Rapid die clamping system for bending machine

A bending die and bending machine technology, applied in the field of bending machines, can solve the problems of low die changing efficiency, high labor intensity, complicated operation, etc., achieve consistent clamping force, reduce labor intensity of workers, and improve operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

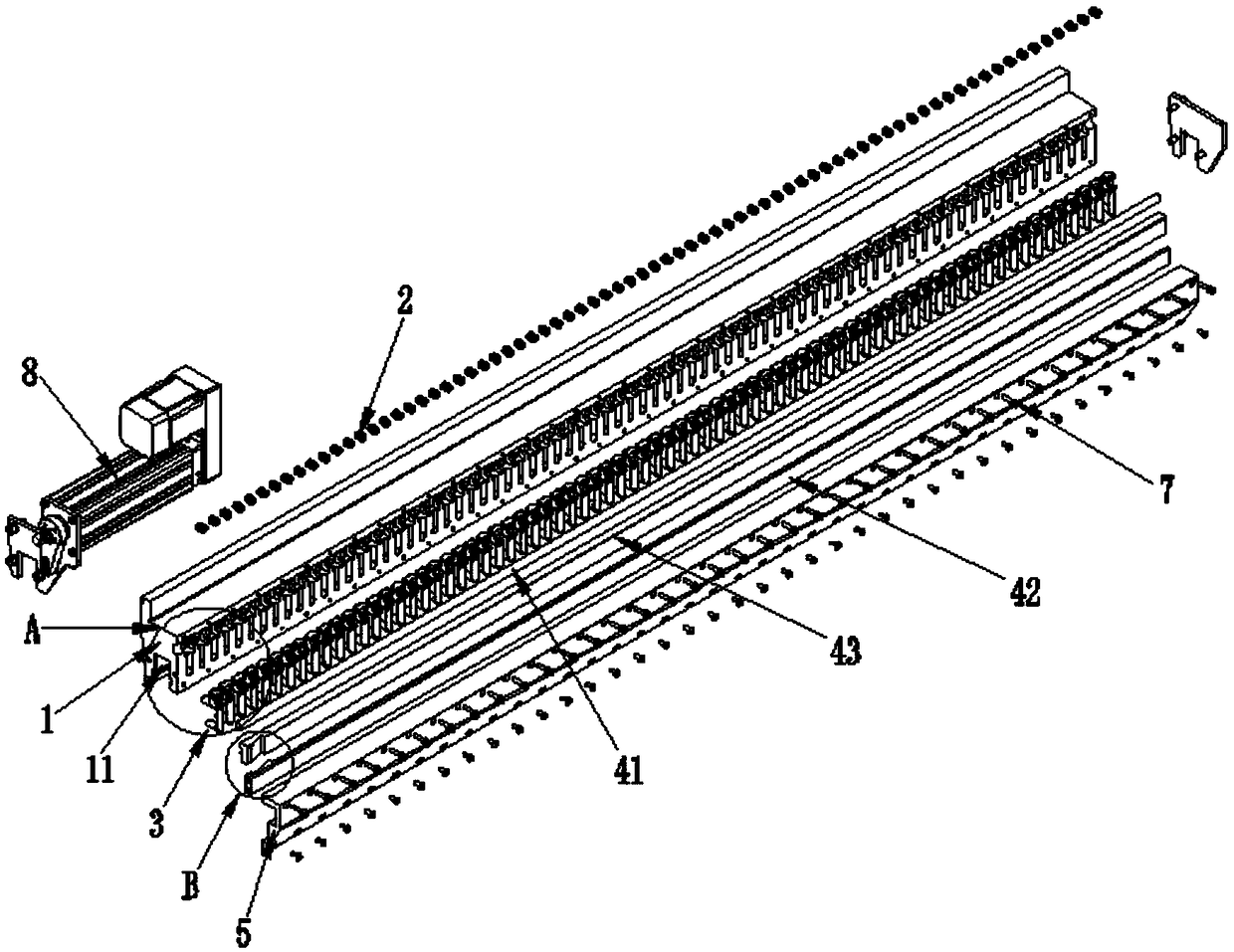

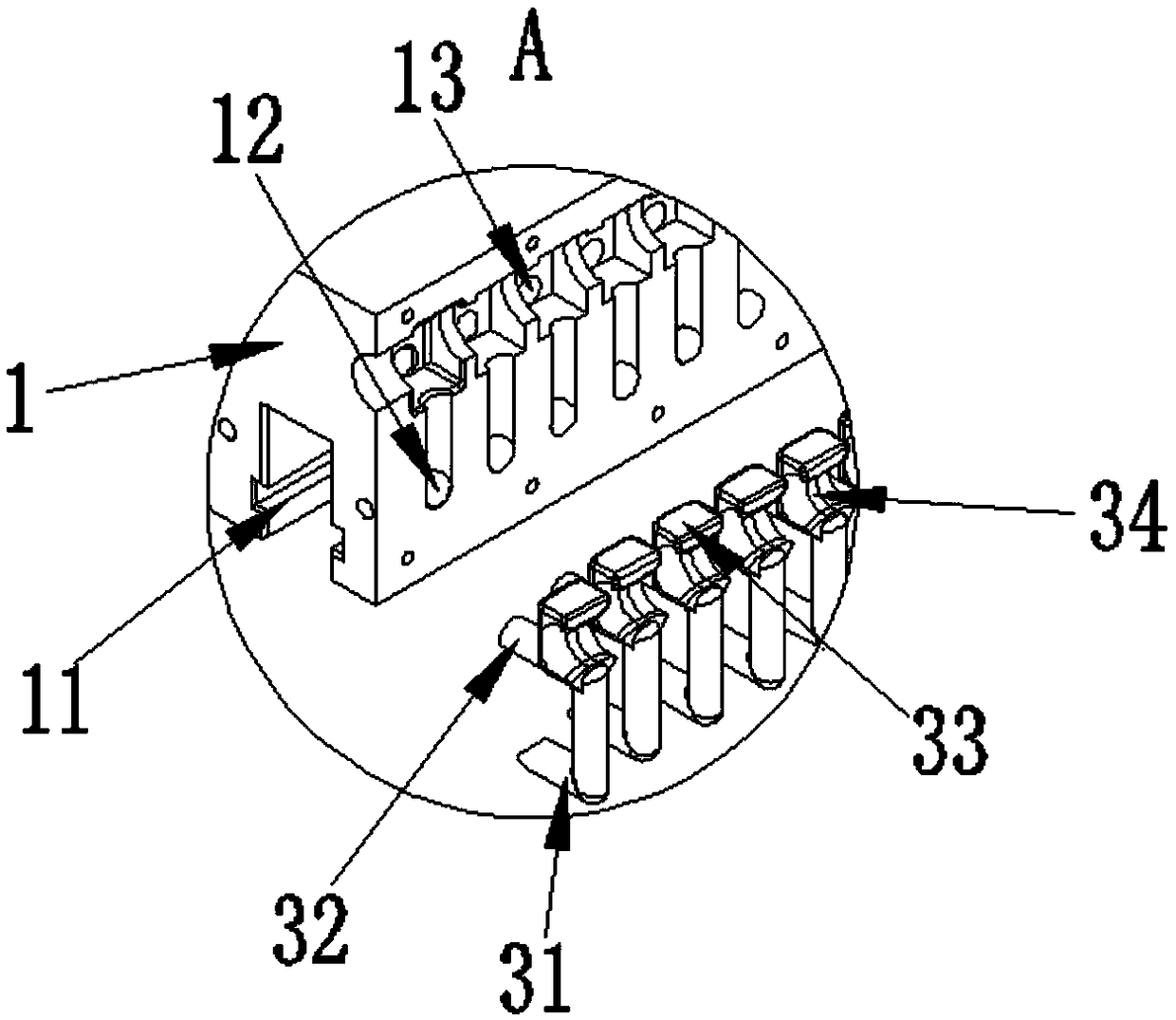

[0038] Such as Figure 1 to Figure 5 As shown, a quick mold clamping system for a bending machine includes a clamping base 1, clamping teeth 3, a pushing mechanism 4, and a reset elastic member.

[0039] The clamping base 1 is provided with a first installation groove 11 for installing the bending die 6 and a sliding groove 12 for passing through the clamping end 31 of the clamping tooth 3, and the sliding groove 12 extends to the first The installation groove 11 communicates with the first installation groove 11 . The upper end of the bending die 6 is installed in the first installation groove 11, one side of the bending die 6 is close to the wall groove of the first installation groove 11, and the other side of the bending die 6 is used to connect with the clamping teeth 3 The snap-in end 31 cooperates, and the bending die 6 is clamped by the snap-in end 31 pressing the bending die 6 . The entire clamping base 1 is subjected to corresponding heat treatment process for stre...

