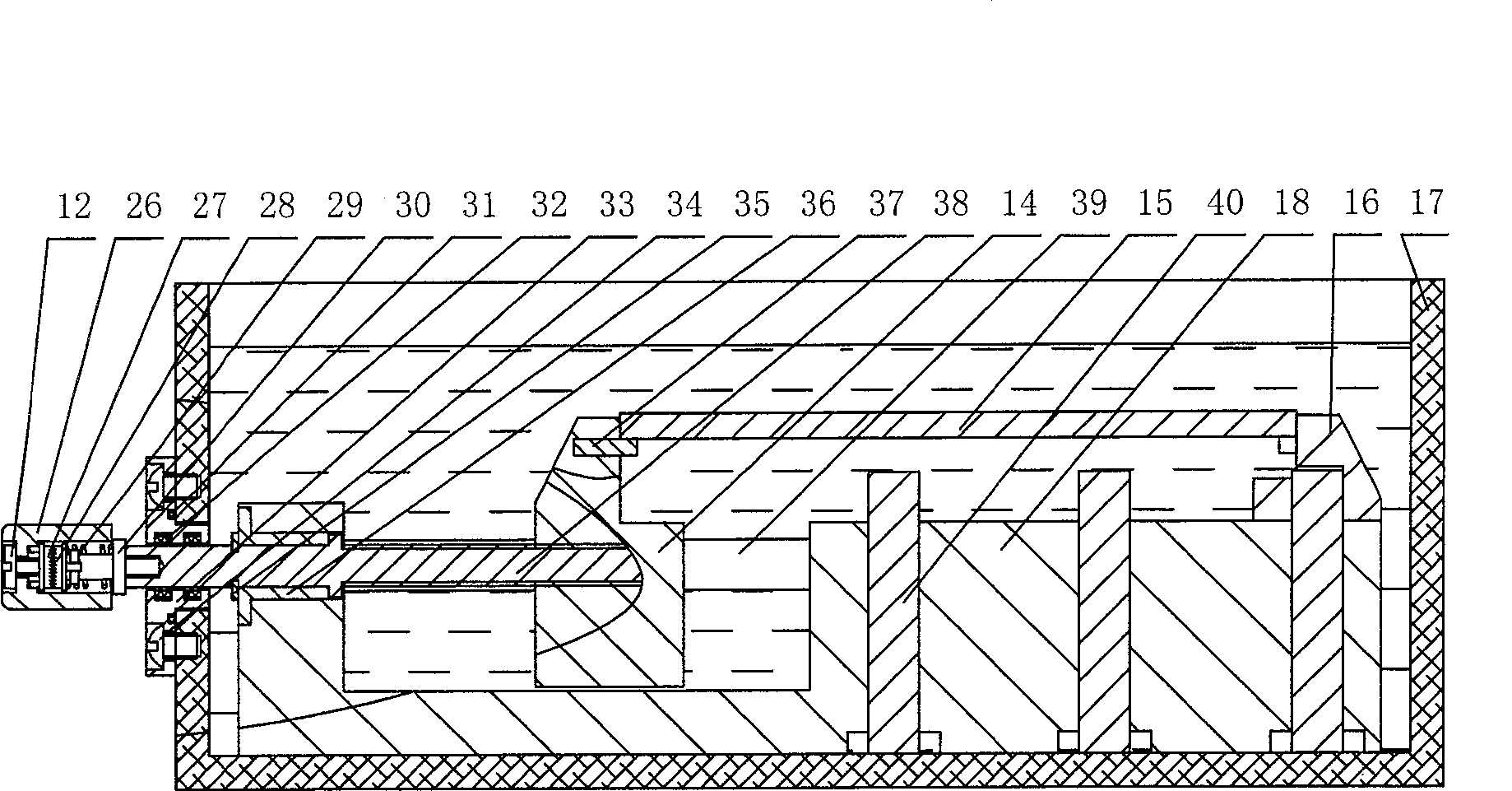

Ultrasonic method and device for testing macroscopic cleanness of continuous casting billet

ActiveCN1959404ANo low-speed crawling phenomenonHigh movement precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationSlag

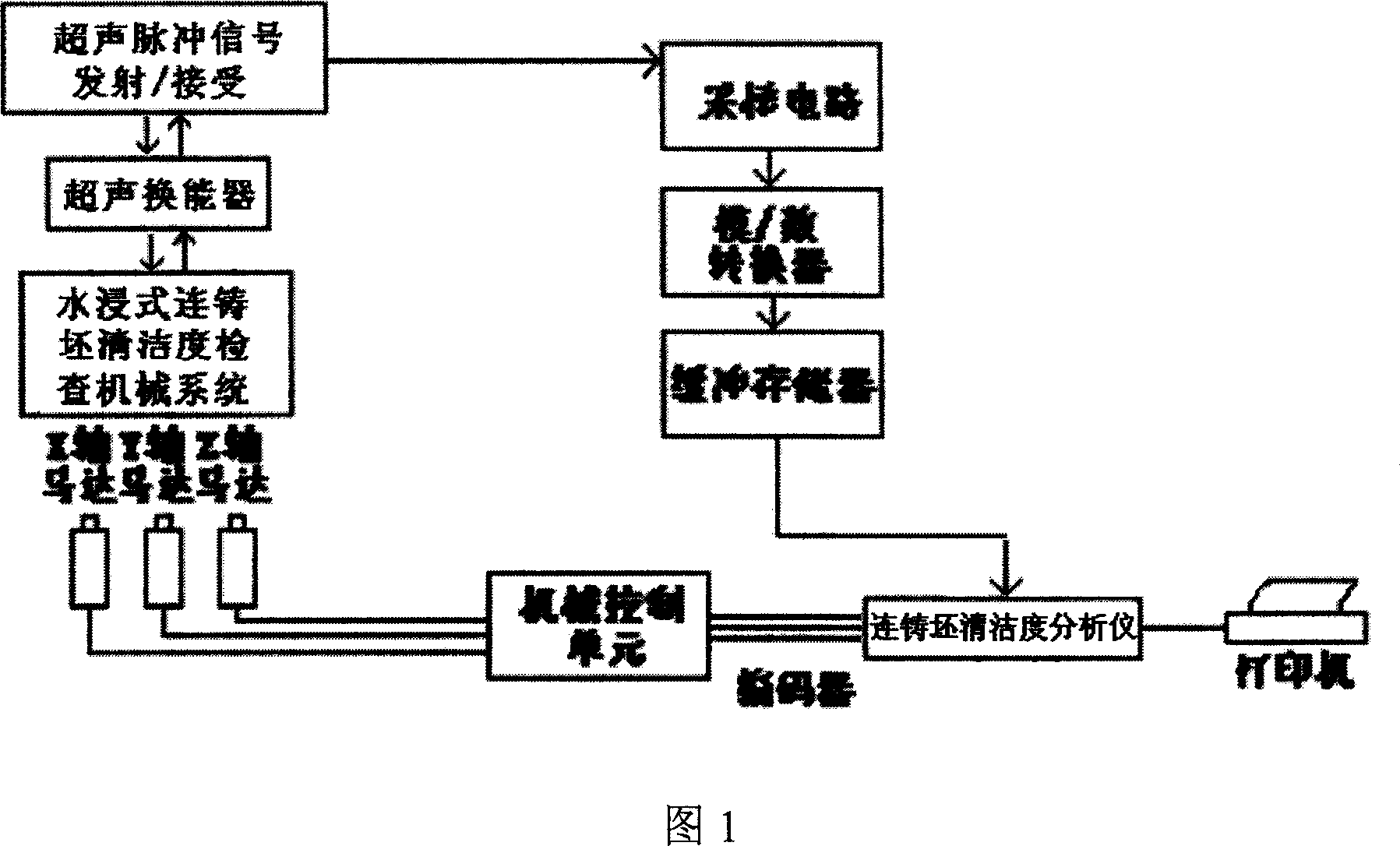

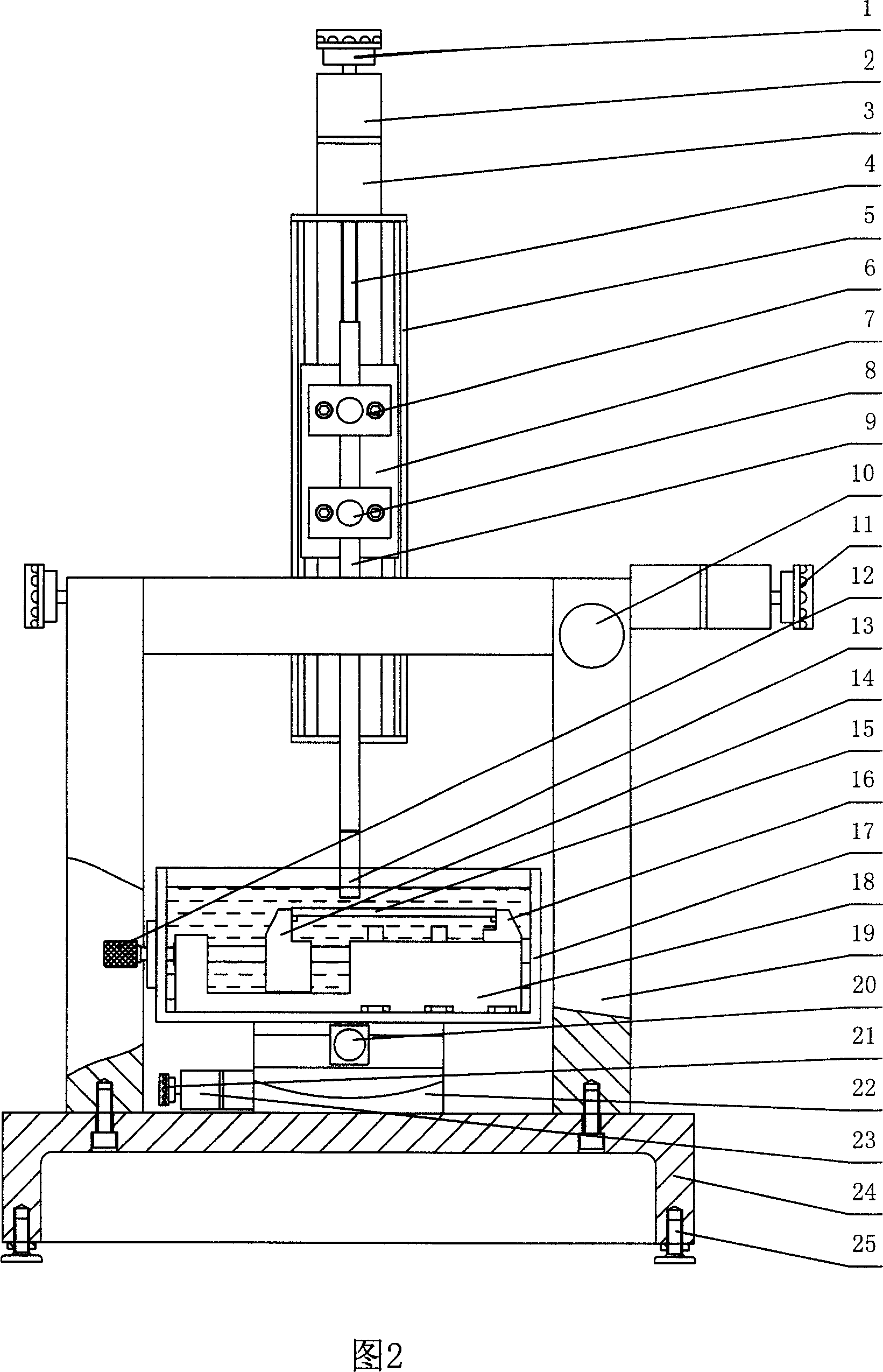

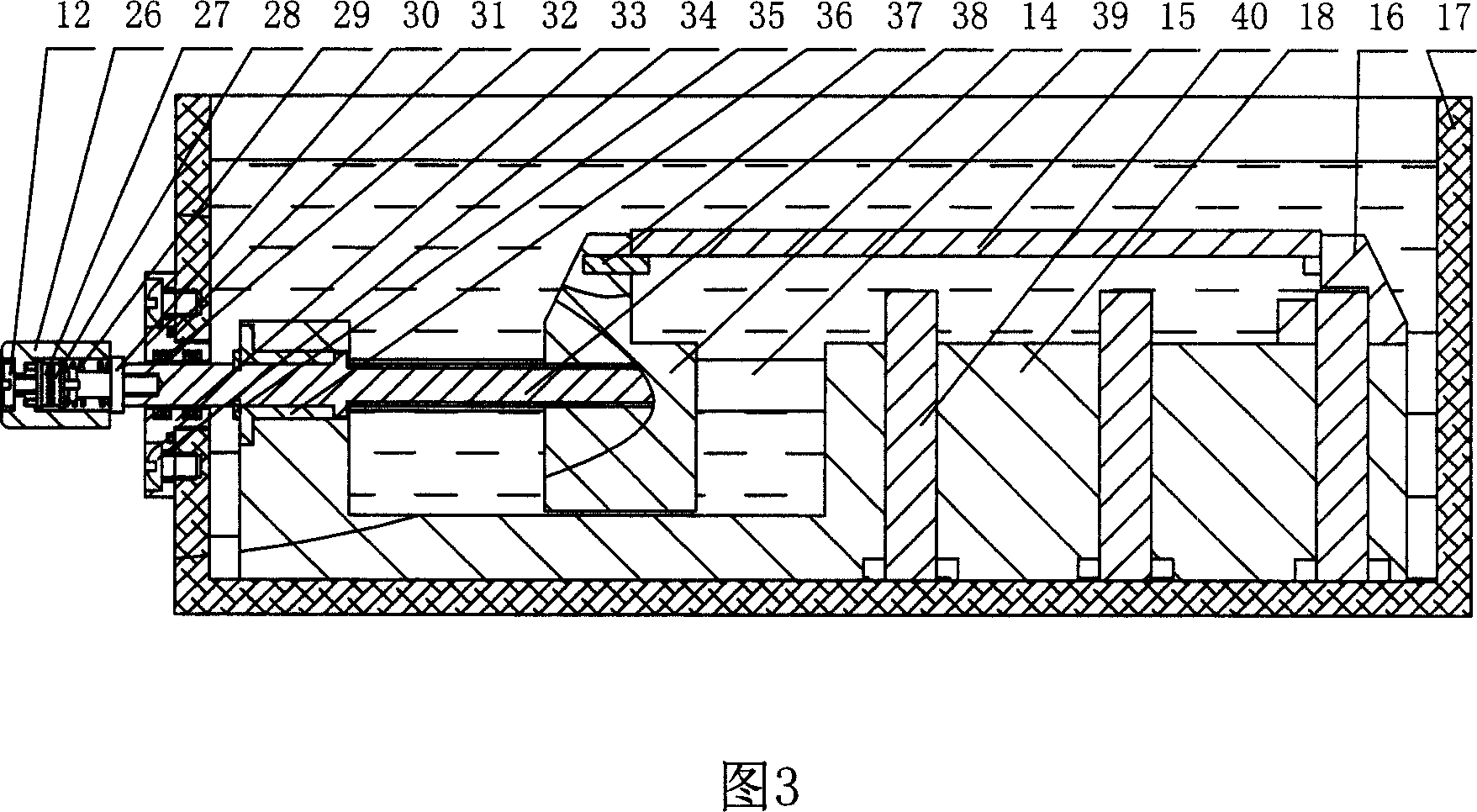

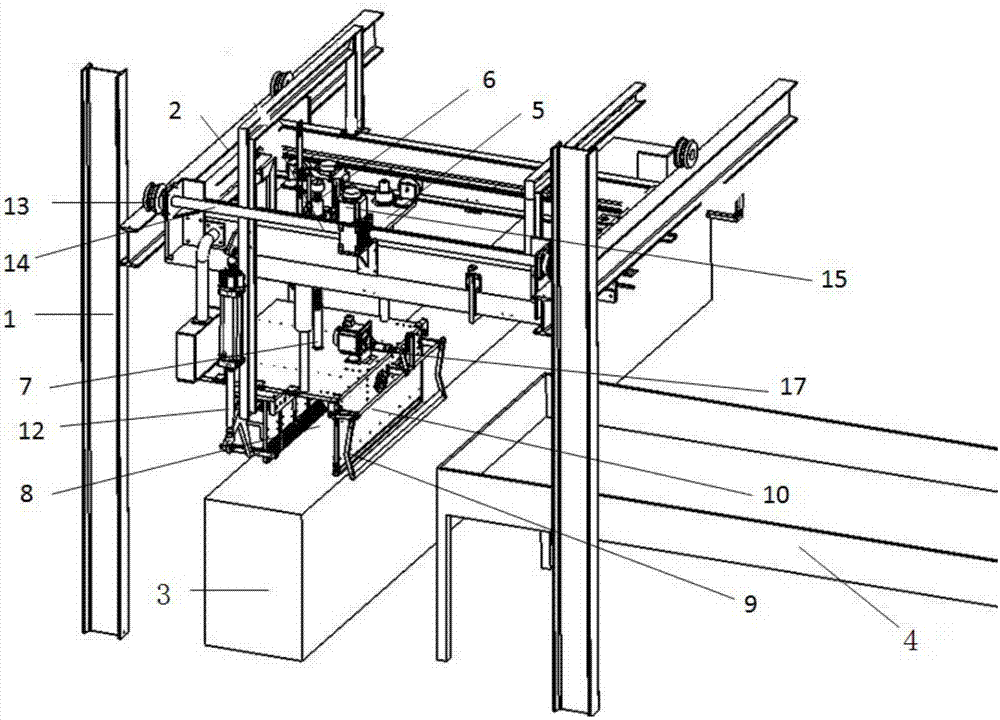

A ultrasonic detection method of macrocleanness on continuous casting billet includes using multiple resolution analysis means to carry out analysis on original ultrasonic echo signal series at different frequency scope and carrying out treatment on analysis said echo signal with reasonable time frequency analysis, reconfigurating treated signal to generate signal with the same length as said echo signal series, comparing treated signal with defect judgment standard used at production unit to form planar distribution drawing of slag as per sample surface distribution.

