Intelligent precise rolling mill producing bars

A precision and rolling mill technology, applied in the field of intelligent precision rolling mills, can solve the problems of inability to produce high-quality products, affect the development of enterprise technology, and require high equipment maintenance, so as to reduce downtime and human intervention, wide adaptability, and consistent clamping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

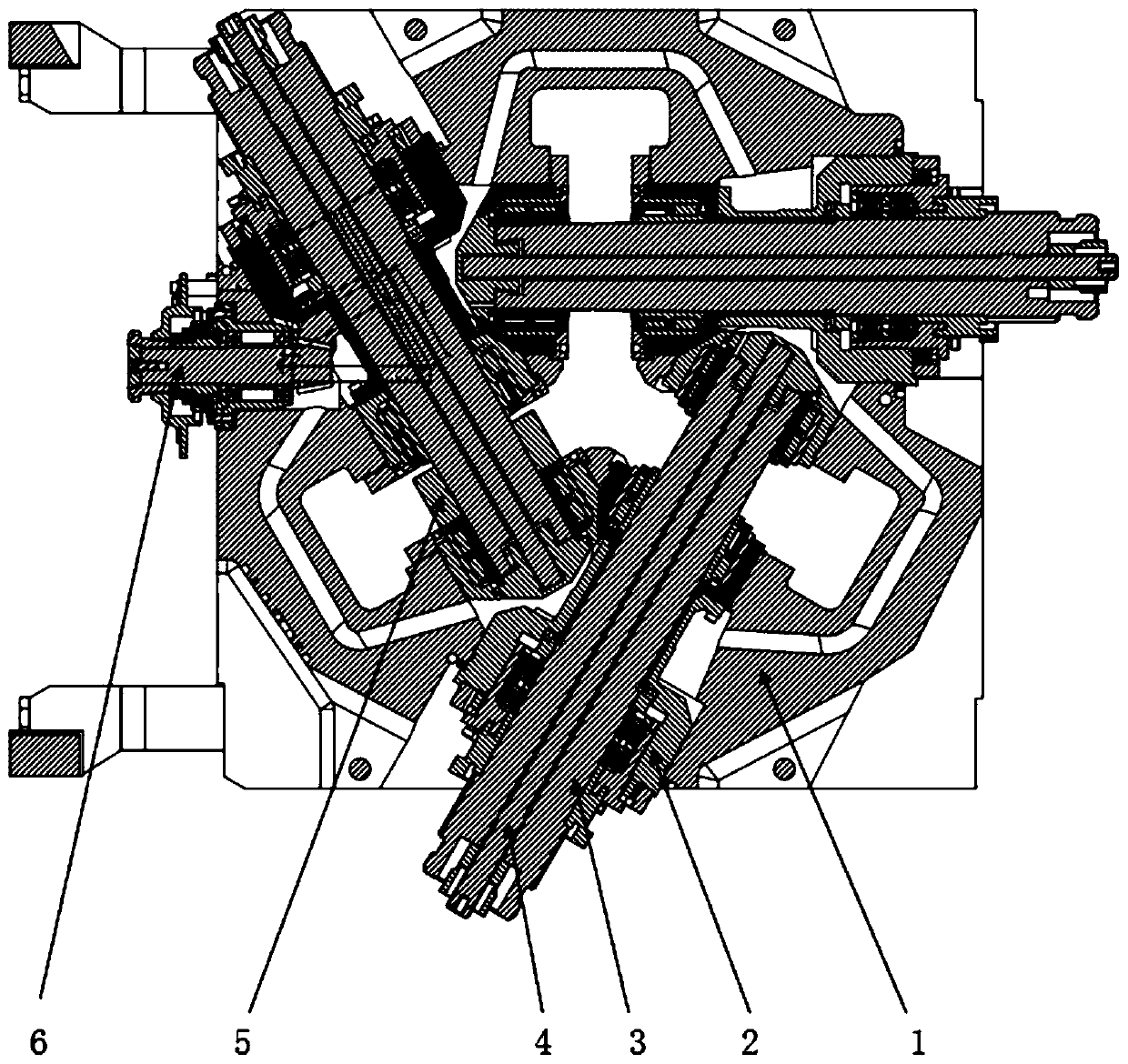

[0040] Such as figure 1 and Figure 5 Shown, a kind of intelligent precision rolling mill of the present invention produces bar, comprises:

