Fin type heat exchanger convenient to clean

A fin heat exchanger and heat exchanger technology, applied in the field of fin heat exchangers, can solve the problems of blockage, the fin heat exchanger cannot withstand high pressure, cannot be cleaned, etc., and achieves enhanced heat transfer effect, Good decompression and ensure the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

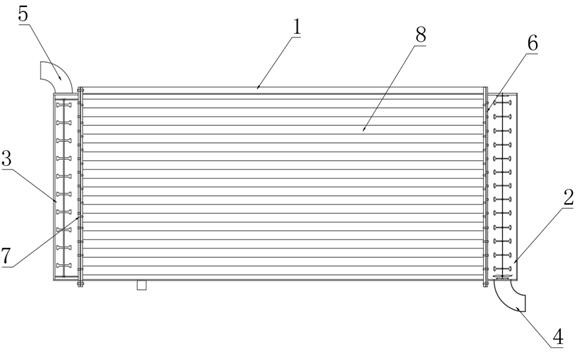

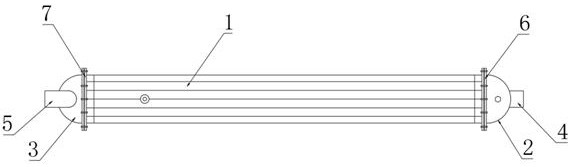

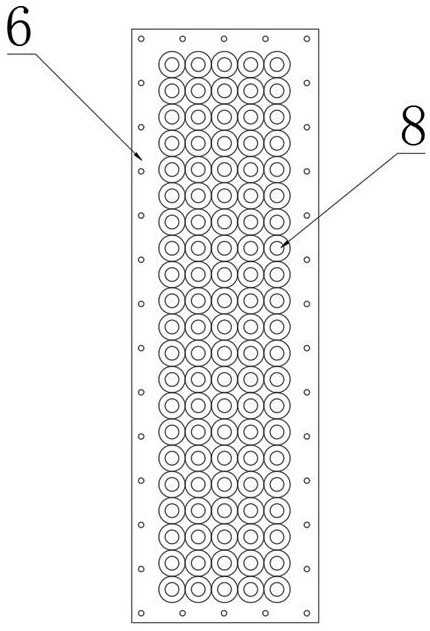

[0036] Example: such as Figure 1-3As shown, the present invention provides a technical solution, a finned heat exchanger that is convenient for decontamination, including a heat exchanger body 1, and one side of the heat exchanger body 1 is fixedly connected with a water inlet bearing for reducing the water inlet pressure. The pressure pipe 2, the other side end of the heat exchanger body 1 and the water inlet pressure pipe 2 are fixedly connected with the water outlet pressure pipe 3 to reduce the water outlet pressure, and the bottom end of the water inlet pressure pipe 2 is vertically fixed for further The water inlet pipe 4 and the top of the outlet pressure bearing pipe 3 are vertically fixedly connected with an outlet pipe 5 for drainage;

[0037] One side end of the water inlet pressure-bearing pipe 2 close to the heat exchanger body 1 is fixedly installed with an inlet water pressure-bearing flange 6 to withstand the water inlet pressure, and one side end of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com