Owner:BAOSHAN IRON & STEEL CO LTD +1

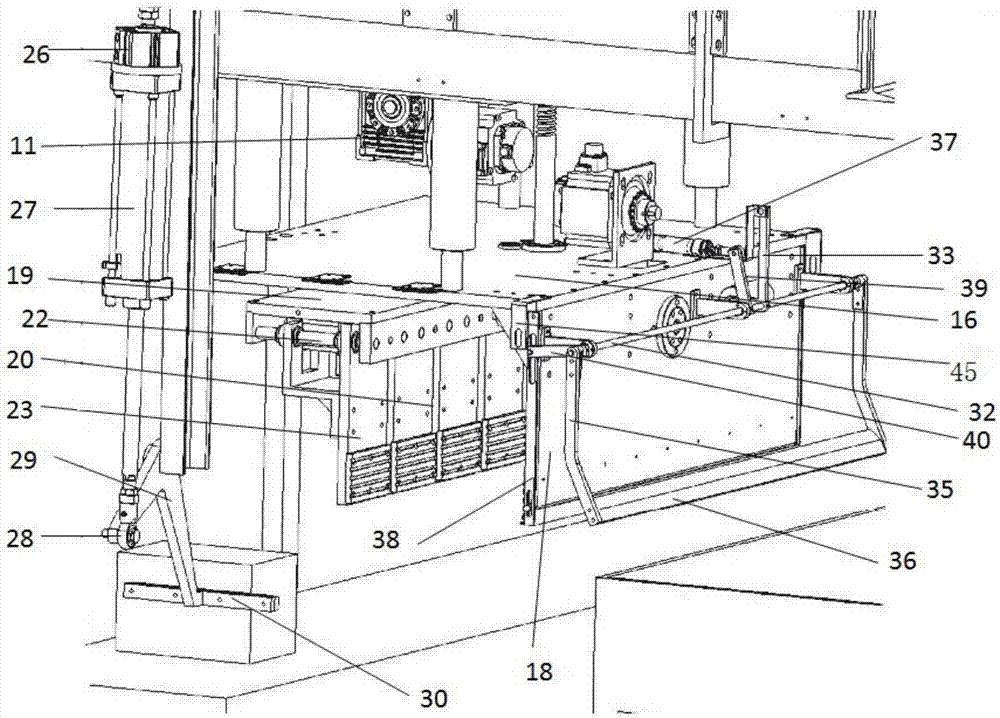

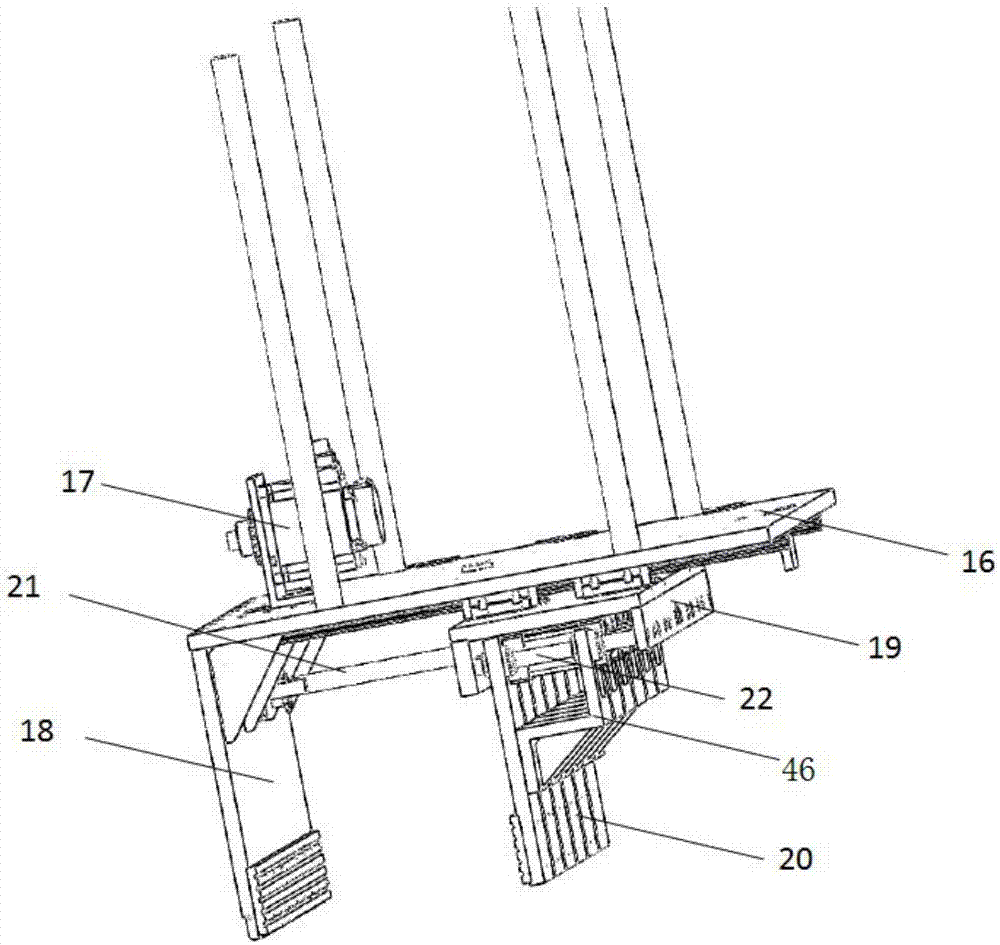

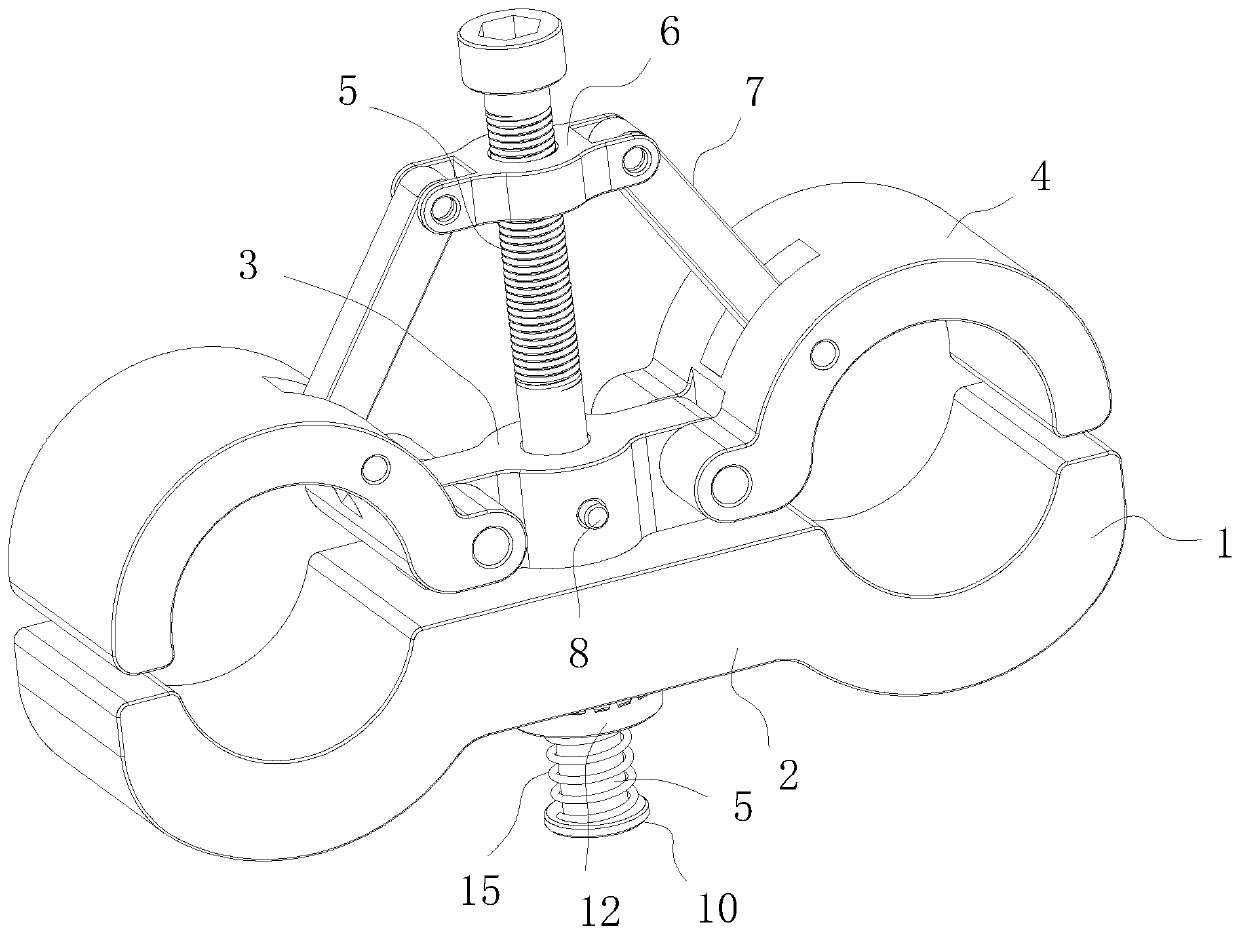

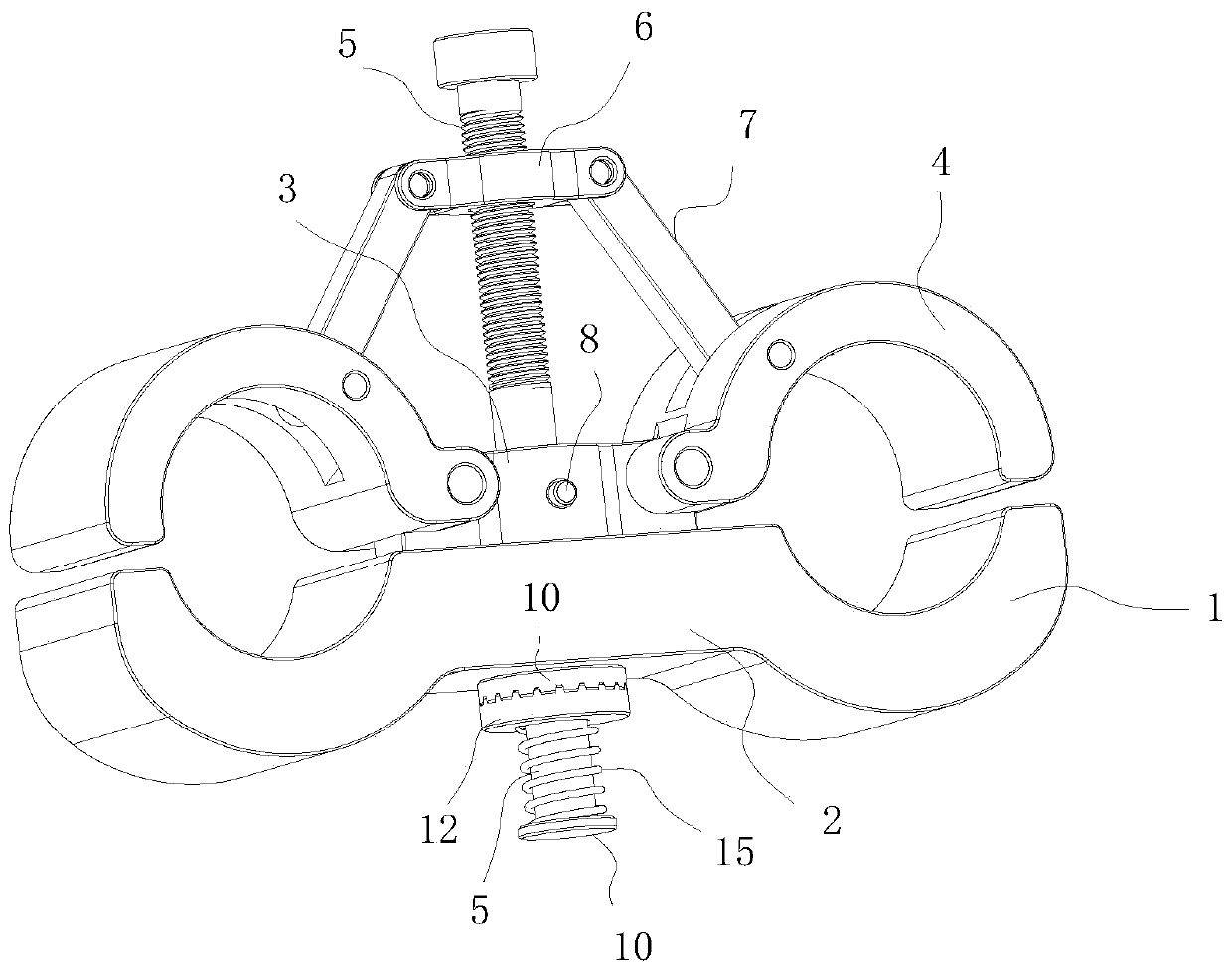

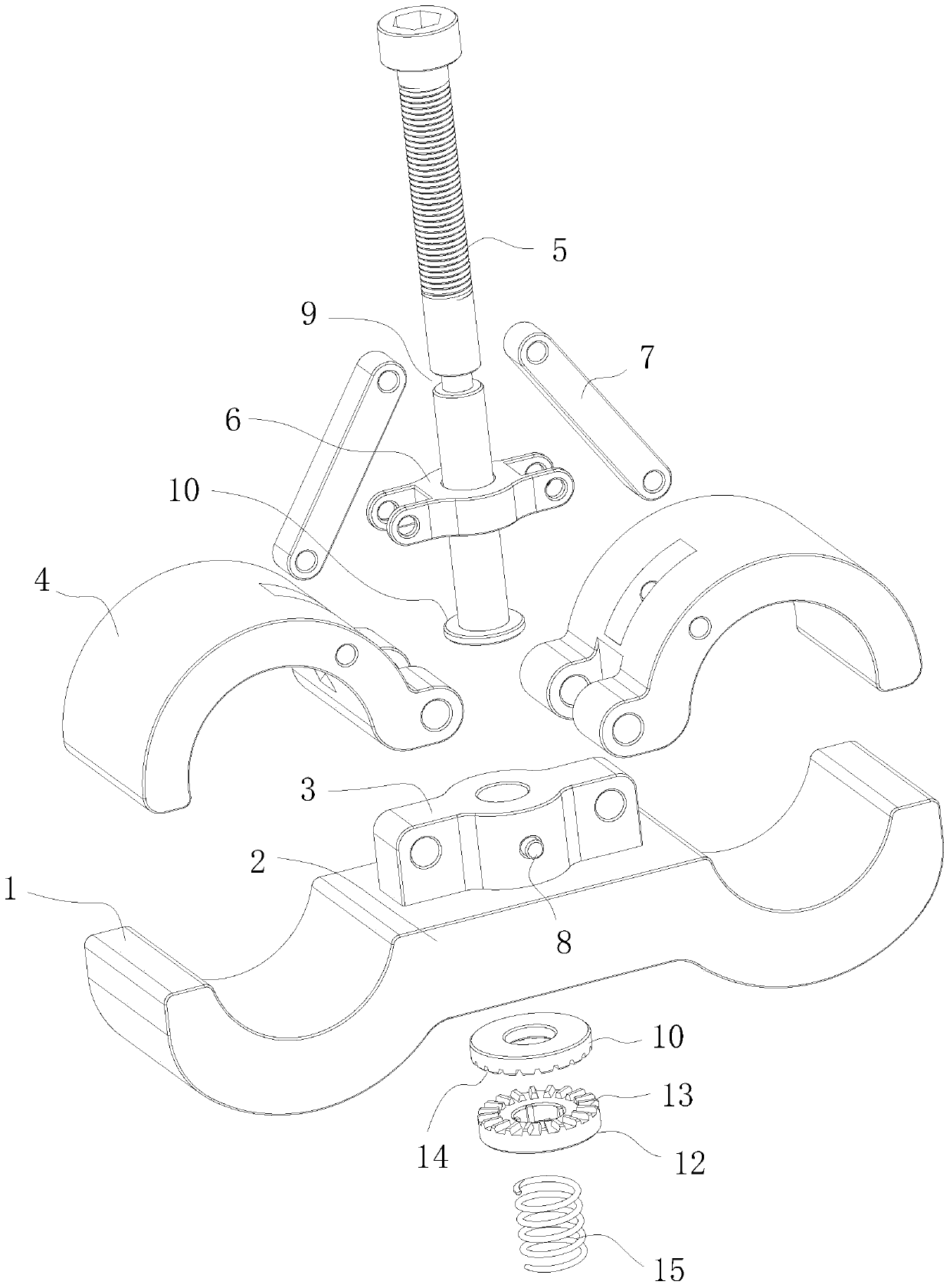

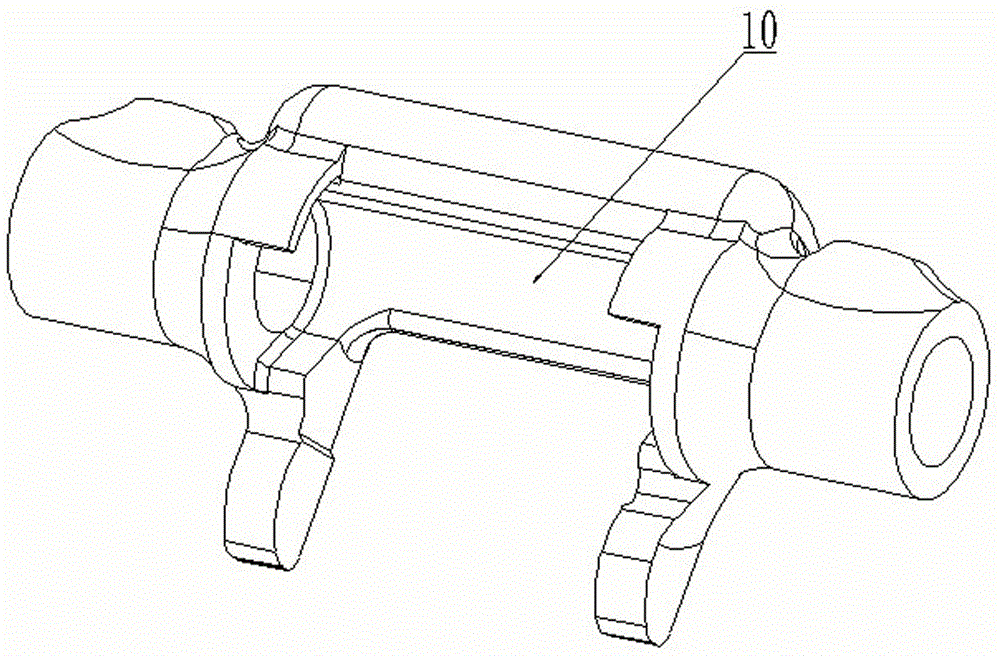

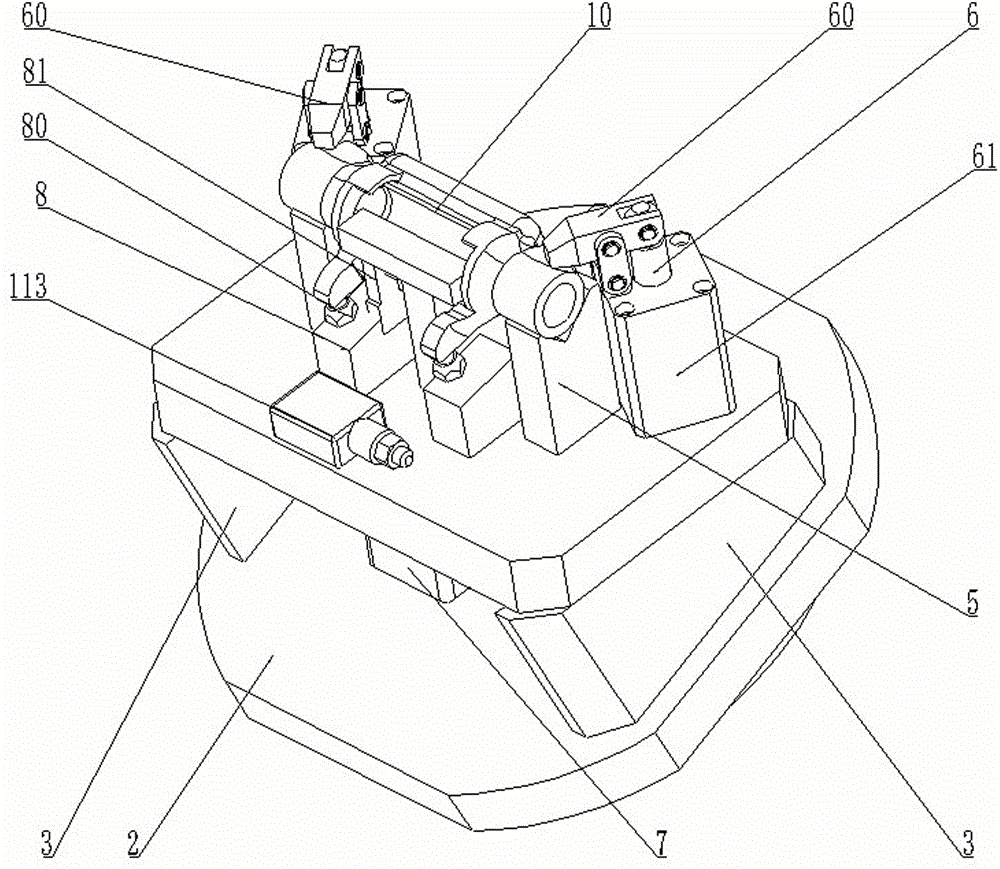

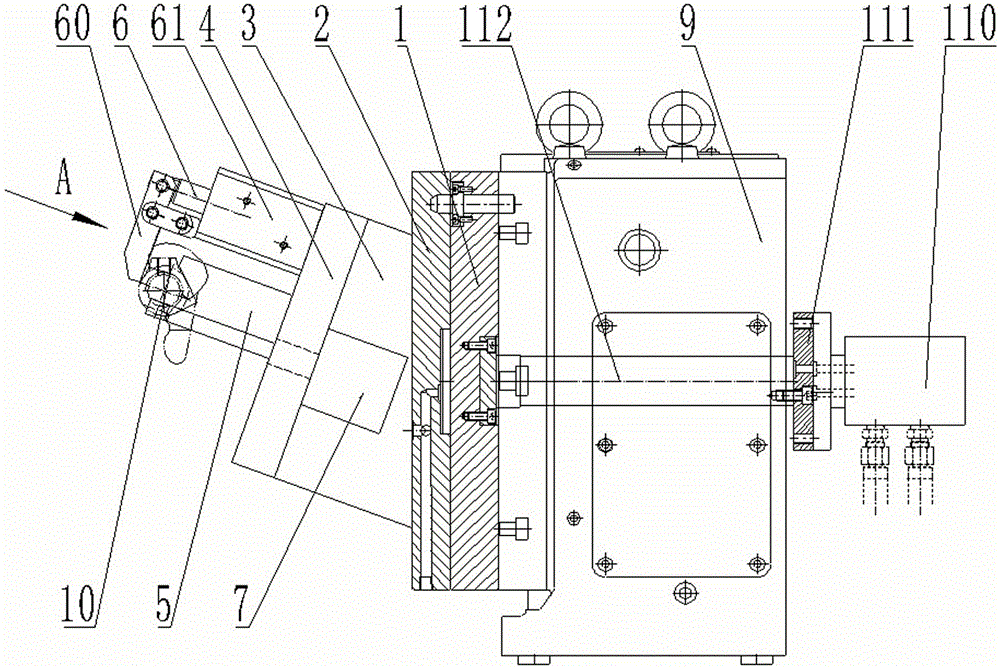

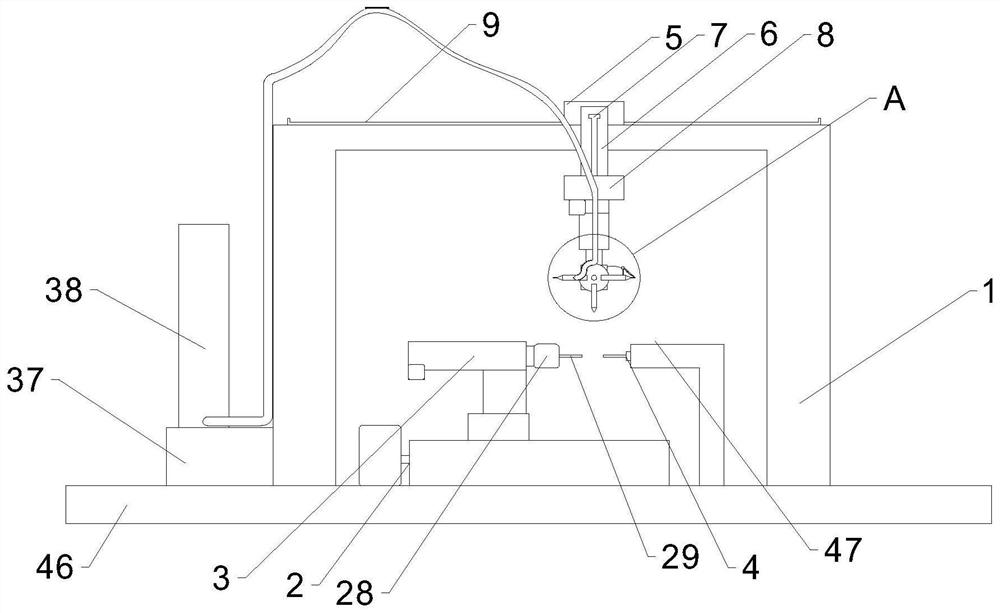

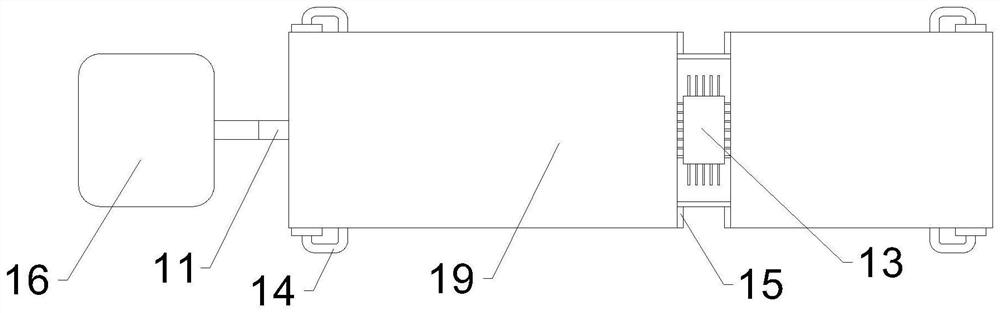

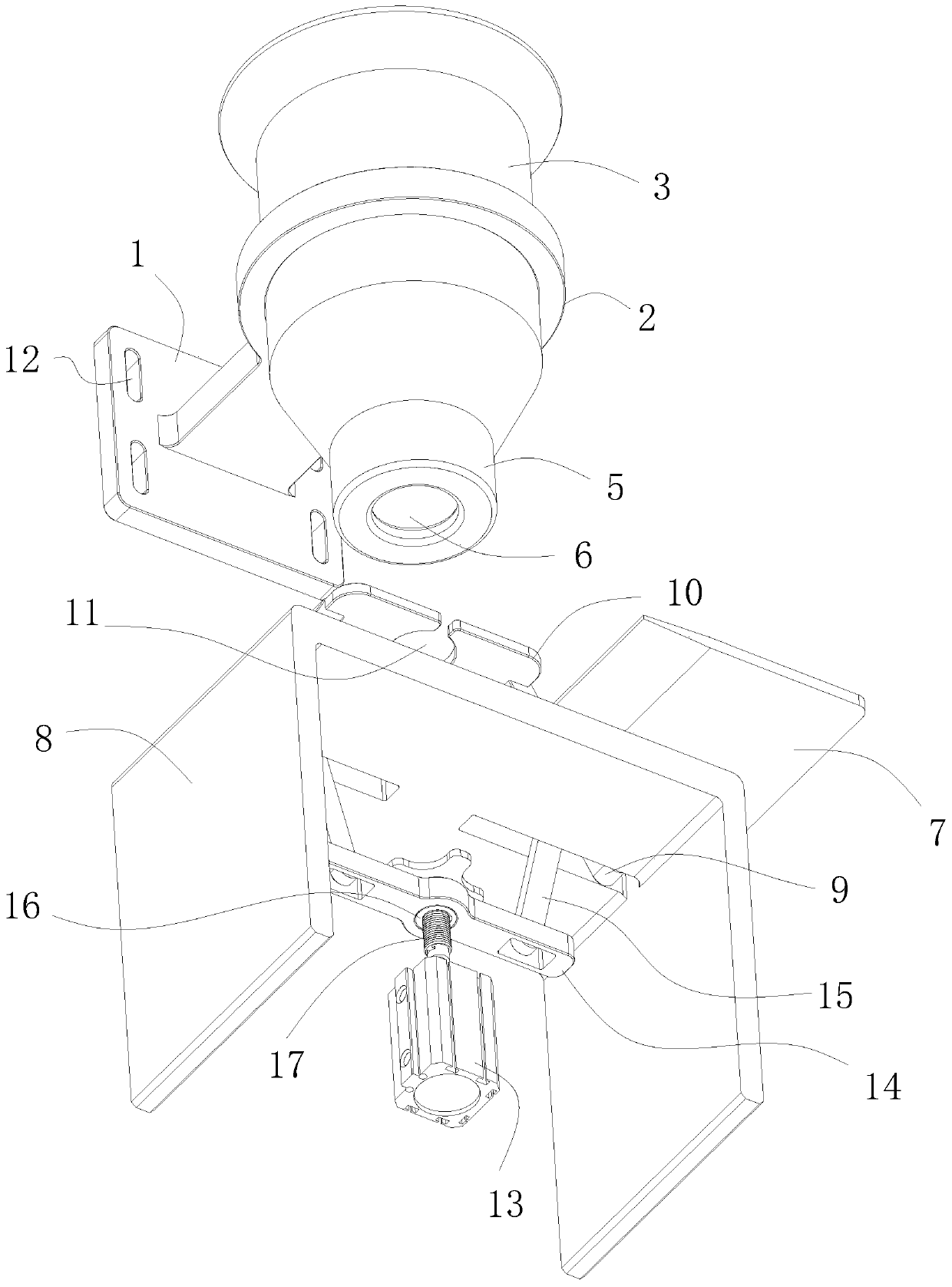

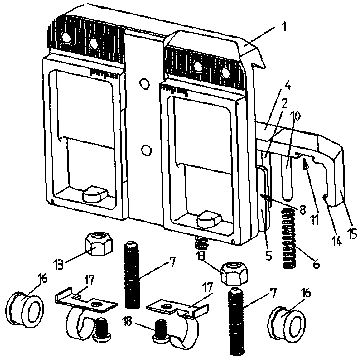

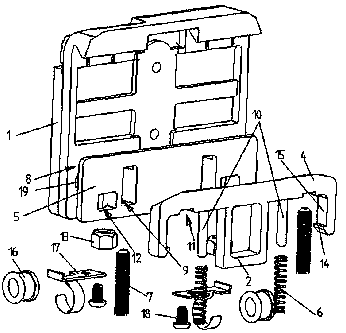

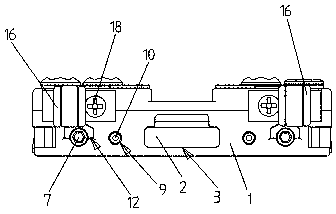

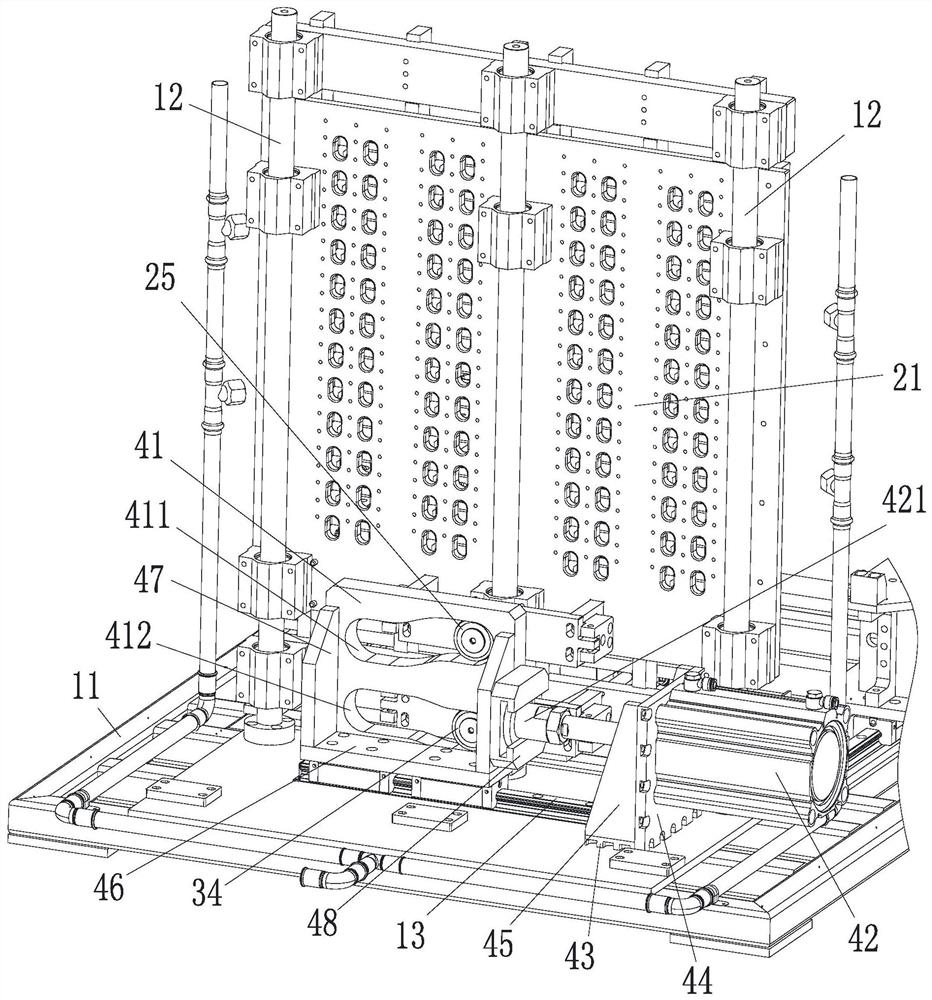

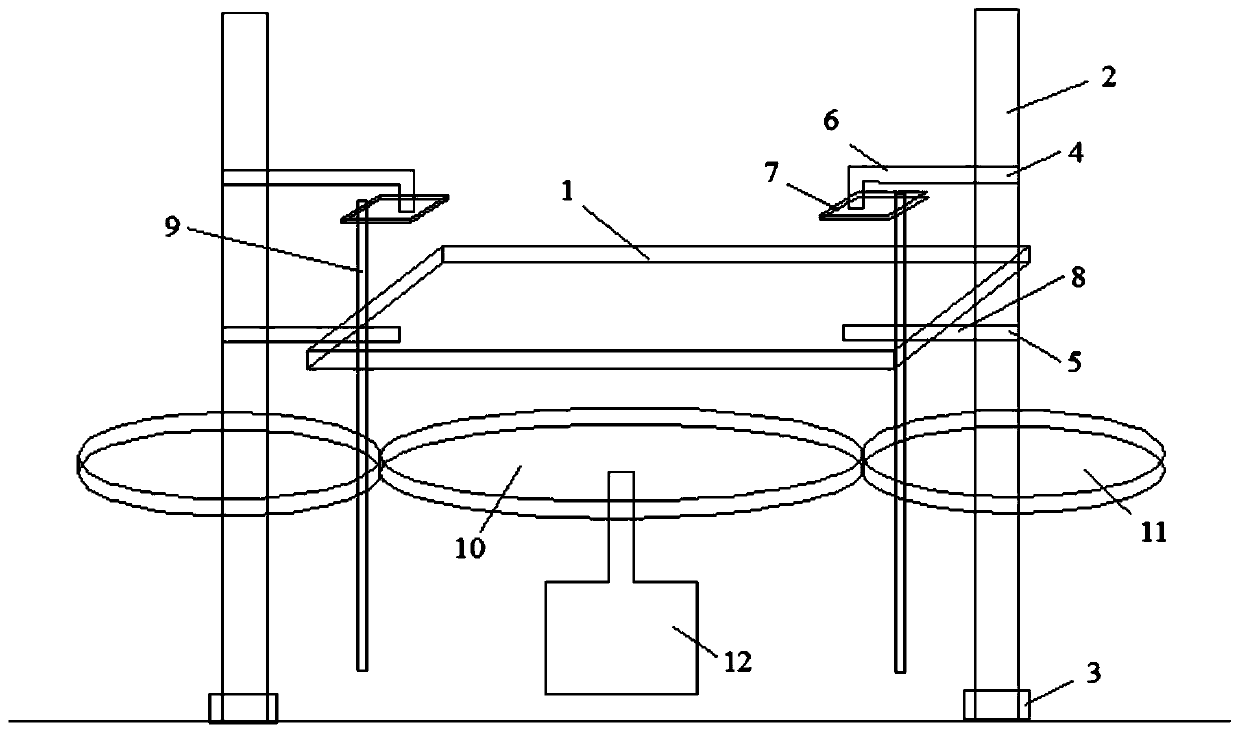

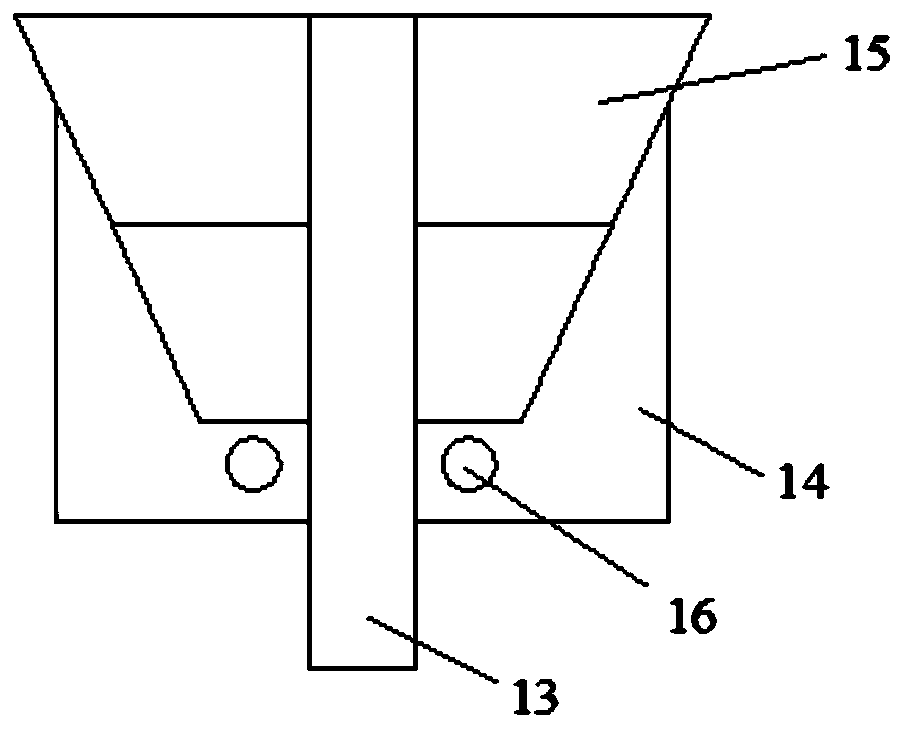

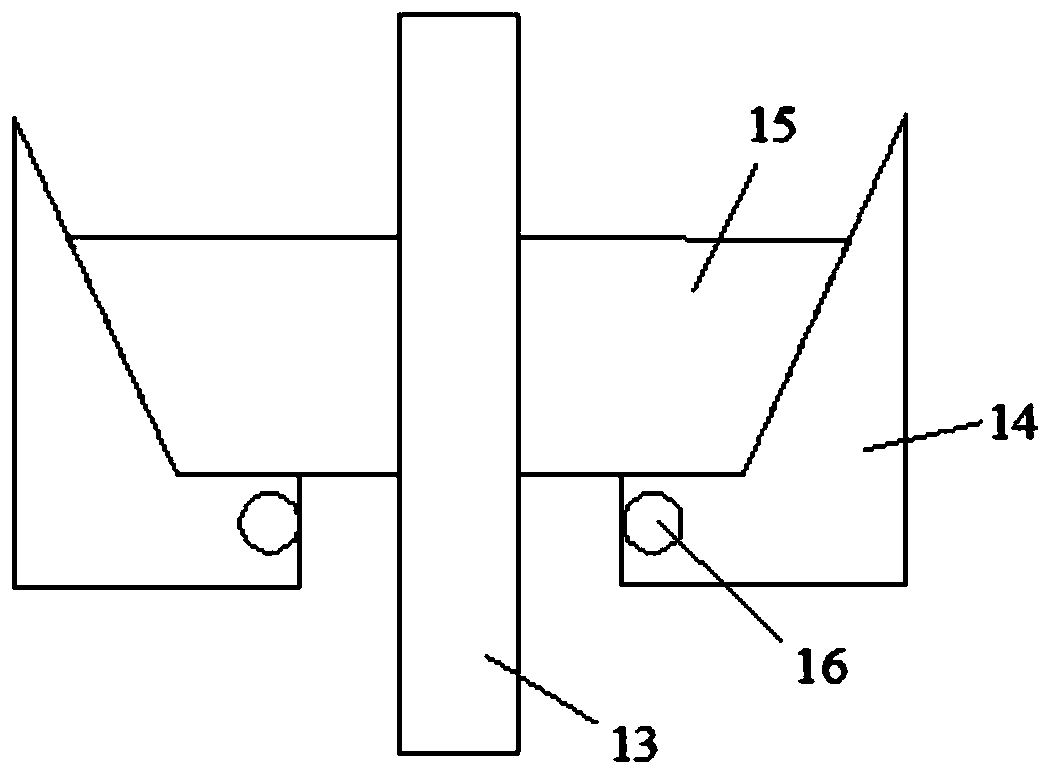

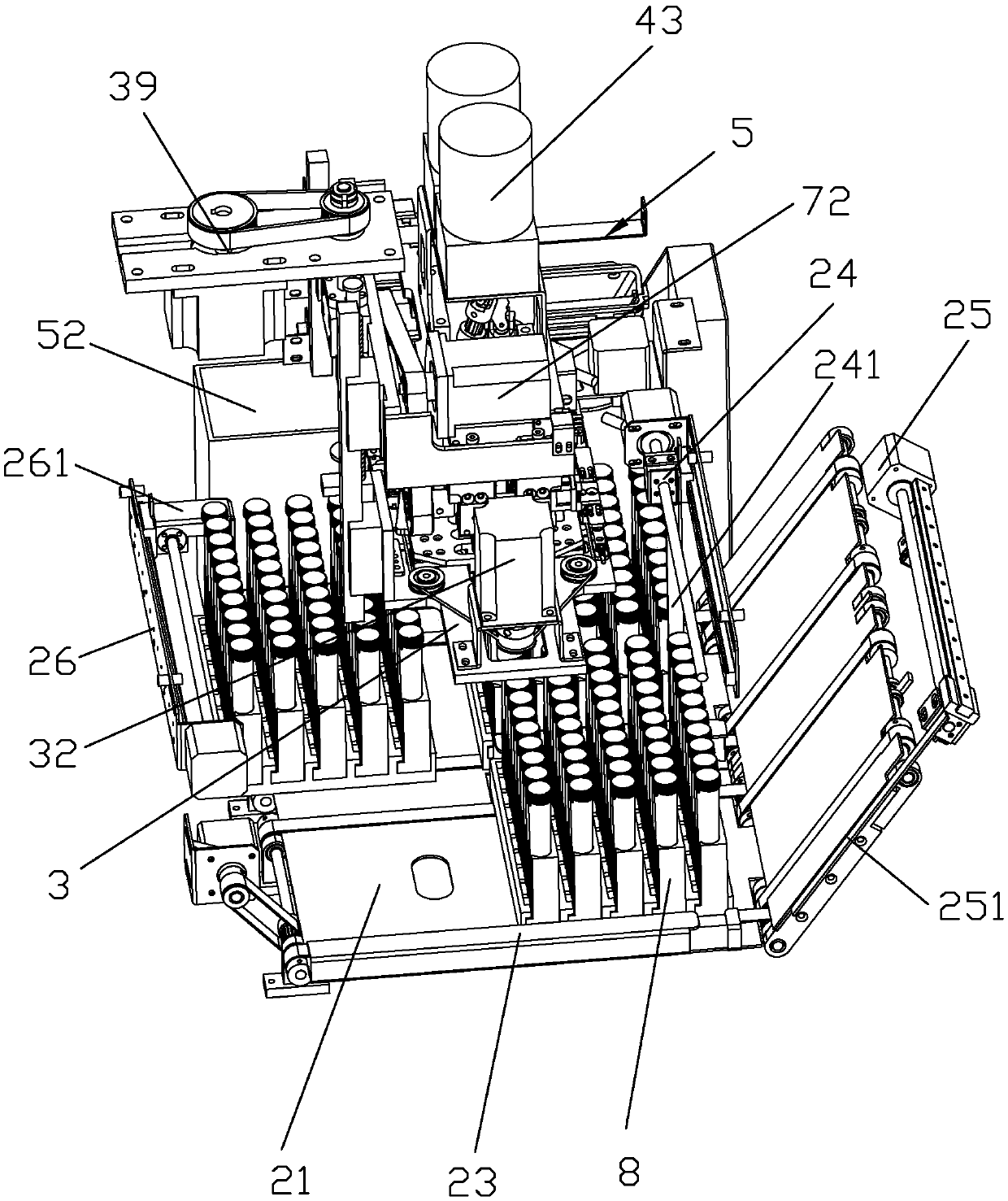

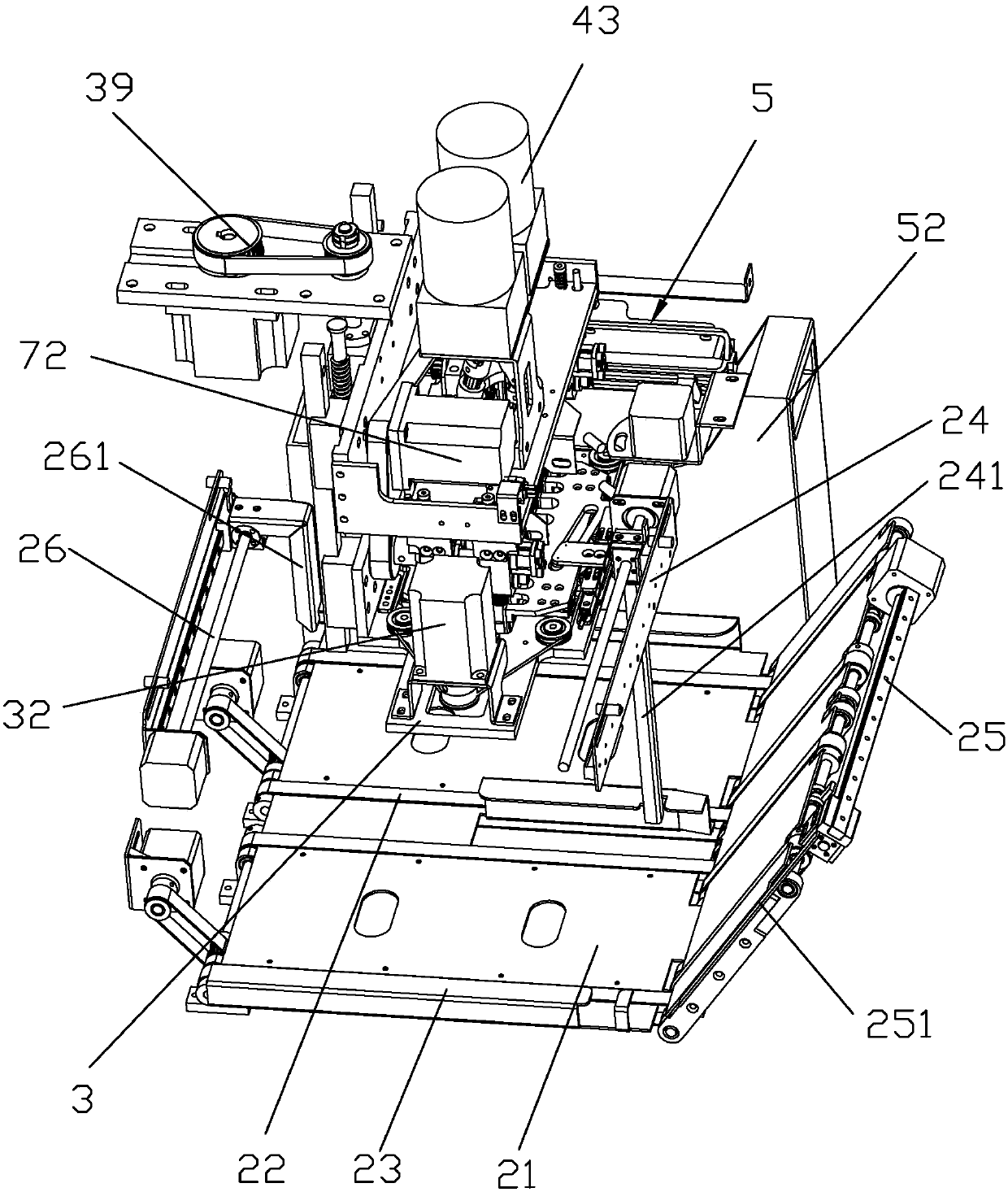

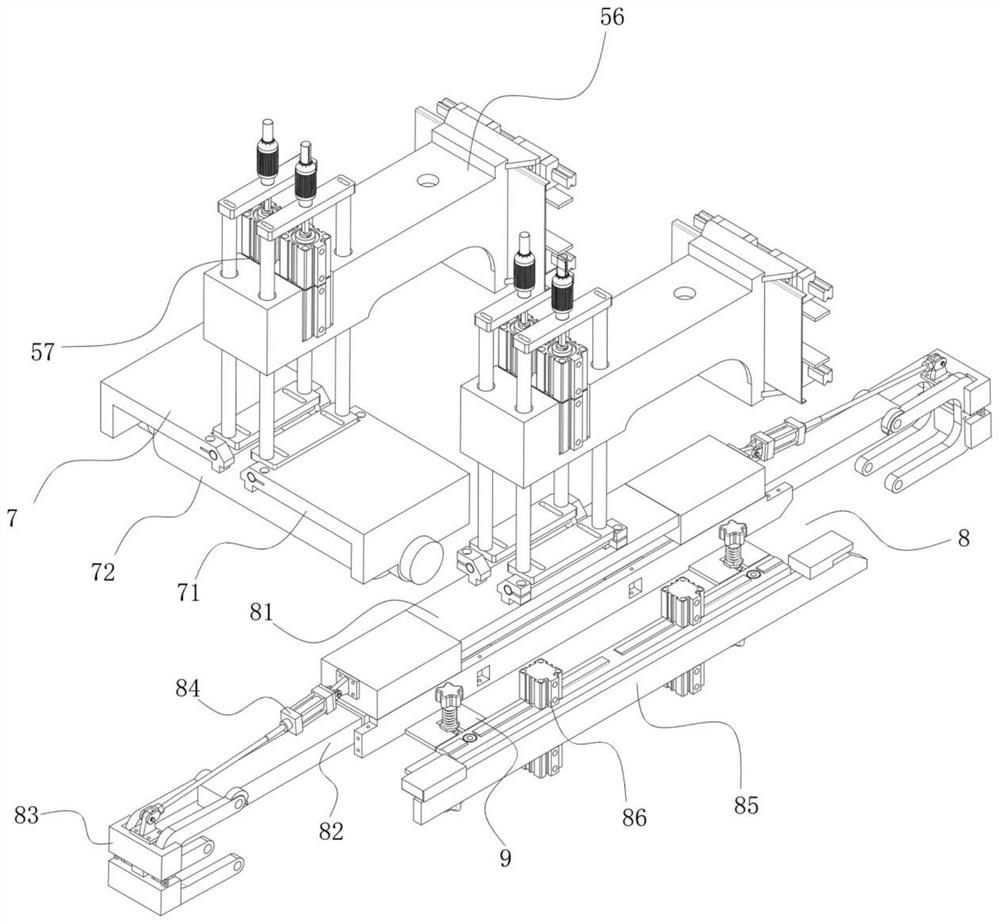

Grabbing mechanical arm for lead-acid storage batteries

ActiveCN107298307AConsistent clamping forceInhibit sheddingFinal product manufactureGripping headsEngineeringManipulator

Owner:江苏金帆新程装备有限公司

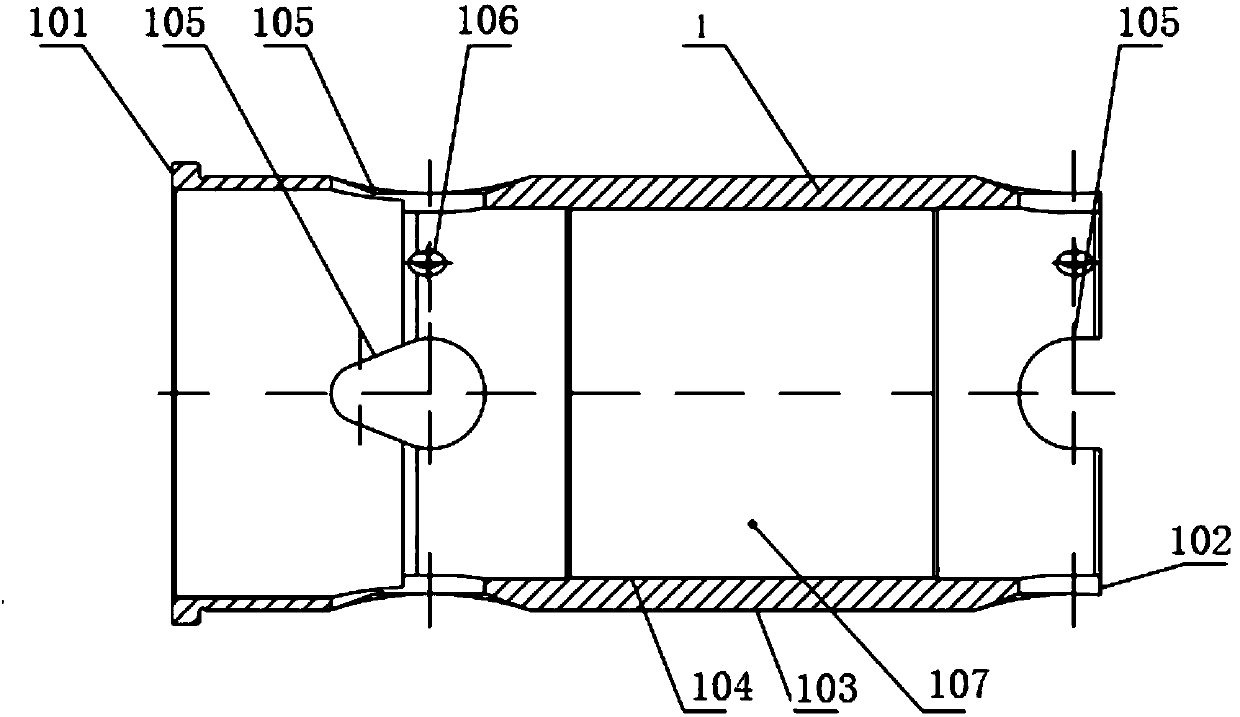

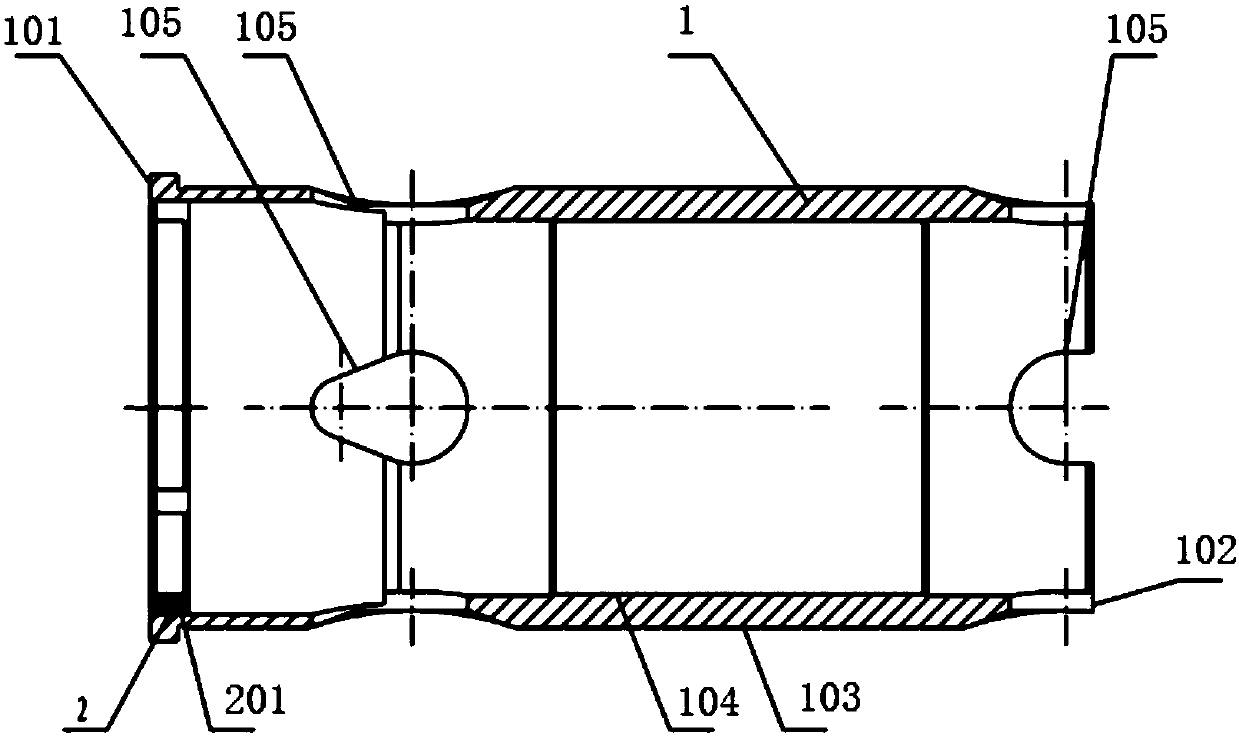

Machining technology of thin-walled and deep-hole air cylinder sleeve

The invention discloses a machining technology of a thin-walled and deep-hole air cylinder sleeve. The machining technology comprises the following steps that firstly, the semi-finish turning workingprocedure is conducted, specifically, the outer circle, the two end faces and an inner hole of the air cylinder sleeve are sequentially subjected to semi-finish turning; a large end inner hole is supported through an elastic sleeve, the inner holes is subjected to finish turning through cooperation of a lathe center frame, and the small end face is subjected to finish turning; the lathe center frame is removed, a jacking tool is additionally mounted at a small end inner hole and jacked through a jacking tip, and the outer circle of the cylinder sleeve is subjected to finish turning; and the outer circle and the inner hole are polished through a polishing device. An elastic sleeve clamping tool is used, it can be guaranteed that rigidity is enhanced, and meanwhile it is also guaranteed thatclamping force of a chuck to a workpiece is kept