Low-inertia plunger resisting pressure impact

A low-inertia, anti-pressure technology, applied in the field of plungers, can solve the problem that the plunger cannot take into account low inertia and flow pulsation, and achieve the effects of reducing inertial force, reducing noise, and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

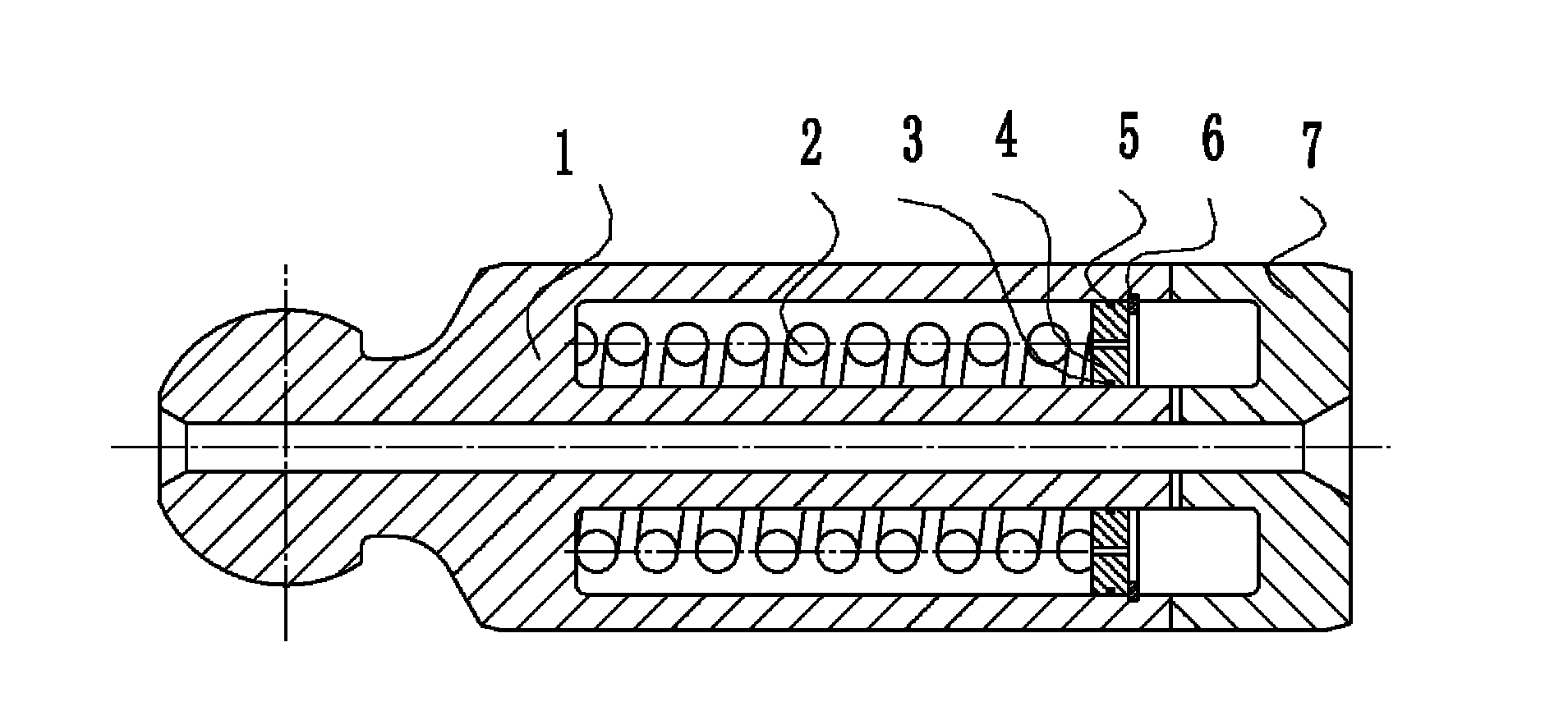

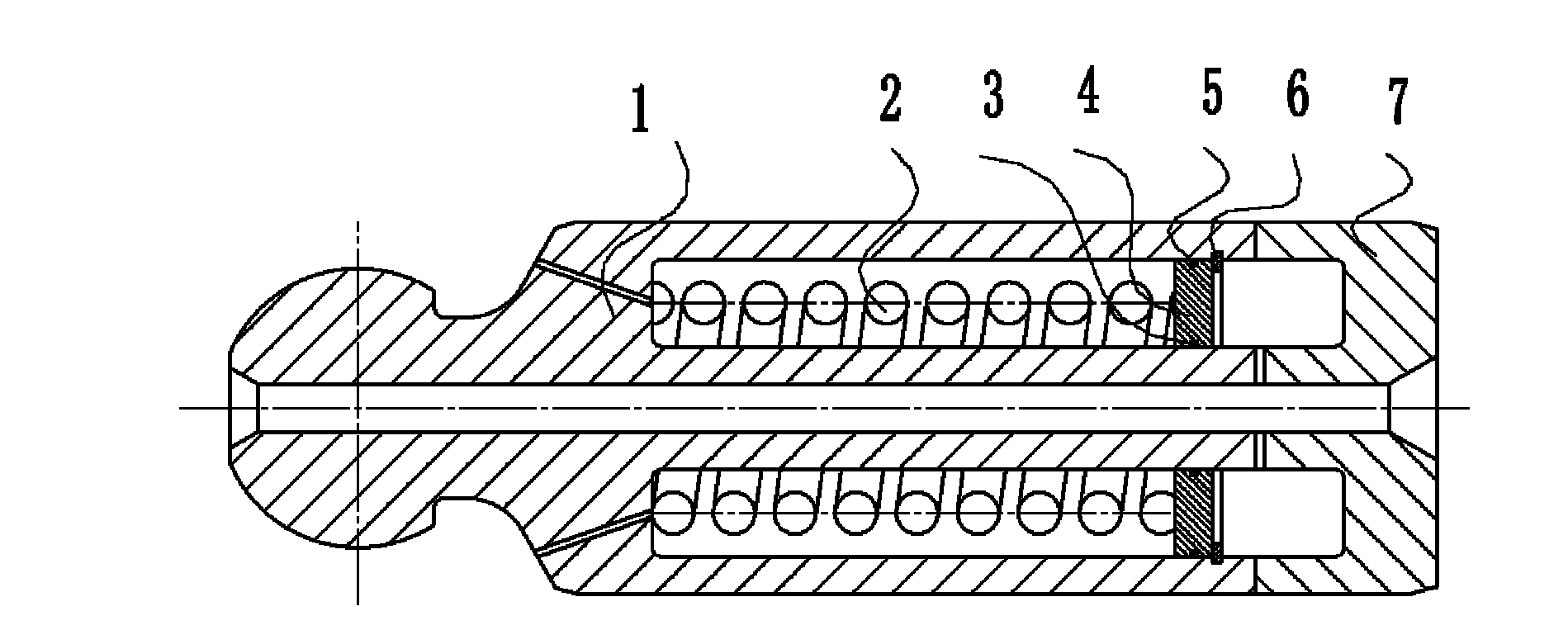

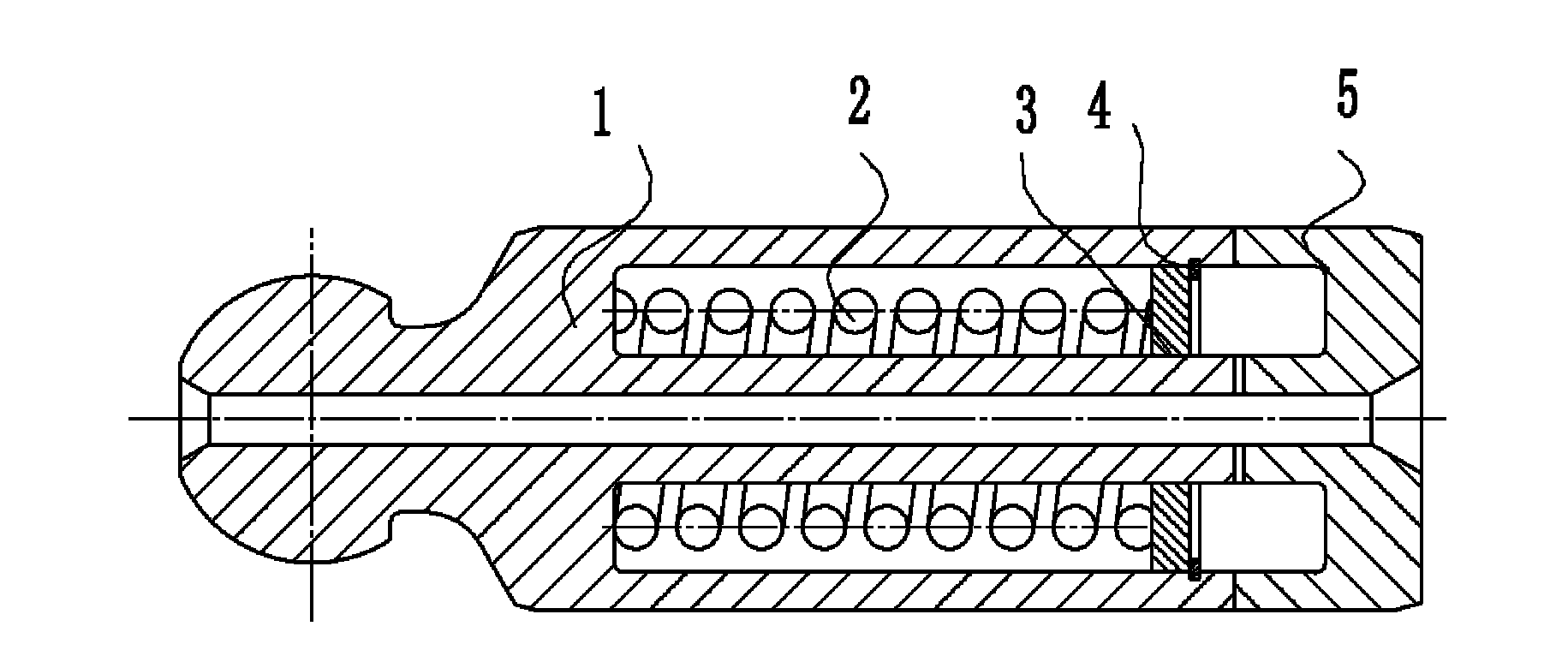

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] refer to Figure 1 to Figure 5 , a low-inertia plunger resistant to pressure shock, the low-inertia plunger includes a left plunger body 1 and a right plunger body 7, the right end face of the left plunger body 1 and the left end face of the right plunger body 7 Fixedly connected, the middle part of the left plunger body 1 and the right plunger body 7 is provided with a central cavity; the left plunger body 1 is processed with an axially arranged left annular groove, and the opening of the left annular groove is located at On the right end face of the left plunger body, a spring 2, an annular retaining ring 4, an inner sealing ring 3, an outer sealing ring 5 and a snap ring 6 are installed in the left annular groove, and the rear end of the spring 2 is pushed against the left The bottom of the annular groove, the front end of the spring 2 is on the annular reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com