Patents

Literature

46results about How to "Steady diversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

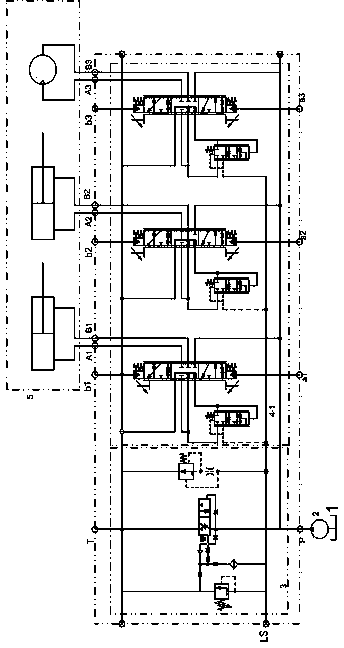

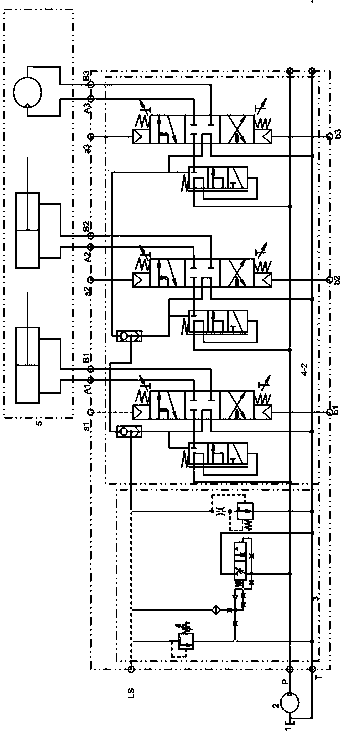

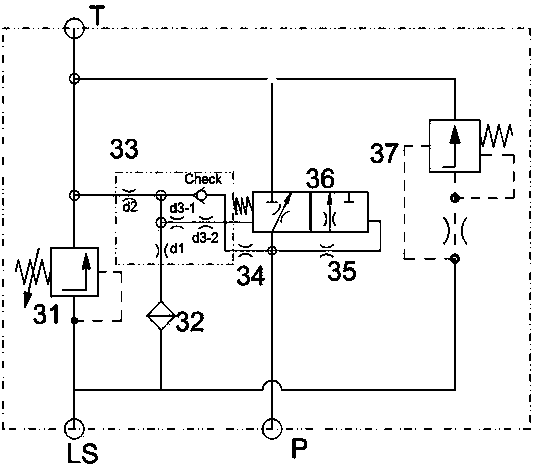

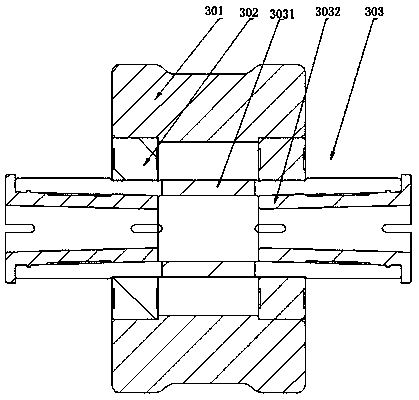

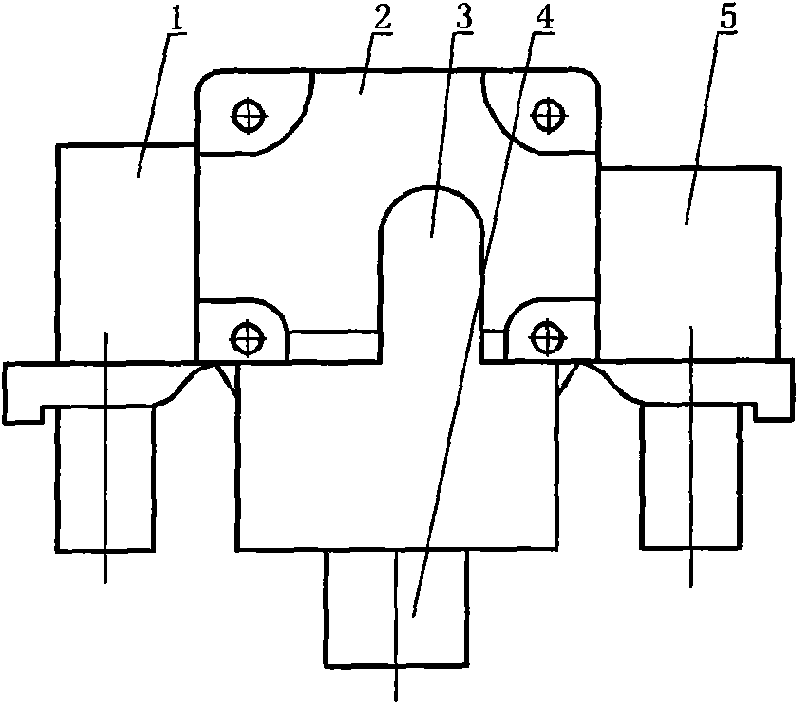

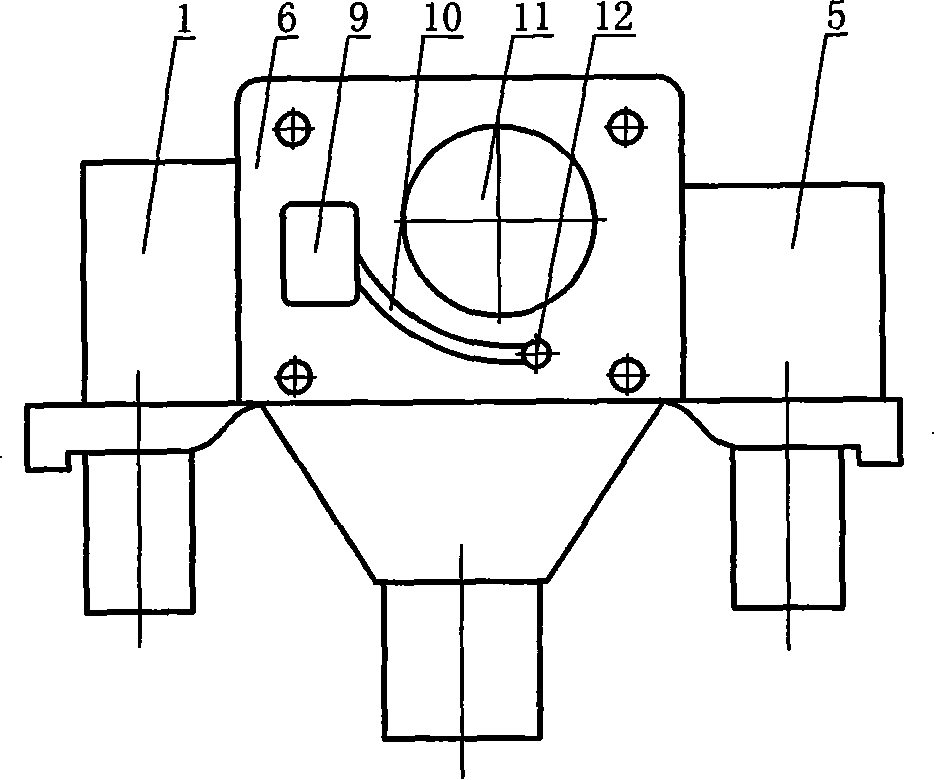

Three-way pressure compensator assembly

ActiveCN104047931AStable pressure control signalNo pressure pulsationServomotor componentsFluid-pressure actuator componentsEngineeringPeak value

The invention provides a three-way pressure compensator assembly. A three-way pressure compensator has two working positions. A spring cavity of the three-way pressure compensator is communicated with an LS port and a T port through a liquid resistance network and communicated with a P port through a dynamic damping hole. One end of the liquid resistance network is communicated with the T port, and the other end of the liquid resistance network is communicated with the LS port through a filter screen. A lower cavity of the three-way pressure compensator is communicated with the P port through a damping hole. The three-way pressure compensator assembly has the advantages that the half-bridge liquid resistance network, the dynamic damping hole and the oil inlet fixing damping hole are matched, stability of LS feedback pressure of the three-way pressure compensator is effectively achieved, it is guaranteed that a valve element of the three-way pressure compensator moves stably, and therefore stable flow division is achieved; the peak value of fluctuation of load pressure is effectively eliminated, pressure gains are reduced, and it is guaranteed that all actuators are stable; a quantitative load-sensitive system can achieve the functions that the flow is small when pressure is high and the flow is large when pressure is low.

Owner:广西中源机械有限公司 +2

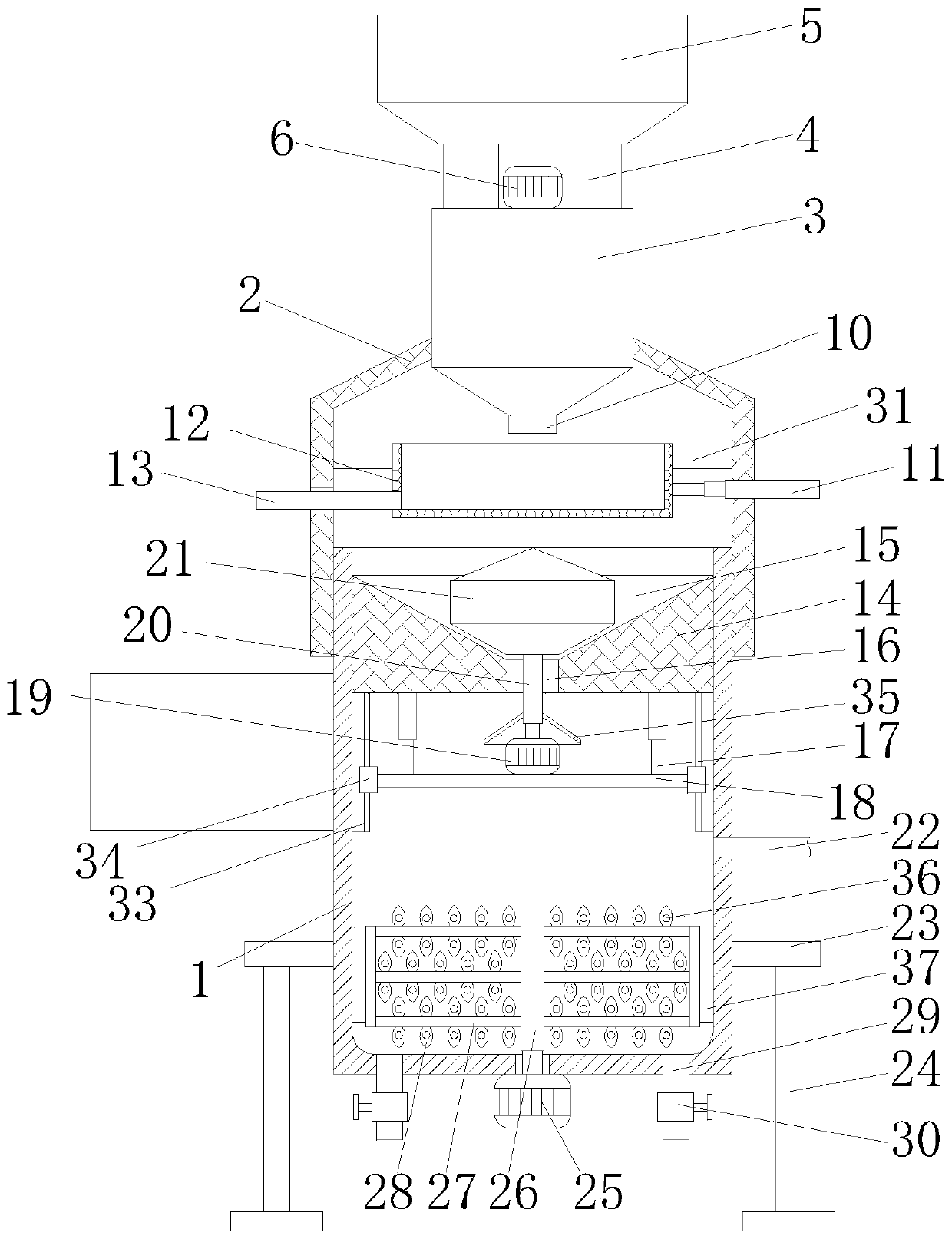

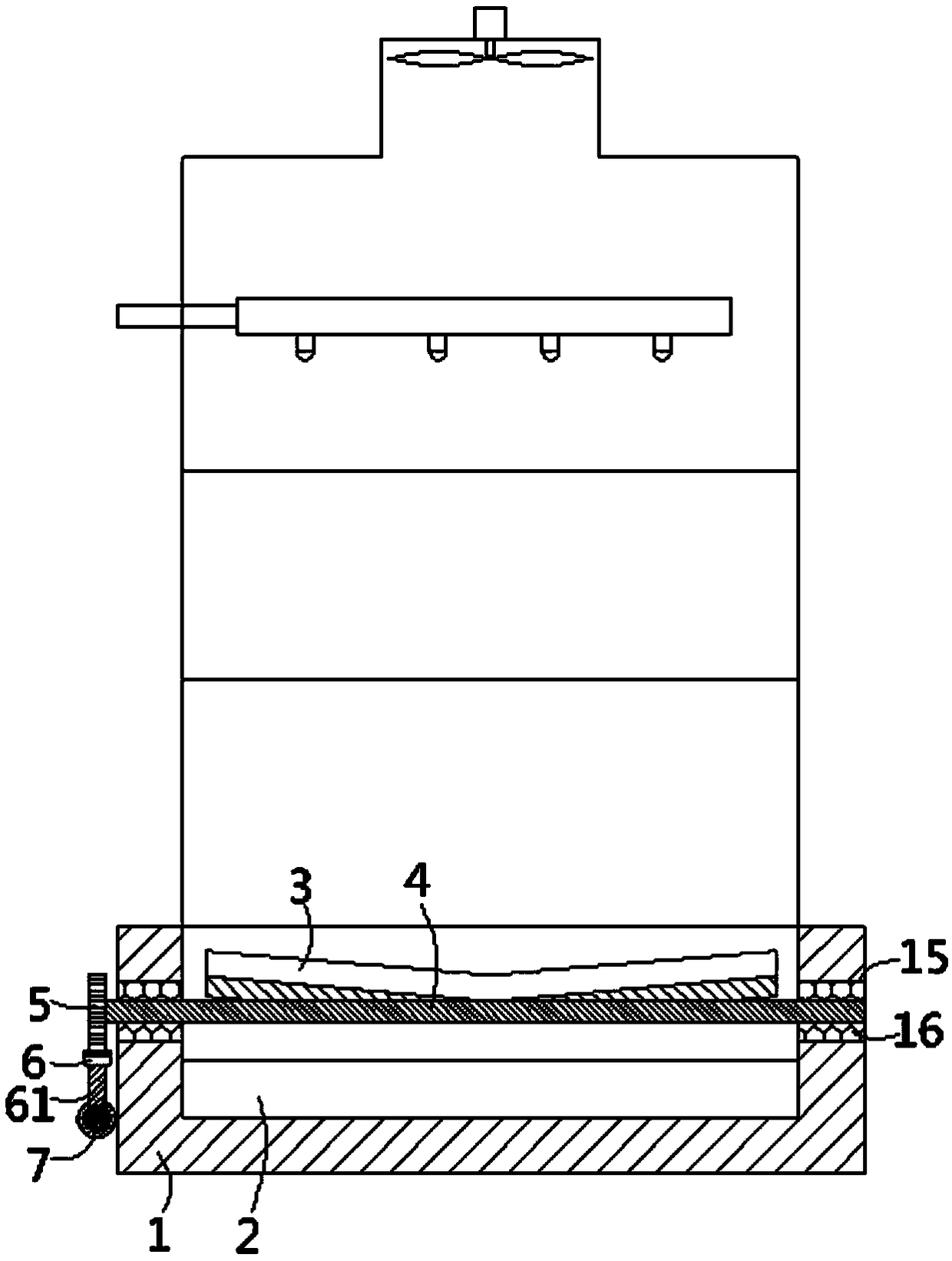

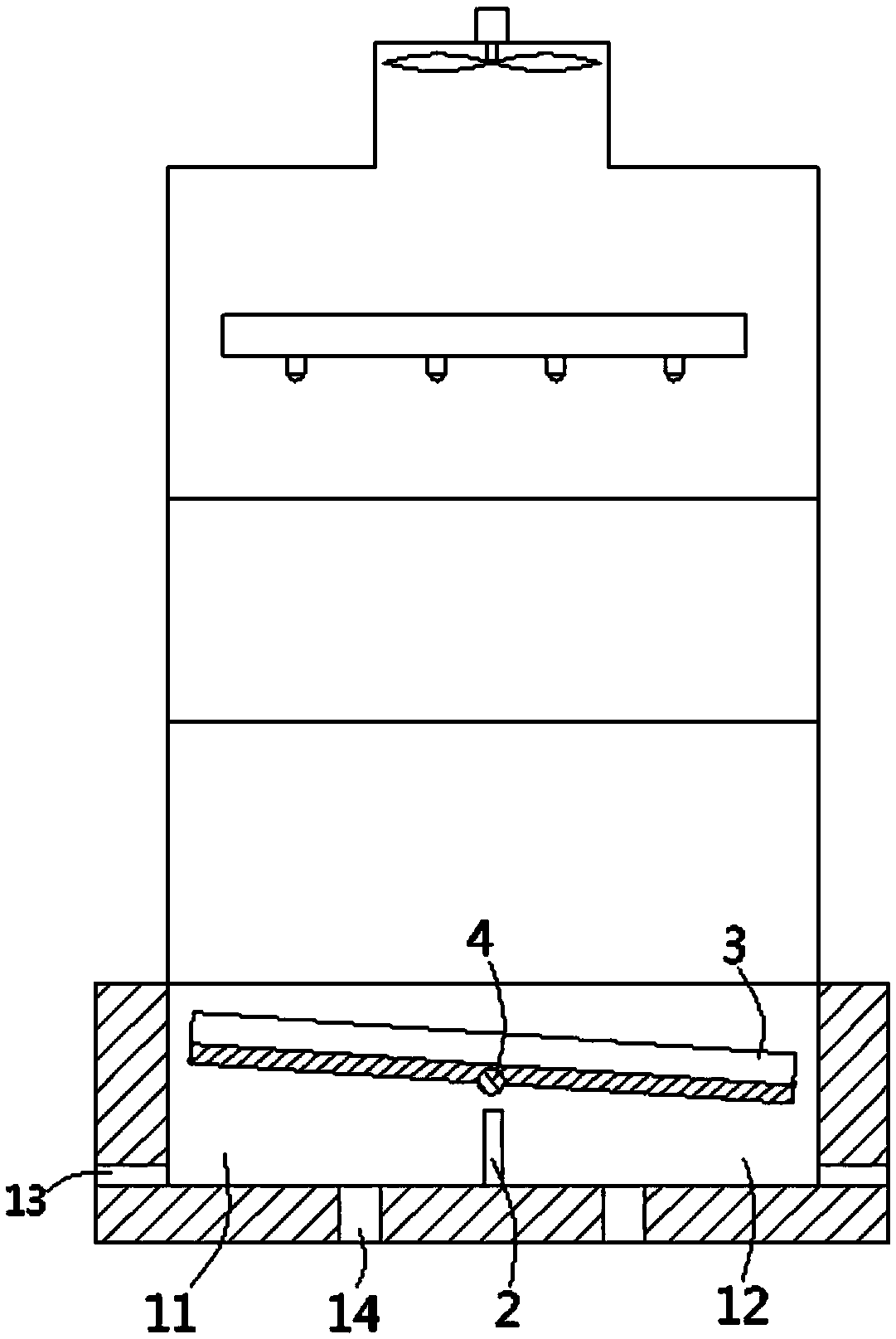

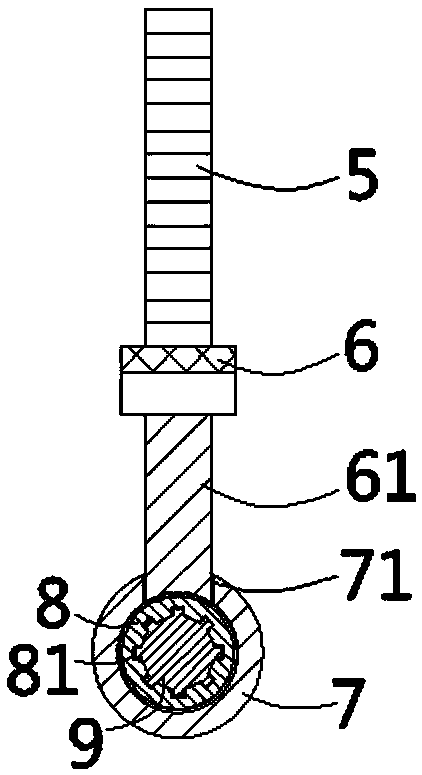

Efficient processing device for environment-protecting paint and using method of efficient processing device

InactiveCN111359756AWell mixedQuality improvementRotary stirring mixersTransportation and packagingElectric machineryProcess engineering

The invention discloses an efficient processing device for environment-protecting paint and a using method of the efficient processing device. The efficient processing device comprises a mixing box, wherein the tops of two sides of the mixing box are fixedly connected with supporting plates, and the tops of one opposite sides of the supporting plates are fixedly connected with a crushing box; thetwo sides of the top of the crushing box communicate with feeding pipes, and the tops of the feeding pipes communicates with a feeding hopper; and the top of the crushing box is fixedly connected witha first motor, the bottom of a rotating shaft of the first motor penetrates into an inner cavity of the crushing box, the bottom of the rotating shaft of the first motor is fixedly connected with a crushing shaft, and the surface of the crushing shaft is fixedly connected with first blades. The efficient processing device for the environment-protecting paint has the advantages of integrated design of crushing, grinding and mixing, uniform mixing of materials, high quality of finished products and high processing efficiency, and solves the problems that the quality of the finished products isreduced and the processing efficiency is reduced at the same time due to uneven mixing of the materials and slow mixing speed caused by the fact that a paint processing device cannot crush and grind large-particle materials in advance.