consistent; in order to meet the requirement of the roughness of the outer circle, the polishing device is specially designed, a motor is utilized fordriving, and the special polishing device is designed for mounting a grinding wheel and polishing the outer circle and the inner hole; and the machining technology is high in working efficiency, lowin manufacturing cost, high in product precision and low in scrap rate.

Owner:SINOPEC OILFIELD EQUIP CORP

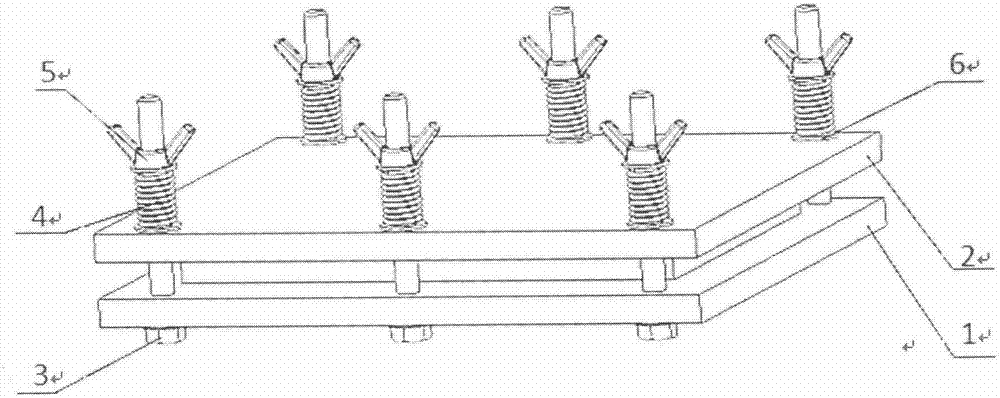

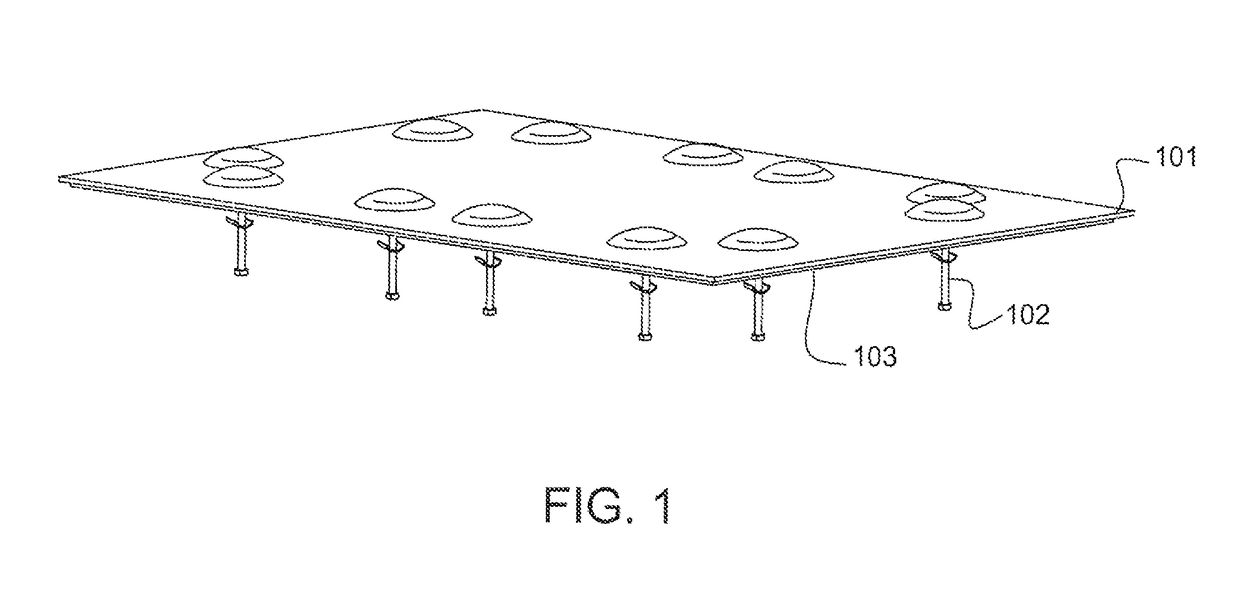

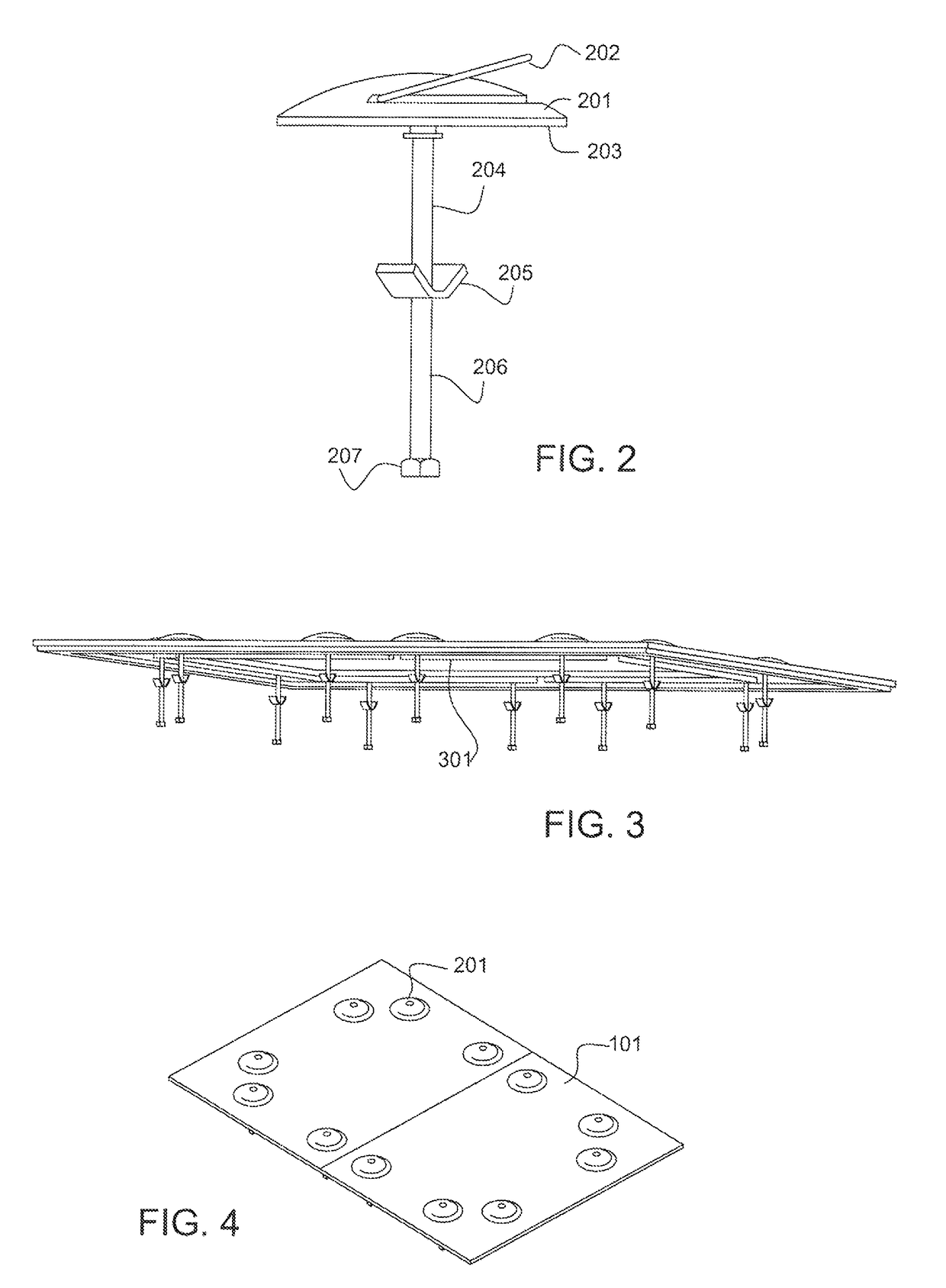

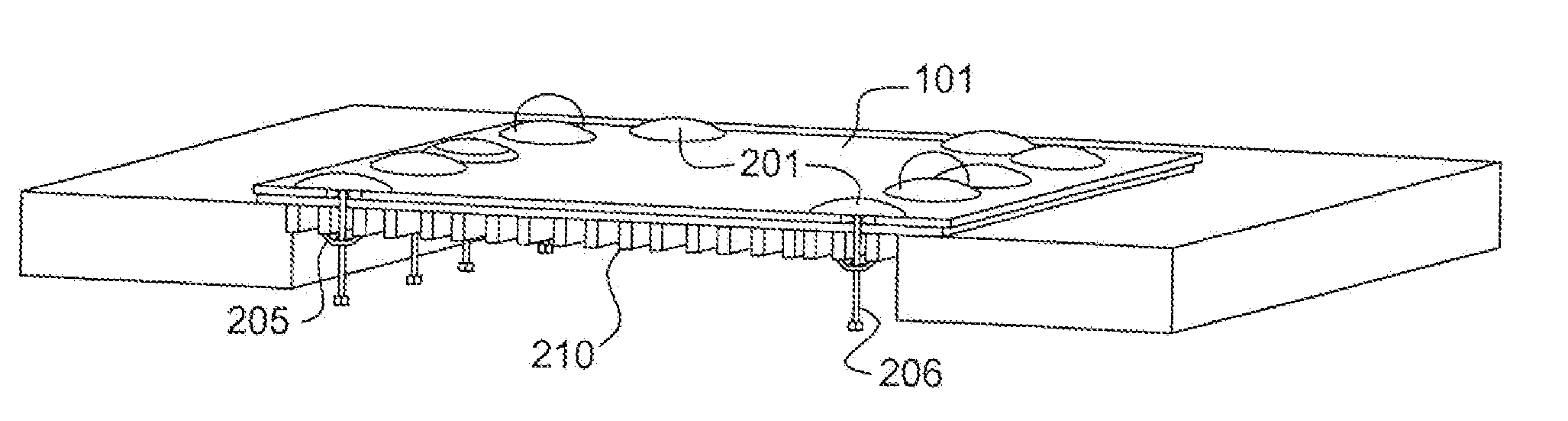

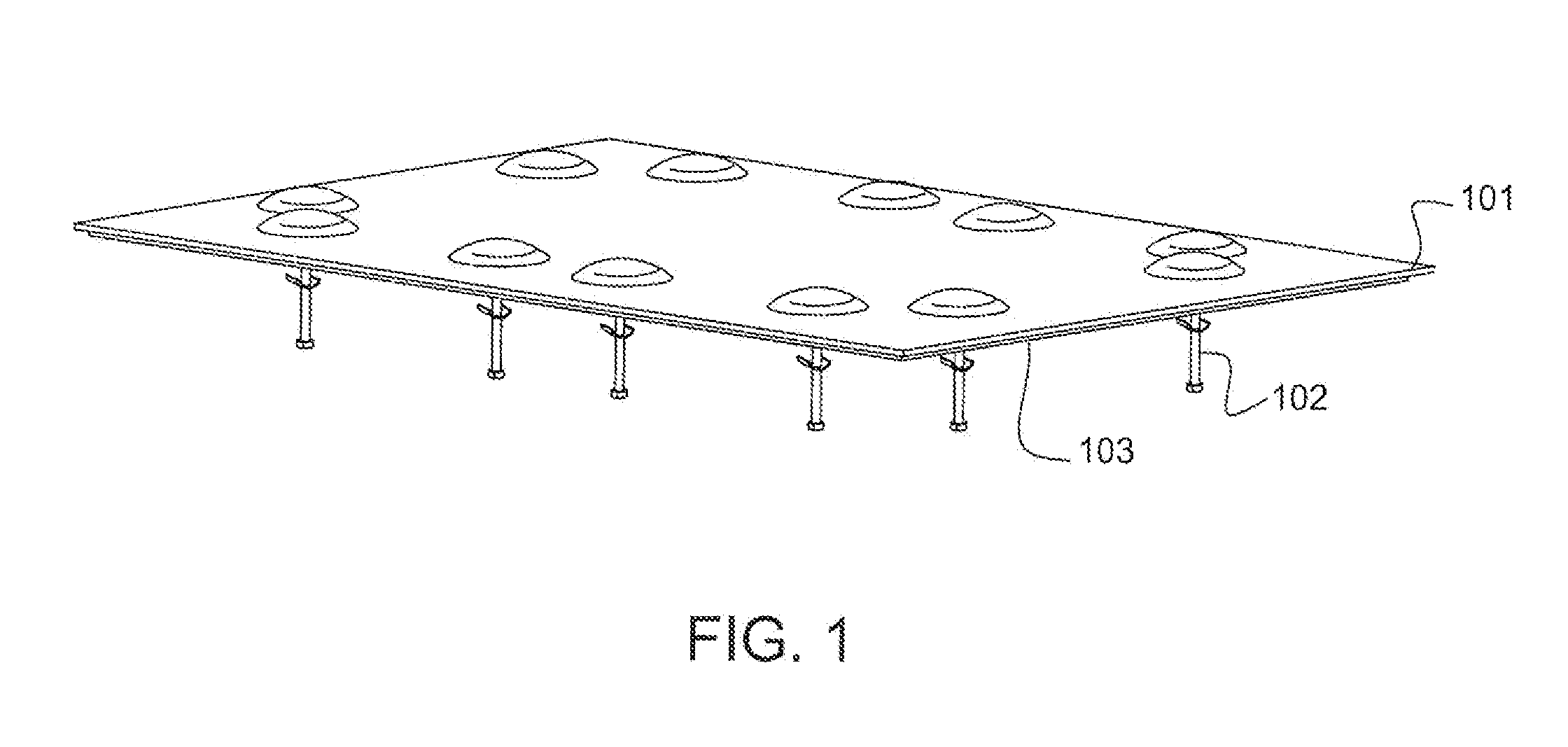

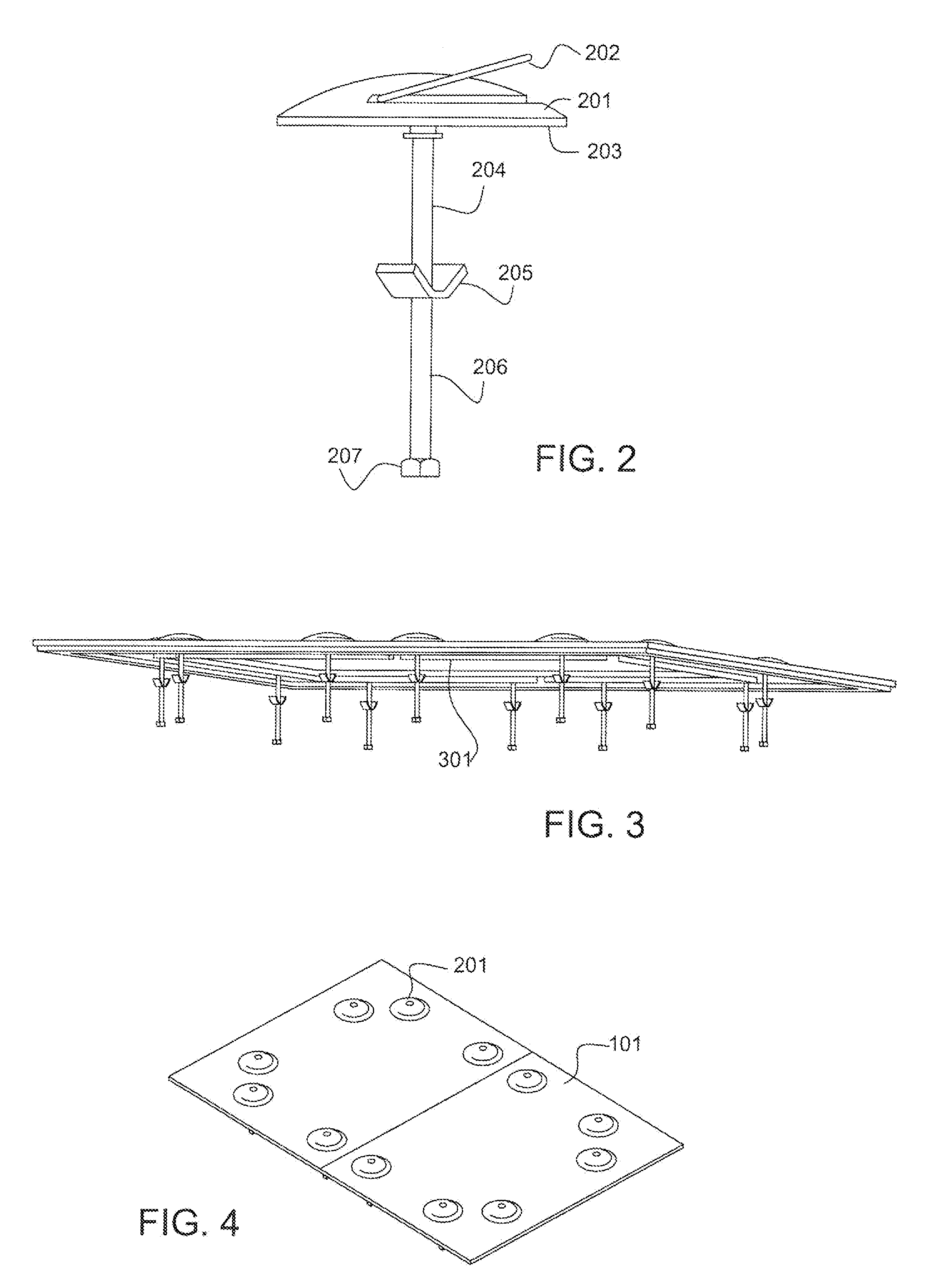

Clamping method of vacuum freeze drying water solution deacidified books and fixture device

InactiveCN107152865AConsistent clamping forceMeet the technical requirements of drying treatmentDrying solid materials without heatDrying chambers/containersSurface layerFreeze-drying

The invention relates to a clamping method of vacuum freeze drying water solution deacidified books and a fixture device. The fixture device consists of upper and lower clamping plates, clamping bolts, pressing springs, nuts, gaskets and the like. Water-contained books are placed between two metal plates; bolts are inserted in metal plate holes; the pressing springs are added between the bolts and the nuts; the nuts are uniformly screwed to enable the two metal plates to gradually clamp the water-contained books to extrude out redundant water solution and to further level papers of the books; after the clamping force is increased to a preset range, the nuts are stopped screwing; the metal plates and the books are sent to subsequent freezing and drying procedures; and the metal plates transfer the sublimation heat. The clamping method can enable the books to obtain proper initial clamping force to remove redundant water; in the freezing process, a certain space is automatically released to accommodate the volume expansion of the books; and after the papers on the surface layers of the books are sublimated and dried, proper pressure is applied to the papers to stop excessive drying deformation of the papers so as to meet the requirements of a freeze drying process in the book water solution method deacidification work.

