Miniature thermal conductivity detector being insensitive to flow rate

A thermal conductivity detector, miniature technology, applied in semiconductor/solid-state device parts, light guide, microstructure technology, etc., can solve the difficulty of Wheatstone bridge and related circuit connection, poor stability of supporting film, easy damage, etc. Problems, to achieve good thermal insulation effect, to avoid the effect of heat transfer reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

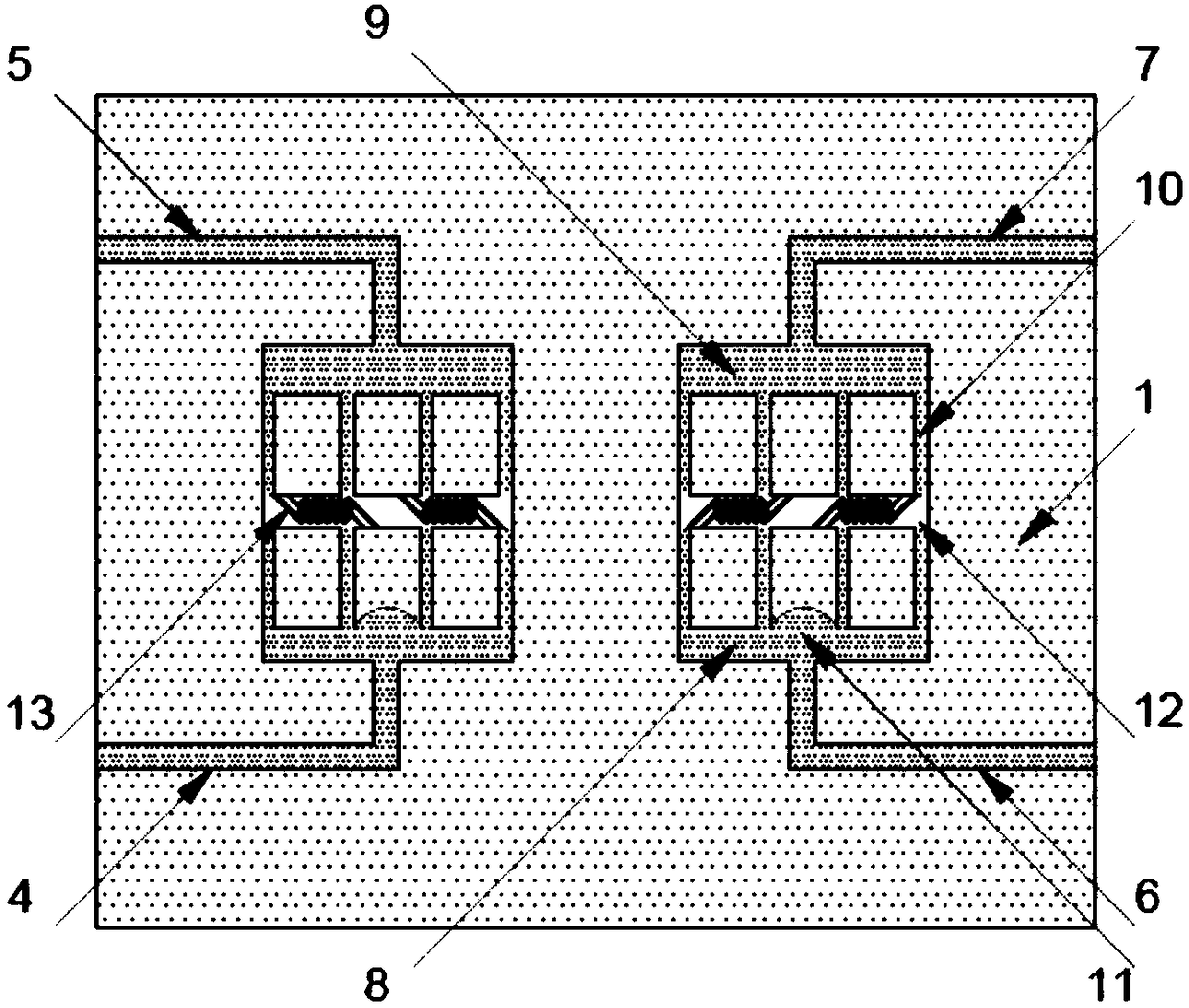