Owner:淮北森诺环保科技有限公司

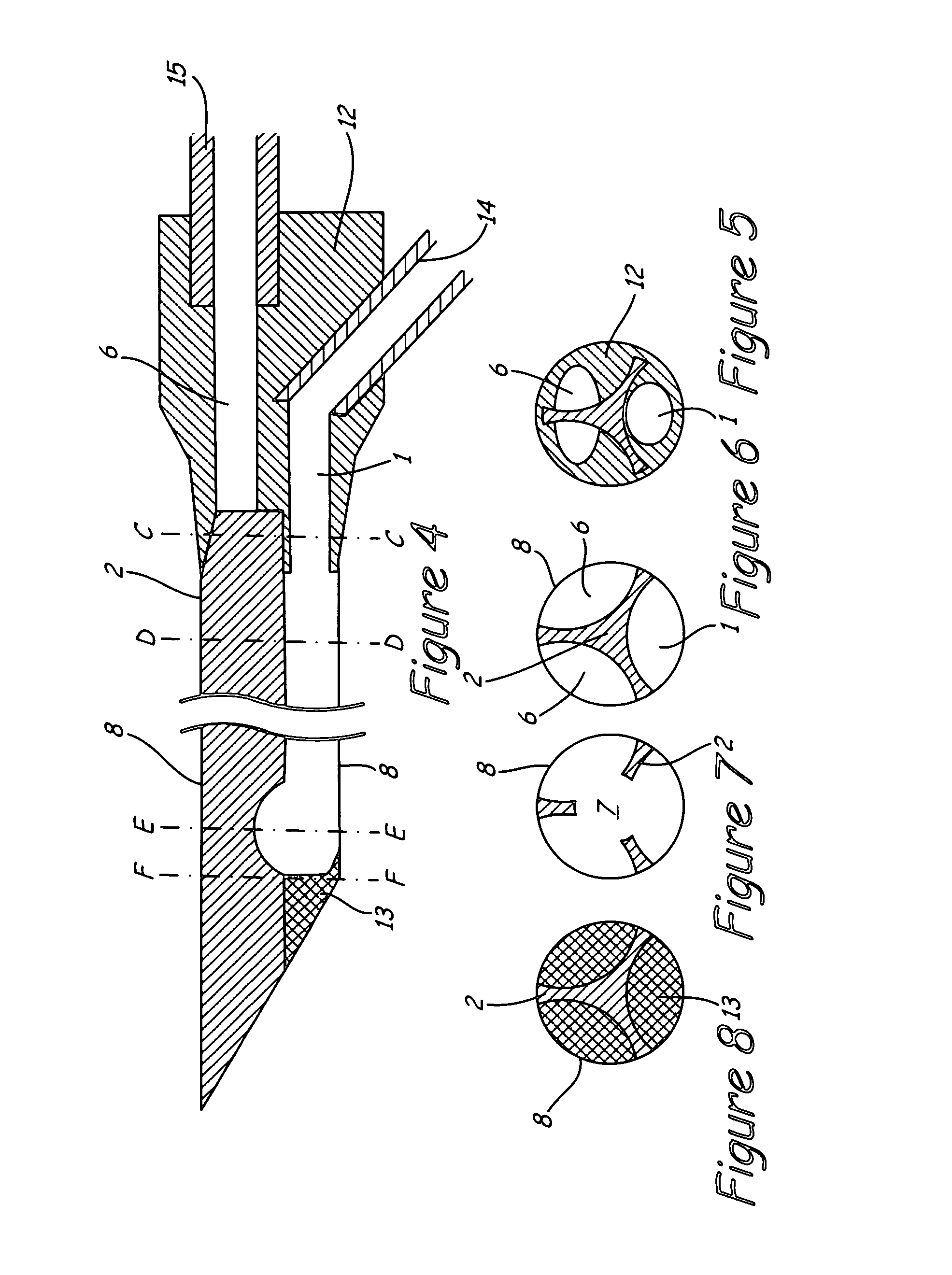

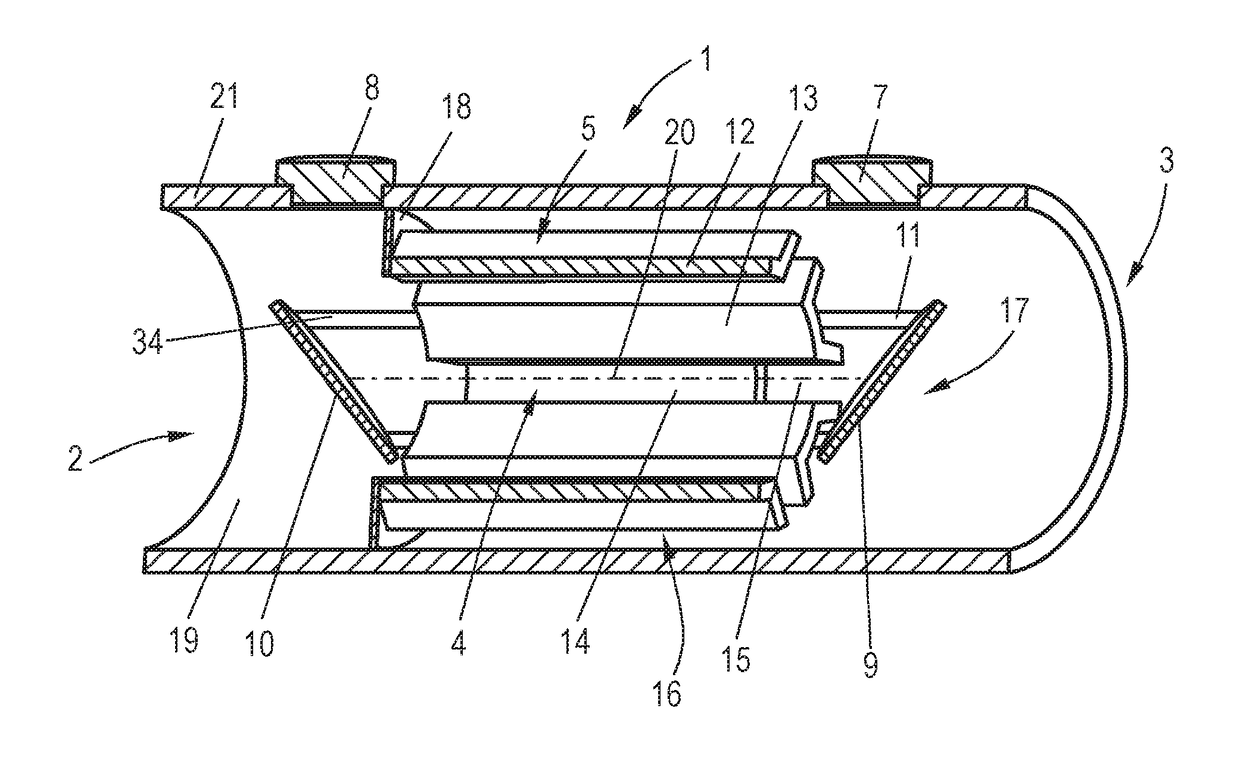

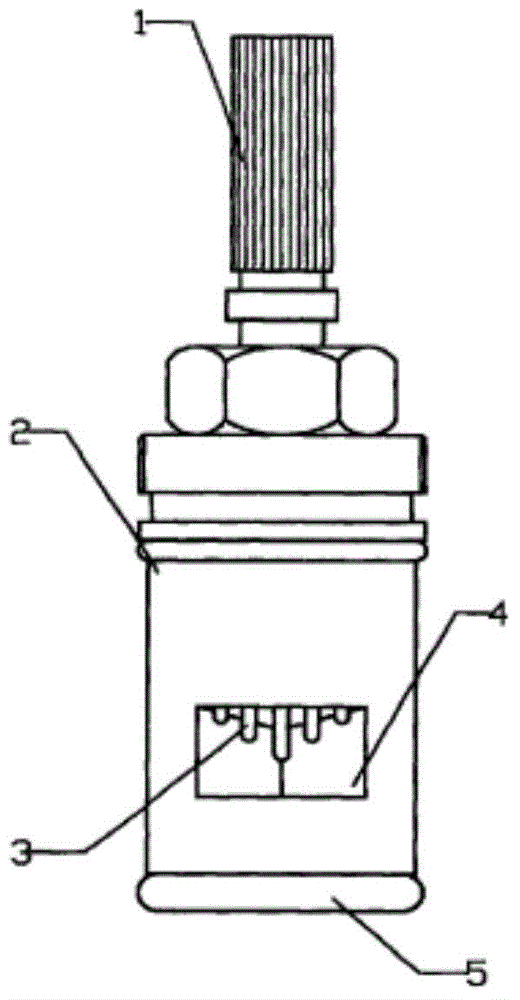

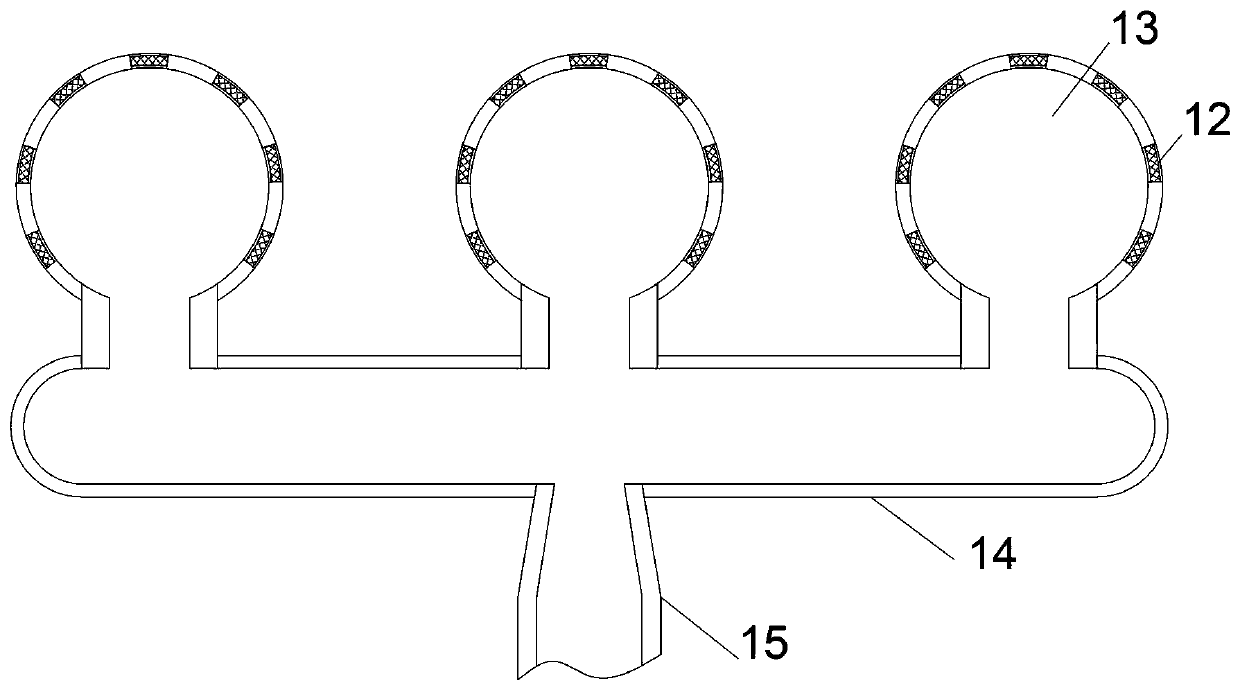

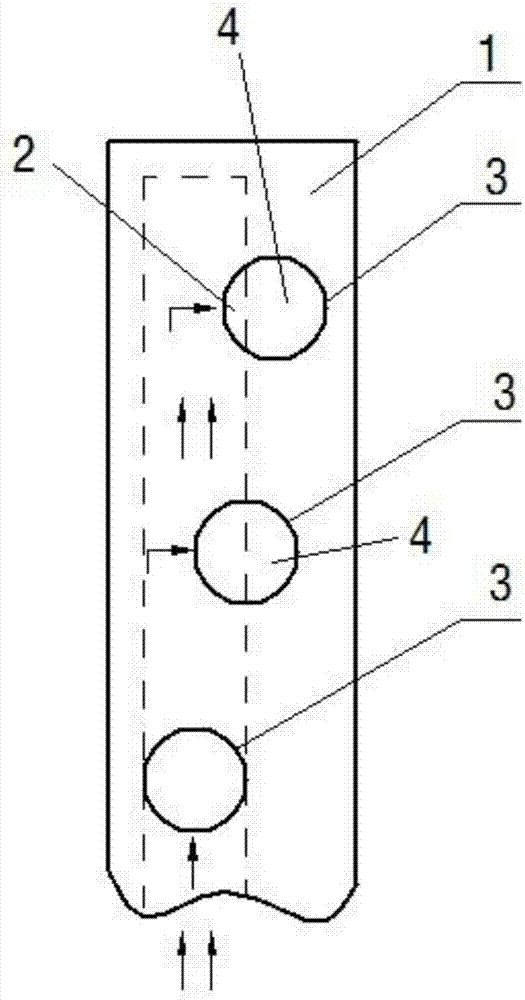

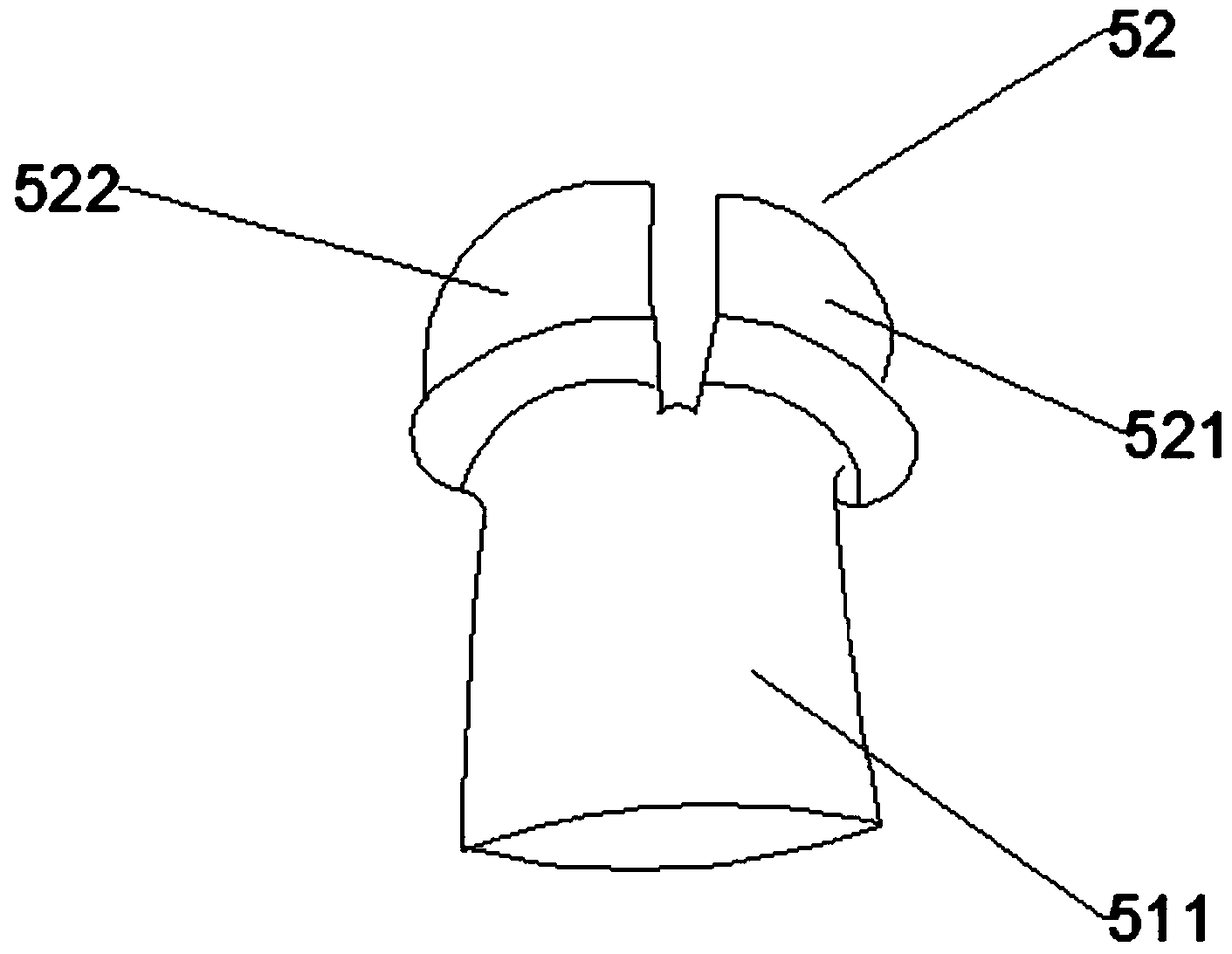

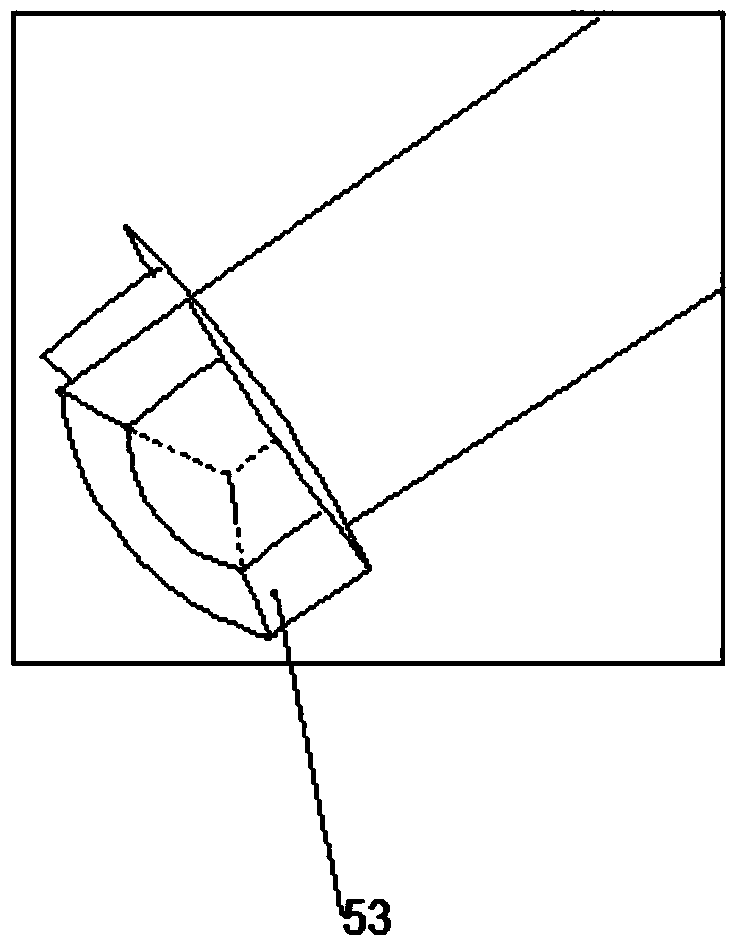

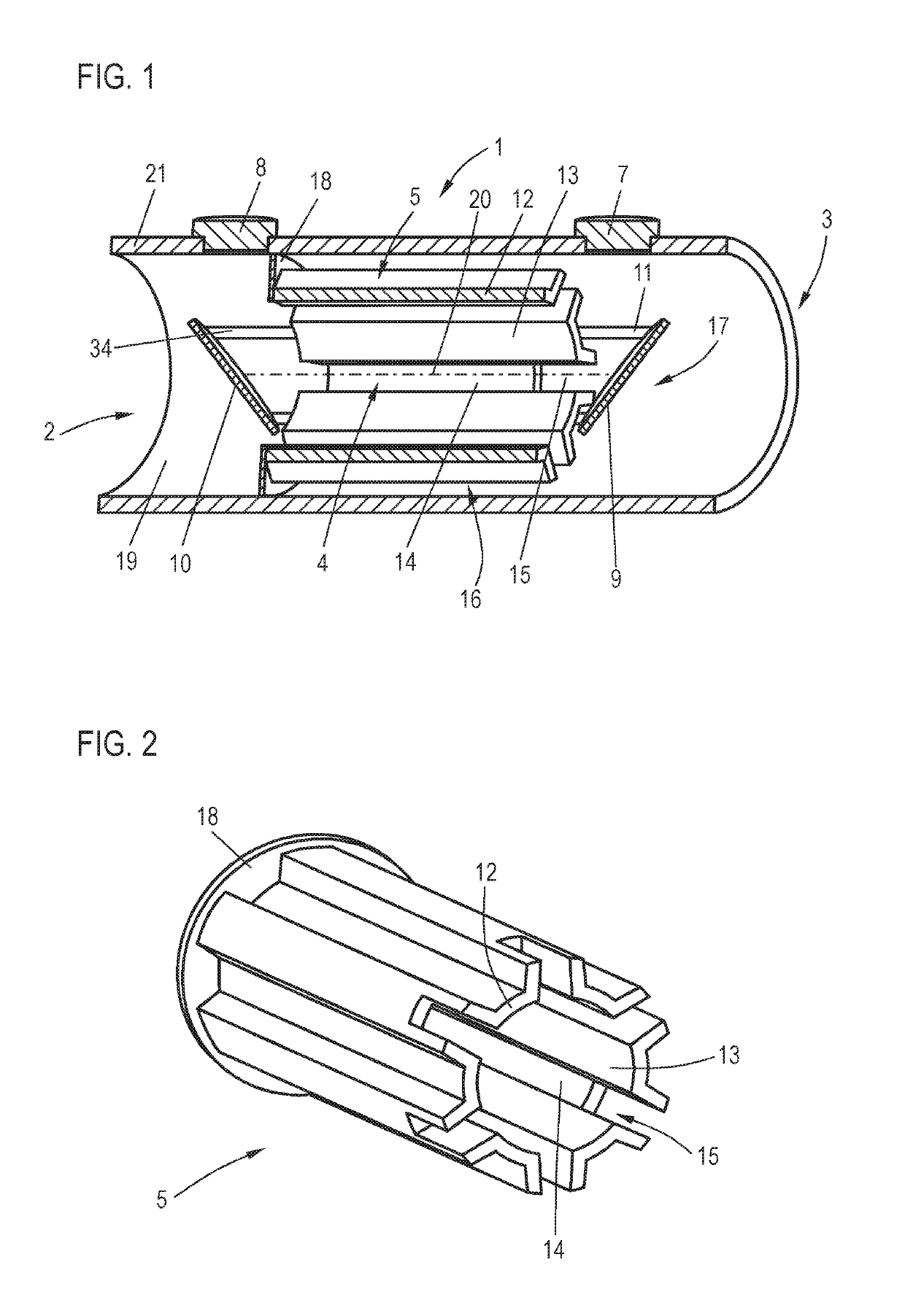

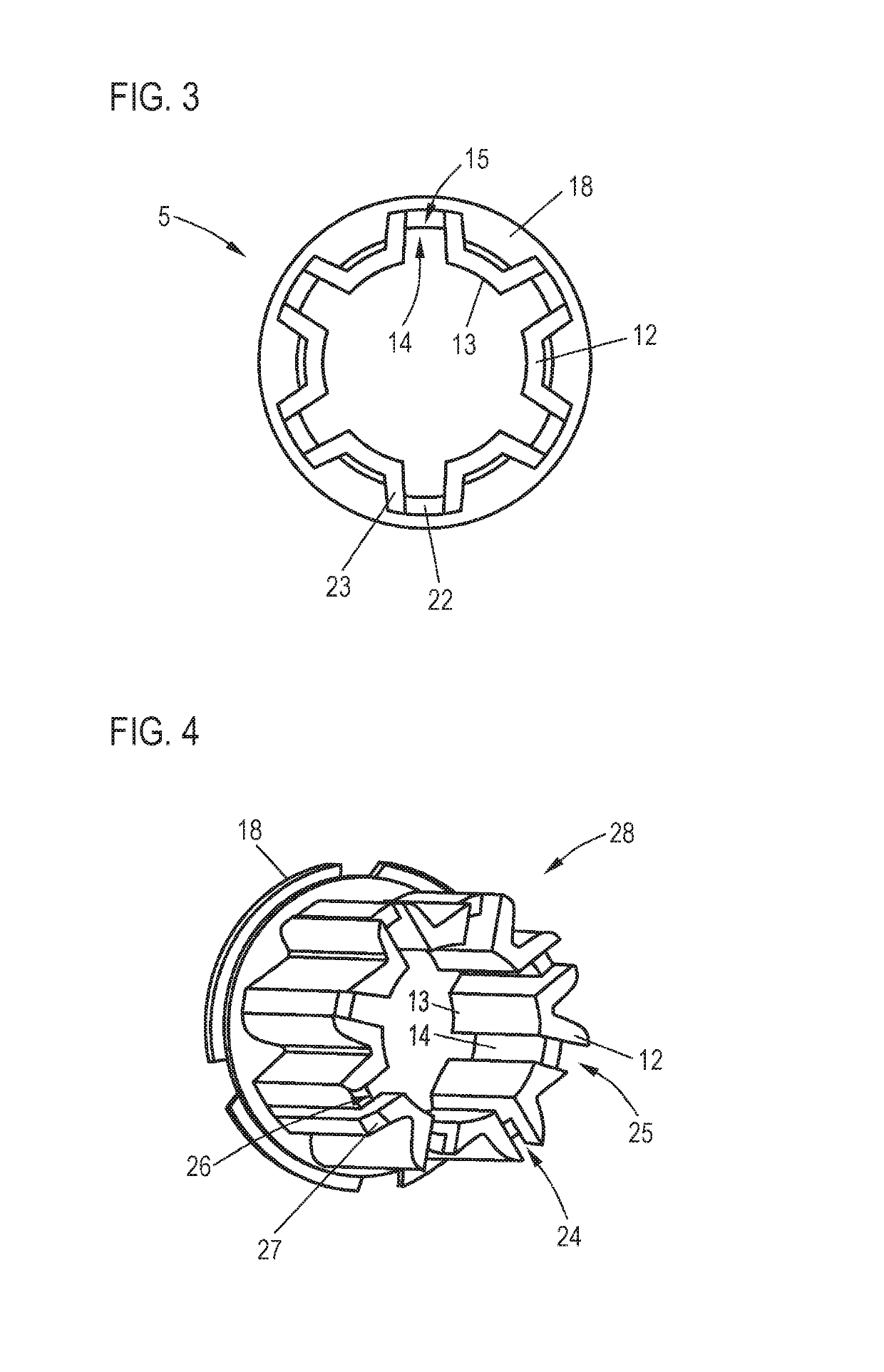

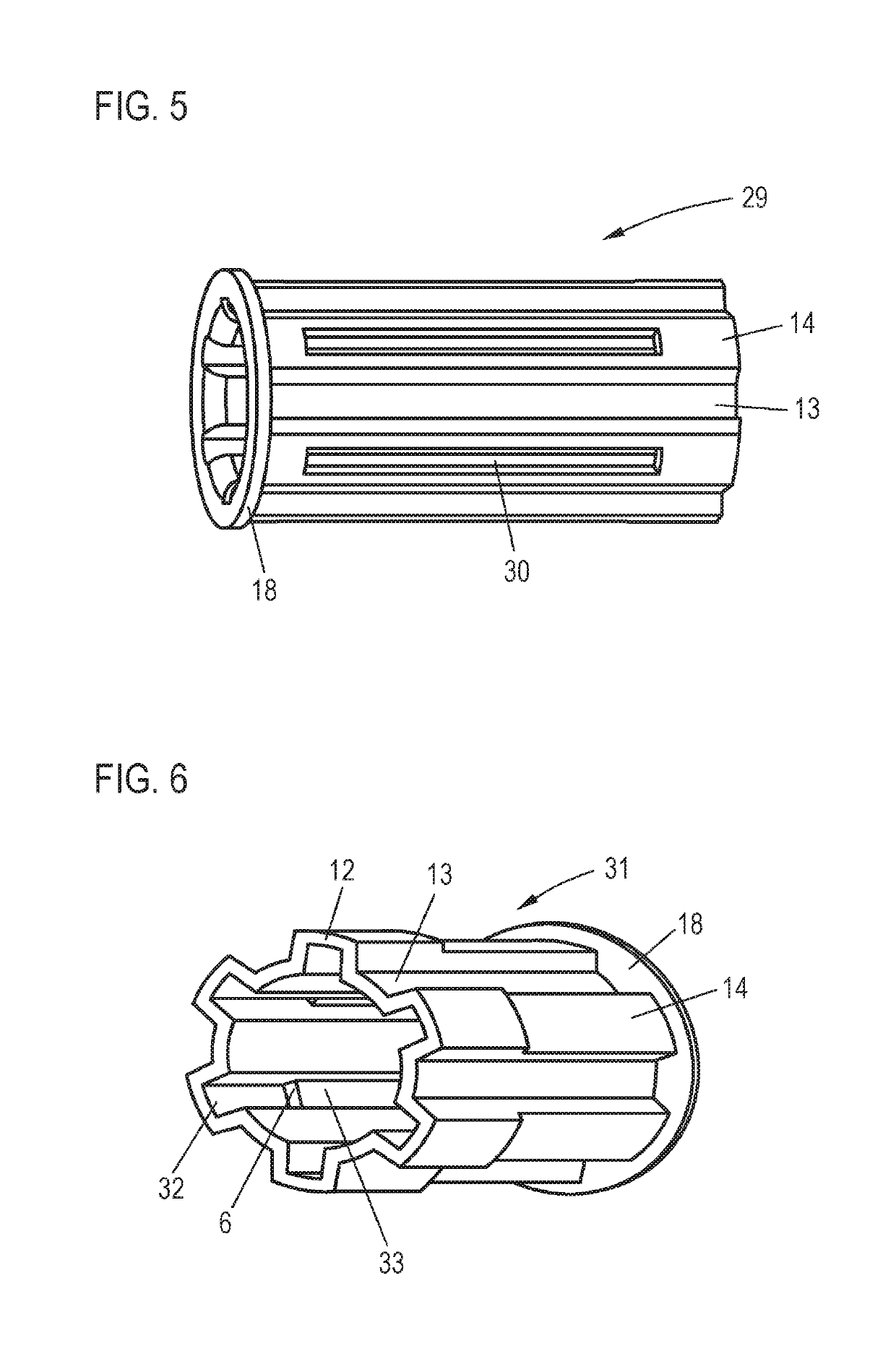

Micro-dialysis probe

InactiveUS7008398B2Increase flow ratePromotes concentration equalisationInfusion devicesDialysis systemsLine tubingBiomedical engineering

A micro-dialysis probe extending longitudinally between a proximal probe opening and a distal probe tip and having a supply line and a drainage line for a drip-feed solution. A tube may be provided for supporting the drainage line. A dialysis section, wherein the flow channel for the drip-feed solution experiences an inversion, is formed generally between the supply line and the drainage line, in the vicinity of the distal probe tip. The supply line and the drainage line are arranged substantially side by side and together form the probe shaft of the micro-dialysis probe.