Owner:NANJING NORMAL UNIVERSITY

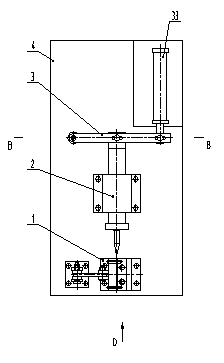

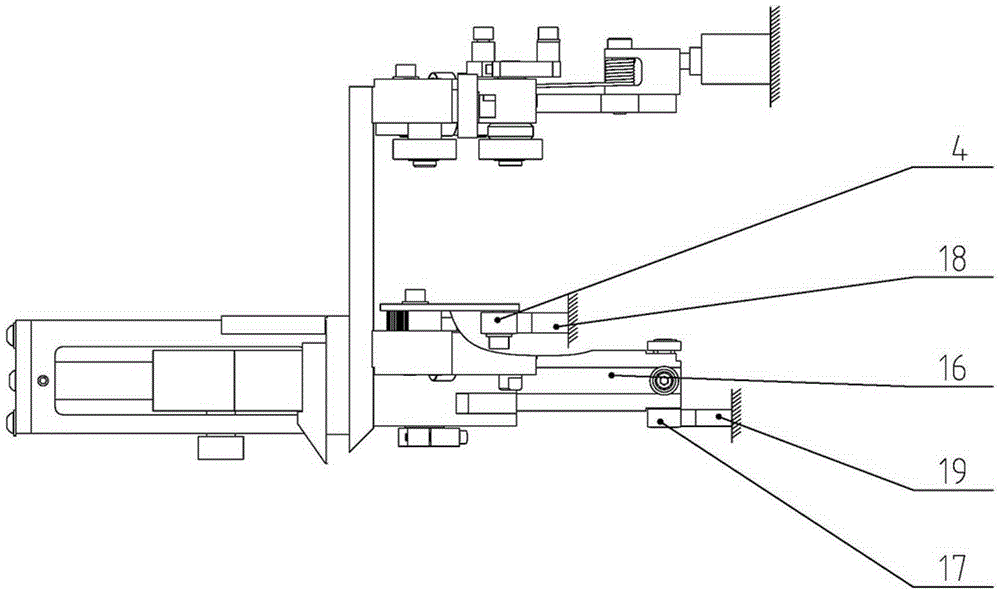

Pneumatic flaring machine

InactiveCN102825153AImprove work efficiencyReduce labor intensityUltimate tensile strengthMechanical engineering

The invention discloses a pneumatic belling machine which comprises a clamping tool, a flaring tool and a base. The clamping tool comprises a clamping tool base and a positioning mechanism; the positioning mechanism comprises a left positioning block, a right positioning block and a guiding column; the right positioning block is fixedly connected on the clamping tool base and can move left and right along the guiding column; the opposite side surface of the left positioning block and the right positioning block are provided with opposite horizontal semicircular-arc shaped holes; a pneumatic lever clamping mechanism is connected with the left positioning block; the flaring tool comprises a mold core, a push rod and a support base; the push rod is horizontally supported in the support base; the mold core is fixedly connected on the front end of the push rod; the mold core shares the same axis with the opposite semicircular-arc shaped holes on the left positioning block and the right positioning block; and a pneumatic driving mechanism is connected with the flaring tool. When the pneumatic belling machine is in use, the pneumatic lever clamping mechanism is used for clamping, and the pneumatic driving mechanism is used for flaring by pressing the mold core by pressing in a pipe. The work efficiency is high in the whole process, and the labor intensity is low.

Owner:JIANGSU XINCHENG ELECTRICAL APPLIANCE GENERAL FACTORY

Improved pipe clamp for automobile oil pipe

PendingCN110657284AConsistent clamping forceEasy to adjust clamping forcePipe supportsEngineeringScrew thread

The invention relates to the technical field of accessories for automobile oil pipes, and particularly relates to an improved pipe clamp for an automobile oil pipe. The pipe clamp comprises lower pipeclamps, a connecting part, a protruding part, upper pipe clamps and a driving mechanism, wherein the driving mechanism comprises a screw, a swivel nut and hinge rods. The pipe clamp has the beneficial effects that by rotating the screw, the swivel nut is driven to move vertically on the screw, the two hinge rods are driven to swing, the upper pipe clamps are caused to rotate along the hinge jointwith the protruding part, the upper pipe clamps are combined with the lower pipe clamps, so that the oil pipes are clamped, the mode that the upper pipe clamps and the lower pipe clamps are driven tobe combined through thread screwing in the prior art is replaced, the time of operation is at least reduced to some extent, and the assembly efficiency is improved. In addition, the upper pipe clampdo not follow rotation, the assembly efficiency is further improved, meanwhile, the clamping force of the two upper pipe clamps to the oil pipes is basically consistent, and then the clamping force ofthe upper pipe clamps to the oil pipes is conveniently adjusted.

Owner:江苏江洲汽车部件有限公司

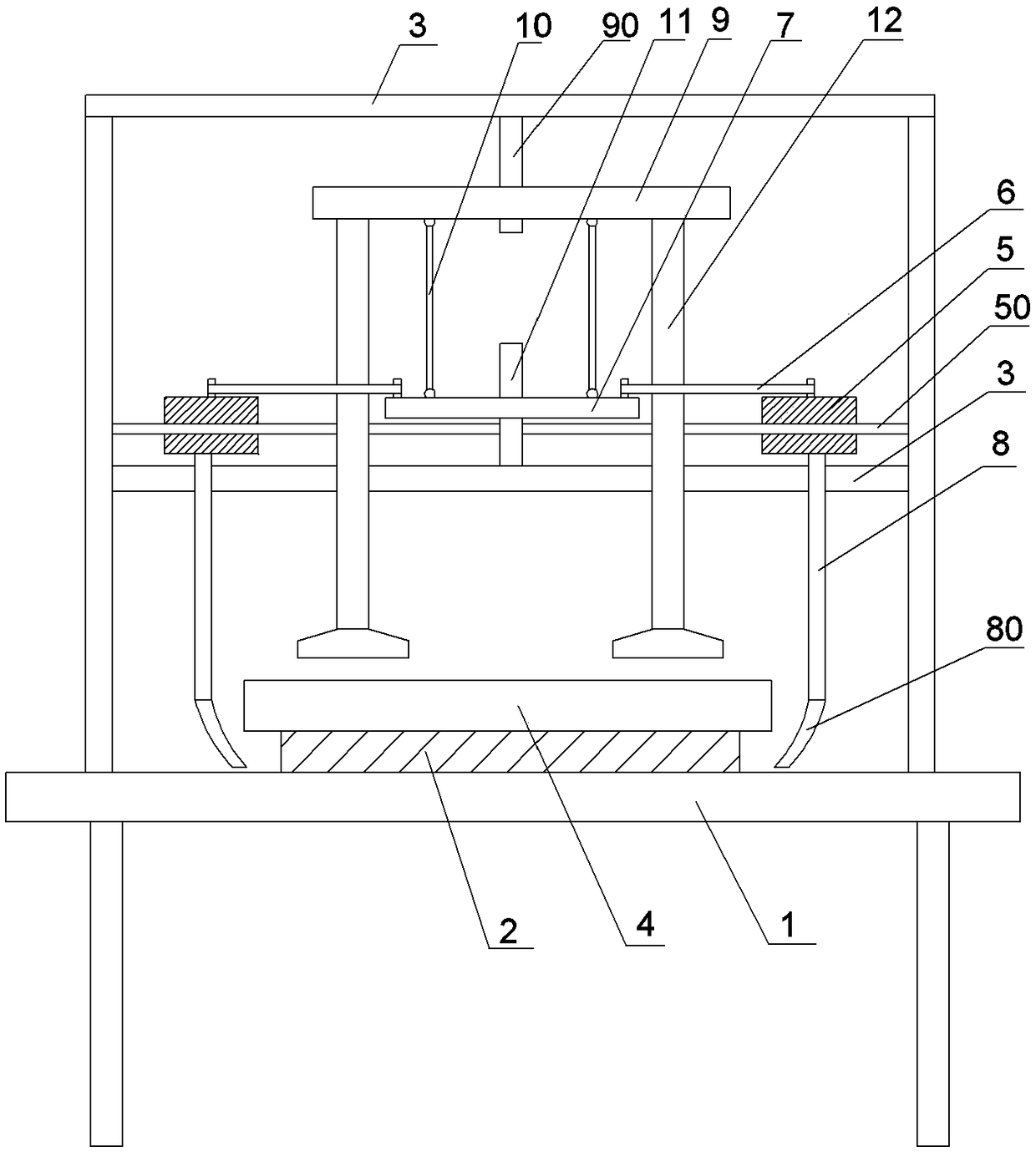

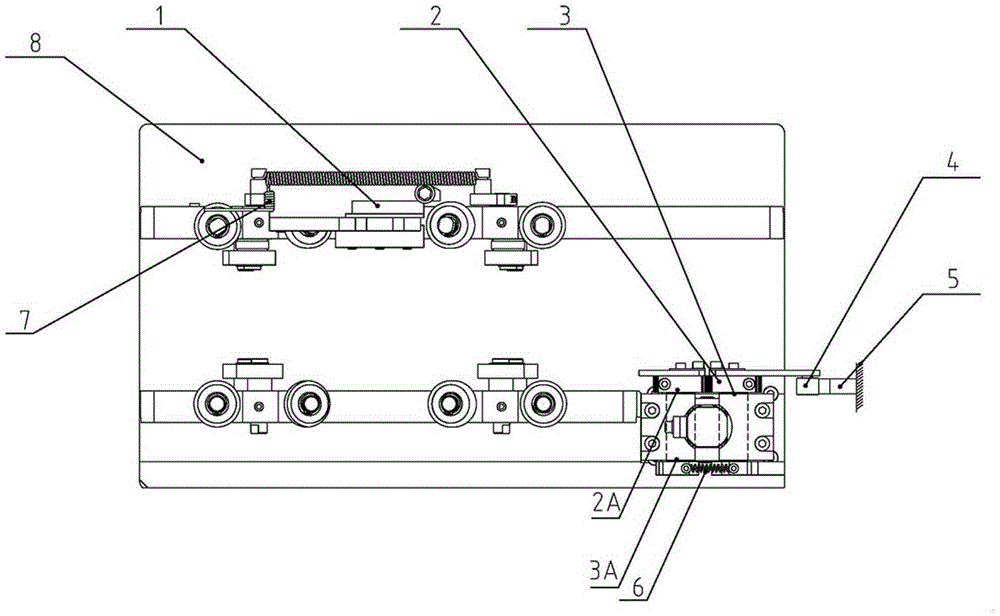

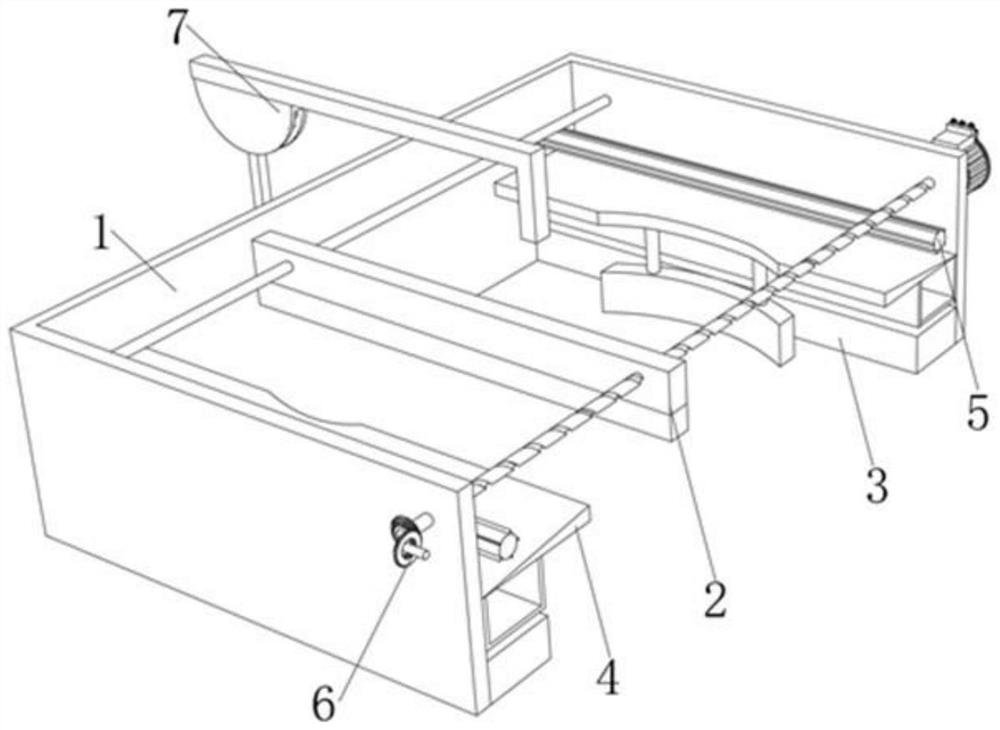

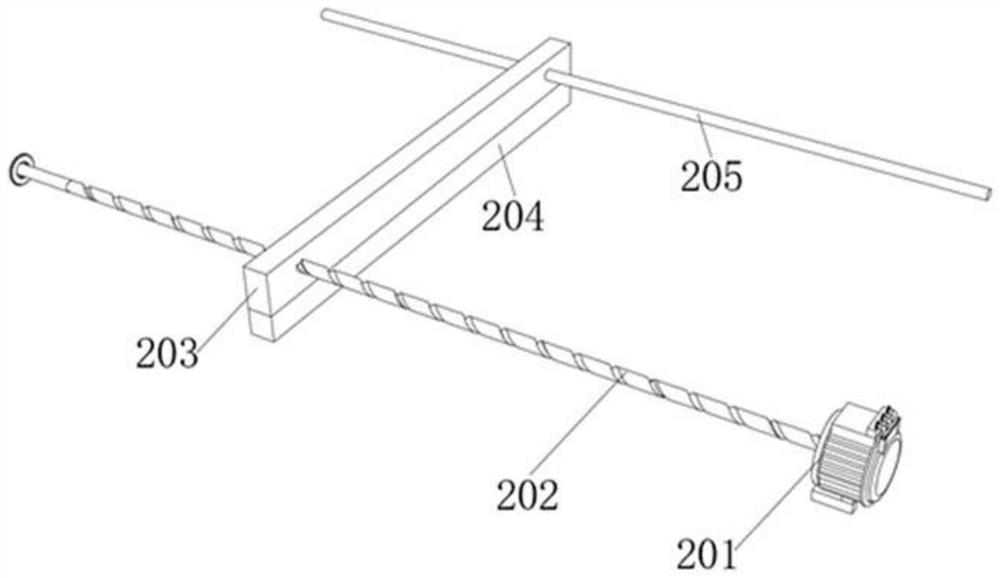

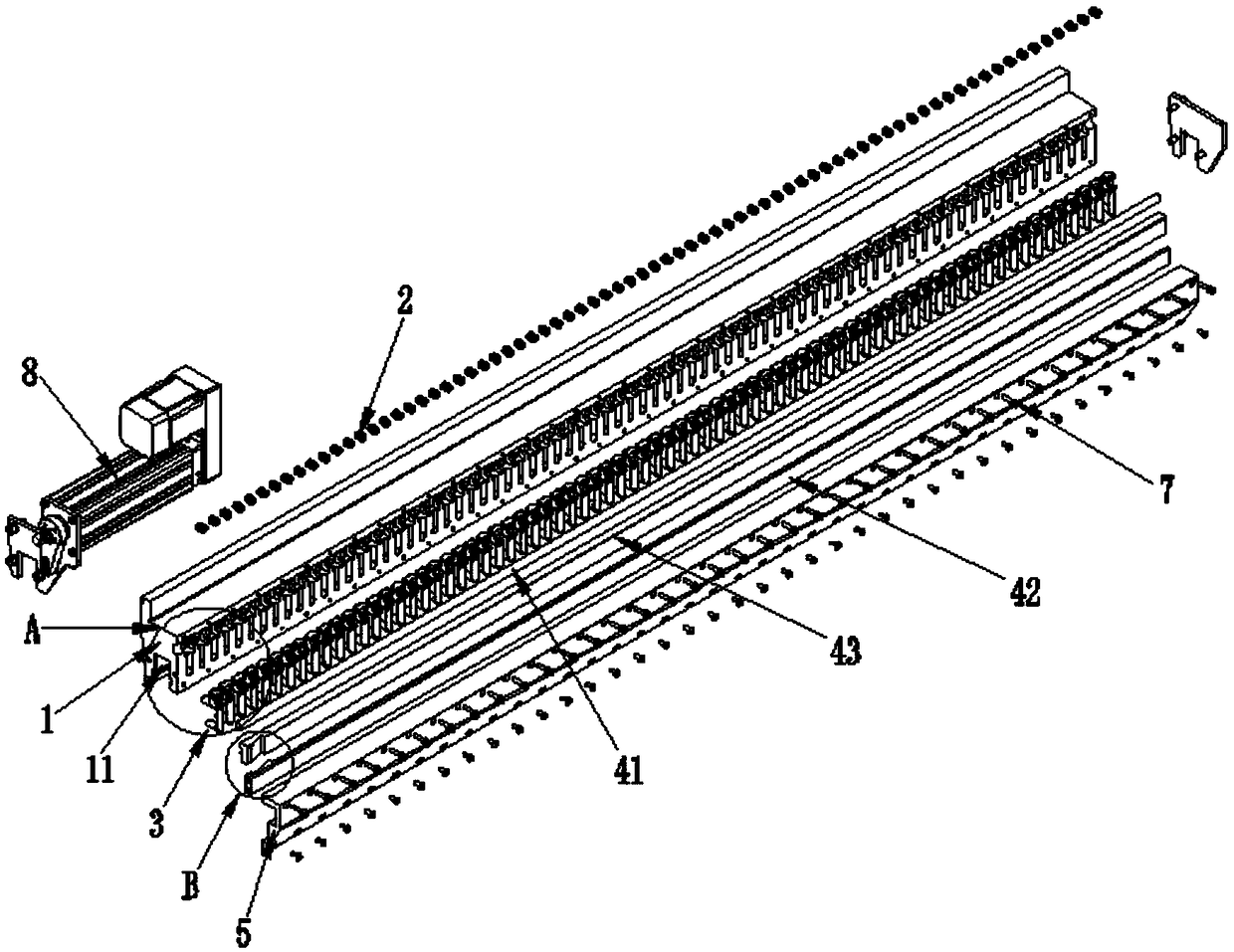

Vehicle-mounted clamping conveying device

The invention belongs to the technical field of vehicle interior production, and particularly discloses a vehicle-mounted clamping conveying device. The vehicle-mounted clamping conveying device comprises a machine frame, the machine frame is detachably connected with a fixing seat, and the fixing seat is slidably connected with two sliding seats. A plurality of clamping jaws are fixedly arrangedat the bottom ends of the sliding seats, and the multiple clamping jaws are distributed in the length direction of the sliding seats. Bending portions are arranged at the bottom ends of the clamping jaws, and the bending portions of every two clamping jaws are oppositely disposed. A conveyor belt is further arranged on the machine frame below the clamping jaws, and a rotating shaft is rotatably connected to the fixing seat between the two sliding seats. A rotating frame is fixedly arranged on the rotating shaft in a sleeving mode, and first connecting rods are separately hinged between the twoends of the rotating frame and the two sliding seats. A sliding frame is slidably connected to the fixing seat above the rotating frame, and the sliding direction of the sliding frame is parallel with the axial direction of the rotating shaft. A plurality of second connecting rods are hinged between the sliding frame and the rotating frame, and a pressing member is fixedly connected to the bottomof the sliding frame. The operation of the assembly and disassembly process of workpieces of the vehicle-mounted clamping conveying device is simple.

