Plasma waste incinerator and incineration system thereof

A waste incinerator and plasma technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of low service life, short service life of electrodes, complicated process, etc., achieve the effect of increasing service life and ensuring high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

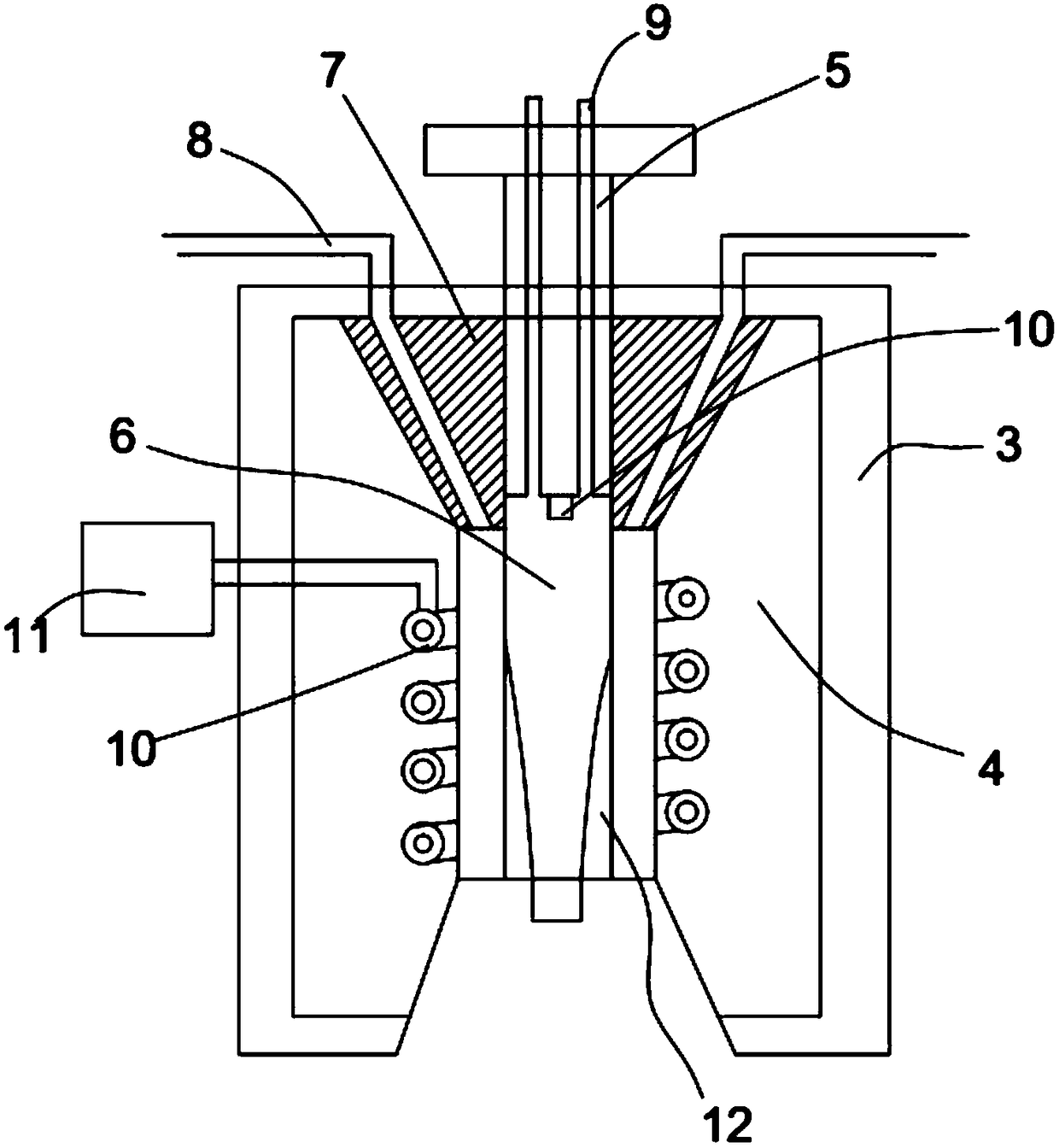

[0033] The present invention proposes a plasma waste incinerator 15, comprising a furnace body 1, a plasma torch 2 is provided on the top of the furnace body 1, and the plasma torch 2 includes a pipe body 3, and the pipe body 3 is provided with a An anode 4 and a cathode 5; the center of the anode 4 is provided with an ionization chamber 6, and the upper part of the ionization chamber 6 is an inverted tapered groove, and a gas guide block 7 is arranged in the tapered groove; the cathode 5 passes through the The gas guide block 7 extends to the upper part of the ionization chamber 6; the first air guide tube 8 is connected to the gas guide block 7, and the first air guide tube 8 is arranged along the gas guide block 7 and directed to the ionization chamber. cavity 6; at least one second air duct 9 is connected to the cathode 5; a trigger electrode 10 is provided at the bottom of the cathode 5.

