A double-connected three-gear internal meshing compound motor pump driven by a switched flux motor

A switching flux motor, composite motor technology, applied in the direction of machine/engine, pump, mechanical equipment, etc., can solve the problems of restricting pump pressure level, flow pulsation, uneven radial force, etc., to reduce intermediate transmission links, Safe working performance and the effect of increasing flow pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

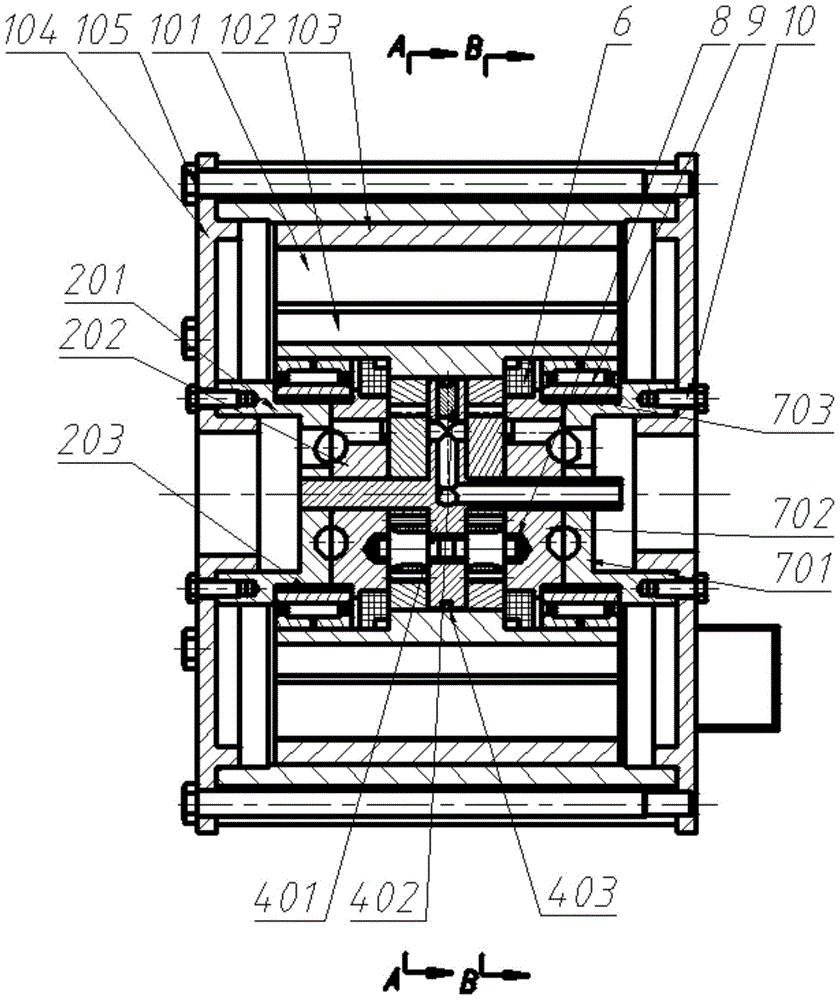

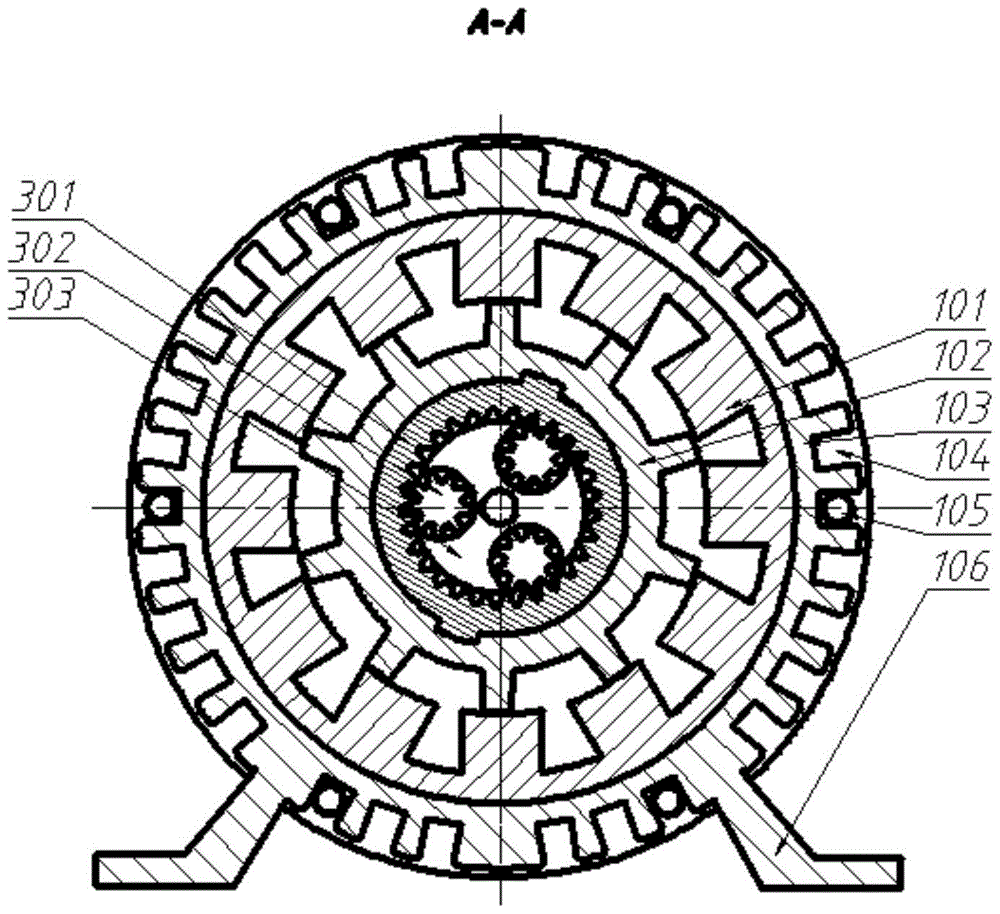

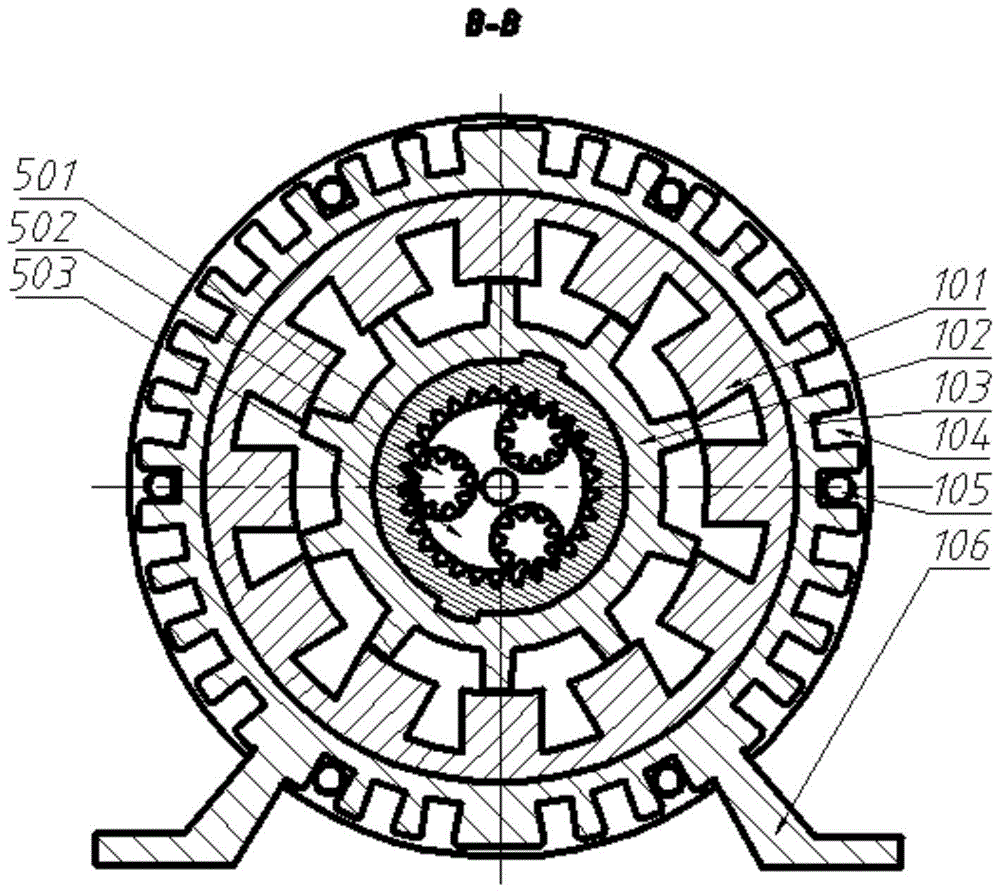

[0020] refer to figure 1 , a double-connected three-gear internal meshing composite motor pump driven by a switched flux motor, including a motor stator 101, the motor stator 101 is fixedly connected to the motor casing 103, the motor casing 103 is solidly welded on the motor support 106, and the motor casing 103 is two The end is connected with a motor end cover 104, and is fixedly connected by a tension screw 105. The motor rotor 102 is a hollow structure inside, and the first outer ring gear 301 and the second outer ring gear 501 are embedded in the motor rotor 102 through a key connection. The ring gear 301 meshes with the first pinion 302, the first outer ring gear 301, the first pinion 302, and the first partition 303 are connected to form the first pump body, the second outer ring gear 501 meshes with the second pinion 502, The second outer ring gear 501, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com