Owner:SHANDONG STREET MOBILE SHOP NEW ENERGY TECH CO LTD

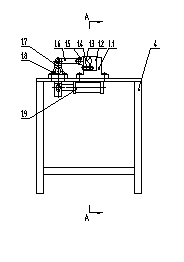

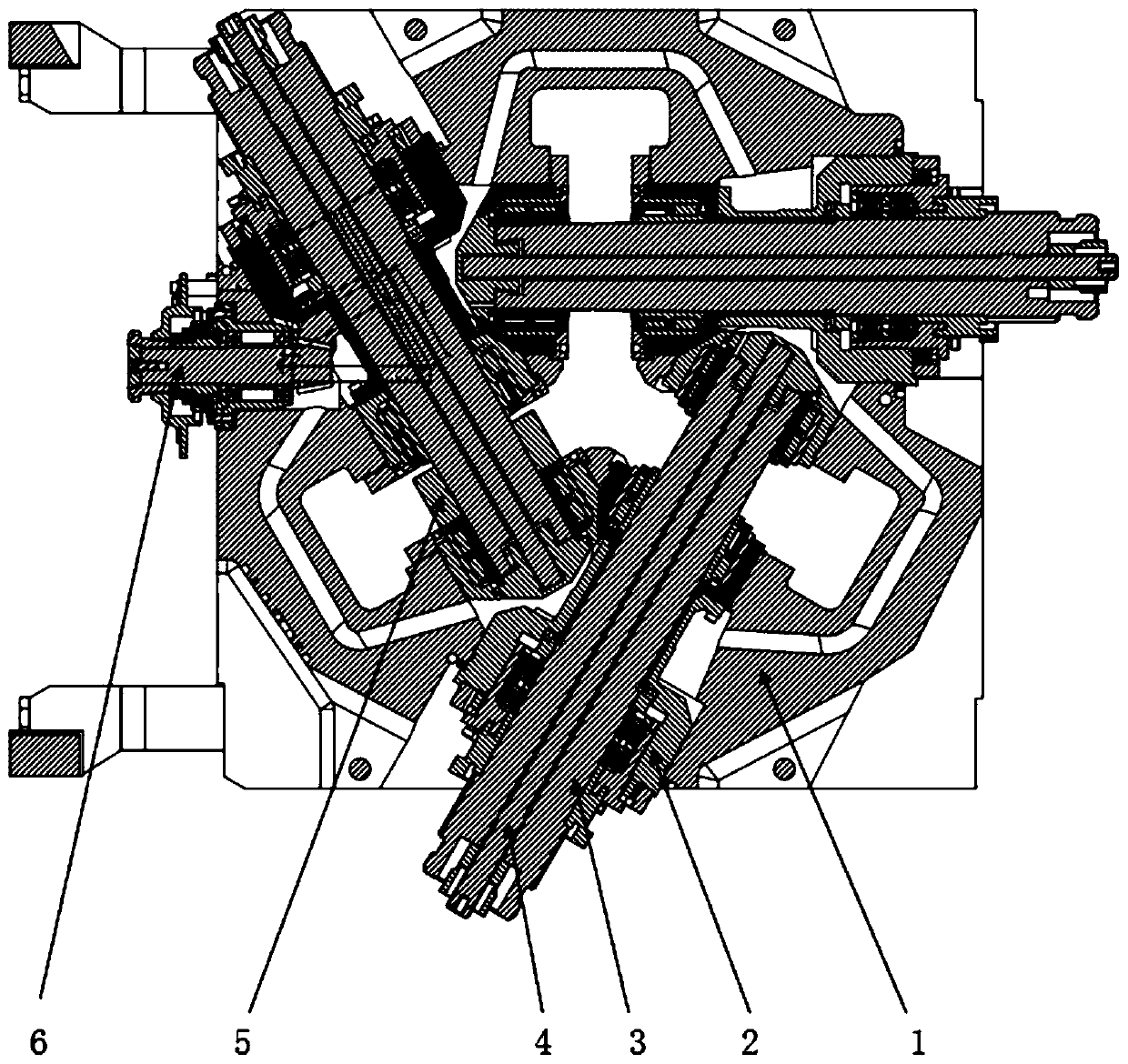

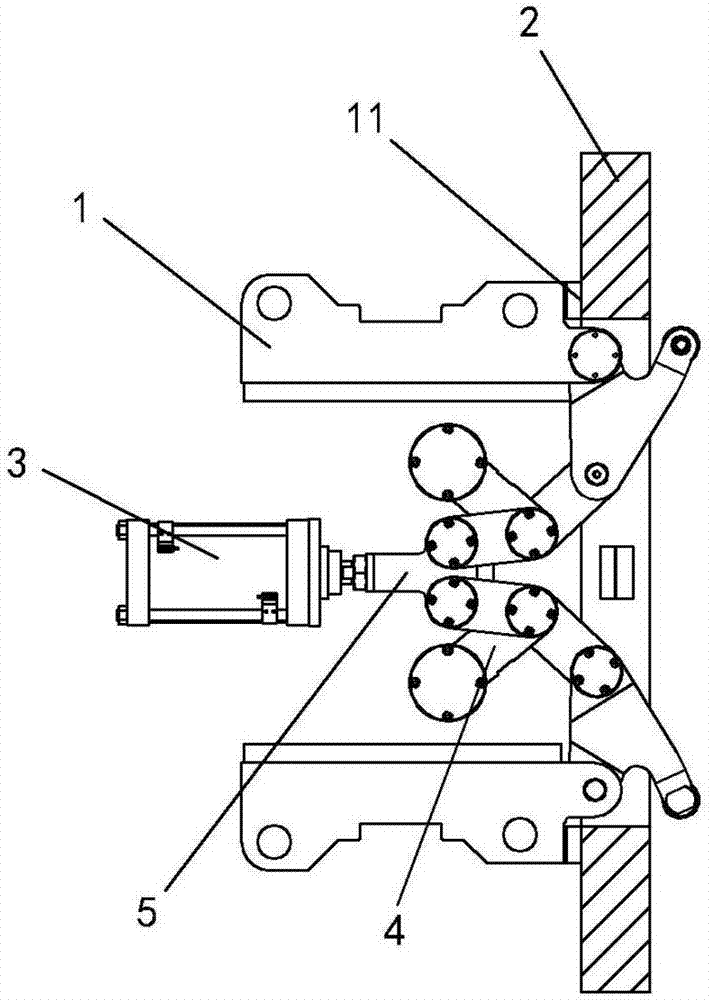

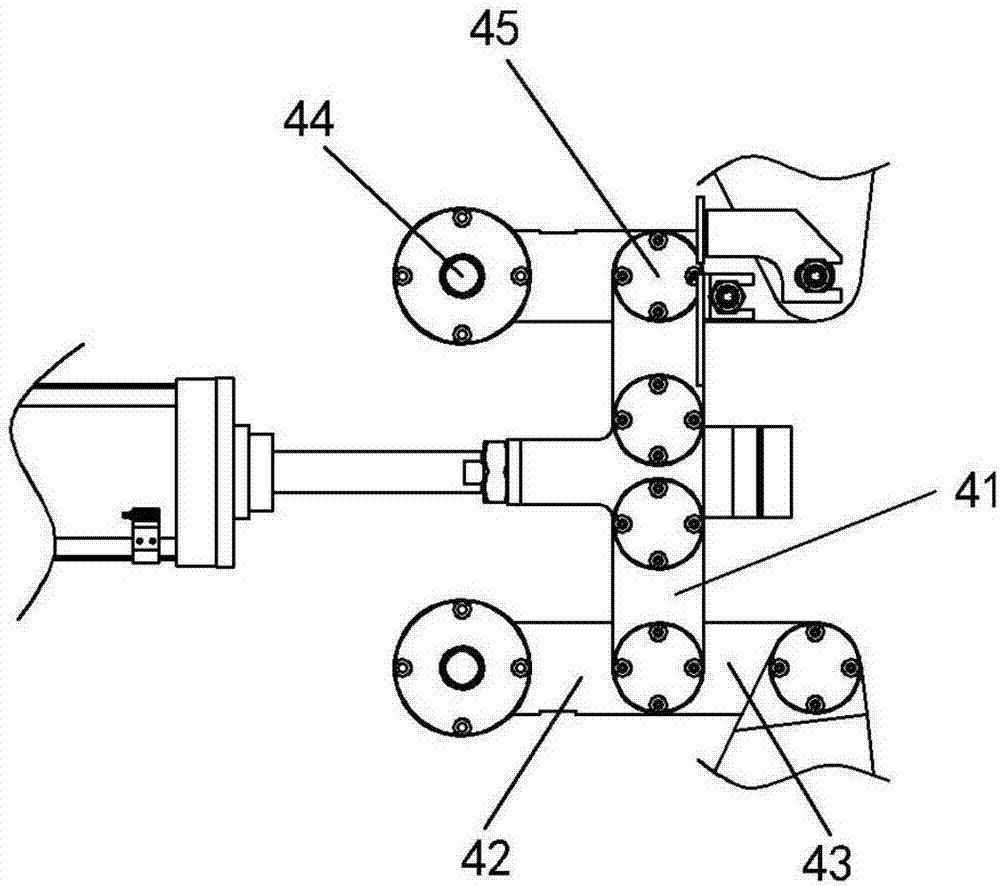

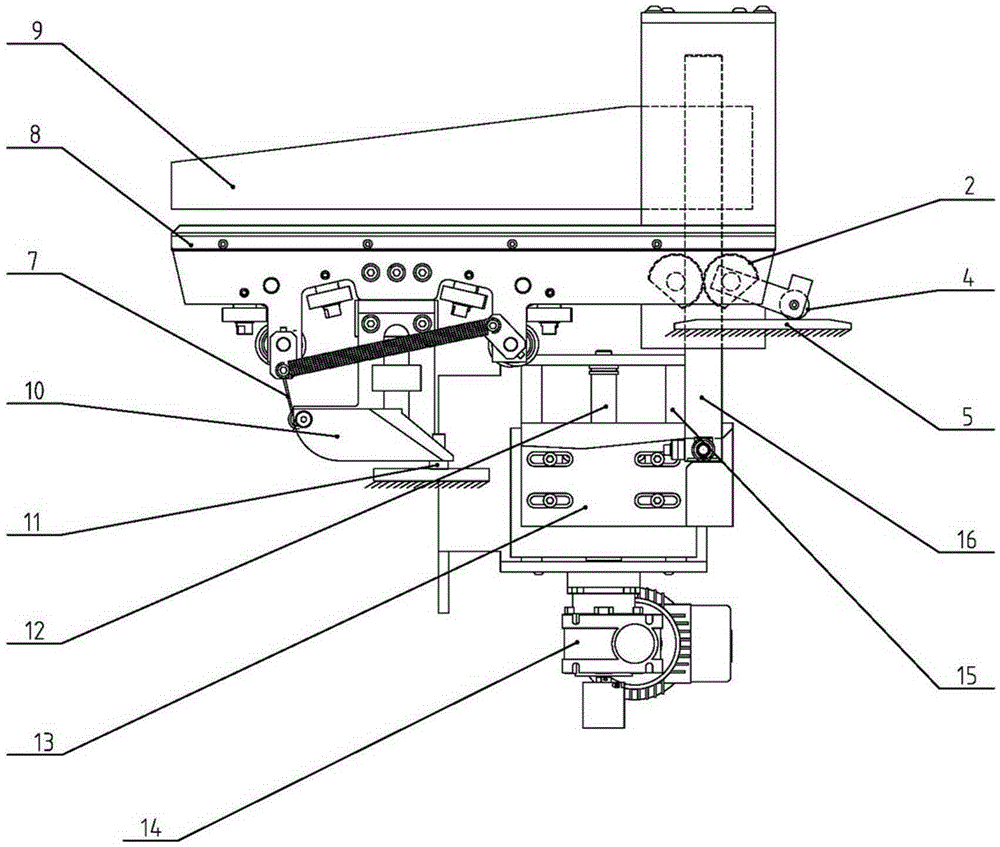

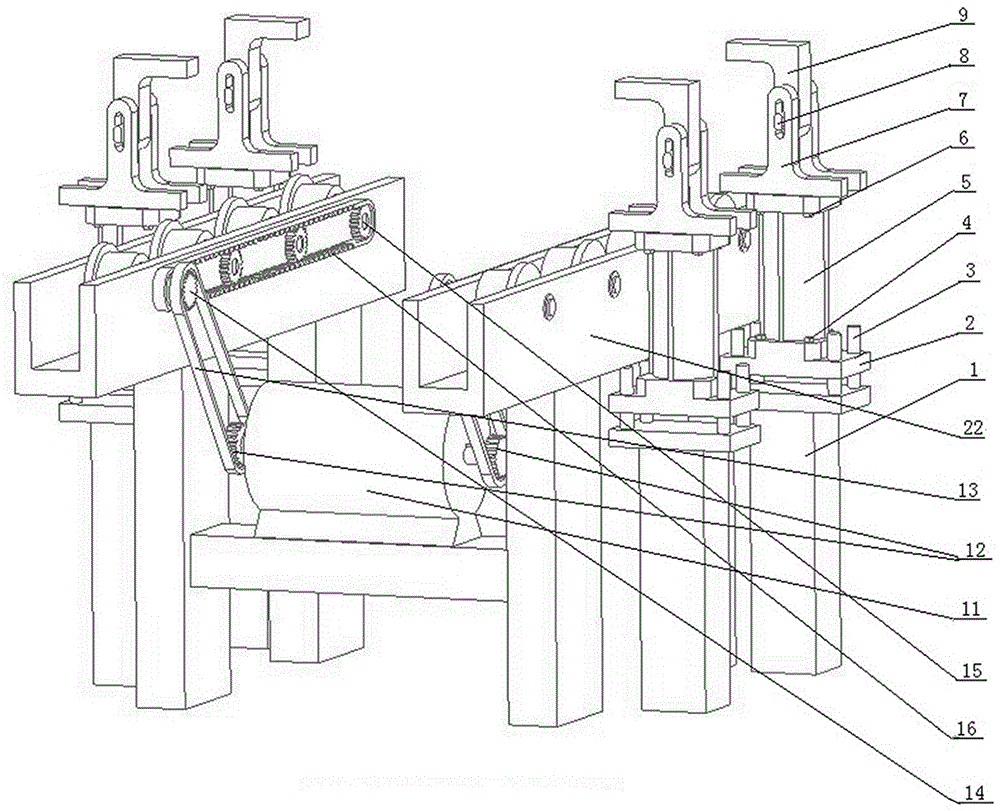

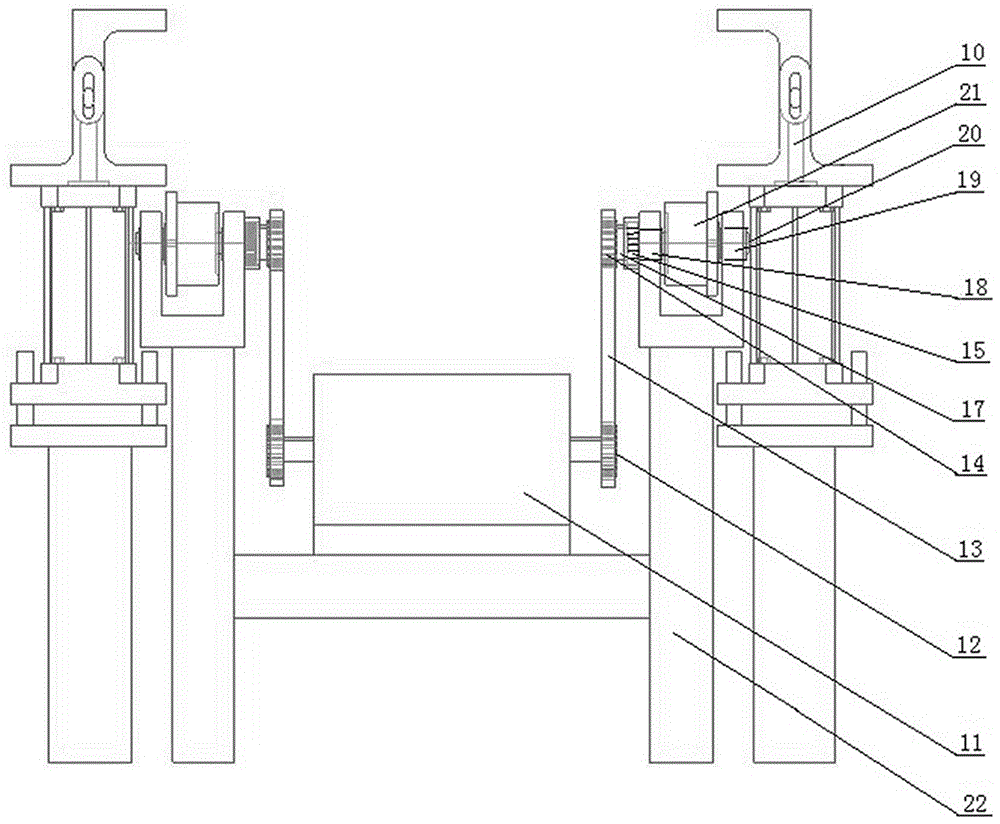

Intelligent precise rolling mill producing bars

InactiveCN110404961AWide adaptabilityReduce in quantityRoll mill control devicesMeasuring devicesControl systemRemote control

The invention discloses an intelligent precise rolling mill producing bars. The intelligent precise rolling mill comprises a precise adjustable rolling mill, roller guide and guard units and an intelligent adjusting E-SYS operation system. The precise adjustable rolling mill comprises a main rack, multiple sets of eccentric bushing assemblies, long shaft assemblies installed in the eccentric bushing assemblies and first adjusting mechanisms. The eccentric bushing assemblies are arranged at the same angle and are installed in the main rack. The first adjusting mechanisms mesh with cone teeth ofthe eccentric bushing assemblies and are used for adjusting the eccentric bushing assemblies. All the eccentric bushing assemblies achieve meshing through the cone teeth. The roller guide and guard units are located at an output port and an input port of the precise adjustable rolling mill. The precise adjustable rolling mill is composed of a guide and guard body, three sets of support arm transmission assemblies and a second adjusting mechanism. The intelligent adjusting E-SYS operation system comprises a bar foundation database, a hole pattern calculation system, a remote control system anda system control operation interface. The intelligent precise rolling mill is adjustable in hole pattern and wide in adaptability, and different cross sections can be rolled in the same multi-roll hole pattern.

Owner:四川易尚天交实业有限公司

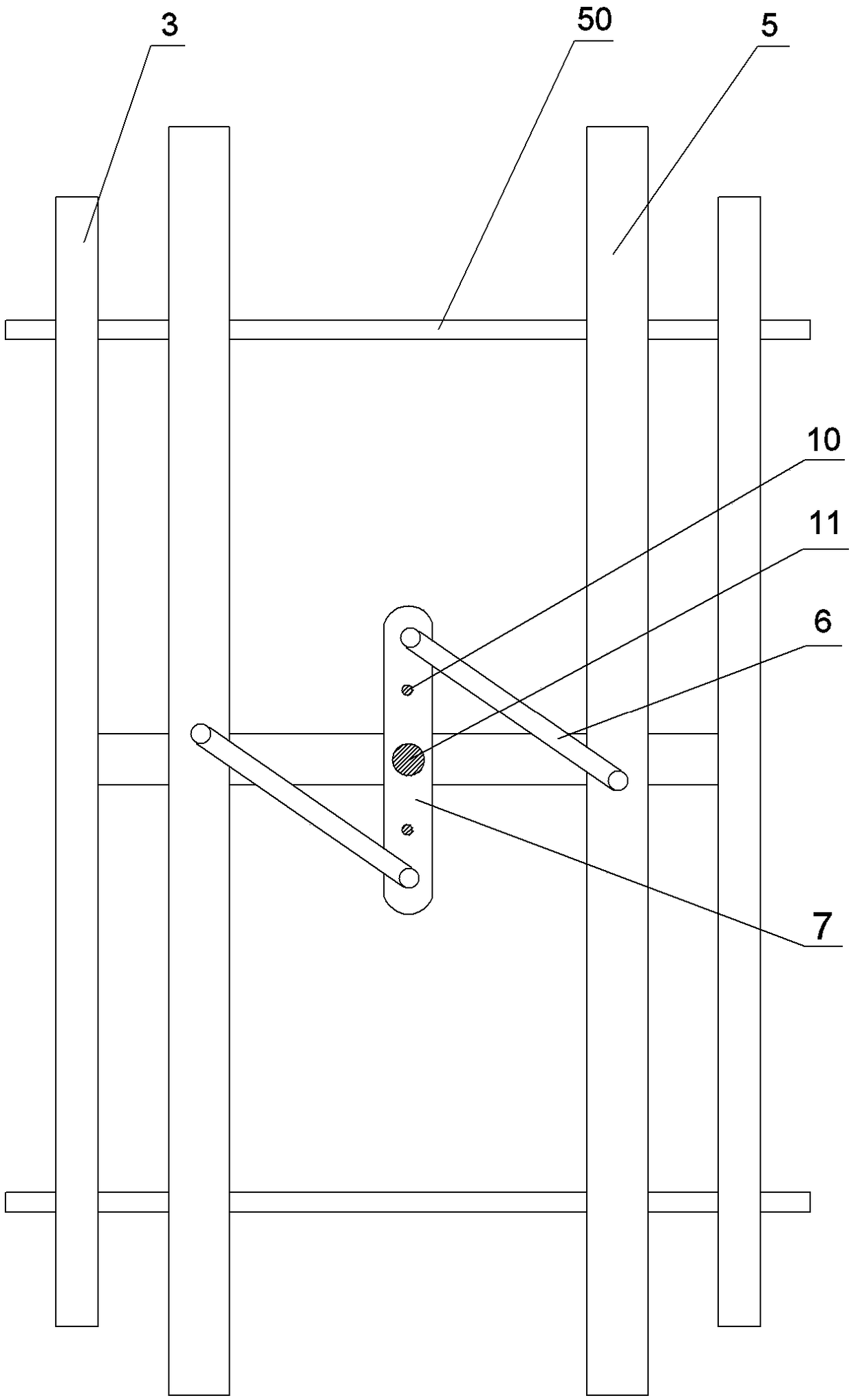

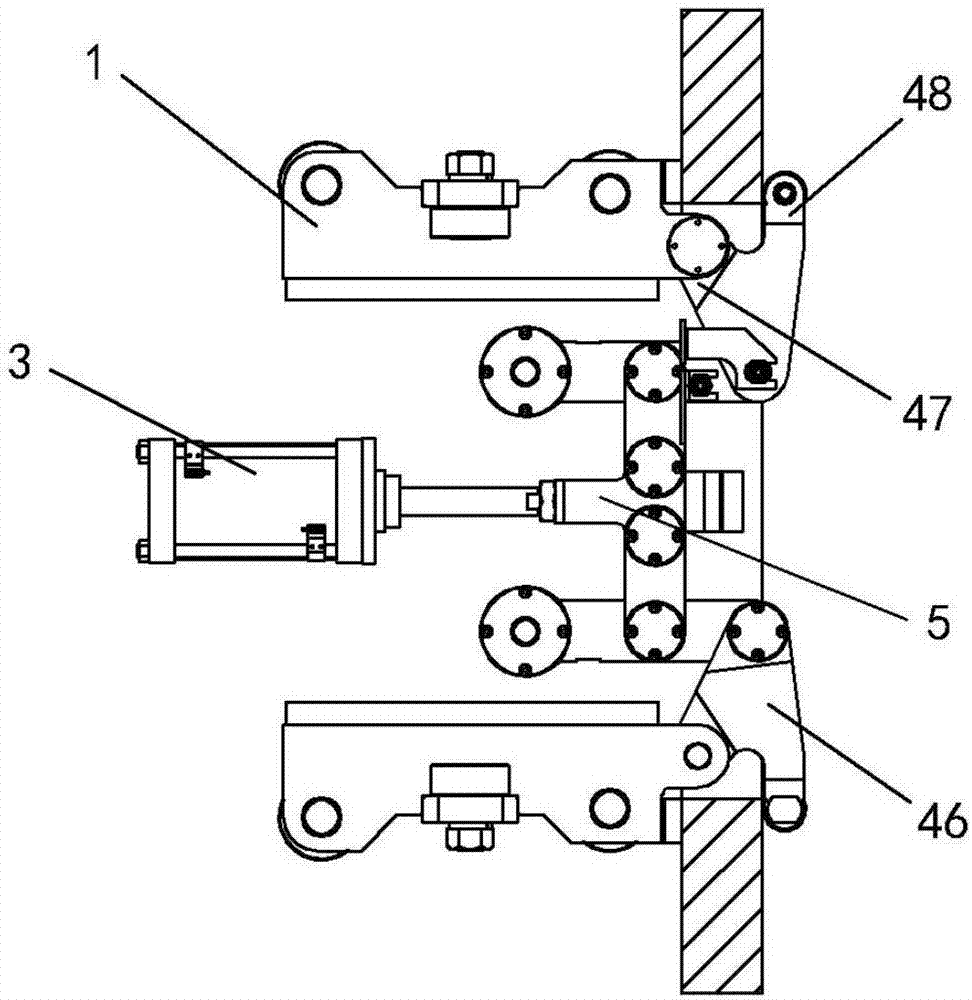

Bodywork Y-direction positioning and locking mechanism for welding assembly line

ActiveCN107378363AConsistent clamping forceFixture positioning is stableWelding/cutting auxillary devicesAuxillary welding devicesSynchronismDead centre

The invention relates to the technical field of positioning mechanisms and discloses a bodywork Y-direction positioning and locking mechanism for a welding assembly line. Mounting seats and an air cylinder are fixedly connected to a fixed operating platform, and two link mechanisms are symmetrically connected to the tail end of an output shaft of the air cylinder. Front ends of each second connecting rod and a corresponding third connecting rod are connected to the tail end of a corresponding first connecting rod through a corresponding rotating point to form one link mechanism along with a tail end structure hinged to the tail end of the corresponding third connecting rod, the front end of each first connecting rod is connected to the tail end of the output shaft of the air cylinder through the corresponding rotating point, and the tail end of each third connecting rod is connected to the fixed operating platform through a fixing point. The bodywork Y-direction positioning and locking mechanism has advantages that two-point positioning and locking can be realized synchronously without synchronism difference, clamping force uniformity is achieved, and high stability and accuracy in positioning are realized; by multi-link dead point clamping, the connection rotating points of the two link mechanisms are collinear in a clamping state, the rotating points of the first connecting rods, the second connecting rods and the third connecting rods of the two link mechanisms are collinear so as to form three interlocked dead point mechanisms, and self-locking performance and locking reliability of the mechanism are guaranteed.

