Four-axis multi-directional hydraulic fixture and clamping method implemented by same

A hydraulic fixture and multi-directional technology, applied in the field of tooling and fixtures, can solve the problems of uncontrollable workpiece size, mass production, and increased number of tooling, and achieve the effects of good neutrality, compact device structure, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example one

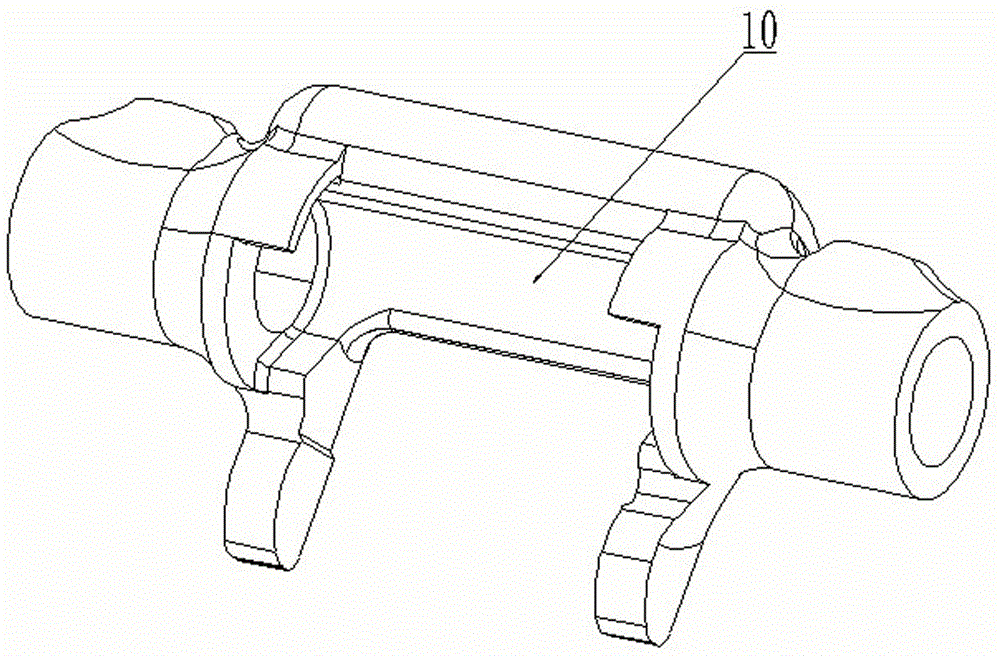

[0020] Such as figure 1 It can be seen that this embodiment is mainly applied to the clamping of the clutch release fork 10 for trucks.

