Method and device for the production of a component, especially a hybrid component for a crossrail of a vehicle, component and use of said component

A technology of mixing components and components, applied in the directions of superstructure, substructure, vehicle components, etc., can solve the problems of irregular fluid flow and sharp air outlet, and achieve the effect of gentle baffle, large amount of baffle, and improved air conditioning comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

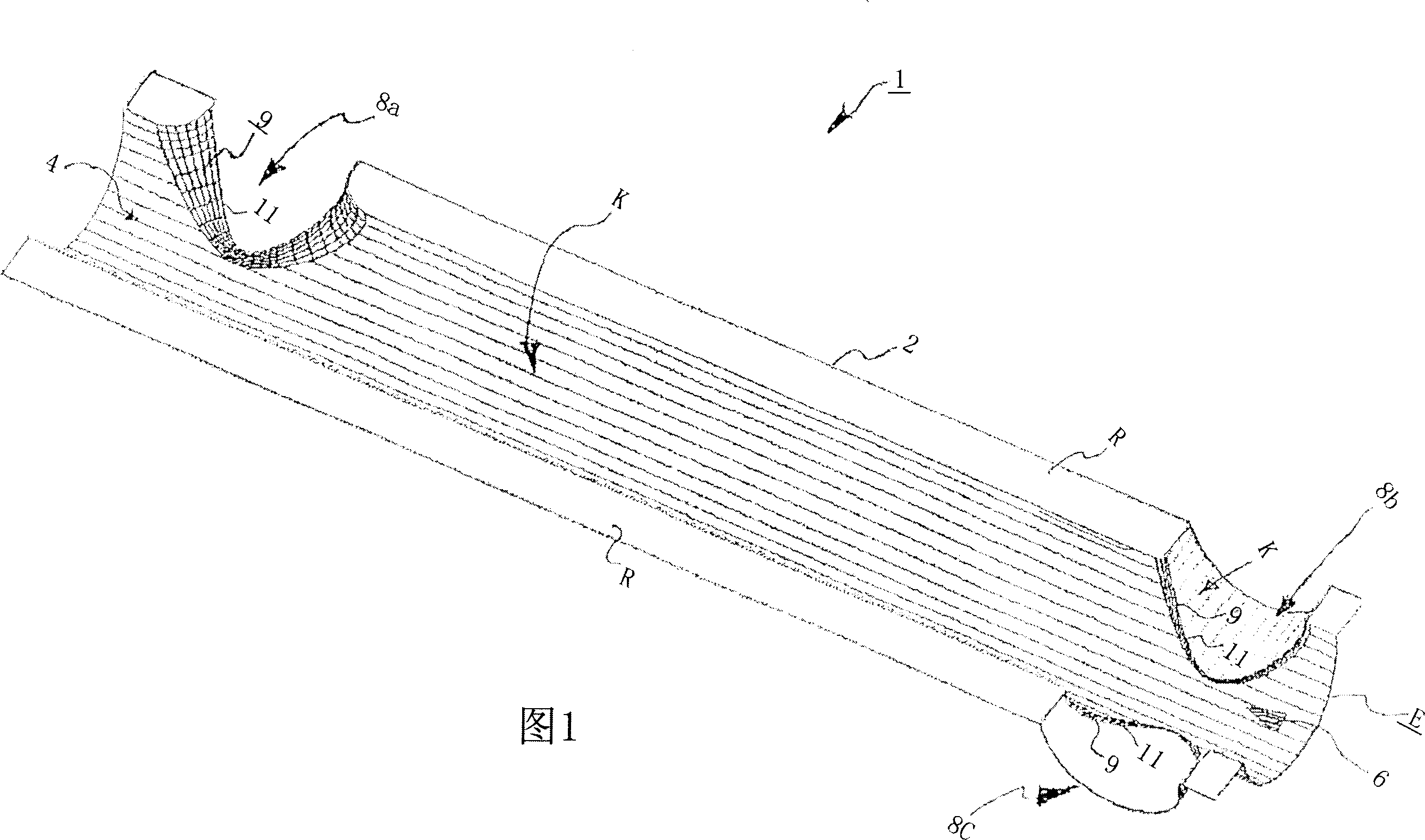

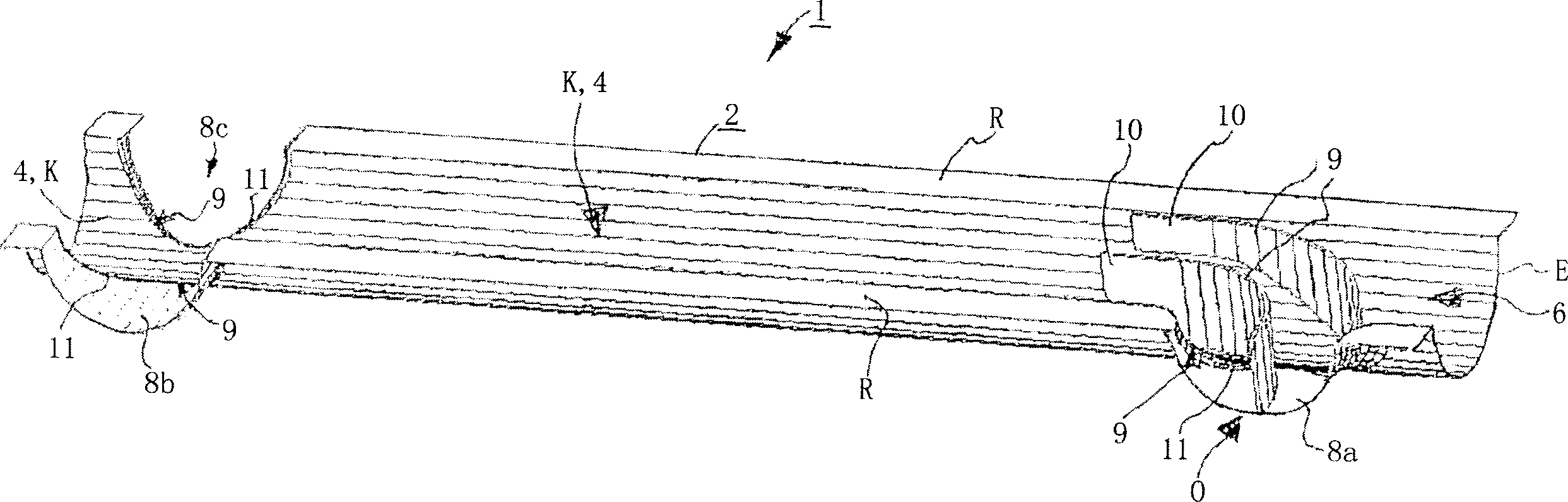

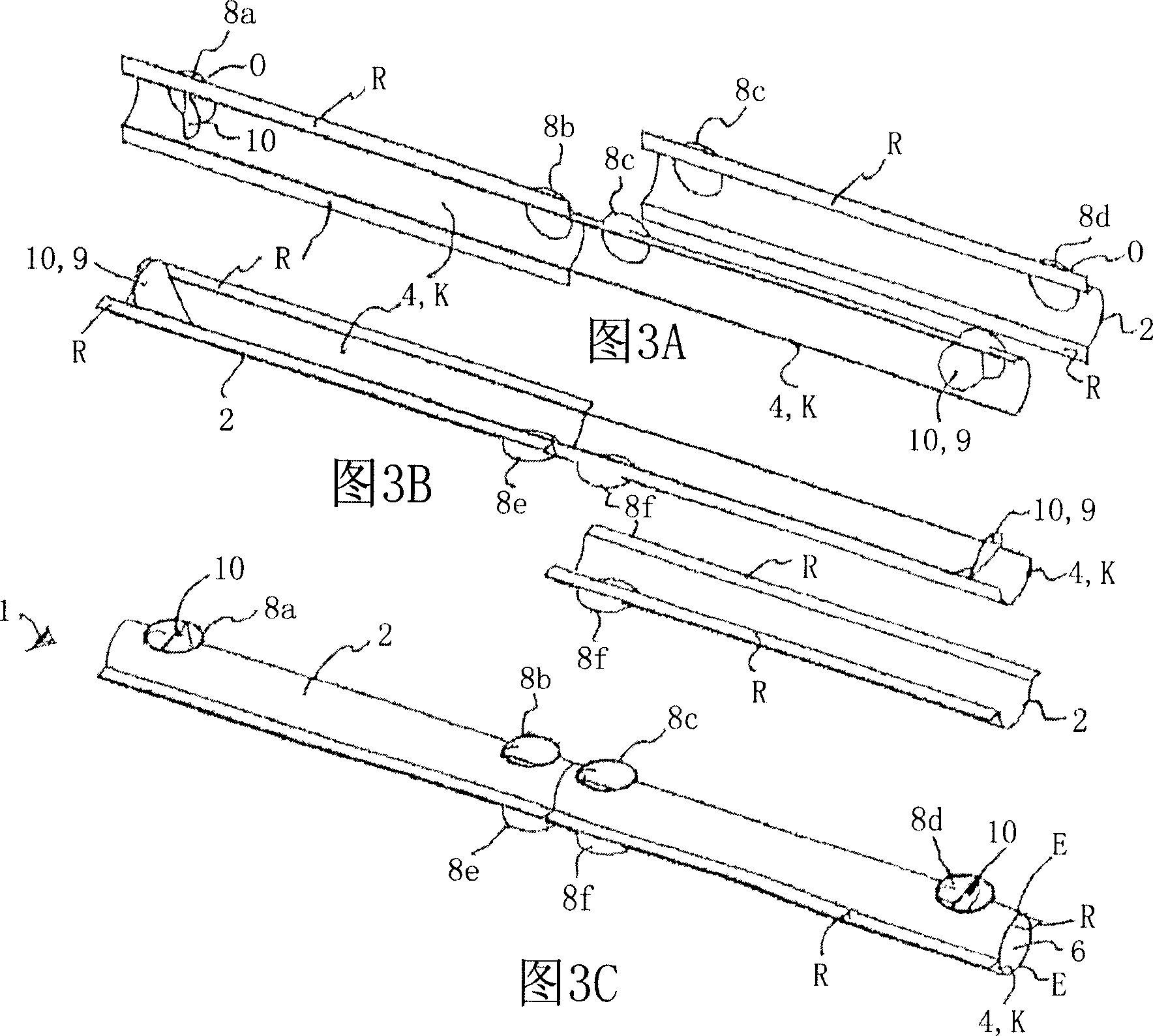

[0030] FIG. 1 is a plan view of an element E of a component 1 , such as a cross member arranged between A-pillars of a motor vehicle (not shown).

[0031] The component 1 here consists of at least two elements E, shown in FIG. 1 as the lower element E, such as a half body or a half shell. An upper element not shown in the figure corresponds to the lower element, and is also a half body or a half shell. The component 1 has a body 2 which is preferably formed from sheet metal, in particular from a light metal sheet such as aluminum sheet or magnesium sheet or high-grade steel sheet. In the embodiment, the body 2 is in a closed state, that is to say, the two elements E are combined to form a hollow structure, in particular a tubular hollow structure. The body 2 can also adopt a hollow structure with a box-shaped cross section, and / or at least part of the area is perforated. In an embodiment with a box-shaped cross section, the body 2 is formed from two elements E, for example a U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com