Owner:HEFEI JEE INTELLIGENT EQUIP CO LTD

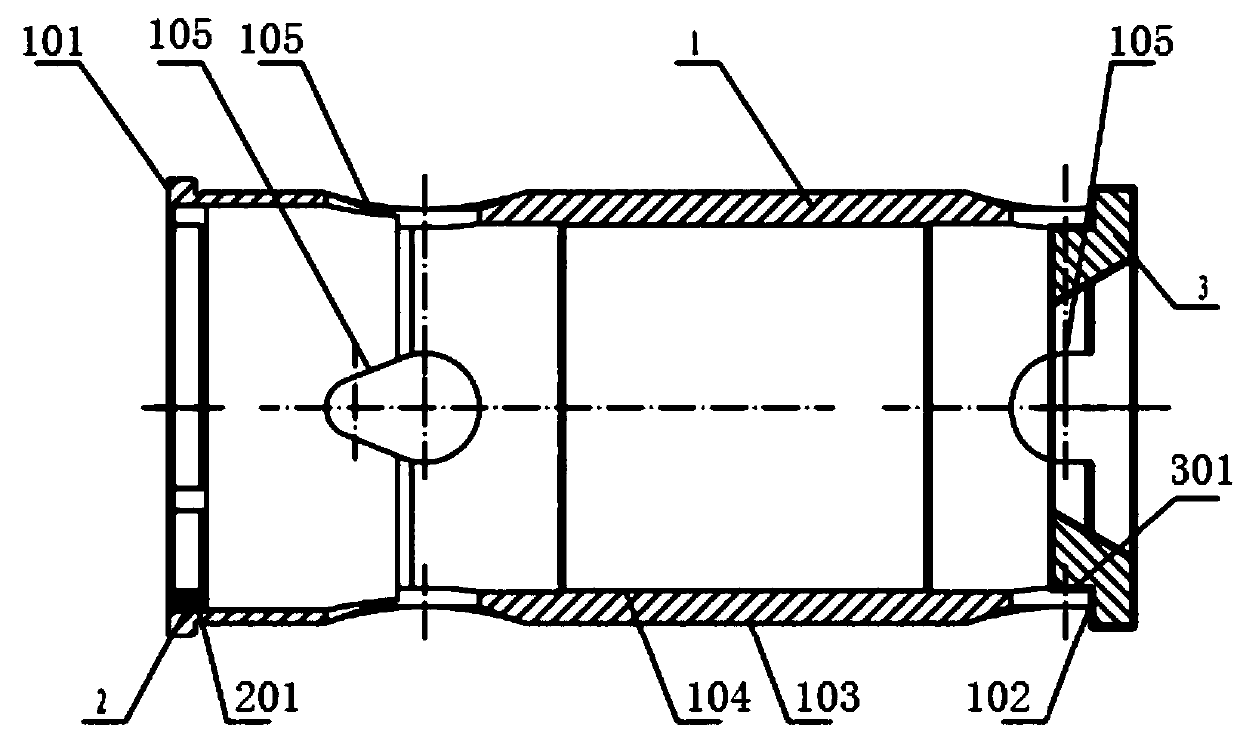

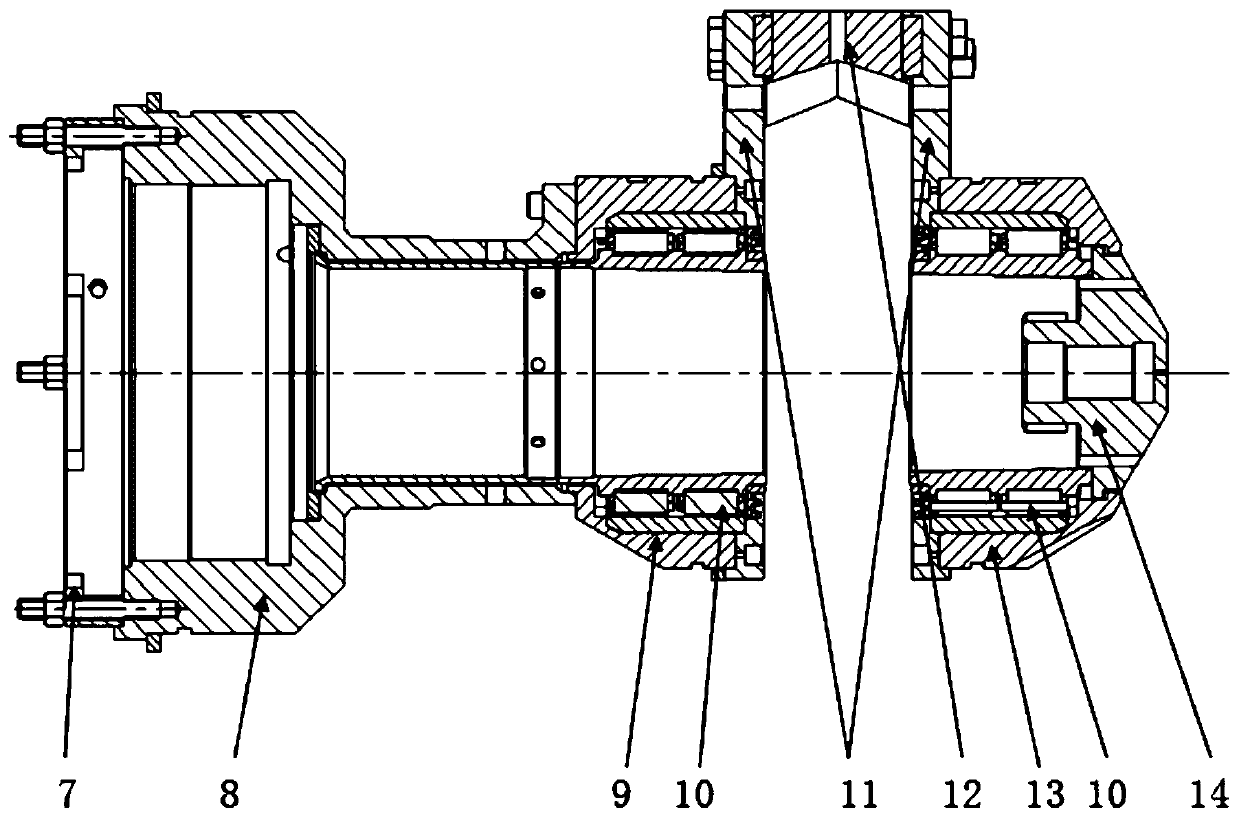

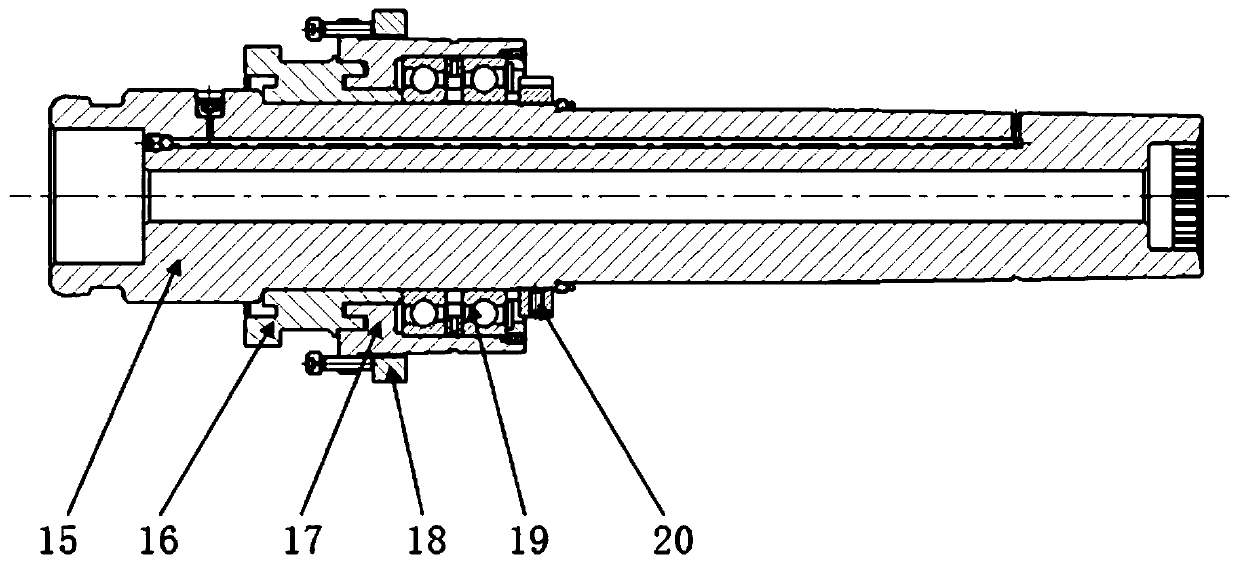

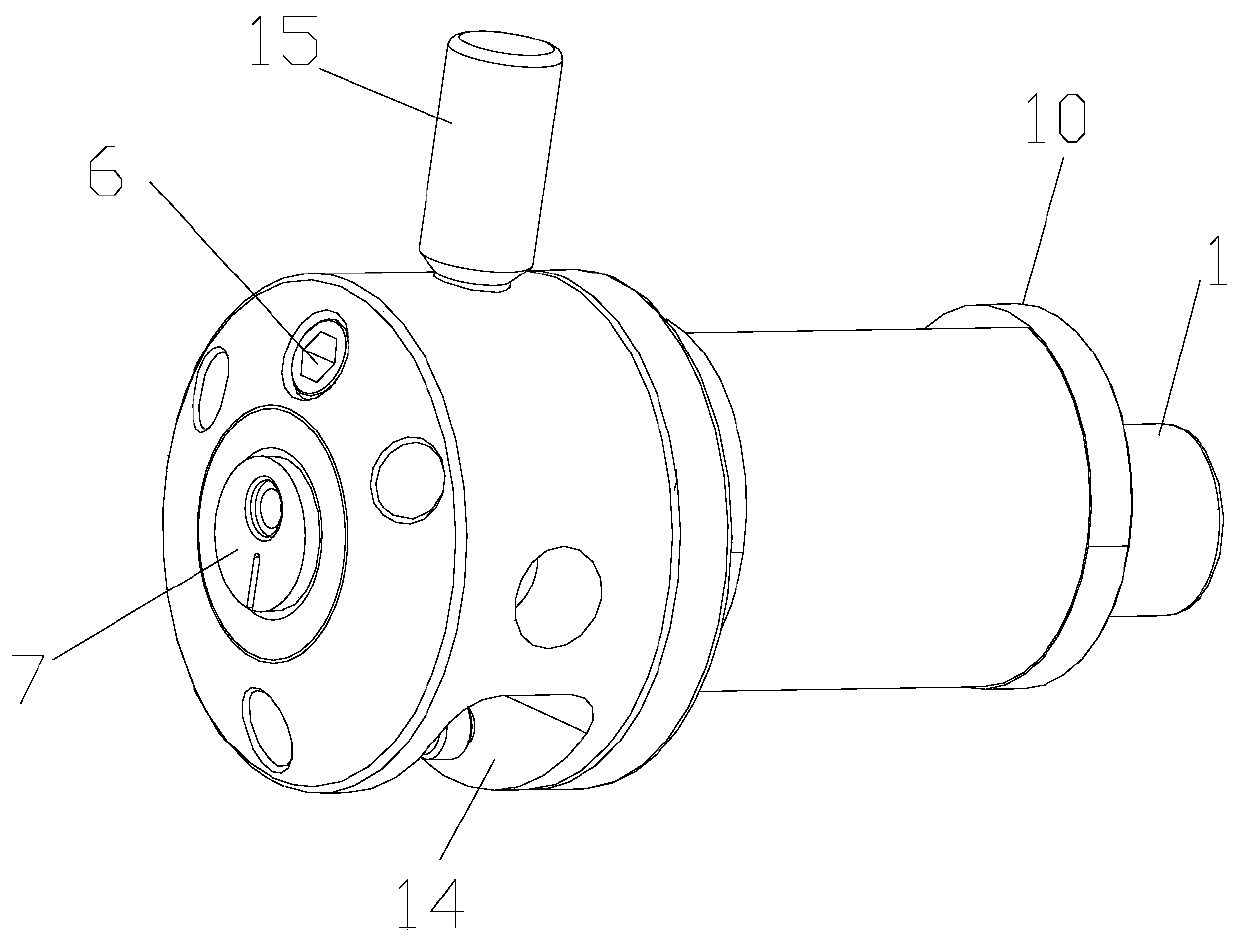

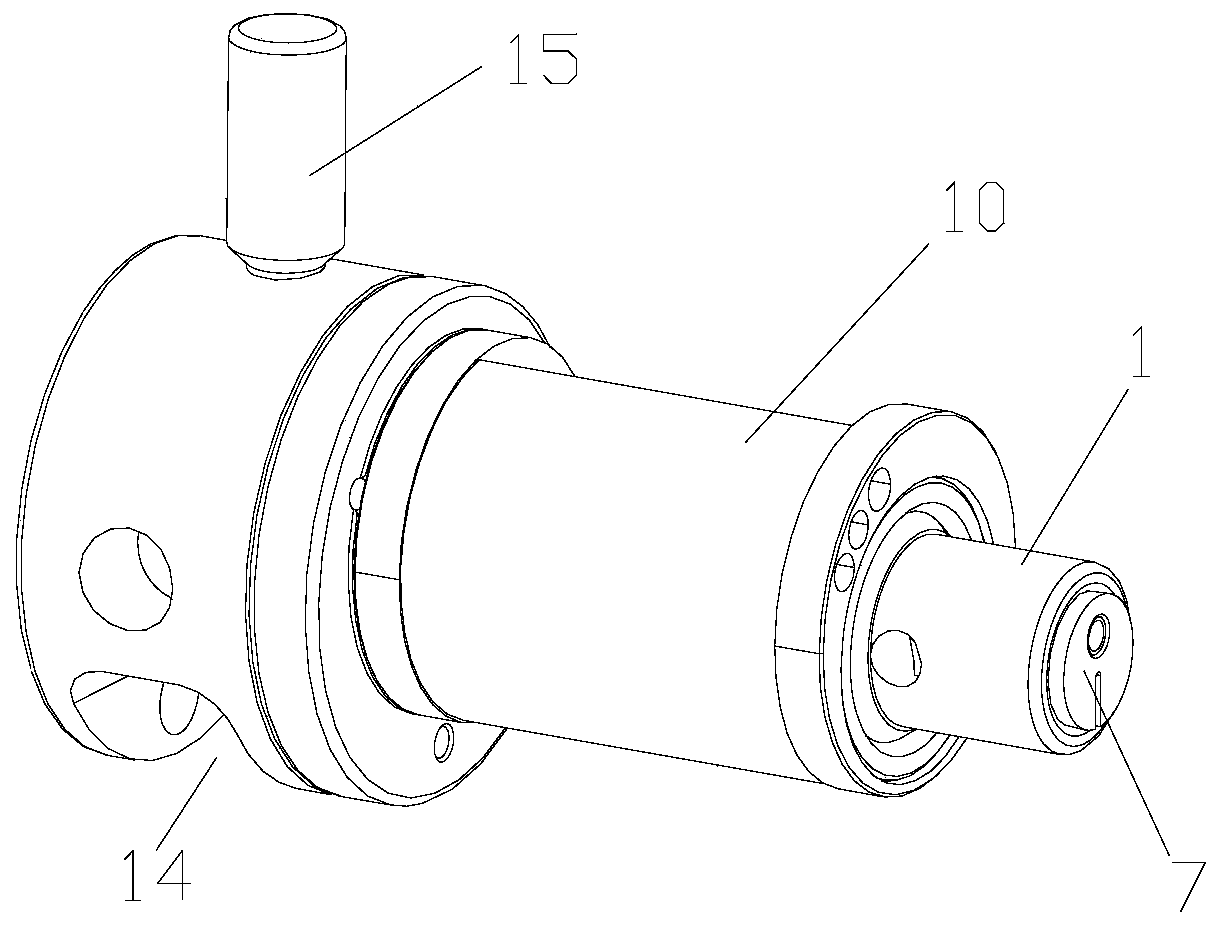

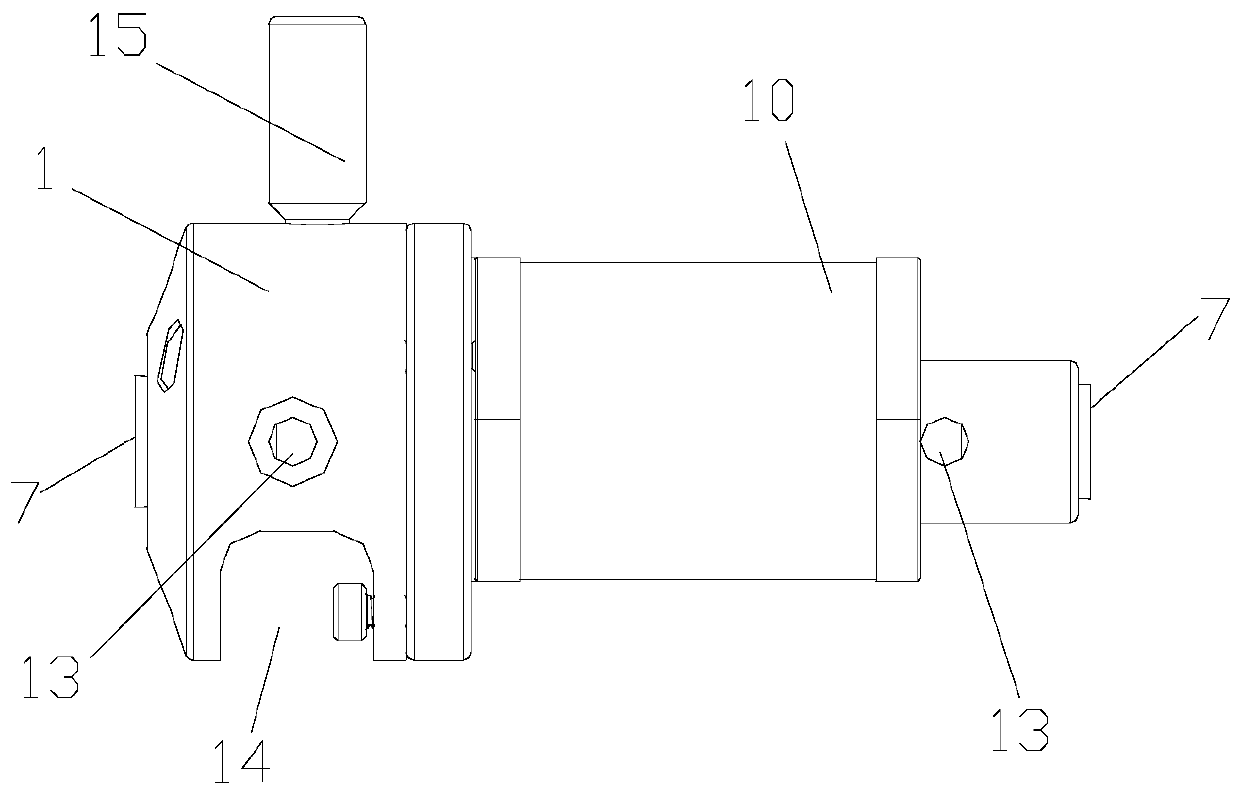

Precise hydraulic clamp

PendingCN109822457AGuaranteed eccentricityGuaranteed parallelismRevolution surface grinding machinesGrinding work supportsEngineeringMechanical engineering

The invention relates to a precise hydraulic clamp. The precise hydraulic clamp comprises a mandrel, an expansion sleeve and a pressurization flow channel. The mandrel is connected with a grinding machine spindle turntable or a center. The expansion sleeve sleeves the outer edge of the mandrel and is used for fixing a workpiece. An expansion space is formed between the expansion sleeve and the mandrel. The expansion space is subjected to oil filling and pressurizing to expand the expansion sleeve, so that the expansion sleeve and the workpiece can be fixed together. The pressurization flow channel is arranged in the mandrel and communicates with the expansion space. A pressurization piston communicating with the expansion space is arranged at the front end of the pressurization flow passage. The precise hydraulic clamp is consistent in clamping force all the time.

Owner:广州德马威工业装备制造有限公司

Portable flexible sealing device for grated openings

Owner:ILC DOVER LP

Book clamp device of full-automatic perfect-binding covering machine

PendingCN105415916AConsistent clamping forceCasing-inBookbinding adhesiveNeedle roller bearingEngineering

The invention discloses a book clamp device of a full-automatic perfect-binding covering machine. The book clamp device comprises a front clamping plate and a rear clamping plate, and a positioning seat and an eccentric mechanism both arranged on the rear clamping plate; the eccentric mechanism comprises an eccentric shaft, a cylindrical gear, a first needle roller bearing, a second needle roller bearing and a pulling plate shaft; the cylindrical gear is arranged on the eccentric shaft; the first needle roller bearing is connected with the cylindrical gear, while the second needle roller bearing is connected with the pulling plate shaft; a front end of the pulling plate shaft is connected with the front clamping plate, while a rear end of the pulling plate shaft is connected with a guide seat assembly through the second needle roller bearing. The book clamp device of the full-automatic perfect-binding covering machine is applied to a full-automatic covering machine, such that remaining of a clamping force of a book clamp to a bookblock is ensured, and conveying speed and accuracy of the bookblock can be guaranteed; additionally, compared with a traditional book clamp, the performance of the book clamp of the present invention is improved, and further the cost is reduced.

Owner:PINGHU BIND EX MACHINERY

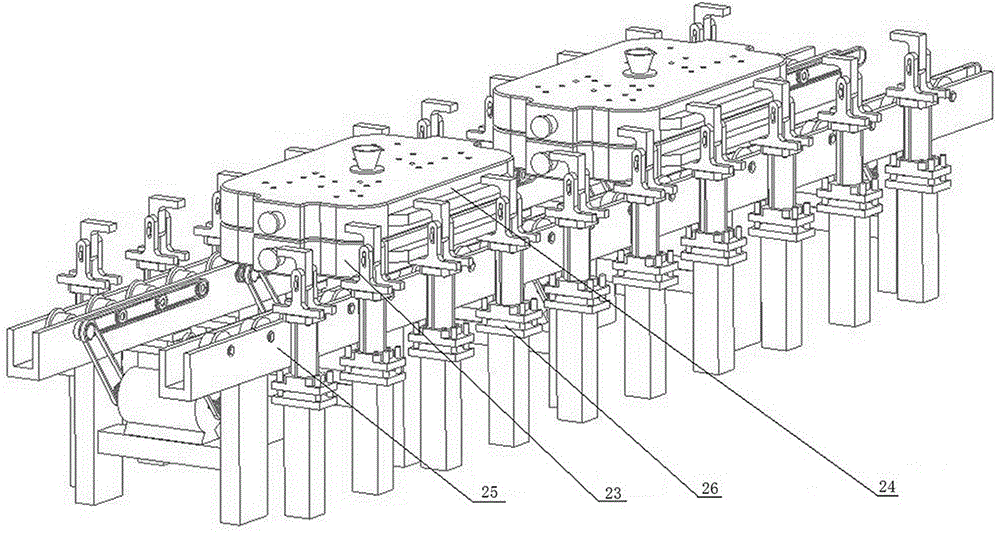

Pouring section line body of iron mould sand coating production line

ActiveCN106041036ASolve the problem of unilateral force firstTransport stableMolten metal conveying equipmentsProduction lineAutomatic control

The invention relates to a pouring section line body of an iron mould sand coating production line. The pouring section line body comprises an automatic roller bed device, a clamping device and a pouring section line body automatic control integration system. During work, the automatic roller bed device is controlled through the pouring section line body automatic control integration system, and iron moulds which are coated with sand cavities are sequentially transferred to pouring positions; before castings are poured, upper iron moulds and lower iron moulds are firmly clamped through the clamping device, so that the internal textures of the castings are compact during the mould filing process of the castings; and after the castings are cooled, the clamping device loosens, and the iron moulds are transferred to a demoulding process by controlling the automatic roller bed device, so that the castings are taken out. By adopting the pouring section line body, the problem of vibration damage to iron mould cavities caused by long-term unilateral load bearing, deformation of side roller racks and instability during transferring processes is solved; movement of the whole iron mould sand coating production line is stable and reliable; labor intensity of workers is greatly lowered, and consistency of quality of castings can be ensured; and tension-resistance and ductility of the castings can be effectively improved.

Owner:山西东鑫衡隆机械制造股份有限公司

Method for producing zinc alloy buckle type valve cock

InactiveCN1990173AReduce manufacturing costEasy to useOther manufacturing equipments/toolsZinc alloysCasting

The invention discloses a making method of zinc alloy button-typed valve cock, which comprises the following steps: dissolving zinc alloy material; casting; shaping; turning length; drilling; casing the screw; turning cavity; plating zinc on the surface; sulfurizing mouth and rubber; unloading mould; loading core; detecting air impermeability; loading nut; packing; storing.

Owner:SHANGHAI BAOLONG AUTOMOTIVE CORP

Four-axis multi-directional hydraulic fixture and clamping method implemented by same

InactiveCN104308617AThe device is compactReasonable layoutPositioning apparatusMetal-working holdersMiddle lineOil pressure

Owner:安徽精科机器有限公司

Welding and dispensing equipment for inductor production and using method thereof

ActiveCN112893008AAvoid pinchingConsistent clamping forcePretreated surfacesCoatingsElectric machineryInductor

The invention discloses welding and dispensing equipment for inductor production. The welding and dispensing equipment for inductor production comprises a first supporting frame, a coarse distance adjusting mechanism, a first fine distance adjusting mechanism, a clamping mechanism, a heater, a glue storage barrel and a second fine distance adjusting mechanism, the coarse distance adjusting mechanism comprises a cloth rolling mechanism, a distance adjusting box, a distance adjusting lead screw and a first motor, a fourth motor is installed on the lower side of the second fine distance adjusting mechanism, the fourth motor is fixedly connected with a supporting rotary disc, a glue dispenser and a spot welding machine are symmetrically installed on the other side face of the supporting rotary disc, a drying fan is installed between the glue dispenser and the spot welding machine, the heater is installed on one side of the first supporting frame, and the glue storage barrel is installed on the upper side of the heater. A heating wire prevents glue liquid in the glue storage barrel and an elastic hose from being solidified, the clamping force applied to each inductor is kept consistent, so that the inductors in the same batch are prevented from being excessively clamped due to the difference between individuals, the welding and dispensing quality of the inductors is greatly improved, and meanwhile, the energy utilization rate is improved.

Owner:深圳市三拓电子有限公司

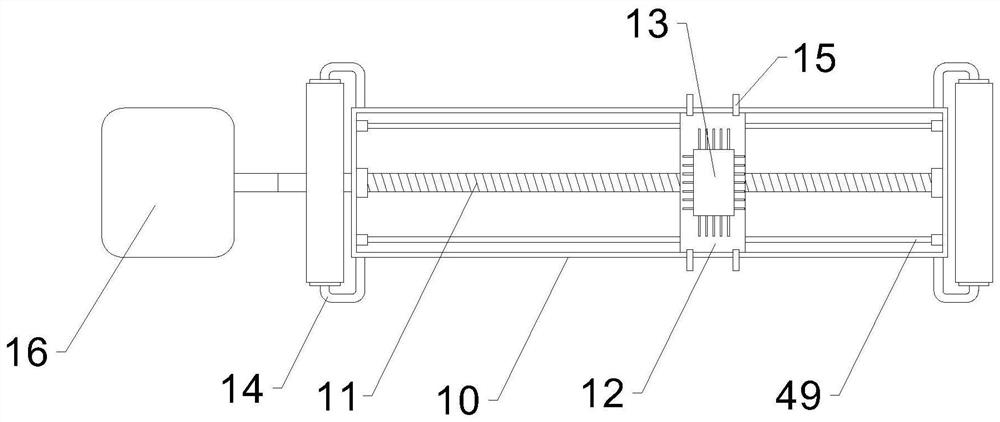

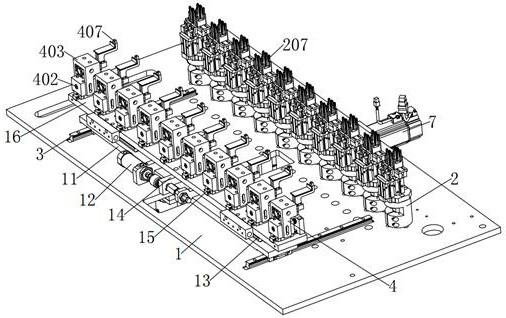

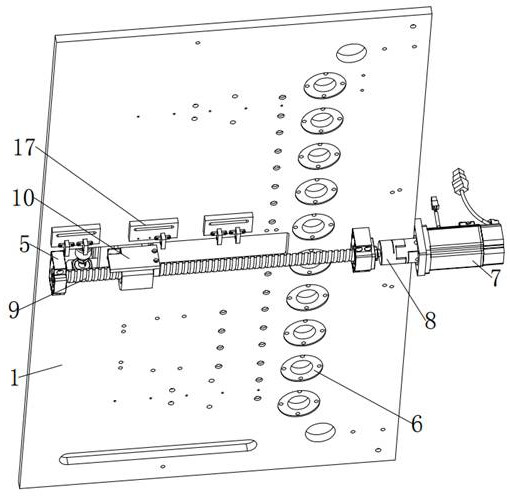

Winding equipment of blood taking needle packaging machine

The invention discloses a blood taking needle packaging machine winding device which comprises a mounting plate, a winding assembly, follow-up guide rails and a clamping assembly, the parallel follow-up guide rails are mounted at the top of the mounting plate, a plurality of fixing rings are fixed in the mounting plate in a penetrating mode, and the winding assembly is mounted in the middle of the fixing rings; a photoelectric switch, a driving motor, a plurality of fixing plates, a fixing bearing and a follow-up motor are mounted at the bottom of the mounting plate, the plurality of fixing plates are arranged in parallel to one side of the fixing plates, the follow-up motor is positioned at the edge of the mounting plate, and the driving motor is perpendicular to the bottom surface of the mounting plate. The clamping clamps are close to each other to clamp the two wings of the blood taking needle, and the opening clamps are far away from each other to open the hose, so that the winding diameter of the hose is greatly increased, the hose is tightened at the same time, the number of winding turns can be reduced, the winding efficiency can be improved, the hose can be tightened, the hose is neater after being wound, the gap is smaller, vacuum packaging air is reduced, and the working efficiency is improved. And the vacuum packaging effect is improved.

Owner:南昌汇恒自动化技术有限公司

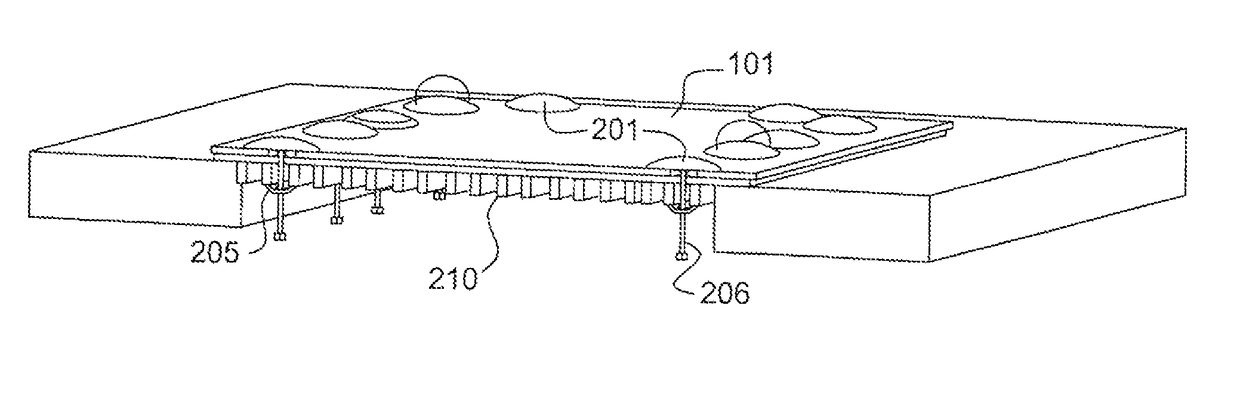

Portable flexible sealing device for grated openings

ActiveUS20160097172A1Decrease in torsional rigidityMaximizes clamping forceFlood panelsSewerage structuresGratingEntry point

A lightweight watertight cover that is easily installed and positively secured in place, which provides a reliable seal to prevent flood water from entering openings such as subway ventilation shaft gratings and other porous openings that serve as entry point for flood water.

