High-current soft package battery test needle bed

A soft-pack battery, testing needle bed technology, applied in the parts of electrical measuring instruments, measuring electricity, measuring devices and other directions, can solve problems such as danger, breakage of tabs, and large impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

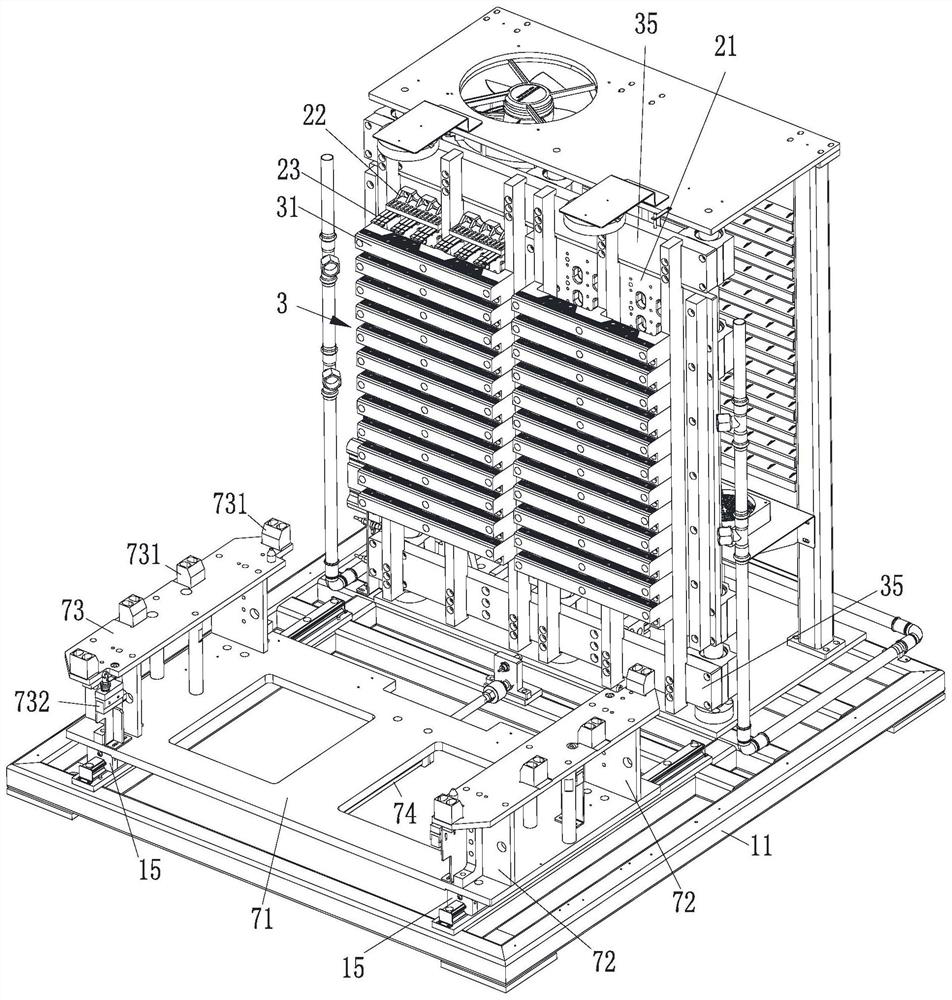

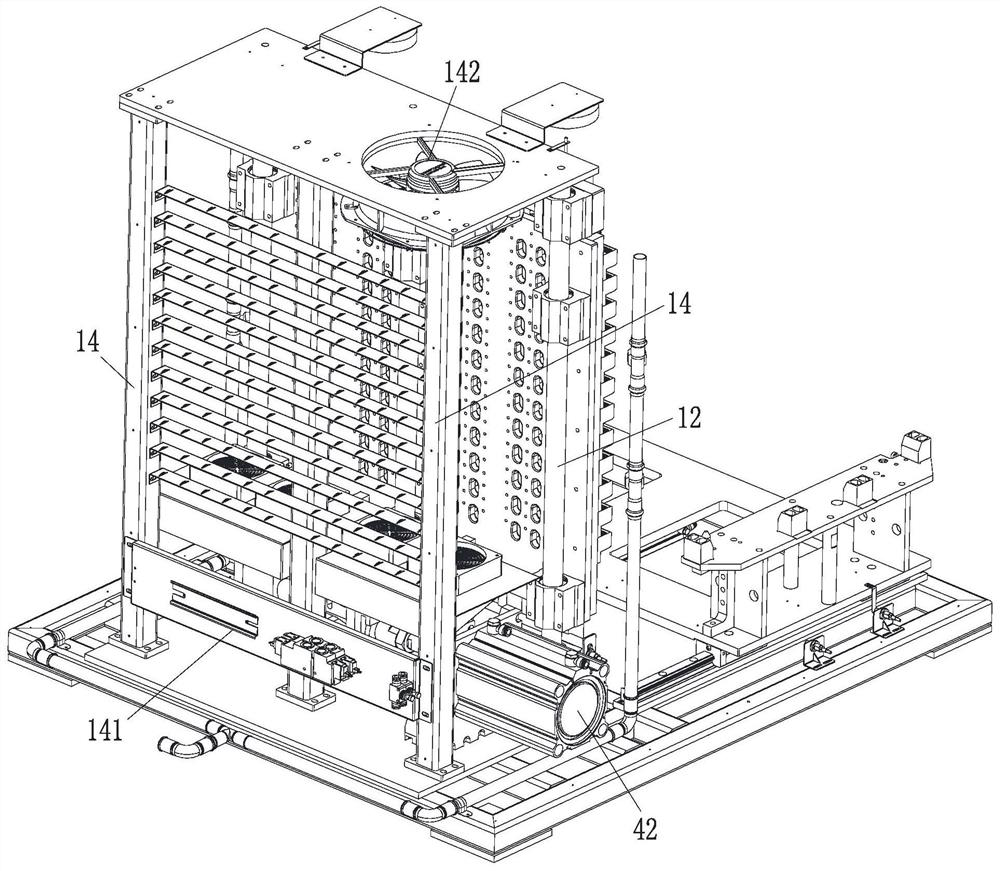

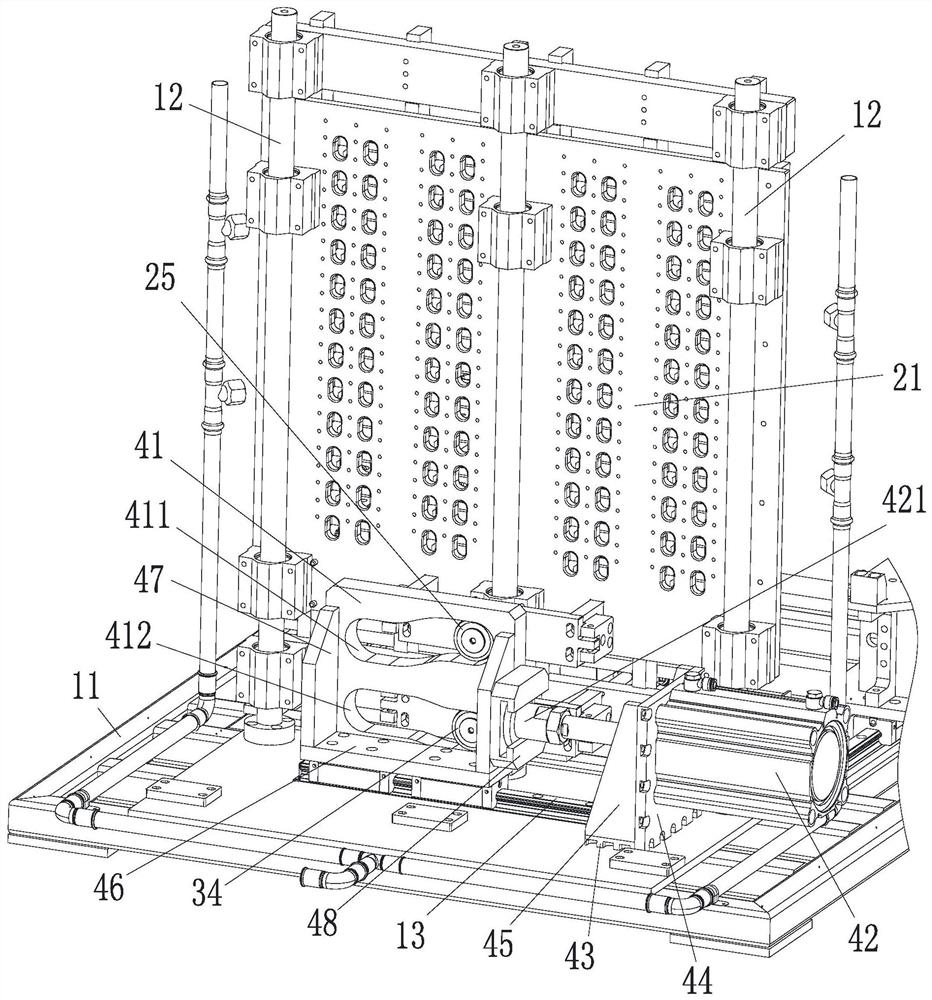

[0030] See Figure 1 to Figure 3 and Figure 6 , High-current pouch battery test needle bed, including: sub-capacity mounting base 11, current clamp mounting plate 21, insulating clamp assembly 3, and cam mounting vertical plate 41.

[0031] See figure 2 , image 3 A plurality of support and guide columns 12 are affixed to the top side of the underframe 11 for sub-capacity installation.

[0032] See image 3 , Figure 5 , The current clip mounting plate 21 is slidably connected to the supporting guide post 12 . A current clamp mounting base 22 is fixedly connected to the front side of the current clamp mounting plate 21 , and the current clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com