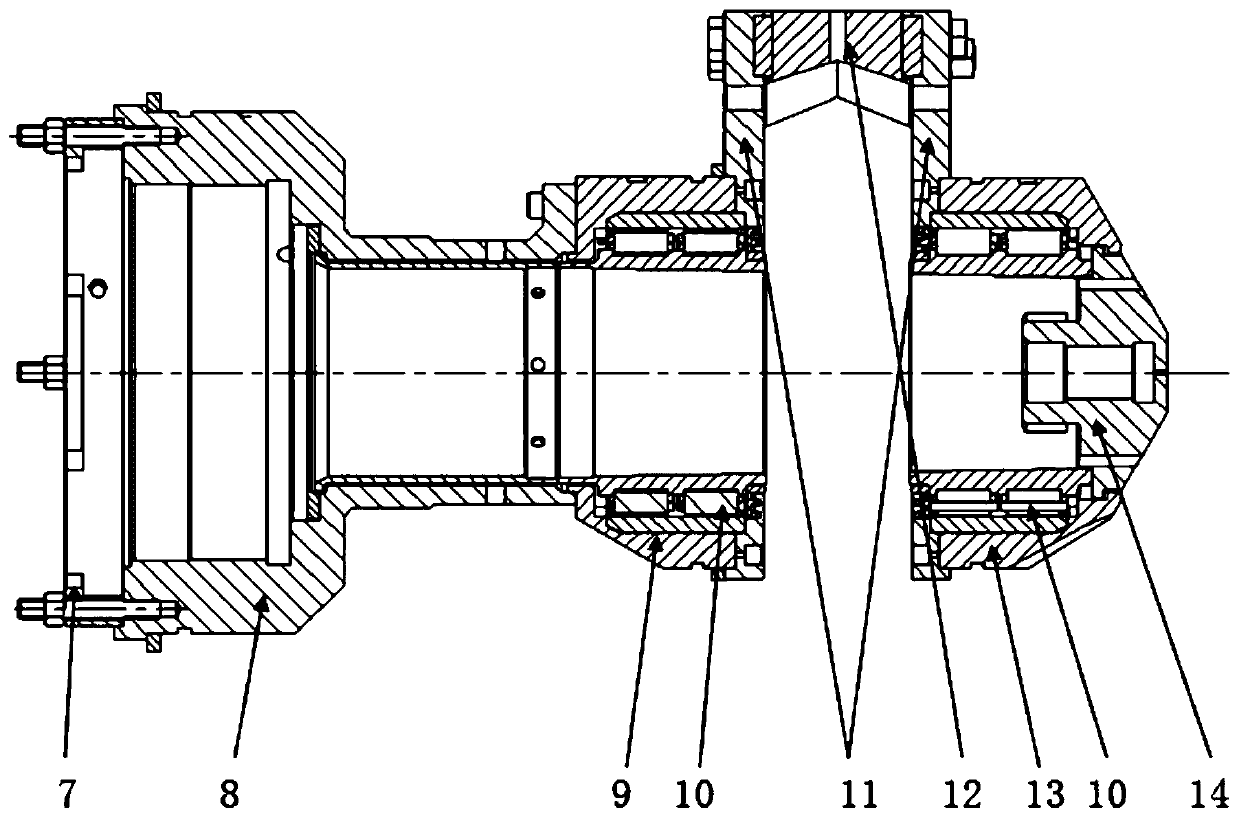

[0041] The precision adjustable rolling mill comprises: a main frame 1, a plurality of sets of eccentric sleeve assemblies 2 installed in the main frame 1 arranged at the same angle to each other, a long axis assembly 3 installed in the eccentric sleeve assembly 2, The first adjustment mechanism 6 engaged with the bevel teeth of the eccentric sleeve assembly 2. The first adjustment mechanism 6 is used to adjust the eccentric sleeve assembly 2. The eccentric sleeve assemblies 2 are engaged with bevel teeth. When adjusting, multiple sets of eccentric sleeve assemblies 2 can be simultaneously Rotate action.

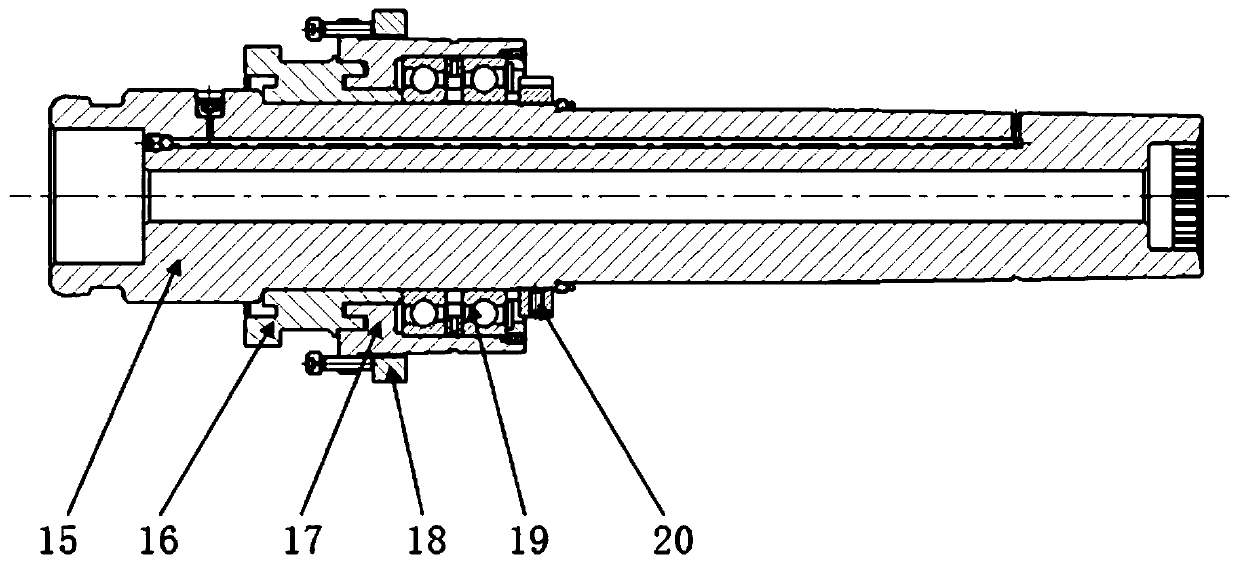

[0042] Rolling guide device, the rolling guide device is located at the output port and output port of the precision adjustable rolling mill. The precision adjustable rolling mill is composed of a guide body 32, three sets of support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com