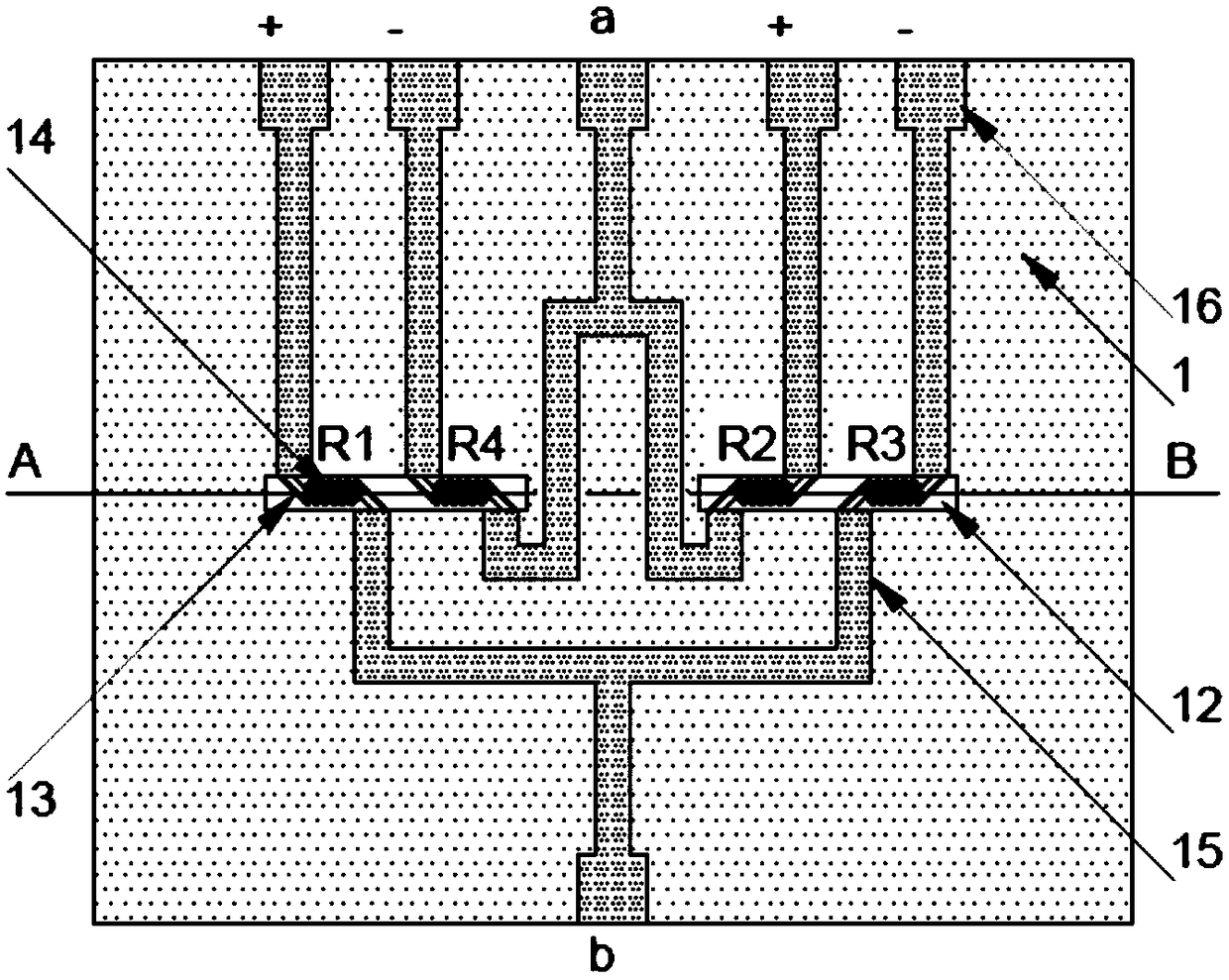

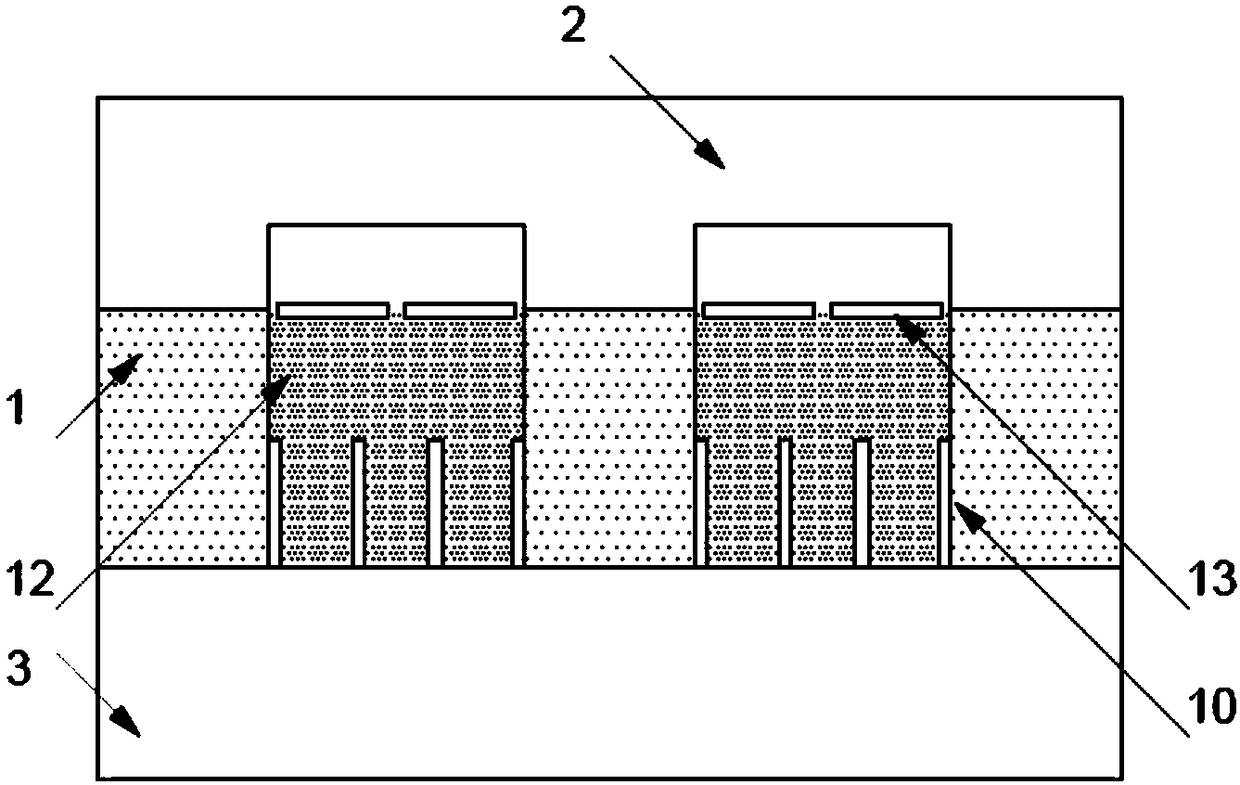

[0035] The present invention provides a miniature thermal conductivity detector that is not sensitive to flow. Its core idea is to process a mesh support film with a thermistor on the front and back of a silicon substrate and a "total score" form of The micro channel realizes its non-coplanar design. At the same time, the micro cuboid thermal conductivity cell penetrates the silicon substrate, and its lower part is connected to the branch channel, which realizes the semi-diffusion design of the air flow channel and the thermal conductivity cell. The overall structure ensures the micro thermal conductivity detection In addition to the requirements for response speed, the influence of gas flow and pressure fluctuations on performance is greatly reduced. At the same time, because there are no microchannels on the front side of the silicon substrate, it is easier to connect the bridge and related circuits on it. The miniature thermal conductivity detector of this design has not bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com