Owner:ROCHE DIABETES CARE INC

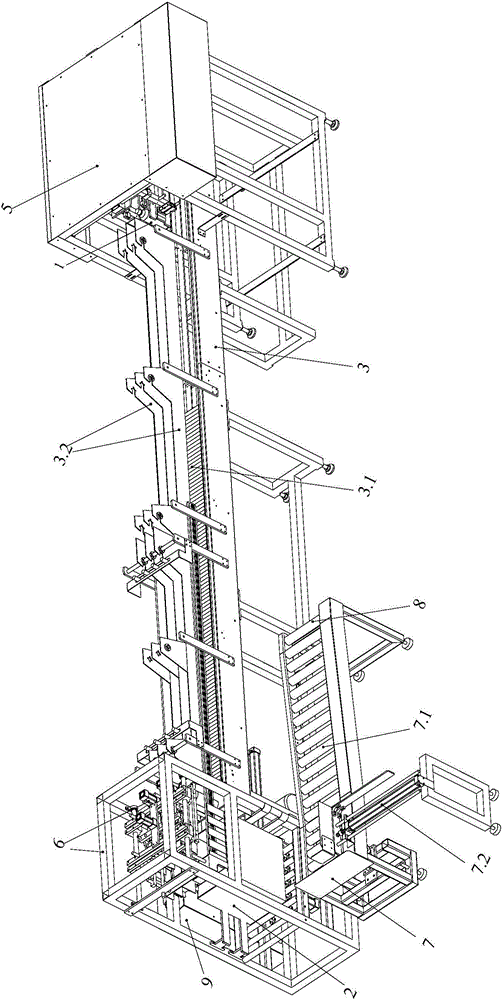

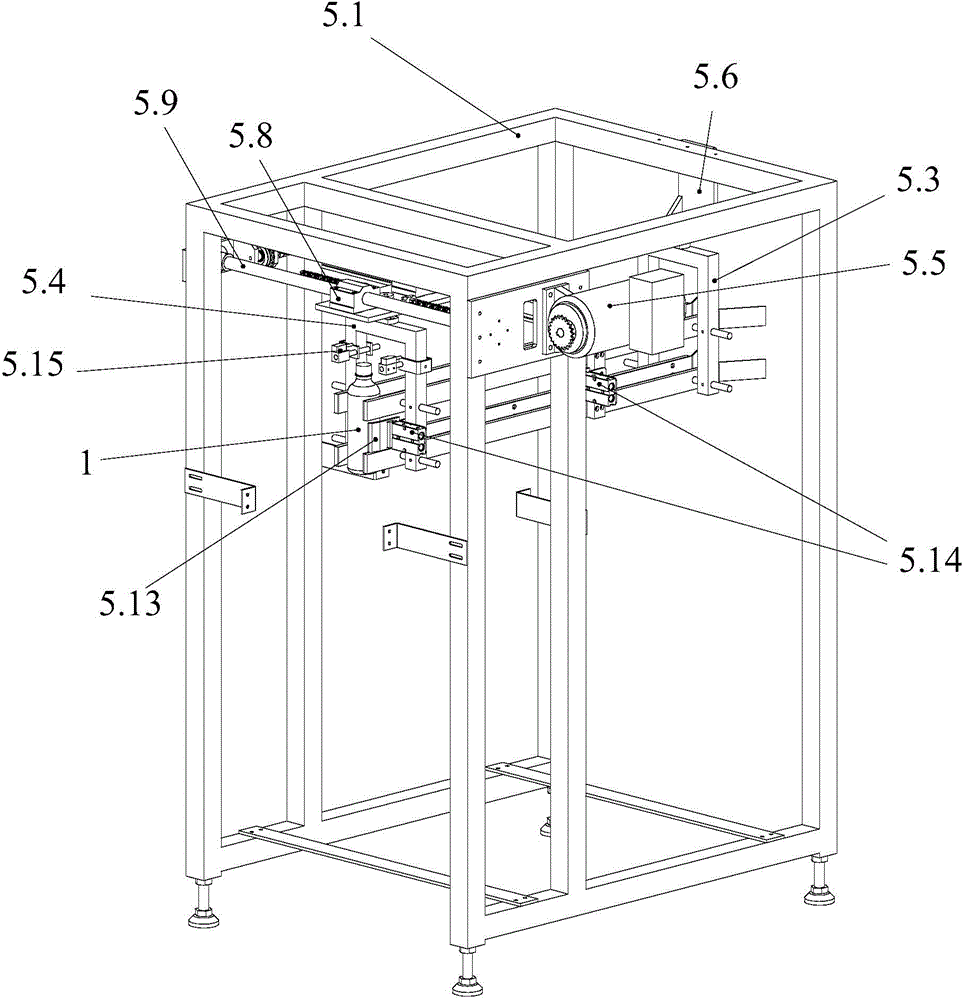

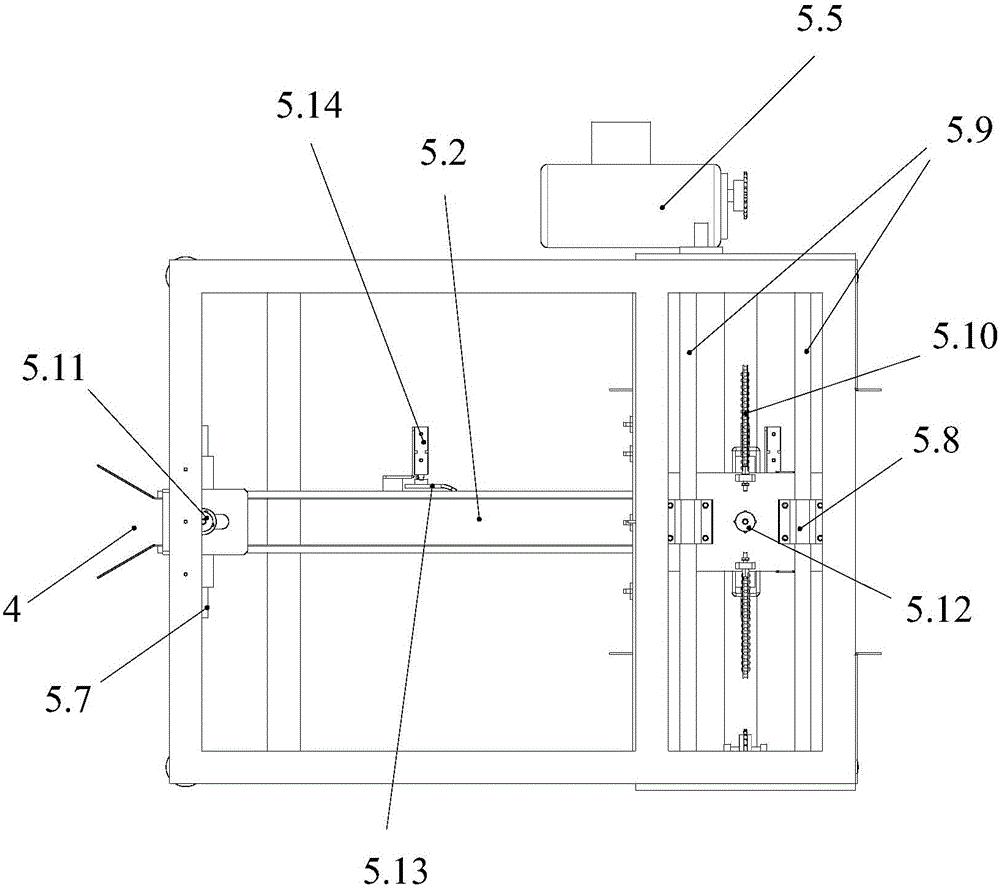

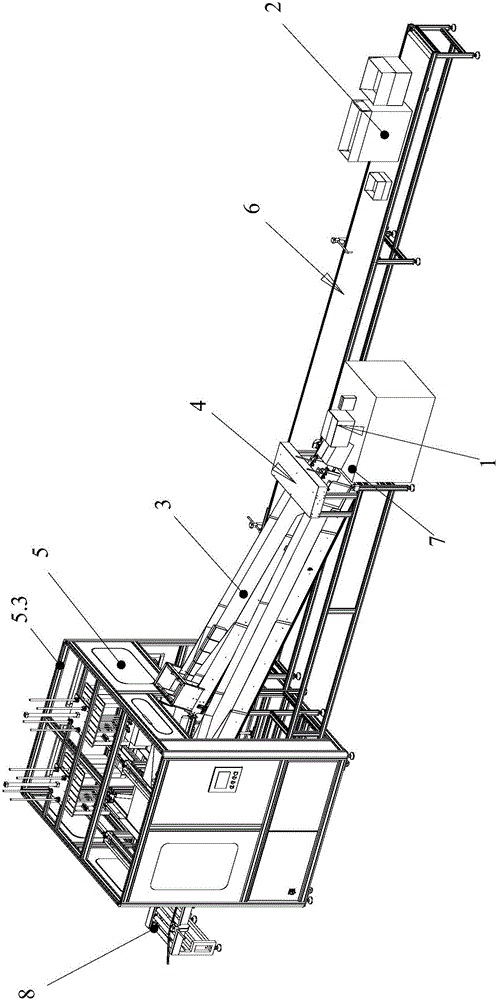

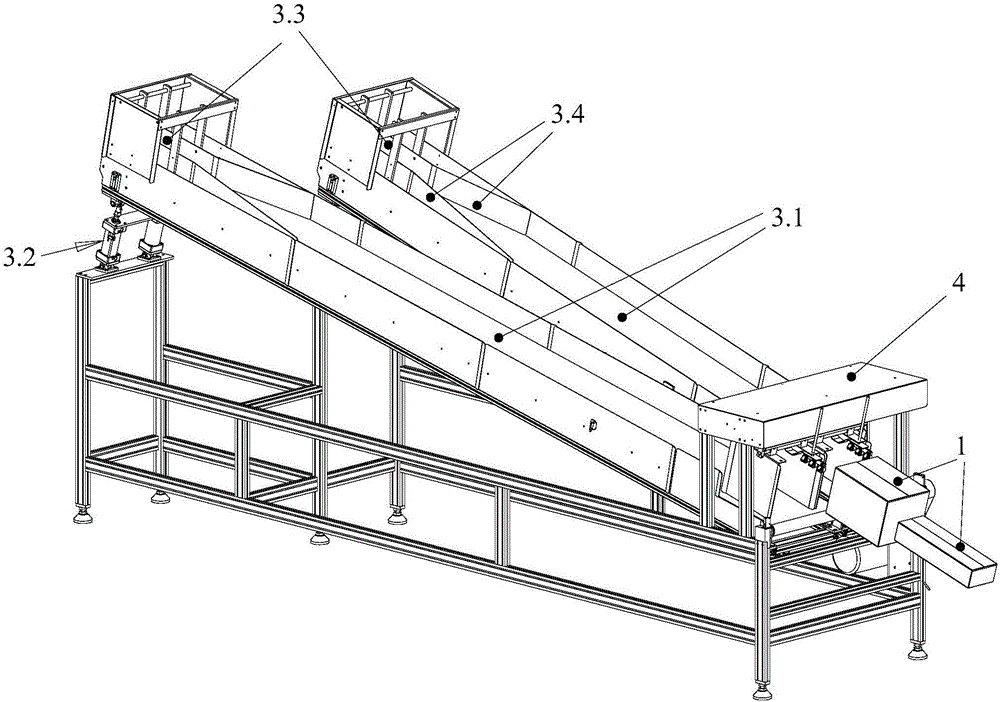

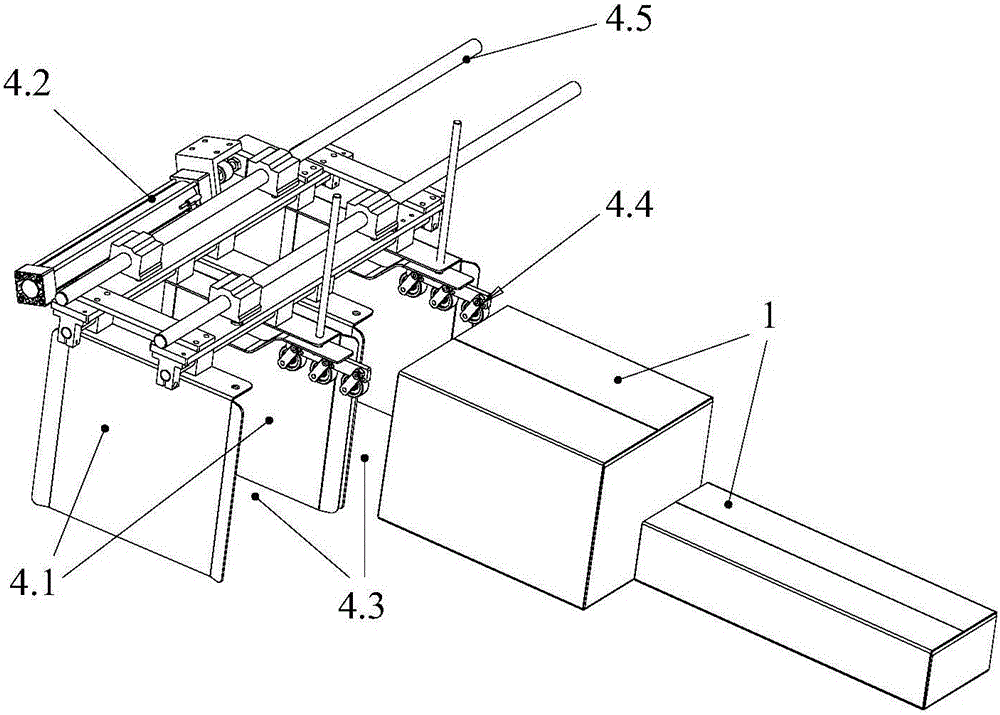

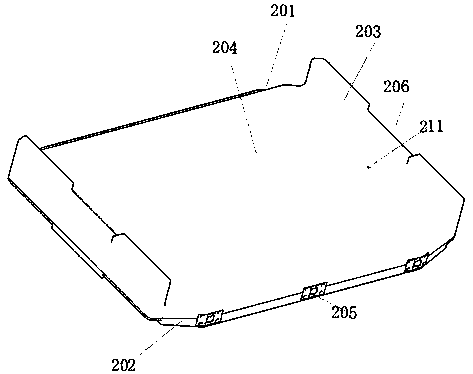

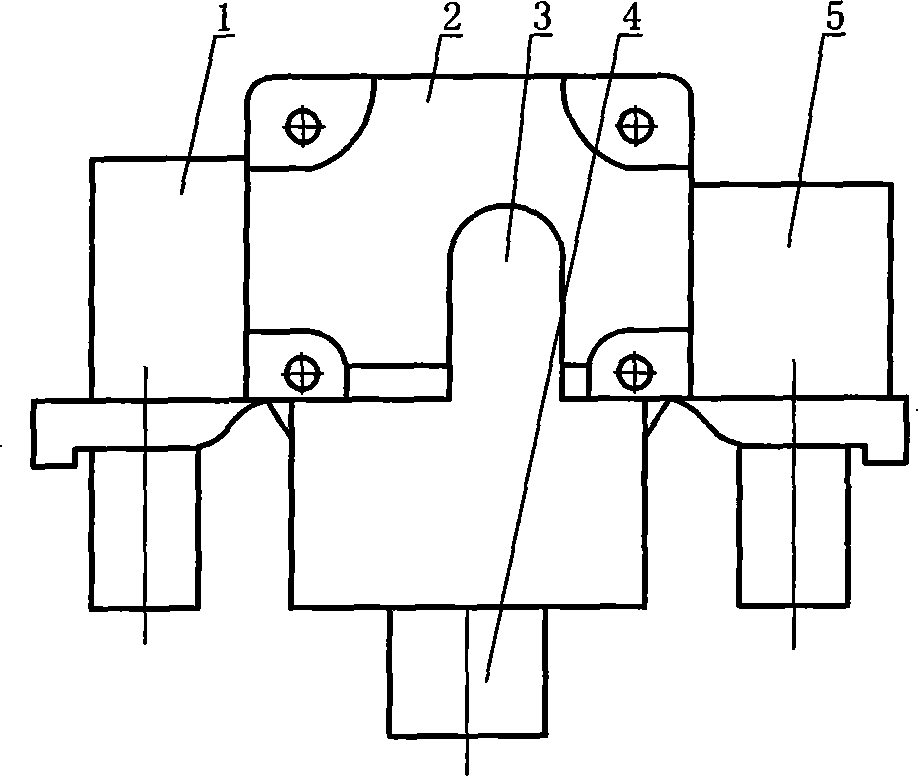

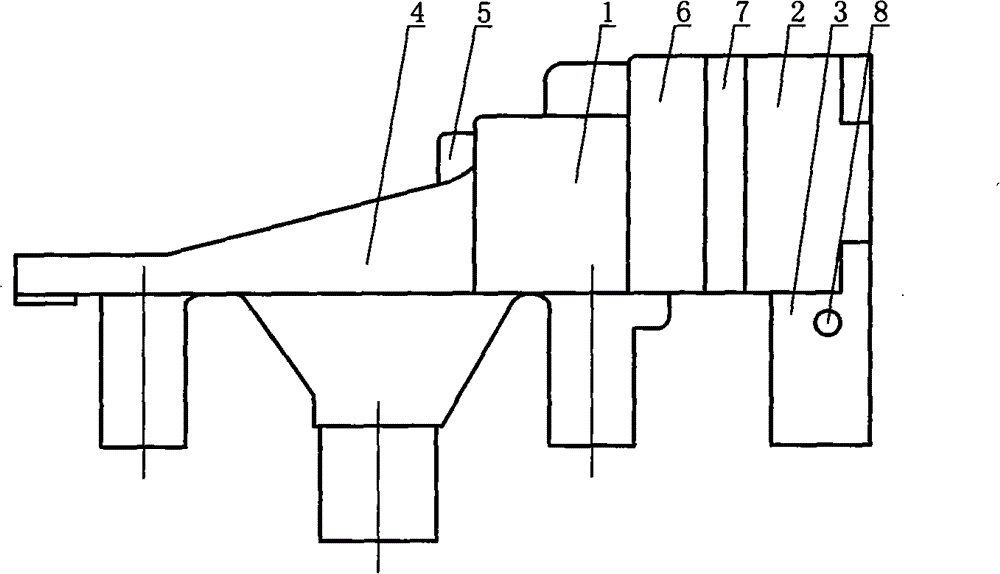

Automatic bottled product encasing device

ActiveCN104443499AHigh speedImprove efficiencyPackaging automatic controlPackaging bottlesMechanical engineeringFast speed

The invention provides an automatic bottled product encasing device. The automatic bottled product encasing device comprises a bottled product conveying mechanism, a shunting mechanism, an encasing mechanism, a box conveying mechanism and a controller. The bottled product conveying mechanism is provided with M conveying channels and used for arranging bottled products according to the preset number of rows / columns of the bottled products needing to be arranged in a box and guiding and conveying the bottled products. One end of the shunting mechanism is connected with a device inlet, the other end of the shunting mechanism is movably connected with the M conveying channels, and the shunting mechanism is used for movably shunting and guiding the bottled products conveyed from the single device inlet into the M conveying channels of the bottled product conveying mechanism. The encasing mechanism is connected with an outlet of the bottled product conveying mechanism and used for arranging the bottled products according to the preset number of rows / columns of the bottled products needing to be arranged in the box, after an array is formed, the whole array of the bottled products fall and are arranged in the box capable of being lifted. The box conveying mechanism is arranged on one side of the encasing mechanism. The encasing device is simple in structure, high in encasing speed and encasing stability, and capable of improving bottled product encasing efficiency and accuracy.

Owner:佛山市嘉荣智能机械有限公司

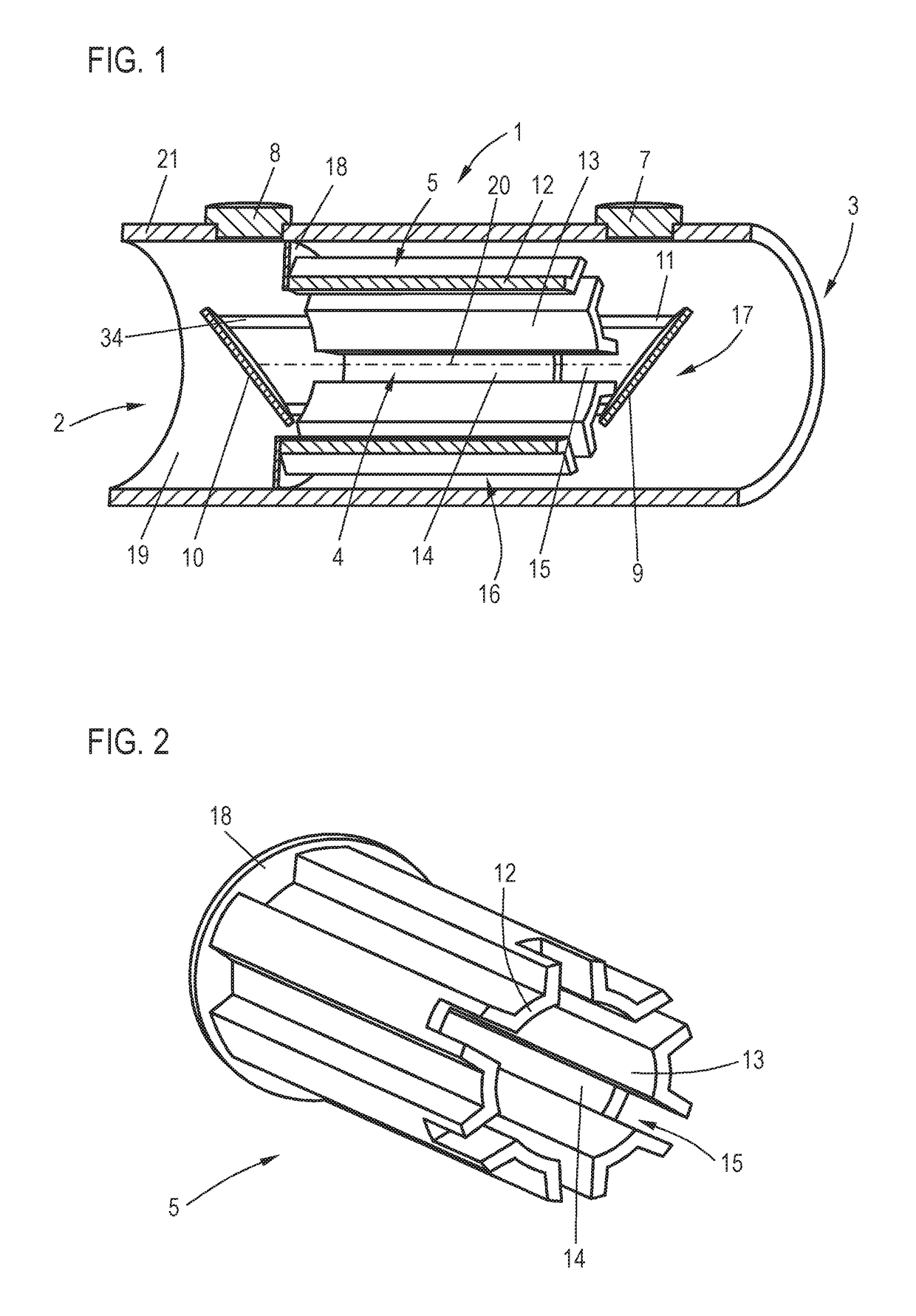

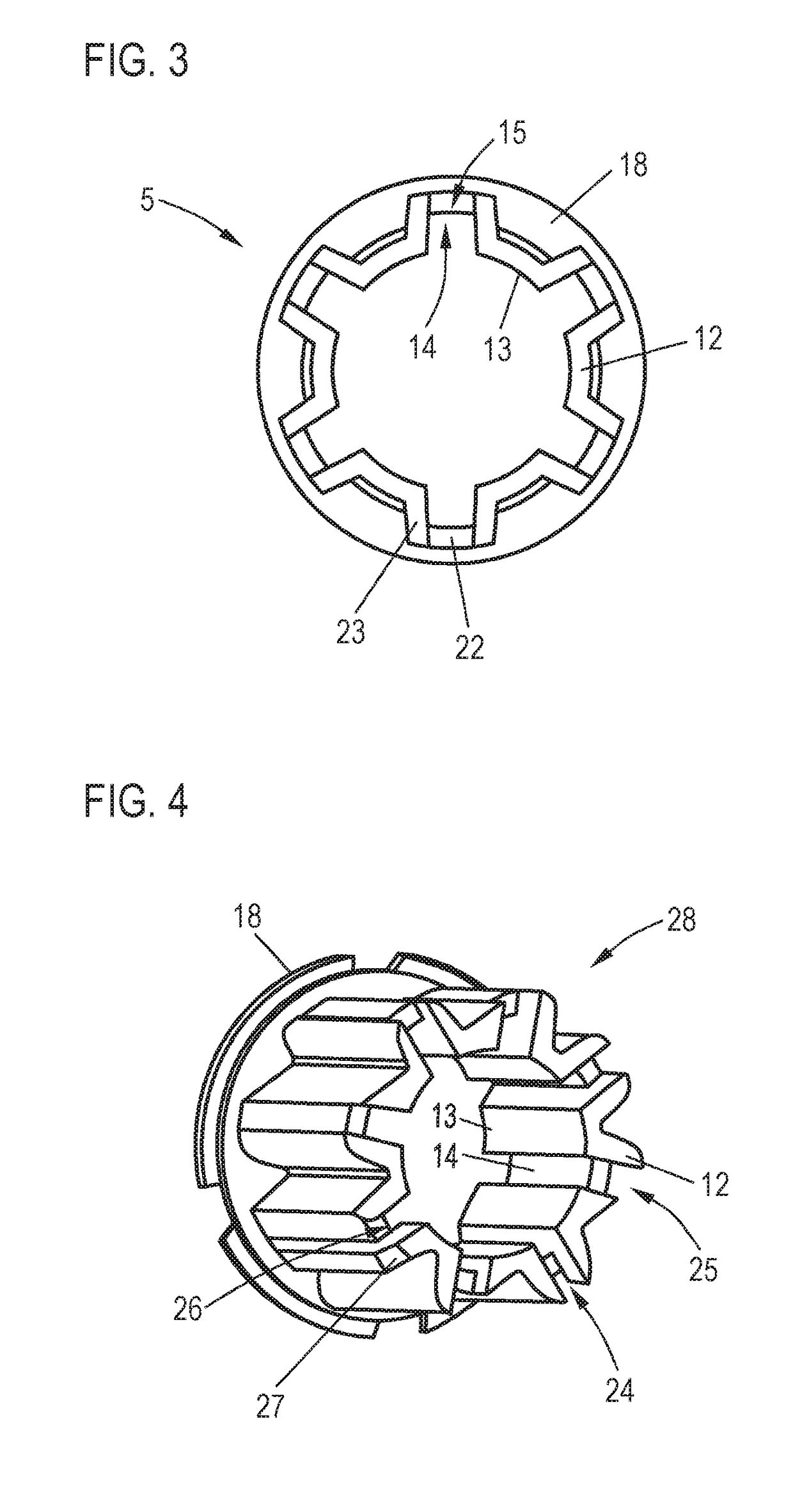

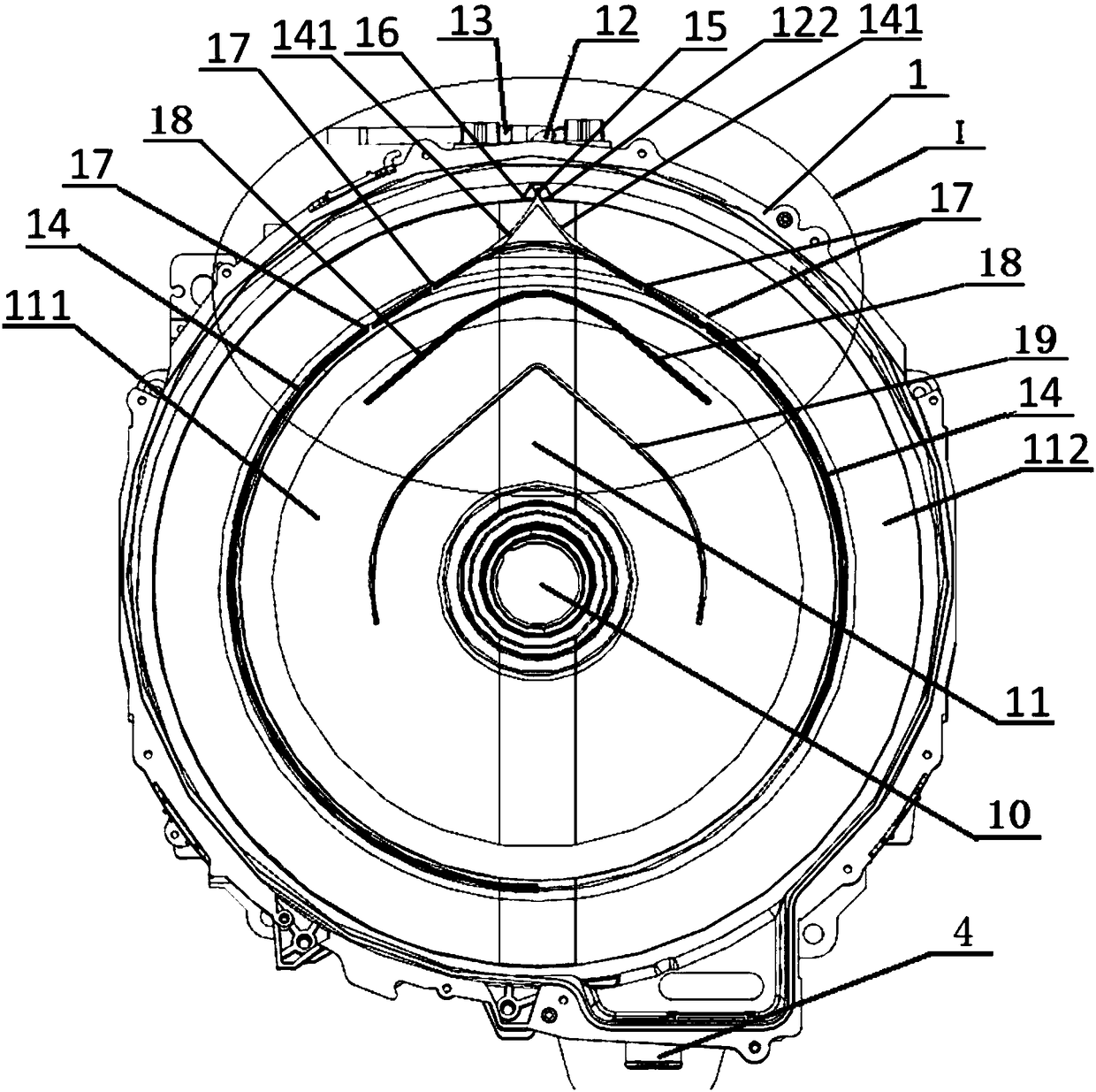

Ultrasonic meter

ActiveUS20180136024A1Improved flow guidanceBest possible stabilizationVolume/mass flow measurementVolume meteringEngineeringUltrasound