Owner:ILC DOVER LP

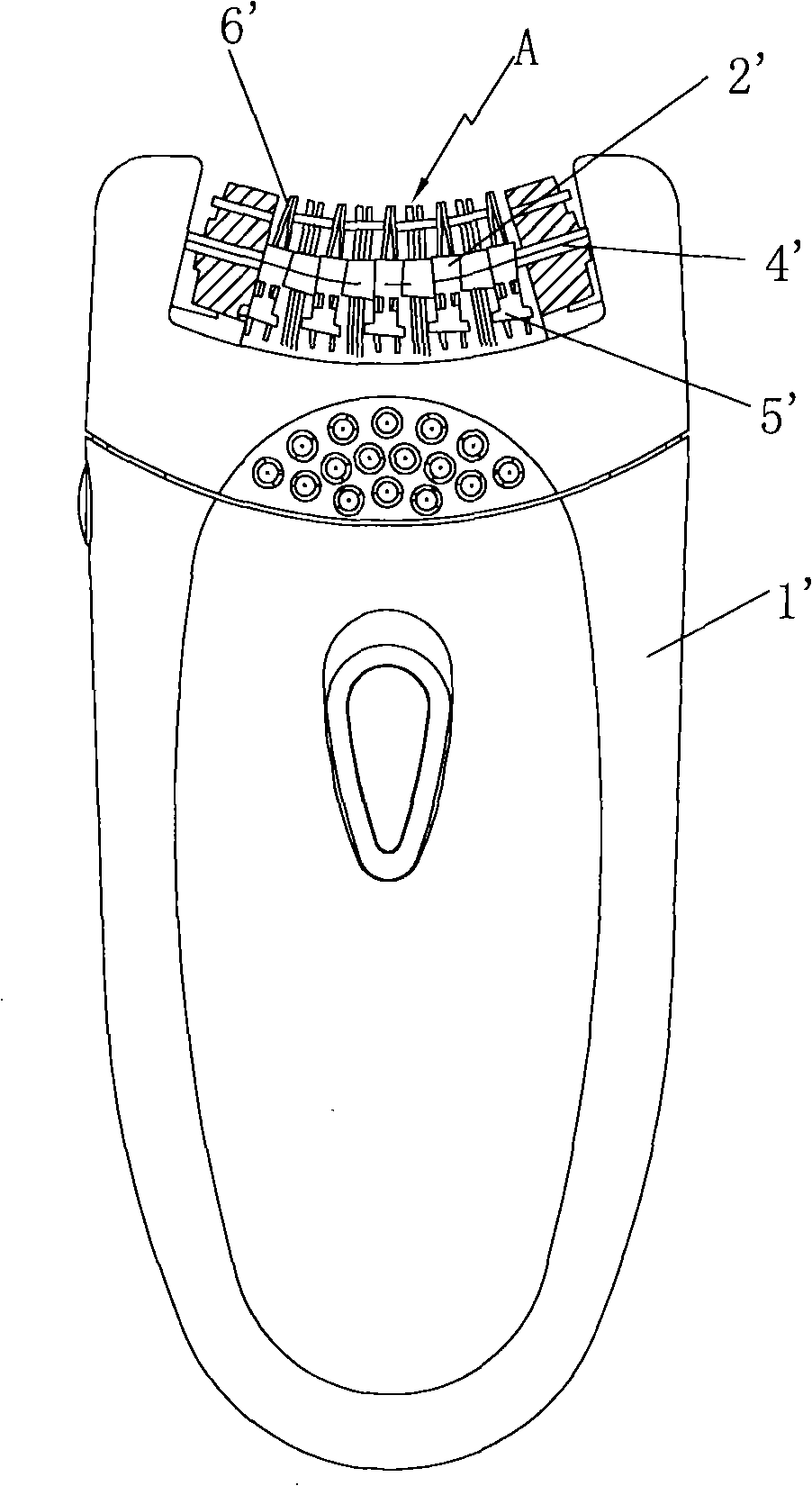

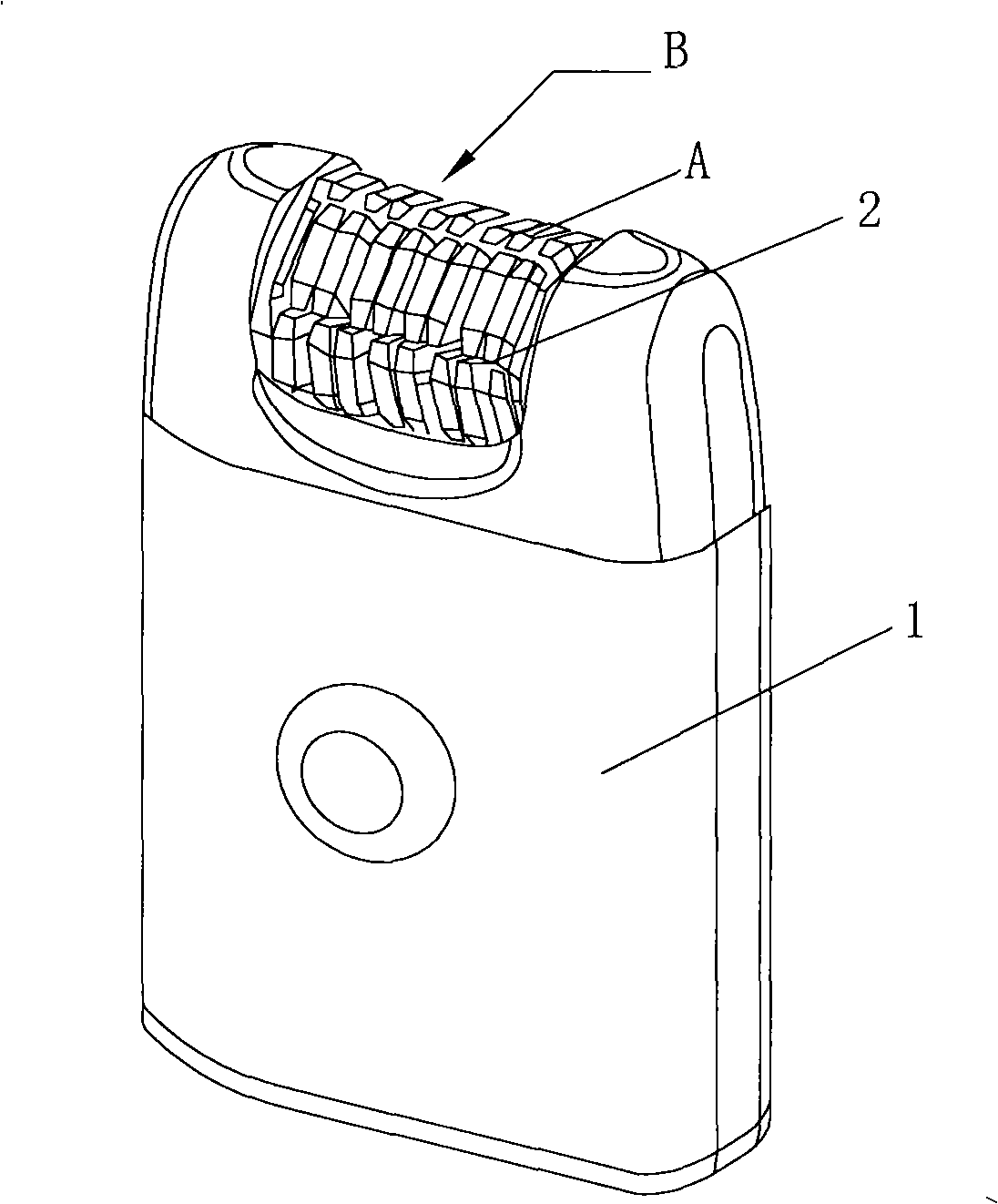

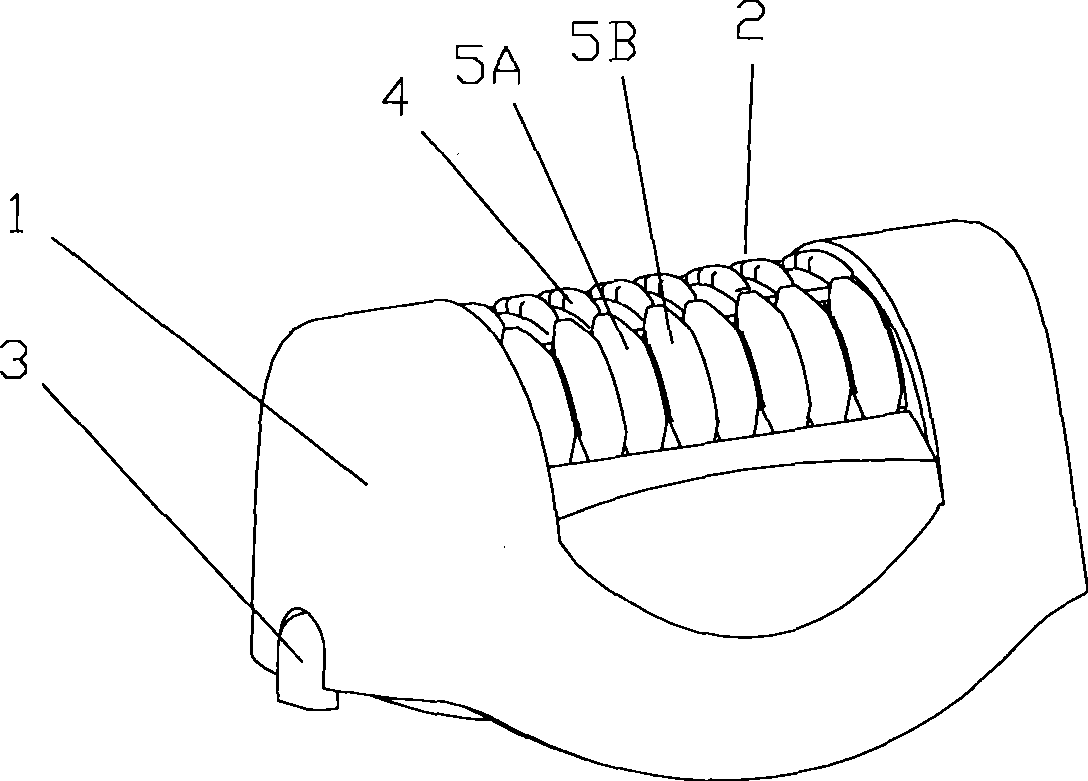

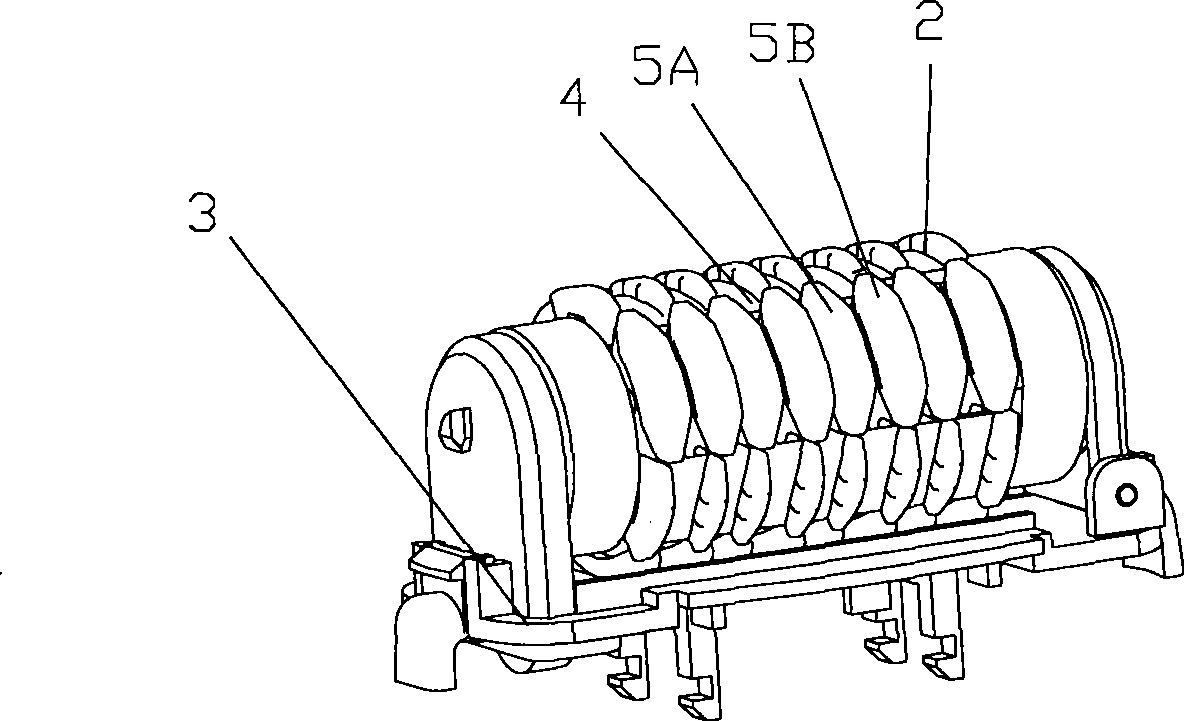

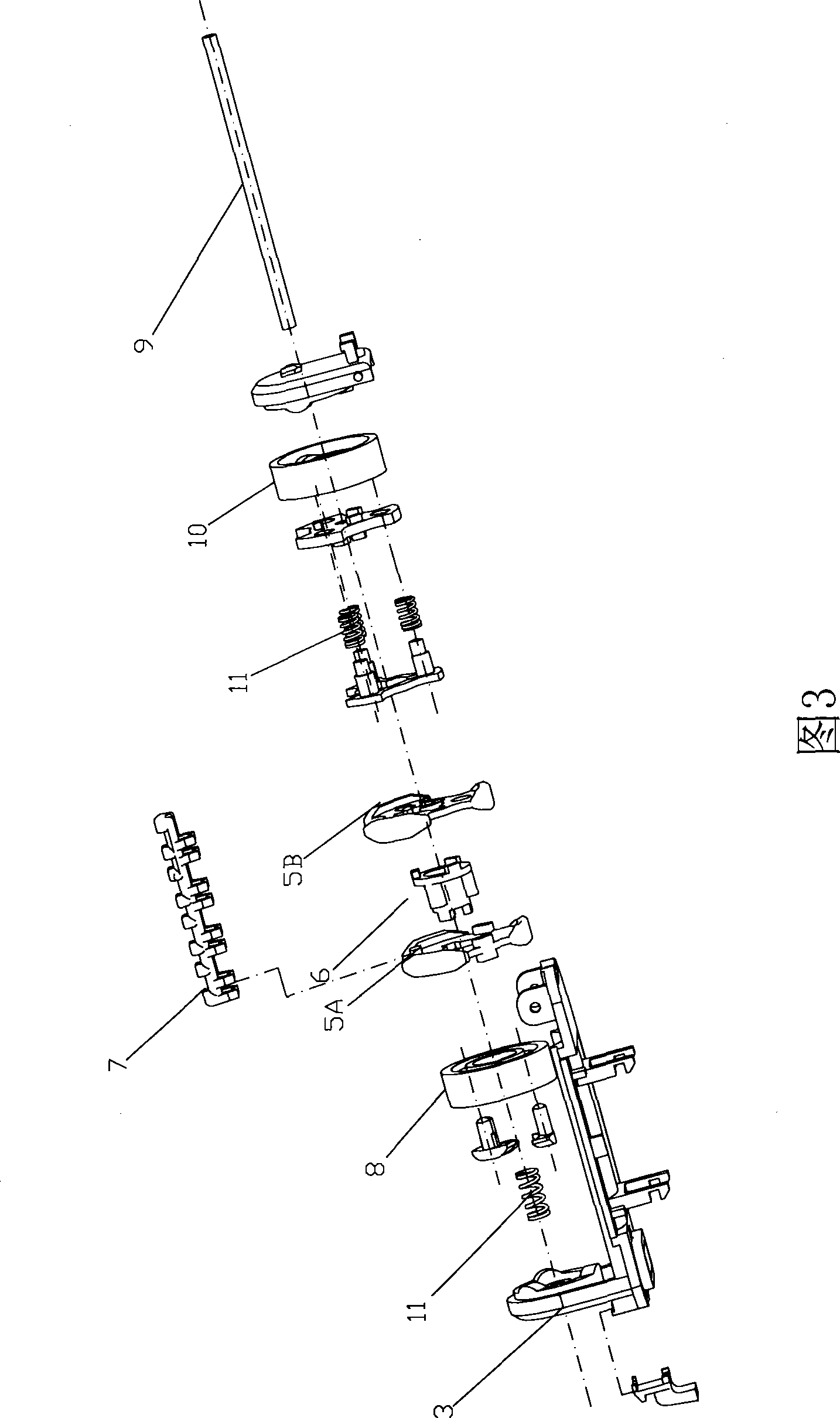

Dynamo-electric plucker

InactiveCN101317712AGood appearance consistencyGood size uniformityHair-singeingPersonal careForceps

The invention relates to an electric defeatherer which pertains to personal-care supplies. The prior art has the defects that troublesome assembly intensifies manufacturing difficulty; stretching hairs to snap rather than pulling out hairs results in pain and aggravated uncomfortable feeling to a user and epilating elements do not have self-adjusting function. The epilating elements of the invention are the integrated structure made from plastic; each epilating element comprises a base clamping part and a forceps element part which is positioned on the surface of the base clamping part. A rotating cylinder is driven by a drive mechanism which is arranged in a shell so as to lead the forceps element part of one epilating element to approach and depart from the forceps element part of the adjacent epilating element, thus the hairs between relatively moving blades are pulled out and released. The invention ensures that the uniformity of size of the epilating elements is improved and the epilating elements have self-adjusting function for deformation when bearing force; when working, the clamping force of each part for clamping hairs tends to accord so as to avoid the pain and uncomfortable feeling for the user caused by pinching off the hairs.

Owner:SUPERMAN GROUP

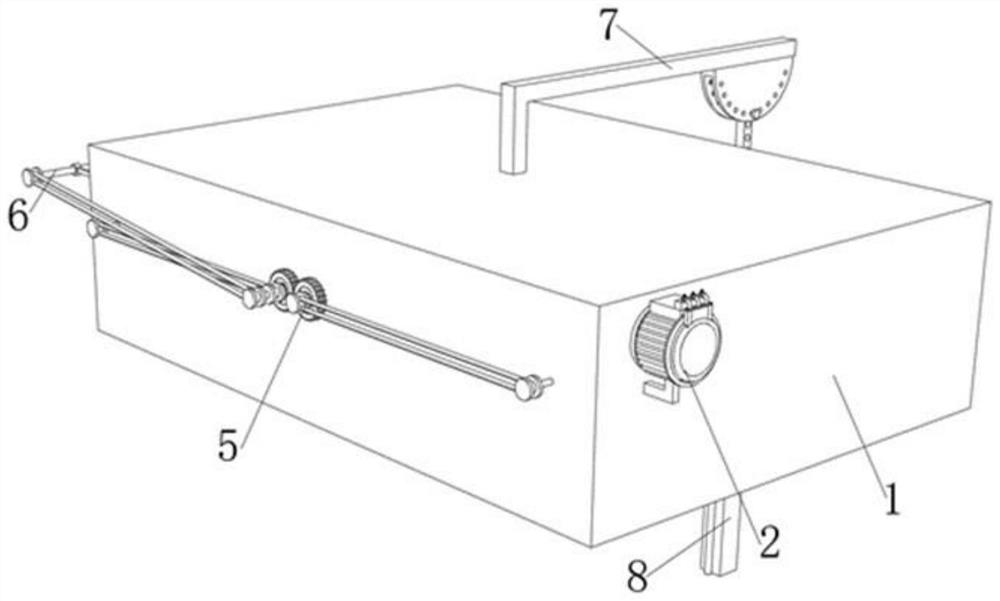

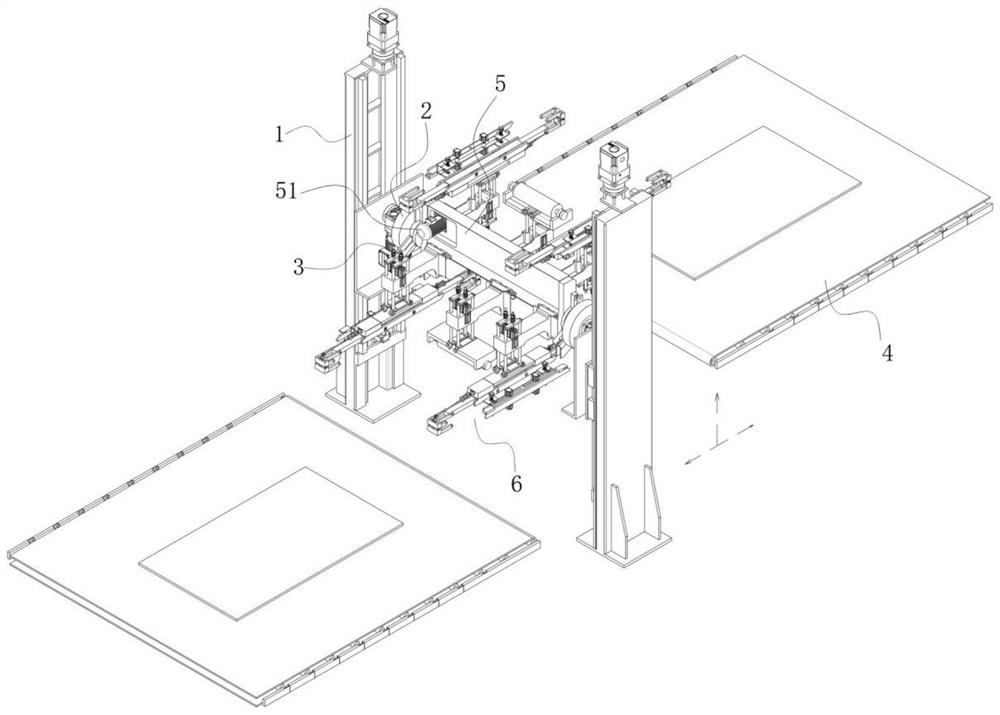

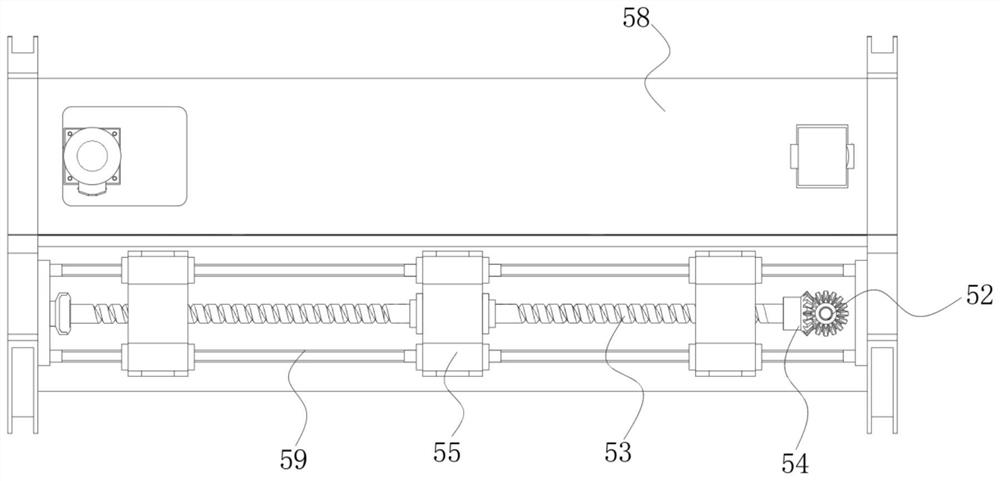

SF6 meter screen wiping device for patrol

ActiveCN114101137ARealize reciprocating motionEasy to observeRod connectionsCleaning using toolsEngineeringStructural engineering

The invention discloses an SF6 meter screen wiping device for inspection, and belongs to the technical field of power meter cleaning equipment.The SF6 meter screen wiping device for inspection comprises a frame (1), a wiping structure (2) is arranged on the side wall of the frame (1), a clamping structure (3) is arranged on the inner wall of the frame (1), and the top end of the clamping structure (3) is fixedly connected with two collecting structures (4); the inner wall of the frame (1) is provided with two cleaning structures (5), a linkage structure (6) is arranged between one cleaning structure (5) and the wiping structure (2), the top end of the frame (1) is fixedly connected with a handheld structure (7), and the bottom end of the handheld structure (7) is provided with a telescopic structure (8). The device is convenient to operate, can effectively remove dust and other stains on the screen of the SF6 meter, is convenient for manual and intelligent robot inspection and observation, and is high in practicability.

Owner:国网河南省电力公司超高压公司 +1

Efficient head removal device for poultry processing

InactiveCN110637867AHigh precisionImprove positioning efficiencyDividing poultryStructural engineeringMechanical engineering

The invention relates to the technical field of poultry processing equipment, in particular to an efficient head removal device for poultry processing. The efficient head removal device for poultry processing comprises a cutter, a connecting plate, a fixing frame, a placing bin, a fixed seat, clamping rods, clamping plates and a driving device. The driving device is used for driving the two clamping rods to rotate along the hinge with the fixed seat. The efficient head removal device for poultry processing has the beneficial effects that the placing bin is arranged, poultry to be removed headsare placed into an accommodating cavity in the placing bin in a head-down way, the poultry heads penetrate through a through slot of a protruding part under the action of gravity, and are located inclamping grooves of the two clamping plates; and through the driving device, it is ensured that the avoidance of necks during head removal of the cutter does not occur, the phenomenon of incomplete cutting the poultry heads is avoided, in addition, because arc grooves on the clamping plates are in arc shape, so that the poultry necks of different thickness adapt to be clamp.

Owner:安徽九颍智能设备有限公司

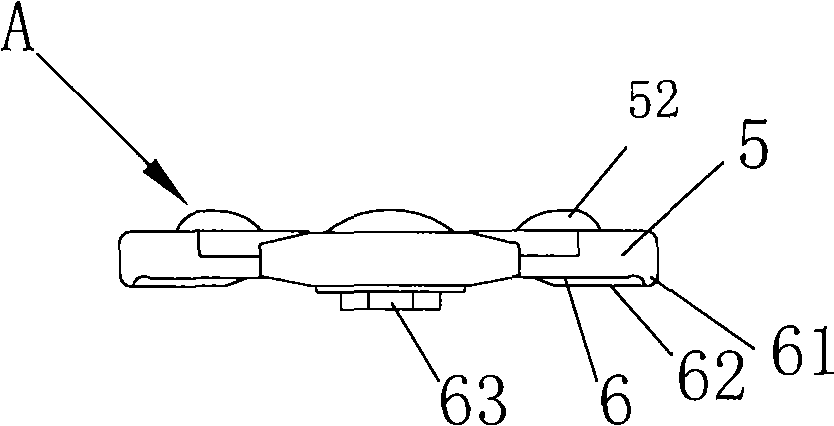

Dynamo-electric defeatherer head

InactiveCN101385588AGood appearance consistencyImproved size uniformityHair-singeingPersonal careDynamo

An electric defeatherer head belongs to the individual nursing appliance and aims at overcoming the technical deficiencies that in the prior art, a movable cutter blade of a hair removal component is lack of gripping force; the electric defeatherer head comprises a net head, a rotating cylinder and a support base, wherein, the rotating cylinder is provided with at least one hair removal component which is composed of a nipper element that touches the skin when in hair removal and a base component; the electric defeatherer head is characterized in that the rotating cylinder is provided with a straight shaft which goes through vertically and is provided with the hair removal component that is made of plastics and rotates around the straight shaft. The technical proposal adopts the longitudinal straight shaft as a core shaft of the rotating cylinder which is arranged straightly; after being tried out, the electric defeatherer is proved to further improve the contacting comfortableness of the users when the head of the electric defeatherer is touched with the skin; the user feels that the comfortableness is improved in the hair removal process; the speed for removing the hair is accelerated and the cleanliness of hair removal is enhanced; after being removed the hair, the trier generally reports the situation that the pain caused by removing hair is weaken, and the comfortableness is enhanced after hair removal.

Owner:SUPERMAN GROUP

Integrated yarn nozzle base

The invention relates to yarn guiding mechanism of a computer flat knitting machine and discloses an integrated yarn nozzle base. The integrated yarn nozzle base comprises a yarn nozzle base body andan inclined guide block assembly connected to the integrated yarn nozzle base body; the inclined guide block assembly comprises an inclined guide block pressure spring, an inclined guide block fine-turning locking member, an inclined guide block base connected to the yarn nozzle base and an inclined guide block body movably connected to the inclined guide block base; a groove for the embedding ofthe lower part of the inclined guide block body is installed between the yarn nozzle base body and the inclined guide block base; the inclined guide block pressure spring is installed between the inclined guide block base and the inclined guide block body; one end of the inclined guide block pressure spring is abutted to the lower end of the inclined guide block base and the other end is abutted to the inclined guide block body; the yarn nozzle base body is provided with through holes for the passing through of the inclined guide block fine-turning locking member; the inclined guide block fine-turning locking member passes through the through hole and is threaded with the inclined guide block base. The yarn nozzle base body of the invention is provided with the inclined guide block fine-turning locking member threaded with an adjusting nut; through rotating the inclined guide block fine-turning locking member, the gap between the yarn nozzle base and a top bar.

Owner:QUANZHOU YONGQI PLASTIC ELECTRON

Rapid die clamping system for bending machine

PendingCN109226527AEasy to adjustRealize repeated dozens of operationsShaping toolsEngineeringMechanical engineering

The invention discloses a rapid die clamping system for a bending machine. The system comprises a clamping base, clamping teeth, a pushing mechanism and a reset elastic part. A first mounting groove for mounting of a bending die and a sliding groove for penetrating through the clamping ends of clamping teeth are formed in the clamping base. The sliding groove is communicated with the first mounting groove. The clamping teeth are mounted on the clamping base, and comprise the clamping ends, and the clamping ends are slidingly assembled in the sliding groove. The pushing mechanism is used for wholly pushing the clamping teeth to enable the clamping ends to slide to the first mounting groove along the sliding groove. The reset elastic part is mounted between the clamping teeth and the clamping base and used for wholly pushing the clamping teeth to enable the clamping ends to slide opposite to the first mounting groove along the sliding groove. The bending die can be rapidly clamped and loosened, one-key clamping is achieved, it is avoided that dozens of times of operations need to be repeated in traditional manual rapid clamping, the die replacement time is saved, and the operation efficiency is improved.

