High-density high-strength fracturing propping agent for oil and gas wells and preparation method thereof

A fracturing proppant, high-strength technology, applied in the field of fracturing proppants, can solve the problems of increasing production costs and unfavorable for large-scale industrial production, and achieve the goal of improving diversion capacity, slowing down the competition of raw materials, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

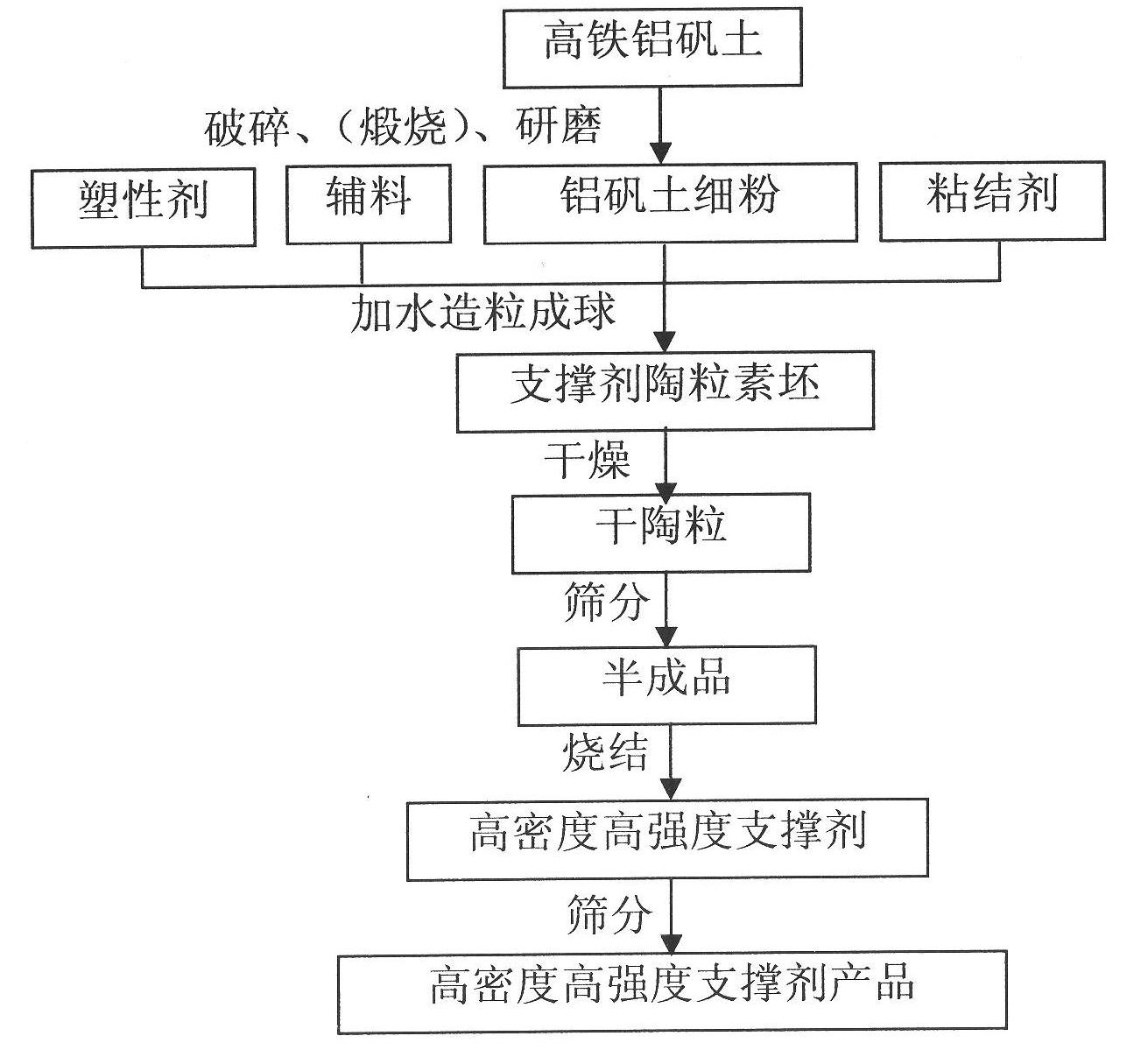

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Take 75.0wt% Al 2 O 3 , 10.0wt% Fe 2 O 3 And 2.0wt% SiO 2 High-iron bauxite 10Kg, iron oxide powder 0.01Kg, bentonite 0.01Kg, starch 0.01Kg. The bauxite was crushed into blocks of less than 15 cm by a counter-roll crusher, then calcined at 800° C. for 1 hour, and then ground by a ball mill into fine powder with a particle size of less than 200 mesh. Put the above-mentioned raw material powder mixture into a disc ball forming machine, add an appropriate amount of water in batches, and obtain a proppant blank by rotating into a ball. Place the proppant blanks in well-ventilated air to dry naturally, and sieve after drying to remove oversized and undersized particles by filtration. Then put it into a tunnel kiln for sintering at 1390°C, holding for 0.5h, cooling down to obtain a proppant sintered body, and finally grading and sieving to prepare high-density and high-strength 20 / 40 mesh fracturing proppant products. The alumina content of the proppant is 74.8%, t...

Embodiment 2

[0030] Example 2: Take 40.0wt% Al 2 O 3 , 45.0wt% Fe 2 O 3 And 12.0wt% SiO 2 High-iron bauxite 10Kg, bentonite 1.0Kg, starch 0.3Kg, dextrin starch 0.2Kg. The bauxite is crushed into blocks of less than 15 cm by a counter-roll crusher, then calcined at 400° C. for 2 hours, and then ground by a ball mill into fine powder with a particle size of less than 200 mesh. Put the above-mentioned raw material powder mixture into a disc ball forming machine, add an appropriate amount of water in batches, and obtain a proppant blank by rotating into a ball. The proppant blank is dried at 70°C, dried and then sieved, and filtered to remove oversized and undersized particles. Then put it into a tunnel kiln for sintering at 1200°C, heat preservation for 2 hours, and after cooling down, the proppant sintered body is obtained, and finally sieved through classification to prepare high-density and high-strength 20 / 40 mesh fracturing proppant products. The alumina content of the proppant is 41.2%,...

Embodiment 3

[0031] Example 3: Take 40.0wt% Al 2 O 3 , 35.0wt% Fe 2 O 3 And 20.0wt% SiO 2 High-iron bauxite 10Kg, iron oxide powder 1.5Kg, clay 1.0Kg, dextrin 0.5Kg. The bauxite is crushed into blocks of less than 15 cm through a jaw crusher, and then ground into fine powder with a particle size of less than 200 mesh through Raymond mill. Put the above-mentioned raw material powder mixture into a high-speed ball forming machine, add an appropriate amount of water in batches, and obtain a proppant blank by rotating into a ball. Dry the proppant blank at 150°C, sieving after drying, and filter to remove oversized and undersized particles. Then it is put into a rotary kiln and sintered at 1510°C, kept for 1 hour, and cooled to obtain a proppant sintered body. Finally, it is classified and screened to prepare high-density and high-strength 20 / 40 mesh fracturing proppant products. The alumina content of the proppant is 41.0%, the iron oxide content is 43.0%, and the bulk density is 1.88g / cm 3 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com