Owner:DIEHL METERING

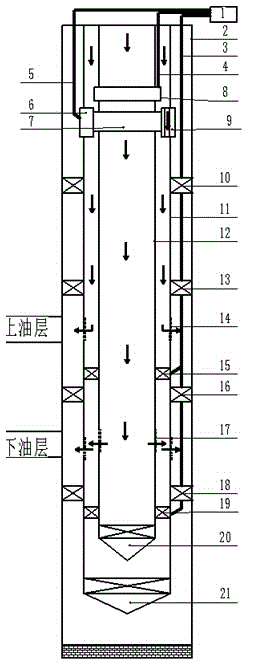

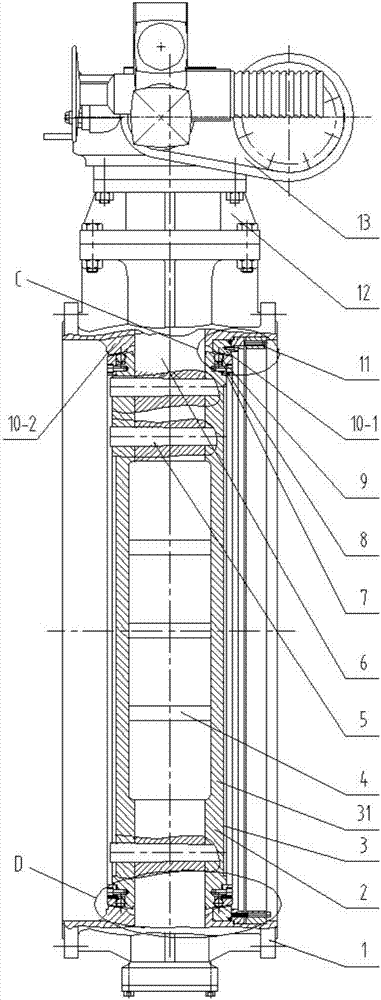

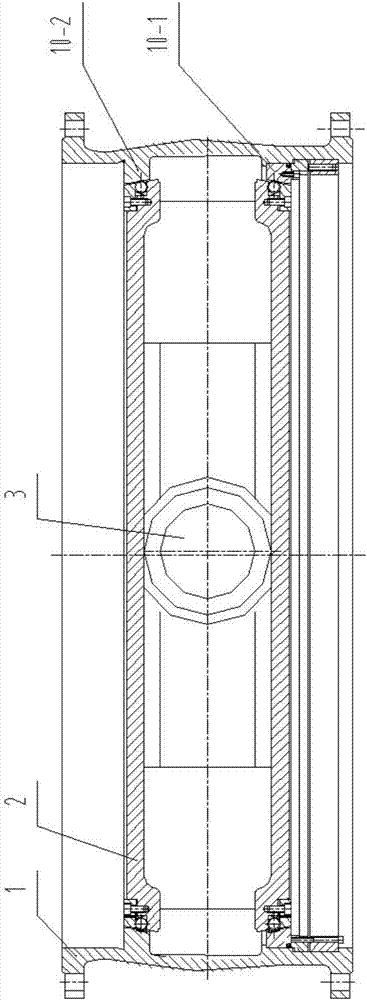

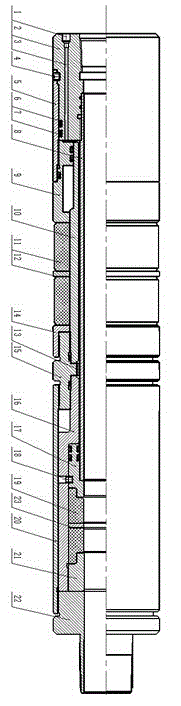

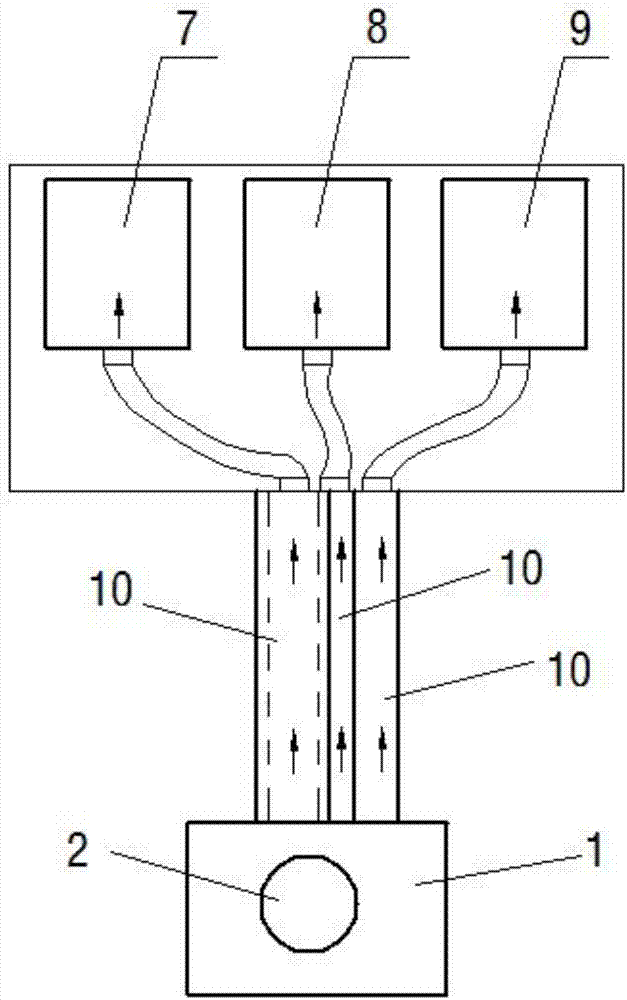

Independent safe long-acting double-pipe water injection pipe column

The invention discloses an independent safe long-acting double-pipe water injection pipe column. The independent safe long-acting double-pipe water injection pipe column comprises an independently arranged inner pipe and an independently arranged outer pipe. The inner pipe is arranged in the outer pipe coaxially. An inner pipe center cavity serves as an inner water injection channel communicating to a lower oil layer. An annulus formed between the inner pipe and the outer pipe serves as an outer water injection channel communicating to an upper oil layer. The annulus positions between the upper end of the inner pipe, the upper end of the outer pipe as well as the upper end outer wall of the outer pipe and a sleeve are all provided with safety control devices which are an inner pipe safety valve, an annulus safety valve and an annulus safety packer correspondingly. The inner pipe safety valve, the annulus safety valve and the annulus safety packer control the three axial channels of the inner pipe, the inner inner-outer-pipe annulus and the outer pipe and sleeve annulus correspondingly, and whole sealing during the shaft emergency condition is achieved. The lower end of the inner pipe is connected with an inner water injection pipe column body. The lower end of the outer pipe is connected with an outer water injection pipe column body. Through the independent safe long-acting double-pipe water injection pipe column, the problems of unreliable safety control, not-in-place inner and outer pipe flow separation, liable failure of an outer pipe and unbalanced pipe column stress existing in the prior art are mainly solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

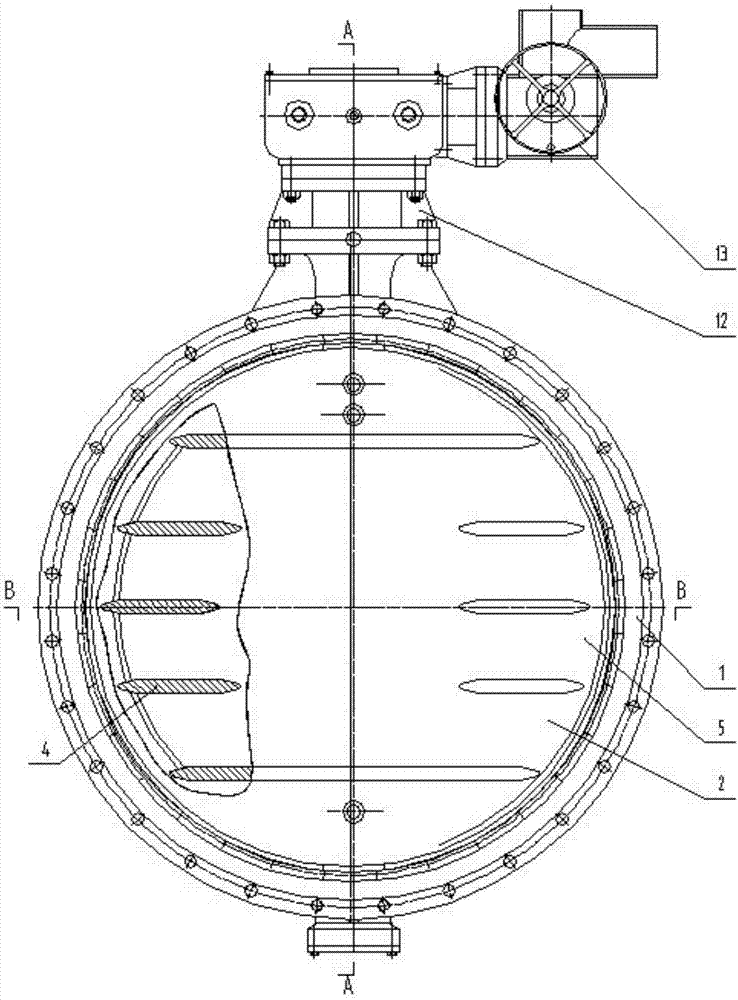

Double-plate double-valve-seat bi-directional metal-sealed butterfly valve

InactiveCN107355548AScientific and reasonable structure designSimple structureLift valveCircular discEngineering

The invention relates to a double-plate double-valve-seat bi-directional metal-sealed butterfly valve, which comprises a drive device, a support, a filler, a filler gland, a bottom cover, a valve body, a butterfly plate, an upper valve shaft, a lower valve shaft, a valve shaft pin, valve seats, a butterfly plate metal seal ring, a pressing plate, a valve seat pressing plate, a check ring and an adjustable valve seat seal ring. The valve seats are oppositely arranged between a disk and the valve body at two sides of the upper valve shaft; the valve seats are oppositely arranged between the disk and the valve body at two sides of the lower valve shaft; and the valve seats are fixed valve seat and / or adjustable valve seats. The butterfly valve has a scientific and reasonable structure design, a simple structure, easiness in processing and manufacturing, large caliber, high flow capacity, high pressure resistance, high temperature resistance, corrosion resistance, diversion stability, small vibration, low noise, long service life, and capability of on-line overhauling and replacing a sealing element, and a double-sealed pair works cooperatively or independently when at a two-way alternative pressure-bearing state so as to further realize two-way sealing.

Owner:王中杰

Carton loading mechanism

ActiveCN105059598AEffective diversionShunt effective averagePackaging automatic controlIndividual articlesCartonAutomation

The invention provides a carton loading mechanism. The mechanism comprises a carton conveying device, a distribution device, a loading device, an outer box conveying device and a control device, wherein the carton conveying device is provided with M conveying channels; one end of the distribution device is connected with a mechanism inlet, and the other end of the distribution device is movably connected with the M conveying channels; the loading device is connected with an outlet of the carton conveying device; by means of the loading device, the cartons are distributed according to a preset sequence one by one to form rows / columns, the rows / columns form layers, then each whole layer of cartons is contained in an outer box, and finally, the cartons are stacked and contained in the outer box layer by layer through descending of the outer box; the outer box conveying device is arranged on one side of the carton conveying device; the control device is in signal connection with the carton conveying device, the distribution device, the loading device and the outer box conveying device. By means of the carton loading mechanism, the cartons can be loaded quickly and stably, and the cartons are loaded in a full-automatic mode according to production requirements, so that the traditional manual loading process is replaced, and production efficiency and accuracy of carton loading are improved; besides, the problems that the existing packaging mechanical industry is low in automation degree and low in production efficiency are solved.

Owner:FOSHAN UNIVERSITY

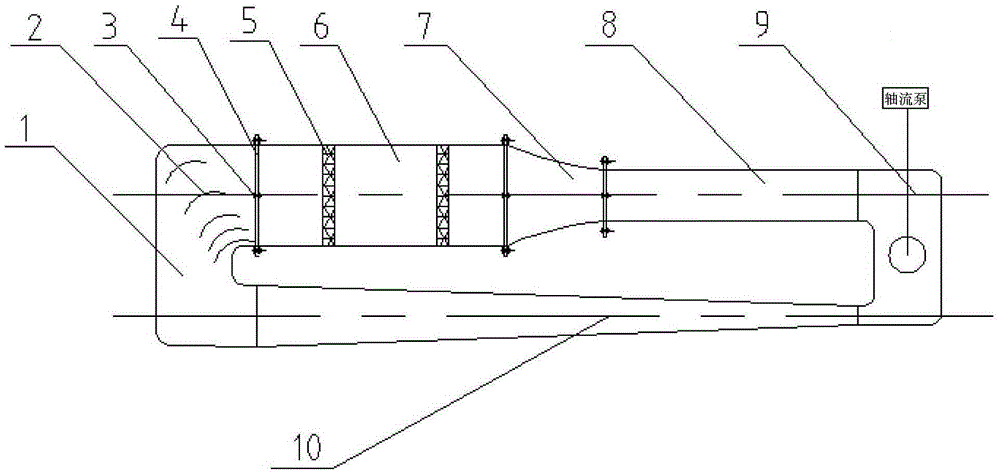

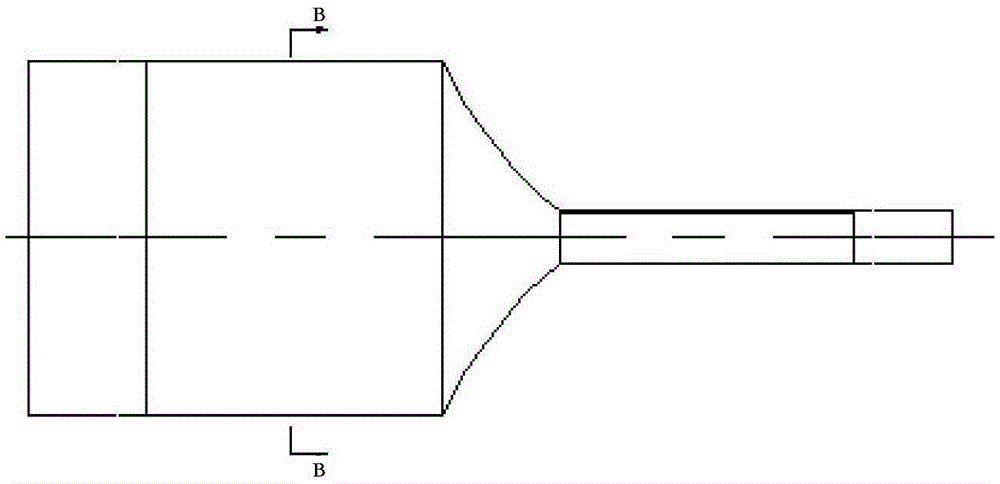

Novel circulation experiment water tank

The invention relates to a novel circulation experiment water tank composed of a U-shaped elbow, wing-shaped flow deflectors, a bolt, a flange, steel wire nets, a straight tube, a cambered tapered tube, a minor-diameter straight tube, a U-shaped water tank body and a long tapered tube. The whole water tank is made of organic glass, and is high in transparency and mechanical strength, light and easy to machine. The wing-shaped flow deflectors are small in resistance and good in diversion feature, and the fluid flow speed is effectively controlled. The straight tube and the cambered tapered tube are connected through the bolt and the flange, and are convenient to dismount. The steel wire nets are installed in the straight tube section, a water flow vortex flowing from the U-shaped elbow is divided into small vortexes, the impact to the water tank is reduced, and the water flow tends to be straight. The long tapered tube effectively prevents an inner bounding layer of the long tapered tube from disengaging. The cambered tapered tube is in a streamline shape and effectively prevents a boundary layer from disengaging, the two ends of the cambered tapered tube are connected through the flange, and the cambered tapered tube is convenient to install and easy to replace. The novel circulation experiment water tank is good in adjusting performance, stable in operation, convenient to manufacture, even in internal fluid flowing speed and simple in structure, brings great convenience to the actual application, and can be widely applied to indoor hydraulics experiments.

Owner:TIANJIN CAIYI TECH

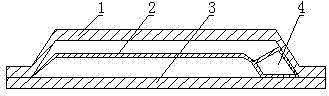

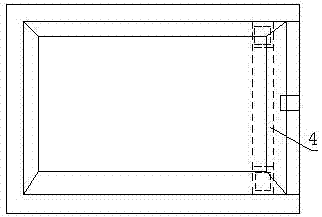

Air duct device of superplastic forming hollow structure and air flow pressure differentiating method

ActiveCN107983818AStabilize and control the forming processStabilize and control qualityEngineeringHigh pressure

The invention relates to an air duct device of a superplastic forming hollow structure. The technical key point of the device is as follows: the device comprises an outer layer plate and an inner layer plate, wherein a rib lattice is arranged between the outer layer plate and the inner layer plate, and one end of the rib lattice is connected to a gas storage cavity. An air flow pressure differentiating method of the air duct of the superplastic forming hollow structure comprises the following steps: S1, forming the rib lattice; S2, Pre-forming the gas storage cavity in the front end of the riblattice; S3, pre-forming an air flow passageway connected to the rib lattice in the side wall of the gas storage cavity; and S4, dividing the air flow in the gas storage cavity by means of impact action of blocking a high pressure air flow to blow up the air flow, and reducing the pressure first and then blowing up second. According to the technical scheme, through the gas storage cavity, the region is expanded quickly in volume to reduce the pressure of the air flow and the air flow is stably divided into vertical rib cavities, so that the vertical rib forming process and quality are stabilized and controlled; by pre-forming the gas storage cavity to cut off the expanded air flow, quick formation of the rib lattice caused by the high pressure air flow is reduced; the blown-up gas is divided into the rib lattice cavities from the gas storage cavity, so that the air pressure differences among the vertical rib forming cavity lattices are reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

