Machining technology of thin-walled and deep-hole air cylinder sleeve

A technology of machining and cylinder liner, applied in the field of machining technology of thin-walled and deep-hole cylinder liner, can solve the problems of large deformation of cylinder liner, increase of accumulated errors and high manufacturing cost, achieve high product precision and improve machining accuracy , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] This embodiment provides a machining process for a thin-walled, deep-hole cylinder liner, comprising the following steps:

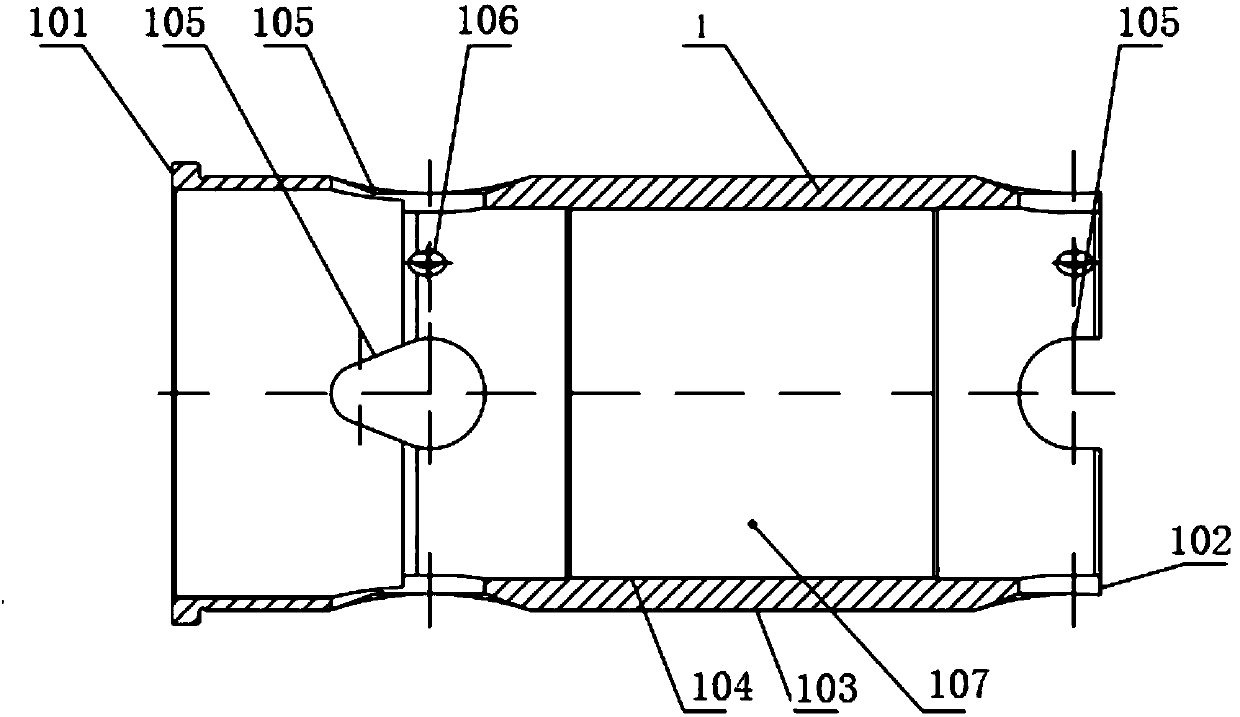

[0034] S1, such as figure 1 As shown, the semi-finishing process is carried out first, specifically: the outer circle 103 of the cylinder liner, the two end faces 101, 102, and the inner hole 104 are semi-finished in turn;

[0035] S2, wire cutting valve hole cone surface 105;

