Double-layer three-color wire extruder head

A technology of extruder head and wire, applied in the field of double-layer three-color wire extruder head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

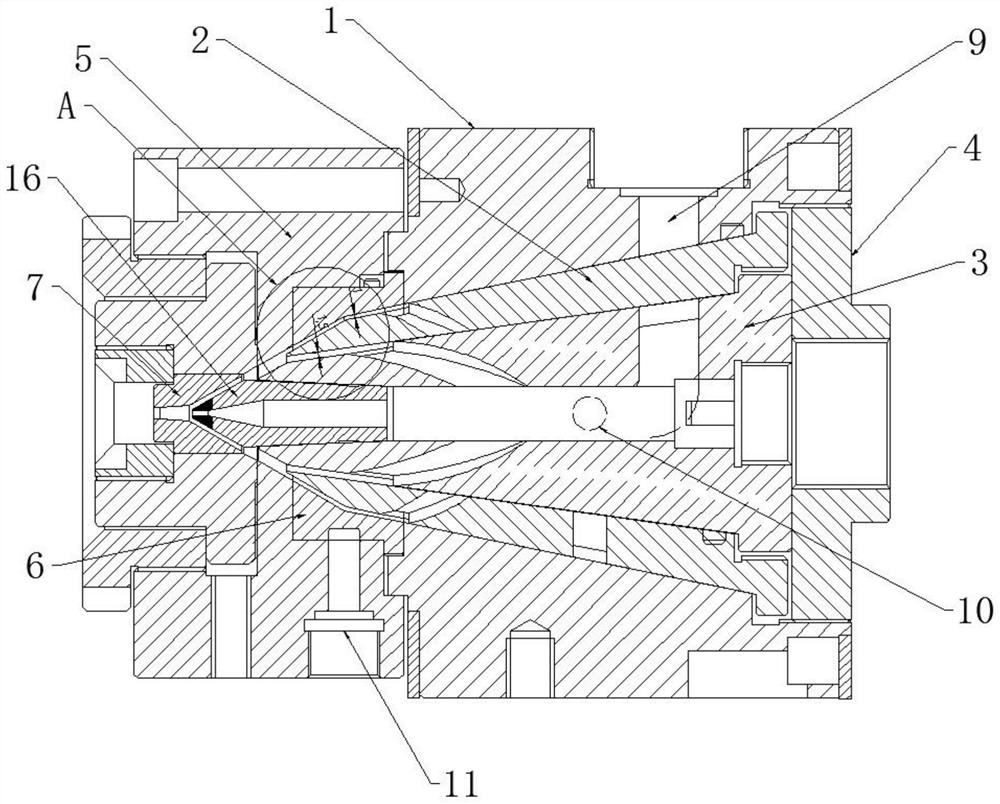

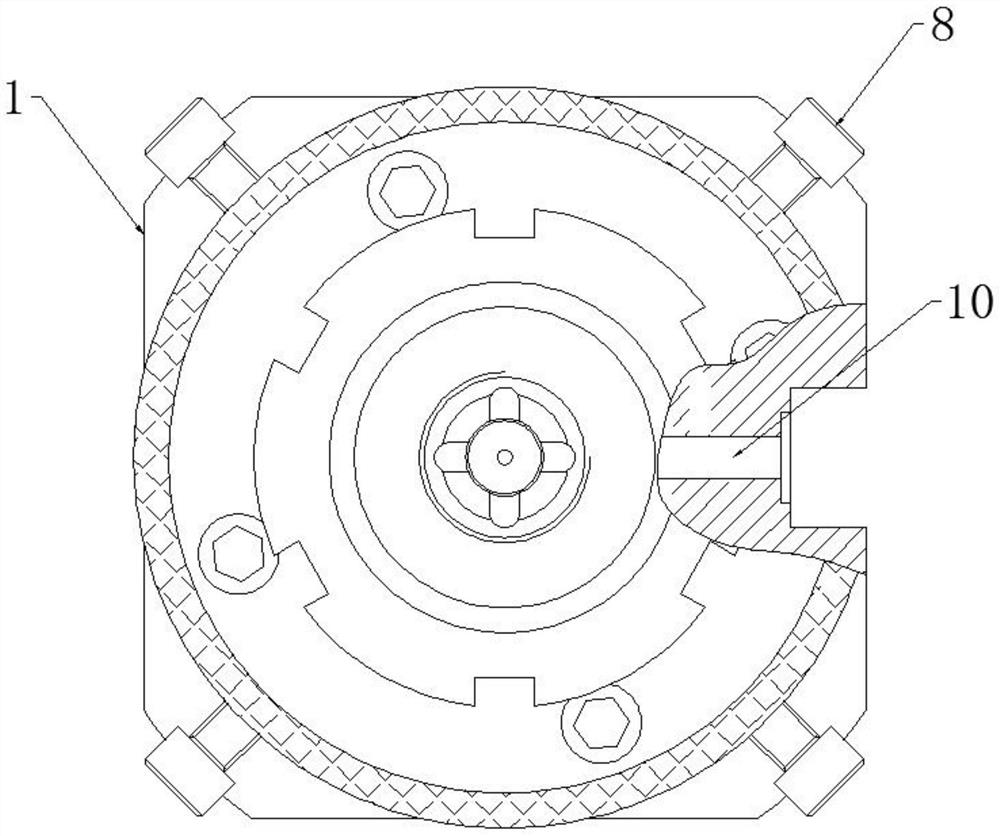

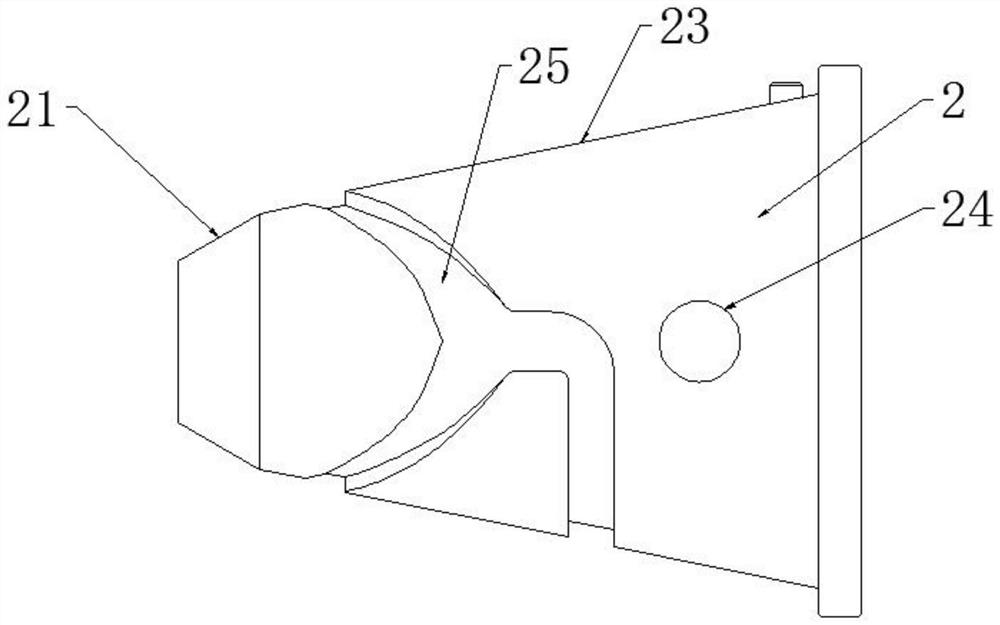

[0019] The reference signs in the accompanying drawings of the description include: machine head body 1, external flow divider 2, external flow distribution surface 21, first mating surface 23, feed hole 24, external flow distribution channel 25, internal flow divider 3, internal flow distribution surface 31 , the second mating surface 33, the inner branch channel 34, the end cover 4, the self-aligning mold base 5, the inner mold cover 6, the wire outer mold 7, the adjusting screw 8, the large feed port 9, the middle feed port 10, the small feed port Material opening 11, wire conductor 12, natural color insulating material 13, yellow insulating material 14, green insulating material 15, wire mold core 16.

[0020] The embodiment is basically as attached figure 1 Shown: a double-layer three-color electric wire extrusion machine head, including a machine head body 1, an inner mold cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com