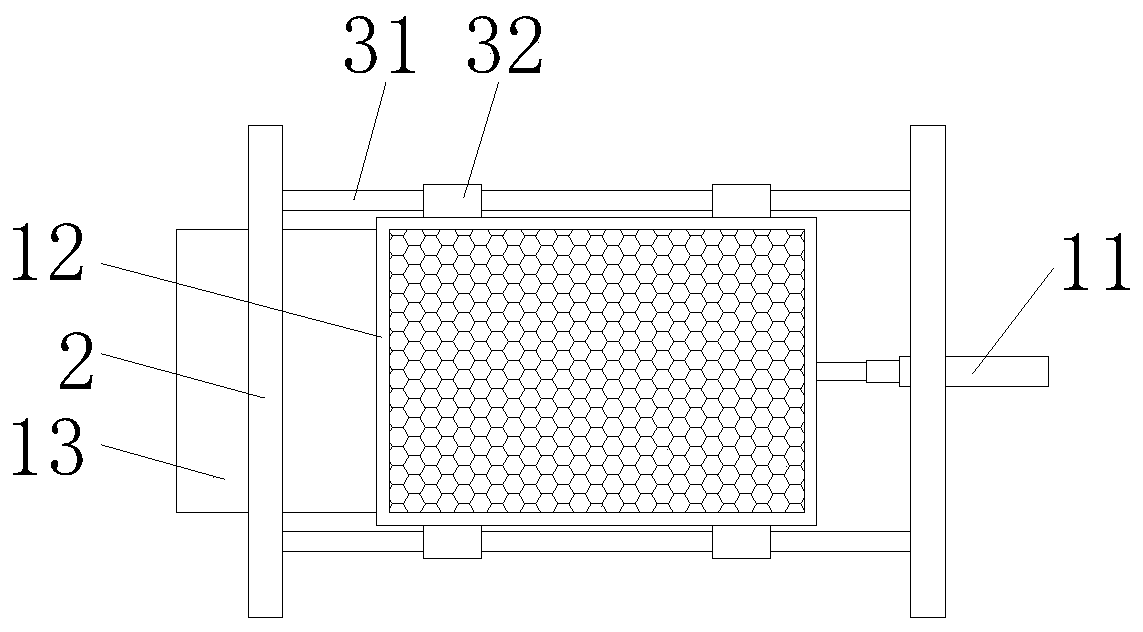

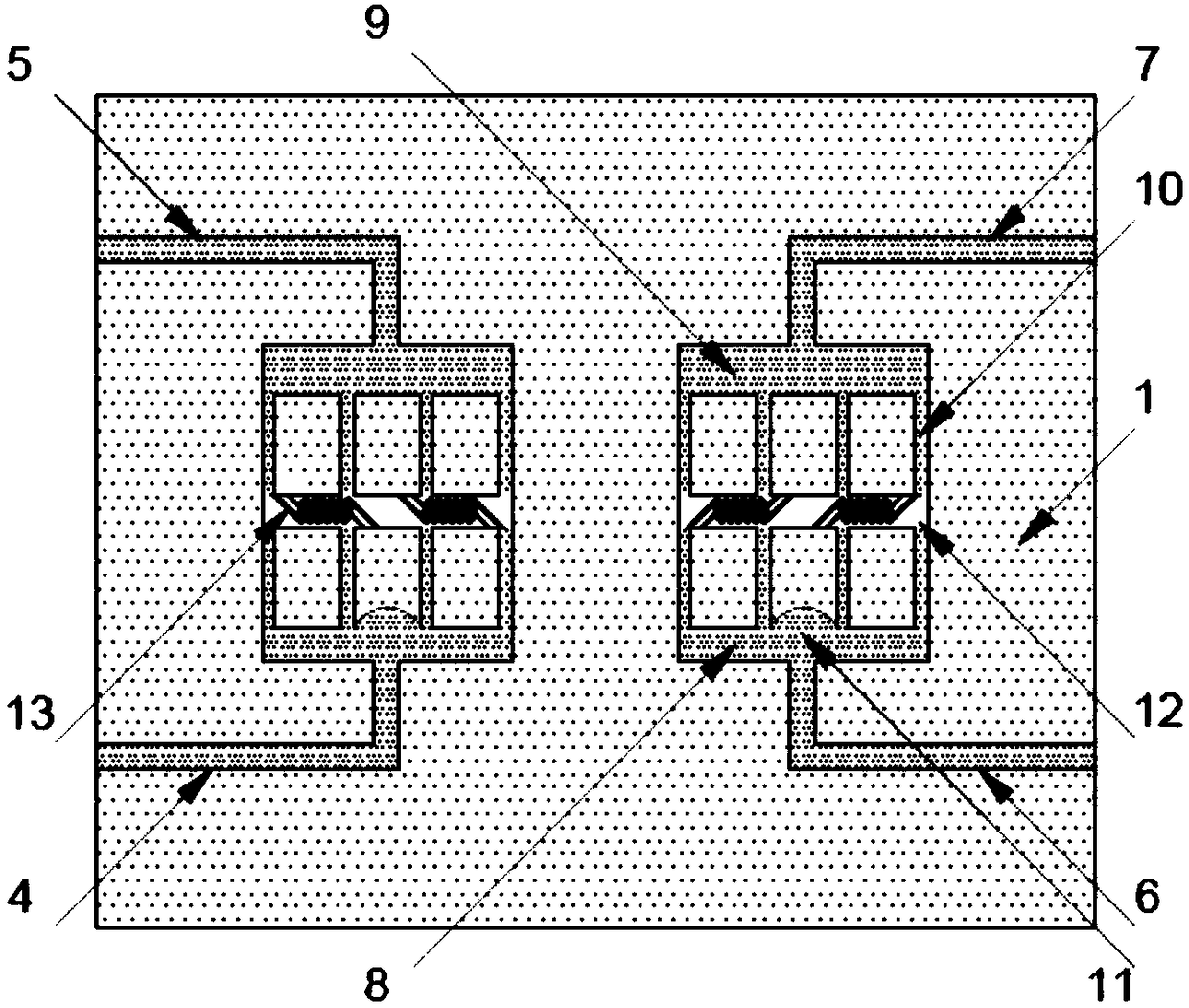

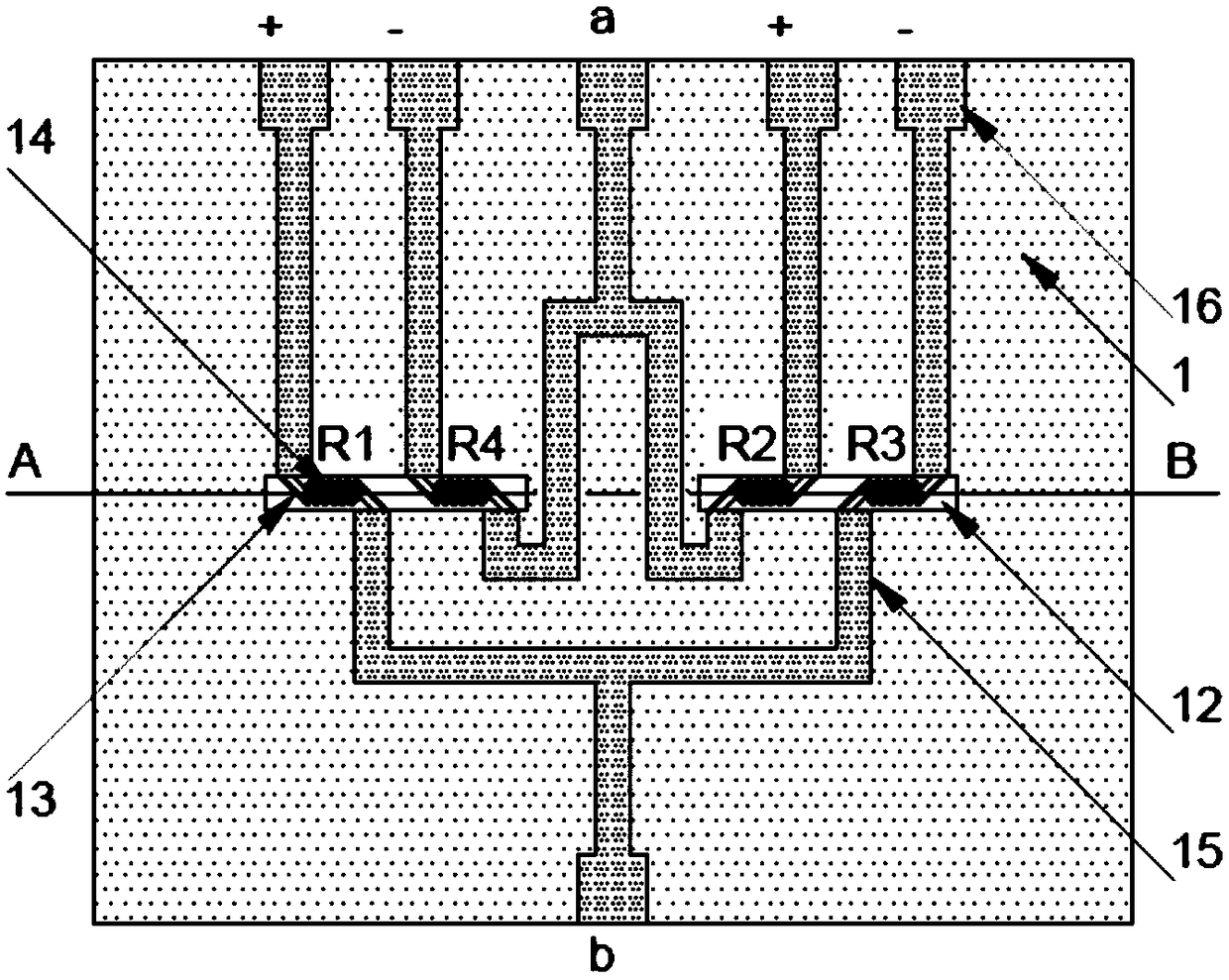

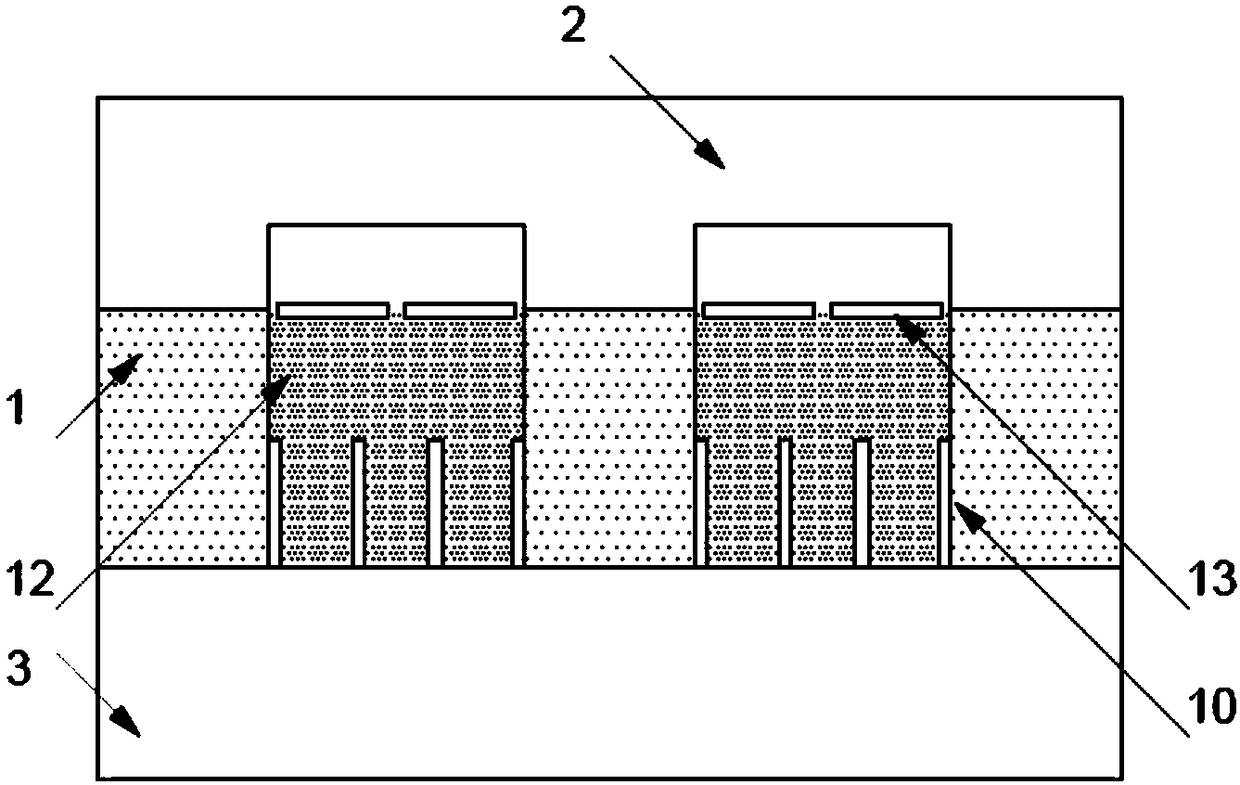

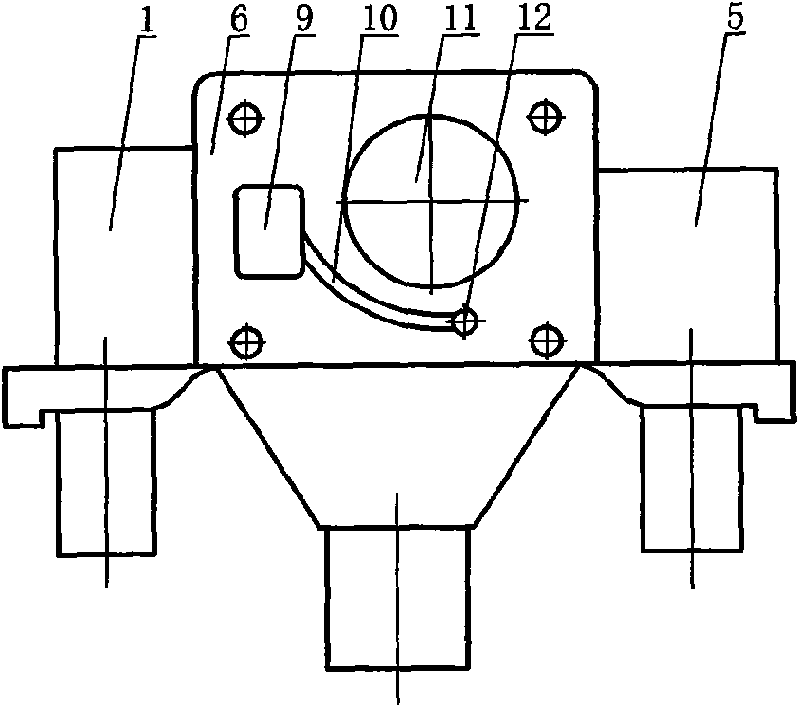

Miniature thermal conductivity detector being insensitive to flow rate

PendingCN108318525AAvoid heat transfer reductionGood insulation effectTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermistorWork performance

Owner:BEIJING UNIV OF TECH

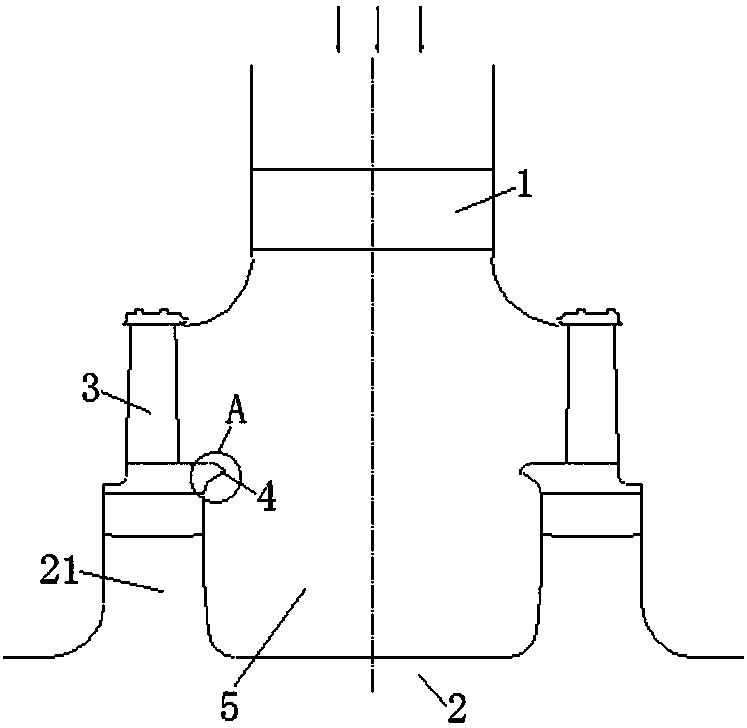

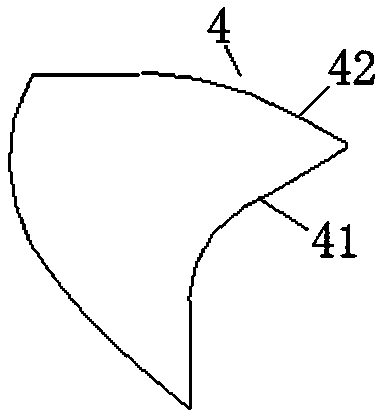

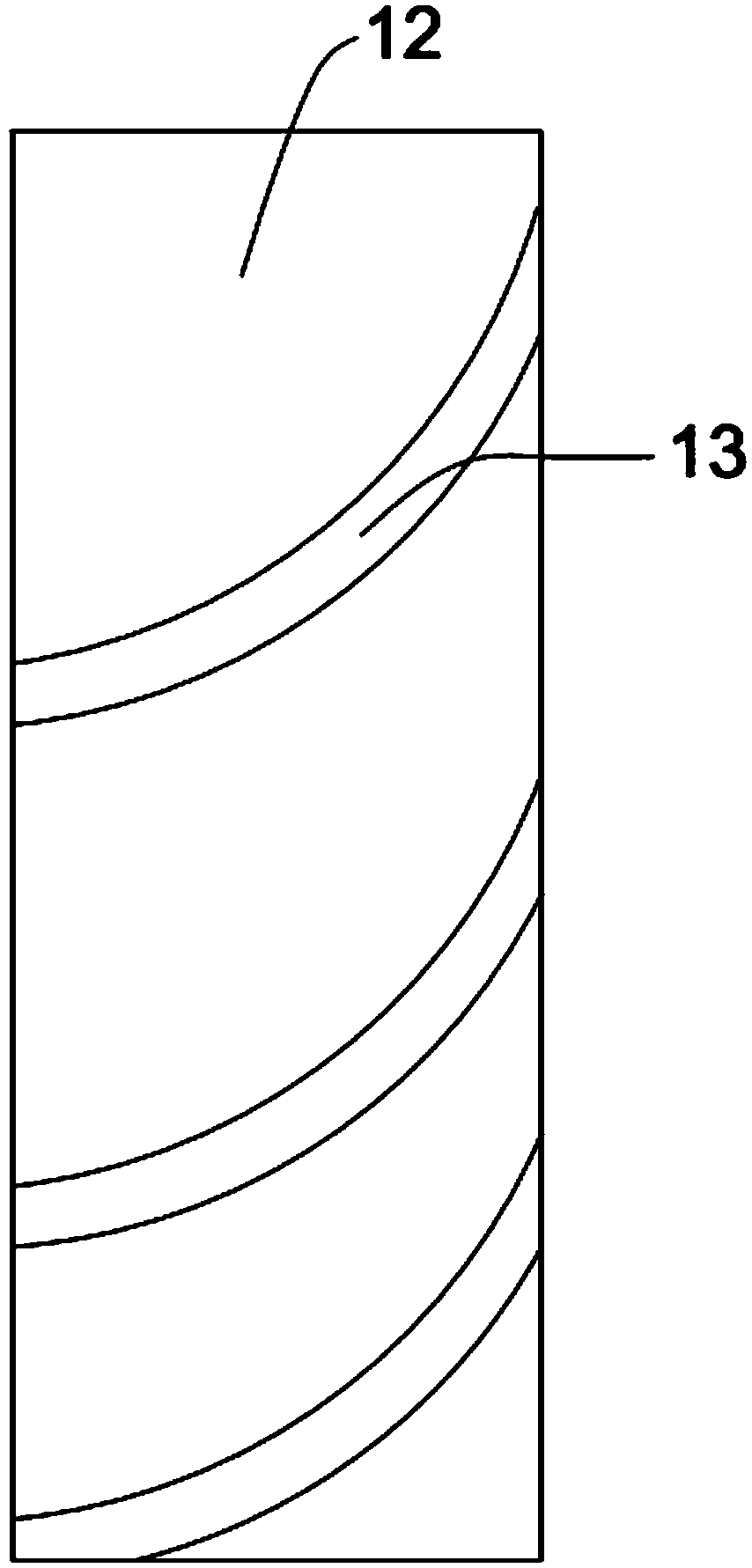

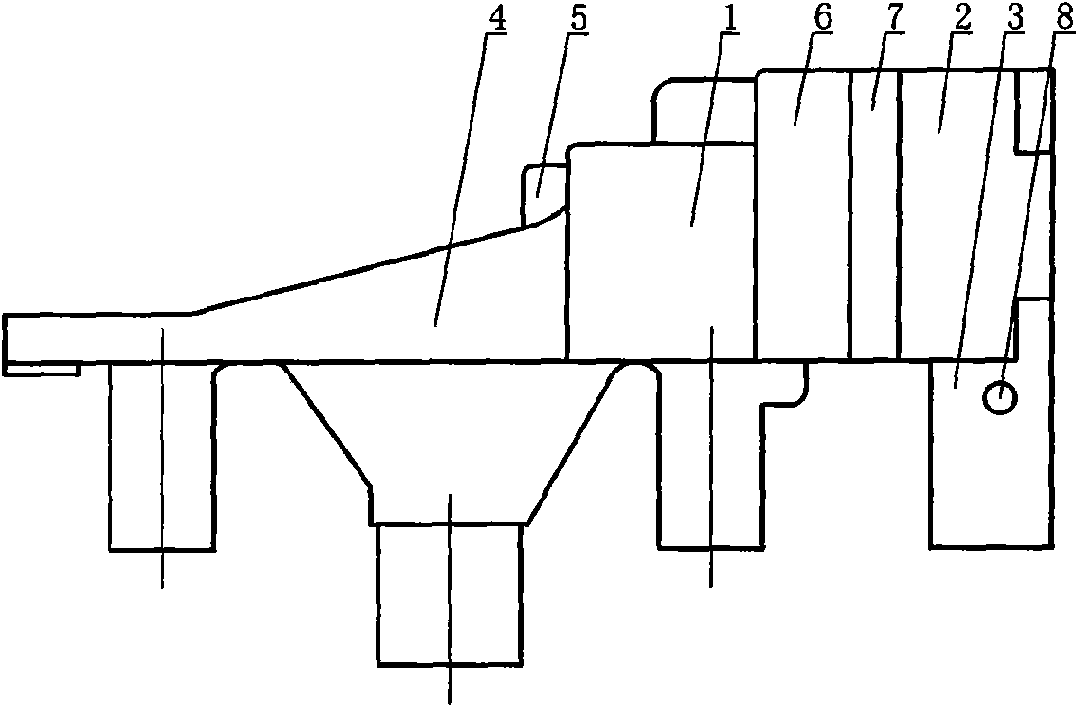

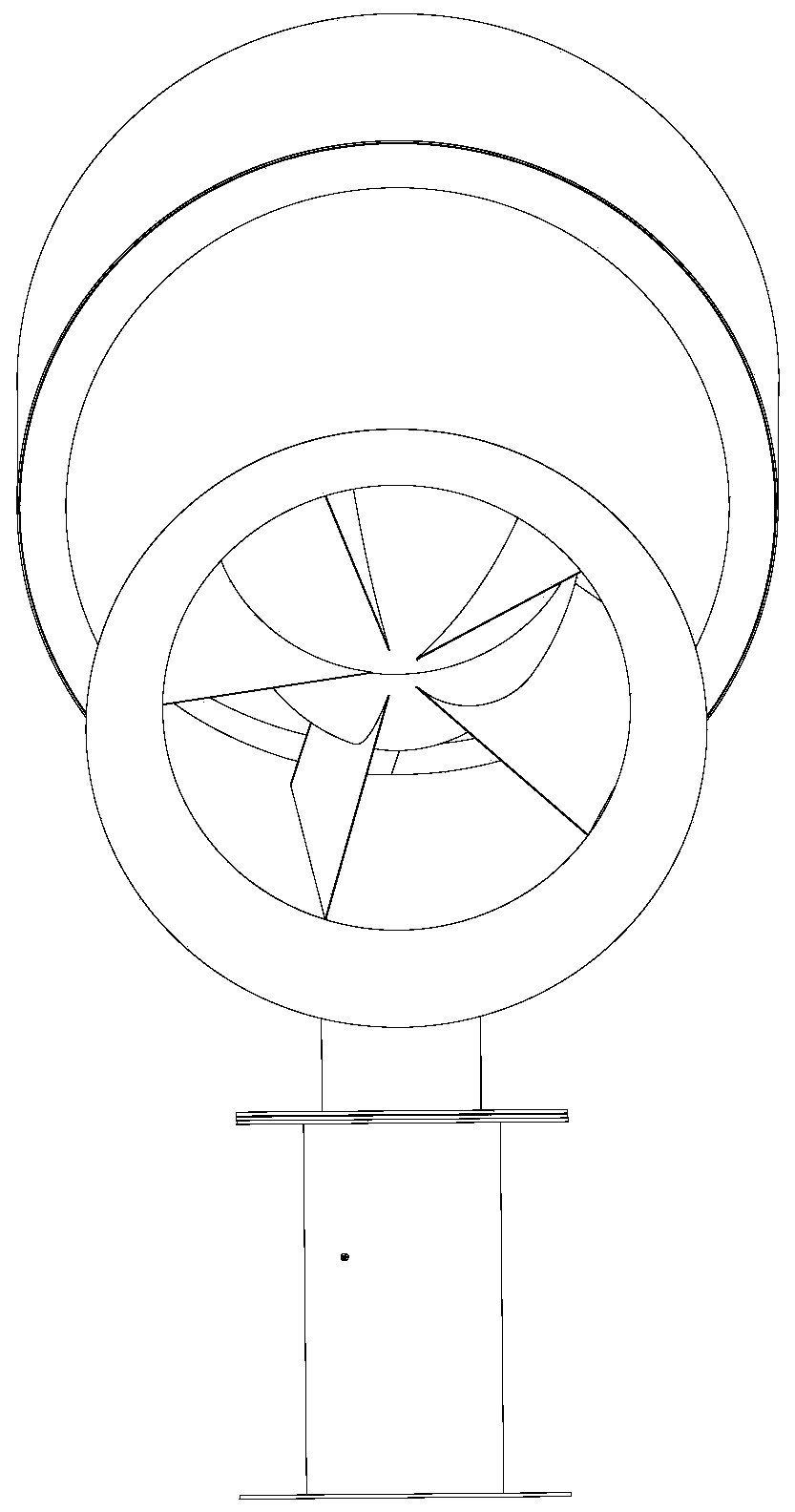

Double-split-flow turbine steam-inlet diversion structure

The invention discloses a double-split-flow turbine steam-inlet diversion structure. The double-split-flow turbine steam-inlet diversion structure comprises a runoff type first-level stator and a wheel type rotor which are correspondingly assembled together. The two sides of the portions, corresponding to the first-level stator, of the wheel type rotor are correspondingly provided with impellers protruding in the radial direction and being used for assembling movable blades. Diversion mold cavities are defined by the first-level static blade, the wheel type rotor and the corresponding movableblades. The movable blade root positions of the two sides of each diversion mold cavity are correspondingly provided with streamline sharply protruding steam inlet diversion portions extending to thediversion mold cavity. The steam inlet diversion portions of the two sides of each diversion mold cavity are oppositely formed. The steam inlet diversion portion on each side and the blade root steaminlet side face and the blade root plane of the corresponding movable blade are in smooth transition in the form of the streamline profile structure. By the adoption of the double-split-flow turbine steam-inlet diversion structure, the stability and reliability of bidirectional conversion from runoff steam to axial flow can be guaranteed effectively; and meanwhile flow separation generated beforethe diverted steam enters the movable blades can be effectively prevented, the uniformization of the steam flow entering the corresponding movable blades is guaranteed, and the acting loss of the movable blades is lowered.

Owner:DONGFANG TURBINE CO LTD

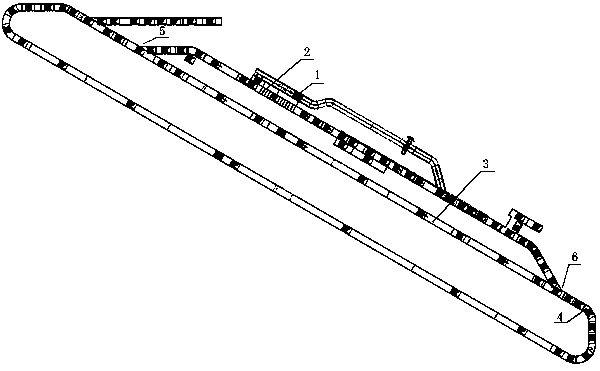

Airport luggage high-speed conveying and sorting system

ActiveCN109160251AImprove stabilityEnsure safetyConveyor partsMechanical conveyorsLogistics managementEngineering

The invention belongs to the civil aviation logistics application field, and particularly relates to an airport luggage high-speed conveying and sorting system. The system comprises a track part, a dynamic sorting device and a luggage high-speed conveying tray; the luggage high-speed conveying tray is used for conveying the luggage on the track part, and the dynamic sorting device is used for carrying out high-speed sorting on the luggage; the track part comprises a straight track, a turning conveyor, at least one section of rapid shunting conveying device and at least one section of rapid confluence conveying device; and a supporting wheel device capable of realizing rapid dismounting and mounting is arranged on the track part. According to the system, high-speed conveying and sorting ofthe airport luggage can be realized; and the whole system is rearranged, a conveying part and a luggage sorting part in the system are mainly improved, so that the speed of conveying the luggage of the whole system can be up to 10 m / s, the stability of the luggage sorting part in the system during tipping is improved, so that the safety and stability when the luggage is conveyed and tipped can beguaranteed on the premise that the system guarantees that the luggage can be conveyed at a high speed.

Owner:CIVIL AVIATION LOGISTICS TECH

Electric hot melt salt valve

InactiveCN106151673ADiversion preventionSteady diversionValve members for heating/coolingMolten saltHot melt

The invention provides an electric hot melt salt valve. The valve comprises a cylindrical valve seat and a valve rod arranged in the cylindrical valve seat, wherein a liquid passing port is formed in the valve seat; the inner side of the valve rod is inserted into the valve seat; a movable valve clack is arranged at the inner side of the valve rod; an upper gap is formed in the lower surface of the movable valve clack; fixed valve clacks corresponding to the circumferential direction of the valve seat are arranged at the inner side of the valve seat and the lower side of the movable valve clack; a lower gap is formed in the upper surface of each fixed valve clack; the positions of the upper gap and the lower gaps correspond to the position of the liquid passing port; a silencer is arranged at the upper gap of the movable valve clack and adopts an elastic structure; an electric tracing band adopts a flexible wrapping substance which can be wound on the valve; electric heating wires are arranged on an insulating layer; nylon adherent buckles which are used for being mutually buckled are correspondingly arranged on an inner waterproof layer and an outer rainproof layer; and a power junction box is connected with the electric heating wires through leads. The valve is arranged at one time, and mounting and construction of an electric heating device are avoided, so that great labor force and time cost are reduced.