Owner:王勇

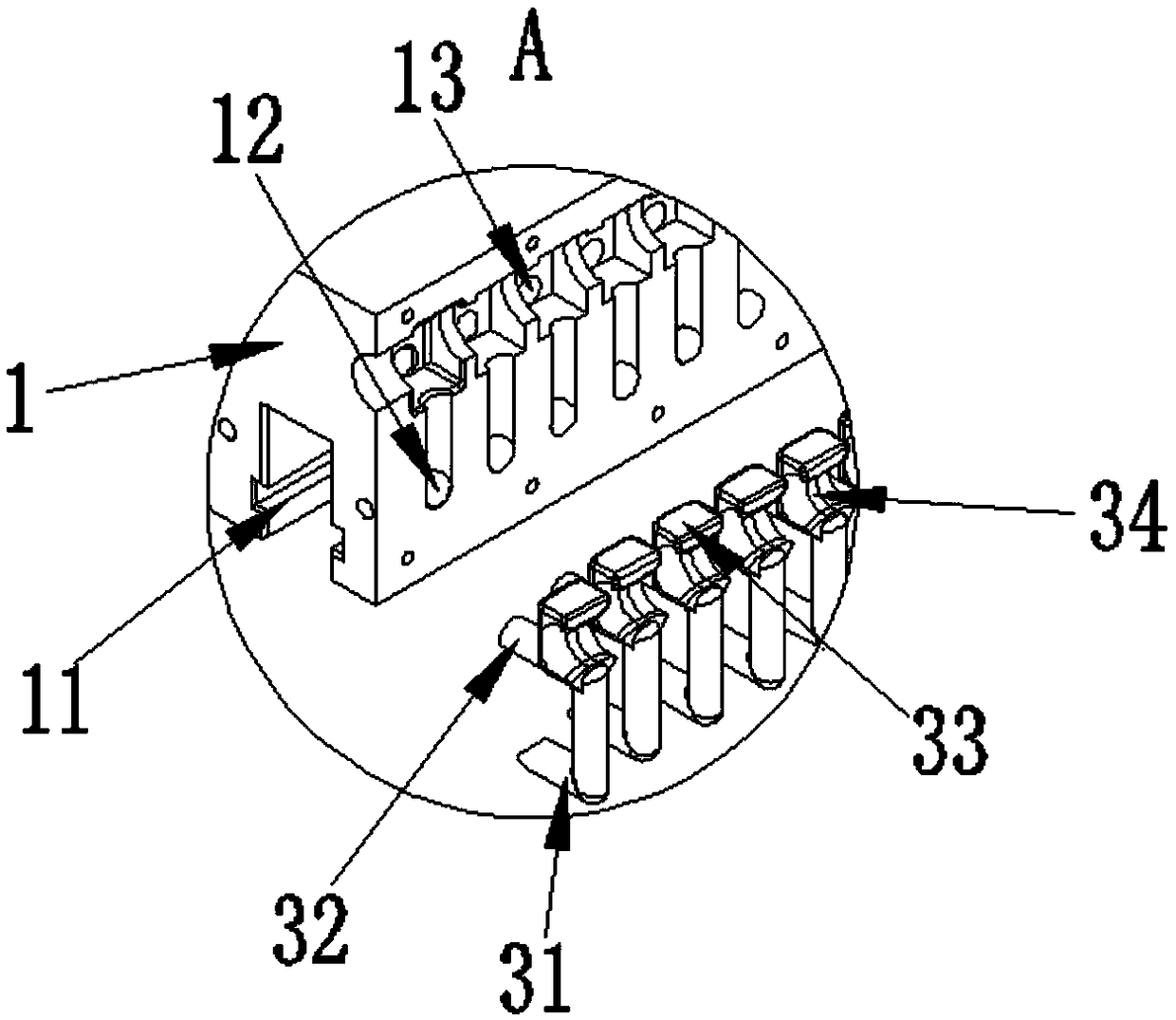

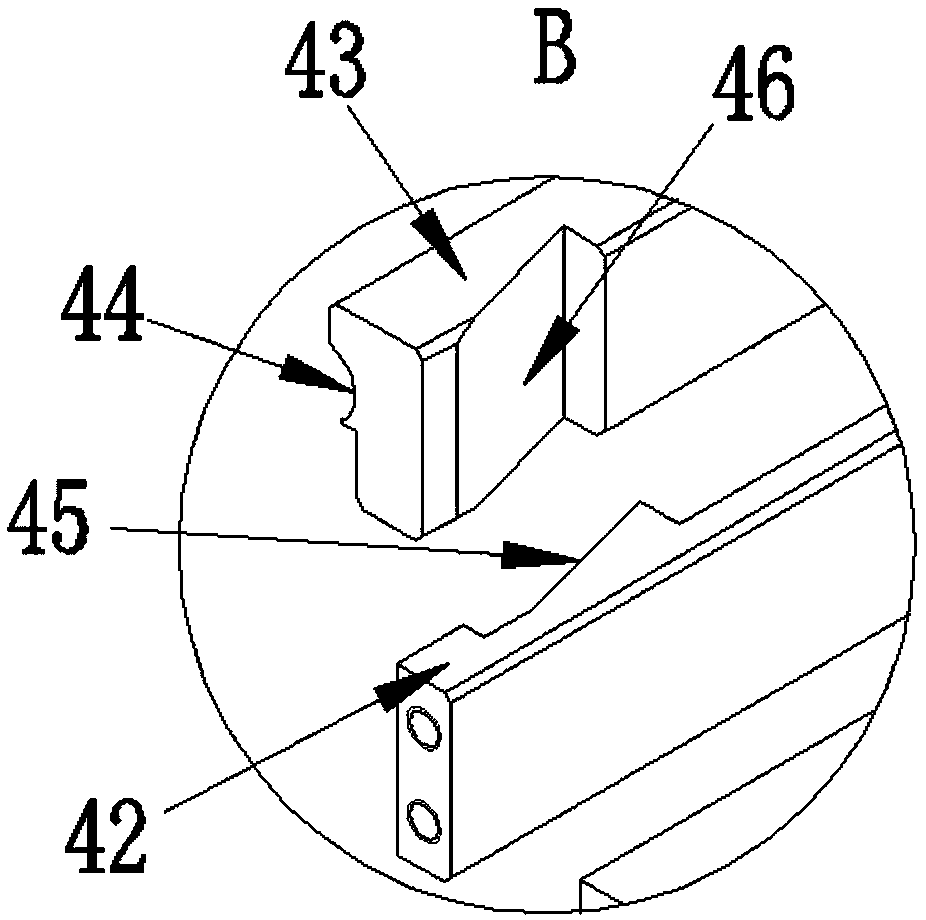

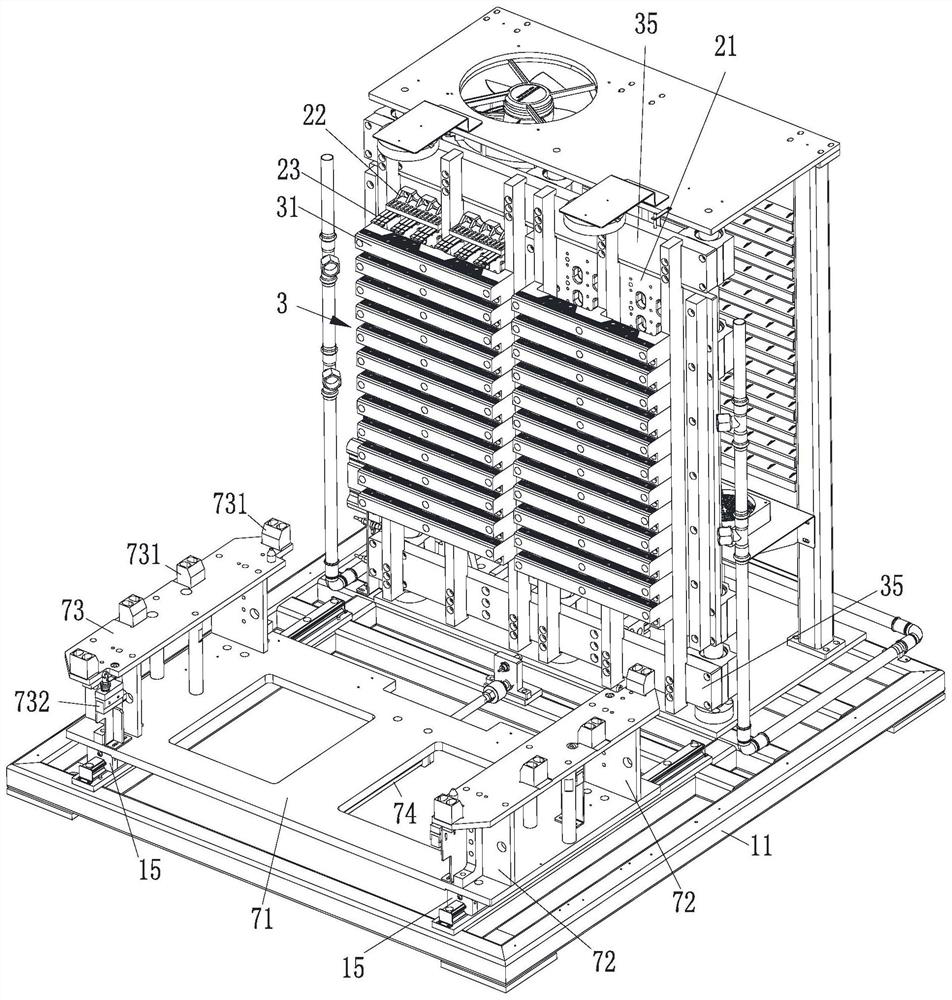

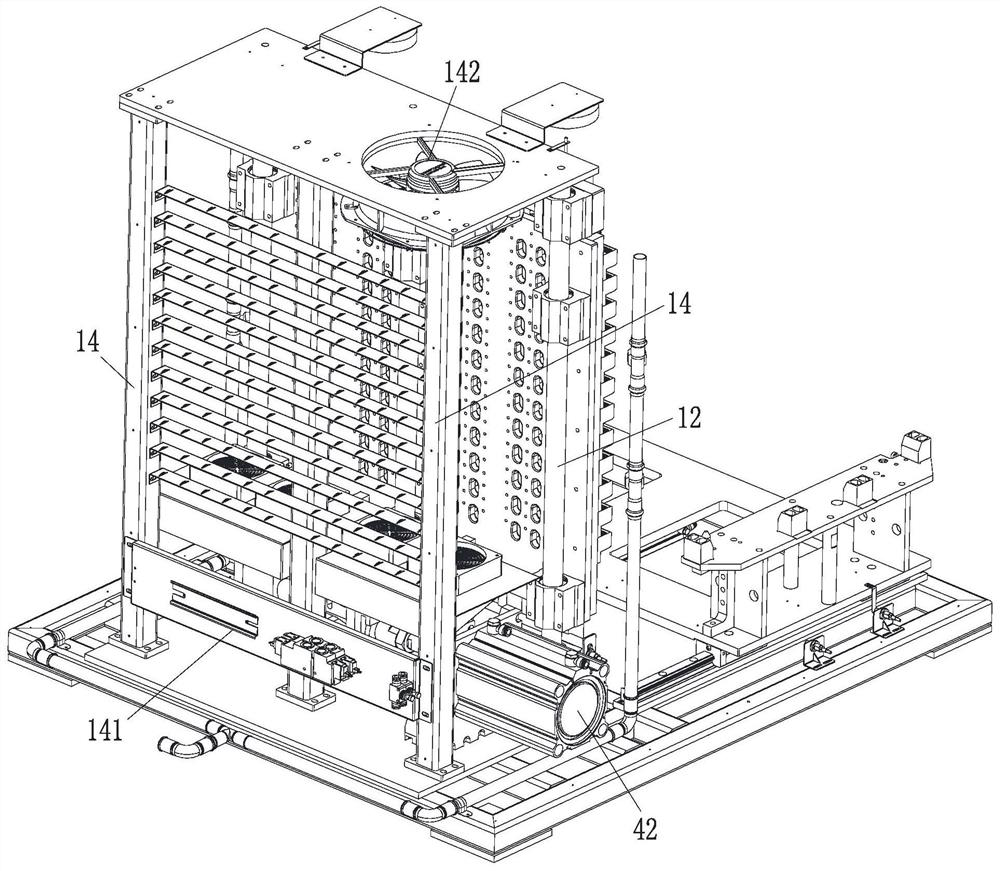

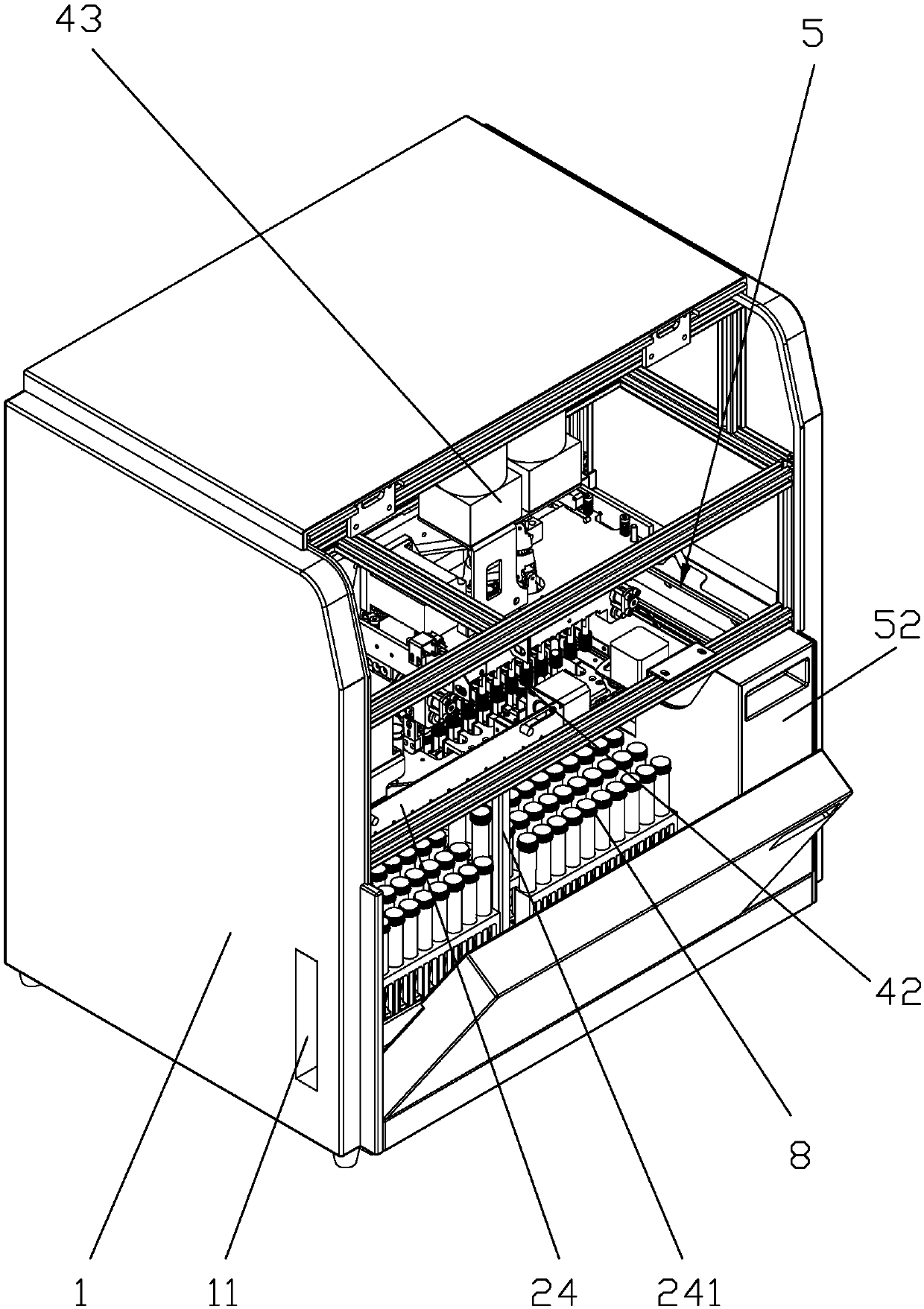

High-current soft package battery test needle bed

PendingCN113189376AConsistent clamping forceAvoid breakingElectrical testingMeasurement instrument housingRoller bearingStructural engineering

The invention discloses a high-current soft package battery test needle bed, which comprises a capacity-grading mounting bottom frame, wherein a plurality of supporting and guiding stand columns are fixedly connected to the top side of the capacity-grading mounting bottom frame; a current clamp mounting plate, wherein the current clamp mounting plate is slidably connected with the supporting and guiding stand columns, and the front side of the current clamp mounting plate is fixedly connected with a current clamp mounting base; an insulation clamp assembly, wherein theinsulation clamp assembly is slidably connected with the supporting and guiding stand column, the insulation clamp assembly is provided with a plurality of insulation current clamp bases, which are provided with metal pole pieces, the rear side of the insulation clamp assembly is fixedly connected with a second roller mandrel, the second roller mandrel being provided with a second roller bearing follower in a rolling manner; and a cam mounting vertical plate which is arranged on the capacity-grading mounting bottom frame in a sliding mode, wherein the capacity-grading mounting bottom frame is provided with a clamping driving air cylinder. According to the invention, the tab can be prevented from being damaged in the detection process, the production cost and the maintenance cost can be reduced, and the test efficiency and accuracy are improved.

Owner:深圳市瑞能创新科技有限公司

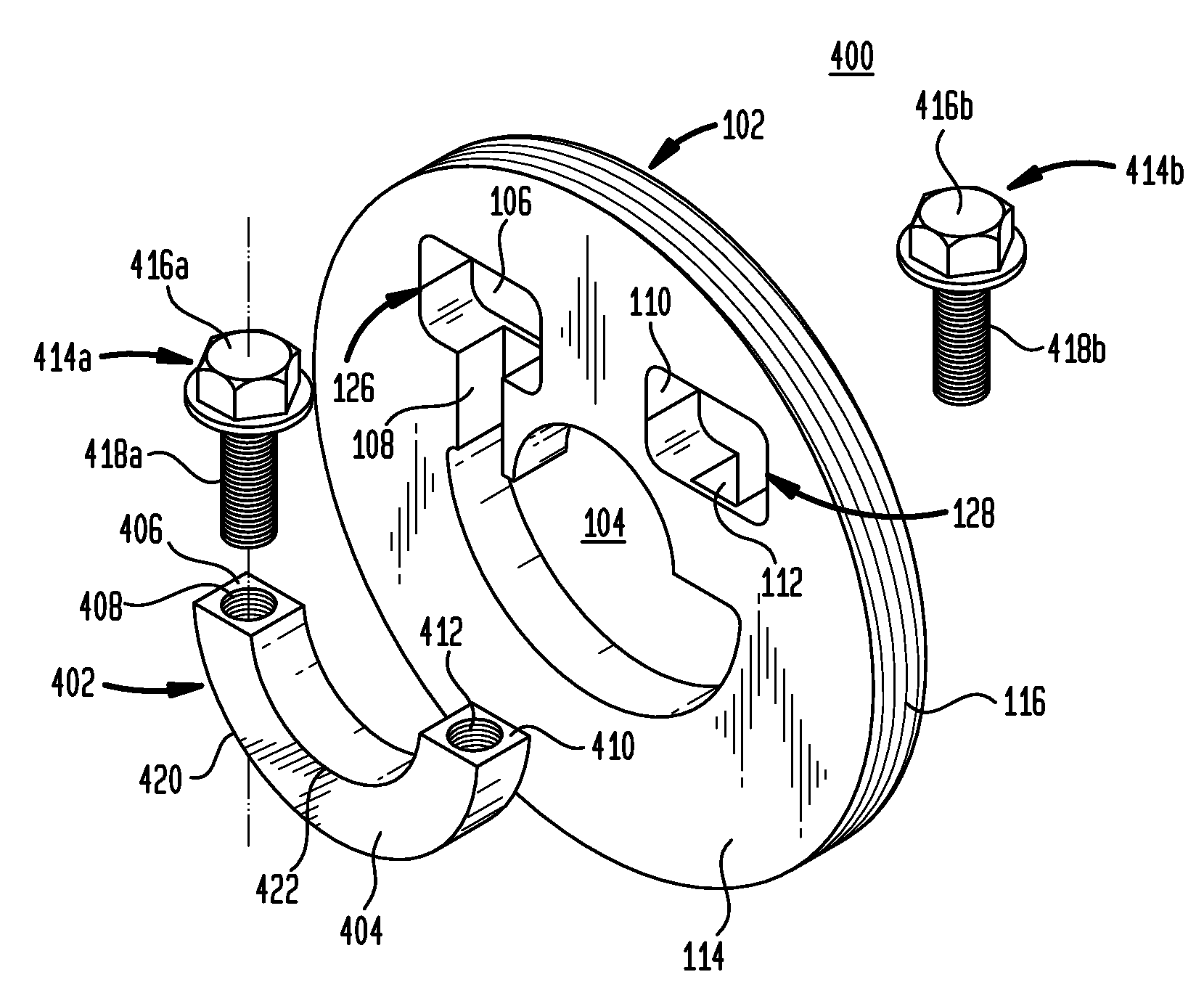

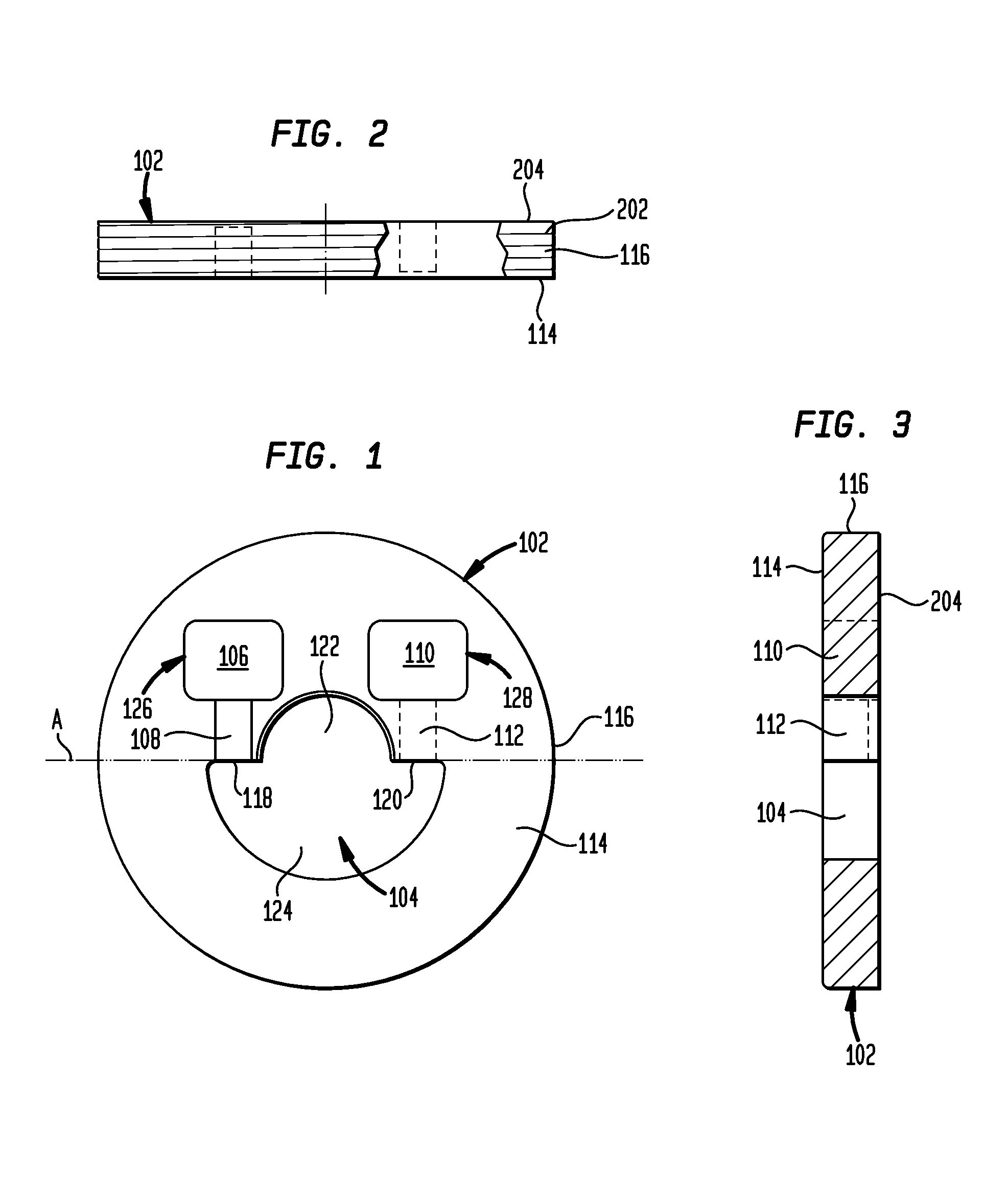

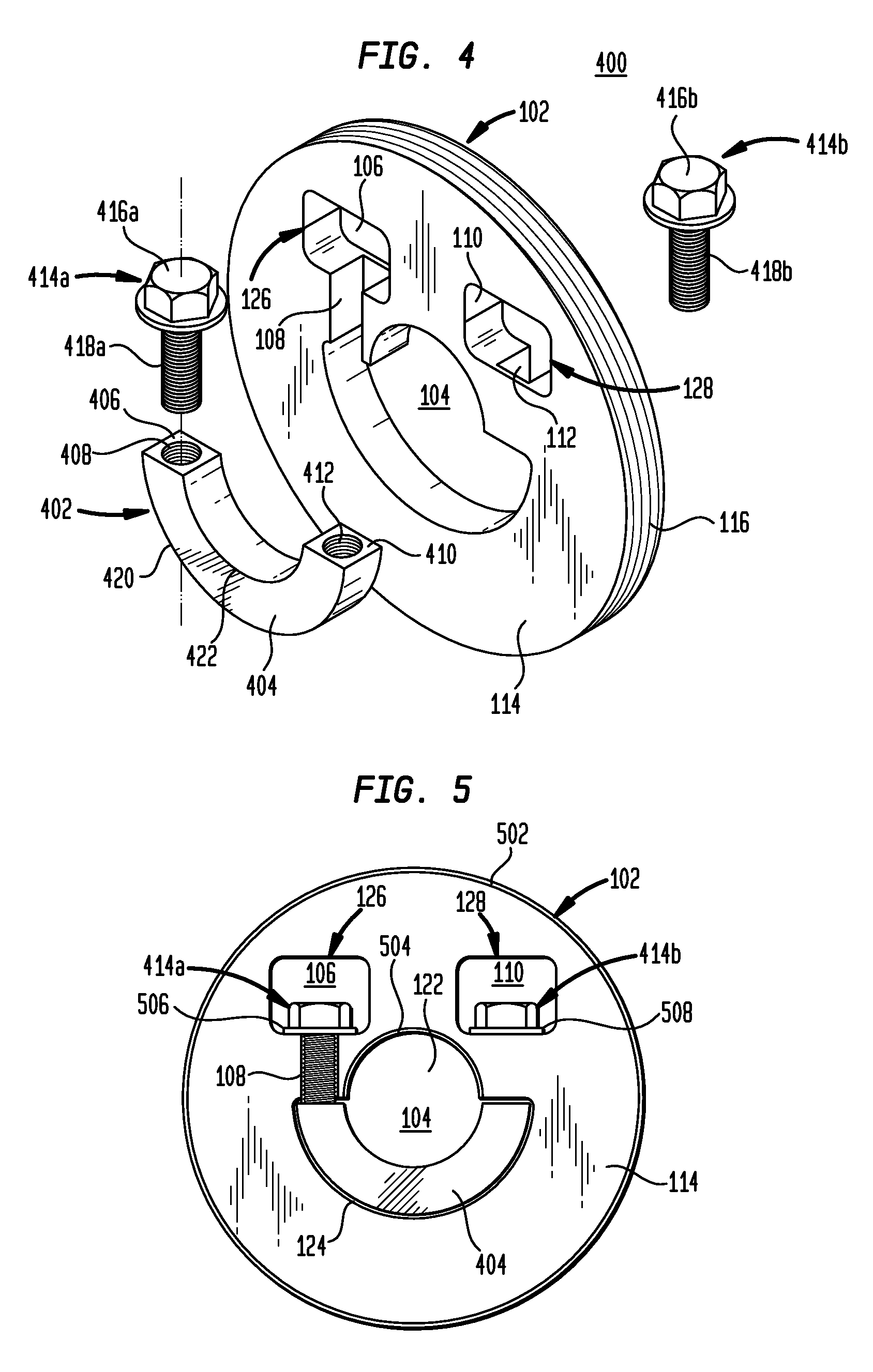

System and method for securing a rotor to a motor drive shaft using a pressure clamp

ActiveUS7516535B1Less prone to failureNarrow profileEngine sealsCouplings for rigid shaftsMotor driveEngineering

A rotor assembly for mounting a rotor to a motor shaft having a rotor with a main aperture defined by a first half and a second half. A C-shaped collar is disposed into the second half of the main aperture with the motor shaft passing through the first half of the main aperture and the interior curve of the collar. The collar is secured to the rotor by a plurality of fasteners.

Owner:NIDEC MOTOR CORP

Easy-to-process automotive engine block fixture

ActiveCN108481022BConsistent clamping forceReliable clamping forcePositioning apparatusMetal-working holdersEngineeringCylinder block

The invention discloses an automobile engine cylinder body clamp facilitating automobile engine cylinder body machining. The clamp comprises a supporting board, a pair of first screw rods, a pair of first through grooves, two pairs of lantern rings, a pair of connecting rods, a pair of fixing rods, a pair of guide columns, a driving gear, a pair of driven gears and two pairs of air cylinders; eachpair of lantern rings comprise the first lantern ring and the second lantern ring, wherein each first lantern ring sleeves the upper part of the corresponding first screw rod and is in threaded connection with the upper part of the corresponding first screw rod, and each second lantern ring sleeves the lower part of the corresponding first screw rod and is in threaded connection with the lower part of the corresponding first screw rod; one ends of the connecting rods are horizontally connected with the first lantern rings corresponding to the first screw rods, and the other end of each connecting rod is vertically downwards connected with a horizontal pressing plate; one sides, close to the first screw rods, of the pressing plates are sunken inwards to form second through grooves; and thelower parts of the guide columns are just clamped in the first through grooves, and the upper parts of the guide columns are just clamped in the second through grooves. The clamp has the advantages of being consistent in clamping force, reliable and stable in clamping, suitable for positioning holes with different sizes and the like, and can be widely applied to the technical field of automobileengine cylinder body clamps.

Owner:WUHAN HONGBOXIN PRECISION MACHINERY IND & TRADE CO LTD

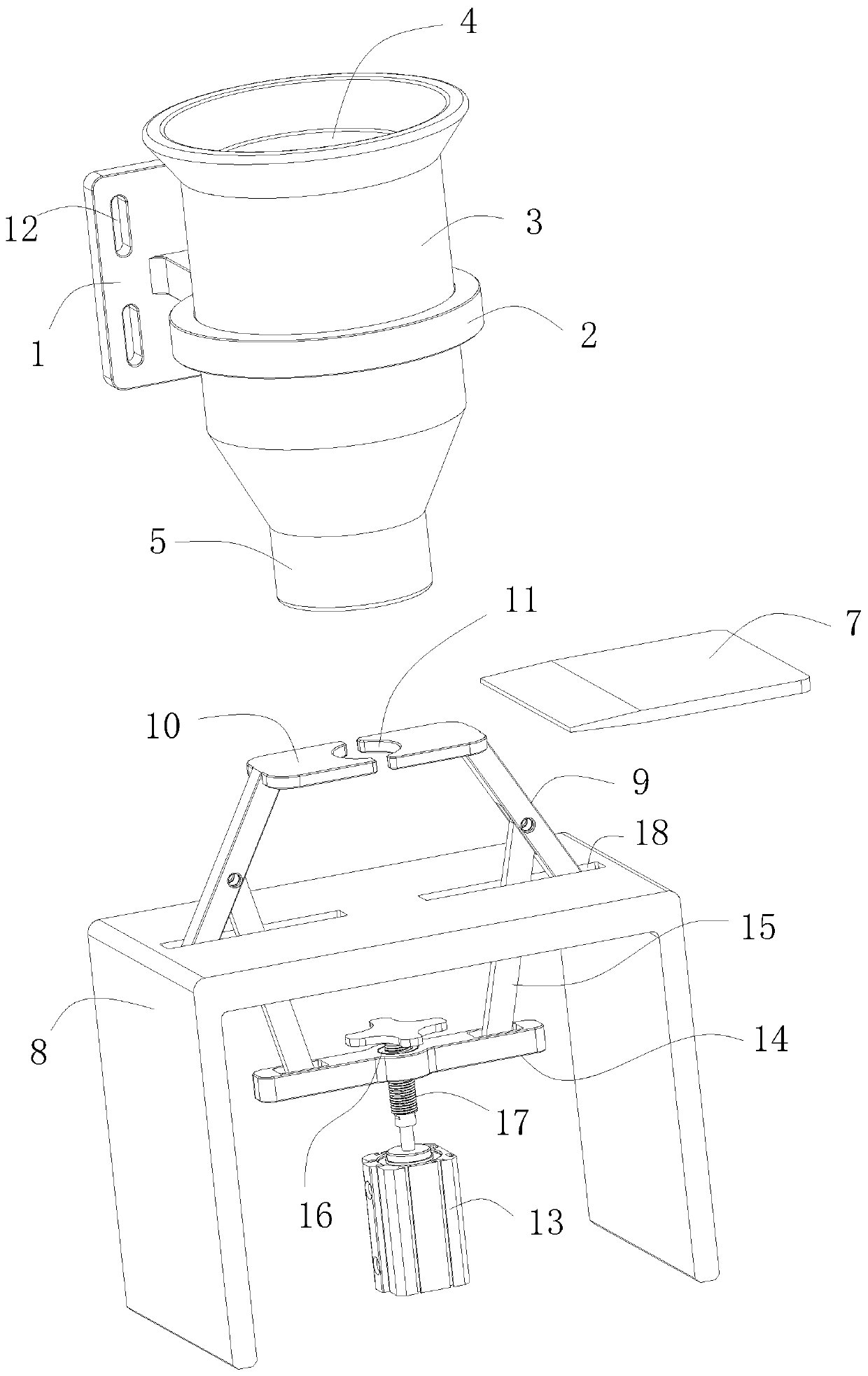

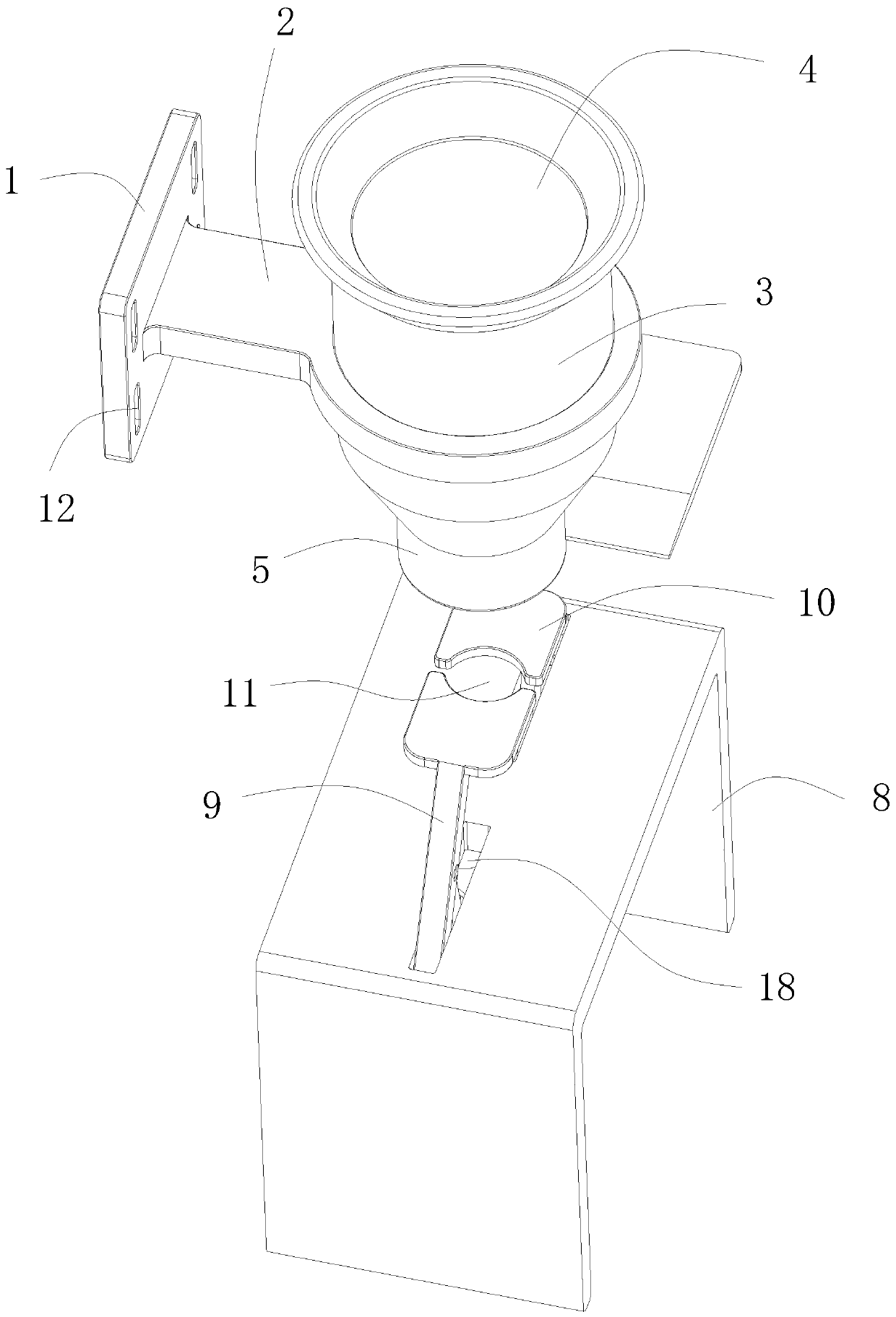

Urine collection tube uncovering machine

ActiveCN108033418AReduce volumeHigh degree of automationOpening closed containersBottle/container closureUrine CollectionsWaste management

The invention relates to the technical field of medical instruments, and discloses a urine collection tube uncovering machine. The uncovering machine comprises a machine shell, a material conveying plate is arranged at the inner bottom of the machine shell, a feeding conveying belt and a discharging conveying belt are arranged on the material conveying plate, and a discharging device is arranged on the left side of the material conveying plate; a cover discharging mechanism is arranged on the right side of the material conveying plate, and a clamping bottom plate is arranged above the materialconveying plate; a pair of symmetric pipe clamping pieces are arranged on the clamping bottom plate, and the pipe clamping pieces are longitudinally and slidably connected to the clamping bottom plate; a clamping driving mechanism for driving the pipe clamping pieces to slide longitudinally is arranged on the clamping bottom plate; a lifting device is arranged on the rear side of the clamping bottom plate, and a cover removal bottom plate is arranged at the upper end of the lifting device; a pair of symmetric cover removal bases are arranged below the cover removal bottom plate, and a movingmechanism for driving the cover removal bases to move longitudinally is arranged between the two cover removal bases; each cover removal base is provided with a row of cover removal rods, the cover removal rods are located above the pipe clamping pieces, and a cover removal motor for driving the cover removal rods to rotate is arranged above the cover removal bottom plate. The machine is compact in structure, small in size and rapid and reliable in work.

Owner:HANGZHOU LONGXIN TECH

Fabricated building material transportation device

PendingCN113511584AImprove securityAccelerated Flip PositioningVibration suppression adjustmentsLoad-engaging elementsConstruction engineeringStructural engineering

The invention discloses a fabricated building material transportation device which comprises two sets of lifting devices, a turnover device and conveying devices. The two sets of lifting devices face each other and drive the turnover device to move up and down; the conveying devices are arranged on the left sides and the right sides of the lifting devices correspondingly; the conveying device on the left side is lower than the conveying device on the right side; two sets of positioning and clamping devices are installed in the turnover device, are arranged on the left side and the right side and correspond to the conveying devices correspondingly; each set of positioning and clamping device comprises two sets of clamping assemblies and an auxiliary pressing assembly; and each two sets of clamping assemblies are horizontally arranged in parallel and located on the front side and the rear side of the corresponding auxiliary pressing assembly on the same plane.

Owner:GUANGZHOU CITY CONSTR COLLEGE

Ultrasonic method and device for testing macroscopic cleanness of continuous casting billet

ActiveCN100495018CNo low-speed crawling phenomenonHigh movement precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationSlag

A ultrasonic detection method of macrocleanness on continuous casting billet includes using multiple resolution analysis means to carry out analysis on original ultrasonic echo signal series at different frequency scope and carrying out treatment on analysis said echo signal with reasonable time frequency analysis, reconfigurating treated signal to generate signal with the same length as said echo signal series, comparing treated signal with defect judgment standard used at production unit to form planar distribution drawing of slag as per sample surface distribution.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com