Book clamp device of full-automatic perfect-binding covering machine

A fully automatic, machine-made book technology, which is applied in the direction of upper book case, book binding, and binding agent for binding. Consistent tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

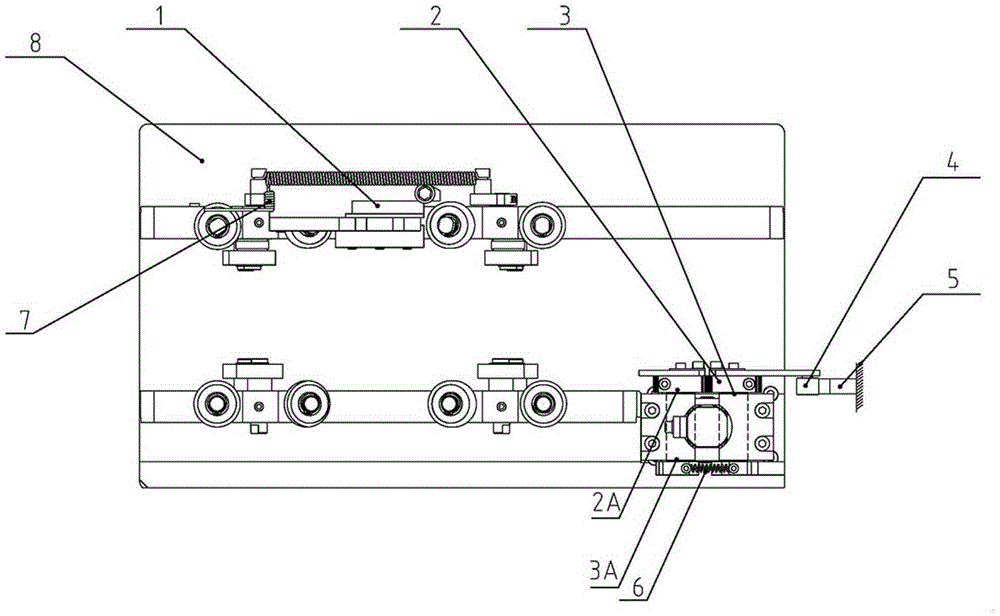

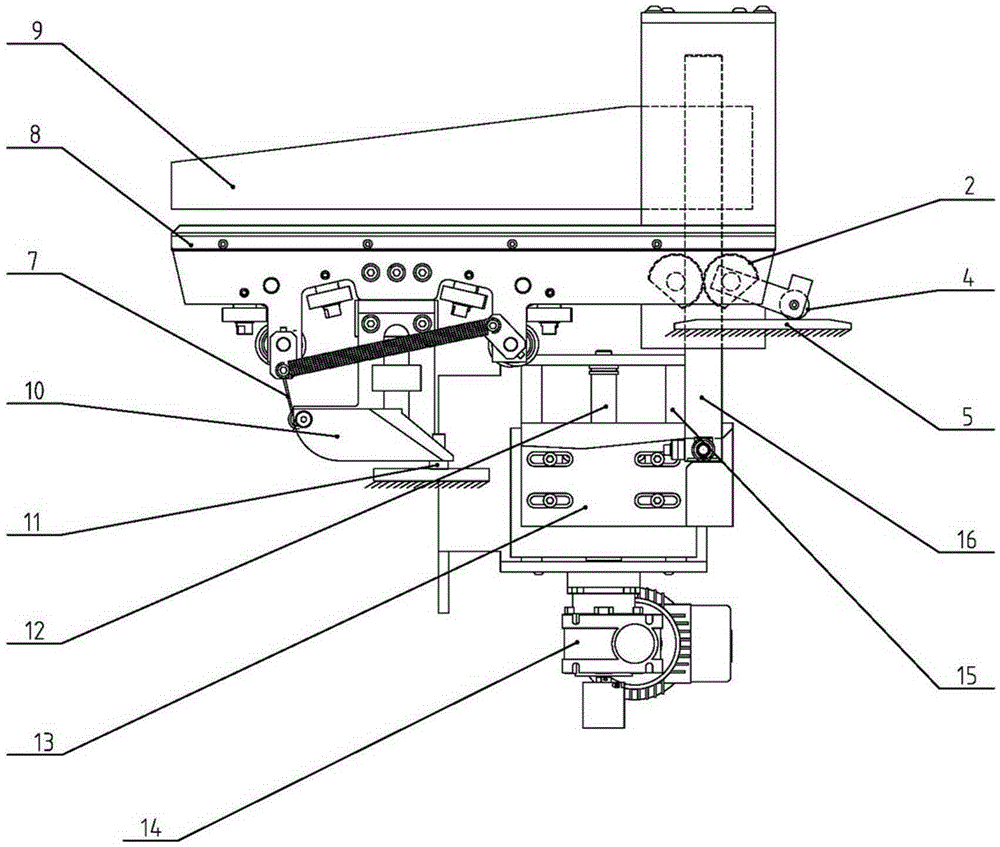

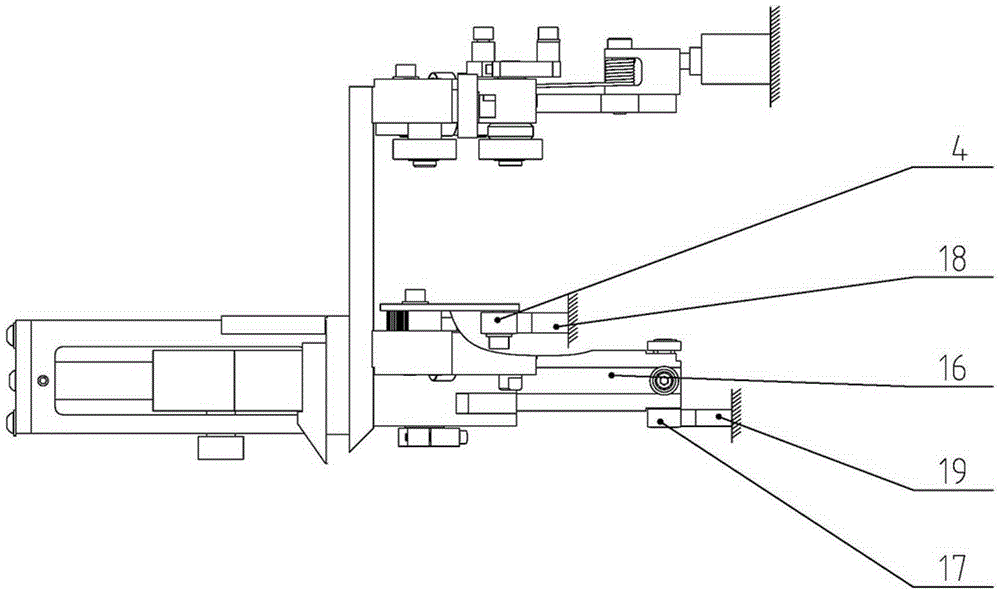

[0013] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0014] As shown in the figure, a fully automatic glue binding package local book clip device includes a front clamping plate 9 and a rear clamping plate 8, a positioning seat 10 and an eccentric mechanism arranged on the rear clamping plate 8, and the eccentric mechanism includes an eccentric shaft, The cylindrical gear, the first needle roller bearing 4, the second needle roller bearing 17 and the pull plate shaft 16, the cylindrical gear is arranged on the eccentric shaft, the first needle roller bearing 4 is connected with the cylindrical gear, the The second needle roller bearing 17 is connected to the pull plate shaft 16 , the front end of the pull plate shaft 16 is connected to the front clamp plate 9 , and the rear end of the pull plate shaft 16 is connected to the guide seat assembly through the second needle roller bearing 17 .

[0015] The eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com