Owner:天津滨海光热发电投资有限公司

Gas shield device for argon arc welding of titanium material

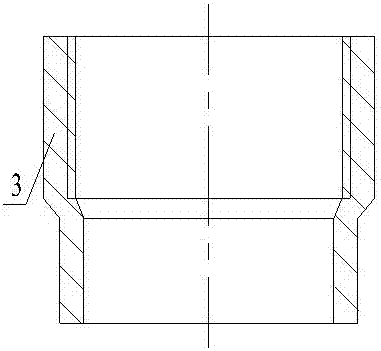

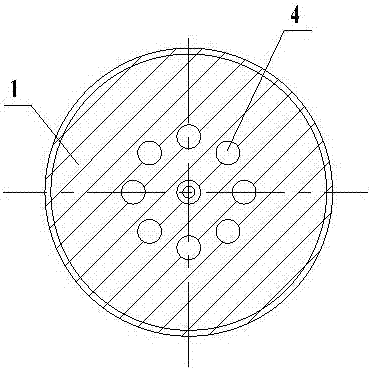

PendingCN107225313AExpand effective coverageIncrease the number ofShielding gas supply/evacuation devicesTitaniumStainless steel wire

The invention discloses a gas shield device for argon arc welding of a titanium material. The gas shield device comprises a nozzle, a ceramic nozzle and a contact tube, wherein the nozzle is sleeved with the ceramic nozzle through a thread, one end of the contact tube is fixed in the nozzle, the nozzle is internally provided with eight distribution holes with the contact tube as a center, the distribution holes are arranged into a ring, the end of the nozzle is provided with a protection cover structure internally provided with a cavity, the end of the nozzle is further provided with two 200-mesh stainless steel screens, and the other end of the contact tube extends out of the nozzle. The gas shield device effectively achieves air isolation, gas dispersion is more uniform, airflow is more stable, a better protection effect is achieved, and the welding effect is good.

Owner:NANTONG EXCEL MACHINERY

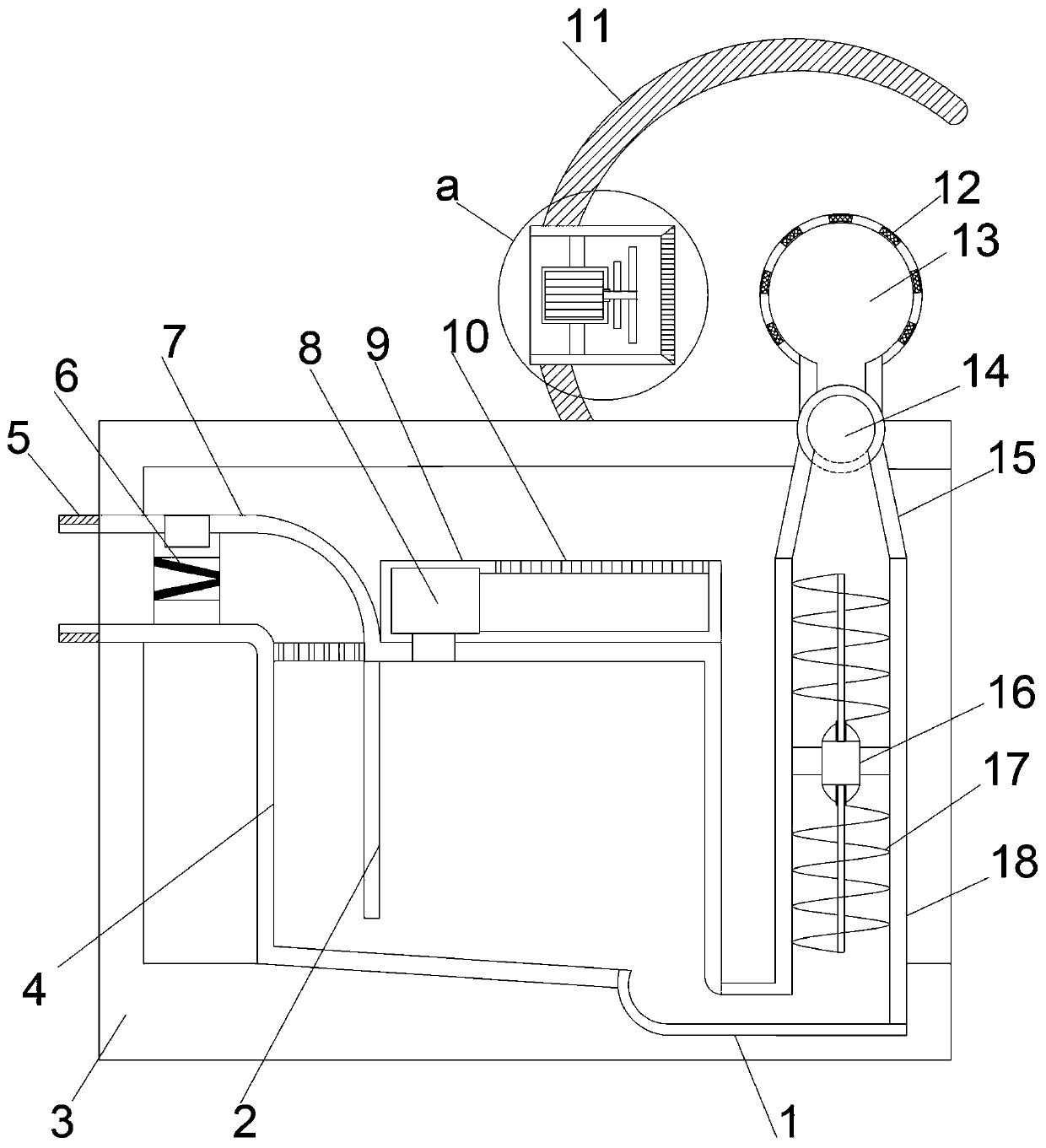

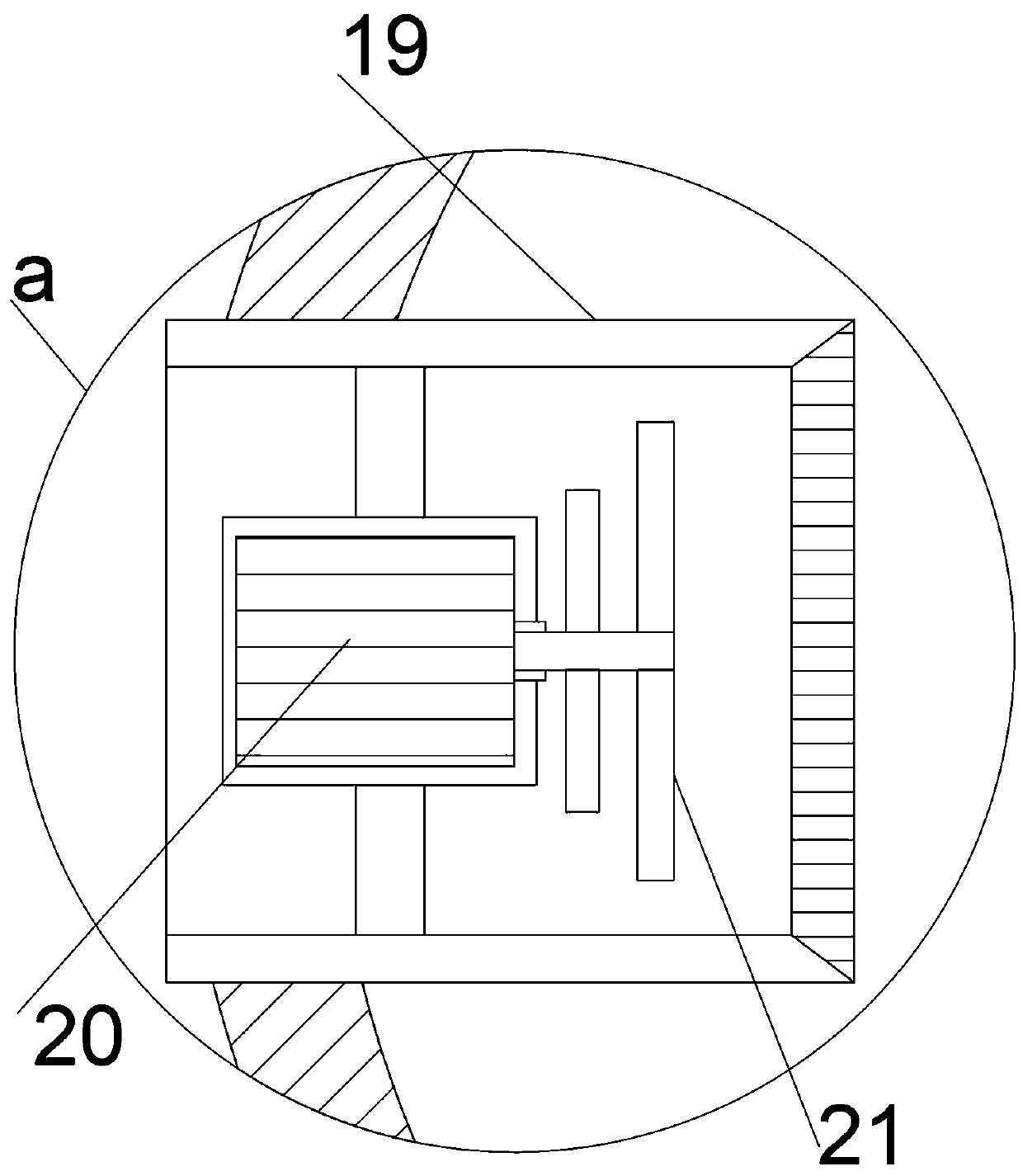

Non-heating environment-friendly humidification device

ActiveCN109520057ASteady diversionSteady ejectionLighting and heating apparatusAir humidification systemsEngineeringInlet flow

The invention relates to the field of environment-friendly humidification equipment, in particular to a non-heating environment-friendly humidification device. A vertically-arranged support installingbarrel is included. An inclined bottom flow guiding installing barrel is arranged at the middle position in the support installing barrel. The upper left end of the inclined bottom flow guiding installing barrel leftwards stretches out of the support installing barrel through an arc connecting pipe to be provided with a water inlet flow guiding pipe, and the part, on the right side of the inclined bottom flow guiding installing barrel, of the support installing barrel is internally and vertically upwards provided with a pressurizing flow guiding pipe through a U-shaped flow guiding pipe, andstable flow guiding of water energy is achieved through one-way flow guiding. Through two-level pressurizing, water is stably atomized and sprayed out, and the non-heating environment-friendly humidification device is suitable for high-fineness atomization sprayer work. Multi-set atomization is synchronously conducted, the atomization area is wide, and the atomization efficiency is high. Through active air blowing and flow guiding, atomized small liquid drops are rapidly guided out, and the atomization and humidification area is wider. Since the diameter of the atomized small liquid drops is obviously smaller than that of atomization equipment used at present, the atomized small liquid drops are rapidly evaporated for air humidification after being blown out, heating for humidification isnot needed, and energy saving and high efficiency are achieved.

Owner:YANCHENG DONGFANG TIANCHENG MACHINERY

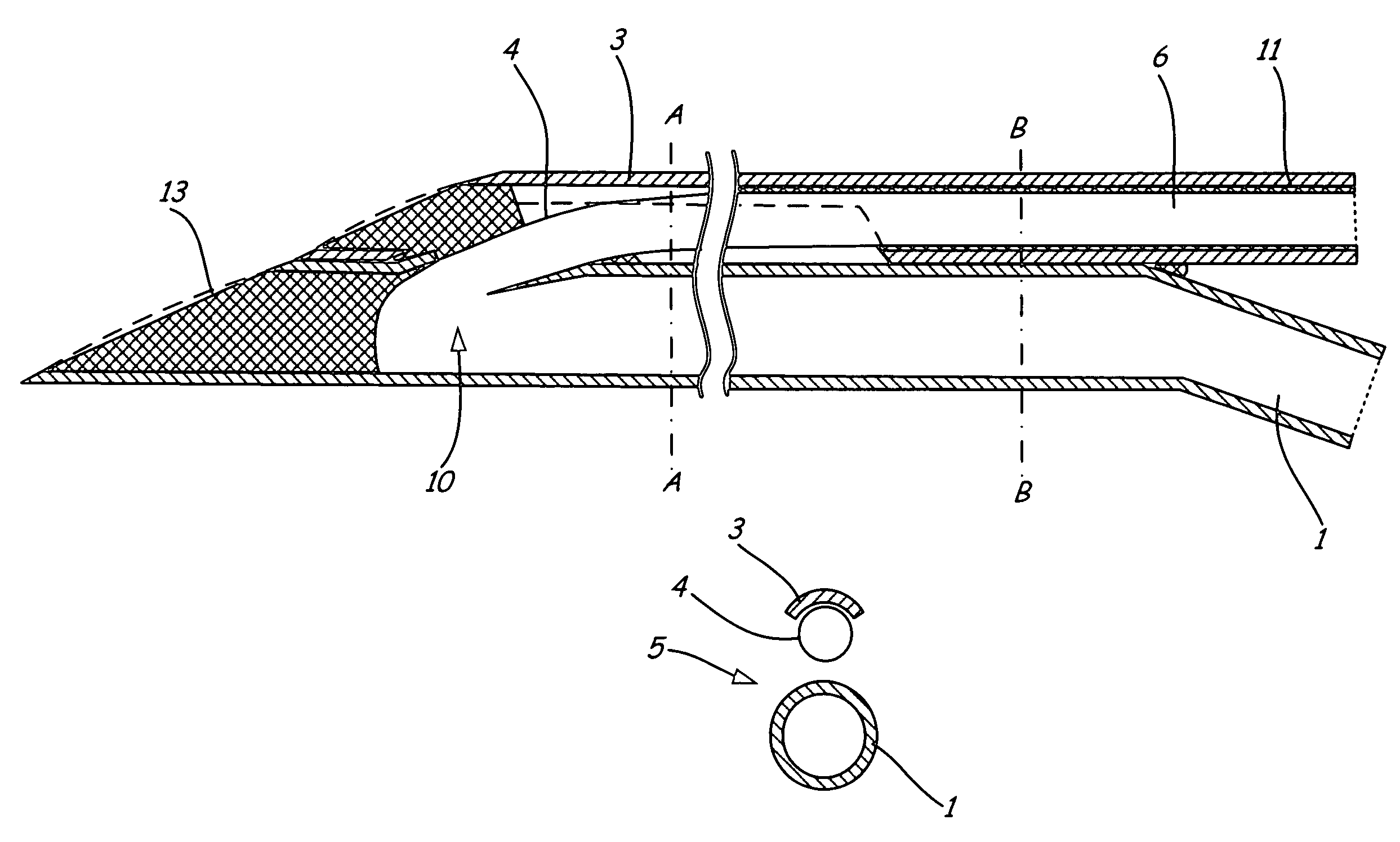

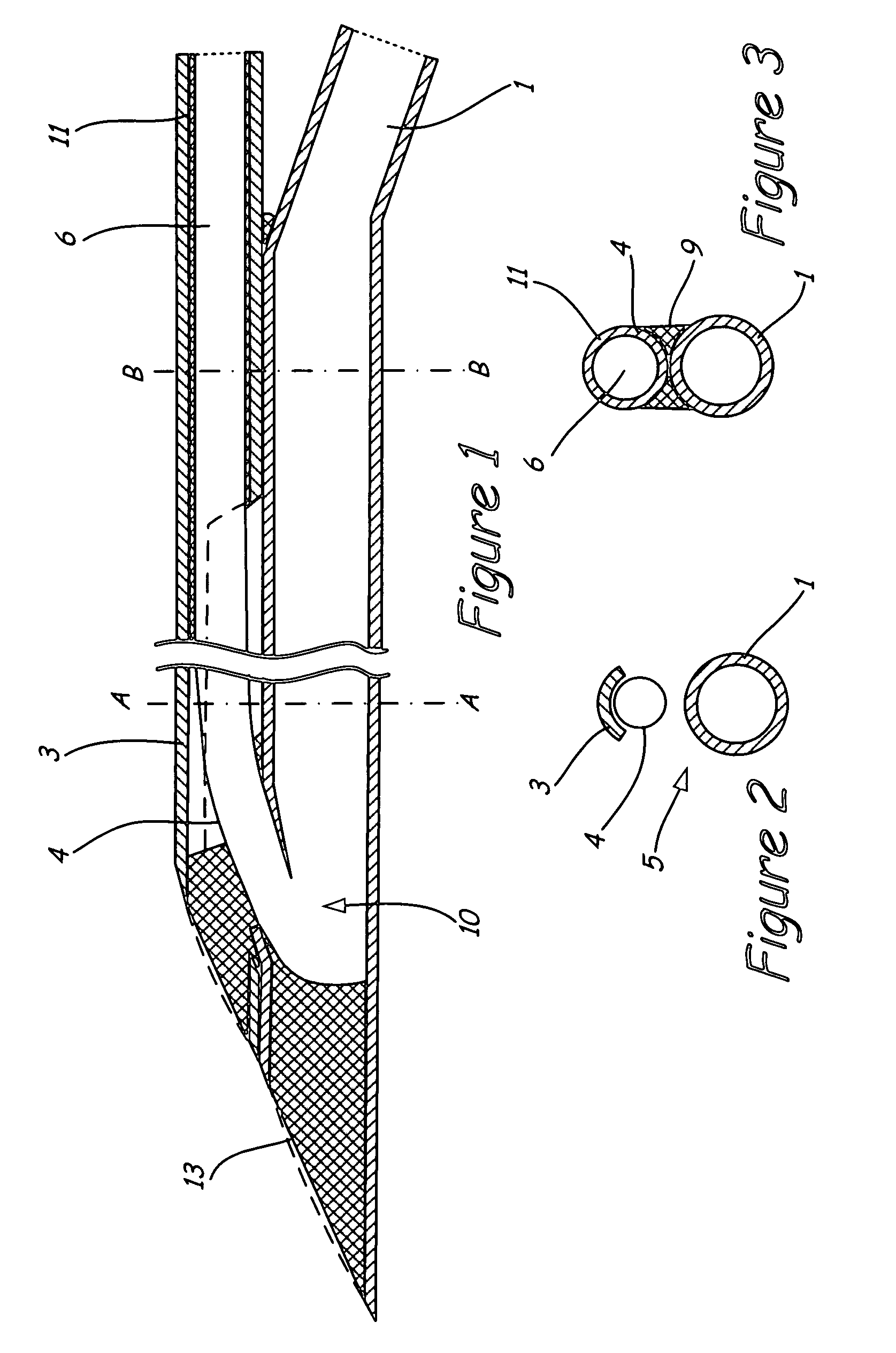

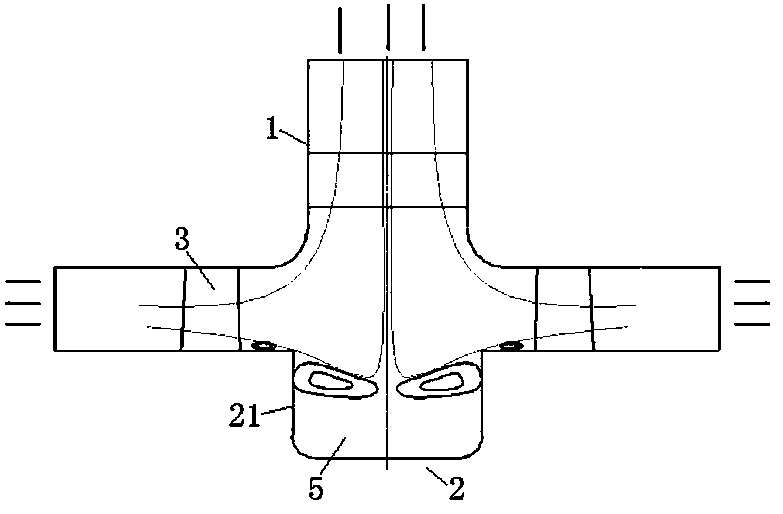

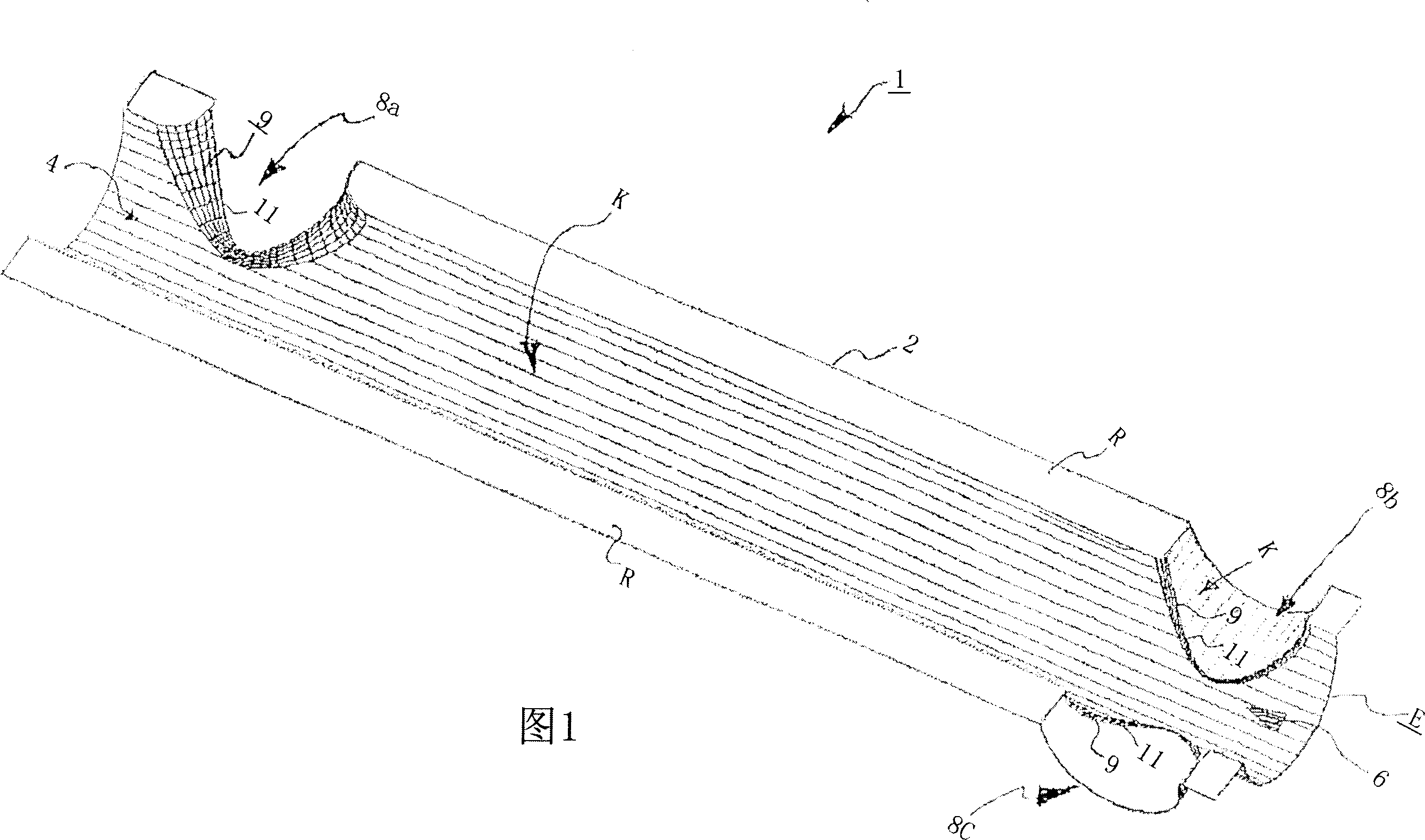

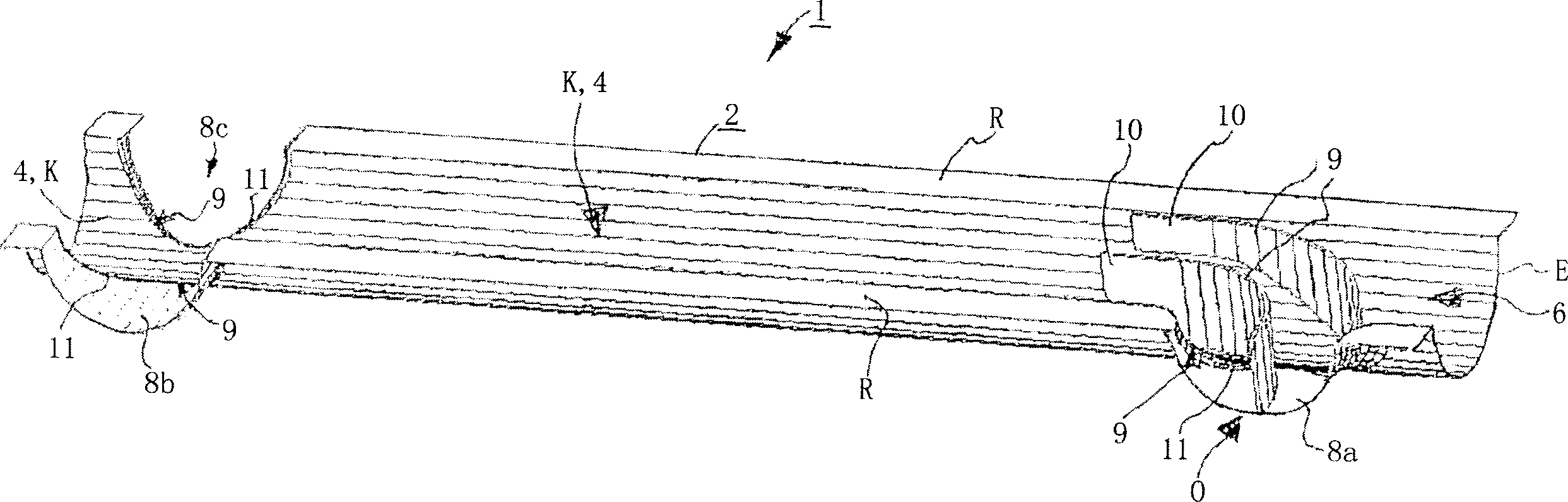

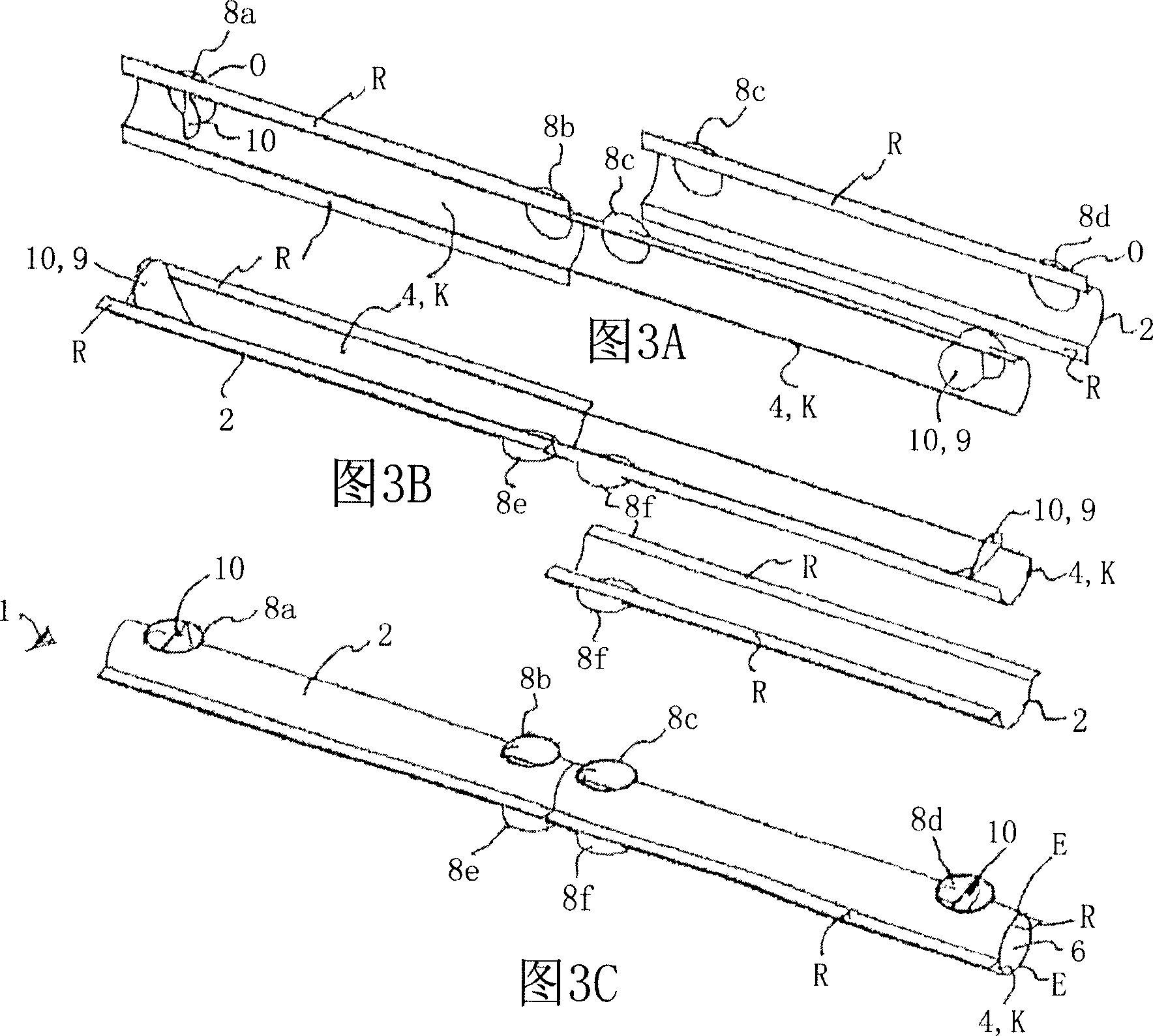

Method and device for the production of a component, especially a hybrid component for a crossrail of a vehicle, component and use of said component

InactiveCN1863687ASteady diversionGentle deflectionAir-treating devicesUnderstructuresEngineeringMechanical engineering

The invention relates to a structural element (1), particularly a hybrid structural element for a cross member of a vehicle, in which a base body (2) is provided, which is at least partially lined with plastic (4) and which is provided with at least one flow tap (8a to 8e). Said base body (2) is, in the area of flow tap (8a to 8e), provided with a flow-guiding means (9).