Embodiment 2

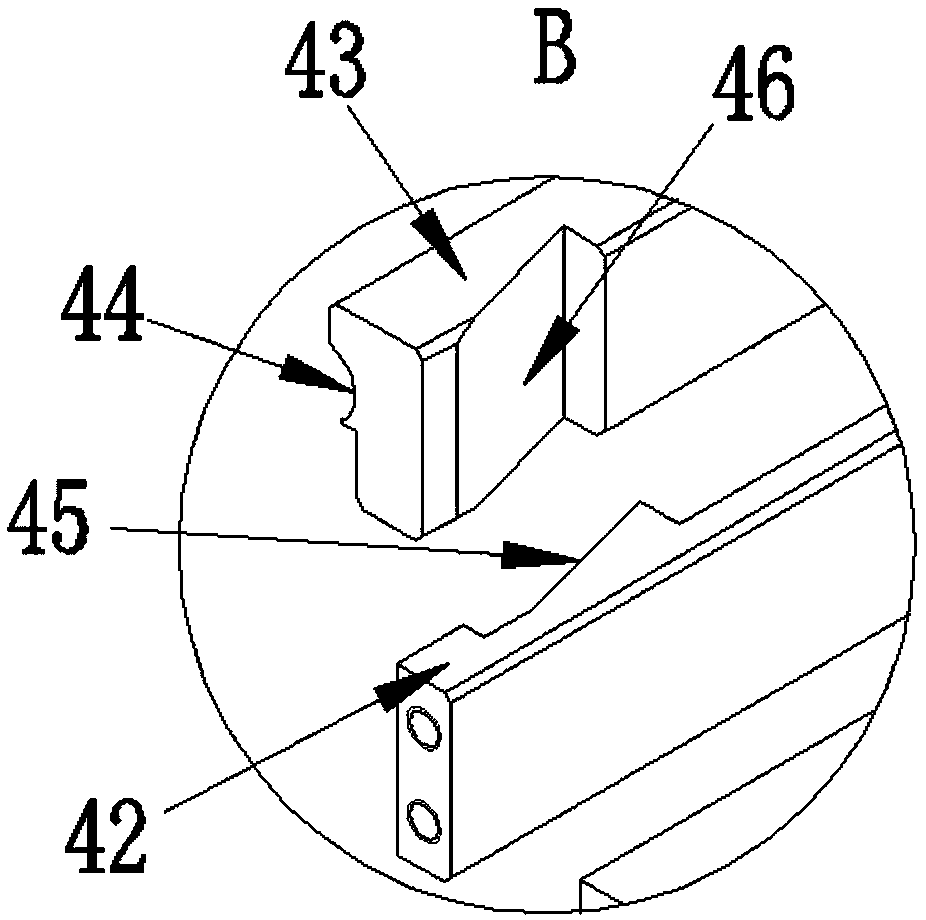

[0055] As a preferred solution, the difference between Embodiment 2 and Embodiment 1 is that the movable wedge 42 is provided with a plurality of first slopes 45 on the side contacting with the rubber hose wedge 43. Similarly, the rubber hose wedge The number of the second slope 46 on the movable wedge 43 is the same as that of the first slope 45 on the movable wedge 42 and corresponds to each other.

[0056] Such as Figure 6 to Figure 8 As shown, a plurality of first slopes 45 are evenly arranged on the movable wedge 42, and two adjacent first slopes 45 are connected by a third slope 47, and the first slope 45 and the third slope 47 form a zigzag structure ; The second slope 46 on the hose wedge 43 is also uniformly provided with a plurality, each second slope 46 cooperates with the corresponding first slope 45, and the fourth slope 48 passes between two adjacent second slopes 46 connection, wherein, the fourth slope 48 cooperates with the third slope 47; when the movable w...

Embodiment 3

[0061] The difference between Embodiment 3 and Embodiment 1 lies in the structure of the pushing mechanism 4 and the structure of the head end 33 of the clamping tooth 3 .

[0062] Such as Figure 9 to Figure 12 As shown, the clamping tooth 3 also includes a head end 33, and the pushing mechanism 4 includes a first pulley 49 installed on the clamping base 1, a second pulley 49 installed on the head end 33 of each clamping tooth Pulley 410, and the steel belt 411 that is wound on the first pulley 49 and the second pulley 410 so that the first pulley 49 and the second pulley 410 form a movable and fixed pulley block structure, and one end of the steel belt 411 is fixed on the clamp On the base 1 , a steel belt fixing block 14 is provided on one side of the clamping base 1 , and one end of the steel belt 411 is fixed on the steel belt fixing block 14 . The other end of the steel belt 411 is connected to the second electric servo drive device 9 , and the steel belt 411 is pulled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com