Winding equipment of blood taking needle packaging machine

A technology for packaging machines and blood collection needles, which is applied in the directions of packaging machines, packaging, transportation and packaging, etc. It can solve the problems of inconvenient loading into packaging bags, inconvenient tensioning force, and insufficient tightness of hoses, so as to reduce the air in vacuum packaging. , The clamping force is consistent with the opening force, which improves the effect of vacuum packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

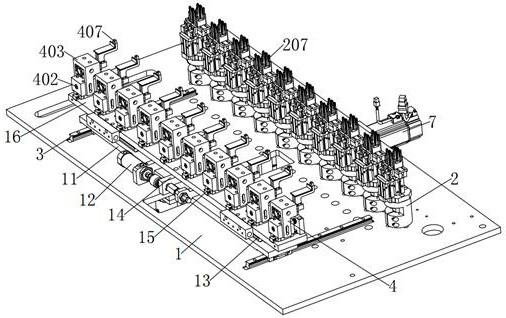

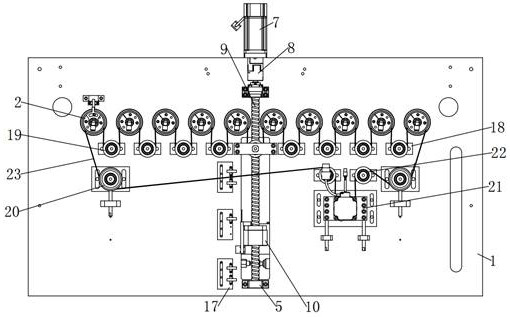

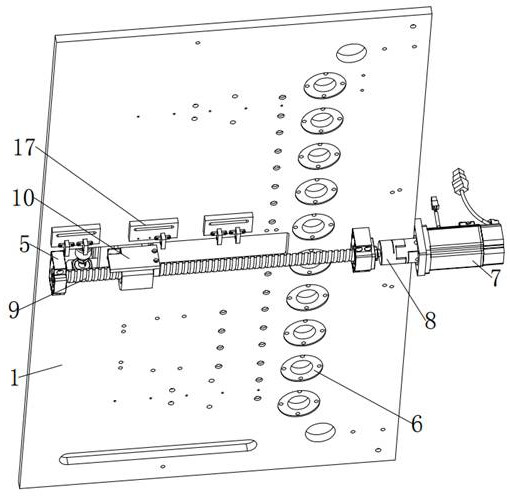

[0038] refer to Figure 1-8, a winding device for a blood collection needle packaging machine, including a mounting plate 1, a winding assembly 2, a follow-up guide rail 3 and a clamping assembly 4, a parallel follow-up guide rail 3 is installed on the top of the installation plate 1, and a Several fixed rings 6, winding assembly 2 is installed in the middle of fixed ring 6, photoelectric switch 17, driving motor 21, several fixed plates 18, fixed bearing 5 and follower motor 7 are installed on the bottom of mounting plate 1, several fixed Plates 18 are juxtaposed in a row and keep parallel with fixed ring 6 and are positioned at one side thereof, and follow-up motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com