Owner:BEHR GMBH & CO KG

Hydraulic control and inside and outside biaxial compression packer

ActiveCN106703740ASolve the problem of unreliable shuntingSteady diversionSealing/packingPressure transmissionControl system

The invention discloses a hydraulic control and inside and outside biaxial compression packer. The packer comprises an external setting mechanism and an internal setting mechanism. The upper end of the external setting mechanism is connected to an upper contact, and the lower end of the external setting mechanism is connected to the internal setting mechanism through a bridging contact. The lower end of the internal setting mechanism is connected to a lower contact. Ground pressure can be transmitted to the external setting mechanism and the internal setting mechanism through a pressure transmission hole and a hydraulic channel of a hydraulic controlled system during the pressurizing process of a ground control system. When a certain pressure is reached and after piston movement, a shear pin is cut, and a rubber sleeve is compressed till the internal and external rubber sleeves block the internal and external annular spaces to achieve the purpose of layering. A large-discharge-capacity inverse well-flushing requirement can be met when pressure relief of the ground control system is conducted and the rubber sleeve is rebounded. The hydraulic control and inside and outside biaxial compression packer solves the problems in the prior art that diversion of inner and outer pipes is not reliable, inverse well-flushing is not smooth, construction procedures are complex, and the service life of tubular columns is short.

Owner:CHINA PETROLEUM & CHEM CORP +1

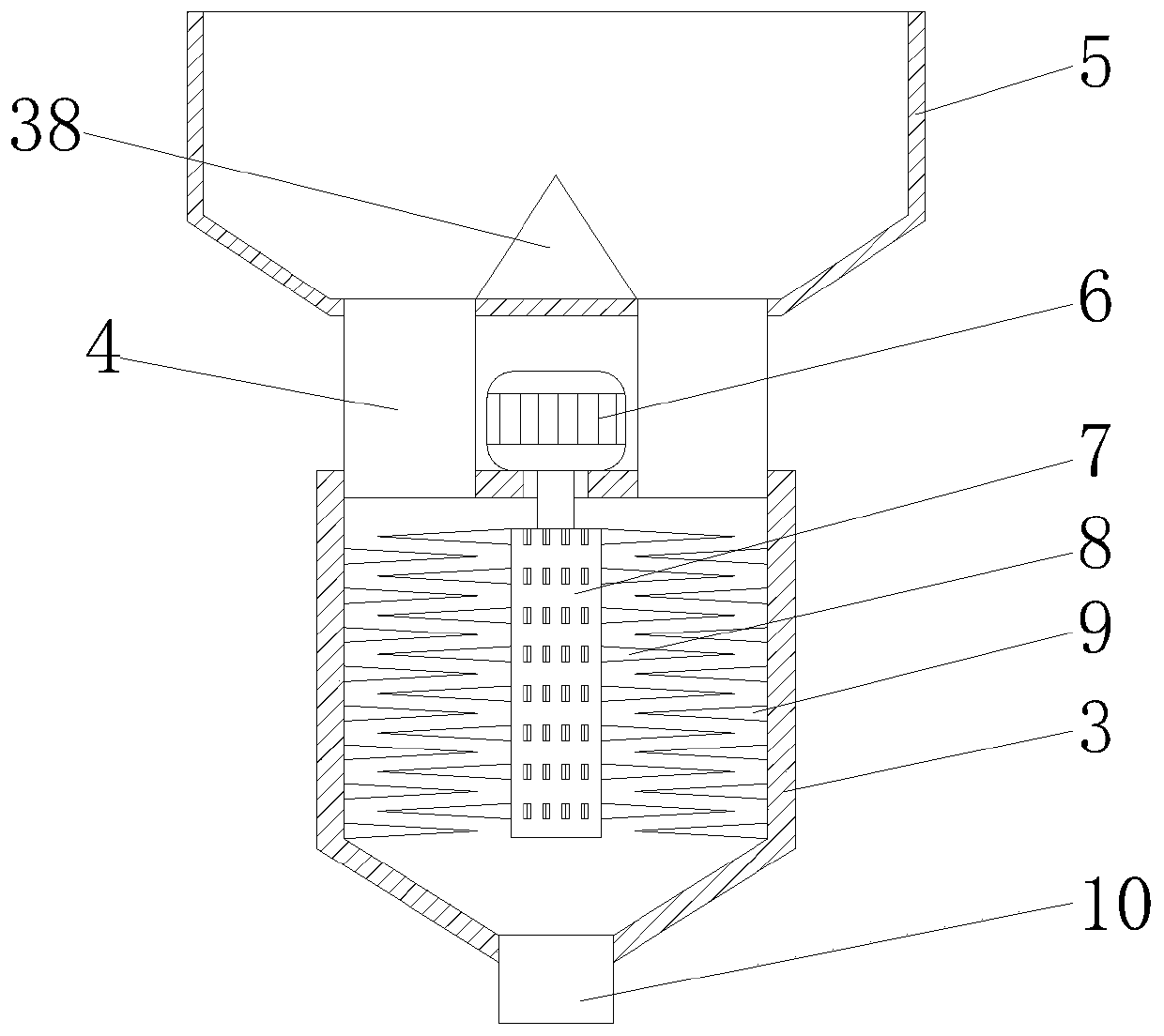

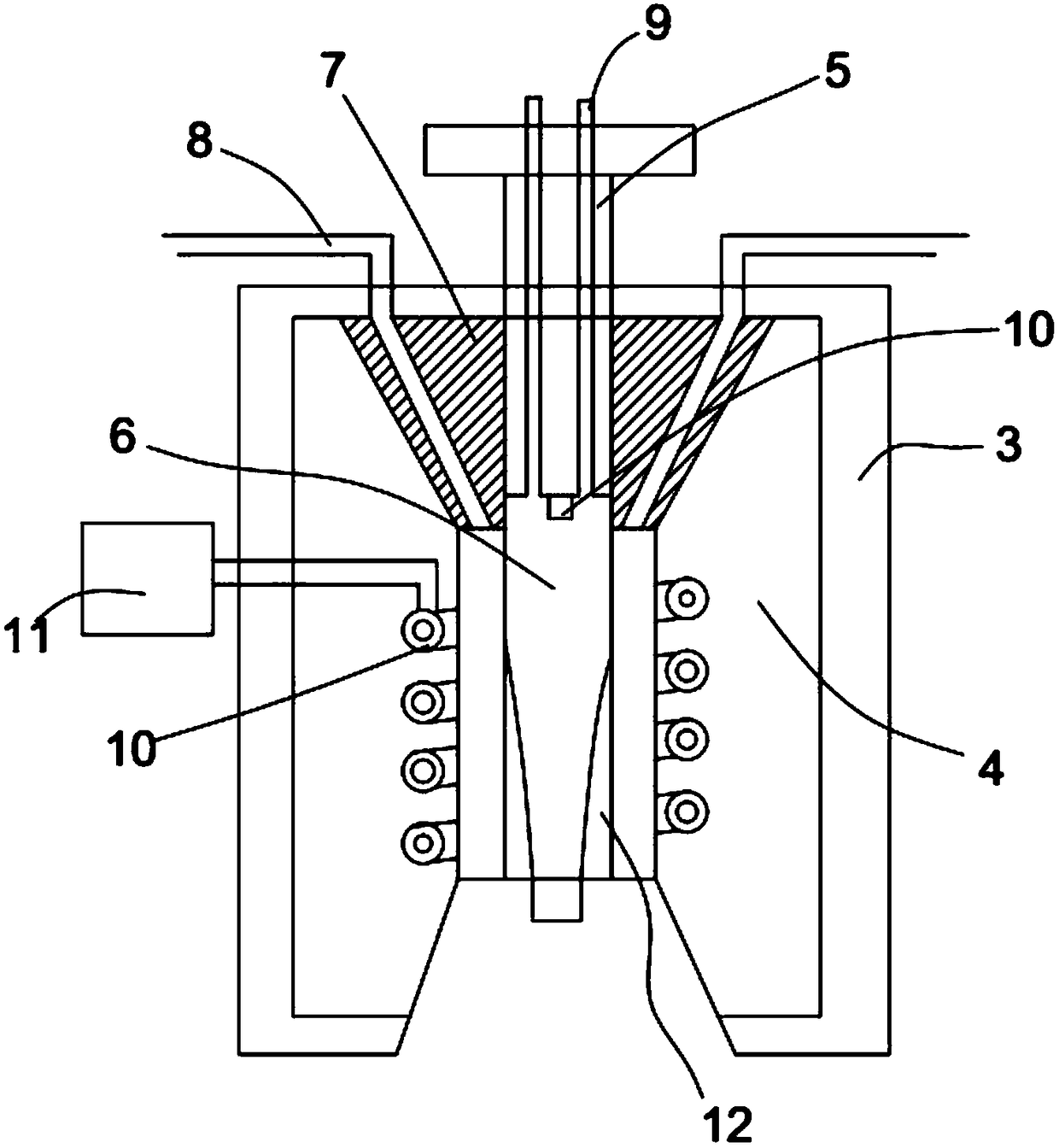

Plasma waste incinerator and incineration system thereof

ActiveCN108253422ASteady diversionConcentrated and efficientIncinerator apparatusCombustion chamberFiltration

The invention provides a plasma waste incinerator and an incineration system thereof. The incinerator comprises an incinerator body, the top of the incinerator body is provided with a plasma torch, the plasma torch comprises a pipe body, and the pipe body is internally provided with a positive electrode and a negative electrode; an ionization cavity is formed in the center of the positive electrode, the upper portion of the ionization cavity is provided with an inverted conical groove, and the conical groove is internally provided with a gas guide block; the negative electrode penetrates through the gas guide block and extends to the upper portion of the ionization cavity; the system comprises a first combustion chamber, the plasma waste incinerator, a heat exchanger, an extremely cold spraying system, a cloth bag dust removal device and a filtration device which are connected sequentially; according to the incinerator, by using the gas guide block, it is ensured that the heat is centralized at a point efficiently during gas ionization, the high efficiency is ensured, and the service life of the plasma torch is greatly prolonged; the incineration system is used for quickly decomposing and destroying treated objects, wherein organic matter is pyrolyzed into flammable small-molecular substances, and inorganic matter is subjected to high-temperature melting to generate glass-similar residues.

Owner:苏州新耀环保科技有限公司

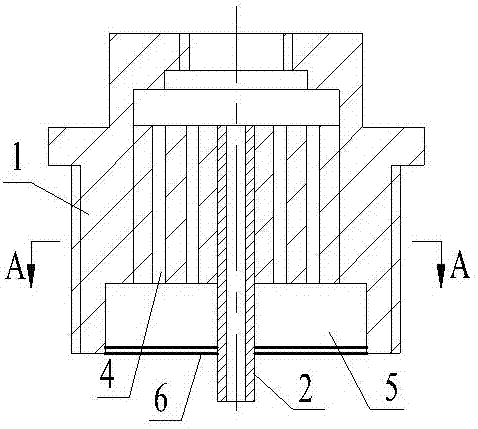

Cylinder body structure of compressor

ActiveCN101624979AReduce flow rateSmall pulsationPositive displacement pump componentsPositive-displacement liquid enginesDynamic balanceCylinder block

The invention relates to a cylinder body structure of a compressor. The upper part of the cylinder body base is provided with a connecting seat, a crankshaft hole, a first-level high-pressure buffering chamber and a second-level high-pressure buffering chamber. The end face of the connecting seat is provided with a piston hole, the connecting seat is coaxially and fixedly arranged with a cylinder cover through a valve plate, and an inspiration muffler is fixedly arranged on the cylinder cover, wherein (1) the end face of the connecting seat is provided with a through hole and a second-level high-pressure chamber air vent respectively, and the through hole is communicated with the second-level high-pressure air vent through a groove formed on the end face of the connecting seat; (2) the valve plate is provided with a first-level high-pressure vent hole, an air suction hole and an exhaust hole; and (3) the air suction hole airtightly covered with an air suction hole valve sheet, and the air exhaust hole is airtightly covered with an air exhaust hole valve sheet. The cylinder body structure has a scientific and reasonable structural design, and high-pressure gas is effectively buffered in the structure to greatly reduce gas pulsation and reduce the overall noises of the compressor, thus the cylinder body structure can keep good dynamic balance.

Owner:扎努西电气机械天津压缩机有限公司

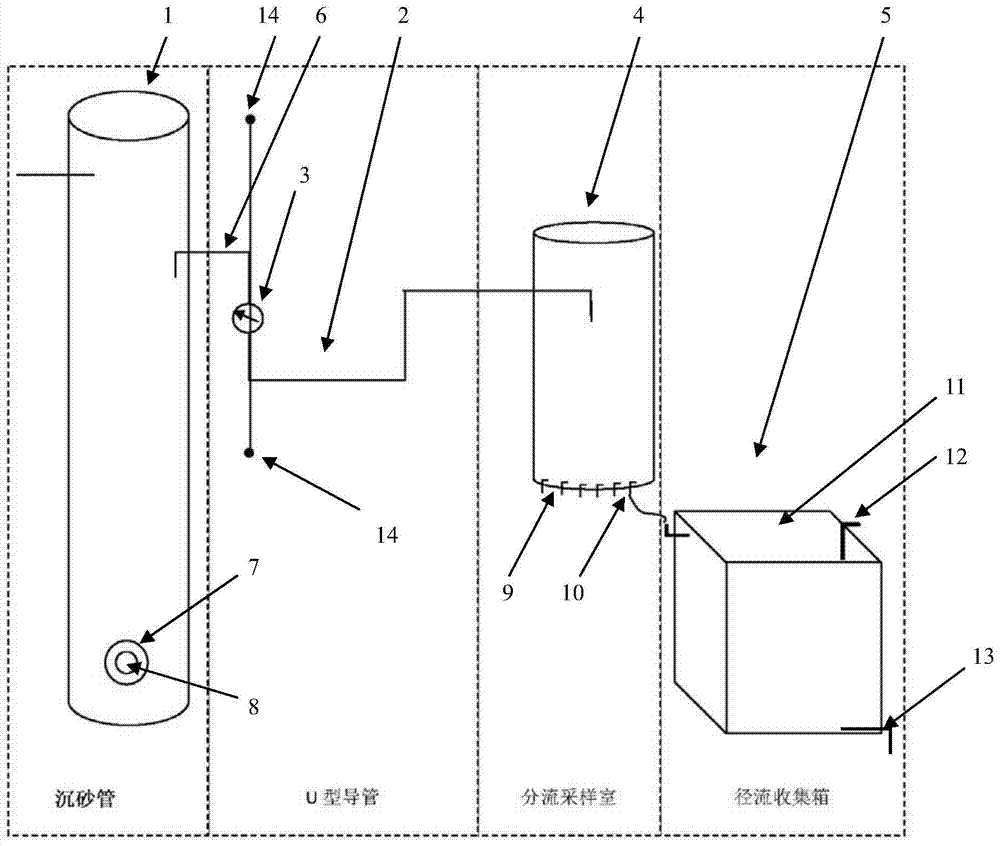

Surface runoff rate measuring and separating flow sampling device

InactiveCN104501881AAccurate recordReduce the amount of sampled waterVolume/mass flow measurementEnvironmental engineeringSmall footprint

The invention discloses a surface runoff rate measuring and separating flow sampling device. The device comprises a sand settling pipe, a U-shaped guide pipe, a water meter, a separating flow sampling chamber and a runoff collection box, wherein the sand settling pipe is provided with a water outlet; a water level positioning pipe is arranged at the water outlet and is communicated with one side of the U-shaped guide pipe; the water meter is arranged on one side of the U-shaped guide pipe; the other side of the U-shaped guide pipe is communicated with the separating flow sampling chamber; the runoff collection box is provided with a water inlet; the water inlet is communicated with the bottom of the separating flow sampling chamber. Runoff in the sand settling pipe is led into the separating flow sampling chamber for flow separation by using the U-shaped guide pipe, so stable flow separation is realized under the condition that the sampling water quantity is greatly reduced, the flow is accurately recorded, the accuracy for sampling is kept, the floor area is small, the building is easy, the engineering is small, the cleaning and maintenance are easy, and the service life is long. The surface runoff rate measuring and separating flow sampling device can be widely applied to the field of agricultural environments.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

Water distribution device and water-consuming system with same

The invention discloses a water distribution device and a water-consuming system with the same. The water distribution device comprises a water distribution device shell, a water inlet chamber formedin the water distribution device shell and at least two water outlet holes which are formed in the water distribution device shell and communicate with the water inlet chamber, and each water outlet hole is provided with an outer side end far away from the water inlet chamber and an inner side end close to the water inlet chamber. The water outlet holes are the same in hole type and hole diameter.The inner side end of at least one water outlet hole is provided with a water blocking piece for blocking part of a water outlet cross section of the water outlet hole. According to the water distribution device, different shunting flows can also be achieved under the situation that no flow control valve is arranged even though all water guide connectors in the same specification are connected with the water distribution water outlet holes, and the using process is very convenient.

