Grabbing mechanical arm for lead-acid storage batteries

A technology of lead-acid batteries and grasping manipulators, applied in the field of manipulators, can solve the problems of unsafe manual handling, battery falling off, inconsistent clamping force, etc., and achieve the effect of stable blocking, avoiding falling off, and consistent clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

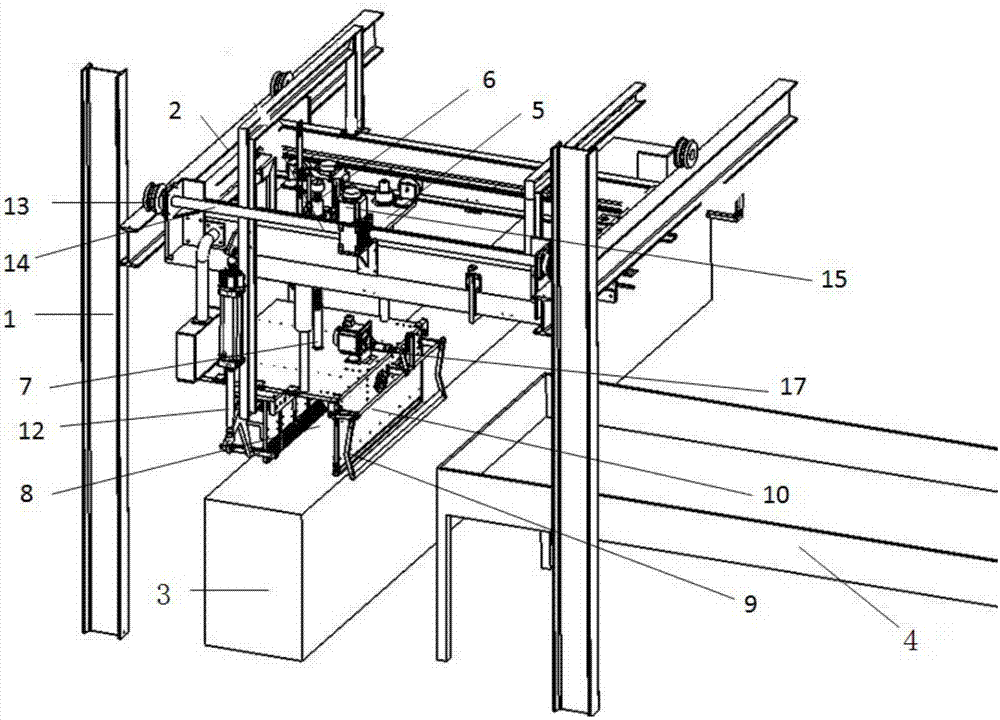

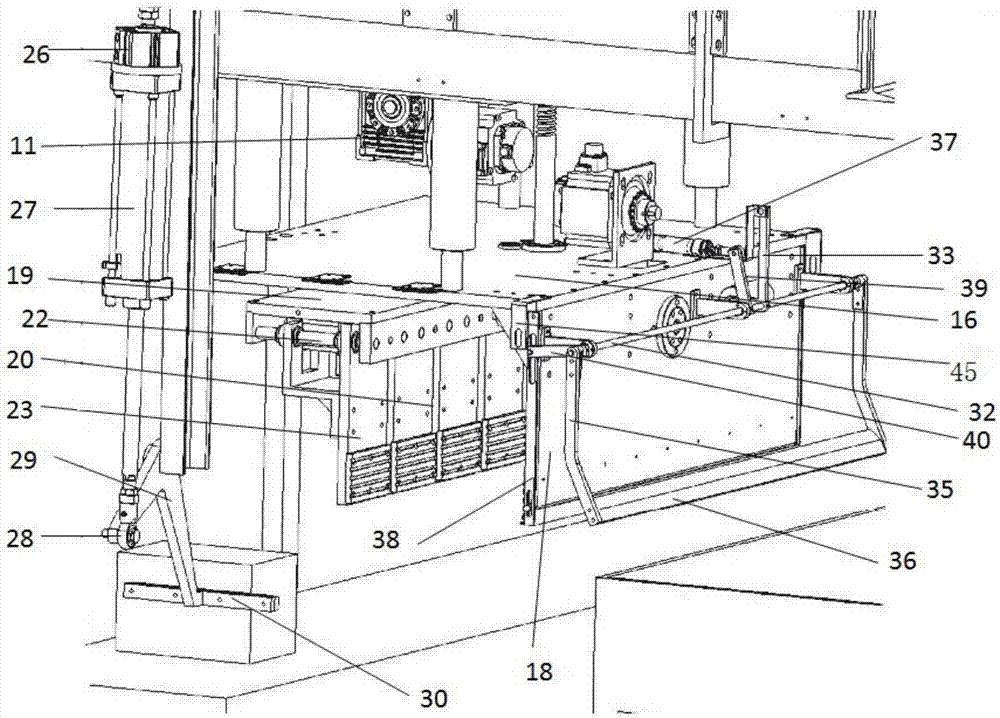

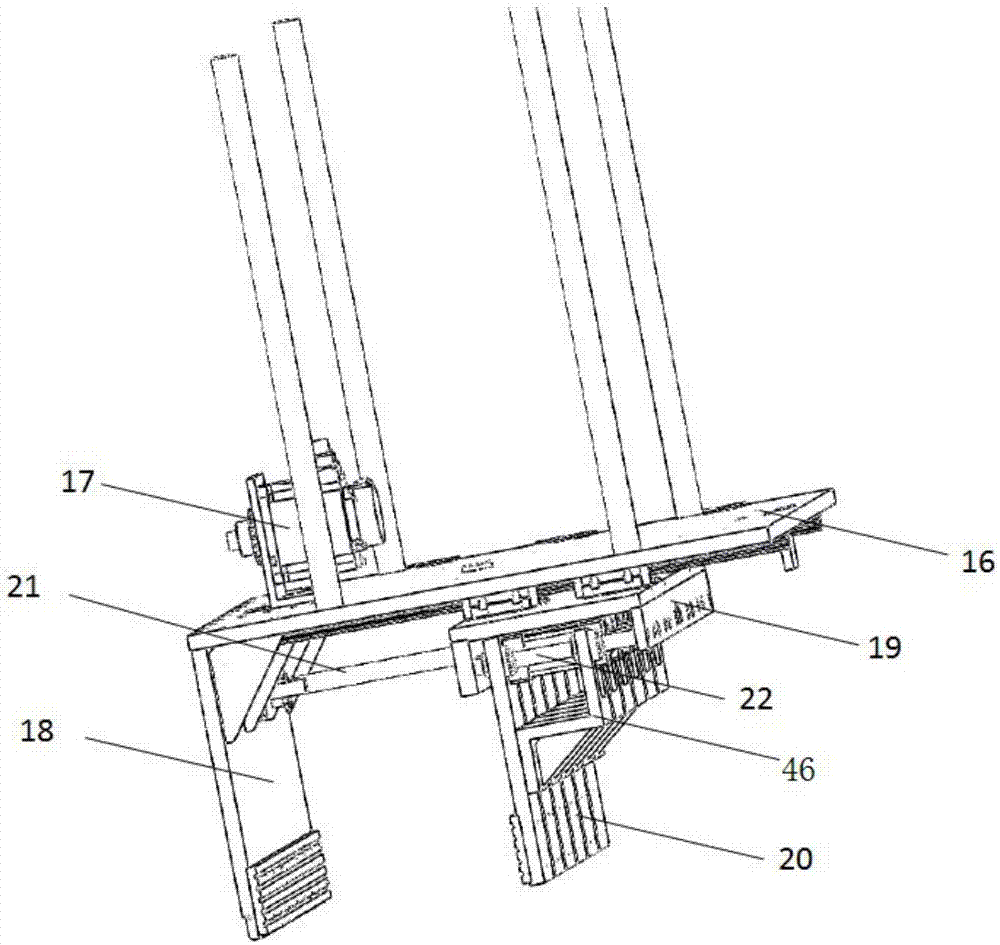

[0029] The manipulator that controls the battery placement distance includes a frame 1 and a three-way motion mechanism arranged on the frame. The three-way motion mechanism of the clamp includes a clamp X-axis motion mechanism, a clamp Y-axis motion mechanism, and a clamp Z-axis motion mechanism.

[0030] The X-axis motion mechanism of the fixture is two pairs of walking rollers 13 arranged on the frame beam 2, each pair of walking rollers 13 is connected by a shaft, and a walking motor 15 is arranged on the shaft;

[0031] The Y-axis motion mechanism of the clamp includes a mounting plate 5 arranged on the frame 1, a clamp translation motor 11 arranged under the mounting plate 5, and a rack arranged at the bottom of the mounting plate 5 to engage with the clamp translation phase 11;

[0032] The Z-axis motion mechanism of the clamp is arranged on the upper and lower motors 6 of the clamp on the mounting plate 5, one end is connected with the upper and lower motors 6 of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com