Air duct device of superplastic forming hollow structure and air flow pressure differentiating method

A technology of hollow structure and superplastic forming, which is applied in the field of superplastic forming hollow structure airway devices, which can solve the problems of thinning of vertical ribs, failure of smooth expansion and rupture of airway grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

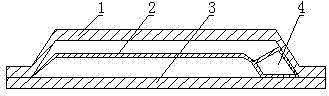

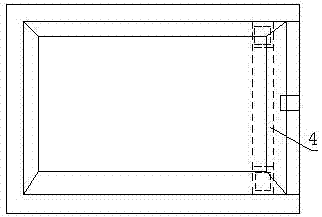

[0031] Such as Figure 1-3 As shown, a superplastic forming hollow structure airway device includes an outer plate 1 and an inner plate 3, a rib grid 2 is arranged between the outer layer plate 1 and the inner layer plate 3, and one end of the rib grid 2 is connected to a storage air cavity4.

Embodiment 2

[0033] Such as Figure 1-3 As shown, a superplastic forming hollow structure airway device includes an outer plate 1 and an inner plate 3, a rib grid 2 is arranged between the outer layer plate 1 and the inner layer plate 3, and one end of the rib grid 2 is connected to a storage Air chamber 4, the side wall of the air storage chamber 4 is provided with an air flow path connected to the rib grid 2, the rib grid 2 and the air storage chamber 4 form a hollow structure, the air storage chamber 4 is located at the front end of the hollow structure, and the air storage chamber The long axis of 4 is perpendicular to the long axis of rib lattice 2.

Embodiment 3

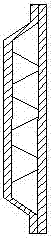

[0035] Such as Figure 1-4 As shown, a superplastic forming hollow structure airway device includes an outer plate 1 and an inner plate 3, a rib grid 2 is arranged between the outer layer plate 1 and the inner layer plate 3, and one end of the rib grid 2 is connected to a storage Air chamber 4, the side wall of the air storage chamber 4 is provided with an air flow path connected to the rib grid 2, the rib grid 2 and the air storage chamber 4 form a hollow structure, the air storage chamber 4 is located at the front end of the hollow structure, and the air storage chamber The long axis of 4 is perpendicular to the long axis of rib lattice 2.

[0036] Before the structure is formed, a core plate 8 is arranged between the outer layer plate 1 and the inner layer plate 3, a backing plate 6 is arranged between the front end of the core plate 8 and the front end of the inner layer plate 3, and the front end of the core plate 8 and the front end of the inner layer plate 3 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com