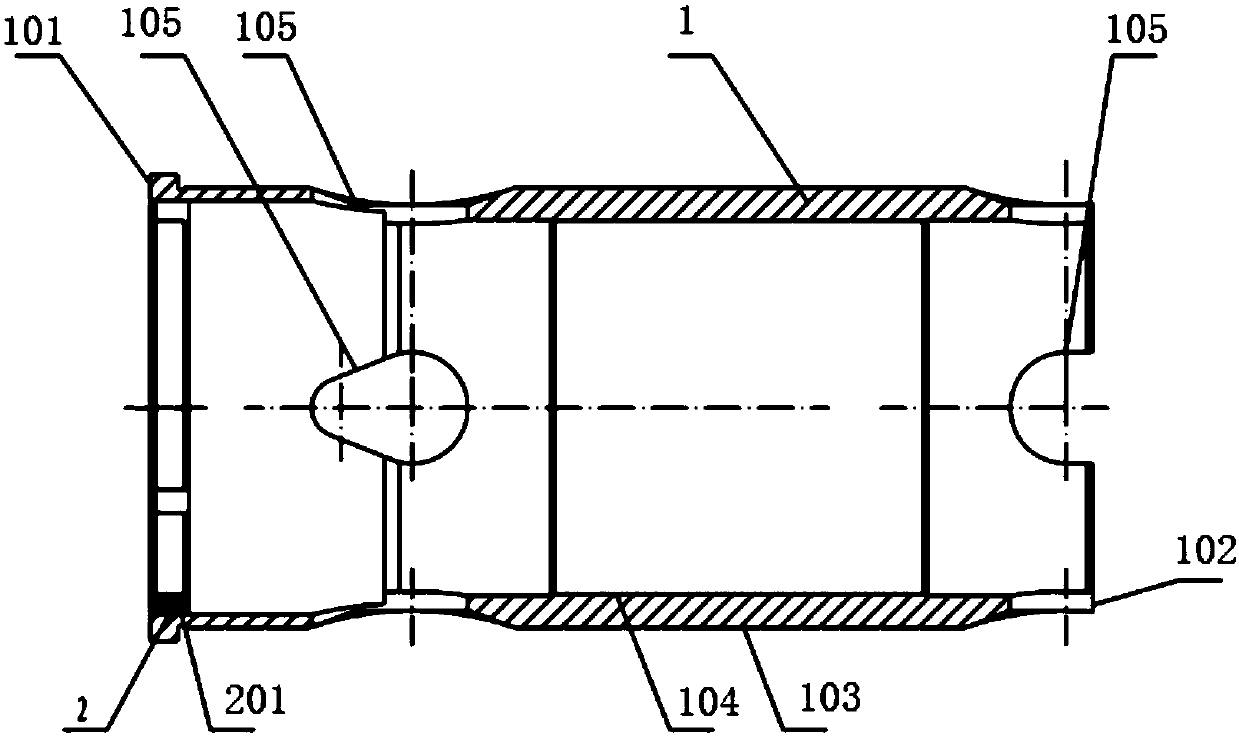

[0036] S3, such as figure 2 As shown, use the elastic sleeve 2 to support the inner hole 201 of the large end, cooperate with the center frame of the lathe, finish the inner hole, and then refine the end face 102 of the small end;

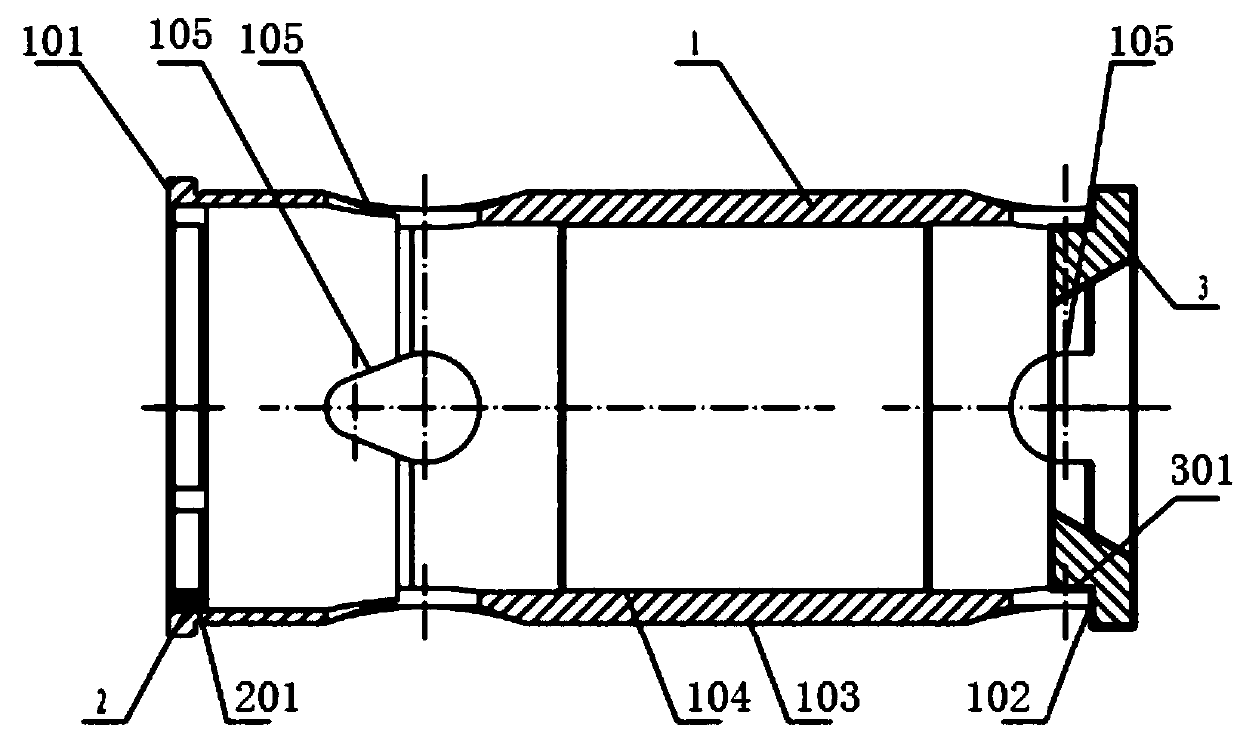

[0037] S4. Remove the center frame of the lathe, install the head tooling 3 at the inner hole of the small end, use the top to withstand the head tooling, and finish the outer circle of the cylinder liner, such as image 3 shown;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com