Owner:苏州众能医疗科技有限公司

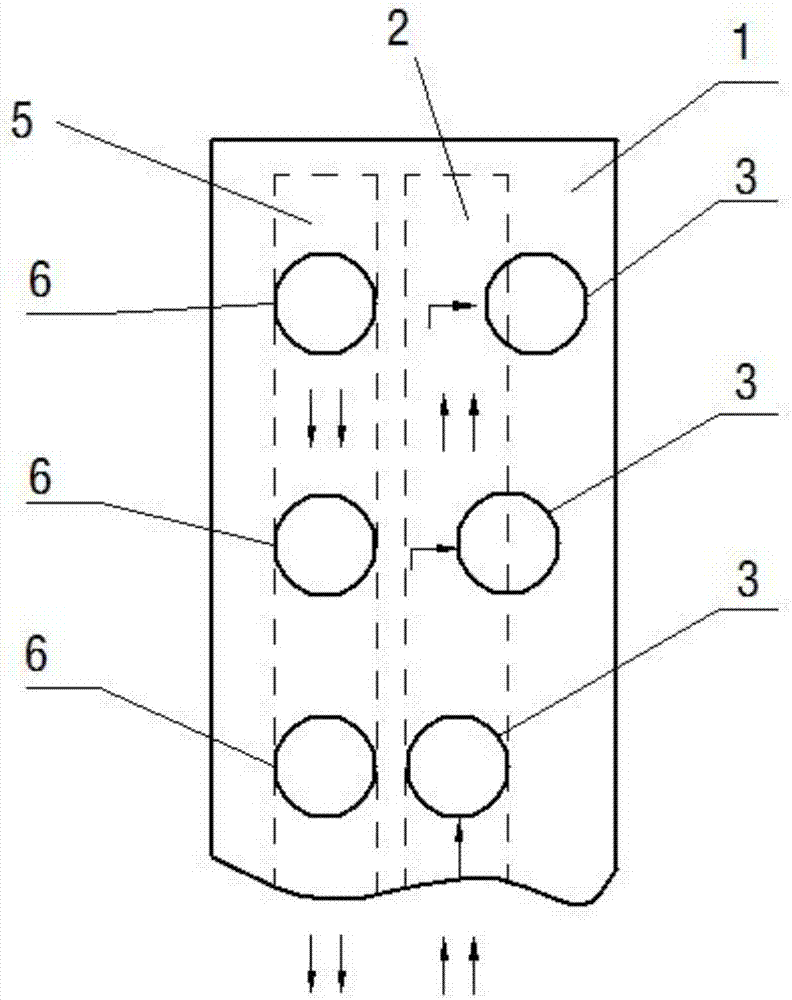

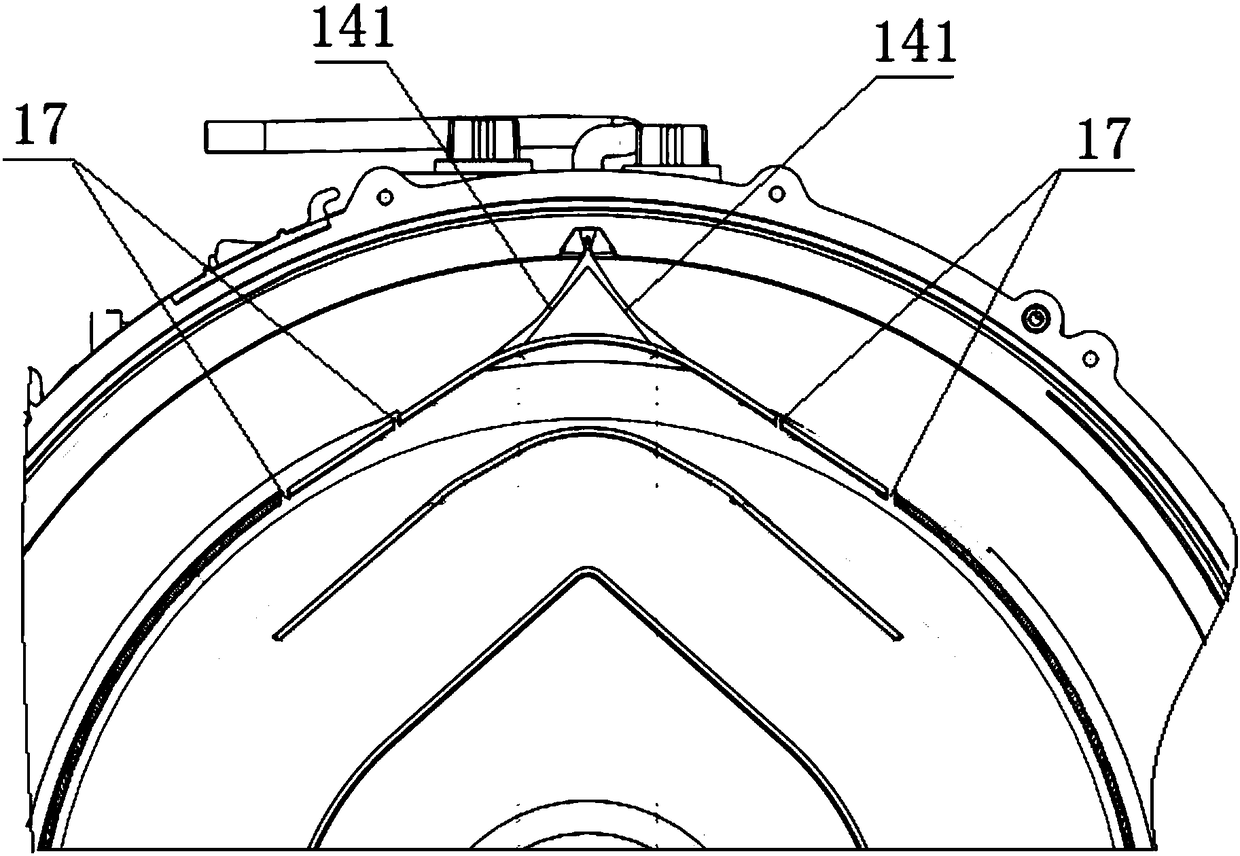

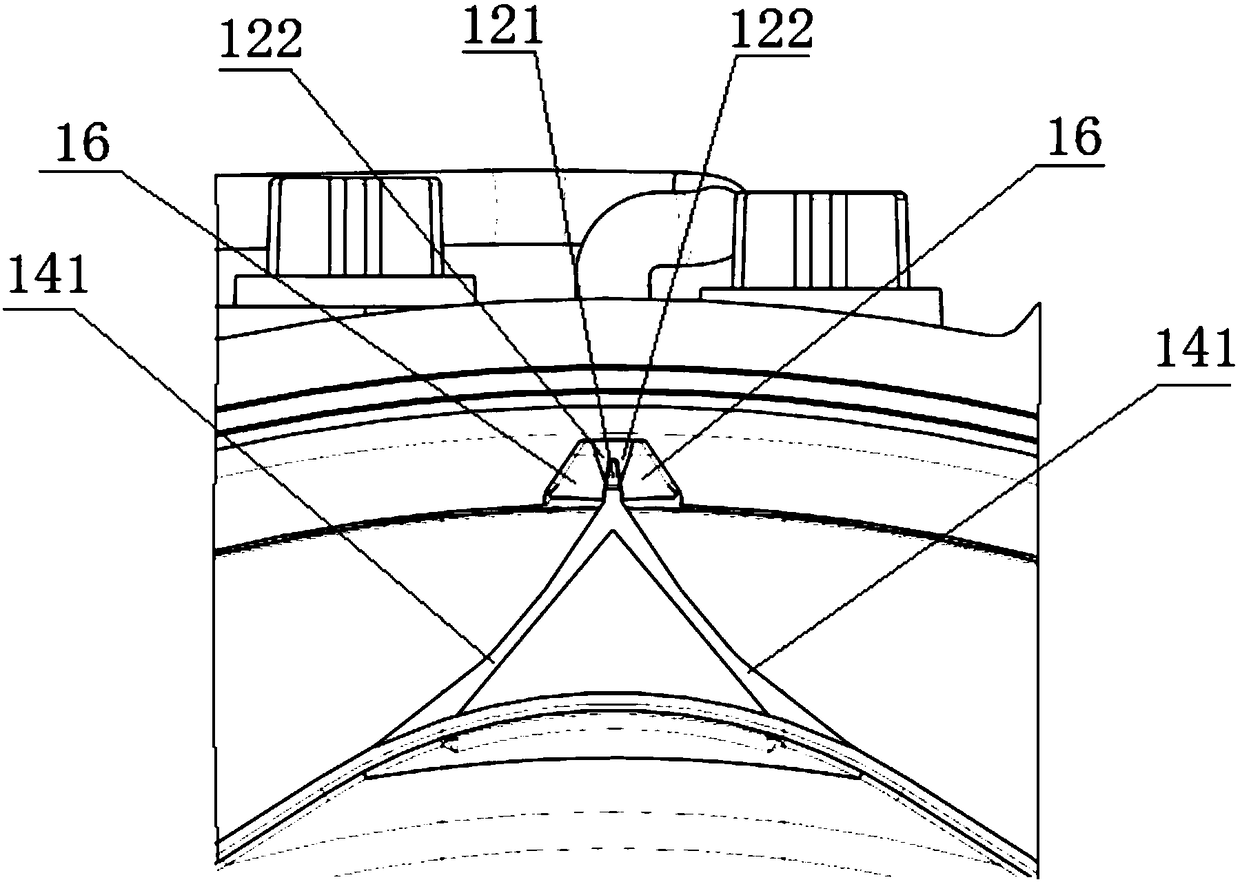

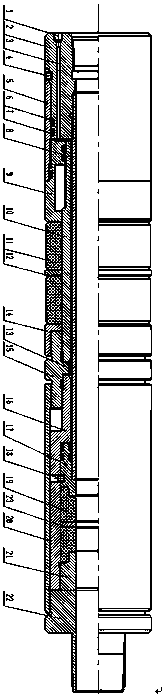

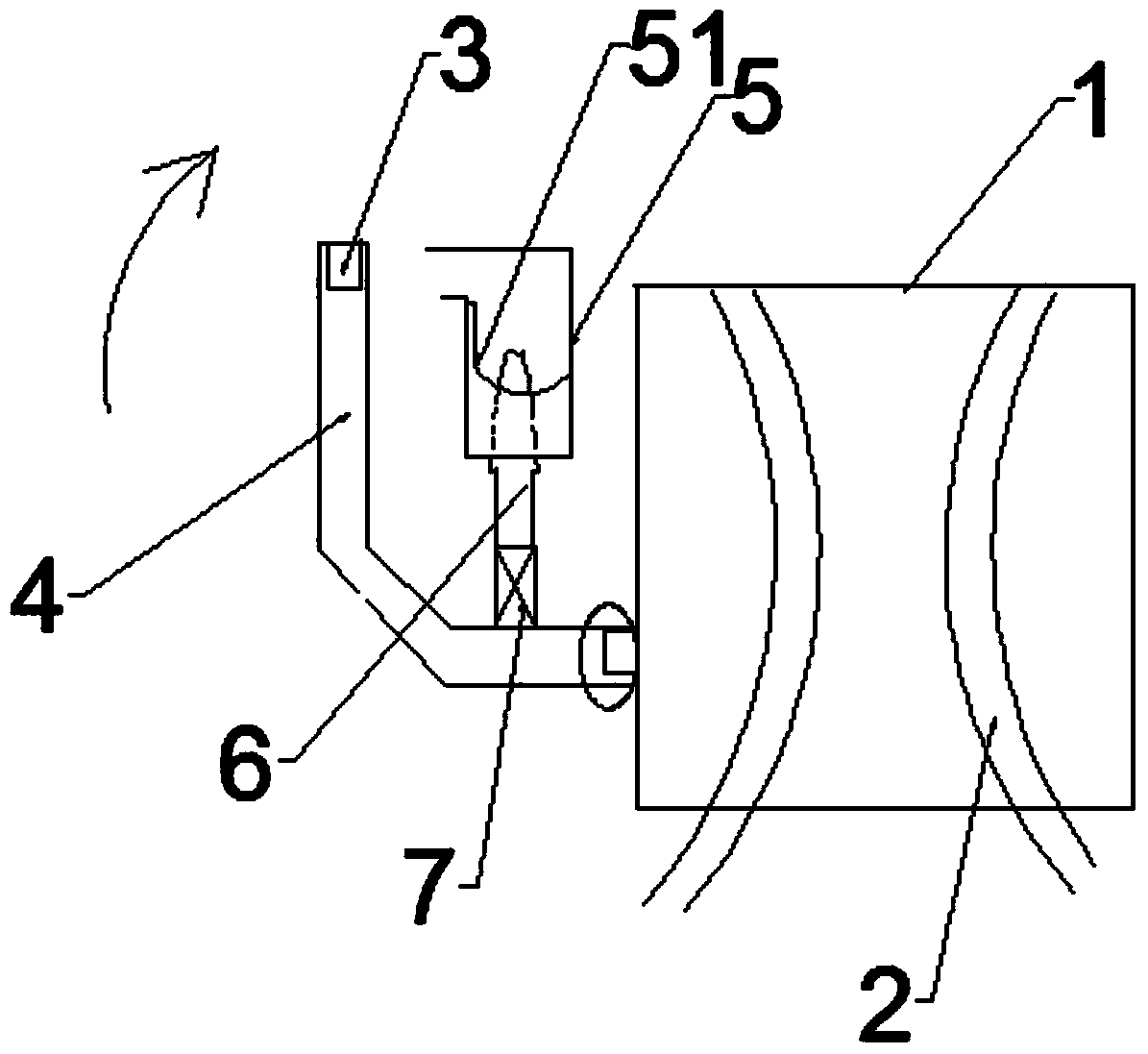

Washing and drying integrated machine with rolling drum

PendingCN108951051ANot easy to splashNot easy to get wetOther washing machinesTextiles and paperWater flowEngineering

The invention discloses a washing and drying integrated machine with a rolling drum. The machine includes a water containing barrel, the rolling drum and a cooling water supply device. The cooling water supply device supplies cooling water to the bottom wall surface of the water containing barrel through a cooling water inlet passage in order to form a condensing surface on the bottom wall surfaceof the water containing barrel, an outlet end of the cooling water inlet passage is formed in the upper portion of the bottom wall surface of the water containing barrel, and a diversion component for diverting cooling water flowing inward is arranged at the outlet end of the cooling water inlet passage; the outlet end is divided by the diversion component into two diversion outlets, and the cooling water is diverted by the diversion component and flows to the bottom wall surface of the water containing barrel through the diversion outlets. The washing and drying integrated machine is concisein structure, capable of preventing splashing of water and saving space and stable in condensation water path.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

Hydraulically controlled internal and external two-way compression packer

ActiveCN106703740BTo achieve the purpose of layeringRealize the requirement of large displacement backwash wellSealing/packingPressure transmissionControl system

The invention discloses a hydraulic control and inside and outside biaxial compression packer. The packer comprises an external setting mechanism and an internal setting mechanism. The upper end of the external setting mechanism is connected to an upper contact, and the lower end of the external setting mechanism is connected to the internal setting mechanism through a bridging contact. The lower end of the internal setting mechanism is connected to a lower contact. Ground pressure can be transmitted to the external setting mechanism and the internal setting mechanism through a pressure transmission hole and a hydraulic channel of a hydraulic controlled system during the pressurizing process of a ground control system. When a certain pressure is reached and after piston movement, a shear pin is cut, and a rubber sleeve is compressed till the internal and external rubber sleeves block the internal and external annular spaces to achieve the purpose of layering. A large-discharge-capacity inverse well-flushing requirement can be met when pressure relief of the ground control system is conducted and the rubber sleeve is rebounded. The hydraulic control and inside and outside biaxial compression packer solves the problems in the prior art that diversion of inner and outer pipes is not reliable, inverse well-flushing is not smooth, construction procedures are complex, and the service life of tubular columns is short.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cotton-specific hair dryer and sprayer thereof

ActiveCN105214870BPlay the role of diverting airSpray evenlyLiquid spraying apparatusInsect catchers and killersAgricultural scienceSprayer

The invention provides a special air cylinder for cotton and a sprayer of the air cylinder. The special air cylinder for cotton comprises an air supplying pipeline, an air entraining pipeline and a fan, wherein an air inlet and an air outlet are formed in the air supplying pipeline; one side of the fan is fixedly arranged at one end port of the air entraining pipeline; the other end port of the air entraining pipeline extends into the air supplying pipeline through the air inlet; a flow divider is also arranged at the air outlet of the air supplying pipeline and comprises a flow dividing pipeline and a flow diving port; the flow dividing port is fixedly connected with one end of the flow dividing pipeline; the other end of the flow dividing pipeline is welded with the air supplying pipeline; the air cylinder is installed on one side of a spraying and driving shaft of the sprayer; the air supplying pipeline of the air cylinder is arranged below a spraying nozzle. According to the special air cylinder for cotton and the sprayer of the air cylinder, pesticides can be guaranteed to be sprayed from the bottom up, and then the sprayed pesticides are blown onto cotton leaves, so that the effect that various types of pests which appear in a cotton planting process is thoroughly eliminated is achieved.

Owner:NANTONG HUANGHAI CHEM MACHINERY

Cylinder body structure of compressor

ActiveCN101624979BReduce flow rateSmall pulsationPositive displacement pump componentsPositive-displacement liquid enginesDynamic balanceEngineering

The invention relates to a cylinder body structure of a compressor. The upper part of the cylinder body base is provided with a connecting seat, a crankshaft hole, a first-level high-pressure buffering chamber and a second-level high-pressure buffering chamber. The end face of the connecting seat is provided with a piston hole, the connecting seat is coaxially and fixedly arranged with a cylindercover through a valve plate, and an inspiration muffler is fixedly arranged on the cylinder cover, wherein (1) the end face of the connecting seat is provided with a through hole and a second-level high-pressure chamber air vent respectively, and the through hole is communicated with the second-level high-pressure air vent through a groove formed on the end face of the connecting seat; (2) the valve plate is provided with a first-level high-pressure vent hole, an air suction hole and an exhaust hole; and (3) the air suction hole airtightly covered with an air suction hole valve sheet, and theair exhaust hole is airtightly covered with an air exhaust hole valve sheet. The cylinder body structure has a scientific and reasonable structural design, and high-pressure gas is effectively buffered in the structure to greatly reduce gas pulsation and reduce the overall noises of the compressor, thus the cylinder body structure can keep good dynamic balance.

Owner:扎努西电气机械天津压缩机有限公司

Cooling tower water accumulation tank convenient to clean

ActiveCN108759551APrevent affecting operationEffective movementTrickle coolersCooling towerEngineering

The invention discloses a cooling tower water accumulation tank convenient to clean. The cooling tower water accumulation tank convenient to clean comprises a water pond and a partition plate; the water pond is divided into a first water pond body and a second water pond body by the partition plate; a rotary shaft and a guide plate are arranged on the partition plate; the middle of the guide plateis bent to form a guide groove, and a rotary shaft is fixedly inserted in the bottom face of the guide plate; one end of the rotary shaft penetrates out of the water pond and is sleeved with a gear in inserted and fixed modes; a rack is arranged at one end of the gear in an engaged mode and fixed to a connection rod; the water pond is fixedly provided with a sleeve, a threaded cover is connectedin the sleeve in a threaded mode, a spline hole is formed in the threaded cover, and a spline shaft is inserted in the spline hole; a limiting through groove is formed in the sleeve, and the connection rod is inserted in the limiting through groove; a circular insertion slot is formed in the end face of one end of the threaded sleeve; one end of the connection rod is provided with a supporting column inserted in the insertion slot; circular limiting grooves are formed in the opposite inner walls of the insertion slot; and the supporting column is provided with a pair of limiting columns inserted in the limiting grooves separately. A refrigeration device does not need to be shut down when the water accumulation tank is cleaned, and normal running of the device is not affected.

Owner:浙江国祥冷却科技有限公司

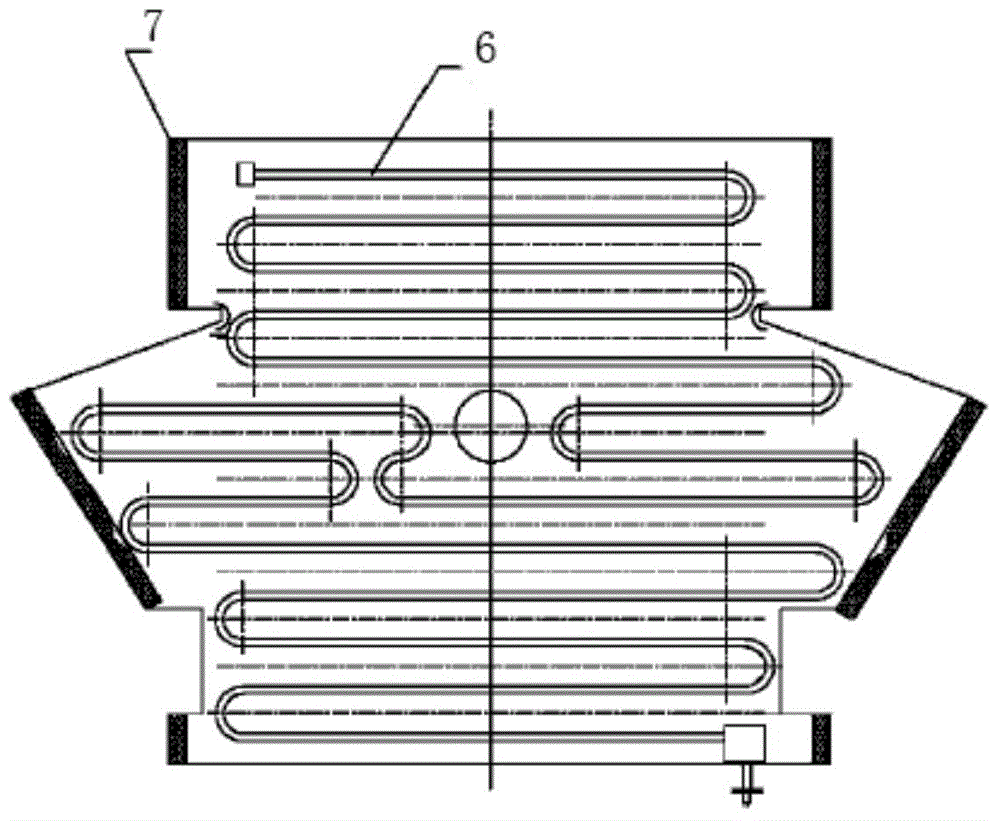

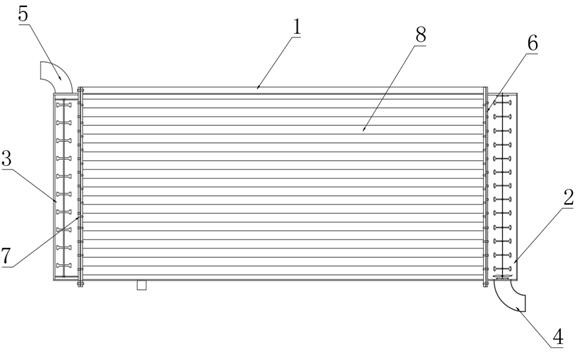

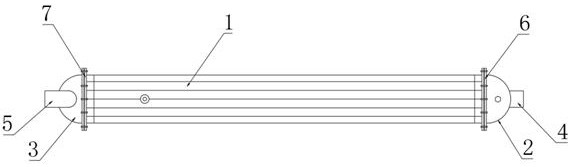

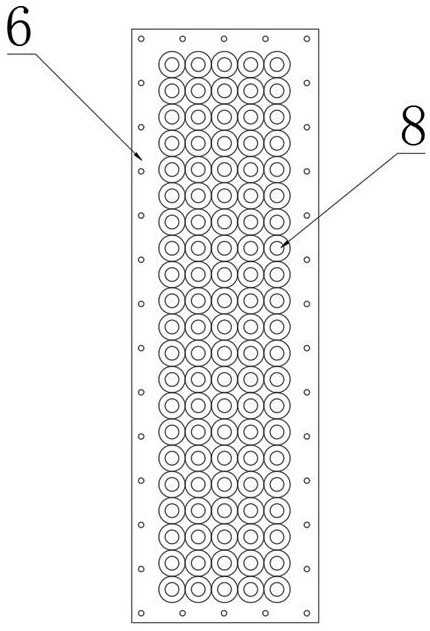

Fin type heat exchanger convenient to clean

PendingCN114152138ARelieve pressureSteady diversionMachines/enginesEngine componentsInlet pressureMechanical engineering

A water inlet pressure-bearing pipe for reducing water inlet pressure is fixedly connected to one side end of a heat exchanger body, and a water outlet pressure-bearing pipe for reducing water outlet pressure is fixedly connected to the position, corresponding to the water inlet pressure-bearing pipe, of the other side end of the heat exchanger body. A water inlet pressure-bearing flange for bearing water inlet pressure is fixedly installed at the position, close to the heat exchanger body, of one side end of the water inlet pressure-bearing pipe, a water outlet pressure-bearing flange for bearing water outlet pressure is fixedly installed at the position, close to the heat exchanger body, of one side end of the water outlet pressure-bearing pipe, and the water inlet pressure-bearing pipe and the water outlet pressure-bearing pipe are each provided with a semicircular pipe. The water inlet pressure-bearing pipe, the water outlet pressure-bearing pipe, the water inlet pressure-bearing flange and the water outlet pressure-bearing flange are arranged at the two ends of the heat exchanger body correspondingly, so that the heat exchanger body can reduce the pressure of inlet water and outlet water to the maximum extent in the water inlet and outlet processes, the heat exchange effect of the heat exchanger body is guaranteed, and the heat transfer effect of the heat exchanger body is enhanced.

Owner:苏州荣轩环保有限公司

Ultrasonic meter

ActiveUS10337896B2Best possible stabilizationReduce widthVolume/mass flow measurementVolume meteringEngineeringUltrasound

Owner:DIEHL METERING

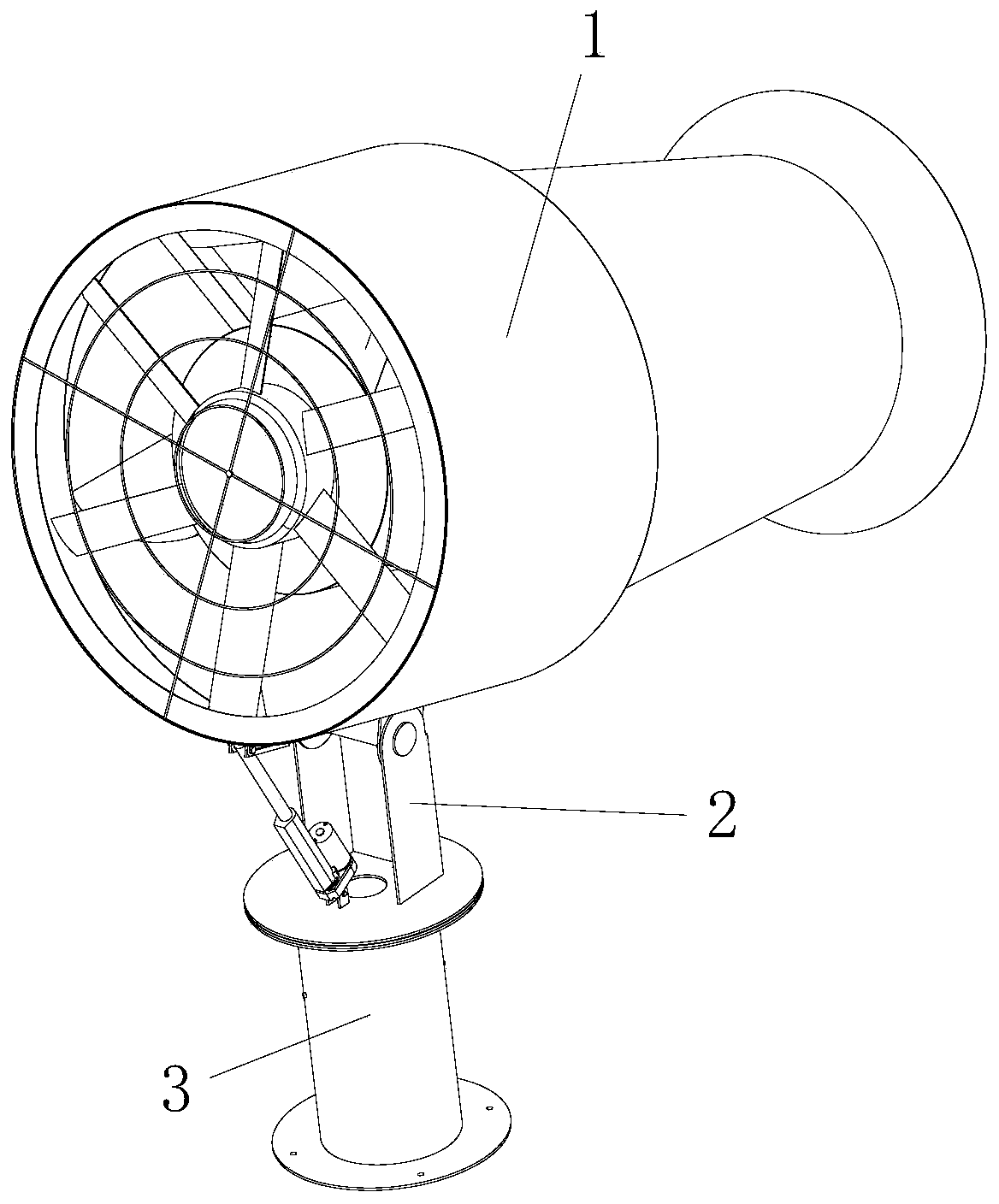

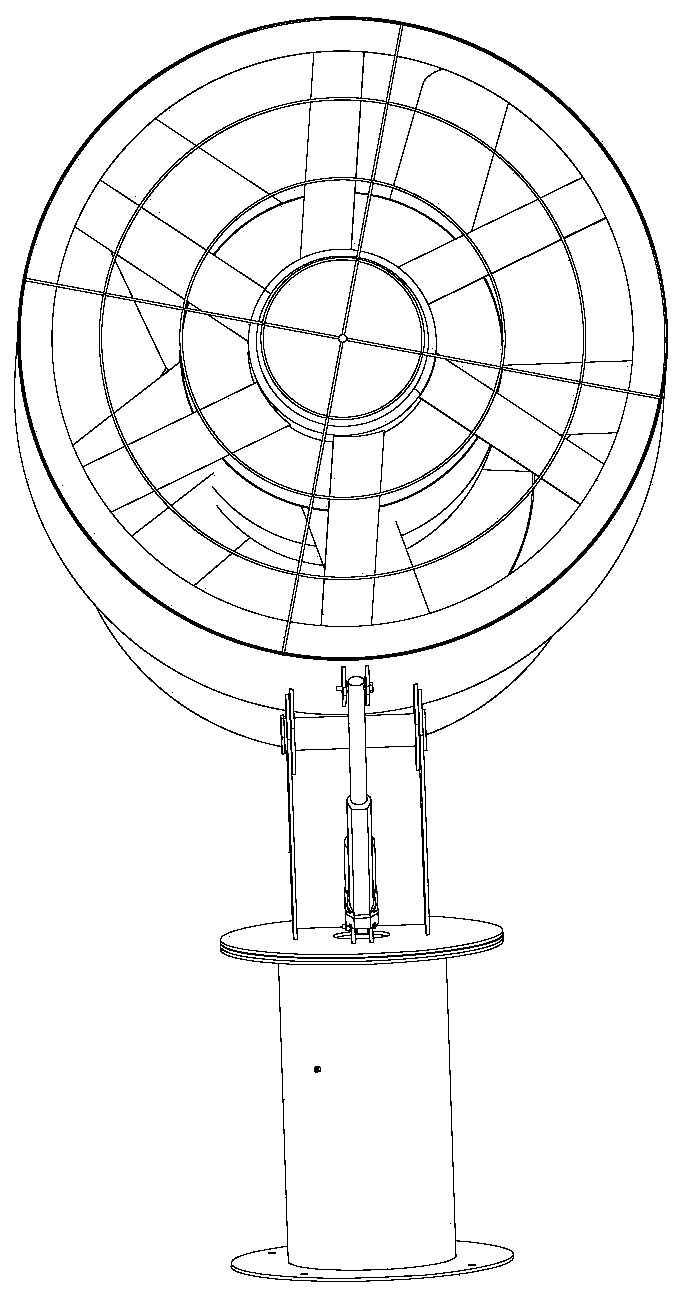

A new type of haze reduction and dust removal machine

ActiveCN108479241BImprove diversion capacityEasy to divertUsing liquid separation agentDust controlElectric machinery

The invention discloses a novel haze-removing dedusting machine. The novel haze-removing dedusting machine comprises an air duct, a pitching mechanism, and a rotary mechanism; the rotary mechanism isfixed; the pitching mechanism is arranged on the rotary mechanism, and is driven to perform horizontal rotating by the rotary mechanism; the air duct is arranged on the pitching mechanism, and the pitching angle of the air duct is adjusted by the pitching mechanism. In operation, an air duct motor is turned on to drive a blower fan to rotate and generate negative pressure, air at the front end ofthe air duct is pumped into the air duct; the pumped in air flows toward the back part of the air duct under the flow diversion effect of a flow deflector along the streamline flow deflector and a flow diversion hammer, then in the gradually reduced space in a tapered cylinder flow forward along the smooth flow diversion hammer streamline external surface rapidly, and is compressed, reaches the tail end of the air duct, and is sprayed out at a horn-shaped opening; when the spray direction of the air duct is needed to be adjusted, an electric push rod is turned on to realize forward stretchingof the electric push rod or backward retraction of the electric push rod, so that the pitching angle of the air duct is adjusted, a construction motor is turned on to drive a supporting seat to rate,so that the rotating angle of the air duct is adjusted.

Owner:广州和易思汇电子信息有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com