A new type of haze reduction and dust removal machine

A haze-reducing dust remover, dust remover technology, applied in the separation method, the use of liquid separation agent, the separation of dispersed particles, etc., can solve the uneven force on the axial pressure bearing surface, affect the use efficiency of the whole machine, shorten the service life, etc. problem, to achieve enhanced diversion effect, simple structure, and low operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

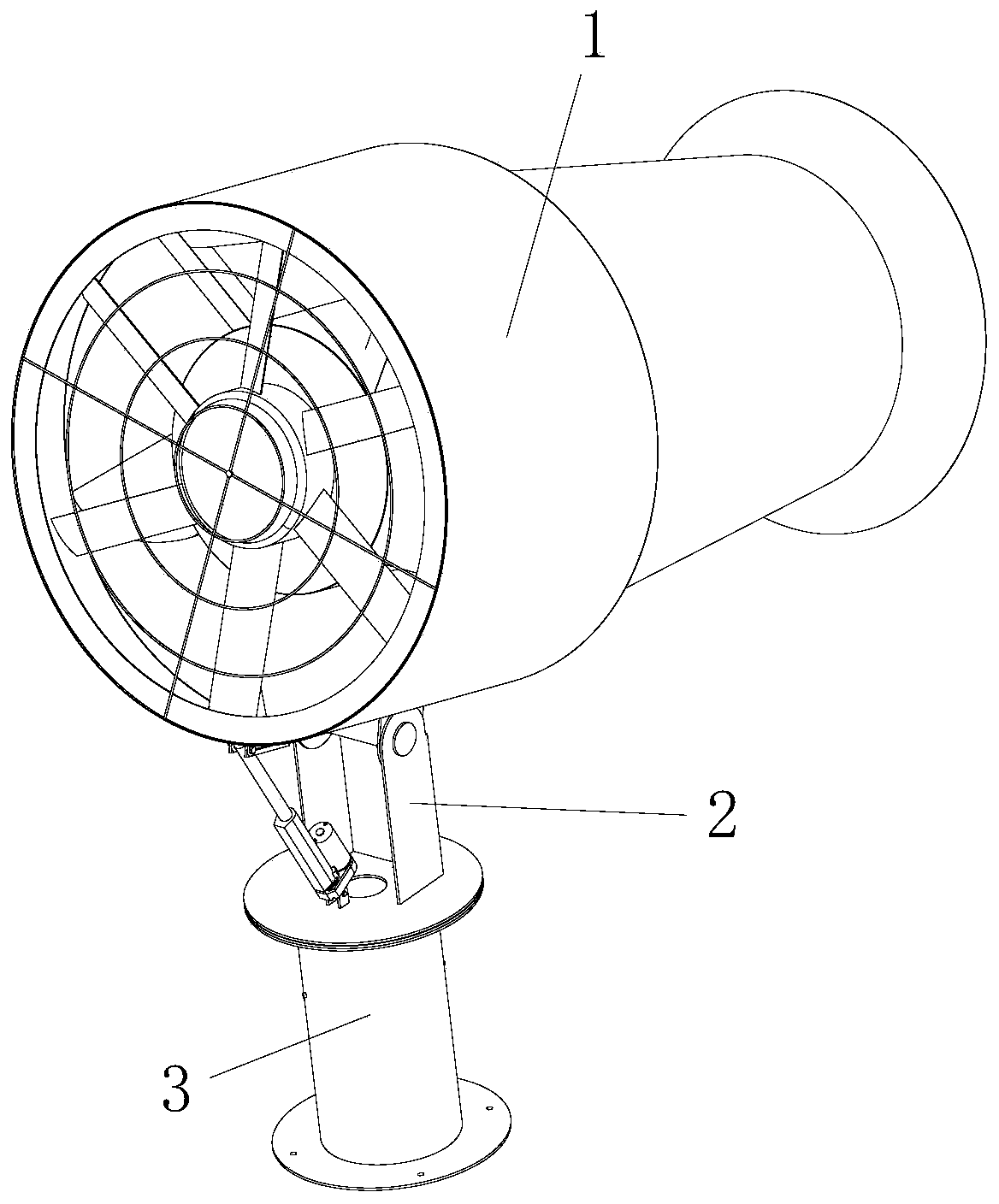

