Precise hydraulic clamp

A hydraulic fixture and precision technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, grinding machines, etc., can solve the problems that the length and size of parts are difficult to control precisely, the eccentricity of parts is difficult to ensure, and the end face grinding is difficult to achieve, so as to achieve uniform force , prevent hydraulic oil leakage, eliminate the effect of precision deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

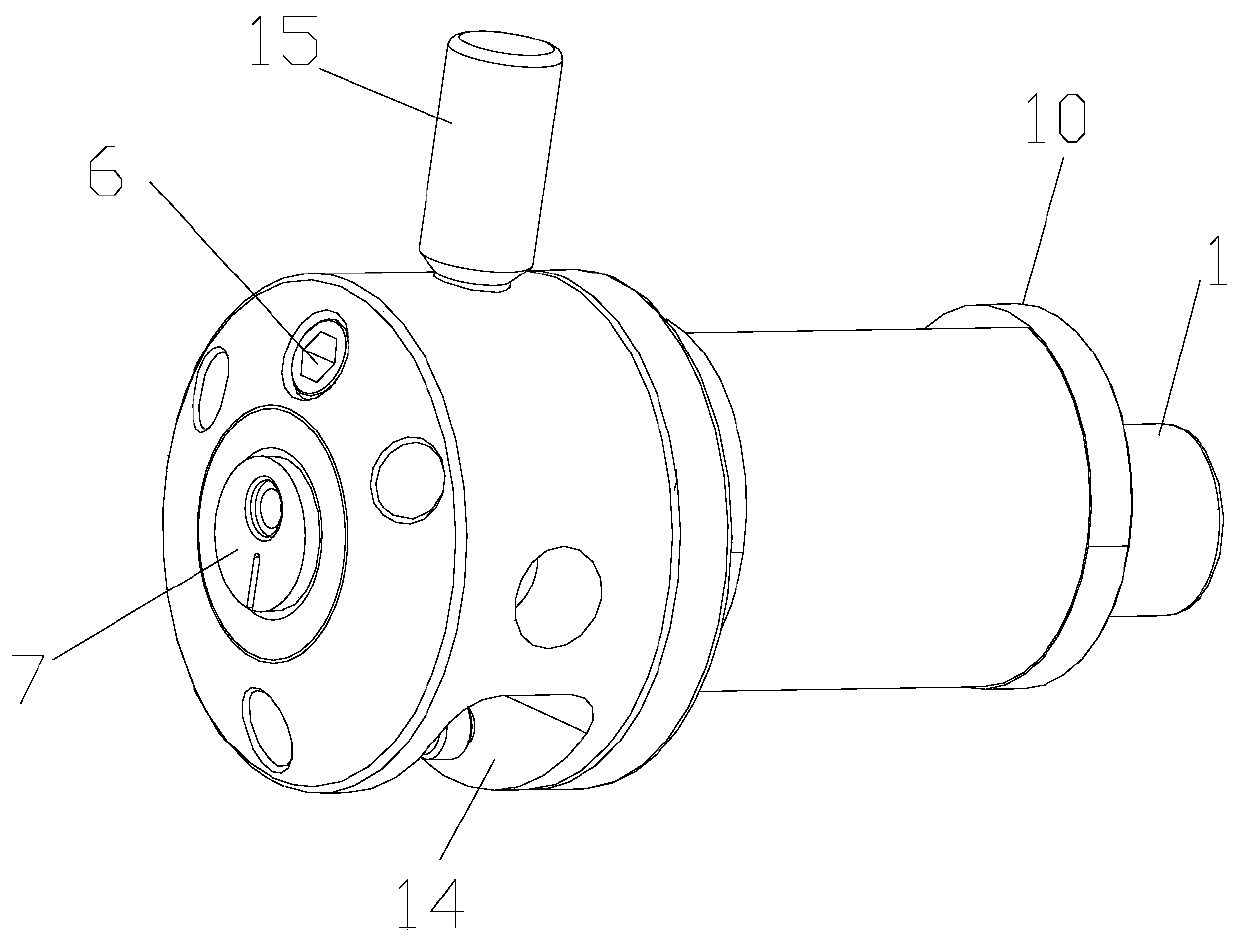

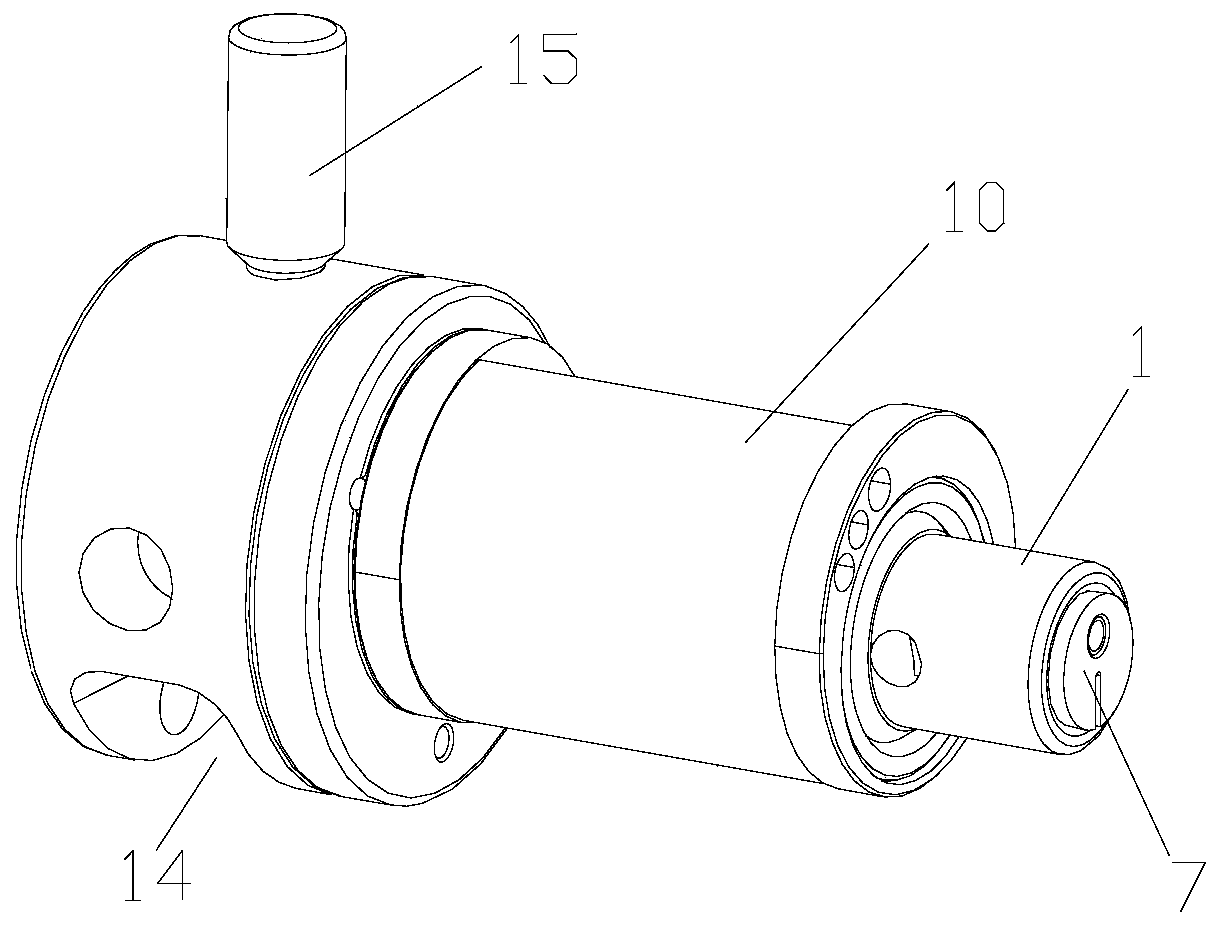

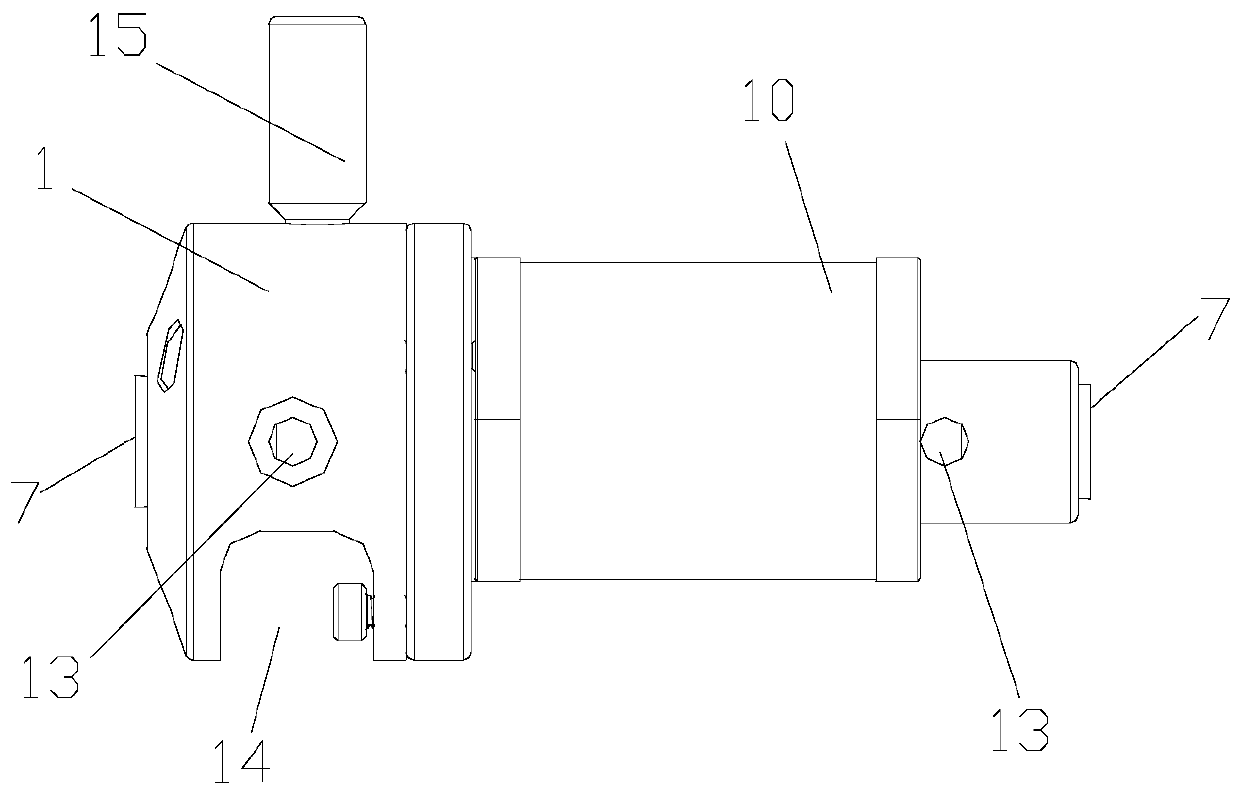

[0036] Such as figure 1 , 2 A precision hydraulic fixture shown in, 3 and 4, comprising: a mandrel 1, which is connected to the rotary table of the grinding machine spindle;

