Variable displacement vane oil pump directly driven by crank shaft flat block

A crankshaft and vane technology, which is applied in the field of variable displacement vane oil pumps, can solve problems affecting flow performance, uneven force on the rotor, and unstable rotor transmission, so as to reduce the risk of cost and loss, and ensure stability and reliability. performance and save power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

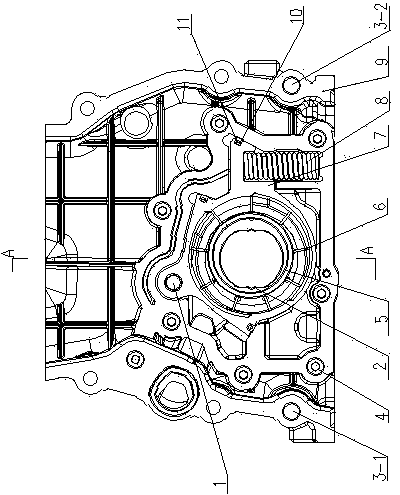

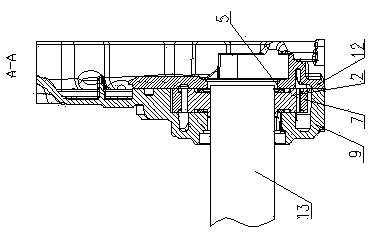

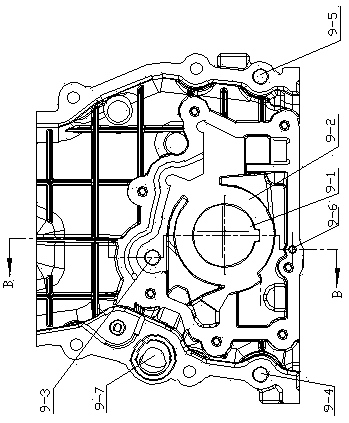

[0030] A variable-displacement vane oil pump directly driven by a flat square crankshaft, which includes a pump body 9, two pump body positioning sleeves 3-1, 3-2, a sliding block rotation positioning pin 1, a pump cover 12, and an eccentric vane support Ring 5, crankshaft 13, blade 6, seal support 11, rectangular seal 10, rotor 2, variable spring 8, pump body pump cover mounting screw 4 and slide block 7.

[0031] The pump body 9 is provided with a cavity 9-2 for installing the variable slider 7, the rotor 2 and the slider spring 8, the crankshaft installation hole 9-1, the positioning sleeve installation holes 9-4, 9-5, the slider rotation positioning Pin installation hole 9-3, pump cover positioning pin installation hole 9-6 and oil outlet 9-7, oil outlet 9-7 communicates with cavity 9-2 through oil passage, slider rotation positioning pin installation hole 9- 3 is a blind hole. The two pump body positioning sleeves 3-1, 3-2 are respectively installed in the two positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com