Integrated yarn nozzle base

An integrated technology of yarn feeder seat, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of yarn feeder seat stuck, yarn feeder seat damage, difficult to control accurately, etc., to achieve consistent clamping force, Ease of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

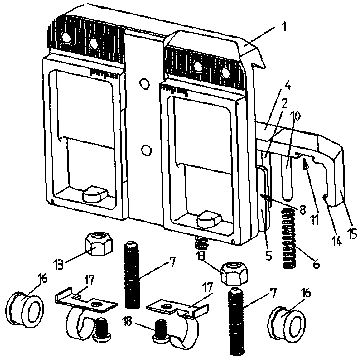

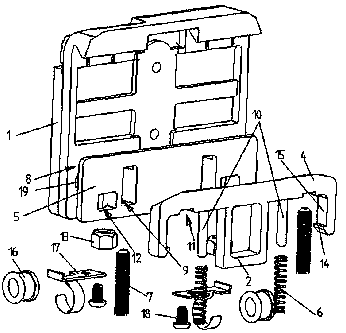

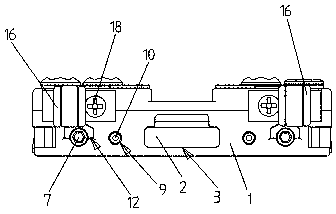

[0024] Integrated yarn carrier, such as Figure 1 to Figure 4 As shown, it includes the yarn carrier body 1, the inclined guide block assembly connected with the yarn carrier body 1, the inclined guide block assembly includes the inclined guide block body 4, the inclined guide block compression spring 6, the inclined guide block fine-tuning locking member 7 and The inclined guide block base 5 with an integrated structure with the yarn carrier body 1, there is a groove 8 for the lower part of the inclined guide block body 4 to be embedded between the yarn carrier body 1 and the inclined guide block base 5, and the inclined guide block body 4 is placed on the yarn The mouth seat body 1 can slide up and down flexibly. Due to the integrated structure of the inclined guide block base 5 and the yarn feeder body 1, the relative positions of the inclined guide block base 5 and the inclined guide block body 1 remain unchanged, so the clamping force between the yarn feeder seat and the ...

Embodiment 2

[0031] Such as Figure 5 As shown, its basic structure is the same as that of Embodiment 1, except that the perforation 12 on the base of the inclined guide block 5 is provided with an internal thread 20 that cooperates with the fine-tuning locking member 7 of the inclined guide block. In this embodiment, The fine-tuning locking part 7 of the oblique guide block adopts a screw, and the fine-tuning locking part 7 of the oblique guide block penetrates the perforation 12 and is threadedly connected with the perforation 12 to face the limit groove 11 on the oblique guide block body 4 . The fine-tuning locking part 7 of the oblique guide block and the perforation 12 are through anti-loosening treatment, and will not loosen due to vibration during the weaving process. The anti-loosening treatment can be provided with a rubber ring or coated with anti-loosening glue. There is no need to add nuts and reduce installation steps.

Embodiment 3

[0033] Such as Figure 5 As shown, its basic structure is the same as that of Embodiment 1, except that a nut insert is embedded in the through hole 12, and the inclined guide block fine-tuning locking member 7 penetrates the through hole 12 and is connected with the nut insert.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com