[0034] Wherein, the anode 4 is made of semiconductor silicon material, the cathode ...

Embodiment 2

[0036] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the materials of the anode 4 and the cathode 5 are selected from traditional materials, and the service life of the final structure is greatly reduced.

Embodiment 3

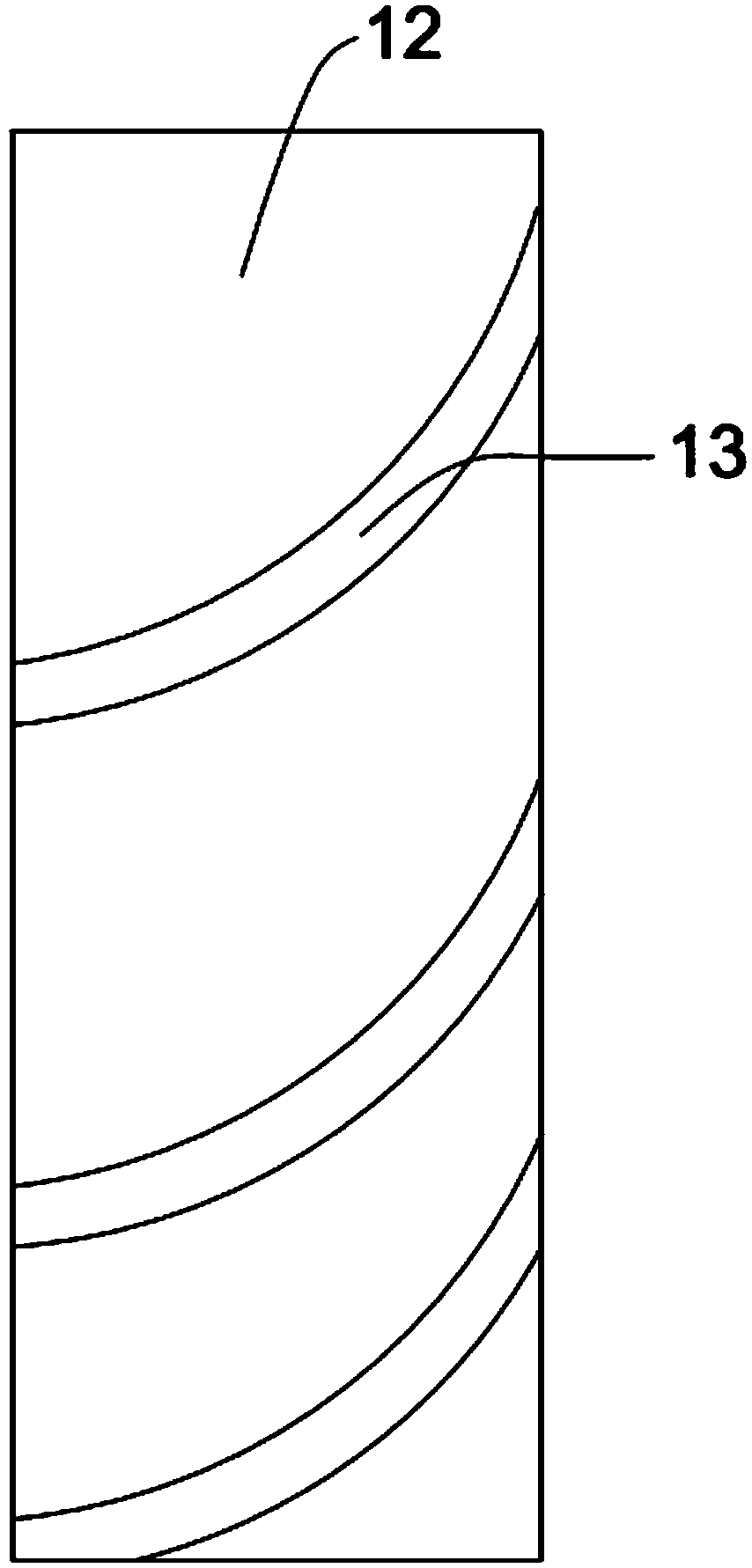

[0038] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the ionization chamber 6 is a cylindrical chamber, and the convex layer 12 and the slit are not provided in the ionization chamber 6, and the temperature of the final reaction zone is reduced, which affects Thermal efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com