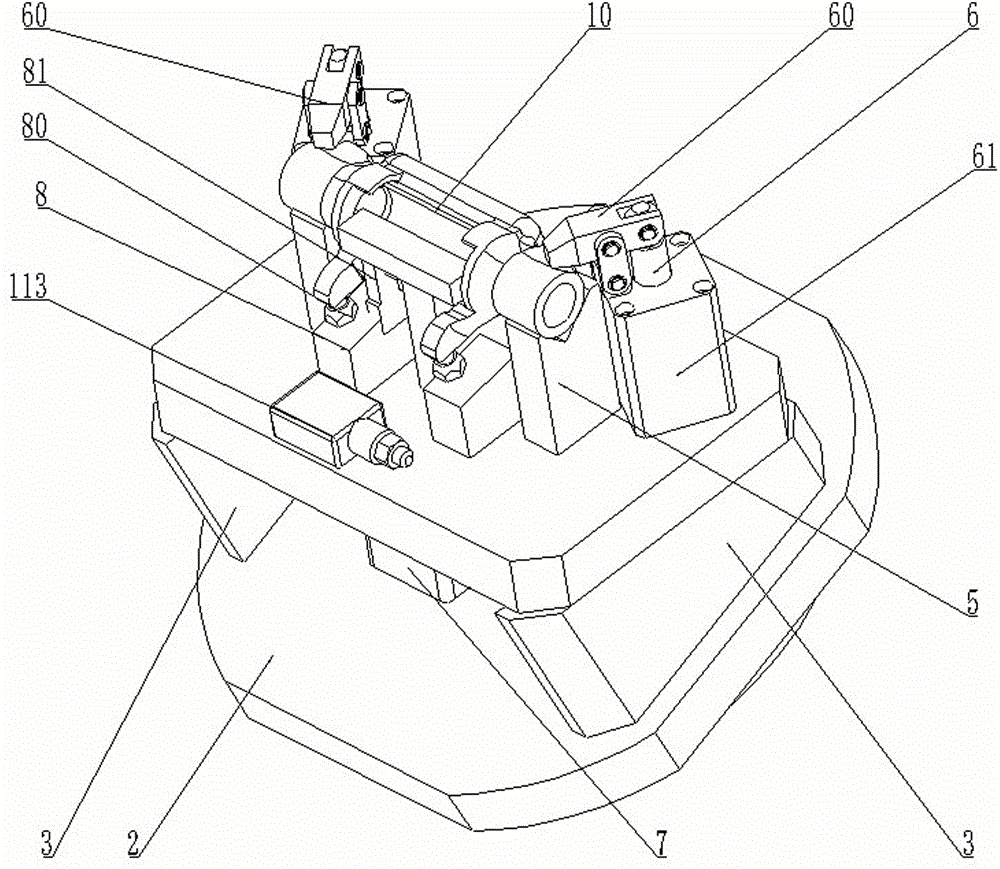

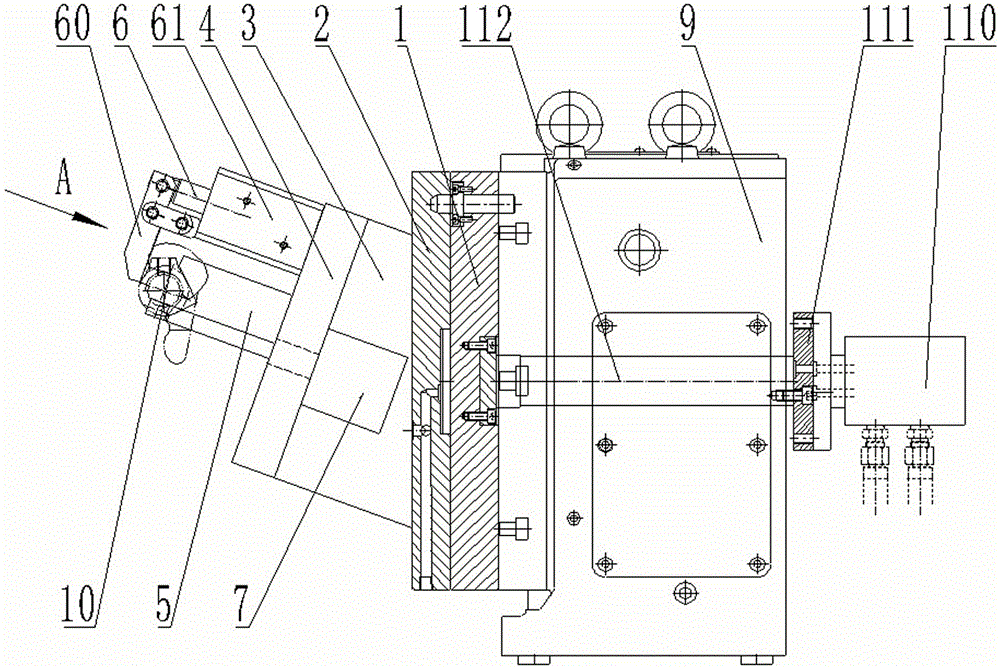

[0021] Such as Figure 2 to Figure 5 It can be seen that the four-axis multi-directional hydraulic clamp of the present invention includes a mounting flange 1, on which a transition disc 2 is fixed, and two right-angle trapezoidal structures are symmetrically provided on the transition disc 2 The two transition blocks 3 are fixedly provided with a bottom plate 4, the bottom plate 4 is fixed with two V-shaped blocks 5 symmetrically along the center line, and the bottom plate 4 is also provided with two lever cylinders 6, which are 6 is fixed on the bottom plate 4 by an oil cylinder backing plate 61; the levers 60 of the two lever cylinders 6 are matched with the two V-shaped blocks 5 respectively; it also includes an auxiliary compression hydraulic cylinder 7 arranged in the middle of the transition disc 2, The end of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com