[0037] The expansion sleeve 2 is sleeved on the outer edge of the mandrel 1 and is used to fix the workpiece 10. There is an expansion space 3 between the expansion sleeve 2 and the mandrel 1, and the expansion sleeve 2 is expanded by injecting oil into the expansion space 3 to apply pressure to it. Work piece 10 is fixed;

[0038] The booster flow passage 4 is arranged in the mandrel 1 and communicates with the expansion space 3. The front end of the booster flow passage 4 is provided with a pressurized piston 5 communicating with the expansion space 3.

[0039] In this embodiment, the pressurized piston 5 is installed after the oil is injected, and the structure is simpler.

[0040] Among them, the expansion sleeve 2 expands uniformly, and evenly applies pressure to the 10 peripheral edges of the workpiece, to...

Embodiment 2

[0042] Such as figure 1 , 2 A precision hydraulic fixture shown in, 3 and 4, comprising: a mandrel 1, which is connected to the rotary table of the grinding machine spindle;

[0043] The expansion sleeve 2 is sleeved on the outer edge of the mandrel 1 and is used to fix the workpiece 10. There is an expansion space 3 between the expansion sleeve 2 and the mandrel 1, and the expansion sleeve 2 is expanded by injecting oil into the expansion space 3 to apply pressure to it. Work piece 10 is fixed;

[0044] The booster flow passage 4 is arranged in the mandrel 1 and communicates with the expansion space 3. The front end of the booster flow passage 4 is provided with a pressurized piston 5 communicating with the expansion space 3.

[0045] Among them, the expansion sleeve 2 expands uniformly and uniformly applies pressure to the 10 circumference of the workpiece to ensure that the clamping force is consistent during the processing, and the force is uniform during processing, to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com