Electric hot melt salt valve

A technology of electric heating and valves, applied in the direction of valve details, valve devices, valve heating/cooling devices, etc., to achieve smooth cut-off, save manpower and time costs, and avoid losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below through specific examples.

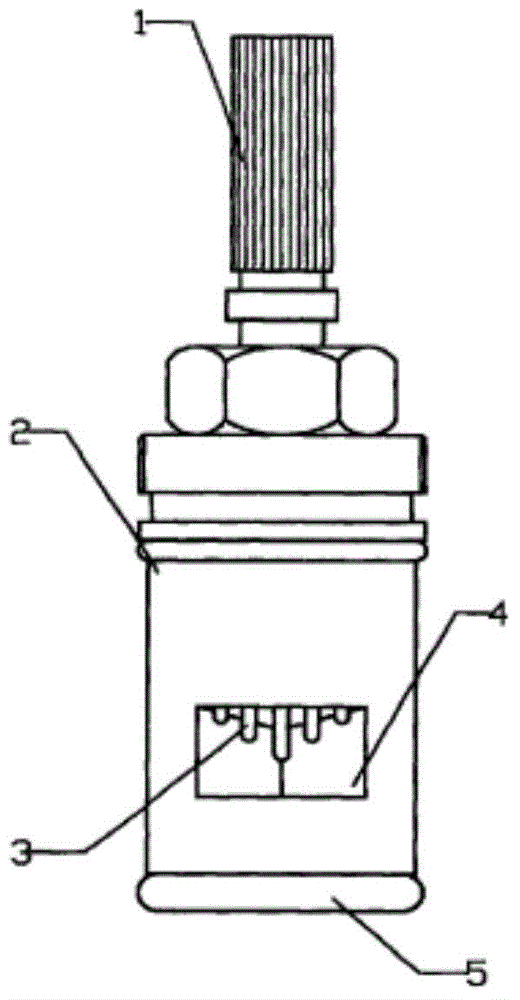

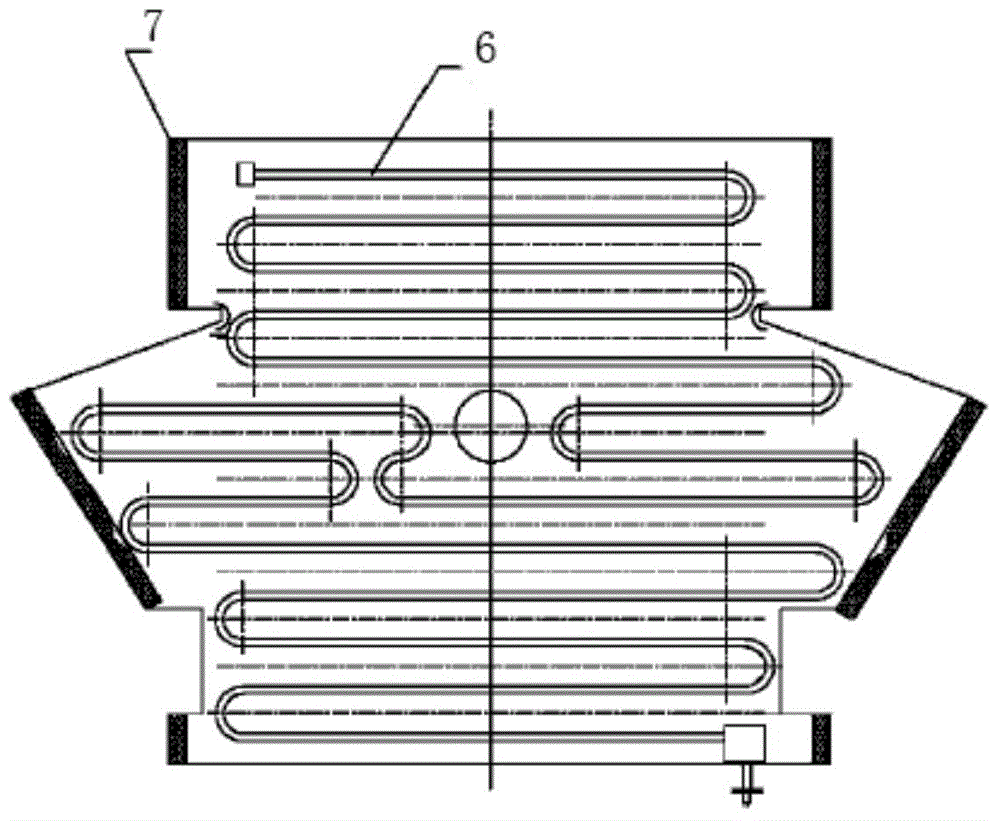

[0019] Such as figure 1 with figure 2 As shown, wherein, 1 is a valve stem, 2 is a valve seat, 3 is a columnar body, 4 is a liquid port, 5 is a seal, 6 is an electric heating wire, and 7 is a Velcro.

[0020] Electric molten salt valve, including valve, electric heating cable and power junction box, the valve includes a cylindrical valve seat, a valve stem set in the cylindrical valve seat, a liquid port is arranged on the valve seat, and the inside of the valve stem is inserted into the valve In the seat, a movable valve disc is arranged on the inner side of the valve stem, and an upper gap is provided on the lower surface of the movable valve disc, and a fixed valve disc corresponding to the circumferential direction of the valve seat is arranged on the inner side of the valve seat and the lower side of the movable valve disc. There is a lower gap on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com