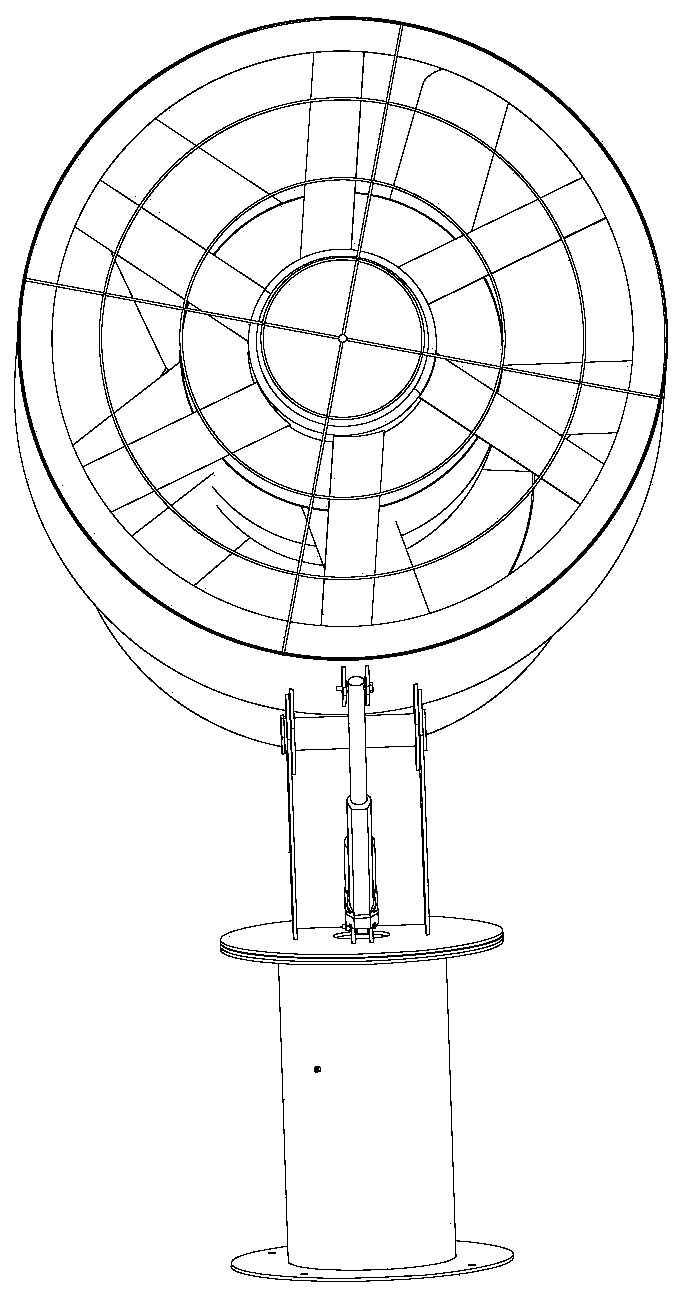

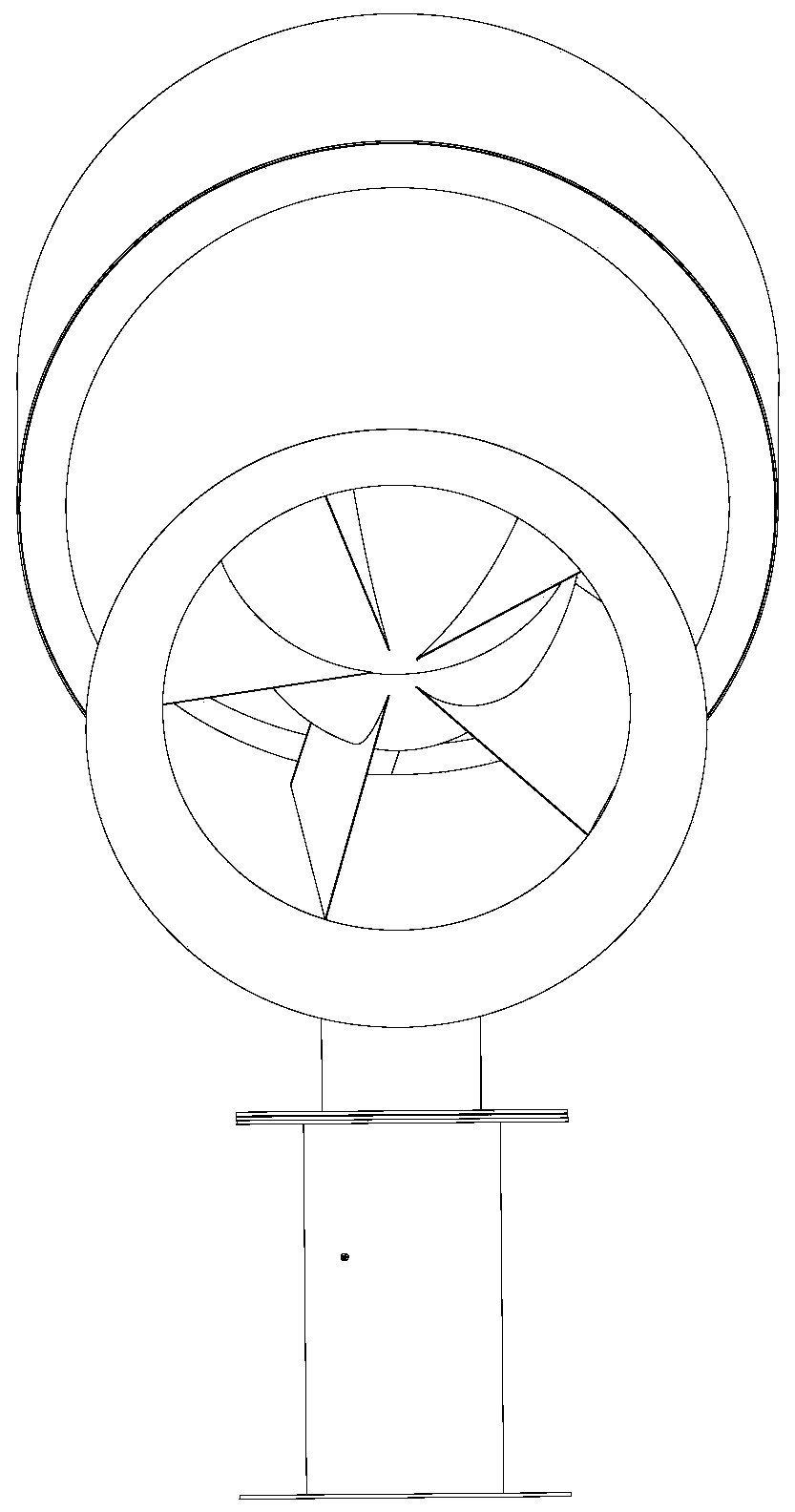

[0064] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention discloses a novel haze reducing and dust removing machine. The novel haze reducing and dust removing machine mainly includes an air cylinder 1 for spraying haze and dust removal, a pitching mechanism 2 for adjusting the spray angle of the air cylinder 1, and a The rotating mechanism 3 that drives the wind cylinder 1 to rotate the angle. The rotating mechanism 3 is fixedly arranged, and the pitching mechanism 2 is arranged on the rotating mechanism 3 , and is driven to rotate horizontally by the rotating mechanism 3 . The air cylinder 1 is installed on the pitch mechanism 2, and the pitch angle of the air cylinder 1 is adjusted by the pitch mechanism 2.

[0065] In order to introduce the internal structure of the present invention in more detail, the blower 1 , pitching mechanism 2 and rotating mechanism 3 will be described respectively below.

[0066] Hair part:

[0067] The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com