Core roller quick replacement device

A core roll and clamping jaw technology, which is applied in metal rolling, metal rolling racks, manufacturing tools, etc., can solve the problems of high labor intensity, frequent replacement, and short service life of core roll shafts, and reduce the number of workers Labor intensity, compact device structure, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

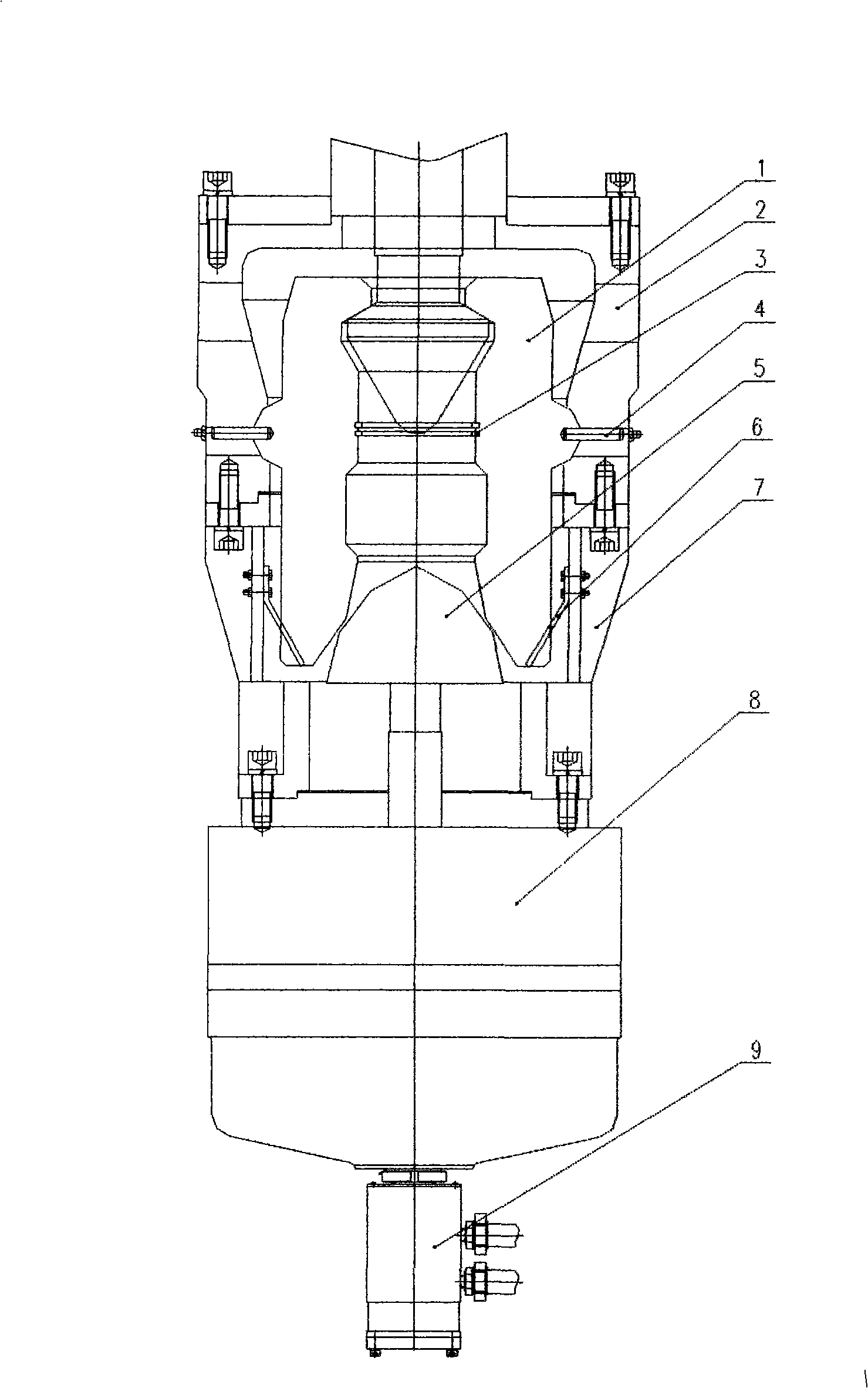

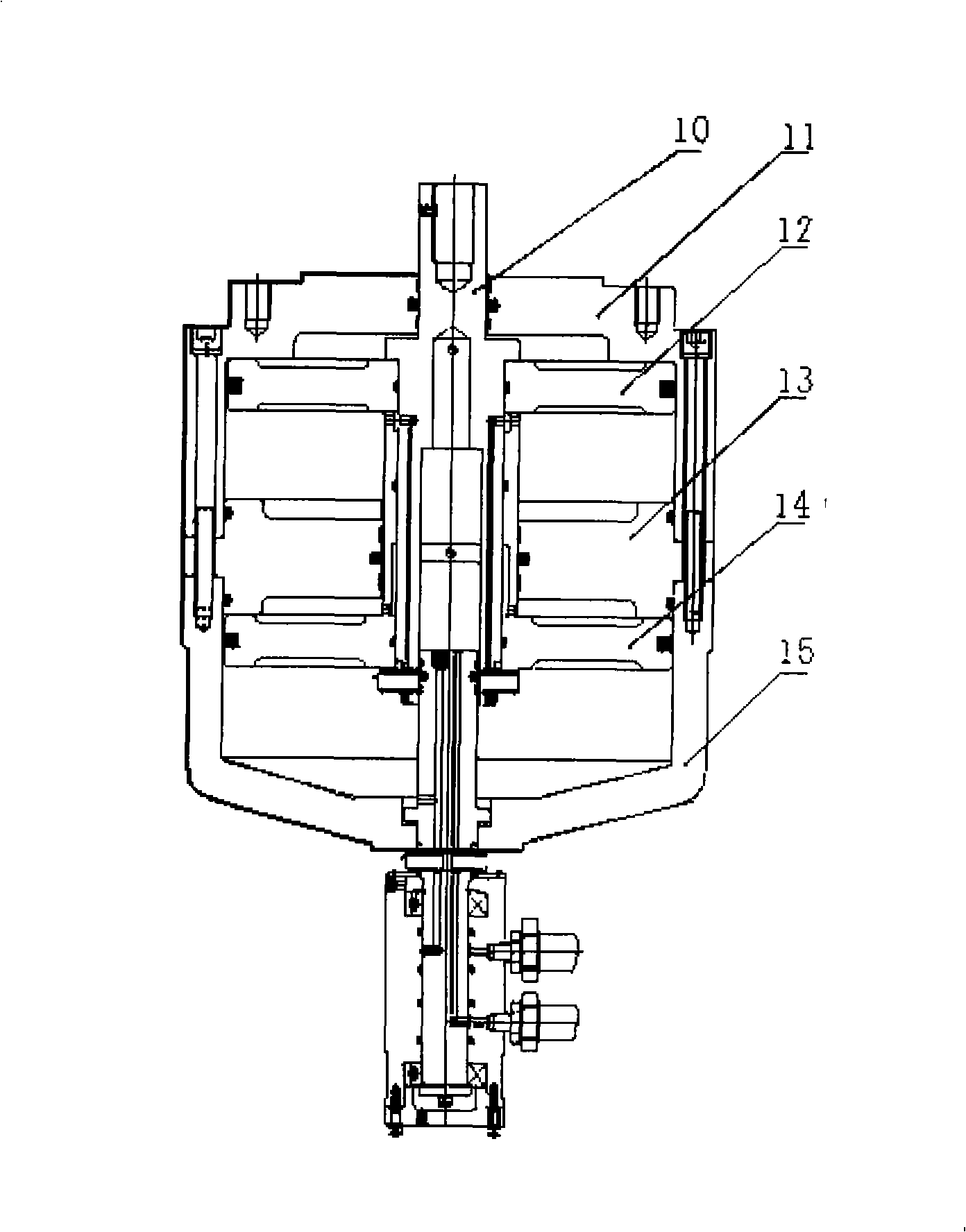

[0021] like figure 1 As shown: it includes multi-lobed clamping claw 1, support sleeve 2, spring expansion ring 3, positioning pin 4, clamping head 5, return spring leaf 6, connecting frame 7, double-piston rotary cylinder 8, rotary joint 9; The joint 9 is fixed on the lower end of the double-piston rotary cylinder 8, the piston rod above the double-piston rotary cylinder 8 is connected with the clamping head 5, the clamping head 5 is screwed on the piston rod of the double-piston rotary cylinder 8, and the connecting frame 7 is fixedly connected On the outer edge above the double-piston rotary cylinder 8, the support sleeve 2 and the double-piston rotary cylinder 8 are connected together, and the return spring piece 6 is fixedly connected to the inner side of the connecting frame 7; The lower end of the flap clamping claw 1 is flexibly connected with the clamping head 5 . The multi-lobed clamping claw 1 is composed of multiple petals. The multi-lobed clamping claw 1 is a mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com