A DC casting device and method for producing steel-aluminum composite pipes

A technology for steel-aluminum composite pipes, applied in the field of DC casting devices for the production of steel-aluminum composite pipes, which can solve the problems of low bonding strength at the matrix/composite layer interface, difficulty in ensuring the metallurgical quality of the composite layer, and long procedures for the extrusion composite method. Achieve the effects of guaranteed eccentricity, high productivity, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

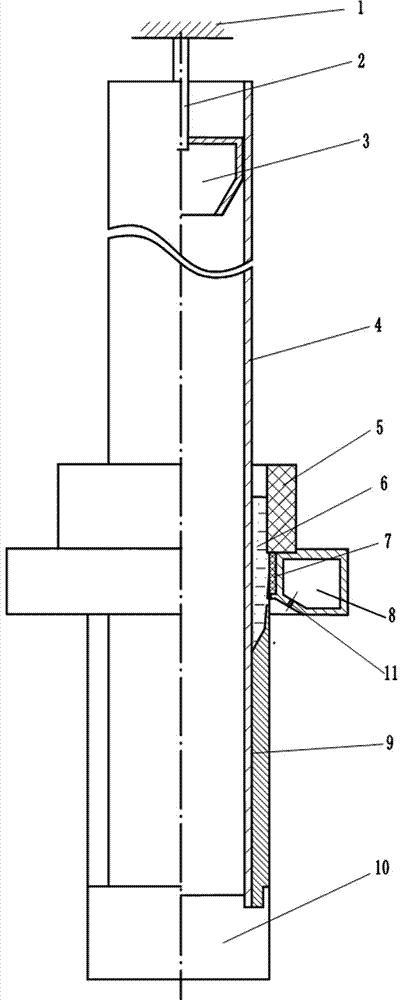

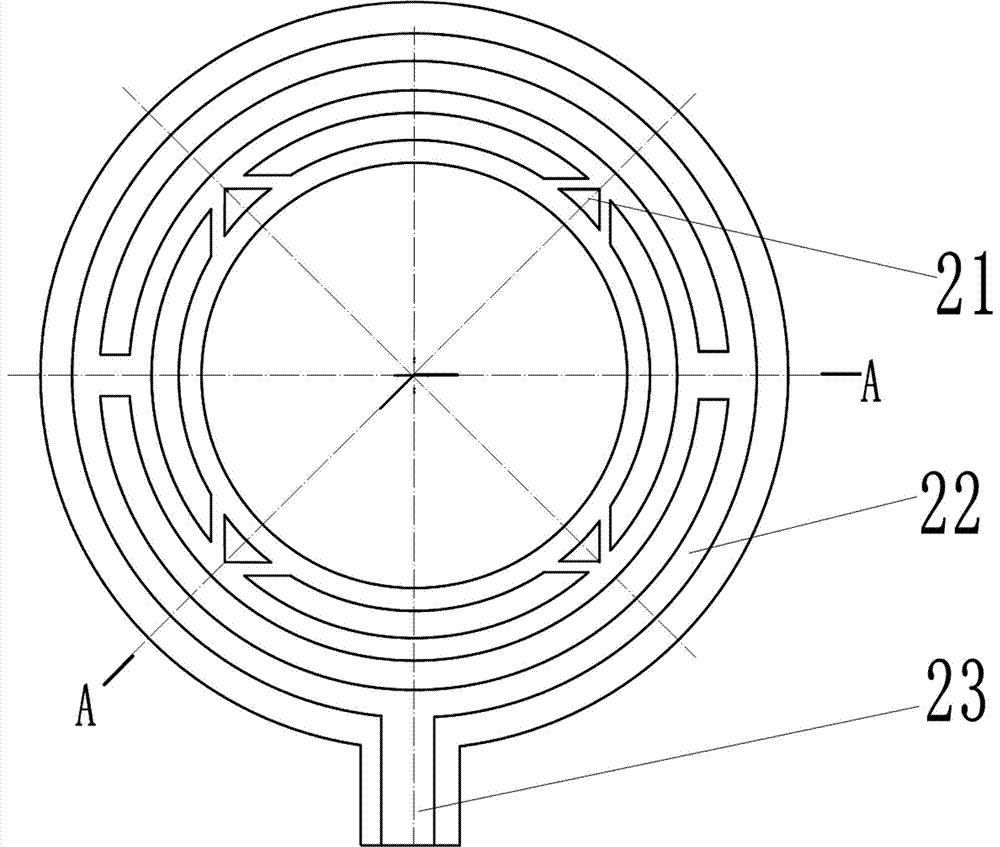

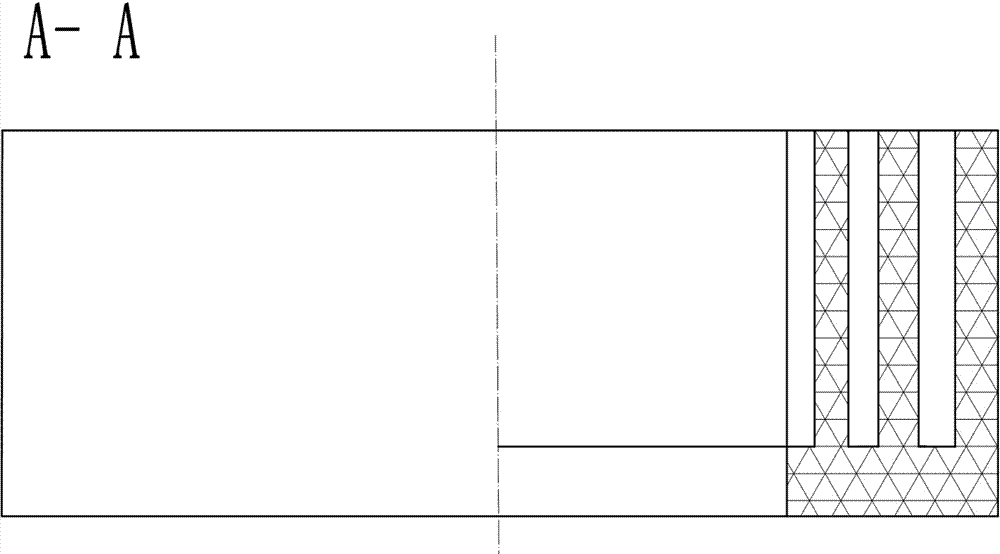

[0033] A DC casting device for producing steel-aluminum composite pipes, such as figure 1 As shown, 1. Fixed end, 2. Guide rod, 3. Guide slider, 4. Steel pipe, 5. Hot top, 6. Aluminum or aluminum alloy melt, 7. Graphite ring, 8. Crystallizer, 9 , Steel-aluminum composite pipe, 10, dummy block, 11 spray holes.

[0034] The affiliated device includes a guide bar 2, a guide slider 3, a hot top 5, a graphite ring 7, a crystallizer 8 and a dummy block 10. The guide slider 3 is inserted on the guide bar 2, and the hot top 5 is located on the crystal Directly above the crystallizer 8, the hot top 5 is fixed on the crystallizer 8 by pressing rods; the graphite ring 7 is embedded on the inner wall of the crystallizer 8 by thermal packing, and the dummy block 10 is arranged directly below the crystallizer 8, and The dummy block is fixed on the platform of the casting machine, and the upper end of the guide bar 2 has a connecting screw hole for connecting the fixed end 1 .

[0035] The...

Embodiment 2

[0050] A DC casting device for producing steel-aluminum composite pipes. The structure of the device is the same as in Embodiment 1, except that the length of the guide bar is 4.1 m, and the guide slider is made of A3 steel.

[0051] The DC casting method for producing steel-aluminum composite pipes by using the above-mentioned device comprises the following process steps:

[0052] (1) The outer surface of the 16Mn low-alloy structural steel with a size of 1.5mm×Φ80mm×4m is derusted and polished in sequence until the fresh metal surface is exposed, and all the treated steel is immersed in flux, and the temperature is 90°C for 5 minutes. Take it out and cool naturally until the outer surface of the steel pipe forms a hoarfrost coating;

[0053] The interval between (2) and step (1) should not exceed 4 hours. Insert the flux-coated pipe into the crystallizer and seat on the dummy block, insert the guide slider into the guide rod, the slider contacts the pipe and keep the pipe v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com